Building in Historical Areas: Identity Values and Energy Performance of Innovative Massive Stone Envelopes with Reference to Traditional Building Solutions

Abstract

:1. Introduction

2. Methods

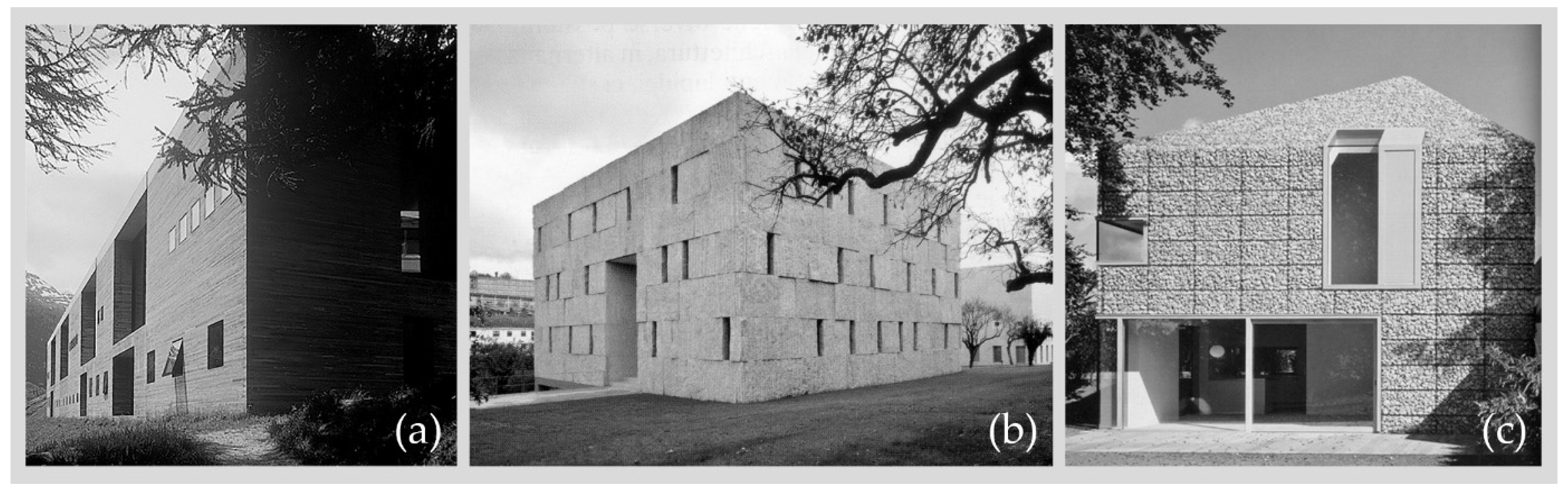

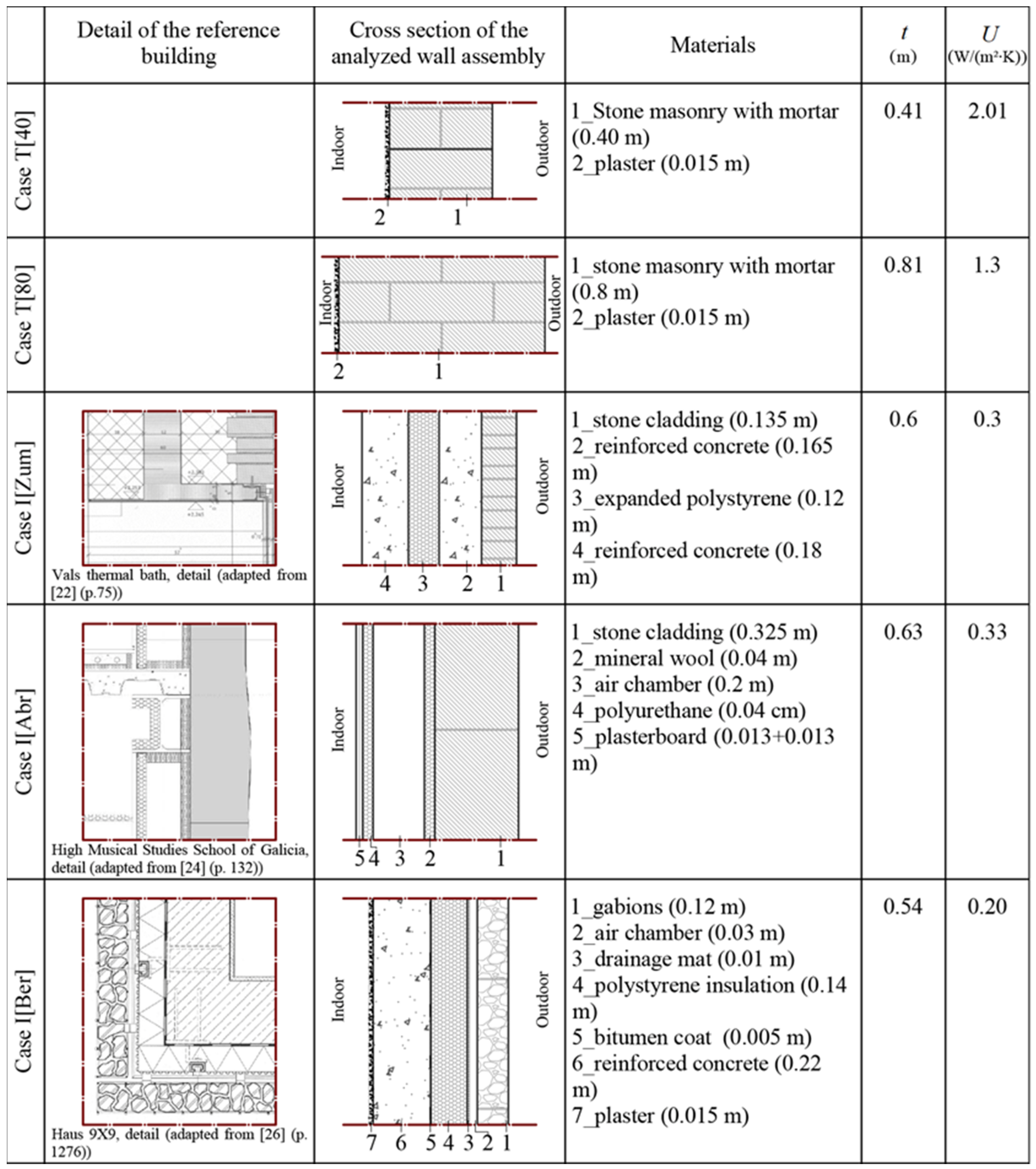

2.1. Innovative Stone Massive Envelope Selection

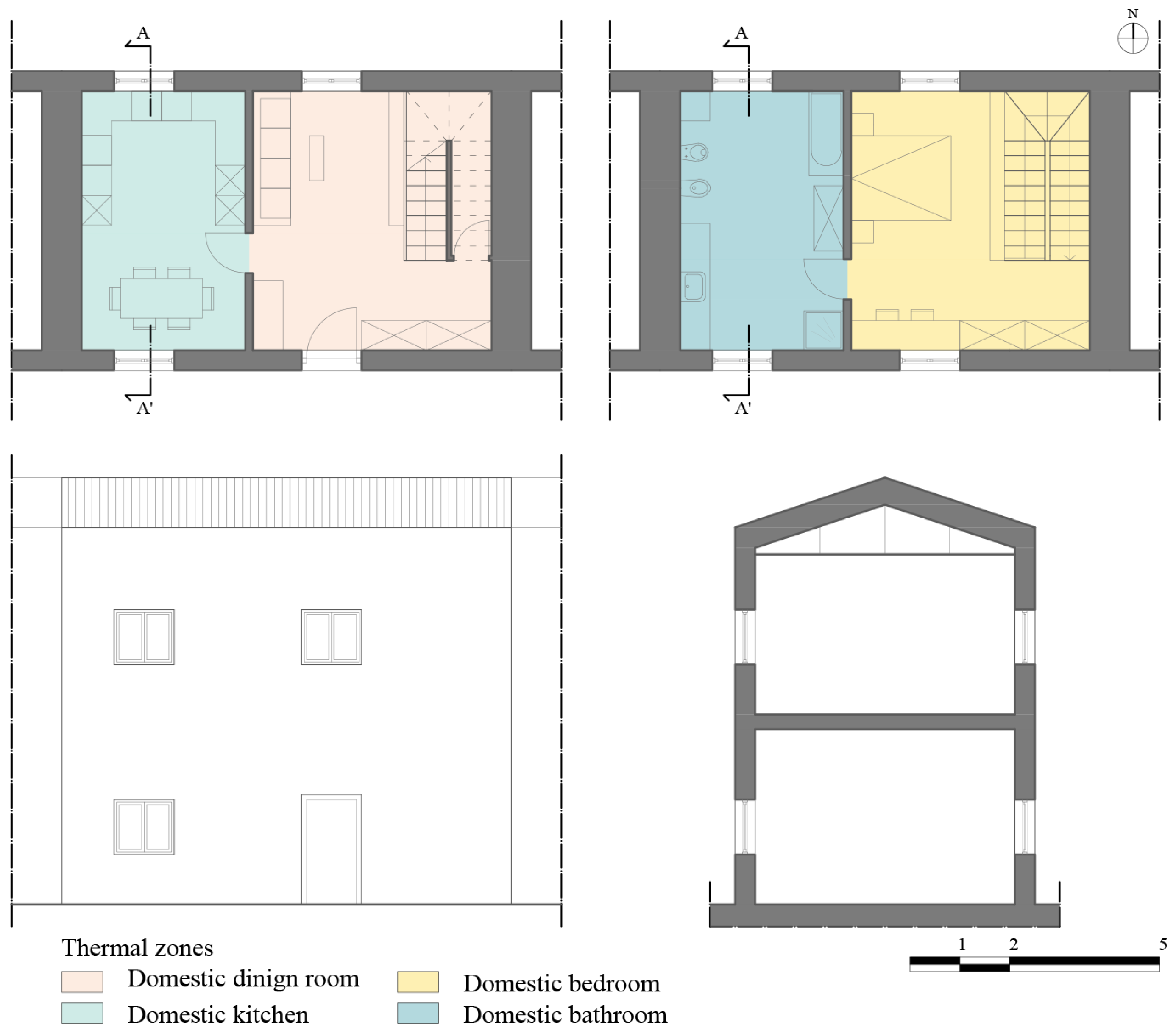

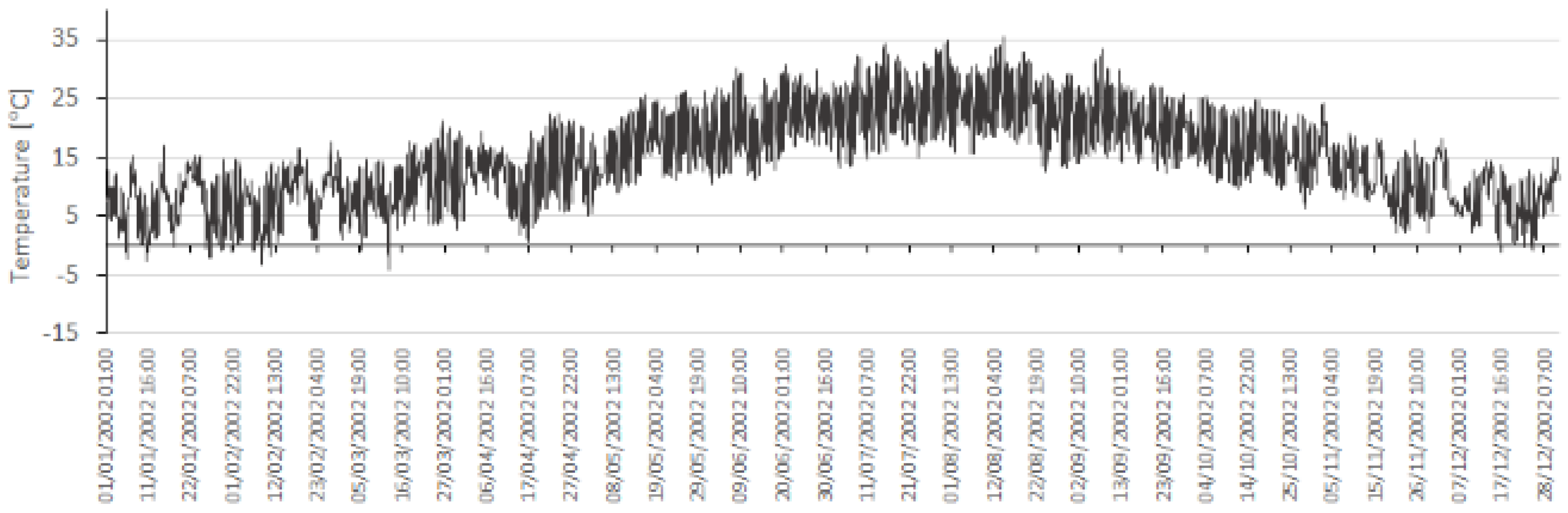

2.2. Case Study Building Definition, Dynamic Simulation and Economic Analysis

3. Results

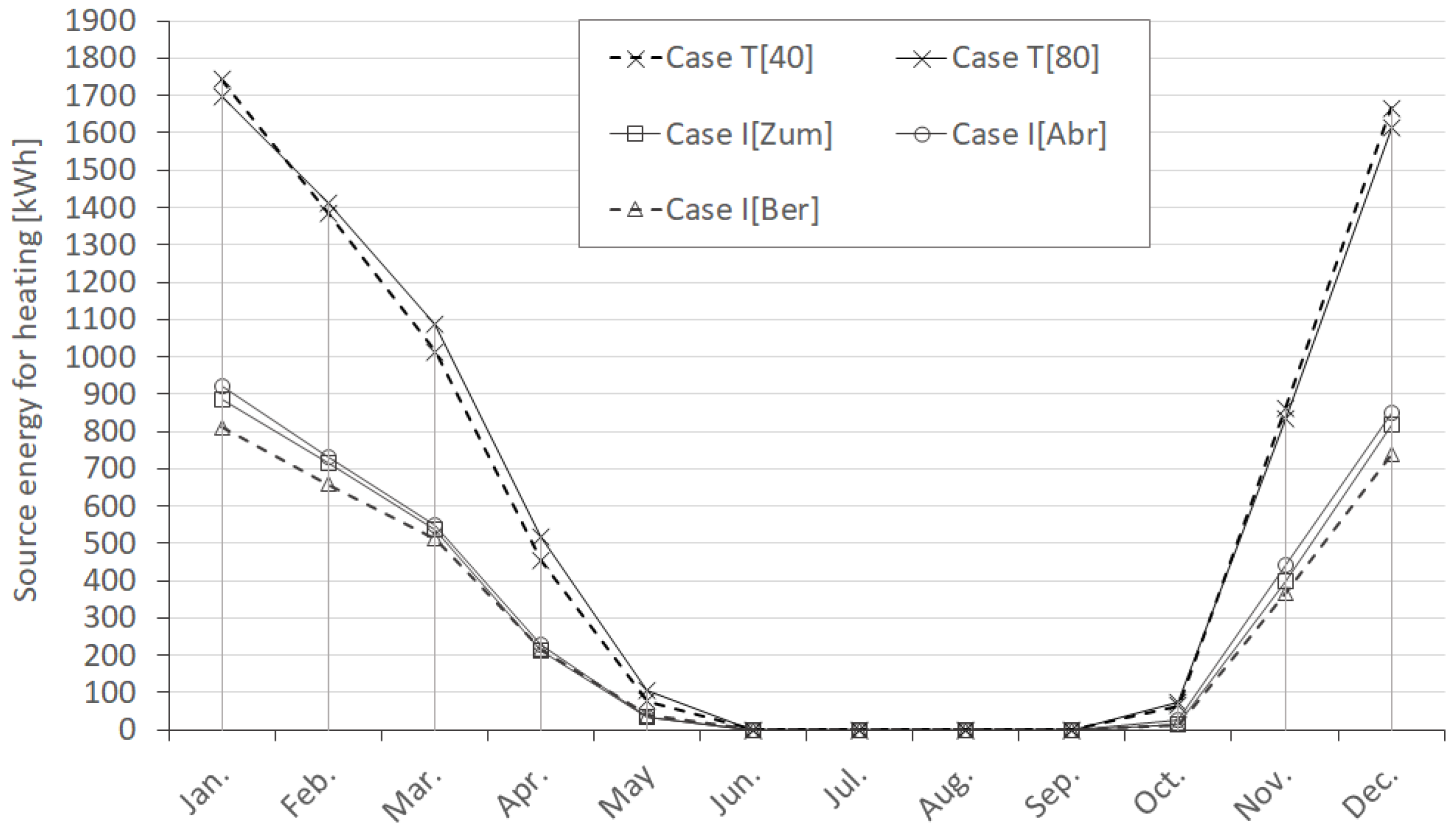

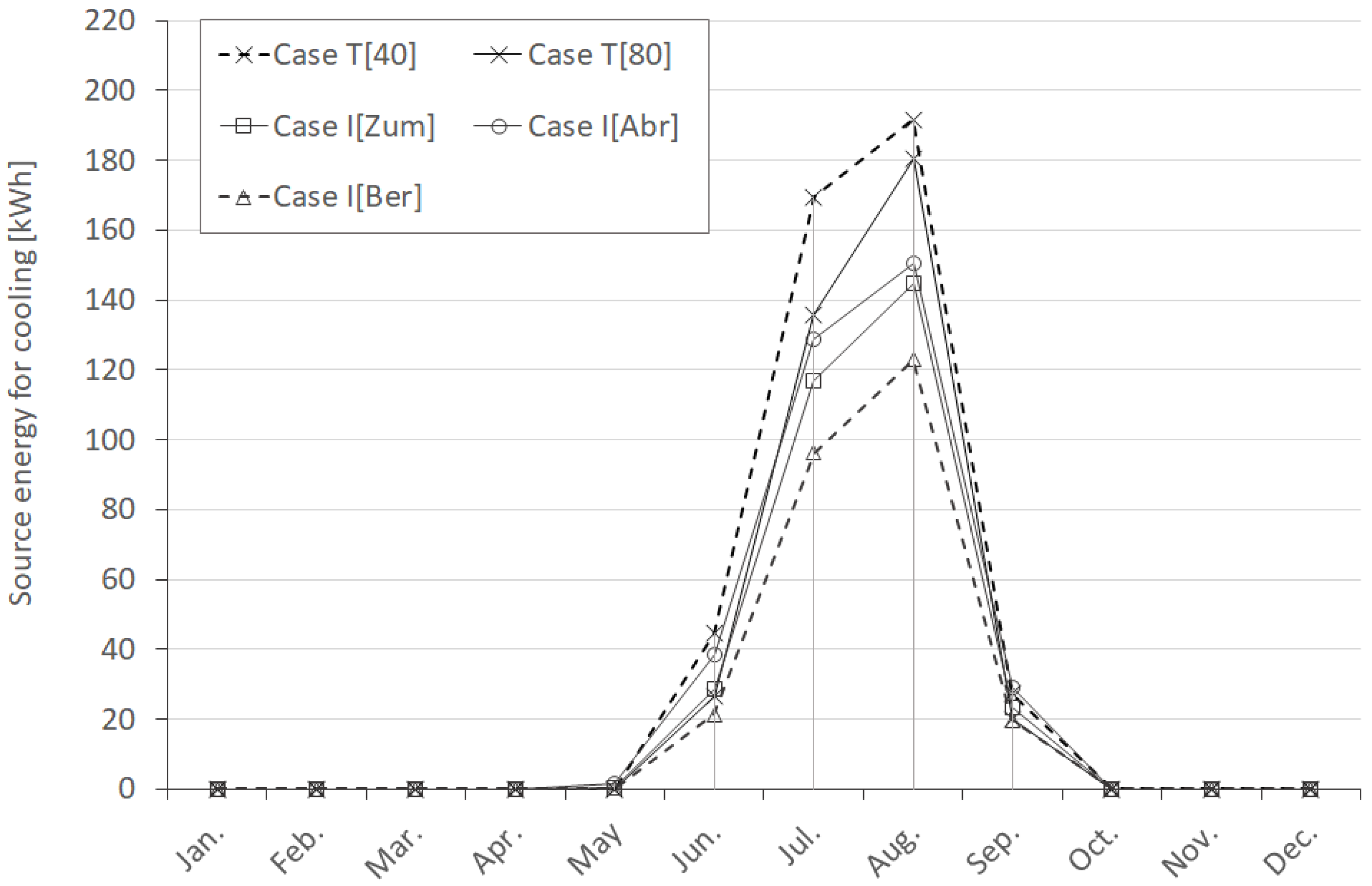

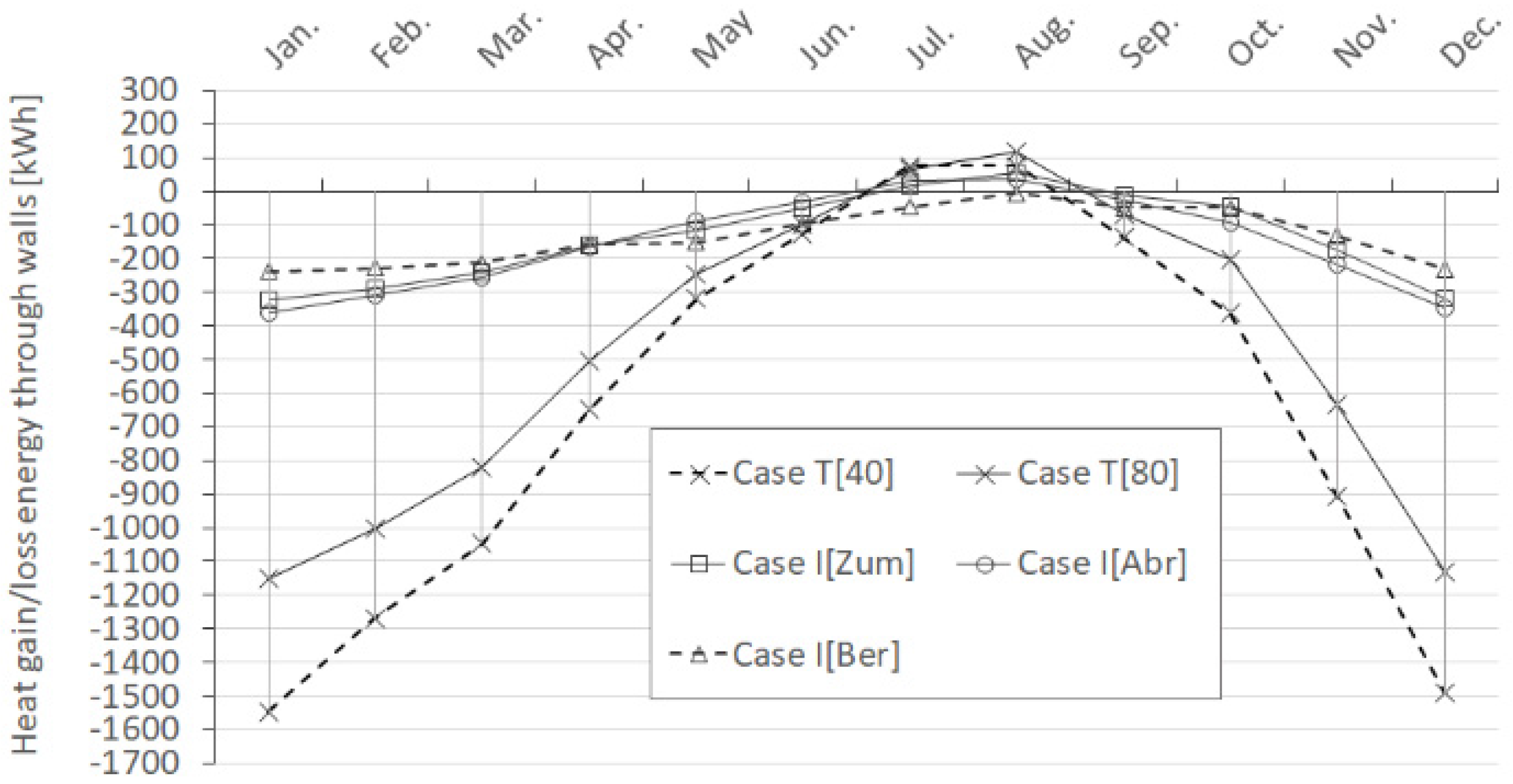

3.1. Energy Performace

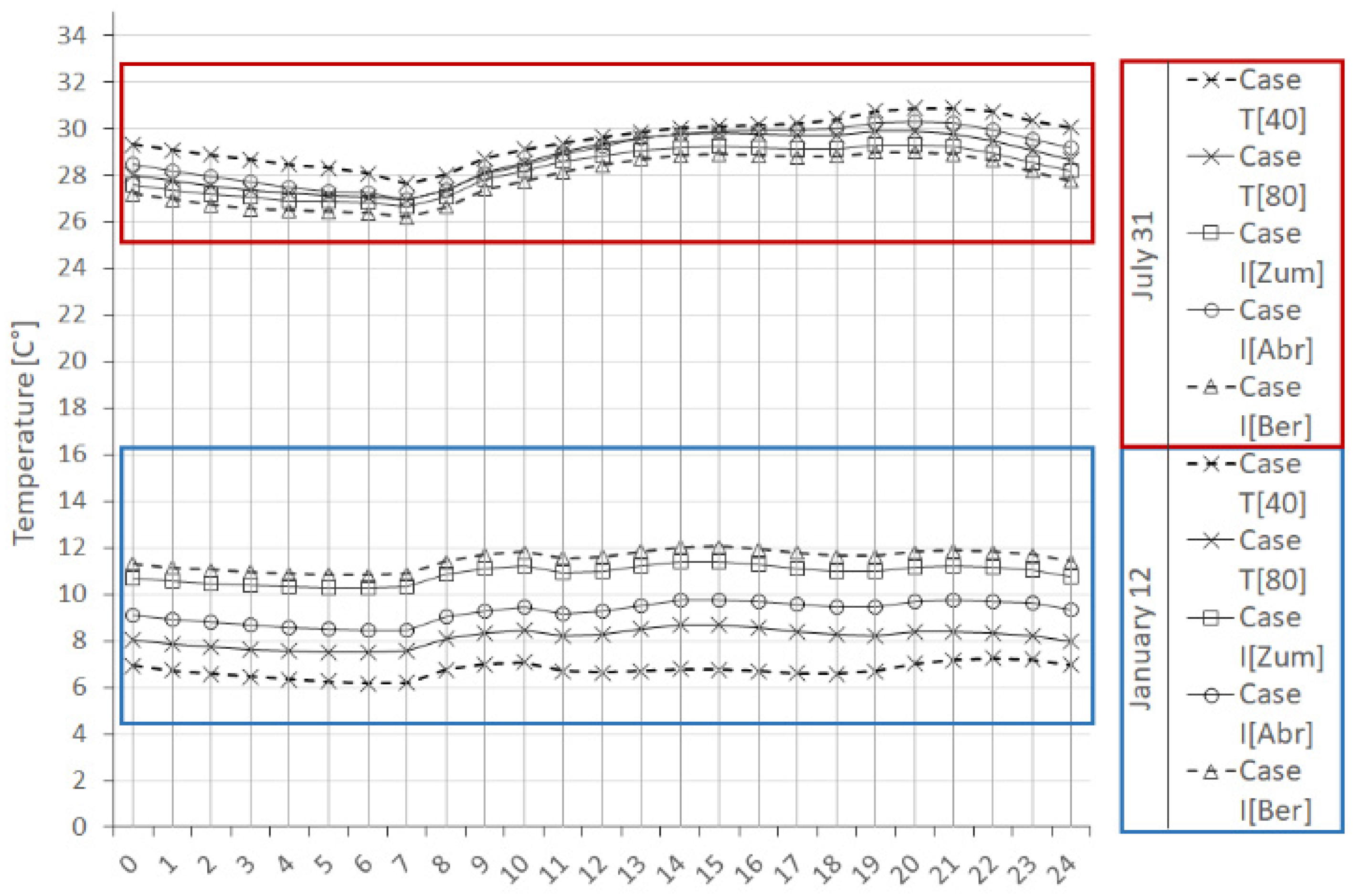

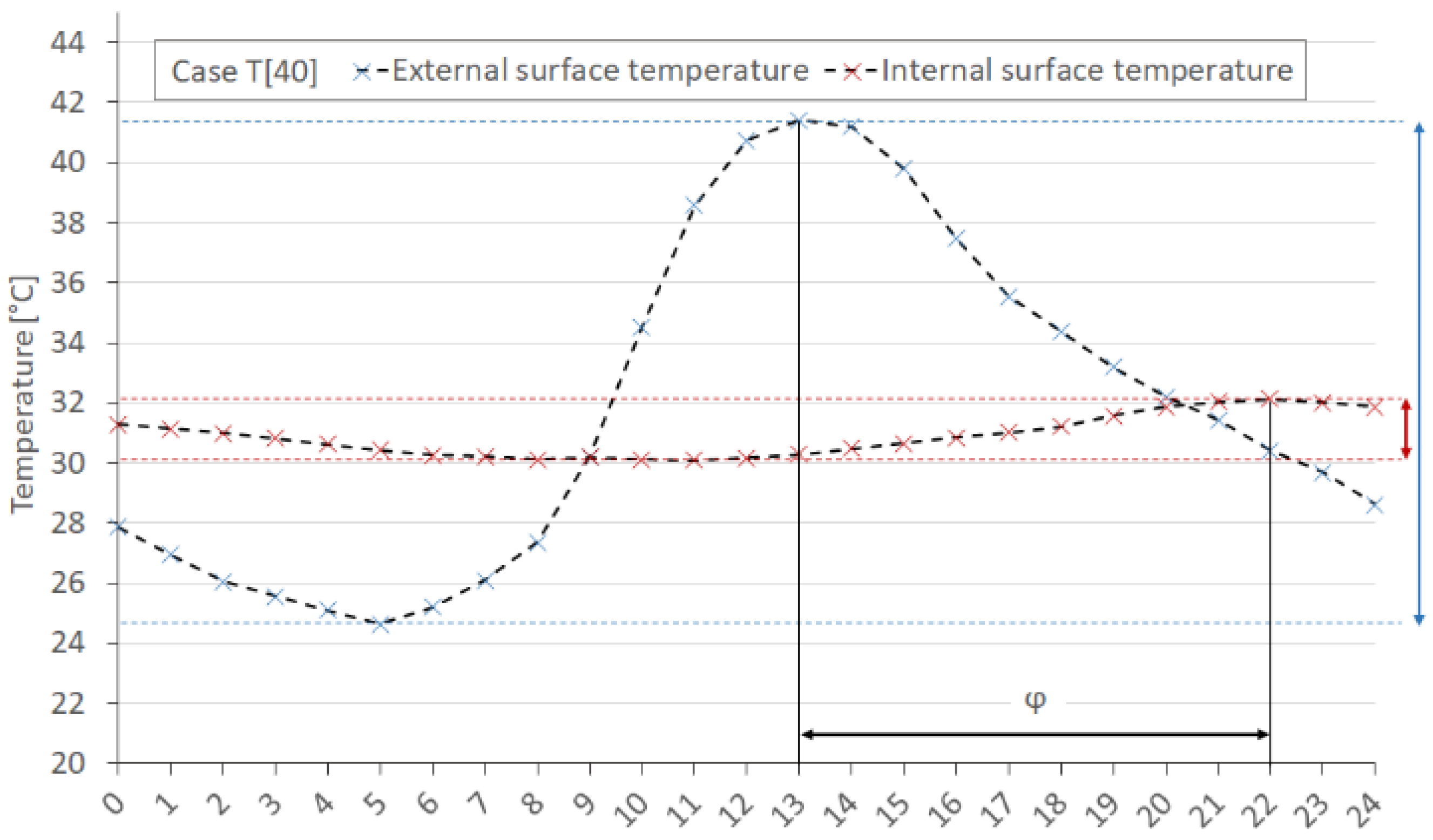

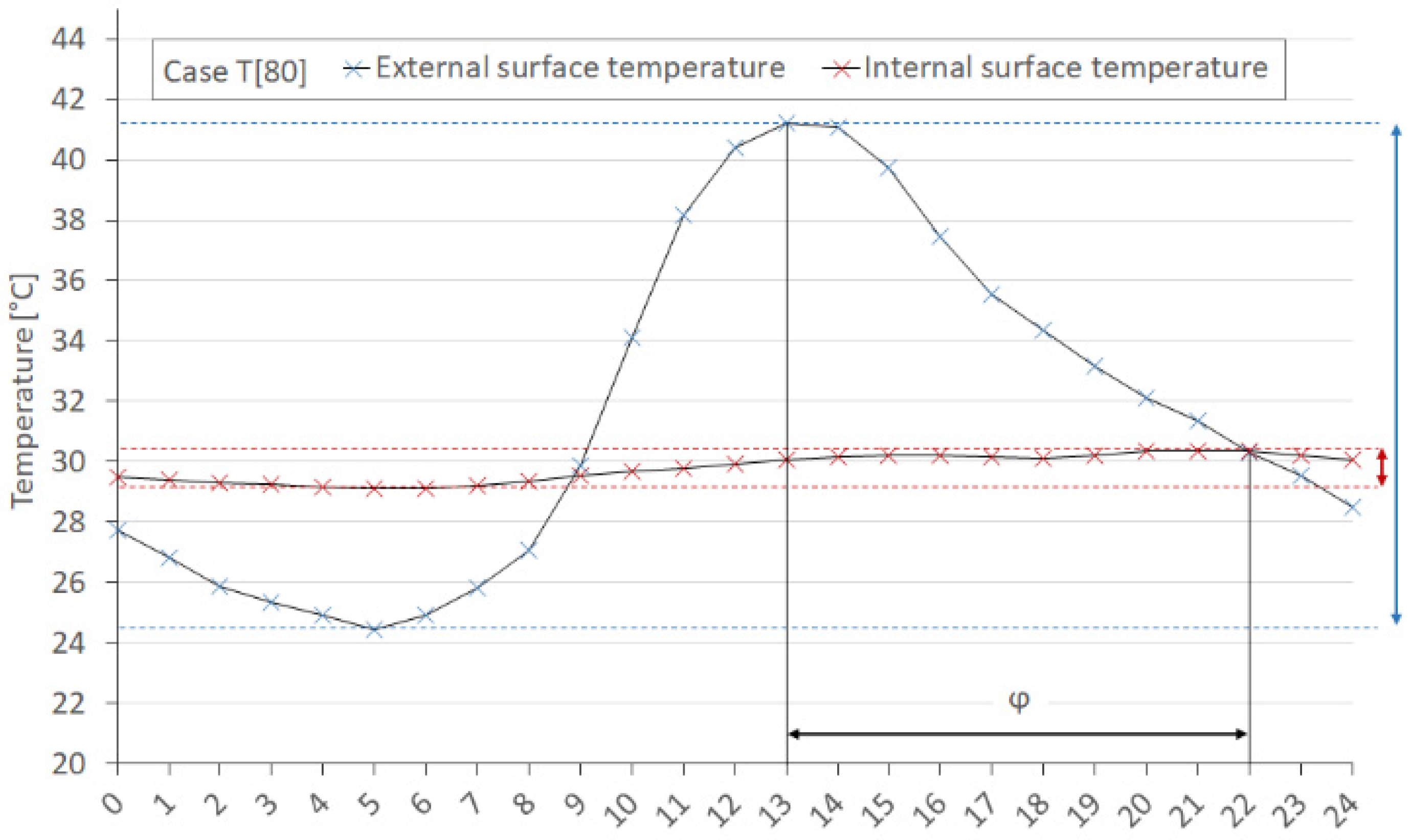

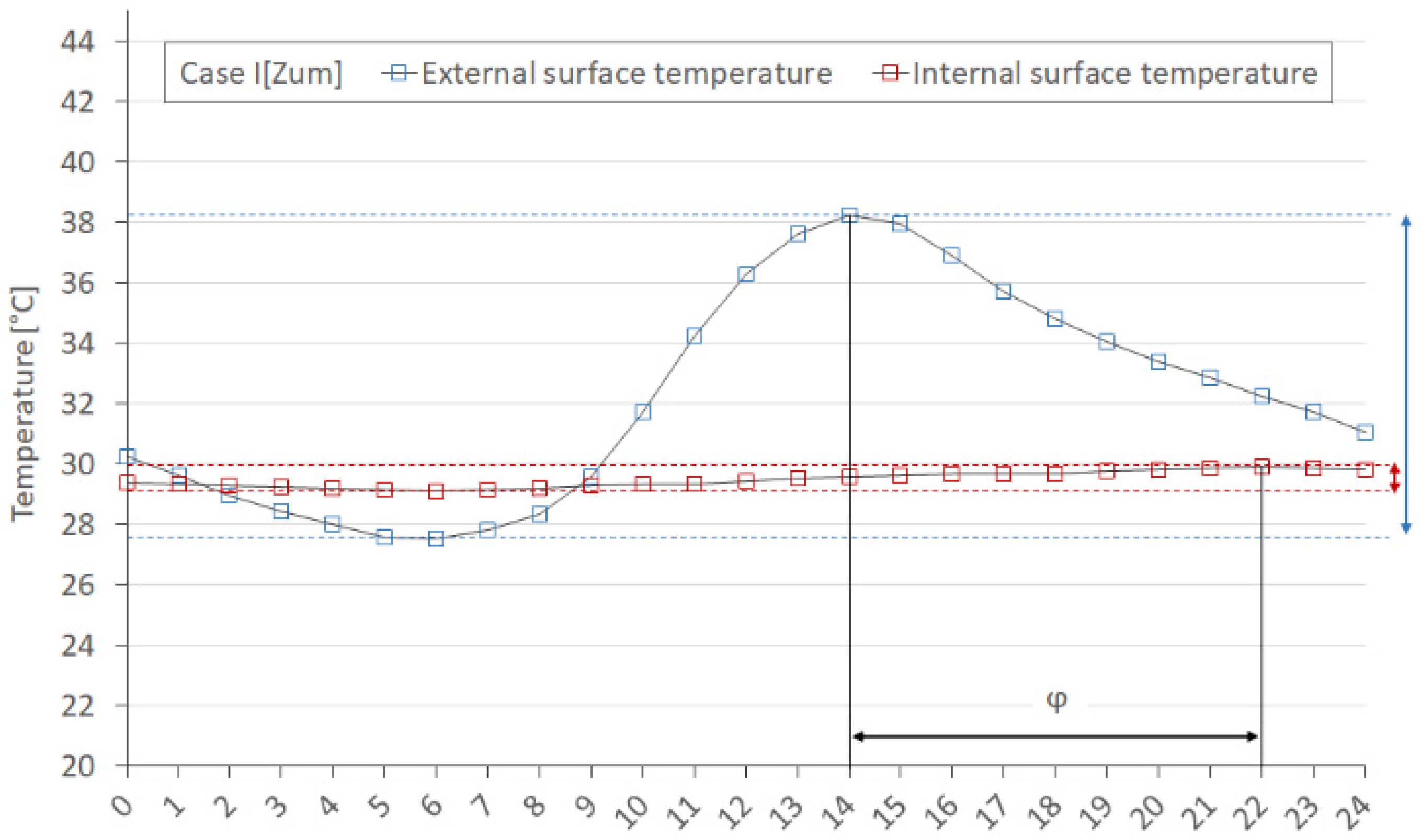

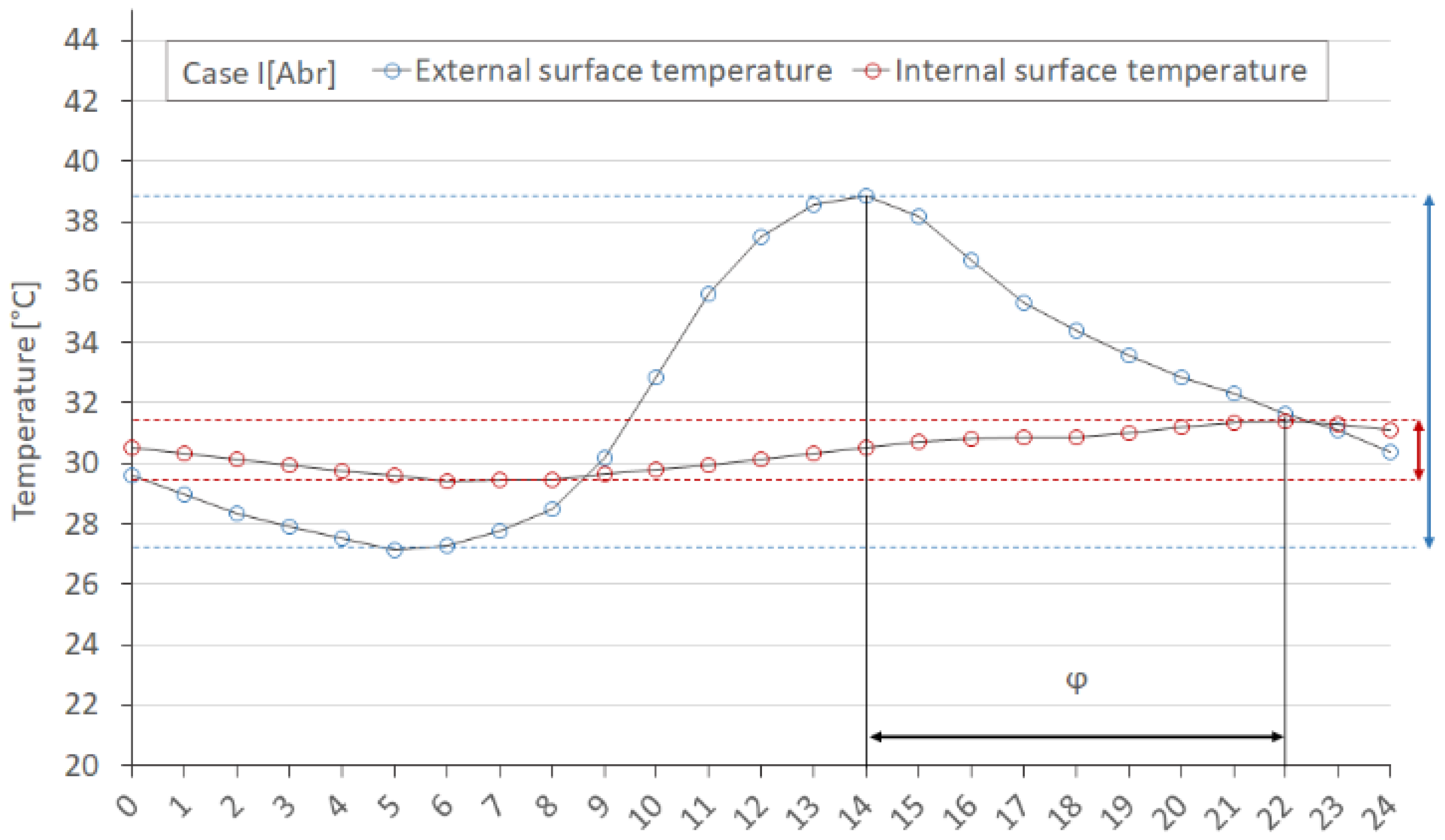

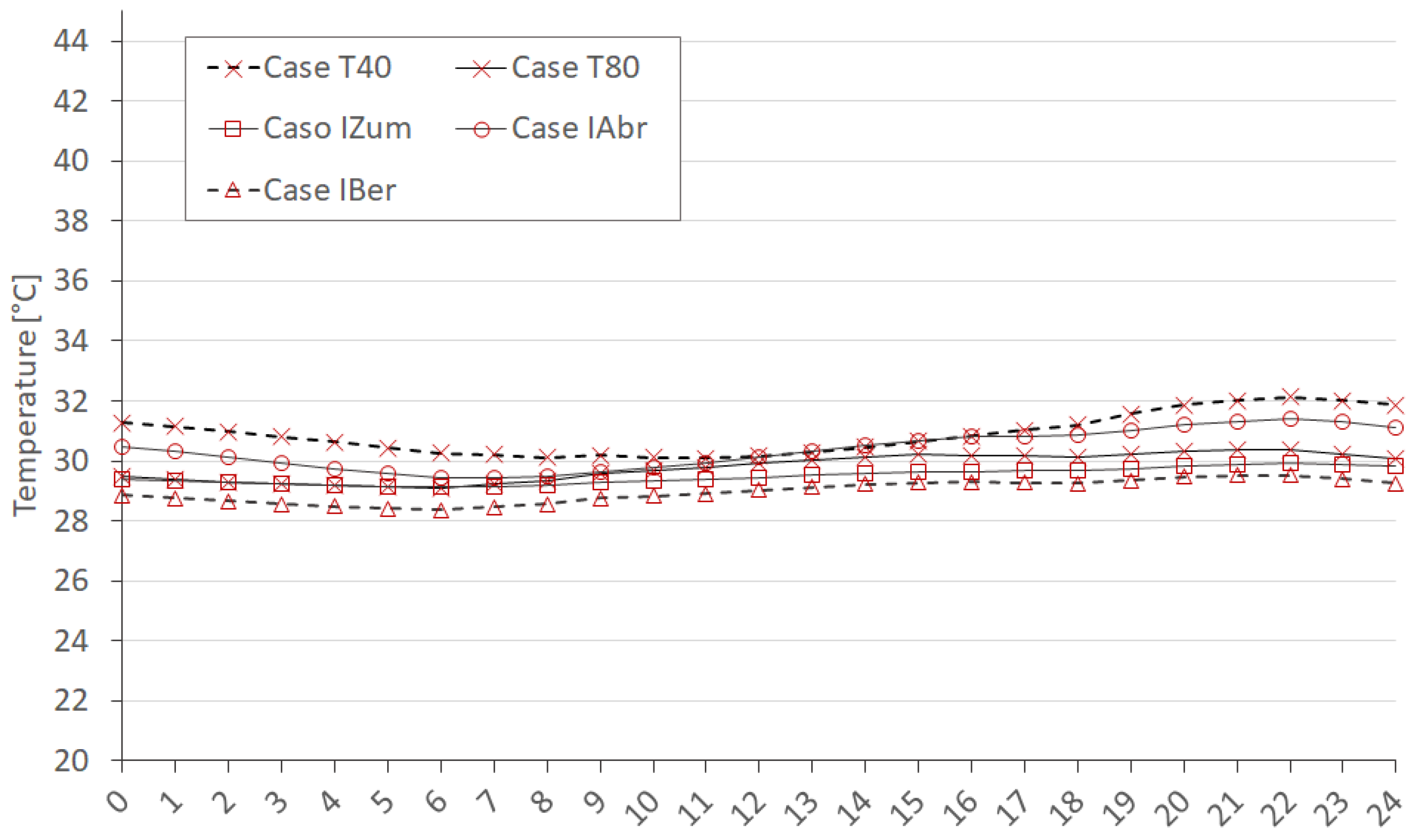

3.2. Thermal Performance

3.3. Economic Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rodolico, F. Le Pietre Delle Città D’italia; Le Monnier: Firenze, Italy, 1965. [Google Scholar]

- Martín, S.; Mazarrón, F.R.; Cañas, I. Study of thermal environment inside rural houses of Navapalos (Spain): The advantages of reuse buildings of high thermal inertia. Constr. Build. Mater. 2010, 24, 666–676. [Google Scholar] [CrossRef]

- De Berardinis, P.; Rotilio, M.; Marchionni, C.; Friedman, A. Improving the energy-efficiency of historic masonry buildings. A case study: A minor centre in the Abruzzo region, Italy. Energy Build. 2014, 80, 415–423. [Google Scholar] [CrossRef]

- Decreto Legislativo n. 311/2006, Disposizioni Correttive ed Integrative al Decreto Legislativo 19 Agosto 2005, n. 192, Recante Attuazione della Direttiva 2002/91/CE, Relativa al Rendimento Energetico in Edilizia. Available online: http://www.gazzettaufficiale.it/eli/id/2007/02/01/007G0007/sg (accessed on 25 January 2018).

- Evola, G.; Marletta, L.; Costanzo, V.; Caruso, G. Different strategies for improving summer thermal comfort in heavyweight traditional buildings. Energy Procedia 2015, 78, 3228–3233. [Google Scholar] [CrossRef]

- Stazi, F.; Angeletti, F.; Di Perna, C. Traditional Houses with Stone Walls in Temperate Climates: The Impact of Various Insulation Strategies. In Effective Thermal Insulation—The Operative Factor of a Passive Building Model; InTech: London, UK, 2012. [Google Scholar]

- Pavan, V. I linguaggi dell’architettura contemporanea. In Dalla Pietra All’architettura; Claudio Grenzi Editore: Foggia, Italy, 2006. [Google Scholar]

- Gil-Martìn, L.M.; Gonzàlez-Lòpez, M.J.; Grindlay, A.L.; Segura-Naya, A.; Aschheim, M.A.; Hernàndez-Montes, E. Toward the production of future heritage structures: Considering durability in building performance and sustainability—A philosophical and historical overview. Int. J. Sustain. Built Environ. 2012, 1, 269–273. [Google Scholar] [CrossRef]

- Rosso, F.; Jin, W.; Pisello, A.L.; Ferrero, M.; Ghandehari, M. Translucent marbles for building envelope applications: Weathering effects on surface lightness and finishing when exposed to simulated acid rain. Constr. Build. Mater. 2016, 108, 146–153. [Google Scholar] [CrossRef]

- Rosso, F.; Pisello, A.; Jin, W.; Ghandehari, M.; Cotana, F.; Ferrero, M. Cool Marble Building Envelopes: The Effect of Aging on Energy Performance and Aesthetics. Sustainability 2016, 8, 753. [Google Scholar] [CrossRef]

- DPR n. 59 del 2/4/2009, Regolamento di Attuazione Dell’art.4, Comma 1, Lettere a) e b) del D.Lgs. 192/2005. Available online: http://www.gazzettaufficiale.it/atto/serie_generale/caricaDettaglioAtto/originario?atto.dataPubblicazioneGazzetta=2009-06-10&atto.codiceRedazionale=009G0068&elenco30giorni=false (accessed on 25 January 2018).

- Di Perna, C.; Stazi, F.; Ursini Casalena, A.; D’Orazio, M. Influence of the internal inertia of the building envelope on summertime comfort in buildings with high internal heat loads. Energy Build. 2011, 43, 200–206. [Google Scholar] [CrossRef]

- Stéphan, E.; Cantin, R.; Caucheteux, A.; Tasca-Guernouti, S.; Michel, P. Experimental assessment of thermal inertia in insulated and non-insulated old limestone buildings. Build. Environ. 2014, 80, 241–248. [Google Scholar] [CrossRef]

- Aste, N.; Angelotti, A.; Buzzetti, M. The influence of the external walls thermal inertia on the energy performance of well insulated buildings. Energy Build. 2009, 41, 1181–1187. [Google Scholar] [CrossRef]

- Aste, N.; Leonforte, F.; Manfren, M.; Mazzon, M. Thermal inertia and energy efficiency—Parametric simulation assessment on a calibrated case study. Appl. Energy 2015, 145, 111–123. [Google Scholar] [CrossRef]

- Turrini, D. Architetture di gabbioni. Archit. Pietra 2007. Available online: http://www.architetturadipietra.it/wp/?p=1144 (accessed on 25 January 2018).

- Galetakis, M.; Soultana, A. A review on the utilisation of quarry and ornamental stone industry fine by-products in the construction sector. Constr. Build. Mater. 2016, 102, 769–781. [Google Scholar] [CrossRef]

- Sardinha, M.; de Brito, J.; Rodrigues, R. Durability properties of structural concrete containing very fine aggregates of marble sludge. Constr. Build. Mater. 2016, 119, 45–52. [Google Scholar] [CrossRef]

- Rosso, F.; Pisello, A.L.; Cotana, F.; Ferrero, M. On the thermal and visual pedestrians’ perception about cool natural stones for urban paving: A field survey in summer conditions. Build. Environ. 2016, 107, 198–214. [Google Scholar] [CrossRef]

- Acocella, A. L’architettura di Pietra. Antichi e Nuovi Magisteri Costruttivi; Alinea: Lucca/Firenze, Italy, 2004. [Google Scholar]

- Acocella, A. Bagni termali a Vals di Peter Zumthor (1994–1996). In L’Architettura di Pietra; Lucense-Alinea: Firenze, Italy, 2004. [Google Scholar]

- Zumthor, P. Le Terme di Vals. Casabella 1997, 648, 56–75. [Google Scholar]

- Hugues, T.; Steiger, L.; Weber, J. Pietra Naturale; UTET Scienze Tecniche: Torino, Italy, 2007. [Google Scholar]

- Pavan, V. Antón García-Abril—Scuola di Alti Studi Musicali della Galizia Santiago de Compostela, Spagna, 1999–2003. Archit. Pietra 2013. Available online: http://www.architetturadipietra.it/wp/?p=5697 (accessed on 25 January 2018).

- Pongratz, C.R.; Perbellini, M.R. Cyber Stone: Innovazioni Digitali Sulla Pietra; Edilstampa: Roma, Italy, 2009. [Google Scholar]

- Bernhard, T. Wohnhaus in Stadtbergen. Detail 2003, 11, 1274–1277. [Google Scholar]

- Susorova, I.; Tabibzadeh, M.; Rahman, A.; Clack, H.L.; Elnimeiri, M. The effect of geometry factors on fenestration energy performance and energy savings in office buildings. Energy Build. 2013, 57, 6–13. [Google Scholar] [CrossRef]

- Ascione, F.; De Masi, R.F.; de Rossi, F.; Ruggiero, S.; Vanoli, G.P. Optimization of building envelope design for nZEBs in Mediterranean climate: Performance analysis of residential case study. Appl. Energy 2016, 183, 938–957. [Google Scholar] [CrossRef]

- Salata, F.; Golasi, I.; Domestico, U.; Banditelli, M.; Lo Basso, G.; Nastasi, B.; de Lieto Vollaro, A. Heading towards the nZEB through CHP + HP systems. A comparison between retrofit solutions able to increase the energy performance for the heating and domestic hot water production in residential buildings. Energy Convers. Manag. 2017, 138, 61–76. [Google Scholar] [CrossRef]

- Zerbi, S. La pietra “pretagliata” e la ricostruzione in Francia dopo la Seconda Guerra Mondiale. Archit. Pietra 2010. Available online: http://www.architetturadipietra.it/wp/?p=3711 (accessed on 25 January 2018).

- Dernie, D. New Stone Architecture; Laurence King Publishing: London, UK, 2003. [Google Scholar]

- Titus Bernhard Architekten. Available online: http://www.bernhardarchitekten.com/ (accessed on 26 September 2017).

- Li, D.H.W.; Pan, W.; Lam, J.C. A comparison of global bioclimates in the 20th and 21st centuries and building energy consumption implications. Build. Environ. 2014, 75, 236–249. [Google Scholar] [CrossRef]

- Rosso, F.; Pisello, A.; Cotana, F.; Ferrero, M. Integrated Thermal-Energy Analysis of Innovative Translucent White Marble for Building Envelope Application. Sustainability 2014, 6, 5439–5462. [Google Scholar] [CrossRef]

- Pisello, A.L.; Petrozzi, A.; Castaldo, V.L.; Cotana, F. On an innovative integrated technique for energy refurbishment of historical buildings: Thermal-energy, economic and environmental analysis of a case study. Appl. Energy 2014, 162, 1313–1322. [Google Scholar] [CrossRef]

- Mateus, N.M.; Pinto, A.; Carrilho, G. Validation of EnergyPlus thermal simulation of a double skin naturally and mechanically ventilated test cell. Energy Build. 2014, 75, 511–522. [Google Scholar] [CrossRef]

- Lazio. Bollettino Ufficiale della Regione Lazio n 41; Lazio regional authority: Rome, Italy, 2012. [Google Scholar]

- Autorità per L’energia Elettrica il Gas e il Sistema Idrico. Available online: https://www.arera.it/it/index.htm (accessed on 25 January 2018).

- Verbeke, S.; Audenaert, A. Thermal inertia in buildings: A review of impacts across climate and building use. Renew. Sustain. Energy Rev. 2017, 1–19. [Google Scholar] [CrossRef]

- Stazi, F.; Bonfigli, C.; Tomassoni, E.; Di Perna, C.; Munafò, P. The effect of high thermal insulation on high thermal mass: Is the dynamic behaviour of traditional envelopes in Mediterranean climates still possible? Energy Build. 2015, 88, 367–383. [Google Scholar] [CrossRef]

- Asan, H. Numerical computation of time lags and decrement factors for different building materials. Build. Environ. 2006, 41, 615–620. [Google Scholar] [CrossRef]

| WMO Station Identifier 162,060 | Latitude: 42.75; Longitude 11.07 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | |

| Outside Dry-Bulb Temperature (°C) | 6.9 | 7.8 | 9.3 | 12.4 | 16.7 | 20.6 | 23.6 | 23.7 | 20.8 | 16.3 | 11.4 | 8.1 |

| Construction Element | Materials | Thickness | Thermal Transmittance |

|---|---|---|---|

| Ground floor | Timber flooring | 0.03 m | 0.20 W/(m2∙K) |

| Floor screed | 0.07 m | ||

| Glass fiber insulation | 0.15 m | ||

| Concrete | 0.2 m | ||

| Internal floor | Timber flooring | 0.03 m | 0.52 W/(m2∙K) |

| Floor screed | 0.07 m | ||

| Concrete | 0.2 m | ||

| False ceiling | Plasterborad | 0.03 m | 2.19 W/(m2∙K) |

| Roof | Clay tile | 0.025 m | 0.13 W/(m2∙K) |

| Roofing felt | 0.005 m | ||

| Stone wool | 0.24 m | ||

| Concrete | 0.25 m | ||

| Partition | Gypsum plasterboard | 0.025 m | 1.64 W/(m2∙K) |

| Air gap | 0.1 m | ||

| Gypsum plasterboard | 0.025 m | ||

| Windows | PYR B clear | 0.003 m | 1.96 W/(m2∙K) |

| Air | 0.013 m | ||

| PYR B clear | 0.003 m |

| Thermal Zone | Characteristics |

|---|---|

| 1. Domestic dining room (ground floor) | Density: 0.017 people/m2 Activity metabolic rate: eating-drinking 110 W/person Target illuminance: 150 lux Equipment gain: 3.06 W/m2, radiant fraction 20% Schedule: from 6:00 am to 10:00 am and from 6:00 pm to 10:00 pm, 7 days/week |

| 2. Domestic kitchen (ground floor) | Density: 0.024 people/m2 Activity metabolic rate: work involving walking etc 160 W/person Target illuminance: 300 lux Equipment gain: 30.28 W/m2, radiant fraction 20% Schedule: from 7:00 am to 10:00 am and from 7:00 pm to 11:00 pm, 7 days/week |

| 3. Domestic bedroom (first floor) | Density: 0.023 people/m2 Activity metabolic rate: bedroom 90 W/person Target illuminance: 100 lux Equipment gain: 3.58 W/m2, radiant fraction 20% Schedule: from 10:00 pm to 9:00 am, 7 days/week |

| 4. Domestic bathroom (first floor) | Density: 0.019 people/m2 Activity metabolic rate: light work 120 W/person Target illuminance: 150 lux Equipment gain: 1.67 W/m2, radiant fraction 20% Schedule: from 7:00 am to 10:00 am and from 7:00 pm to 11:00 pm, 7 days/week |

| Energy | Case T[40] | Case T[80] | Case I[Zum] | Case I[Abr] | Case I[Ber] |

|---|---|---|---|---|---|

| Total site energy (kWh) | 11,981.5 | 11,052.6 | 8259.0 | 8464.7 | 8075.7 |

| Energy savings with reference to the case T[40] (%) | - | 7.8 | 31.1 | 29.4 | 32.6 |

| Time Lag and Decrement Factor | Case T[40] | Case T[80] | Case I[Zum] | Case I[Abr] | Case I[Ber] |

|---|---|---|---|---|---|

| φ (h) | 9 | 9 | 8 | 8 | 8 |

| f (-) | 0.12 | 0.08 | 0.08 | 0.17 | 0.07 |

| Construction Cost | Case T[40] | Case T[80] | Case I[Zum] | Case I[Abr] | Case I[Ber] |

|---|---|---|---|---|---|

| Cost per square meter [€/m2] | 159.1 | 271.1 | 316.8 | 332.8 | 239.2 |

| Total cost [€] | 34,114.1 | 58,127.5 | 67,921.5 | 71,347.7 | 51,285.8 |

| Energy Cost | Case T[40] | Case T[80] | Case I[Zum] | Case I[Abr] | Case I[Ber] |

|---|---|---|---|---|---|

| Annual cost for heating [€] | 421.5 | 426.1 | 209.5 | 219.6 | 194.6 |

| Annual cost for cooling [€] | 132.5 | 111.1 | 96.1 | 106.6 | 79.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mariani, S.; Rosso, F.; Ferrero, M. Building in Historical Areas: Identity Values and Energy Performance of Innovative Massive Stone Envelopes with Reference to Traditional Building Solutions. Buildings 2018, 8, 17. https://doi.org/10.3390/buildings8020017

Mariani S, Rosso F, Ferrero M. Building in Historical Areas: Identity Values and Energy Performance of Innovative Massive Stone Envelopes with Reference to Traditional Building Solutions. Buildings. 2018; 8(2):17. https://doi.org/10.3390/buildings8020017

Chicago/Turabian StyleMariani, Silvia, Federica Rosso, and Marco Ferrero. 2018. "Building in Historical Areas: Identity Values and Energy Performance of Innovative Massive Stone Envelopes with Reference to Traditional Building Solutions" Buildings 8, no. 2: 17. https://doi.org/10.3390/buildings8020017