Feasibility Study of Mass-Timber Cores for the UBC Tall Wood Building

Abstract

:1. Introduction

2. UBC Tall Wood Building

2.1. Background

2.2. Building Regulation

2.3. Structural System

2.4. Connection Design

2.5. Objectives

3. Numerical Investigation

3.1. Design Options

3.2. Material Parameters

3.3. Design Requirements

3.4. Numerical Model

3.5. Analysis

4. Results and Discussion

4.1. Dynamic Elastic Behavior

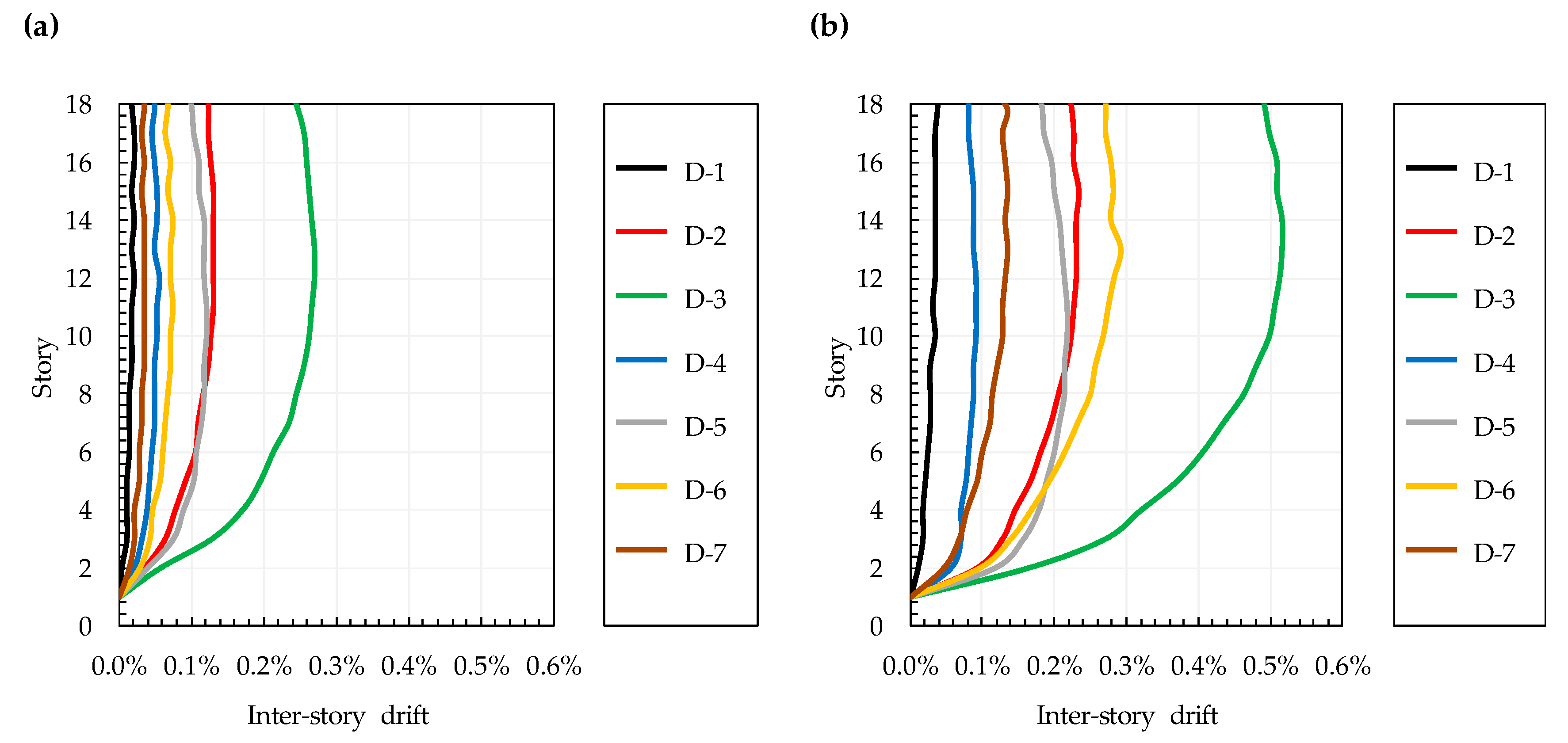

4.2. Lateral Response

4.3. Discussion

5. Life Cycle Analyses

5.1. Methods

5.2. Results and Discussion

6. Conclusions

- The side position of the cores induced a notable torsional component on the lateral response of the building, particularly evident in the case of mass-timber cores. The findings suggest the inclusion of additional shear walls to help reduce plan torsional sensitivity;

- Only design options D-4 and D-7 with LVL walls met all NBCC lateral design requirements; however, only the solution with additional ‘C-shaped’ walls appears feasible since it is unrealistic for timber panels to use completely rigid joints to build monolithic cores as assumed for D-4;

- The LVL design D-5, which had the stiffness of cores reduced by 50% to account for the joints between panels as per the authors simplified preliminary design assumption, exhibited seismic and wind performance close to code limits of 2.5% and 0.2%, respectively;

- Even for a model assuming monolithic cores, it seems unreasonable to pursue the solution with CLT for the TWB with the original layout. This recommendation is also conditioned by the commercially available CLT panel thickness, currently limited to 315 mm in Canada;

- The LCA demonstrated that the use of a mass-timber LLRS for the UBC TWB would have significant environmental benefits in regard to the impact categories recognized by LEED v4;

- Future research should investigate (i) the stiffness and capacity of horizontal and vertical connections for CLT and LVL cores; (ii) the impact of adding un-bonded post-tensioned cables; and (iii) the behavior of balloon-framed CLT/LVL systems to provide Ro and Rd factors;

- With such further research, code provisions and design rules could be developed to increase the use of mass-timber as lateral load-resisting systems.

Author Contributions

Funding

Conflicts of Interest

References

- Foliente, G. History of timber construction. In Wood Structures: A Global Forum on the Treatment, Conservation and Repair of Cultural Heritage; Kelley, S., Loferski, J., Salenikovich, A., Stern, E., Eds.; ASTM International: West Conshohocken, PA, USA, 2000; pp. 3–22. [Google Scholar]

- Buchanan, A.H.; John, S.; Love, S. LCA and carbon footprint of multi-story timber buildings compared with steel and concrete buildings. N. Z. J. For. 2013, 57, 9–18. [Google Scholar]

- De Wolf, C.; Pomponi, F.; Moncaster, A. Measuring embodied carbon dioxide equivalent of buildings: A review and critique of current industry practice. Energy Build. 2017, 140, 68–80. [Google Scholar] [CrossRef]

- Karacabeyli, E.; Lum, C. Technical Guide for the Design and Construction of Tall Wood Buildings in Canada; Special Publication SP-55E; FPInnovations: Vancouver, BC, Canada, 2014. [Google Scholar]

- Smith, I.; Frangi, A. Use of Timber in Tall Multi-Story Buildings; Structural Engineering Document 13 (SED13); International Association for Bridge and Structural Engineering (IABSE): Zurich, Switzerland, 2014; ISBN 978-3-85748-132-1. [Google Scholar]

- Green, M.; Karsh, J.E. Tall Wood-The Case for Tall Wood Buildings, 2nd ed.; Wood Enterprise Coalition: Vancouver, BC, Canada, 2018. [Google Scholar]

- National Research Council of Canada (NRCC). British Columbia Building Code; NRCC: Victoria, BC, Canada, 2012; ISBN 978-0-7726-6593-5. [Google Scholar]

- Jeske, J.; Esposito, D. Reference Guide: Mid-Rise Wood Construction in the Ontario Building Code Report; Report No. 2150027.00; Hershfield, M., Ed.; Ontario Wood WORKS: North Bay, ON, Canada, 2015. [Google Scholar]

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross laminated timber (CLT): Overview and development. Eur. J. Wood Wood Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- Ceccotti, A.; Sandhaas, C.; Okabe, M.; Yasumura, M.; Minowa, C.; Kawai, N. SOFIE project—3D shaking table test on a seven-story full-scale cross-laminated timber building. Earthq. Eng. Struct. Dyn. 2013, 42, 2003–2021. [Google Scholar] [CrossRef]

- Gavric, I.; Fragiacomo, M.; Ceccotti, A. Cyclic behavior of CLT wall systems: Experimental tests and analytical prediction models. J. Struct. Eng. 2015, 141, 04015034. [Google Scholar] [CrossRef]

- Pei, S.; van de Lindt, J.W.; Popovski, M.; Berman, J.W.; Dolan, J.D.; Ricles, J.M.; Sause, R.; Blomgren, H.; Rammer, D.R. Cross laminated timber for seismic regions: Progress and challenges for research and implementation. J. Struct. Eng. 2016, 142, E2514001. [Google Scholar] [CrossRef]

- Shahnewaz, M.; Tannert, T.; Alam, M.S.; Popovski, M. In-plane stiffness of cross-laminated timber panels with openings. Struct. Eng. Int. 2017, 27, 217–223. [Google Scholar] [CrossRef]

- Dietsch, P.; Brandner, R. Self-tapping screws and threaded rods as reinforcement for structural timber elements—A state-of-the-art report. Constr. Build. Mater. 2015, 97, 78–89. [Google Scholar] [CrossRef]

- Hossain, A.; Danzig, I.; Tannert, T. Cross-laminated timber shear connection with innovative self-tapping screw assemblies. J. Struct. Eng. 2016, 142, 04016099. [Google Scholar] [CrossRef]

- Hossain, A.; Popovski, M.; Tannert, T. Cross-laminated timber connections assembled with a combination of screws in withdrawal and screws in shear. Eng. Struct. 2018, 168, 1–11. [Google Scholar] [CrossRef]

- Newcombe, M.P.; Pampanin, S.; Buchanan, A.; Palermo, A. Section analysis and cyclic behavior of post-tensioned jointed ductile connections for multi-story timber buildings. J. Earthq. Eng. 2008, 12, 83–110. [Google Scholar] [CrossRef]

- Iqbal, A.; Pampanin, S.; Buchanan, A.H. Seismic performance of full-scale post-tensioned timber beam-column connections. J. Earthq. Eng. 2016, 20, 383–405. [Google Scholar] [CrossRef]

- Ganey, R.; Berman, J.; Akbas, T.; Loftus, S.; Dolan, J.D.; Sause, R.; Ricles, J.; Pei, S.; van de Lindt, J.; Blomgren, H.E. Experimental investigation of self-centering cross-laminated timber walls. J. Struct. Eng. 2017, 143, 04017135. [Google Scholar] [CrossRef]

- Tesfamariam, S.; Stiemer, S.F.; Dickof, C.; Bezabeh, M.A. Seismic vulnerability assessment of hybrid steel-timber structure: Steel moment resisting frames with CLT infill. J. Earthq. Eng. 2014, 18, 929–944. [Google Scholar] [CrossRef]

- Zhang, X.; Fairhurst, M.; Tannert, T. Ductility estimation for a novel timber–steel hybrid system. J. Struct. Eng. 2016, 142, E4015001. [Google Scholar] [CrossRef]

- Zhang, X.; Riasat, A.; Bhat, P.; Popovski, M.; Tannert, T. Seismic performance of embedded steel beam connection in cross-laminated timber panels for tall-wood hybrid system. Can. J. Civ. Eng. 2017, 44, 611–618. [Google Scholar] [CrossRef] [Green Version]

- Skidmore, Owings & Merrill (SOM), LLP. Timber Tower Research Project; Final Report; SOM: Chicago, IL, USA, 2013; Available online: http://www.som.com (accessed on 20 June 2018).

- Dias, A.; Skinner, J.; Crews, K.; Tannert, T. Timber-concrete-composites increasing the use of timber in construction. Eur. J. Wood Wood Prod. 2016, 74, 443–451. [Google Scholar] [CrossRef]

- Skidmore, Owings & Merrill (SOM), LLP. AISC Steel & Timber Research for High-Rise Residential Buildings; Final Report; SOM: Chicago, IL, USA, 2017; Available online: http://www.som.com (accessed on 20 June 2018).

- Loss, C.; Frangi, A. Experimental investigation on in-plane stiffness and strength of innovative steel-timber hybrid floor diaphragms. J. Eng. Struct. 2017, 138, 229–244. [Google Scholar] [CrossRef]

- Loss, C.; Rossi, S.; Tannert, T. In-plane stiffness of hybrid steel-cross-laminated timber floor diaphragms. J. Struct. Eng. 2018, 144, 04018128. [Google Scholar] [CrossRef]

- Poirier, E.; Moudgil, M.; Fallahi, A.; Staub-French, S.; Tannert, T. Design and construction of a 53 meter tall timber building at the university of British Columbia. In Proceedings of the World Conference on Timber Engineering (WCTE2016), Vienna, Austria, 22–25 August 2016. [Google Scholar]

- Malo, K.A.; Abrahamsen, R.B.; Bjertnæs, M.A. Some structural design issues of the 14-story timber framed building “Treet” in Norway. Eur. J. Wood Wood Prod. 2016, 74, 407–424. [Google Scholar] [CrossRef]

- Tannert, T.; Moudgil, M. Structural design, approval and monitoring of UBC Tall Wood Building. In Proceedings of the ASCE Structures Congress, Denver, CO, USA, 6–8 April 2017. [Google Scholar]

- Bergen, N. Case study of UBC Brock Commons—Construction details and methods. In Proceedings of the World Conference on Timber Engineering (WCTE2016), Vienna, Austria, 22–25 August 2016. [Google Scholar]

- Fast, P.; Gafner, B.; Jackson, R.; Li, J. Case study: An 18 story tall mass timber hybrid student residence at the University of British Columbia, Vancouver. In Proceedings of the World Conference on Timber Engineering (WCTE2016), Vienna, Austria, 22–25 August 2016. [Google Scholar]

- Flatscher, G.; Schickhofer, G. Displacement-based determination of laterally loaded cross laminated timber (CLT) wall systems. In Proceedings of the International Network on Timber Engineering Research (INTER2016), Graz, Austria, 16–19 August 2016. [Google Scholar]

- Polastri, A.; Loss, C.; Pozza, L.; Smith, I. CLT buildings laterally braced with core and perimeter walls. In Proceedings of the World Conference on Timber Engineering (WCTE2016), Vienna, Austria, 22–25 August 2016. [Google Scholar]

- Izzi, M.; Polastri, A.; Fragiacomo, M. Investigating the hysteretic behavior of Cross-Laminated Timber wall systems due to connections. J. Struct. Eng. 2018, 144. [Google Scholar] [CrossRef]

- National Research Council of Canada (NRCC). National Building Code of Canada 2015; NRCC: Ottawa, ON, Canada, 2015; Volume 1, p. 708; Volume 2, p. 696. [Google Scholar]

- Canadian Standards Association (CSA). CSA-O86-2016 Engineering Design in Wood; 2016 update to the 2014 standard edition; CSA Group: Mississauga, ON, Canada, 2016. [Google Scholar]

- Canadian Standards Association (CSA). A23.3-14 Design of Concrete Structures; CSA Group: Ottawa, ON, Canada, 2014. [Google Scholar]

- Crosslam® CLT-Technical Design Guide. Available online: http://www.structurlam.com/ (accessed on 20 June 2018).

- Canadian Construction and Materials Centre (CCMC). Evaluation Report CCMC 11518-R: LP-Solid Start LVL. 2015. Available online: https://lpcorp.com (accessed on 20 June 2018).

- Natural Resources Canada (NRC). Determine 2015 National Building Code of Canada Seismic Hazard Values; NRC: Ottawa, ON, Canada; Available online: http://www.earthquakescanada.nrcan.gc.ca/ (accessed on 30 October 2017).

- Dlubal. Structural Engineering Software for Analysis and Design; RFEM Version 5.11; Dlubal Software, Inc.: Philadelphia, PA, USA, 2017. [Google Scholar]

- Athena Institute. Athena Impact Estimator for Buildings Version 5.2.0119; Athena Sustainable Materials Institute: Ottawa, ON, Canada, 2017. [Google Scholar]

- LEED Canada for New Construction and Major Renovations 2009: Rating System. Available online: https://www.cagbc.org (accessed on 20 June 2018).

- Skog, K.E.; Nicholson, G.A. Carbon Cycling through wood products: The role of wood and paper products in carbon sequestration. For. Prod. J. 1998, 48, 75–83. [Google Scholar]

| Property | Concrete | CLT | LVL |

|---|---|---|---|

| E1 | 26,540 | 12,400 (0°-layers) 9500 (90°-layers) | 13,800 |

| G23 | 11,058 | 78 (0°-layers); 59 (90°-layers) | 55 |

| G12, G13 | 775 (0°-layers); 594 (90°-layers) | 550 |

| Design | T1 (s) | T2 (s) | T3 (s) | ∑mx (%) | ∑my (%) |

|---|---|---|---|---|---|

| D-1* | 2.0 | 1.7 | 1.4 | n/a | n/a |

| D-1 | 2.0 | 1.5 | 1.3 | 77 | 61 |

| D-2 | 4.3 | 3.0 | 2.8 | 87 | 84 |

| D-3 | 6.1 | 4.3 | 4.3 | 89 | 89 |

| D-4 | 3.0 | 2.1 | 2.0 | 87 | 86 |

| D-5 | 4.3 | 3.1 | 3.0 | 89 | 90 |

| D-6 | 3.9 | 3.5 | 3.1 | 83 | 83 |

| D-7 | 2.8 | 2.6 | 2.3 | 84 | 84 |

| Design | Vb,X (kN) | Vb,Y (kN) | θmax,X (%) | θmax,Y (%) |

|---|---|---|---|---|

| D-1 | 34,285 (6122) | 36,847 (7184) | 1.1 | 1.3 |

| D-2 | 20,882 (19,322) | 30,209 (23,238) | 1.9 | 2.7 |

| D-3 | 22,662 (19,322) | 25,118 (19,322) | 3.5 | 3.3 |

| D-4 | 28,617 (22,013) | 34,624 (26,634) | 1.5 | 1.8 |

| D-5 | 21,405 (19,931) | 30,870 (23,746) | 1.8 | 2.6 |

| D-6 | 25,056 (19,743) | 27,752 (21,348) | 1.6 | 3.0 |

| D-7 | 30,682 (23,602) | 33,829 (26,022) | 1.3 | 2.5 |

| Design | Vb,X (kN) | Vb,Y (kN) | θmax,X (%) | θmax,Y (%) |

|---|---|---|---|---|

| D-1 | 615 | 2319 | 0.02 | 0.04 |

| D-2 | 804 | 2856 | 0.13 | 0.23 |

| D-3 | 925 | 3286 | 0.27 | 0.52 |

| D-4 | 699 | 2538 | 0.06 | 0.09 |

| D-5 | 808 | 2867 | 0.12 | 0.22 |

| D-6 | 747 | 2633 | 0.07 | 0.32 |

| D-7 | 668 | 2412 | 0.04 | 0.14 |

| Design | Cores | Caps + Stairs | ||

|---|---|---|---|---|

| Material | Volume (m3) | Material | Volume (m3) | |

| D-1 | Concrete | 1314 | Concrete | 147 |

| D-2 | CLT | 928 | CLT | 116 |

| D-4 | LVL | 1311 | CLT | 116 |

| D-6 | CLT | 1583 | CLT | 116 |

| D-7 | LVL | 2236 | CLT | 116 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Connolly, T.; Loss, C.; Iqbal, A.; Tannert, T. Feasibility Study of Mass-Timber Cores for the UBC Tall Wood Building. Buildings 2018, 8, 98. https://doi.org/10.3390/buildings8080098

Connolly T, Loss C, Iqbal A, Tannert T. Feasibility Study of Mass-Timber Cores for the UBC Tall Wood Building. Buildings. 2018; 8(8):98. https://doi.org/10.3390/buildings8080098

Chicago/Turabian StyleConnolly, Thomas, Cristiano Loss, Asif Iqbal, and Thomas Tannert. 2018. "Feasibility Study of Mass-Timber Cores for the UBC Tall Wood Building" Buildings 8, no. 8: 98. https://doi.org/10.3390/buildings8080098