The Nature and Articulation of Ethical Codes on Tailings Management in South Africa

Abstract

:1. Introduction

1.1. Background and Problem Statement

1.2. Methodology

2. Current Status of Tailings Management in South Africa

2.1. Stakeholders and Expectations

- Government;

- Mine management;

- Holders of prospecting or mining rights;

- Mine employees;

- Shareholders;

- Regulators;

2.2. Handling Methods and Policies

2.3. Environmental Health Issues and the Plight of Womenfolk

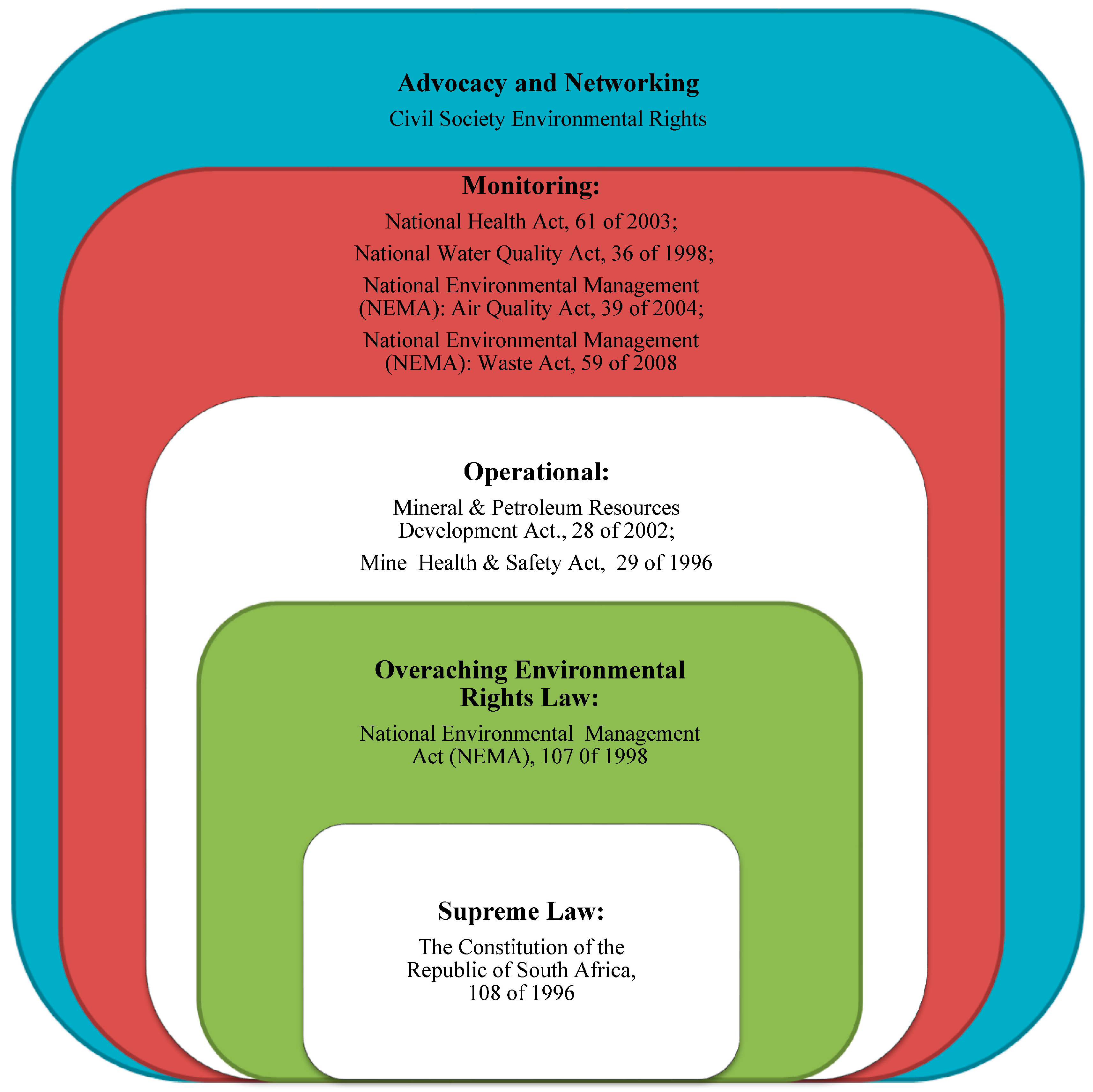

3. Relevant Legislation and Modes of Articulation

- The Constitution of the Republic of South Africa Act No. 108 of 1996 (CRSA);

- The Mineral and Petroleum Resources Development Act No. 28 of 2002 (MPRDA);

- The Code of Practice for Mine Residue Deposits (CPMRD);

- The National Environmental Management Act No. 107 of 1998 (NEMA);

- The National Water Act No. 36 of 1998 (NWA);

- The Minerals Act No. 50 of 1991;

- The National Environmental Management: Waste Act No. 59 of 2008 (NEMWA);

- The National Environmental Management: Air Quality Act 39 of 2004 (NEMAQA);

- The Mine Health and Safety Act 29 of 1996 (MHSA);

- The Radioactive Waste Management Policy and Strategy for the Republic of South Africa (RWMPS).

3.1. The Constitution of the Republic of South Africa Act No. 108 of 1996

3.2. The Mineral and Petroleum Resources Development Act No. 28 of 2002

3.3. The Code of Practice for Mine Residue Deposits

3.4. National Environmental Management Act No. 107 of 1998

3.5. The National Water Act No. 36 of 1998

3.6. The Minerals Act No. 50 of 1991

3.7. National Environmental Management: Waste Act No. 59 of 2008

3.8. The National Environmental Management: Air Quality Act 39 of 2004

- pollution avoidance or minimization—that pollution and degradation of the environment must be avoided, or, where they cannot be altogether avoided, are minimized and remedied;

- waste avoidance and consideration of life cycle assessment—that waste is avoided, or where it cannot be altogether avoided, it must be minimized and re-used or recycled where possible, or disposed of in a responsible manner [39].

3.9. The Mine Health and Safety Act 29 of 1996

- Sections 2 and 5, where the employer must ensure and maintain a safe and healthy environment at the mine, during commissioning, operation, decommissioning and closure;

- Sections 6, 10 and 11 make provision for the employer to provide and supply adequate health and safety equipment and training, and to assess and respond to any risk or hazard to which employees may be exposed;

- Sections 12 and 13 pertain to the medical surveillance system;

- Sections 19, 22 and 23 pertain to employees’ rights with regard to access to information, duties for health and safety and permission to leave a dangerous working place if circumstances arise [54].

3.10. The Radioactive Waste Management Policy and Strategy for the Republic of South Africa

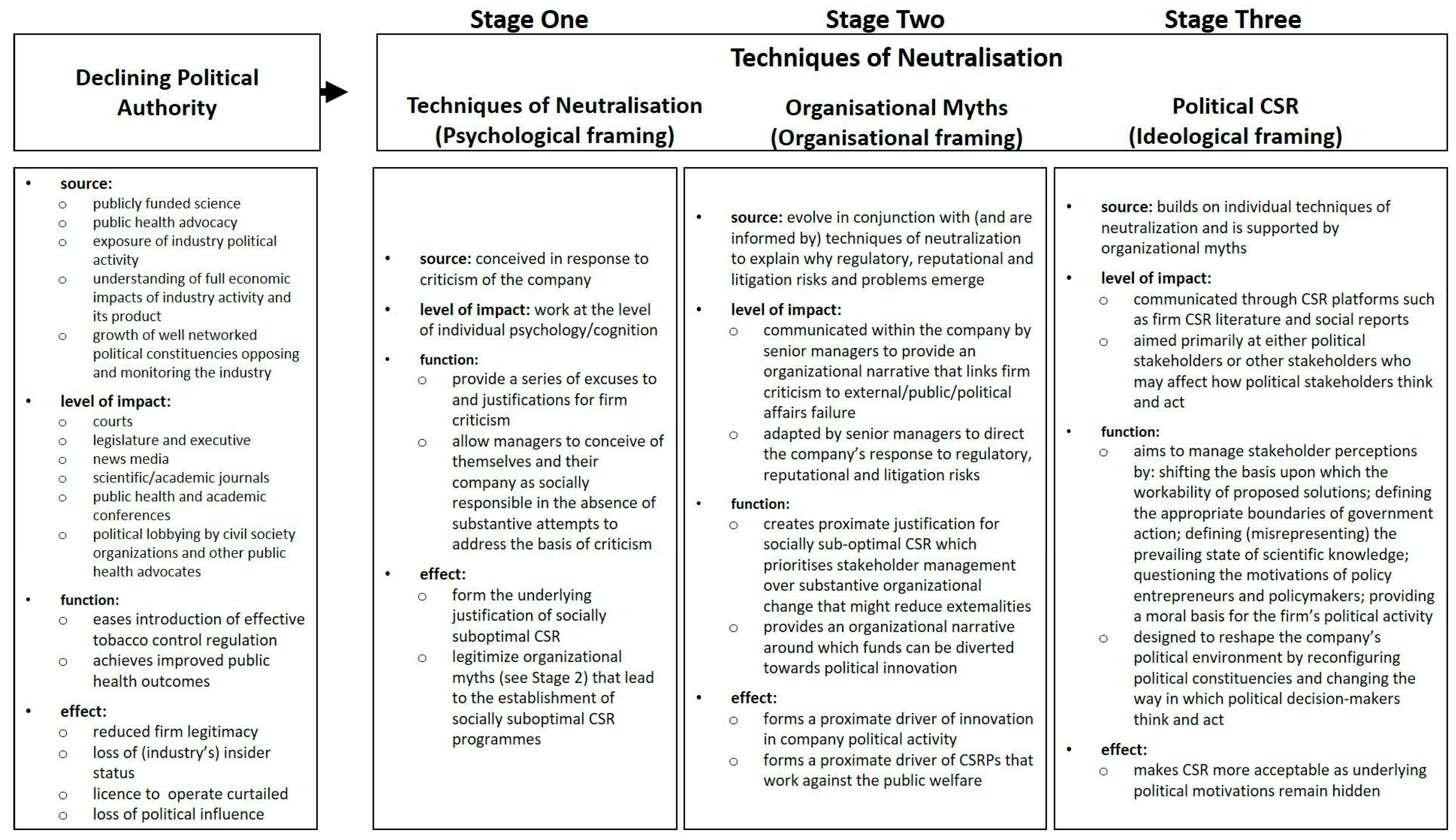

4. Ethical Values and CSR

4.1. Present Status in Articulation of CSR in South African Mining

4.1.1. The King Reports—The “Codex” of South African CSR

4.1.2. The Concept of Neutralization

4.2. Compliance Monitoring

5. Mining Ethics and Sustainability in Tailings Management

5.1. Inclusivity

5.2. The Place of Women on the Table

6. Addressing the Issues

6.1. Imperative 1: Giving the Devil His Due, but Coming Out Strongly on Defaulters

6.2. Imperative 2: Create a Strong Stakeholder Management Base

6.3. Imperative 3: Strengthen Regulatory Measures

6.4. Imperative 4: Promote an Ethical Mining Culture

6.5. Imperative 5: Tailings Should be Usefully Applied

7. Conclusions

Acknowledgments

Conflicts of Interest

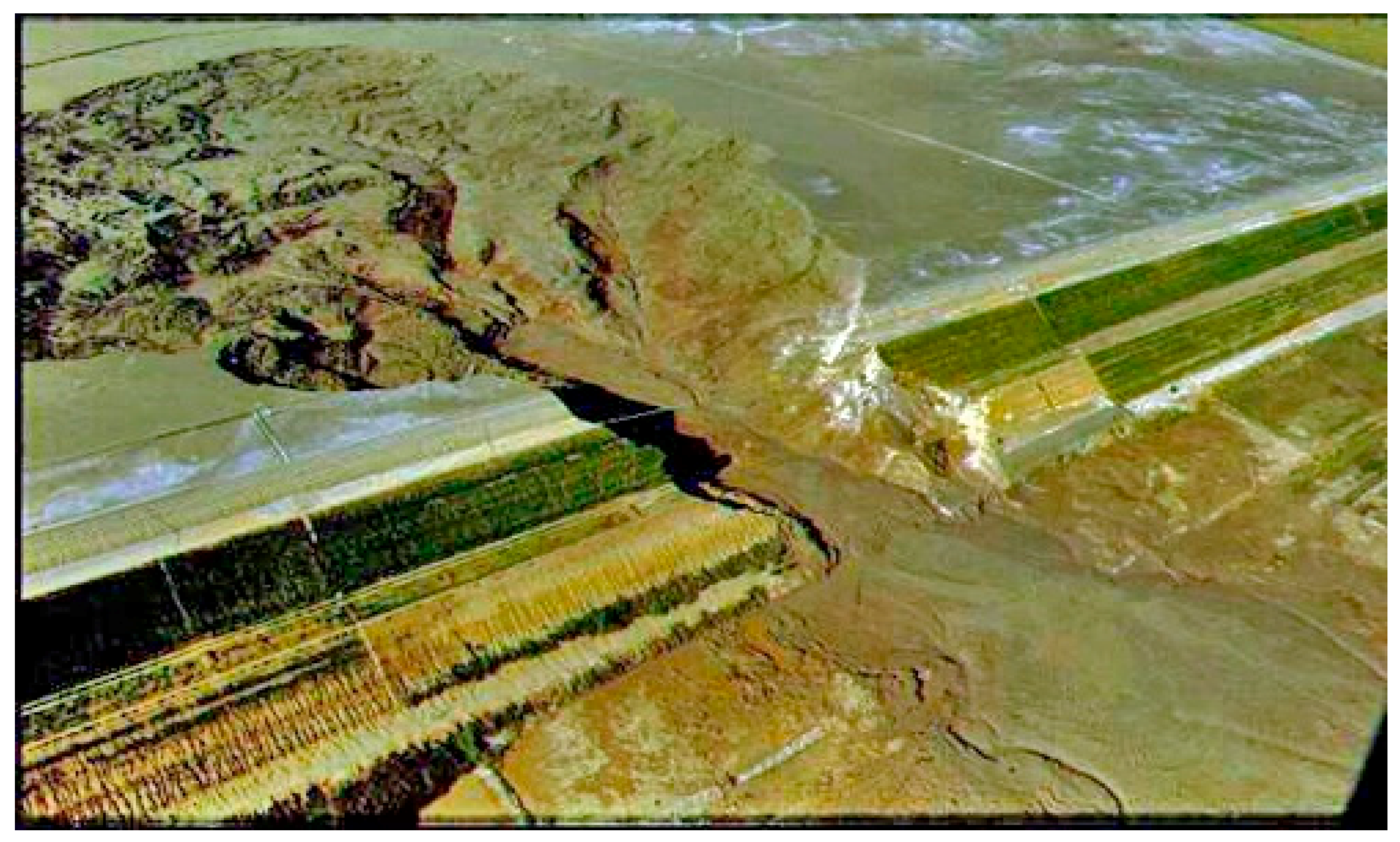

Appendix A. Case Study 1: Causes and Consequences of the Merriespruit Tailings Dam Failure

“On the night of 22 February 1994, the 31 m high northern wall of the number four tailings dam of the Harmony Gold mine collapsed. The tailings dam is situated 320 m up-slope of Merriespruit, a suburb of Virginia in the Free State Goldfields of South Africa. More than 2.5 million tonnes of liquefied tailings ripped through the sleeping mining village. Eighty houses were largely swept away and 200 others were severely damaged. Seventeen people were killed. The failure of this tailings dam shocked everybody who followed the unfolding drama of loss of life and destruction of property in the press. At the inquest following the disaster, the judge called this tailings dam a time bomb that was waiting to explode. For the first time in South African history, processed satellite images were allowed as scientific evidence in court. Together with eyewitness reports, all the evidence pointed overwhelmingly to the cause of the failure as being overtopping. The owner, the operator and six of their employees were subsequently found guilty of negligence (contravening Section 37 of the Minerals Act), and heavy fines were imposed. The Merriespruit disaster provided the State and the mining industry with the impetus to ensure the safe disposal of tailings. It also made the mining industry and all those involved with the design and operation of tailings dams take stock of their management and tailing disposal methods”.

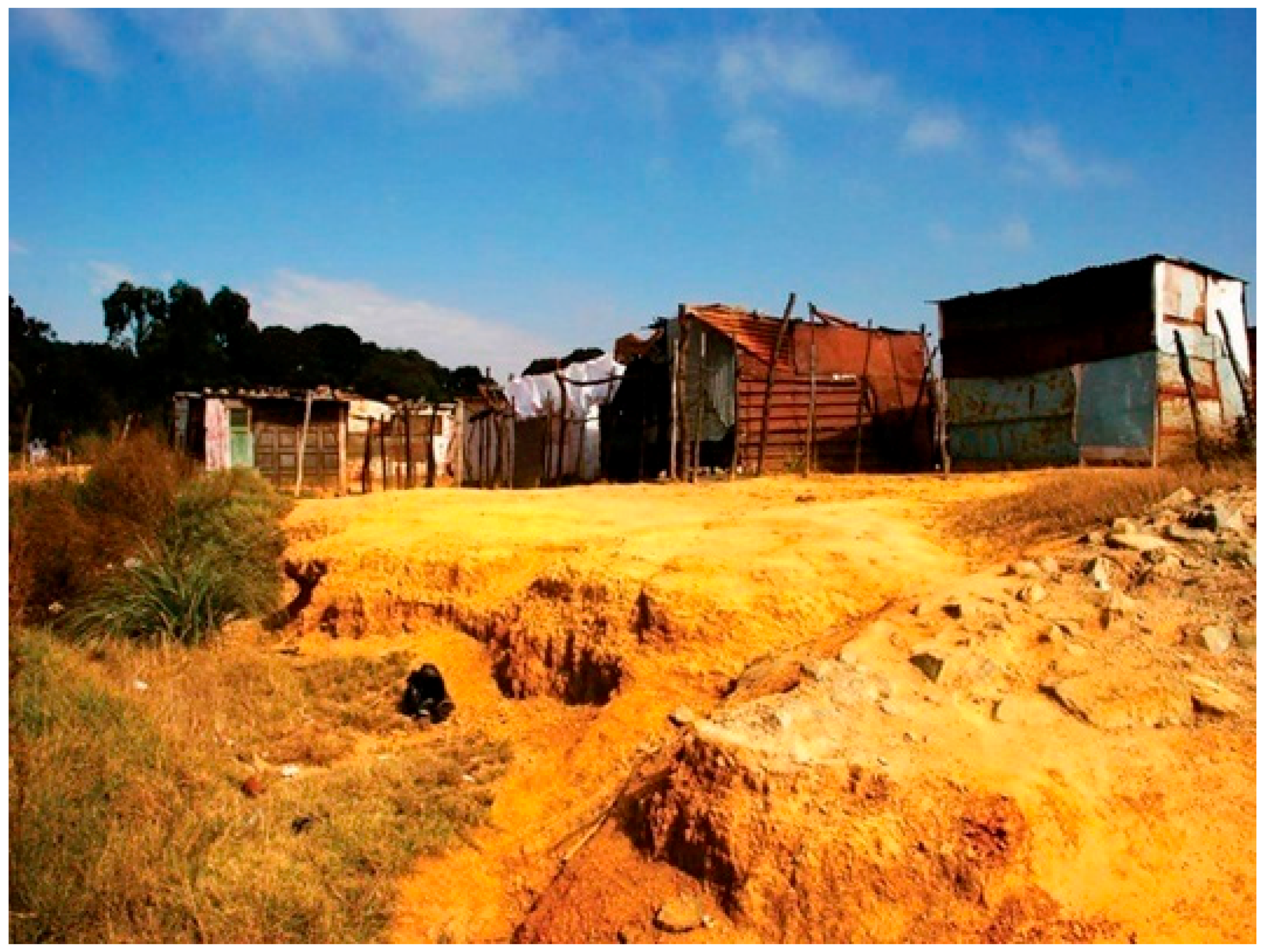

Appendix B. Case Study 2: Interviews with Tudor Shaft Community Members—17 January 2013

“About 2000 residents continue to live in shacks on a gold mine tailings dump. A recent soil sample analysis requested by the Federation for a Sustainable Environment showed elevated levels of aluminium, arsenic, cadmium, cobalt, copper, mercury, manganese, nickel, zinc and uranium. An independent international expert in 2011 found radiation levels 15 times higher than the regulated level. He advised on the immediate relocation of the community. The National Nuclear Regulator of South Africa confirmed the grounds were indeed radioactive and Parliament recommended relocation of the community in 2011. The majority of them are still living here. No health outcome studies related to the exposure of the community to high levels of radiation is as yet available. Here is what community members had to say: We have been living here for up to 10 years. Our children are sick from birth with flu and chest problems. I have to take my 9 month old son to the clinic almost every week with a runny nose and cough. The water is not good and there is only 4 taps for all of us. Children commonly have vomiting and diarrhoea. Toilets are broken and never clean and too few for all of us living here. Itching of the skin is common and worse for children. TB is getting worse. The dust from the new mining on the dumps makes coughing worse. We attend the clinic but the treatment for TB is not helping anymore. We have no electricity for cooking. Cooking with paraffin and coal is bad for the flu and dangerous for fires. In winter it is worse when it is very cold. We have toyi-toyi’d and have attended many meetings. We get promises for new stands but we are still here. Our story have been in the newspapers. A few families have been given houses near Kagiso. This is the start of a new year and we are hopeful for new homes. An elderly woman next to the Tudor dam explained that mining now started right next to her home. She worked for about 45 years as a domestic worker and now lives next to the mine dumps. She is suffering from high blood pressure and has very poor eyesight. She has no running water in her home and no electricity. The future is uncertain. No-one has come to talk to her about the new mining or the relocation. During the interview we heard the deafening sounds of nearby mine blasts”.

Appendix C. Case Study 3. “The Legacy of Gold Mining Activities around Johannesburg”

“The legacy of gold mining activities around Johannesburg consists of enormous heaps of tailings dumps extending over many square kilometres. These sites must be considered as potential sources of mobile uranium to the biosphere. Gamma spectrometric analysis points to significant leaching of U from tailings dumps. This has caused some radioactive disequilibrium as U has been decoupled from the decay series. Very high concentrations were obtained in water bodies in the proximity of tailings dumps whereas significant attenuation was realized in areas far from the sources. The processing of mine dumps has also contributed to enhancing acid drainage and probably oxidation of dump material, thus enhancing U mobility. Wetland sediments showed that they act as traps or sinks for U and other heavy metals, this being strongly demonstrated by BCR (the Community Bureau of Reference) sequential extraction. The oxide-bound fractions from this protocol point to co-precipitation as the main U removal process from the water column. It should be noted that the toxicity of U is not as a result of its radioactive nature, but rather its chemical nature. The kidney is considered the target organ for uranium’s chemical toxicity”.

References

- Hydralok. Top Five Mining Countries in the World and Their GDP. 2016. Available online: https://www.hydralok.net/top-five-mining-countries-in-the-world-and-their-gdp/ (accessed on 31 March 2016).

- World Bank. Chapter 2: Sub-Saharan Africa. In Global Economic Prospects; A World Bank Flagship Report; International Bank for Reconstruction and Development: Washington, DC, USA; The World Bank: Washington, DC, USA, 2016; pp. 153–176. [Google Scholar]

- Republic of South Africa Department of Minerals and Energy (RSA DME). South Africa’s Mineral Industry 1996/97; Department of Minerals and Energy: Johannesburg, South Africa, 1996.

- Oliveira, D. South African Gold Production Remained Flat in 2016—WGC. Creamer’s Media Mining Weekly. 2017. Available online: http://www.miningweekly.com/article/south-african-gold-production-remained-flat-in-2016-2017-02-24/rep_id:3650 (accessed on 19 September 2017).

- Cronje, F.; Reyneke, S.; van Wyk, D. Local communities and health disaster management in the mining sector. J. Disaster Risk Stud. 2013, 5. [Google Scholar] [CrossRef]

- Eweje, G. Hazardous employment and regulatory regimes in the South African mining industry: Arguments for corporate ethics at workplace. J. Bus. Ethics 2005, 56, 163–183. [Google Scholar] [CrossRef]

- Diale, A.J. Corporate social responsibility in the South African mining industry: Necessity, conformity or convenience? Int. J. Bus. Econ. Dev. 2014, 2, 16–26. [Google Scholar]

- Manungufala, T.E.; Sabiti-Kalule, M.; Aucamp, I. Investigation into the slimes dams, mine dumps and landfills (residue deposits) as environmental constraints to low-cost housing projects in Gauteng, South Africa. In Proceedings of the XXIII IAHS World Congress on Housing: Transforming Housing Environments through Design, Pretoria, South Africa, 27–30 September 2005. [Google Scholar]

- Schonfeld, S.J.; Winde, F.; Albrecht, C.; Kielkowski, D.; Liefferink, M.; Patel, M.; Sewram, V.; Stoch, L.; Whitaker, C.; Schüz, J.; et al. Health effects in populations living around the uraniferous gold mine tailings in South Africa: Gaps and opportunities for research. Cancer Epidemiol. 2014, 38, 628–632. [Google Scholar] [CrossRef] [PubMed]

- Wright, C.Y.; Matooane, M.; Oosthuizen, M.A.; Phala, N. Risk perceptions of dust and its impacts among communities living in a mining area of the Witwatersrand, South Africa. Clean Air J. 2014, 24, 22–27. [Google Scholar]

- Lèbre, E.; Corder, G. Integrating industrial ecology thinking into the management of mining waste. Resources 2015, 4, 765–786. [Google Scholar] [CrossRef] [Green Version]

- Republic of South Africa Department of Minerals and Energy (RSA DME). Guideline for the Compilation of a Mandatory Code of Practice on Mine Residue Deposits; Department of Minerals and Energy: Pretoria, South Africa, 2000; 23p.

- Chamber of Mines of South Africa. Statistics of the Chamber of Mines of South Africa; Chamber of Mines of South Africa: Johannesburg, South Africa, 2001. [Google Scholar]

- Rademeyer, B. The Influence of Environmental Impacts on Tailings Impoundment Design. Ph.D. Thesis, University of Pretoria, Pretoria, South Africa, 2007; 328p. Available online: http://upetd.up.ac.za/thesis/available/etd-01292008-172436/unrestricted/00front.pdf (accessed on 4 January 2015).

- Republic of South Africa Department of Environmental Affairs (RSA DEA). 2012 South Africa Environment Outlook’; Chapter 9: Waste Management, Draft 2; Department of Environmental Affairs: Pretoria, South Africa, 2012; 31p. Available online: http://soer.deat.gov.za/dm_documents/2012_SAEO_Waste_Management_Draft2_IleRc.pdf (accessed on 10 January 2015).

- Sutton, M.W.; Weiersbye, I.M. South African legislation pertinent to gold mine closure and residual risk. In Mine Closure 2007, Proceedings of the Second International Seminar on Mine Closure, Santiago, Chile, 16–19 October 2007; Fourie, A., Tibbett, M., Wiertz, J., Eds.; Australian Centre for Geomechanics: Perth, Australia, 2007. [Google Scholar]

- Fooks, G.; Gilmore, A.; Collin, J.; Holden, C.; Lee, K. The limits of corporate social responsibility: Techniques of neutralisation, stakeholder management and political CSR. J. Bus. Ethics 2013, 112, 283–299. [Google Scholar] [CrossRef] [PubMed]

- Anglo American. Guidelines for the Operation of Tailings Disposal Facilities: International Perspective and Explanatory Notes. Safety, Health and Environment Bulletin, No. S133/2005. April 2005. Available online: http://www.mirmgate.com.au/docs/Anglo_American/AAC_SHEB_000133.pdf (accessed on 17 September 2017).

- Martin, T.E.; Davies, M.P.; Rice, S.; Higgs, T.; Lighthall, P.C. Stewardship of Tailings Facilities. In Proceedings of the Report No. 20 of the Mining, Minerals and Sustainable Development (MMSD) Project of the International Institute of Environment and Development (IIED) and the World Business Council for Sustainable Development (WBCSD), Vancouver, BC, Canada, April 2002; Available online: http://www.pebblescience.org/pdfs/Martin_et_al._2002_Stewardship_of_Tailings_facilities.pdf (accessed on 1 January 2015).

- Swart, E. The South African legislative framework for mine closure. J. S. Afr. Inst. Min. Metall. 2003, 103, 489–492. [Google Scholar]

- Snyman, B.J.; Brent, A.C. Aligning Environmental and Regulatory Procedures with a Holistic Project Management Approach for Residue Deposits: Mine Waste Disposal and Achievement of Mine Closure—What Does It Take? The South African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2006; 20p. [Google Scholar]

- Reichardt, M. A History of Mine Waste Rehabilitation Techniques in South Africa: A Multi-Disciplinary Overview of Mine Waste Rehabilitation and the Nonscientific Drivers for Its Implementation 1950s–1980s; University of Witwatersrand: Johannesburg, South Africa, 2012; Available online: http://www.imhc.co.za/assets/pdf/papers/Konferenz%20Papier-Reichardt.pdf (accessed on 23 February 2016).

- Vermeulen, N.J. The Composition and State of Gold Tailings. Ph.D. Thesis, University of Pretoria, Pretoria, South Africa, 2001. Available online: repository.up.ac.za/bitstream/handle/2263/23079/00front.pdf (accessed on 31 March 2016).

- Robertson, A.M.; Caldwell, J.A. Tailings facility review and evaluation standards. In Proceedings of the Tailings and Mine Waste Conference, Vancouver, BC, Canada, 26–28 October 2015. [Google Scholar]

- South African Bureau of Standards (SABS). SABS 0286:1998: Code of Practice—Mine Residue Deposits; SABS 0286:1998 (ICS 73.020); South African Bureau of Standards: Pretoria, South Africa, 1998; 117p, Available online: http://docslide.us/documents/sans-10286.html (accessed on 31 March 2016).

- Mannak, M. South Africa: Mines Threaten the Environment. 2012. Available online: http://www.ethicalliving.co.za/south-africa-mines-threaten-the-environment/ (accessed on 21 December 2014).

- McGuire, G. Environmental impacts of mining on women in Indonesia and northern Australia. In Proceedings of the Women in Mining Conference, Madang, Indonesia, 3–6 August 2003; Available online: siteresources.worldbank.org/.../mcguireenvironmentalimpacts.pdf (accessed on 30 March 2016).

- Davies, T.C.; Mundalamo, H.R. Environmental health impacts of dispersed mineralisation in South Africa. J. Afr. Earth Sci. 2010, 58, 652–666. [Google Scholar] [CrossRef]

- Republic of South Africa Office of the President (RSA OP). Constitution of the Republic of South Africa No. 108 of 1996; Office of the President: Cape Town, South Africa, 1996. Available online: http://www.gov.za/sites/www.gov.za/files/images/a108-96.pdf (accessed on 2 January 2016).

- Republic of South Africa Office of the President (RSA OP). The Mineral and Petroleum Resources Development Act 28 of 2002; Office of the President: Cape Town, South Africa, 2002. Available online: https://www.capetown.gov.za/en/EnvironmentalResourceManagement/publications/Documents/Minerals-and-Petroleum-Resources-Development-Act-28-of-2002.pdf (accessed on 2 January 2016).

- Feris, J. Mine dumps in South Africa: An ownership dilemma. 2013. Available online: http://www.environment.co.za/mining-2/mine-dumps-south-africa-ownership-dilemma.html (accessed on 26 March 2016).

- Roodt, N.J.; Van Der Want, M.; Picas, C. Mine dumps under the amended Mineral and Petroleum Resources Development Act 28 of 2002. J. S. Afr. Inst. Min. Metall. 2012, 110, 469–472. [Google Scholar]

- South African National Standards (SANS). SANS 10286 1998: Code of Practice – Mine Residue; South African Bureau of Standards: Pretoria, South Africa, 1998. [Google Scholar]

- Kilani, J. The Codes of Practice for Mine Residue Deposits. In Proceedings of the Workshop on Risk Management and Contingency Planning in the Management of Mine Tailings, Buenos Aires, Argentina, 5–6 November 1998. [Google Scholar]

- Republic of South Africa Department of Environmental Affairs (RSA DEA). National Waste Management Strategy; First Draft for Public Comment; Department of Environmental Affairs: Pretoria, South Africa, 2010; p. 155.

- Republic of South Africa Government Printing Works (RSA GPW). Government Gazette (Staatskoerant); Vol. 601, No. 3902; Government Printing Works: Pretoria, South Africa, 2015; p. 20.

- Cullinan, C. Stringent New Legislation for SA Mine Dumps and Stockpiles. 2015. Available online: http://www.miningreview.com/features/stringent-new-legislation-for-sa-mine-dumps-and-stockpiles/ (accessed on 26 March 2016).

- Lake, J. Regulations Regarding the Planning and Management of of Residue Stockpiles and Residue Deposits. SRK Consulting: Cape Town, South Africa, 2017; Available online: http://www.srk.com/sites/default/files/file/JLake_RegulationsOfResidueStockpiles_2017.pdf (accessed on 18 August 2017).

- Republic of South Africa Department of Environmental Affairs (RSA DEA). The National Environmental Management Act (Act No 107 of1998); The Government Printer: Johannesburg, South Africa, 2009.

- Feris, L.; Kotzé, L.J. The Regulation of Acid Mine Drainage in South Africa: Law and Governance Perspectives. PER: Potchefstroomse Elektroniese Regsblad 2014, 17, 2105–2163. [Google Scholar]

- Republic of South Africa Ministry of Water Affairs (RSA MWA). Regulations in Terms of Section 9c (6) of the Water Act, 1956, Relating to Dams With a Safety Risk; Doc. No. R.1560; Ministry of Water Affairs: Pretoria, South Africa, 1986; p. 35.

- Development Bank of Southern Africa (DBSA). Guide to Best Practice in the Operation, Maintenance and Safety of Dams; Phakisa Communications: Randburg, South Africa, 2004; p. 20. [Google Scholar]

- Goldblatt, M.; Gelb, S.; Davies, G. Macroeconomics and Sustainable Development in Southern Africa; Synthesis Report of South African Study; Development Bank of South Africa: Midrand, South Africa, 2002; p. 88. [Google Scholar]

- Republic of South Africa Office of the Presidency (RSA OP). The National Amendment Act, No. 45 of 1999; Office of the President: Cape Town, South Africa, 1999. Available online: http://pmg-assets.s3-website-eu-west-1.amazonaws.com/docs/081022wateract.pdf (accessed on 1 January 2016).

- Cessford, F. New Mining Regulations: What They Mean for Water Management. In Proceedings of the 2004 Water Institute of Southern Africa (WISA) Biennial Conference, Johannesburg, South Africa, 2–6 May 2004; p. 7. [Google Scholar]

- Republic of South Africa Department of Water Affairs and Forestry (RSA DWAF). Best Practice Guidelines for Water Resource Protection in the South African Mining Industry; Department of Water Affairs and Forestry: Pretoria, South Africa, 2007; Available online: https://commondatastorage.googleapis.com/comsa/Best%20Practice%20Guidlines%20-%20A4_Pollution%20Control%20Dams.pdf (accessed on 1 February 2016).

- Caldwell, J. Republic of South Africa Tailings Impoundment Regulations. 2010. Available online: http://ithinkmining.com/2010/11/15/republic-of-south-africa-tailings-impoundment-regulations/ (accessed on 28 December 2014).

- Mukheibir, P.; Sparks, D. Water Resource Management and Climate Change in South Africa: Visions, Driving Factors and Sustainable Development Indicators; Report for Phase I of the Sustainable Development and Climate Change Project; Energy and Development Research Centre, University of Cape Town: Cape Town, South Africa, 2003; p. 19. [Google Scholar]

- Republic of South Africa Office of the President (RSA OP). The Minerals Act No. 50 of 1991; Office of the President: Cape Town, South Africa, 1991. Available online: http://soer.deat.gov.za/dm_documents/Minerals-Act-50-of-1991_zJ7qk.pdf (accessed on 1 January 2016).

- Republic of South Africa Department of Minerals and Energy (RSA DME). Publication of Environmental Management Plan under Section 15 (2) (b) of the National Environmental Management Act, 1998 (Act No. 107 of 1998); Department of Minerals and Energy: Pretoria, South Africa, 2001; p. 78.

- Gore, S.; Erasmus, T.-E. New Onerous Regulation and Financial Implications for Residue Stockpiles and Deposits. 2015. Available online: https://www.cliffedekkerhofmeyr.com/en/news/publications/2015/environmental/environmental-alert-24-august-new-onerous-regulation-and-financial-implications-for-residue-stockpiles-and-deposits-.html (accessed on 27 March 2016).

- Republic of South Africa Office of the President (RSA OP). Atmospheric Air Pollution Prevention Act 45 of 1965; Office of the President: Cape Town, South Africa, 1965. Available online: http://soer.deat.gov.za/dm_documents/Act_Atmospheric_Pollution_Prevention_Act_-_45_of_1965_O4ZGw.pdf (accessed on 2 January 2016).

- Republic of South Africa Office of the President (RSA OP). National Environment Management: Air Quality Act No. 39 of 2004; Office of the President: Cape Town, South Africa, 2005. Available online: https://www.environment.gov.za/sites/default/files/legislations/nema_amendment_act39.pdf (accessed on 2 January 2016).

- Republic of South Africa Office of the President (RSA OP). Mine Health and Safety Act No. 29 of 1996; Office of the President: Cape Town, South Africa, 1996. Available online: http://www.kznhealth.gov.za/occhealth/17242.pdf (accessed on 2 January 2016).

- Republic of South Africa Department of Minerals and Energy (RSA DME). Radioactive Waste Management Policy and Strategy for the Republic of South Africa; Department of Minerals and Energy: Pretoria, South Africa, 2005; p. 33.

- World Nuclear Association (WNA). Safe Decommissioning of Civil Nuclear Industry Sites. 2006. Available online: http://world-nuclear.org/our-association/publications/position-statements/safe-decommissioning-of-civil-nuclear-industry-sit.aspx (accessed on 19 March 2016).

- Liefferink, M. Assessing the Past and the Present Role of the ‘National Nuclear Regulator’ as a Public Protector against Potential Health Injuries: The West and Far West Rand as Case Study; New Contree, No. 62; School for Basic Sciences, Vaal Triangle Campus, North-West University: Vanderbijlpark, South Africa, 2011; pp. 125–153. Available online: dspace.nwu.ac.za/bitstream/handle/.../No_62(2011)_Liefferink_M.pdf?... (accessed on 30 March 2016).

- Kolk, A.; Van Tulder, R.; Welters, C. International codes of conduct and corporate social responsibility: Can transnational corporations regulate themselves? Trans. Corp. 1999, 8, 143–180. [Google Scholar]

- Capel, J. Are Mining Profits Ethically Earned? Business Report 8 February 2012. Available online: http://www.iol.co.za/business/opinion/columnists/are-mining-profits-ethically-earned-1.1229375?showComments=true#.VK-ucSuUfms (accessed on 9 January 2015).

- Clarkson, M.B.E. A stakeholder framework for analyzing and evaluating corporate social performance. Acad. Manag. Rev. 1995, 20, 92–117. [Google Scholar]

- Mabuza, L.; Msezane, N.; Kwata, M. Mining and Corporate Social Responsibility Partnerships in South Africa; Policy Brief Number 15—February 2010; Africa Institute of South Africa (AISA): Pretoria, South Africa, 2010; Available online: http://www.ai.org.za/wp-content/uploads/downloads/2011/11/No-15.-Mining-and-Corporate-Social-Responsibility.pdf (accessed on 4 January 2015).

- Campbell, B. Corporate social responsibility and development in Africa: Reducing the roles and responsibilities of public and private actors in the mining sector. Resour. Policy 2012, 37, 138–143. [Google Scholar] [CrossRef]

- Flores-Araoz, F. Corporate Social Responsibility in South Africa: More than a Nice Situation. 2011. Available online: http://www.consultancyafrica.com/index.php?option=com_content&view=article&id=835:corporate-social-responsibility-in-south-africa-more-than-a-nice-intention&catid=82:african-industry-a-business&Itemid=266 (accessed on 4 January 2015).

- Republic of South Africa Department of Mineral Resources (RSA DMR). Amendment of the Broad-Based Socio-Economic Empowerment Charter for the South African Mining and Minerals Industry; Department of Mineral Resources: Pretoria, South Africa, 2010; p. 20.

- Mariri, T.; Chipunza, C. Corporate governance, corporate social responsibility and sustainability: Comparing corporate priorities within the South African mining industry. J. Hum. Ecol. 2011, 35, 95–111. [Google Scholar]

- Engelbrecht, L. Draft Code of Governance Principles for South Africa—2009; The King Committee on Governance: Parklands, South Africa, 2009; p. 141. [Google Scholar]

- Cliffe Dekker Attorneys. The King Report on Corporate Governance for South Africa; Cliffe Dekker Attorneys: Johannesburg, South Africa, 2002; p. 24. [Google Scholar]

- South African Institute of Chartered Accountants (SAICA). King III: Code, Principles and Practices (Summary); SAICA: Johannesburg, South Africa, 2013; p. 16. [Google Scholar]

- Institute of Directors in Southern Africa (IoDSA). King IV Report on Corporate Governance for South Africa. 2016. Available online: https://c.ymcdn.com/sites/iodsa.site-ym.com/resource/collection/684B68A7-B768-465C-8214-E3A007F15A/IoDSA_King_IV_-_WebVersion.pdf (accessed on 2 December 2016).

- McDonald, D.A. What Is Environmental Justice? In Environmental Justice in South Africa; McDonald, D.A., Ed.; Ohio University Press: Athens/University of Cape Town, South Africa, 2002; pp. 1–12. [Google Scholar]

- Busacca, M. Corporate Social Responsibility in South Africa’s Mining Industry: Redressing the Legacy of Apartheid. CMC Senior Theses, Department of Environment, Economics, and Politics (EEP), Claremont McKenna College, Claremont, CA, USA, 2013. Paper 632. Available online: http://scholarship.claremont.edu/cmc_theses/632 (accessed on 18 December 2015).

- Van Eeden, E.S.; Liefferink, M.; Durand, J.F. Legal issues concerning mine closure and social responsibility on the West Rand. J. Trans. Res. S. Afr. 2009, 5, 51–71. [Google Scholar]

- Porter, M.E.; Kramer, M.R. Strategy and society: The link between competitive advantage and corporate social responsibility. Harv. Bus. Rev. 2006, 84, 78–92. [Google Scholar] [PubMed]

- Bisaillon, V.; Gendron, C.; Turcotte, M.F. Commerce équitable comme vecteur de développement durable? Nouv. Prat. Soc. 2005, 18, 73–89. [Google Scholar] [CrossRef] [Green Version]

- Robinson, R.E. Susainability and Slimes Dams; The Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2010; Available online: http://www.saimm.co.za/journal-comments/137-sustainability-and-slimes-dams (accessed on 2 January 2016).

- Sangonet. Sustainable CSR and Mining in South Africa. 2013. Available online: http://www.ngopulse.org/article/sustainable-csr-and-mining-south-africa (accessed on 4 May 2015).

- Irina, N.; Stückelberger, C. Mining Ethics and Sustainability: Papers from the World Mining Congress; Globethics.net Global 8: Geneva, Switzerland, 2014; p. 198. Available online: http://www.globethics.net/documents/4289936/13403236/GE_Global_8+_Mining_ethics_web_final.pdf/7974f77b-0b67-4155-b75c-418d670abc27 (accessed on 26 December 2014).

- Grunwald, A. The imperative of sustainable development. In Geoethics: Ethical Challenges and Case Studies in Earth Sciences; Wyss, M., Peppoloni, S., Eds.; Elsevier Publishers: Amsterdam, The Netherlands, 2015; pp. 26–36. [Google Scholar]

- The African Mining Indaba. The Alternative Mining Indaba. 2014. Available online: http://www.news24.com/Archives/City-Press/Alternative-Mining-Indaba-calls-for-inclusion-of-communities-20150429 (accessed on 11 March 2016).

- Beierle, T.C. Using social goals to evaluate public participation in environmental decisions. Rev. Policy Res. 1999, 16, 75–103. [Google Scholar] [CrossRef]

- Beierle, T.C.; Konisky, D. What are we gaining from public participation? Observations from environmental planning in the Great Lakes. Environ. Plan. C Gov. Policy 2001, 19, 515–527. [Google Scholar] [CrossRef]

- Goodland, R. Responsible Mining: The Key to Profitable Resource Development; Institute for Environmental Diplomacy and Security (IEDS): Burlington, VT, USA, 2012; p. 32. [Google Scholar]

- Centre for Environmental Rights (CER). Annual Report 2012–2013. 2013. Available online: http://cer.org.za/wp-content/uploads/2013/09/CER-AR-2012-13.pdf (accessed on 10 May 2014).

- Robins, M. Closure of Tailings Facilities: Current Practice Review and Guidelines for Success. Master’s Thesis, University of the Witwatersrand, Johannesburg, South Africa, 2004; p. 248. Available online: file:///C:/Users/User/Downloads/Closurefinal.pdf (accessed on 17 September 2017).

- Fourie, A.; Brent, A.C. A Project-Based Mine Closure Model (MCM) for Sustainable Asset Life Cycle Management Life Cycle Engineering; Department of Engineering and Technology Management, University of Pretoria: Pretoria, South Africa, 2008. [Google Scholar]

- Hart, R.; Coumans, C. Evolving standards and expectations for responsible mining: A civil society perspective. In Mning Ethics and Sustainability. Papers from the World Mining Congress, Montreal, Canada, 12-14 August 2013; Irina, N., Stückelberger, C., Eds.; Globethics.net Global 8: Ganeva, Switzerland, 2014; pp. 41–61. Available online: http://www.globethics.net/documents/4289936/13403236/GE_Global_8+_Mining_ethics_web_final.pdf/7974f77b-0b67-4155-b75c-418d670abc27 (accessed on 31 August 2015).

- Sharma, P.; Pandey, S. Status of phytoremediation in world scenario. Int. J. Environ. Bioremediation Biodegrad. 2014, 2, 178–191. [Google Scholar]

- Arthur, G.D.; Aremu, A.O.; Kulkarni, M.G.; Okem, A.; Stirk, W.A.; Davies, T.C.; Van Staden, J. Can the use of natural biostimulants be a potential means of phytoremediating contaminated soils from goldmines in South Africa? Int. J. Phytoremediation 2015, 18, 427–434. [Google Scholar] [CrossRef] [PubMed]

- Mesjasz-przybyłowicz, J.; Nakonieczny, M.; Migula, P.; Augustyniak, M.; Tarnawska, M.; Reimold, W.U.; Koeberl, C.; Przybyłowicz, W.; Głowacka, E. Uptake of cadmium, lead, nickel and zinc from soil and water solutions by the nickel hyperaccumulator berkheya coddii. Acta Biol. Crac. Ser. Bot. 2004, 46, 75–85. [Google Scholar]

- Amponsah-Dacosta, M.; Reid, D.L. Mineralogical characterisation of selected South African mine tailings for the purpose of mineral carbonation. In An Interdisciplinary Response to Mine Water Challenges; Sui, W., Sun, Y., Wang, C., Eds.; China University of Mining and Technology Press: Xuzhou, China, 2014; pp. 686–692. [Google Scholar]

- Malatse, M.; Ndlovu, S. The viability of using the Witwatersrand gold mine tailings for brickmaking. J. S. Afr. Inst. Min. Metall. 2015, 115, 321–327. Available online: http://www.scielo.org.za/scielo.php?script=sci_arttext&pid=S0038-223X2015000400014 (accessed on 1 April 2016). [CrossRef]

- Meintjes, A. Benefits of dry tailings disposal. In Focus on Tailings—Operational Tailings Management for Successful Closure; Bentel, B., Luppnow, D., Eds.; SRK International Newsletter No. 29: Cape Town, South Africa, 2014; Available online: http://www.srk.co.za/files/File/newsletters/SRKnews29-tailings_A4.pdf (accessed on 30 March 2016).

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2007; Synthesis Report; WHO/UNEP: Geneva, Switzerland, 2008; p. 112. [Google Scholar]

- Assima, G.P.; Larachi, F.; Molson, J.; Beaudoin, G. Comparative study of five Québec ultramafic mining residues for use in direct ambient carbon dioxide mineral sequestration. Chem. Eng. J. 2013, 245, 56–64. [Google Scholar] [CrossRef]

- Beaudoin, G.; Constantin, H.M.; Duchesne, J.; Cecchi, E.; Huot, F.; Vigneau, S.; Fiola, R. Spontaneous carbonation of serpentine in milling and mining waste, southern Québec and Italy. In Proceedings of the 2nd International Conference on Accelerated Carbonation for Environmental and Materials Engineering (ACEME08), Rome, Italy, 1–3 October 2008; pp. 73–82. [Google Scholar]

- Van Niekerk, H.J.; Viljoen, M.J. Causes and consequences of the Merriespruit and other tailings-dam failures. Land Degrad. Dev. (Spec. Issue) 2005, 16, 201–212. [Google Scholar] [CrossRef]

- Cairncross, E.; Kisting, S.; Liefferink, S.; Van Wyk, D. Case Study on Extractive Industries. Report from South Africa; Prepared for the Lancet Commission on Global Governance. 2013, p. 16. Available online: http://www.thejournalist.org.za/wp-content/uploads/2014/09/Lancet-Study-Gold-Platinum-Mines-in-SA.pdf (accessed on 8 January 2015).

- Tutu, H.; Cukrowska, E.; McCarthy, T.S.; Mphephu, N.F.; Hart, R. Determination and modelling of geochemical speciation of uranium in gold mine polluted land in South Africa. In Proceedings of the 8th International Mine Water and the Environment Congress, Johannesburg, South Africa, 29 November 2003; Available online: https://www.imwa.info/docs/imwa_2003/imwa_2003_137-155.pdf (accessed on 16 March 2016).

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poswa, T.T.; Davies, T.C. The Nature and Articulation of Ethical Codes on Tailings Management in South Africa. Geosciences 2017, 7, 101. https://doi.org/10.3390/geosciences7040101

Poswa TT, Davies TC. The Nature and Articulation of Ethical Codes on Tailings Management in South Africa. Geosciences. 2017; 7(4):101. https://doi.org/10.3390/geosciences7040101

Chicago/Turabian StylePoswa, Tobius Thobile, and Theophilus Clavell Davies. 2017. "The Nature and Articulation of Ethical Codes on Tailings Management in South Africa" Geosciences 7, no. 4: 101. https://doi.org/10.3390/geosciences7040101