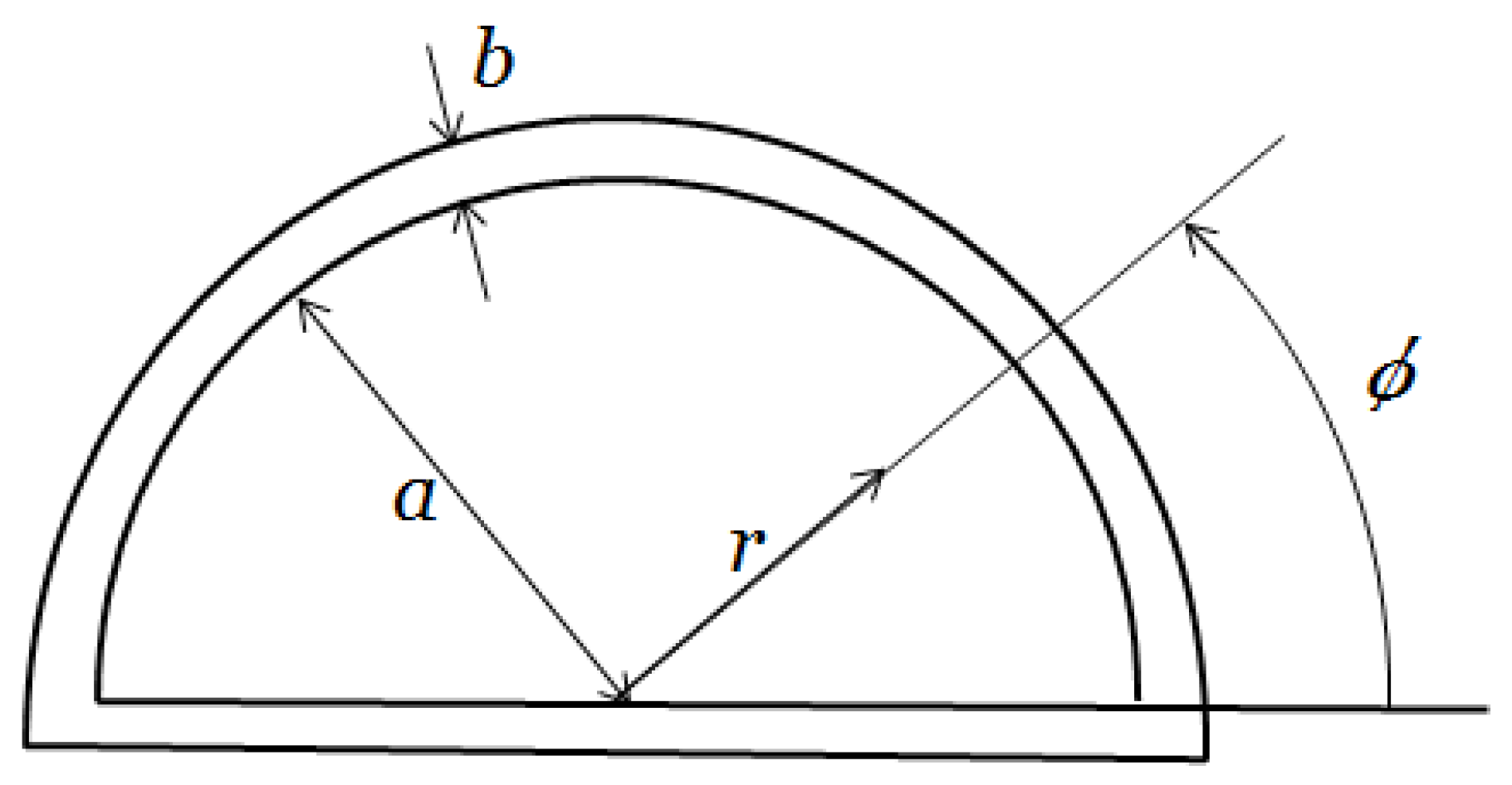

Soft actuators have been getting increased attention with the development of medical techniques and in other fields. Soft actuators are actuators that are composed of flexible materials. Because of their flexibility and high safety for fragile objects, they are expected to be applied in the medical, biological and welfare fields. Many of the soft actuators are driven by air pressure; for example, McKibben artificial muscles and straight fiber-type artificial muscles. However, these actuators have some problems. First, because of their complicated manufacturing process, miniaturizing and cutting cost are limited. Second, if they can be miniaturized, they cannot move greatly. Finally, the number of tubes that are supplied air pressure is increased with increasing the number of bending directions. Thus, a miniature pneumatic bending rubber actuator [

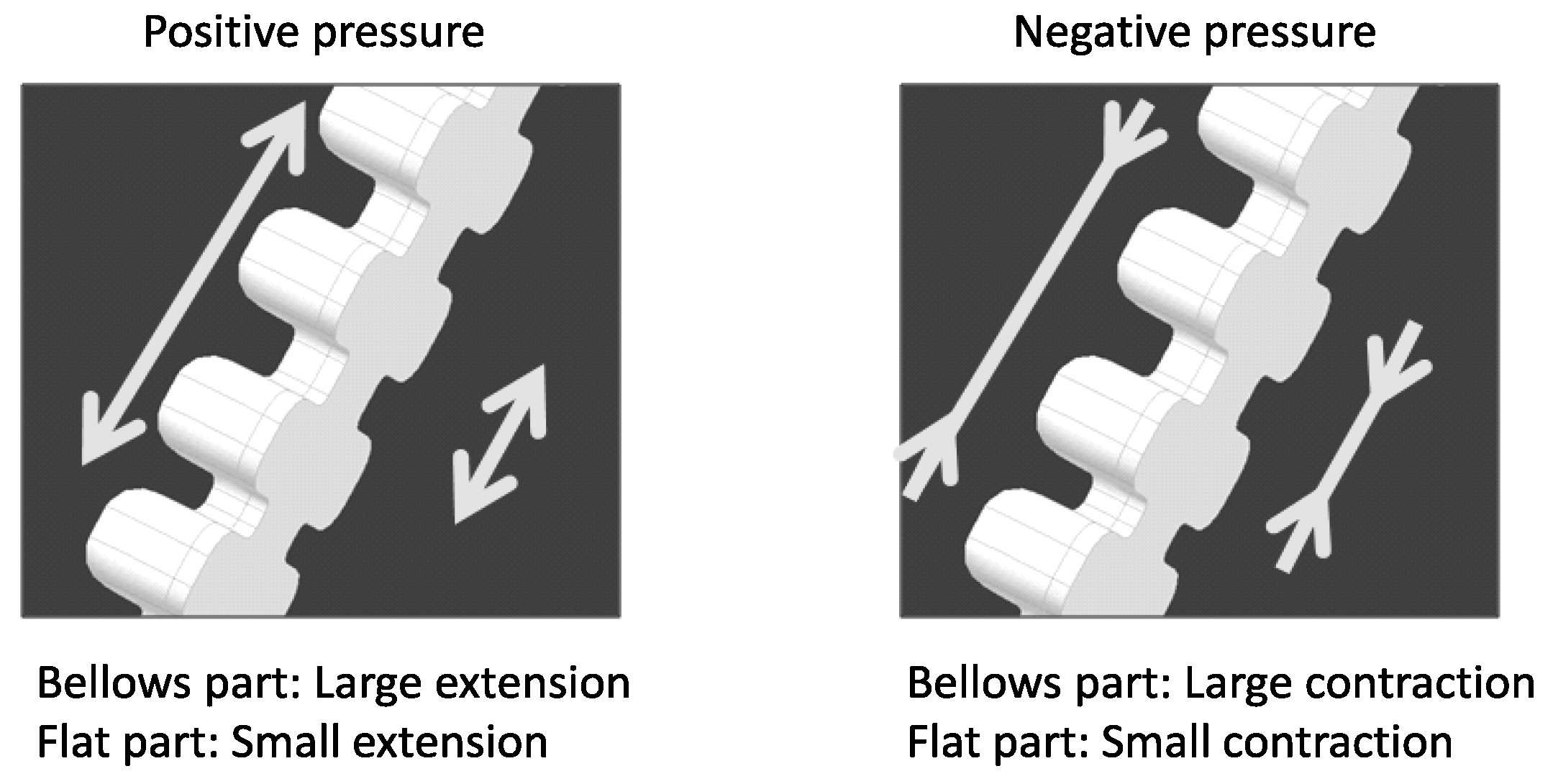

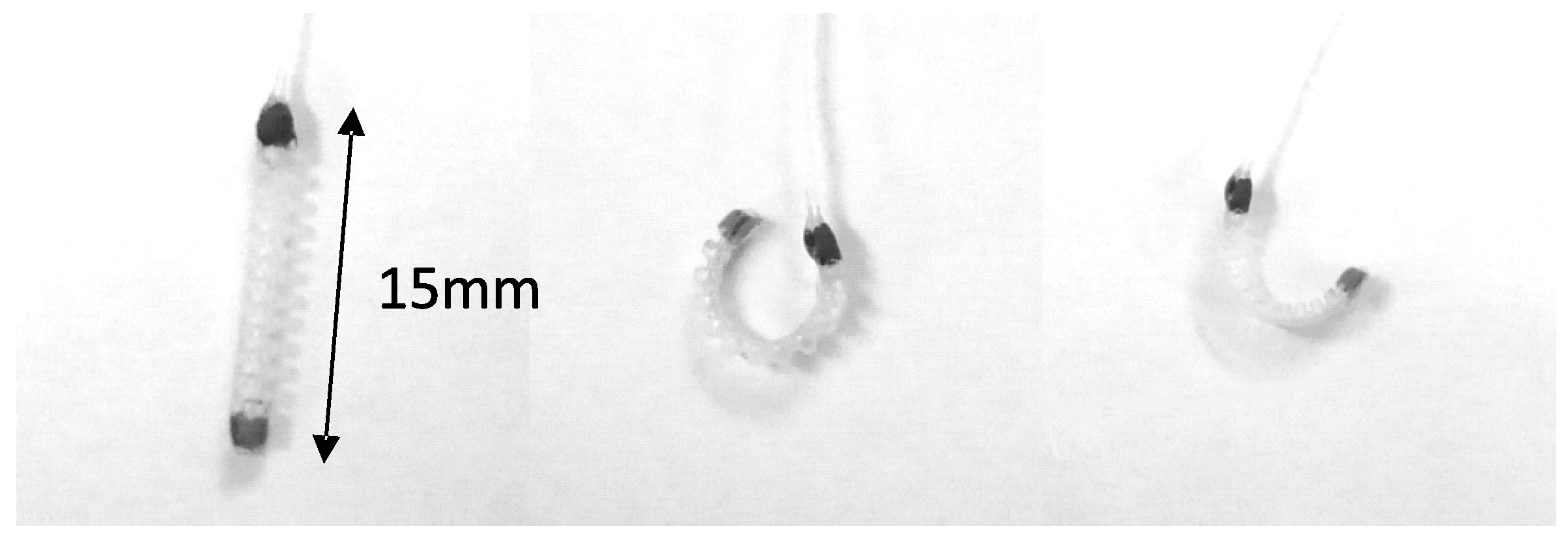

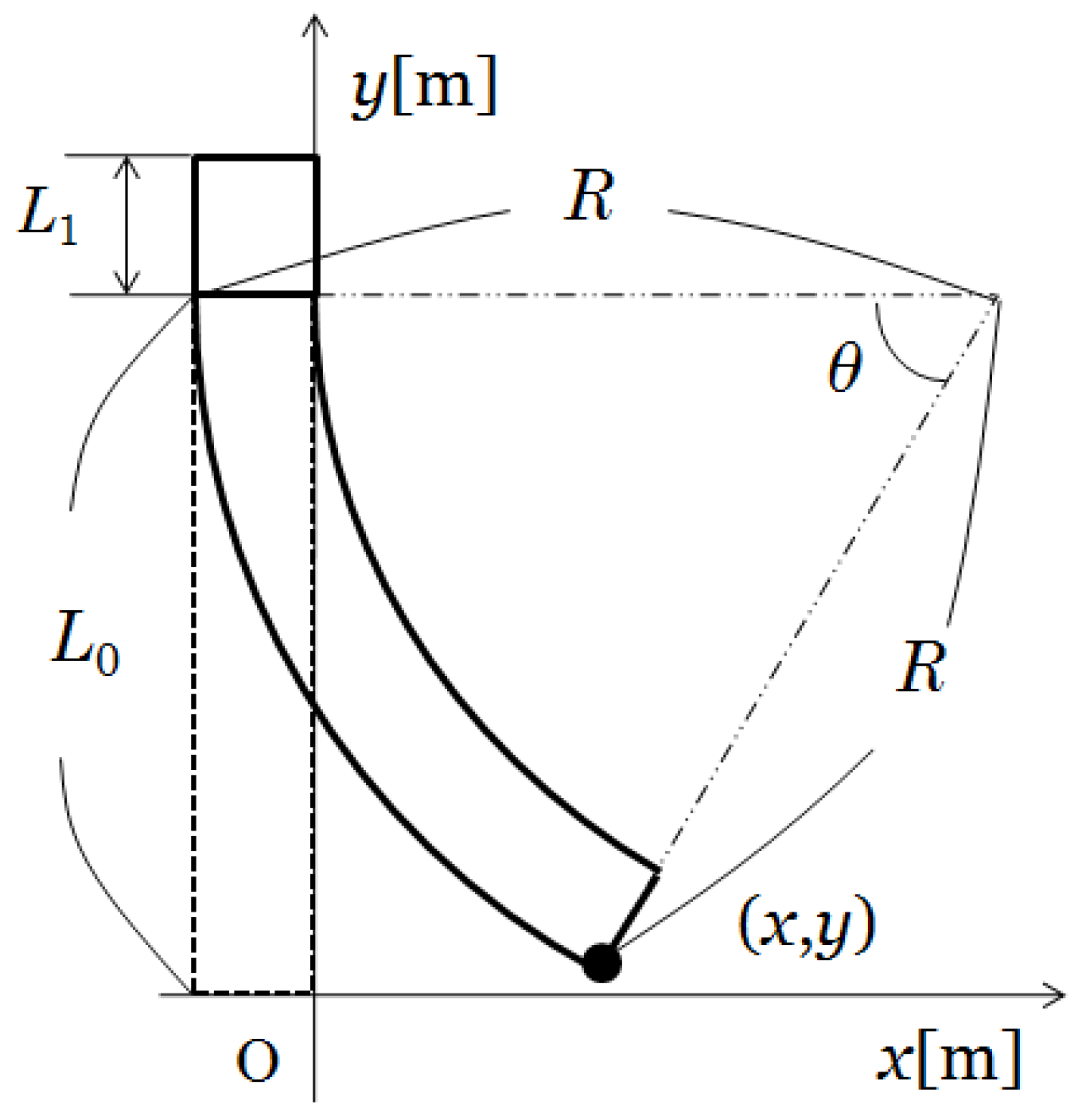

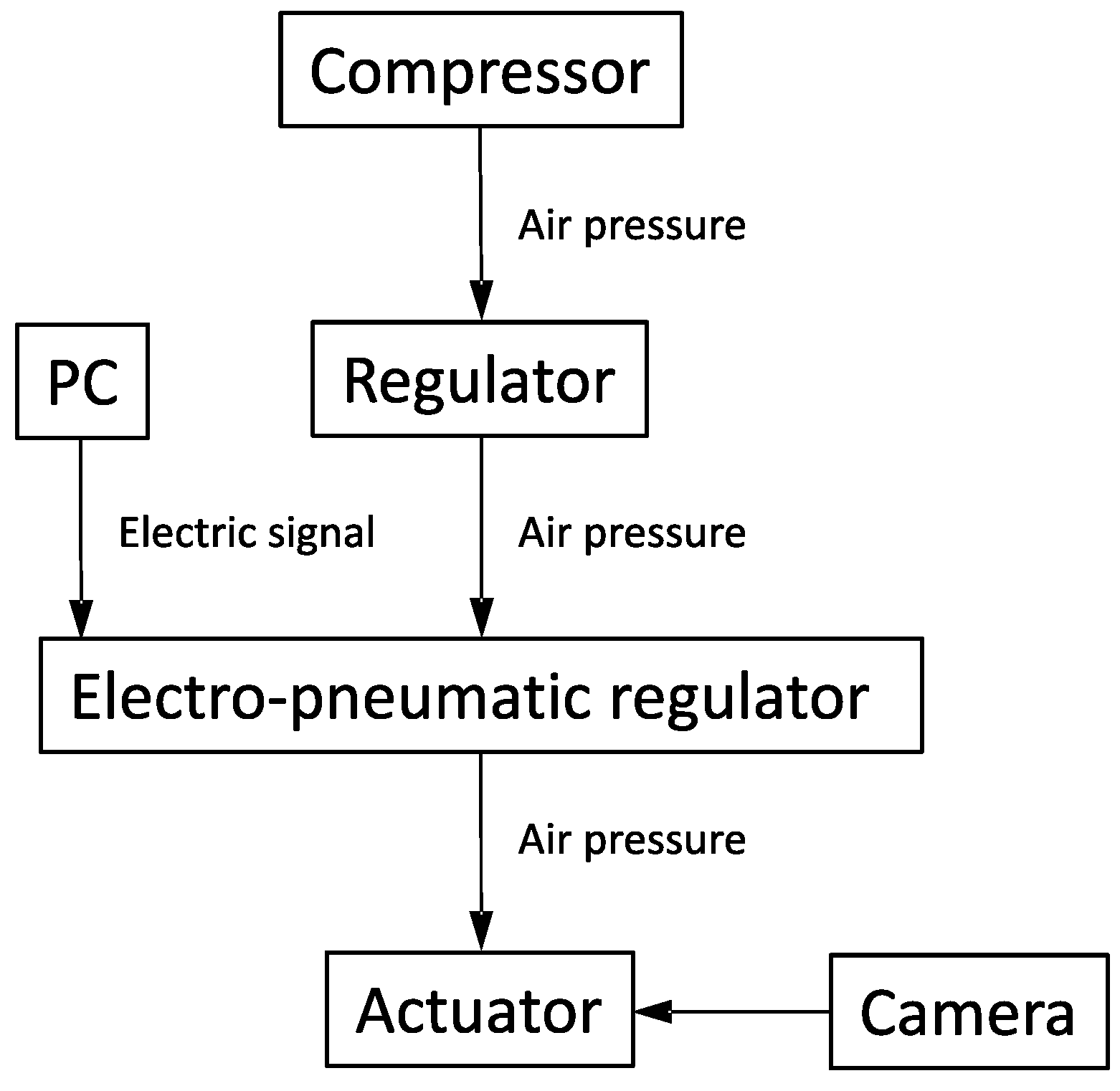

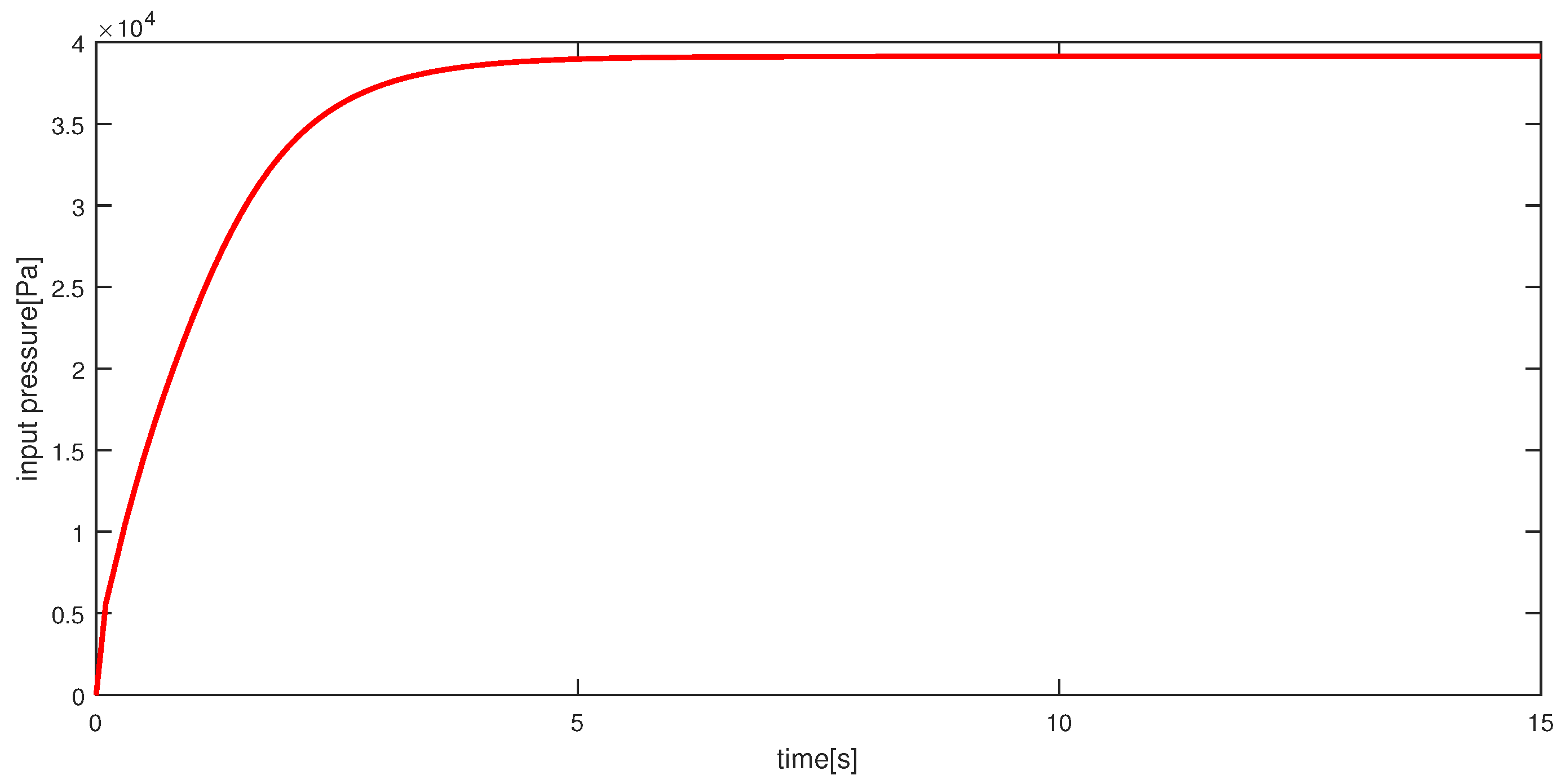

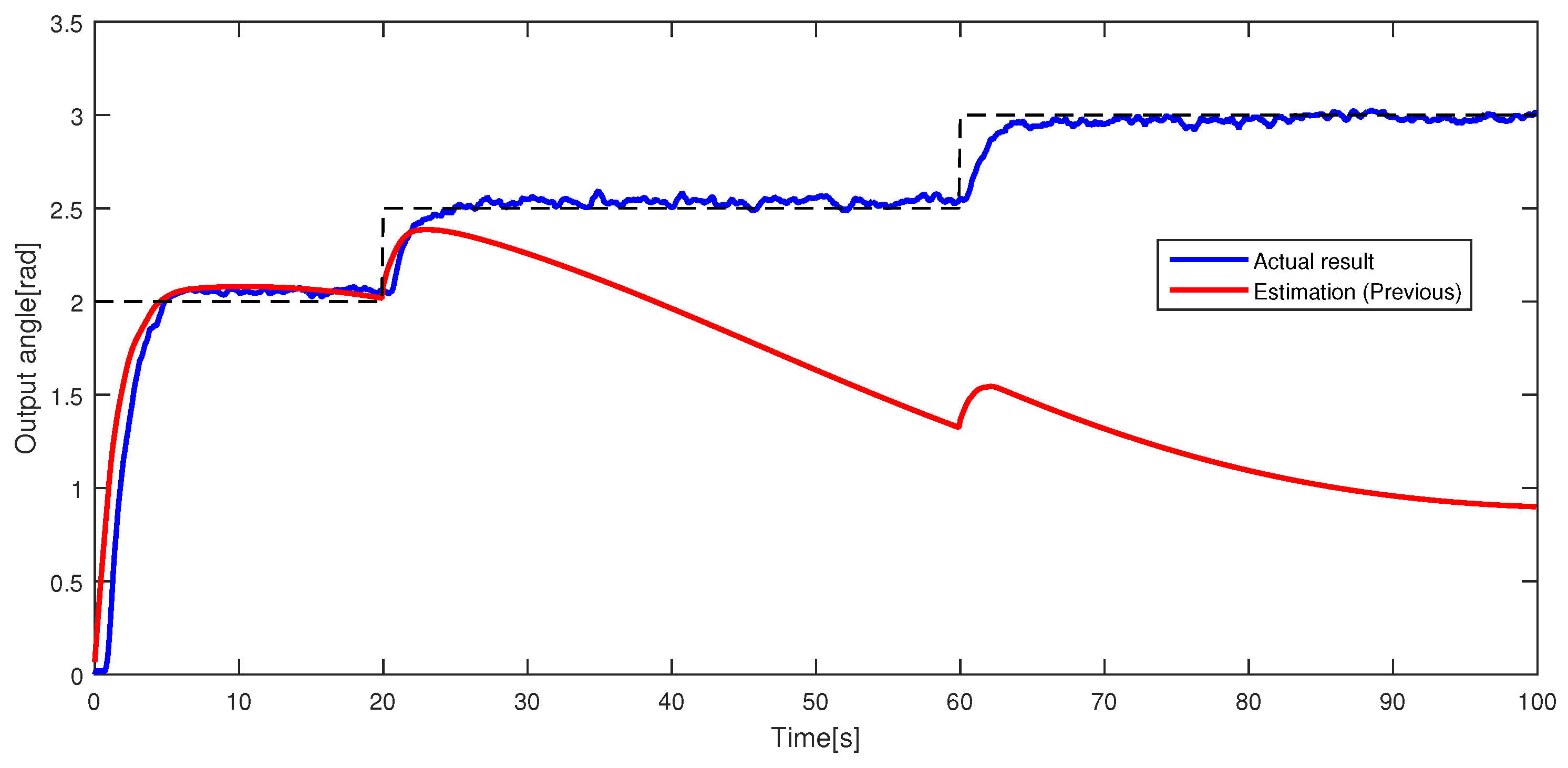

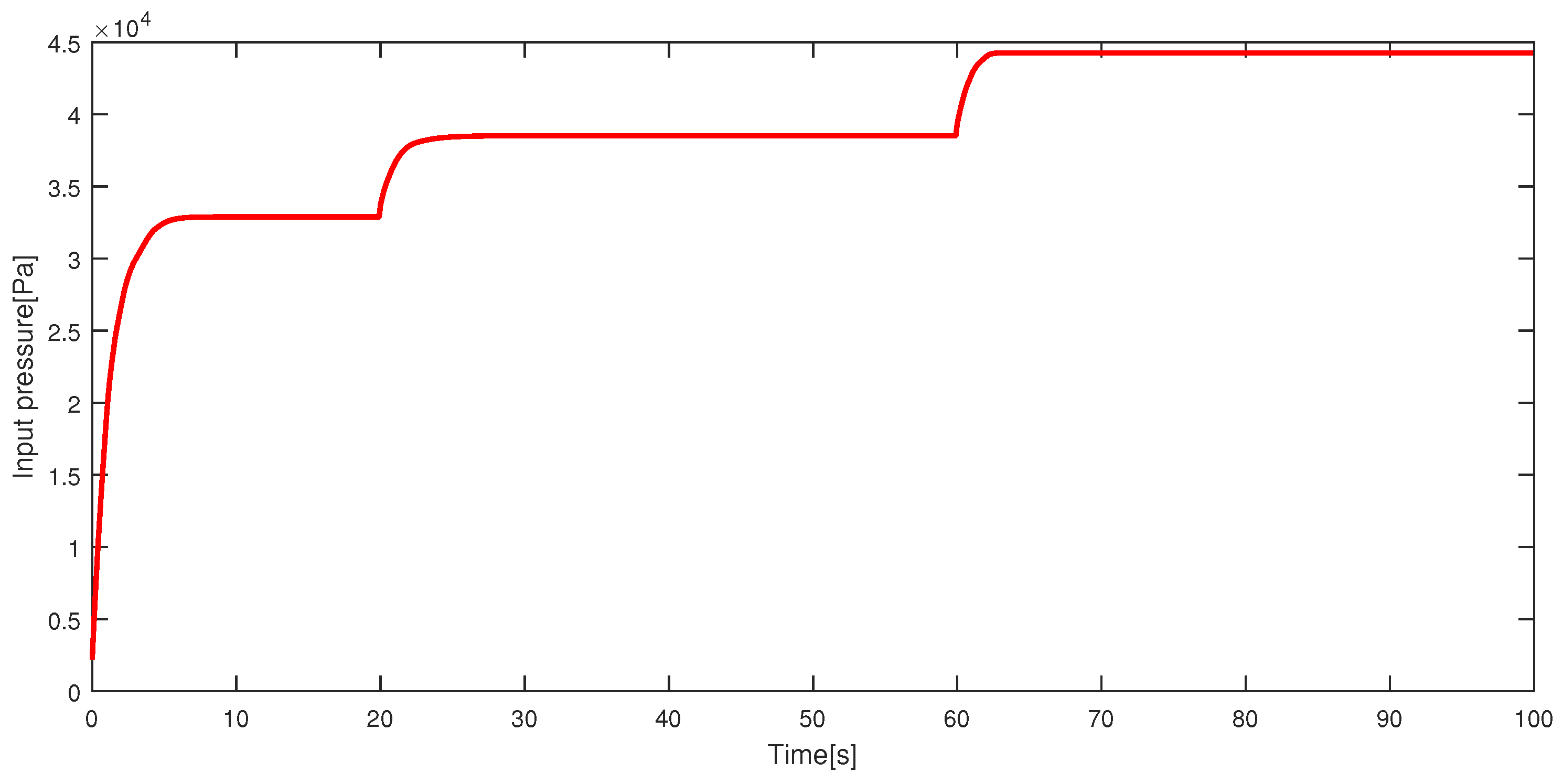

1] was developed to solve these problems as above. A miniature pneumatic bending rubber actuator is one of the soft actuators. It is made of silicone rubber and has a bellows construction on one side. Because of its structure, a miniature pneumatic bending rubber actuator can be made simply, small and inexpensively (a miniature pneumatic bending rubber actuator is often called “a micro-hand” because it will be used in three actuators). On the other hand, this actuator is difficult to model and control due to its nonlinearity. This actuator should be controlled by without sensors, because it is expected to be used for medical fields, especially in operations. Moreover, we have no sensor that can attach itself to this actuator directly because this actuator is too small. Thus, a motion estimation method and nonlinear control system are needed for this actuator.

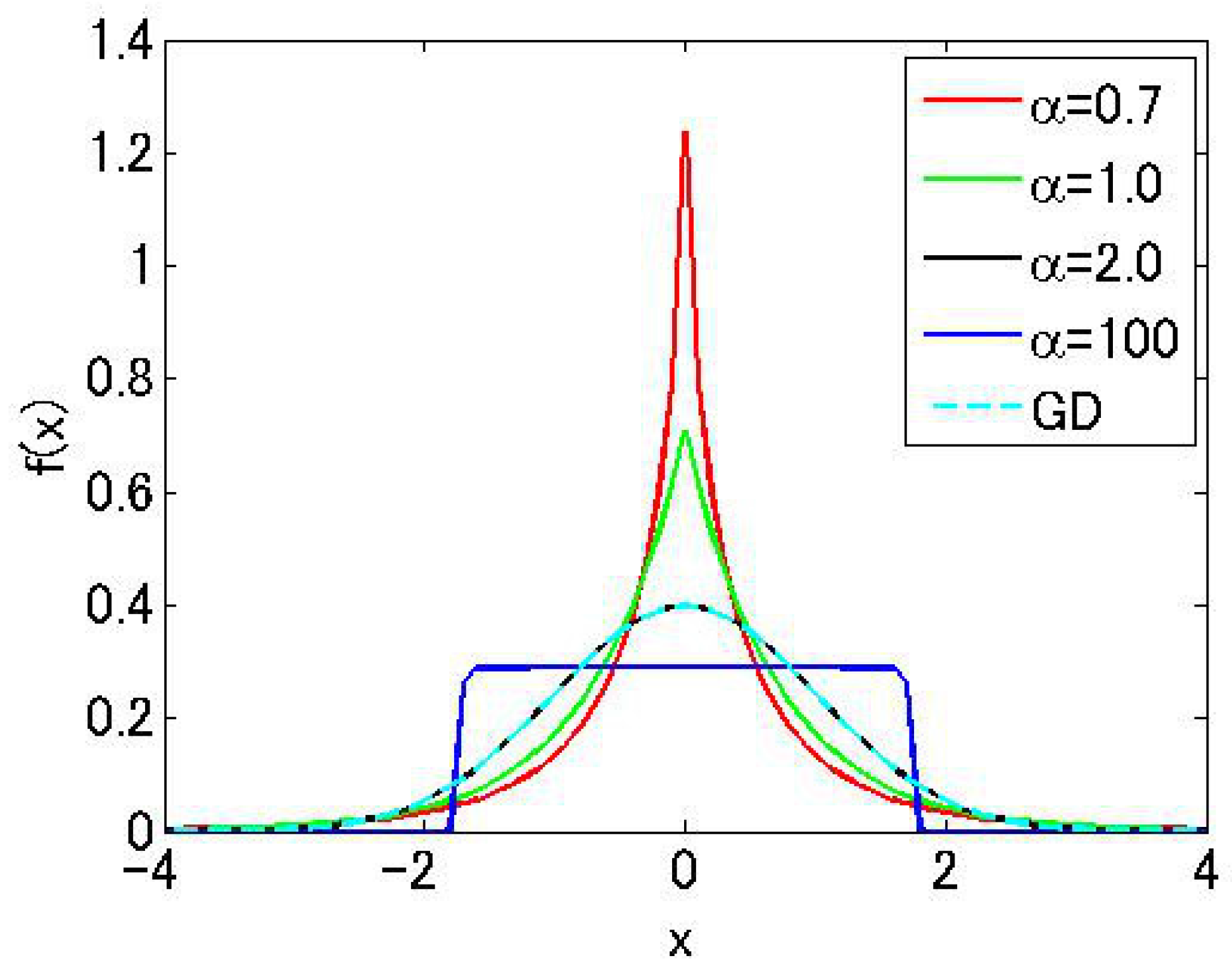

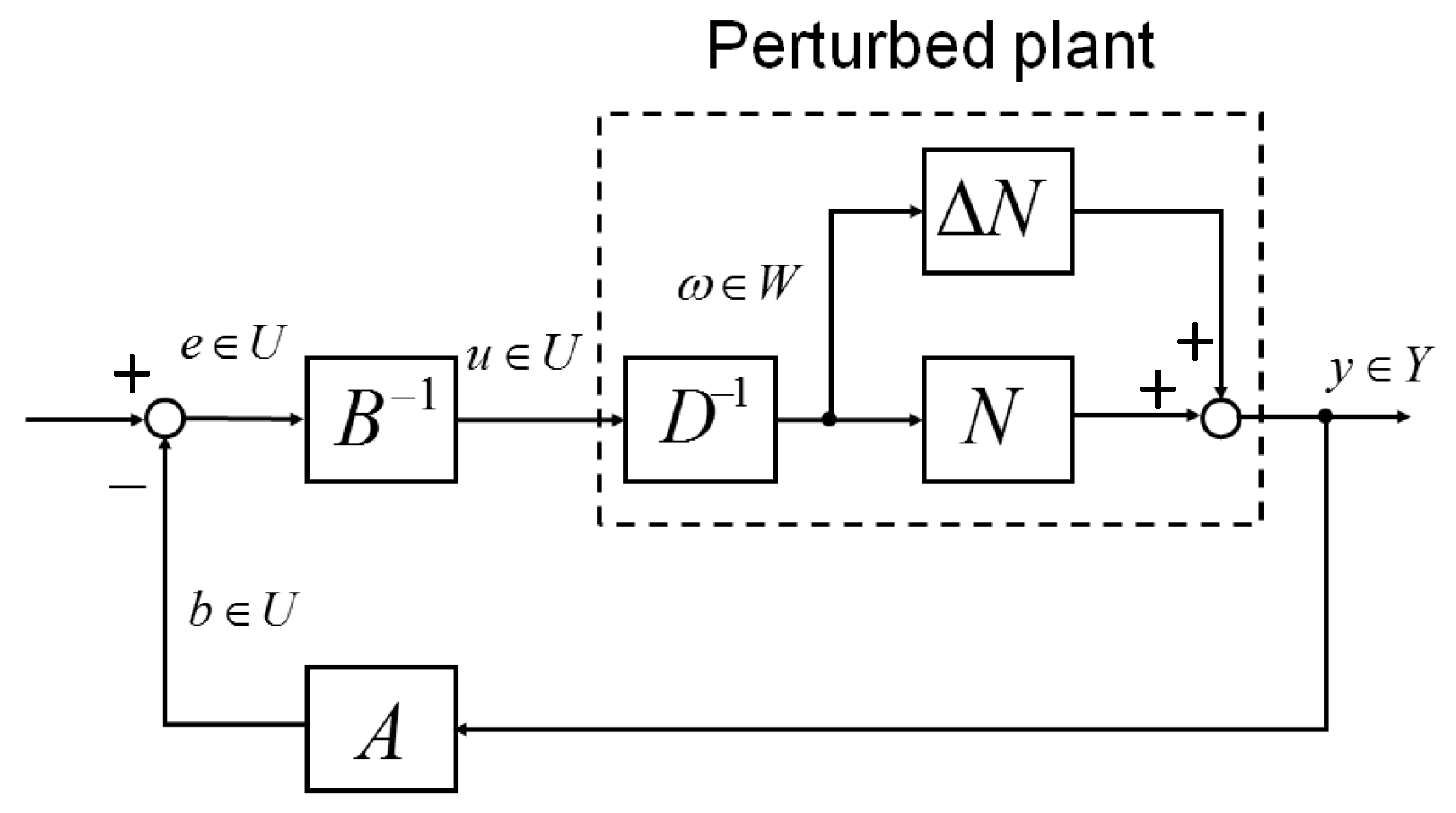

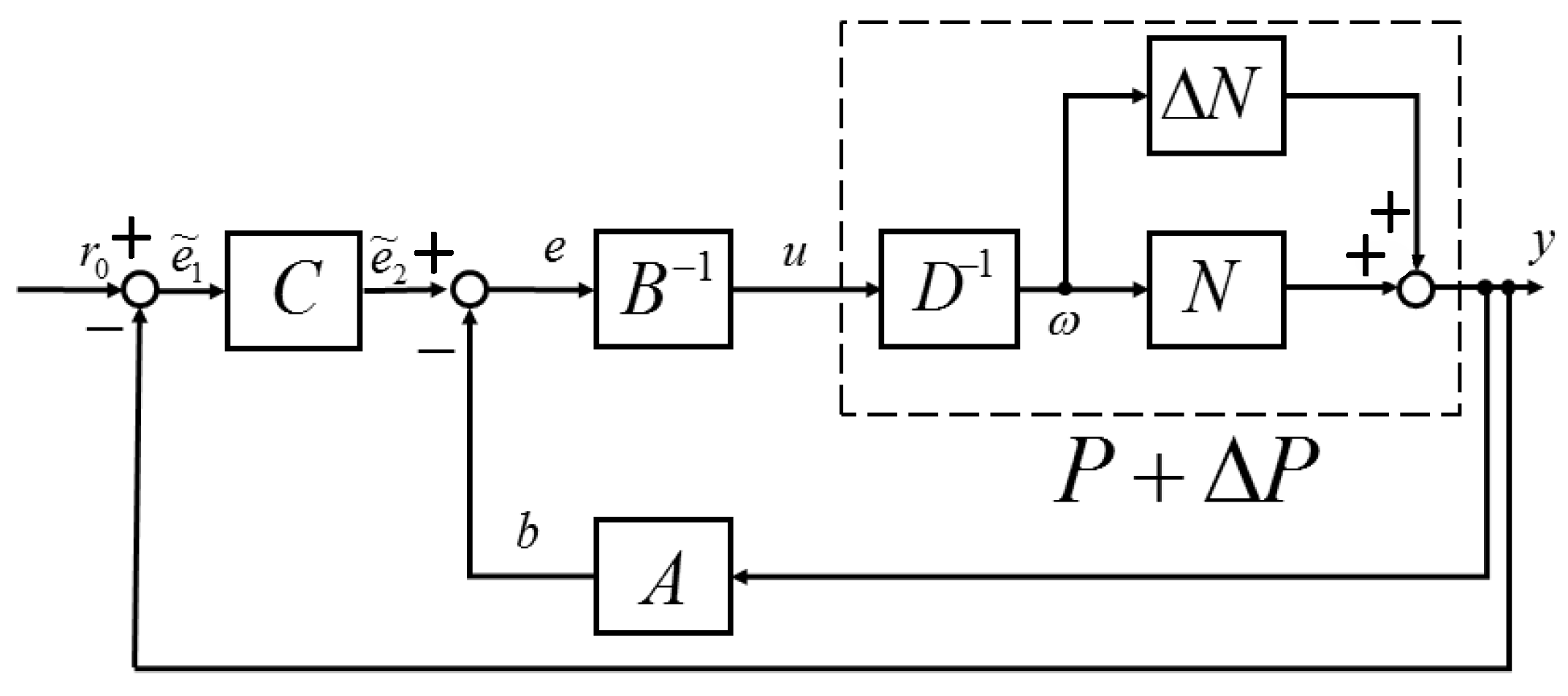

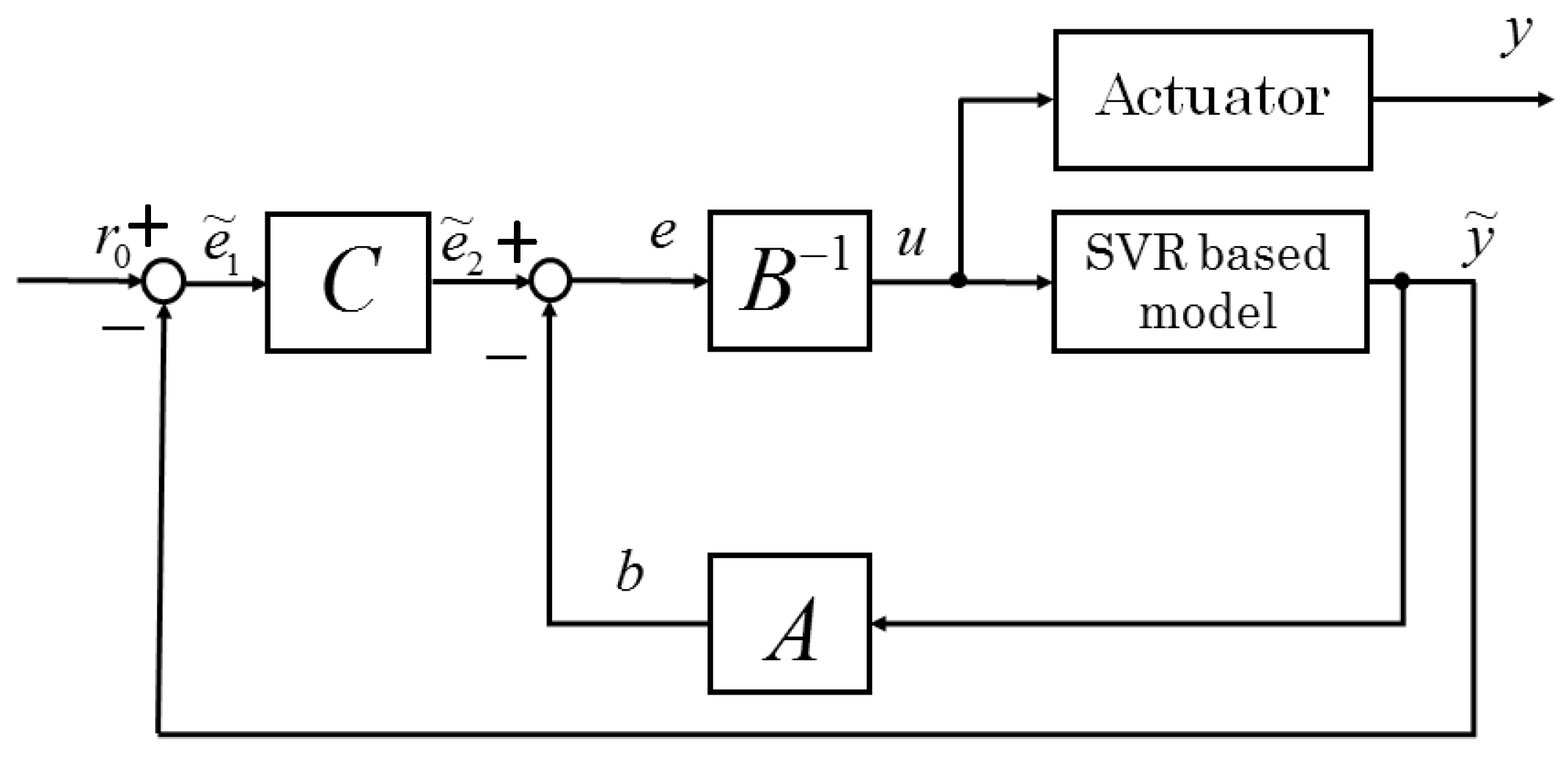

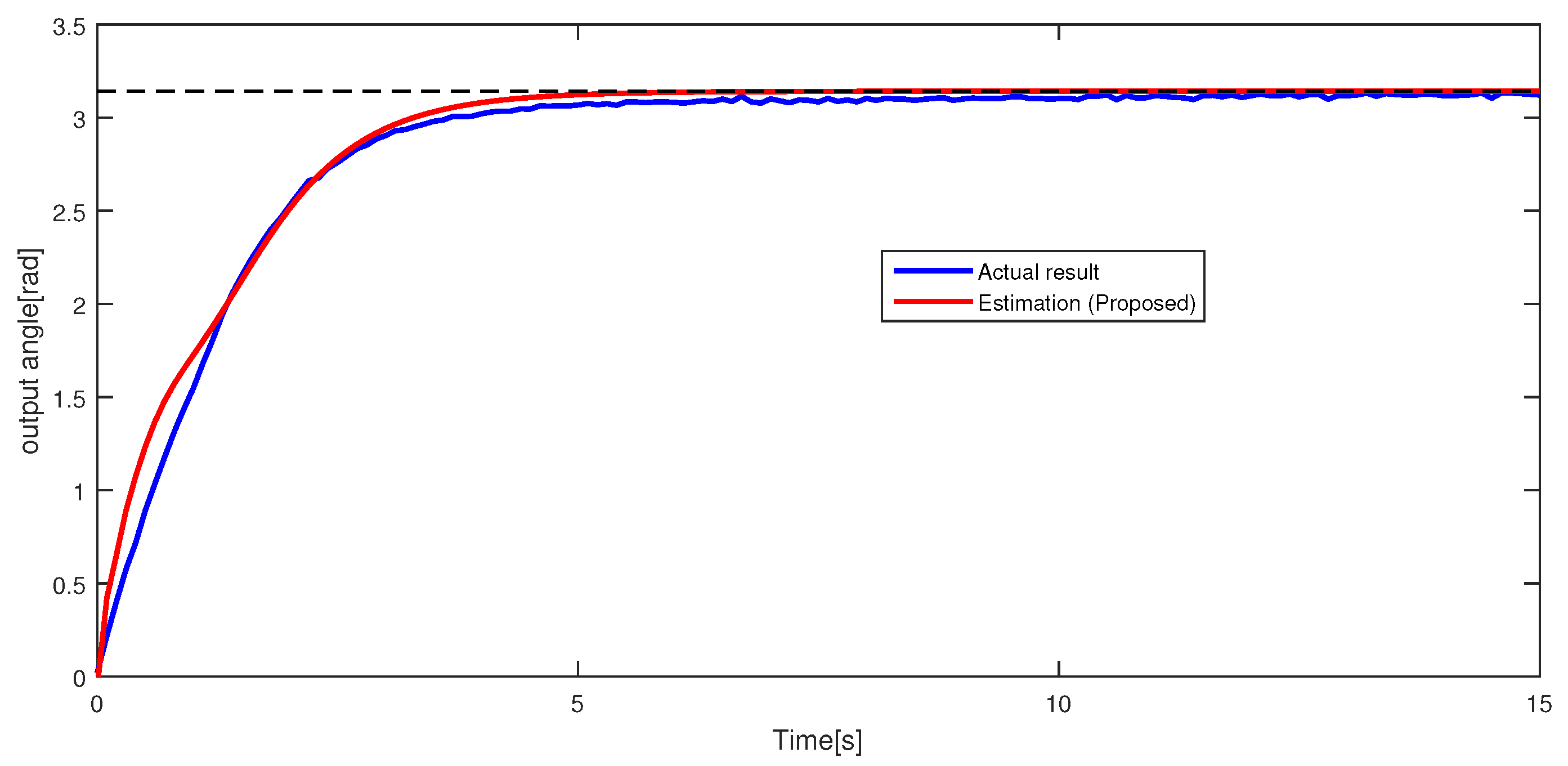

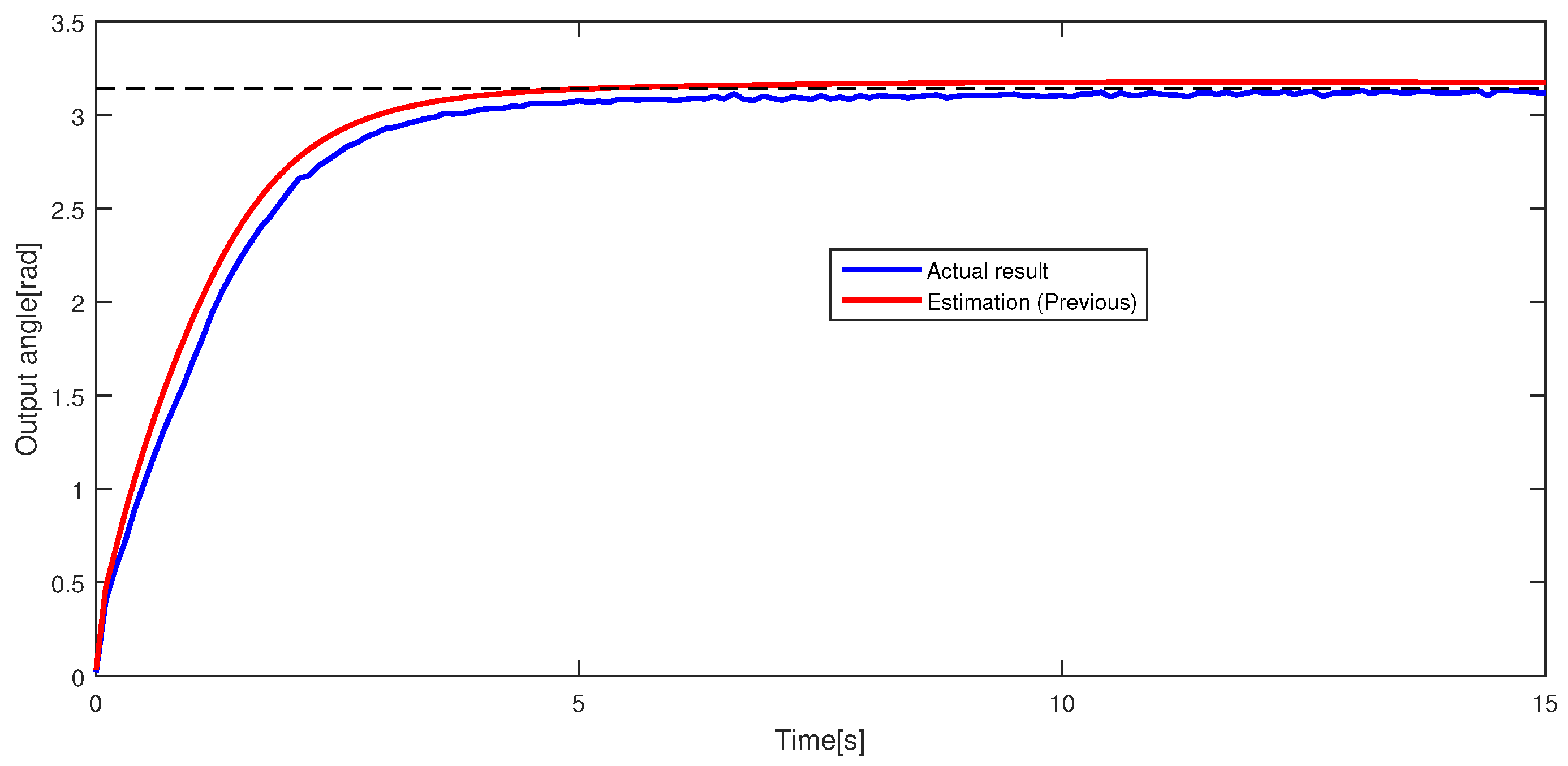

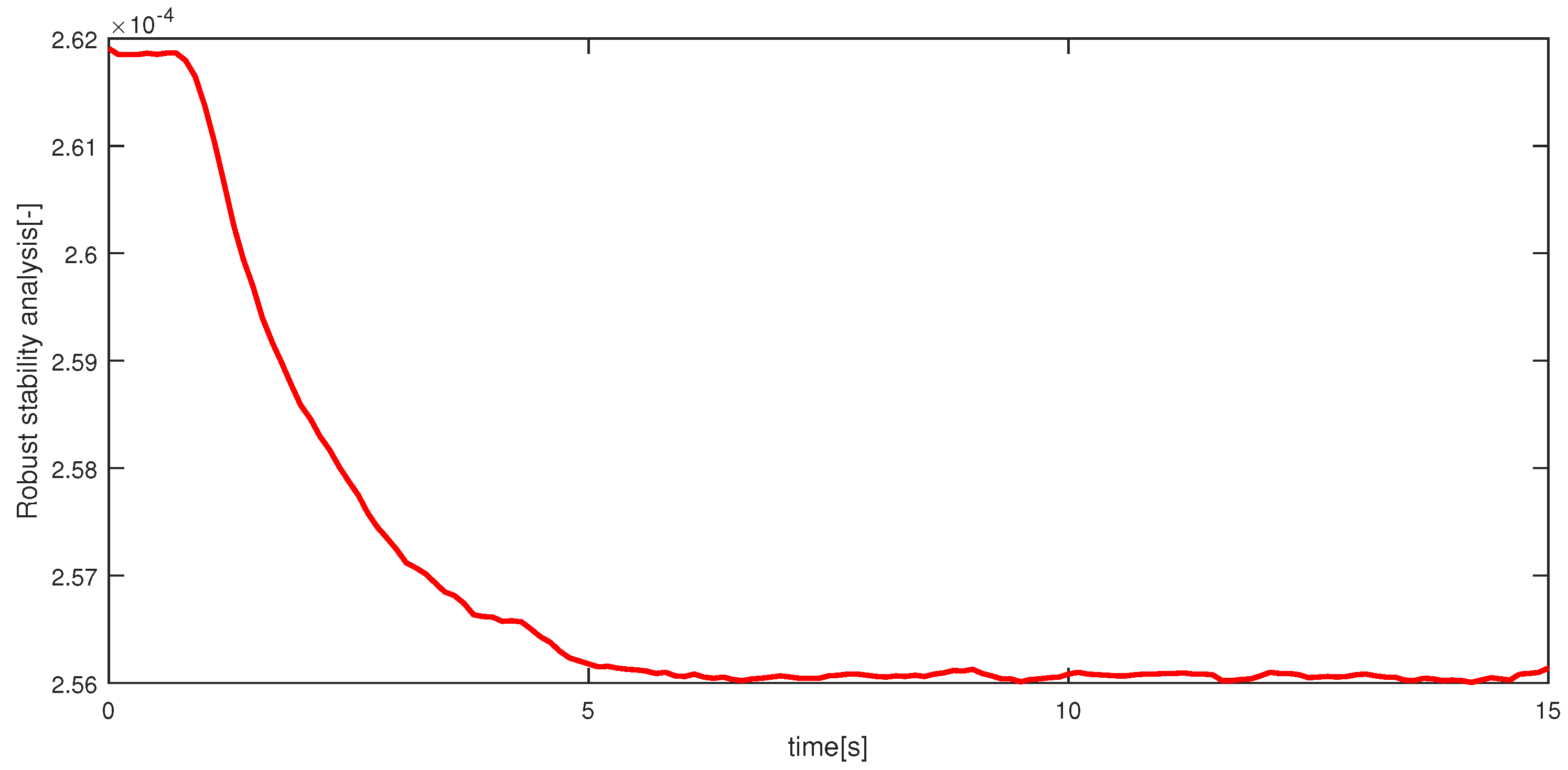

In this paper, support vector regression (SVR) is utilized for output estimation. SVR is a regression machine that is extended from support vector machine (SVM) [

2,

3,

4]. SVR has been utilized by many researchers recently. SVR has some advantages, for example high generalization ability with few training data and valid for a nonlinear model, etc. SVR uses the kernel method. The kernel method makes SVR’s calculation easier. If one function satisfies some properties, it can become a kernel function. Various kernel functions are used for SVR. Especially, the Gaussian kernel, which is applied by the Gaussian distribution (GD), is mainly used for a kernel function in SVR. However, many distributions do not follow GD. The distribution of this actuator is also the same. To solve this problem, SVR with the generalized Gaussian kernel, which is applied from the generalized Gaussian distribution (GGD) [

5], for the estimation of the actuator was proposed [

6]. The effectiveness of SVR with the generalized Gaussian kernel was verified. Thus, this research utilizes GGD for a kernel function. SVR with the GGD kernel has four parameters. Selecting good parameters is needed to improve the estimation ability of SVR. In this paper, particle swarm optimization (PSO) [

7] is utilized for the parameter selecting method. In previous research [

4], SVR-based estimation and nonlinear control for this actuator are considered. However, the estimation ability can be improved. Thus, this research considers improving estimation ability by the method above. To verify the proposed estimation method, an experiment was conducted with a nonlinear control system based on operator theory [

8,

9,

10,

11,

12].