Investigation of an Ironless Permanent Magnet Linear Synchronous Motor with Cooling System

Abstract

:1. Introduction

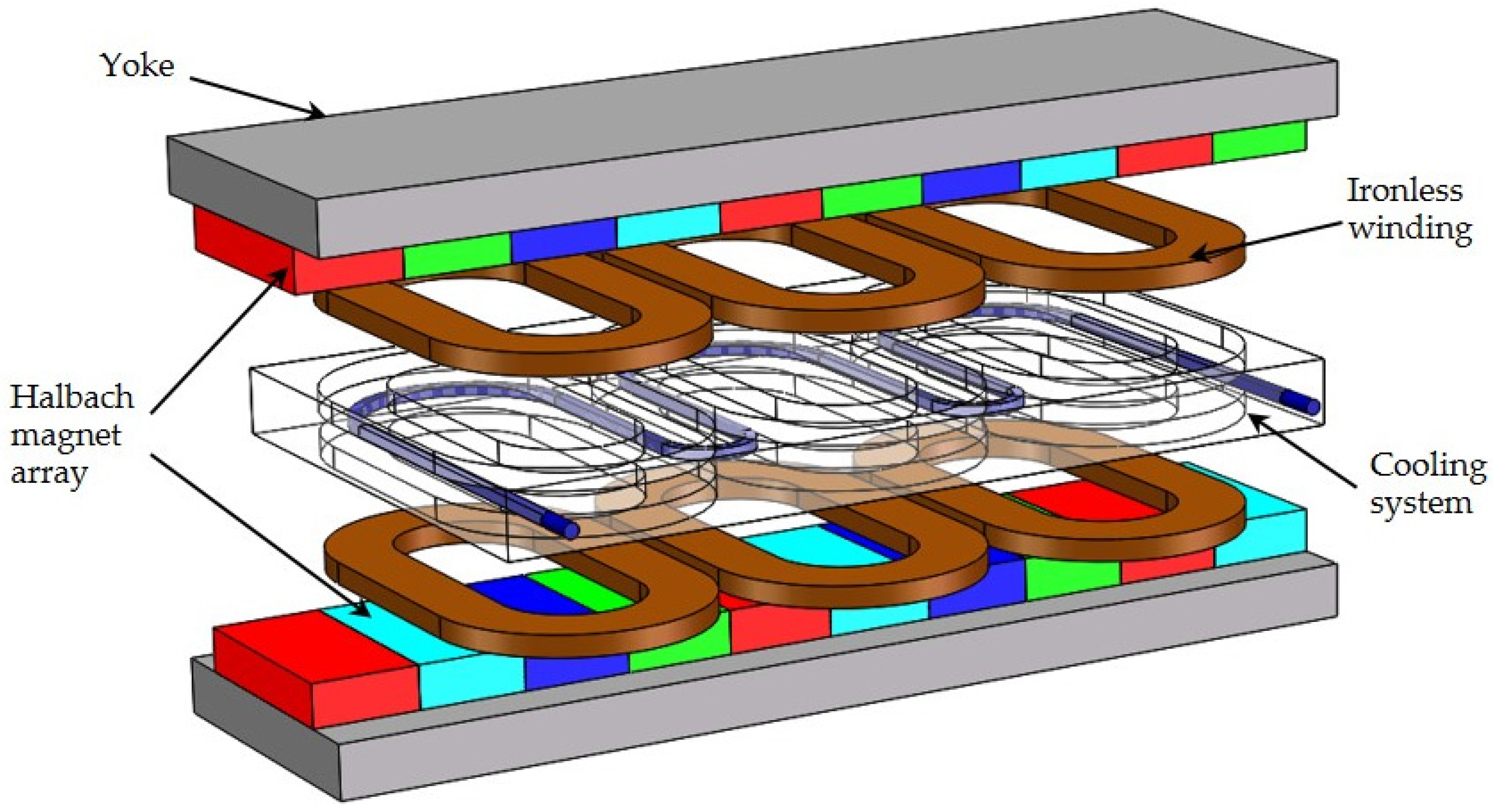

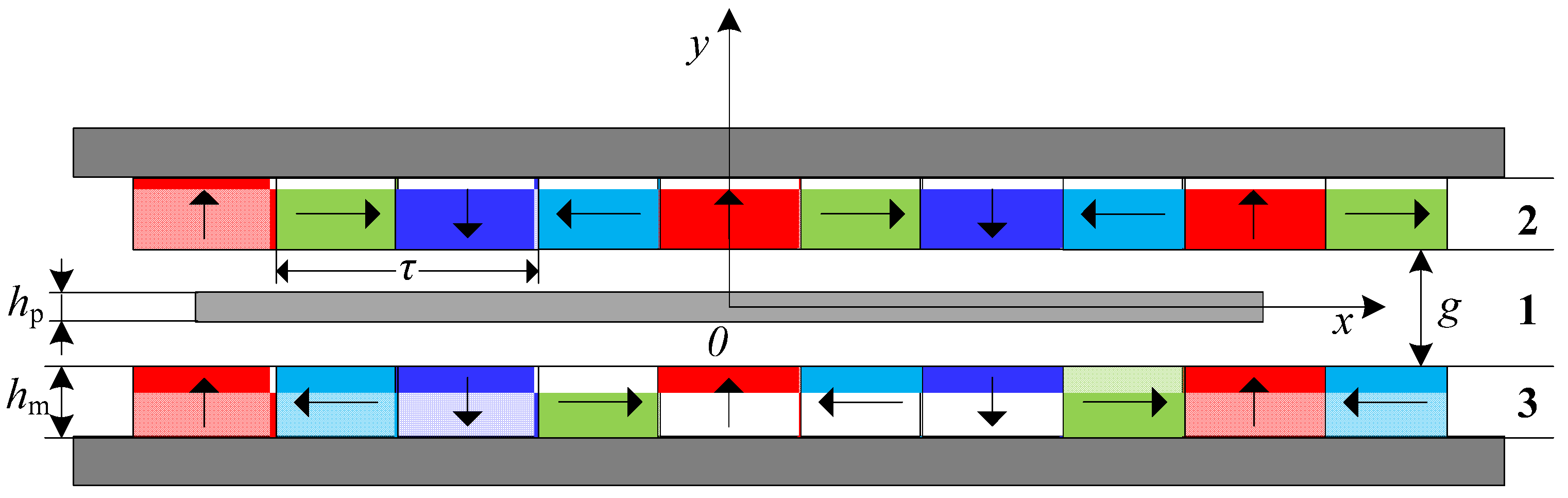

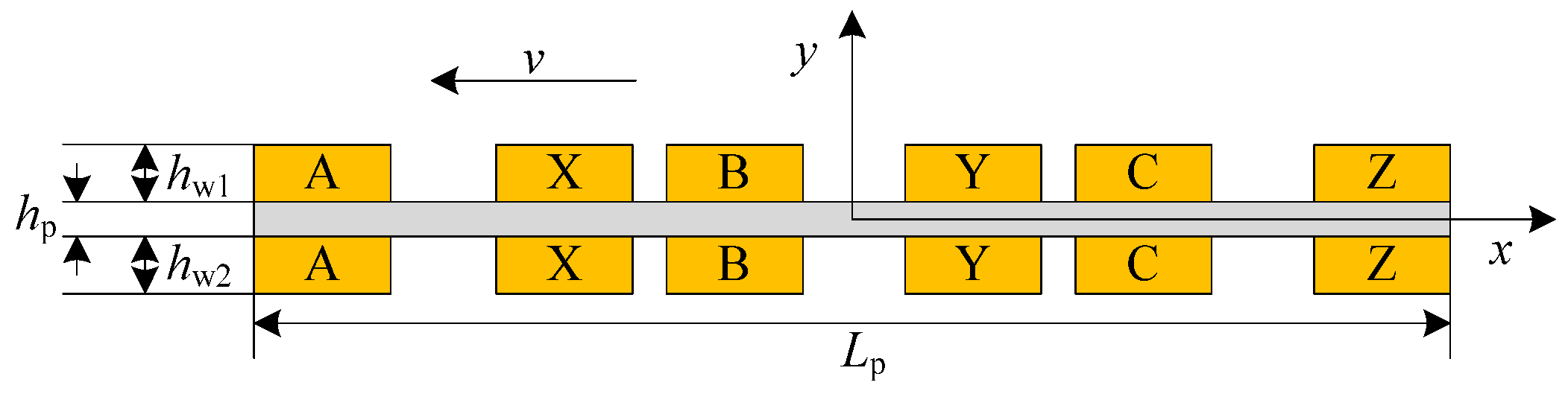

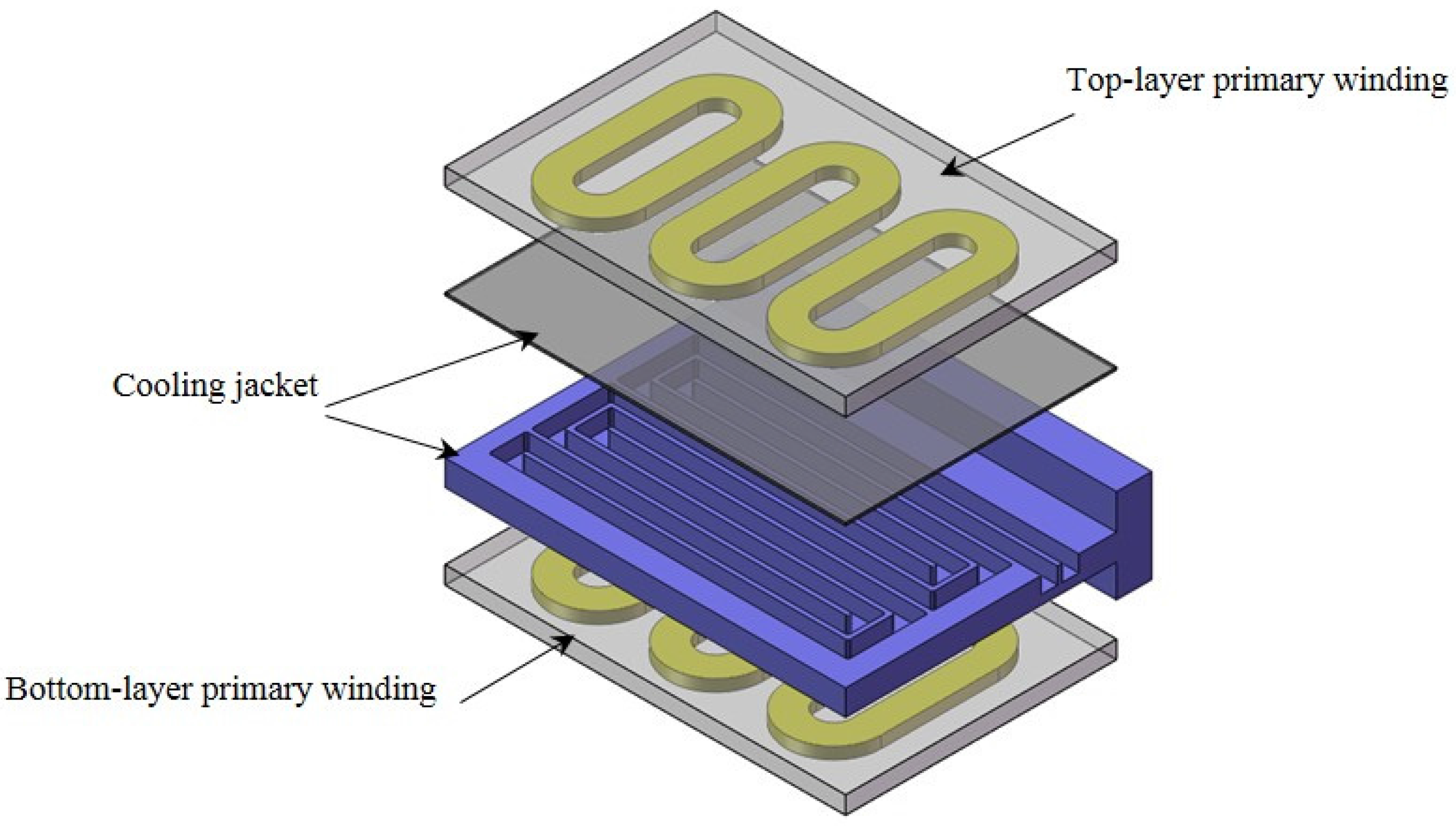

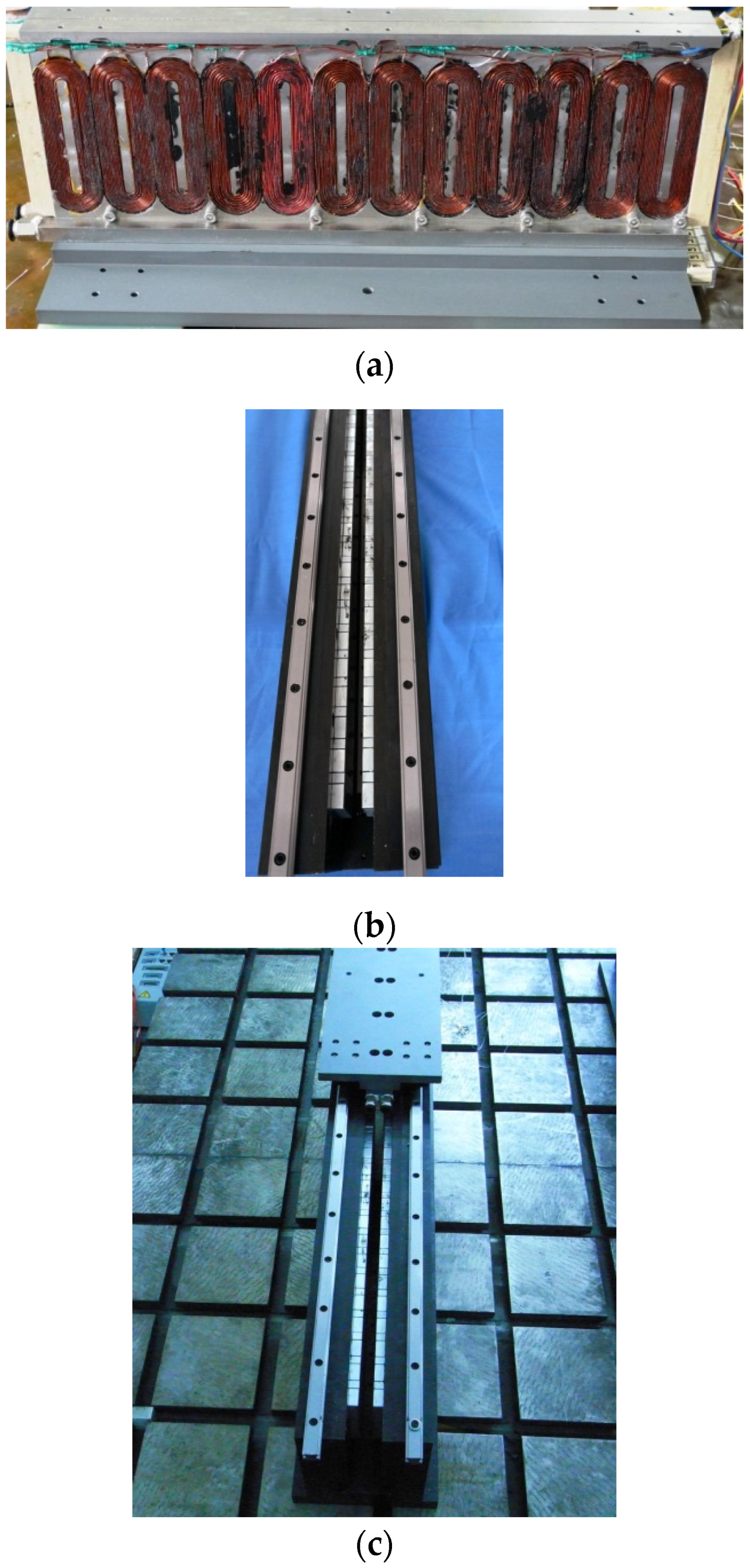

2. Topology of the Novel Ironless LSM with Cooling System

3. Magnetic Field Analysis and Calculation of the Eddy Current Braking Force

3.1. Magnetic Field Produced by the Halbach Magnet Array

- All regions are extended infinitely in the x-direction

- Permanent magnets are periodically distributed along the x-axis

- The permeability of the yoke is infinite and the permeability of the permanent magnet material is equal to the permeability of free space

- The effects of the slots inside the cooling jacket are ignored

3.2. The Eddy Current Density

3.3. The Eddy Current Braking Force

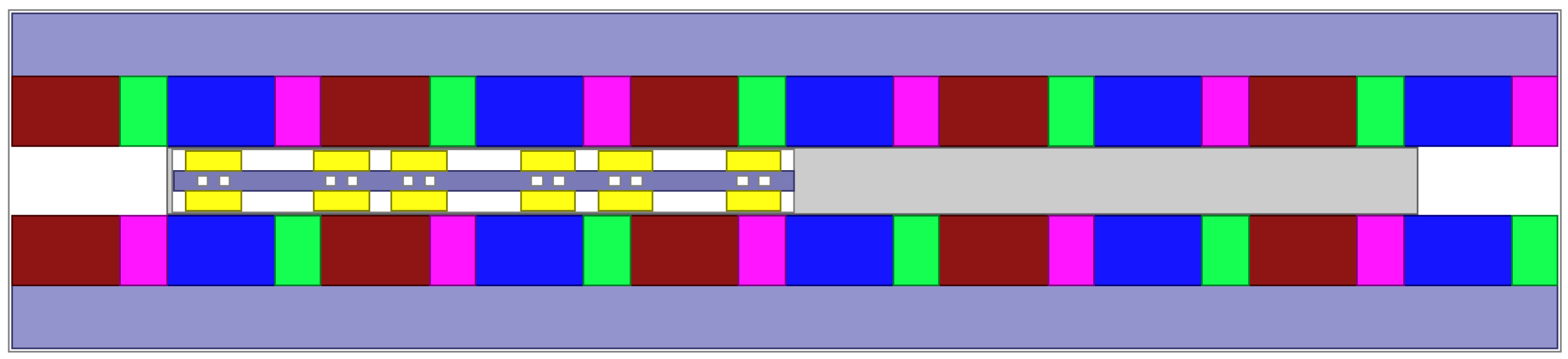

4. Simulation Verification

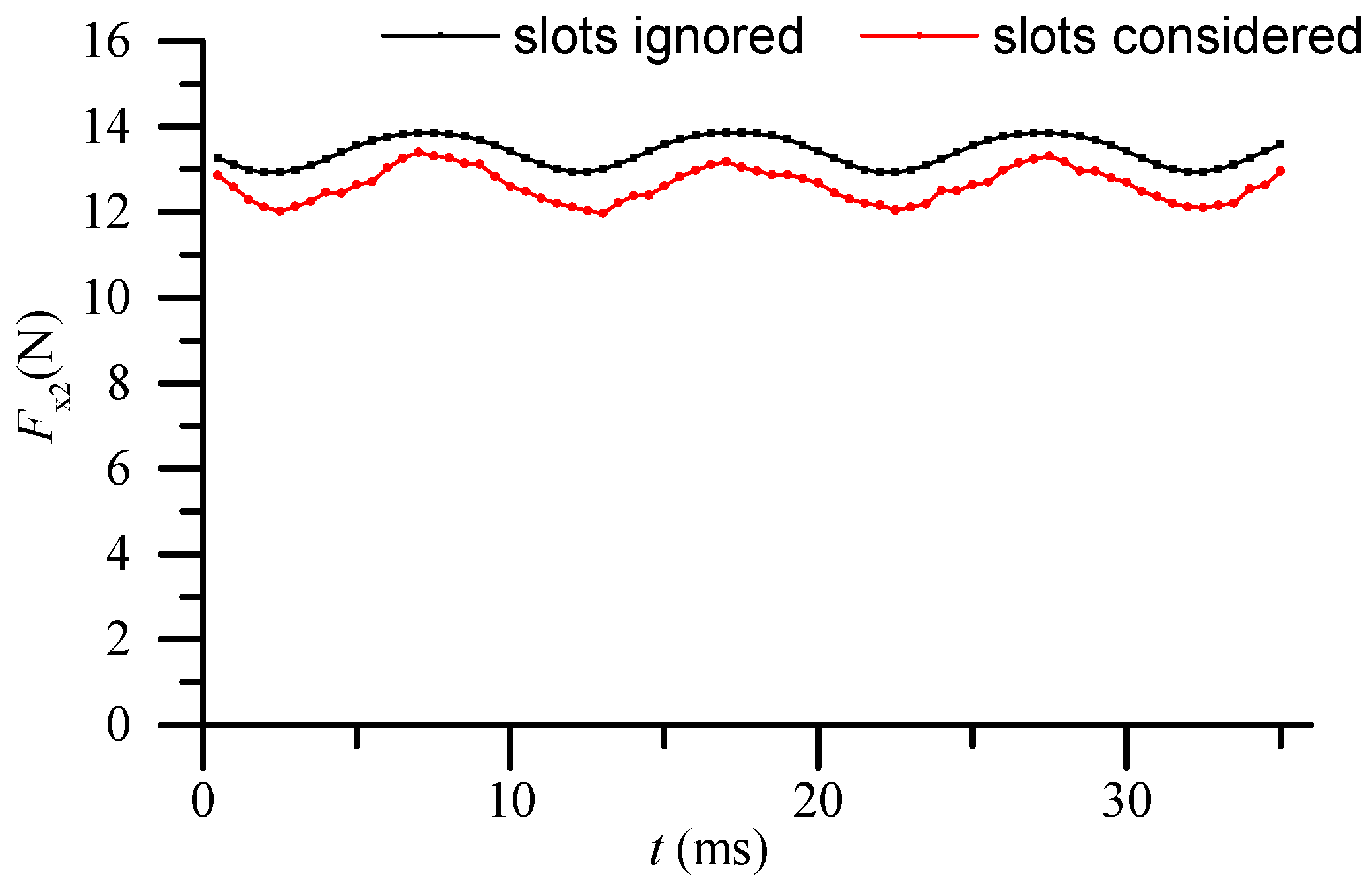

4.1. Simulation Verification

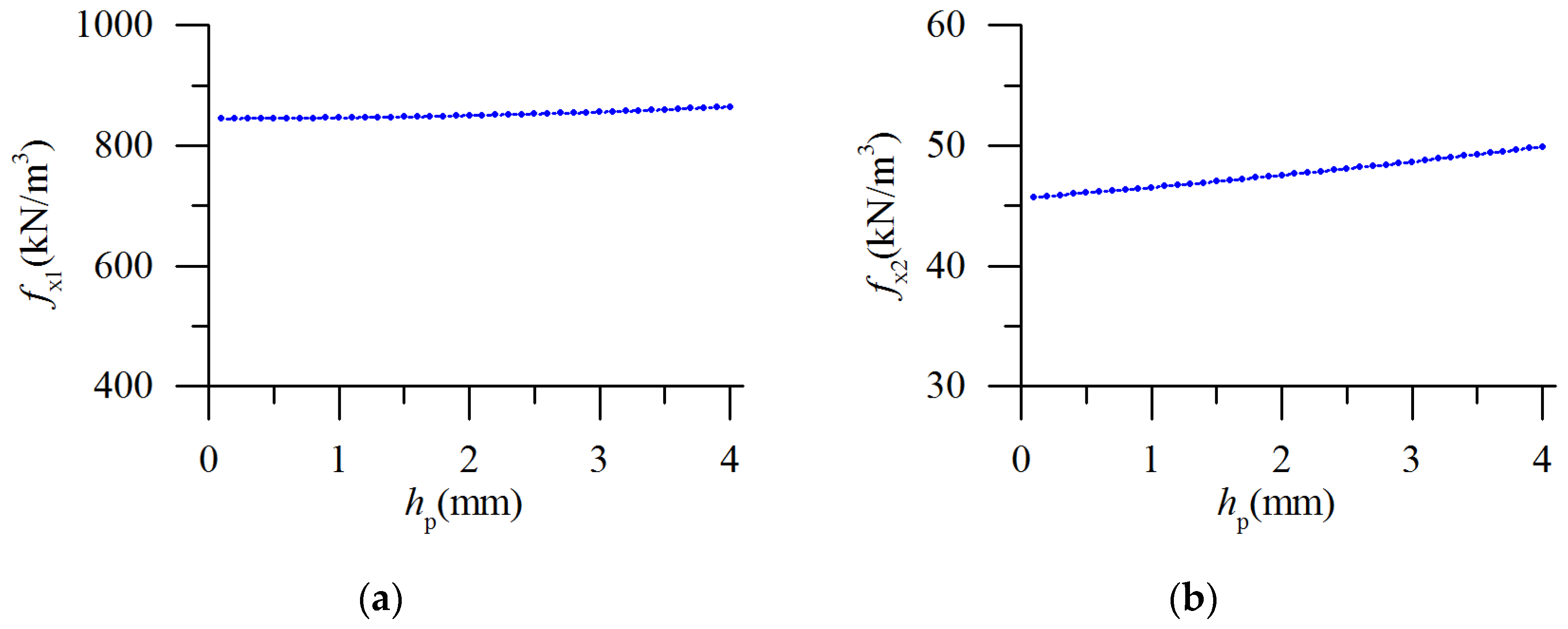

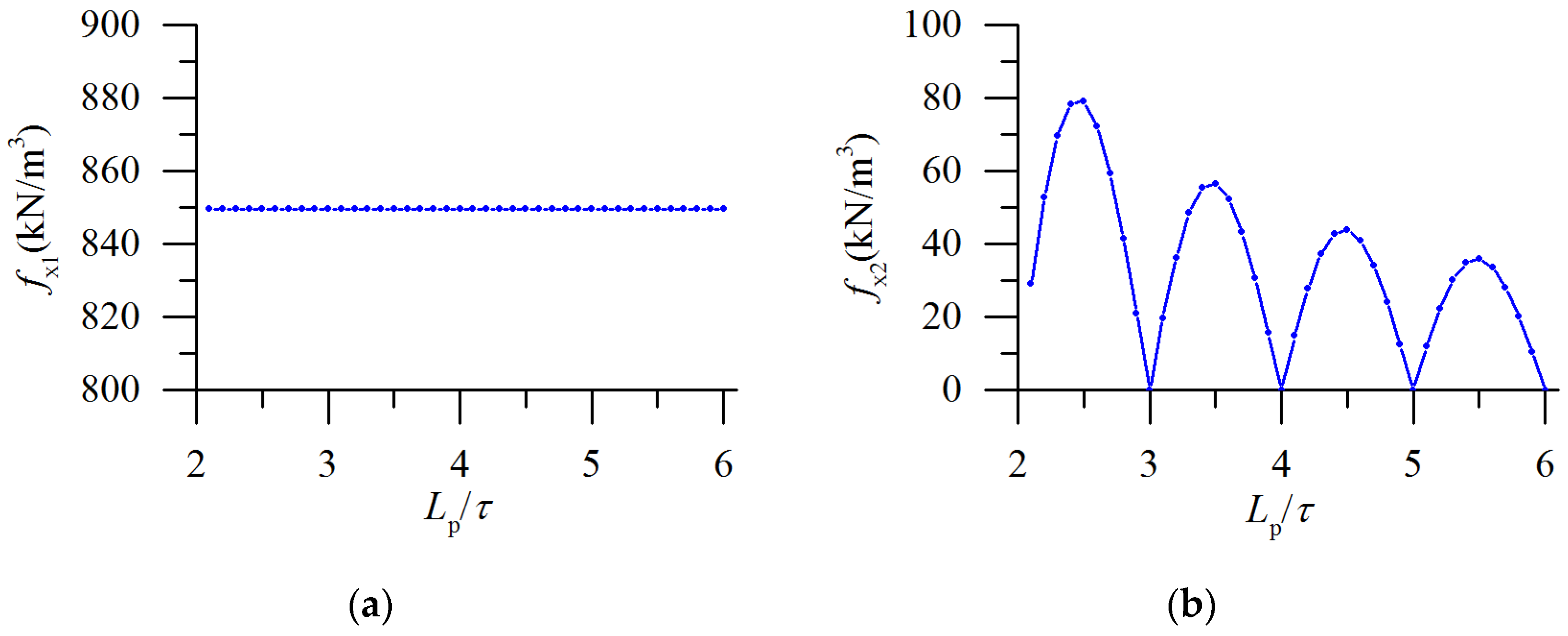

4.2. Influence of the Motor Parameters on the Eddy Current Braking Force

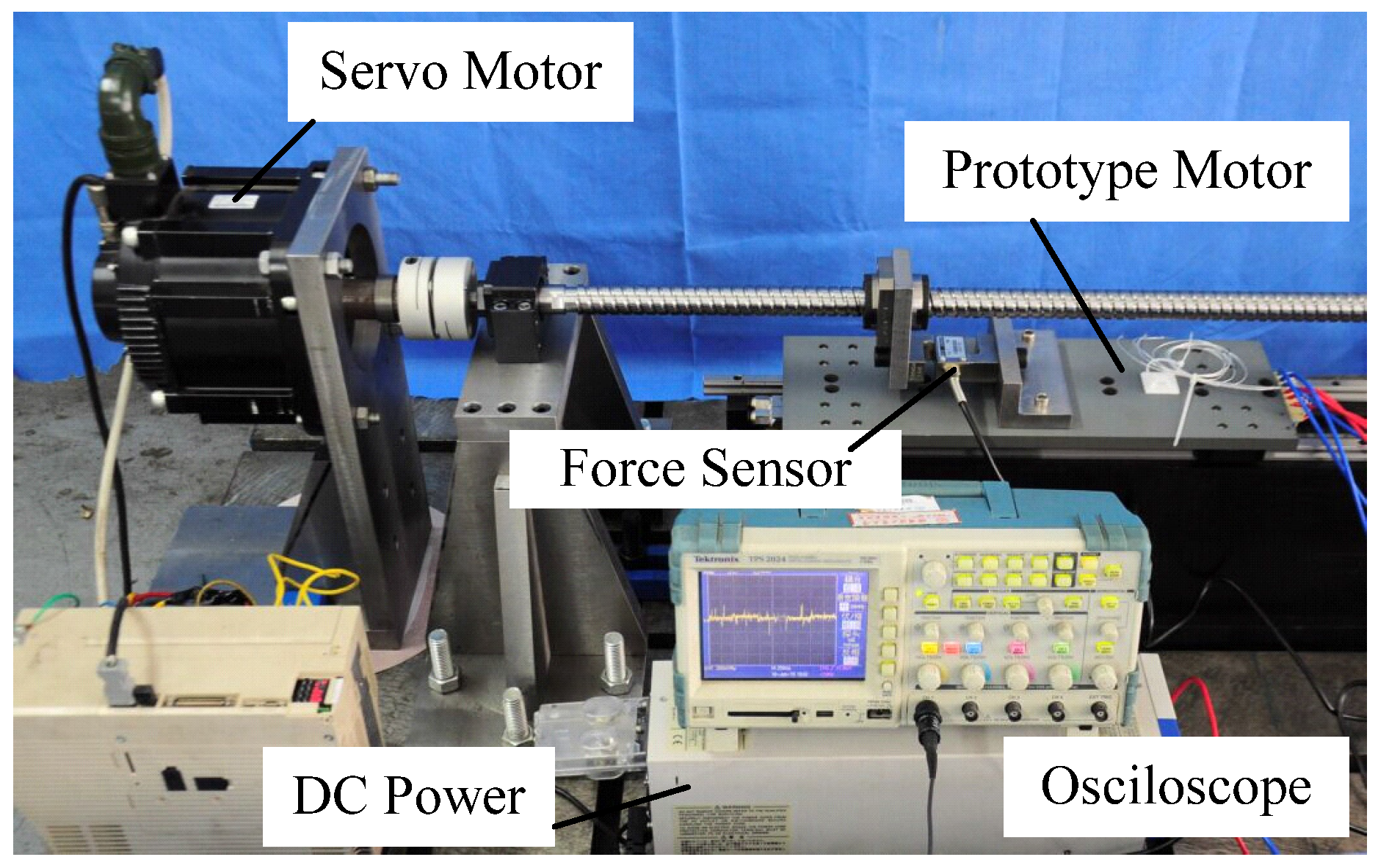

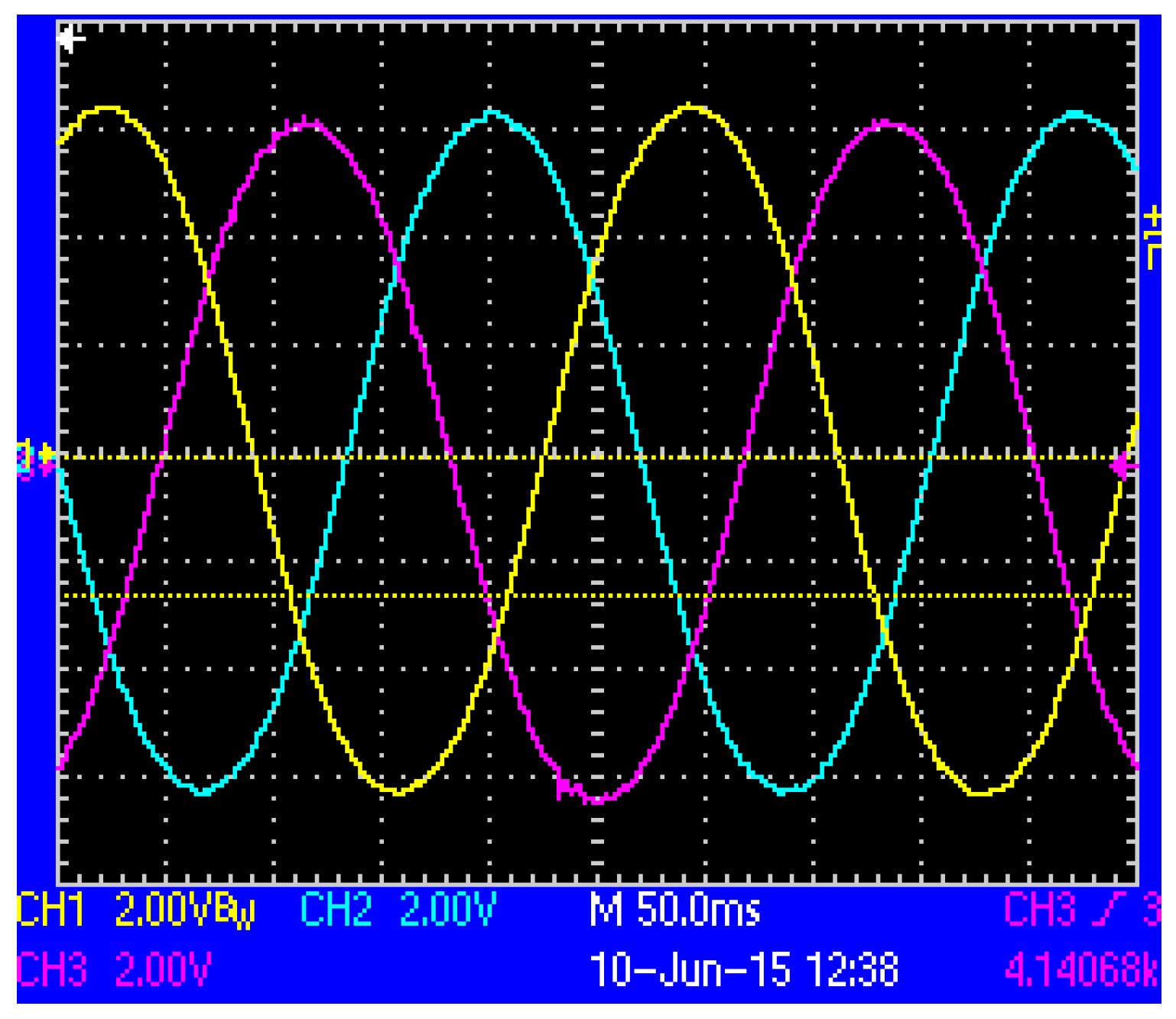

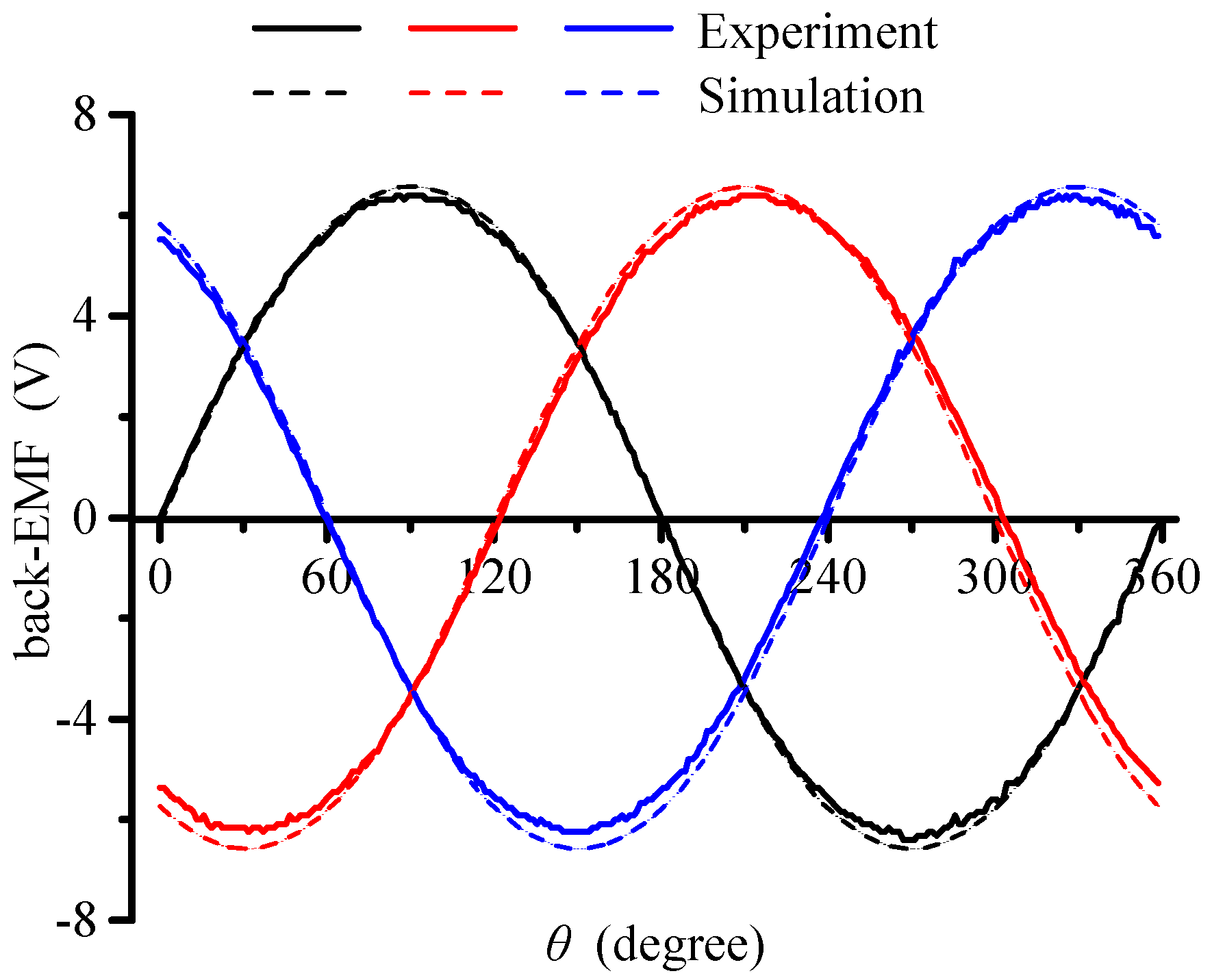

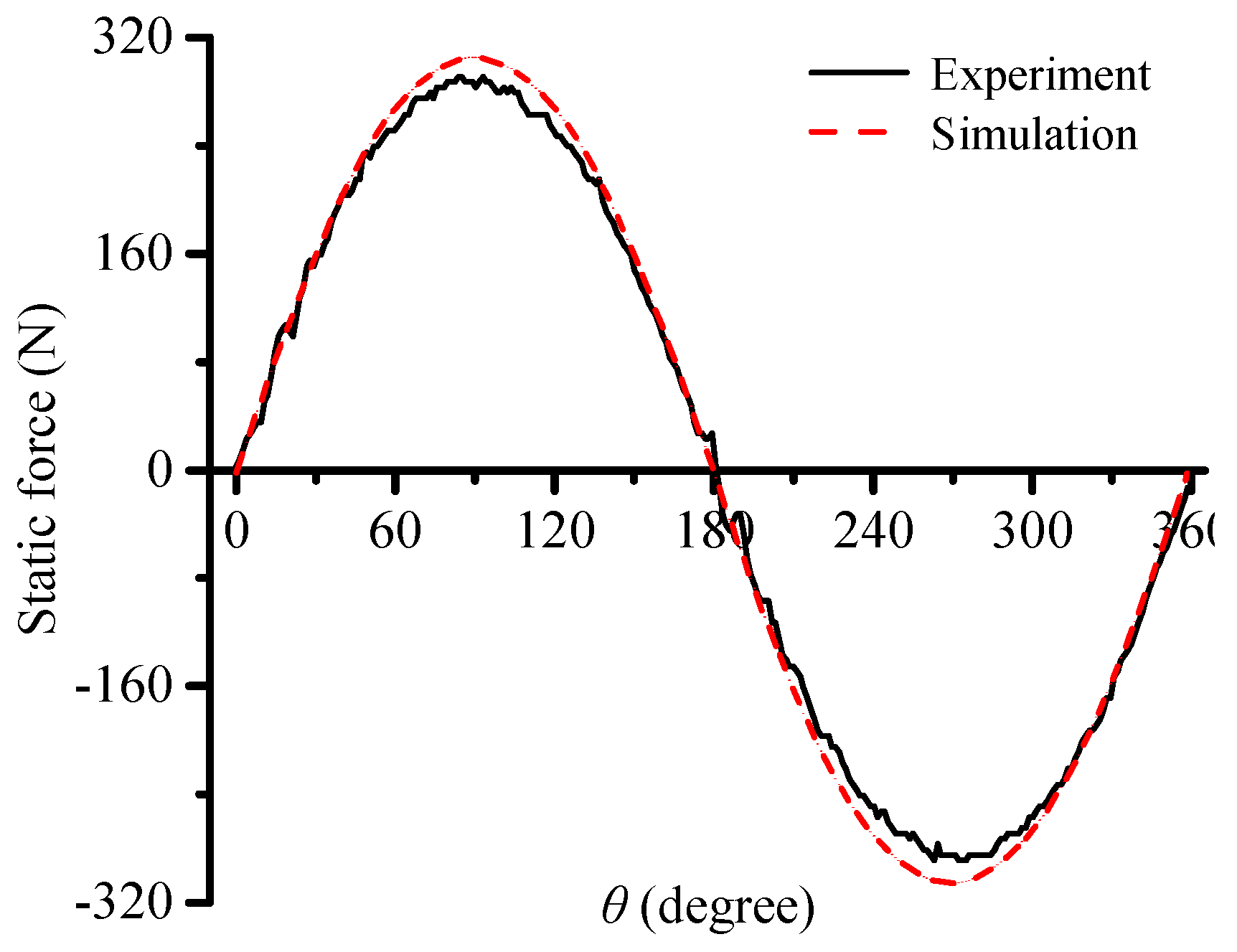

5. Prototype and Experiments

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sun, P.; Zhou, H. Air-gap magnetic field design optimization for U-shaped ironless permanent magnet linear synchronous motors. In Proceedings of the International Conference on Electrical Machines & Systems, Wuhan, China, 17–20 October 2008; pp. 123–138.

- Park, K.S.; Choi, J.; Park, Y.P.; Park, N.C. Thermal deformation of thermally assisted magnetic recording head in binary gas mixture at various temperatures. IEEE Trans. Magn. 2013, 49, 2671–2676. [Google Scholar] [CrossRef]

- Lu, Q.; Zhang, X.; Chen, Y.; Huang, X.; Ye, Y.; Zhu, Z.Q. Modeling and investigation of thermal characteristics of a water-cooled permanent-magnet linear motor. IEEE Trans. Ind. Appl. 2015, 51, 2086–2096. [Google Scholar] [CrossRef]

- Boglietti, A.; Cavagnino, A.; Staton, D.; Shanel, M.; Mueller, M.; Mejuto, C. Evolution and modern approaches for thermal analysis of electrical machines. IEEE Trans. Ind. Electron. 2009, 56, 871–882. [Google Scholar] [CrossRef]

- Chen, Y.; Yao, Y.; Lu, Q.; Ye, Y.; Huang, X. Electromagnetic and thermal coupling analysis of a water-cooled double-sided permanent magnet linear synchronous motor. In Proceedings of the International Conference on Electrical Machines and Systems IEEE, Pattaya, Thailand, 25–28 October 2015; pp. 1136–1140.

- Bracikowski, N.; Hecquet, M.; Brochet, P.; Shirinskii, S.V. Multiphysics modeling of a permanent magnet synchronous machine by using lumped models. IEEE Trans. Ind. Electron. 2012, 59, 2426–2436. [Google Scholar] [CrossRef]

- Jungreuthmayer, C.; Bäuml, T.; Winter, O.; Ganchev, M.; Kapeller, H.; Haumer, A.; Kral, C. A detailed heat and fluid flow analysis of an internal permanent magnet synchronous machine by means of computational fluid dynamics. IEEE Trans. Ind. Electron. 2012, 59, 4568–4578. [Google Scholar] [CrossRef]

- Jankowski, T.A.; Prenger, F.C.; Hill, D.D.; O’Bryan, S.R.; Sheth, K.K.; Brookbank, E.B.; Hunt, D.F.A.; Orrego, Y.A. Development and validation of a thermal model for electric induction motors. IEEE Trans. Ind. Electron. 2010, 57, 4043–4054. [Google Scholar] [CrossRef]

- Kazan, E.; Onat, A. Modeling of air core permanent-magnet linear motors with a simplified nonlinear magnetic analysis. IEEE Trans. Magn. 2011, 47, 1753–1762. [Google Scholar] [CrossRef]

- Tavana, N.R.; Shoulaie, A. Minimizing thrust fluctuation in linear permanent magnet synchronous motor with Halbach array. In Proceedings of the 1st Power Electronic & Drive Systems & Technologies Conference, Tehran, Iran, 17–18 Feburary 2010; pp. 302–306.

- Kang, G.H.; Hong, J.P.; Kim, G.T. A novel design of an air-core type permanent magnet linear brushless motor by space harmonics field analysis. IEEE Trans. Magn. 2001, 37, 3732–3736. [Google Scholar] [CrossRef]

- Chen, Y.S. Research on Ironless Linear Permanent Magnet Synchronous Loading Motor and Cooling System. Master’s Dissertation, Harbin Institute of Technology, Harbin, China, 2012. [Google Scholar]

- Kou, B.; Zhang, L.; Li, L. Modeling and analysis of a novel composite-current driven synchronous permanent magnet planar motor. In Proceedings of the 6th International Conference on Electrical Machines and Systems (ICEMS 2011), Beijing, China, 1–4 August 2011.

- Wang, J.; Lin, H.; Fang, S.; Huang, Y. A general analytical model of permanent magnet eddy current couplings. IEEE Trans. Magn. 2014, 50, 8000109. [Google Scholar] [CrossRef]

- Zhang, L.; Kou, B.; Xing, F.; Zhao, B. Characteristic analysis of an ironless linear synchronous motor with novel Halbach magnet array. In Proceedings of the 17th International Symposium on Electromagnetic Launch Technology, San Diego, CA, USA, 1–5 July 2014.

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| length of air-gap | g | 10.5 | mm |

| pole pitch | τ | 24 | mm |

| lateral width of the cooling jacket | lw | 80 | mm |

| amplitude values of fundamental harmonic | Bym | 0.8 | T |

| thickness of the cooling jacket | hp | 2 | mm |

| length of the cooling jacket | Lp | 100 | mm |

| thickness of the top-layer coil | hw1 | 3.5 | mm |

| thickness of the under-layer coil | hw2 | 3.5 | mm |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Kou, B.; Jin, Y.; Chen, Y.; Liu, Y. Investigation of an Ironless Permanent Magnet Linear Synchronous Motor with Cooling System. Appl. Sci. 2016, 6, 422. https://doi.org/10.3390/app6120422

Zhang L, Kou B, Jin Y, Chen Y, Liu Y. Investigation of an Ironless Permanent Magnet Linear Synchronous Motor with Cooling System. Applied Sciences. 2016; 6(12):422. https://doi.org/10.3390/app6120422

Chicago/Turabian StyleZhang, Lu, Baoquan Kou, Yinxi Jin, Yusheng Chen, and Yanjie Liu. 2016. "Investigation of an Ironless Permanent Magnet Linear Synchronous Motor with Cooling System" Applied Sciences 6, no. 12: 422. https://doi.org/10.3390/app6120422