Leak Detection in Water-Filled Small-Diameter Polyethylene Pipes by Means of Acoustic Emission Measurements †

Abstract

:1. Introduction

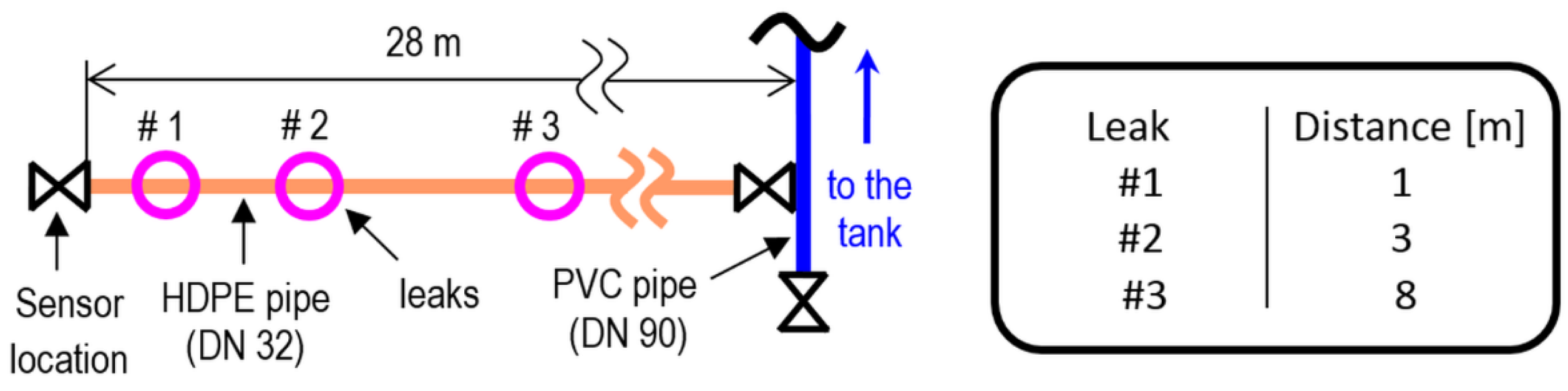

2. Unburied Pipe Tests

2.1. Experimental Setup and Tests

- The non-leaking state (referred to as NL), set by stopping all the leaks with the repair clamps;

- Water leaking from the j-th active leak (Lk-j), a condition set by temporarily removing the corresponding repair clamp (Figure 2a);

- All the leaks activated simultaneously (Lk-123).

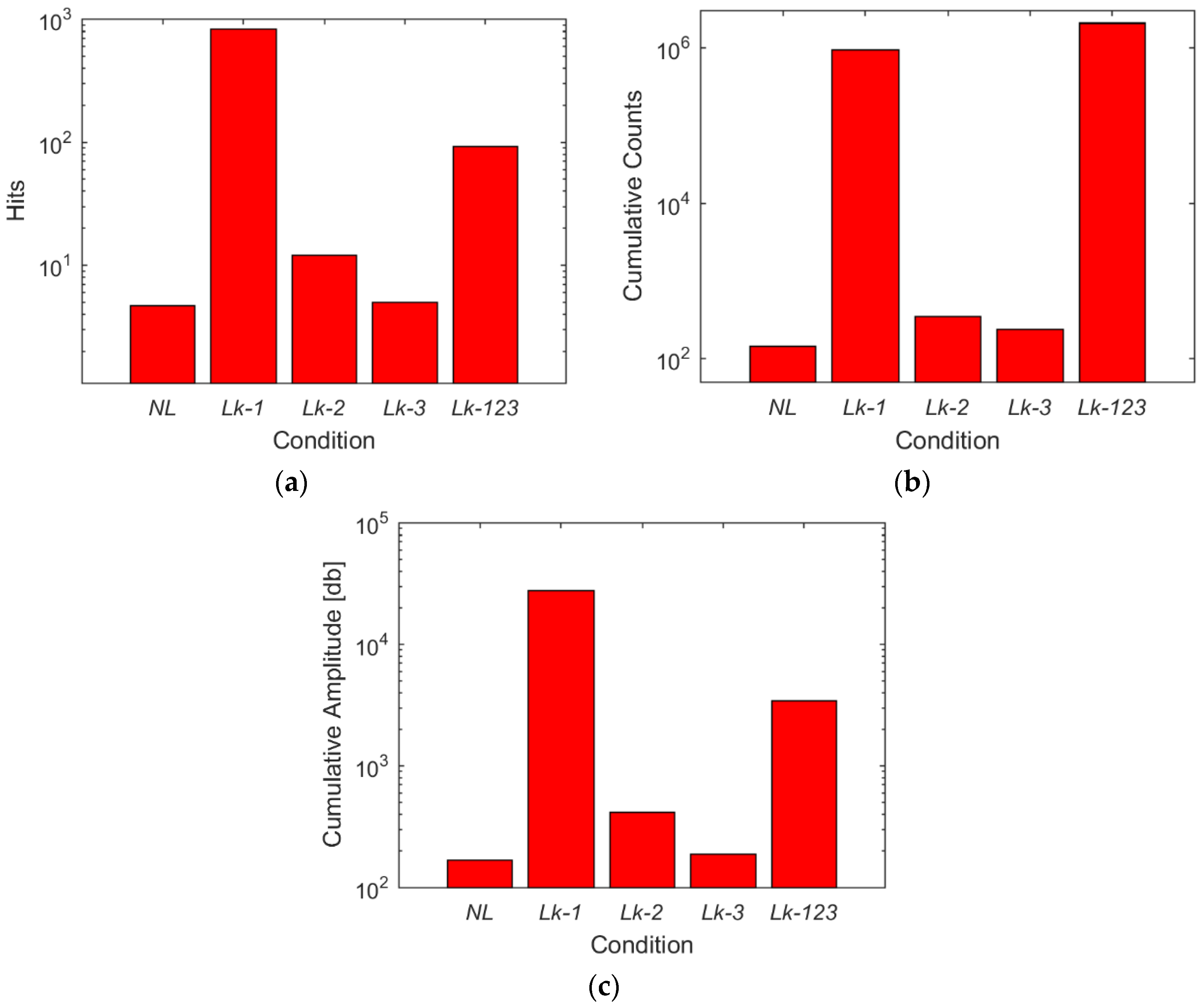

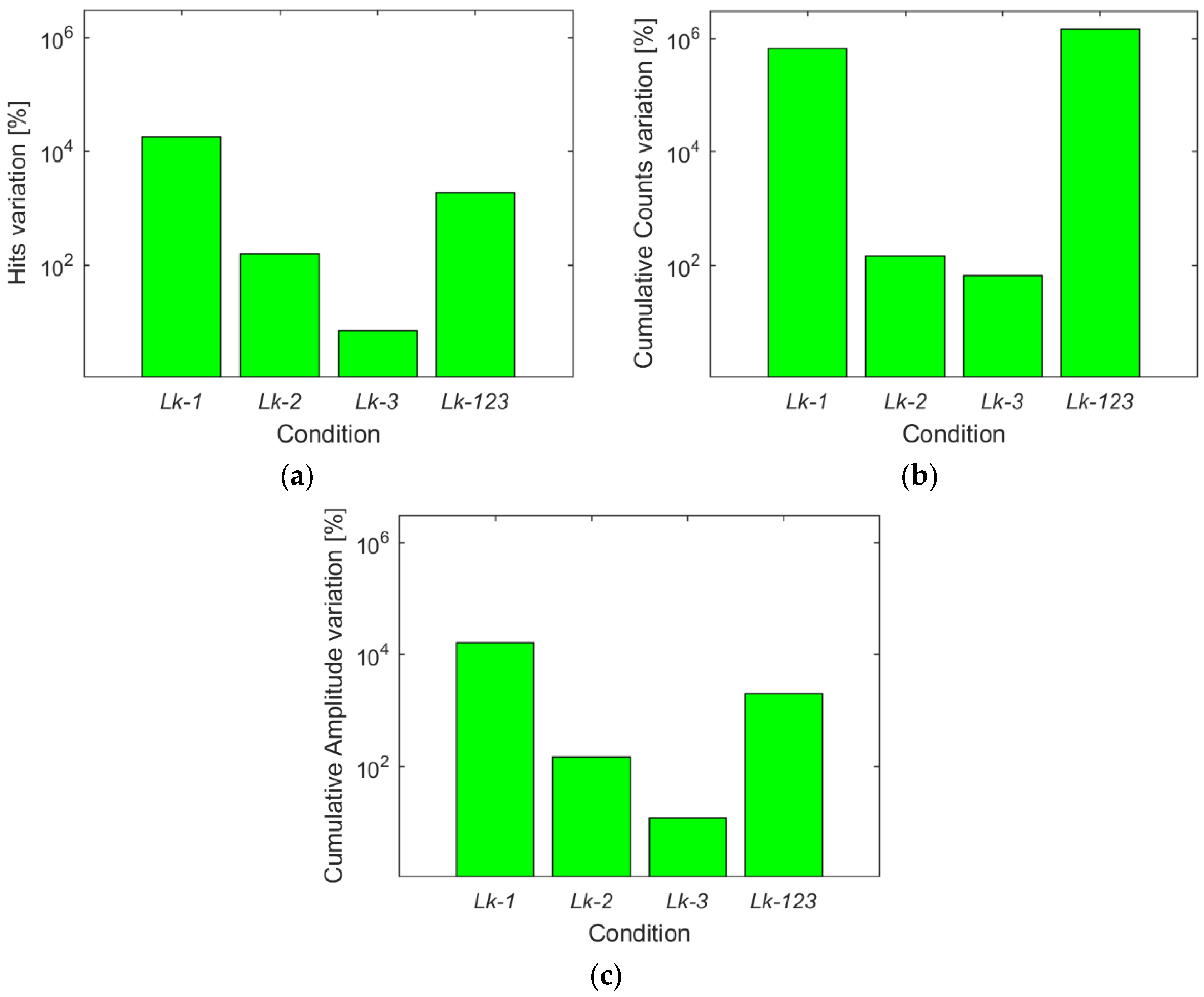

- Total amount of Hits per acquisition, which coincide with the number of AE events for the adopted setup, where only one sensor is installed for measurements;

- Cumulative Counts, computed by summing the Counts of all Hits related to one acquisition;

- Cumulative Amplitude, computed by adding together the Amplitude values of all Hits related to one acquisition.

2.2. Results and Discussion

3. Buried Pipe Tests

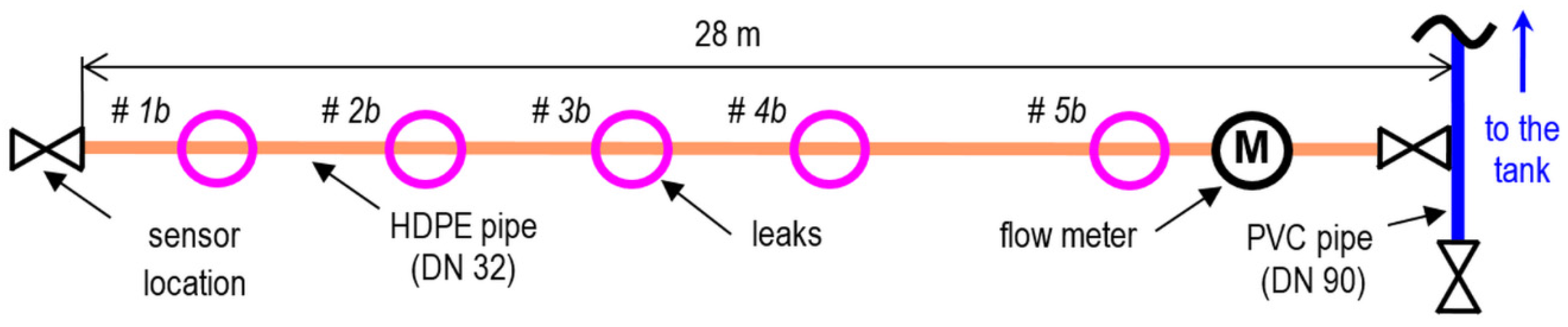

3.1. Experimental Setup and Tests

- acquisitions in non-leaking state (referred to as NLb hereafter), set by deactivating all the leaks with the repair clamps, to assess the environmental noise;

- water leaking against backfill soil from the j-th active leak (Lk-jb), a condition set by temporarily removing the corresponding repair clamp (Figure 8b).

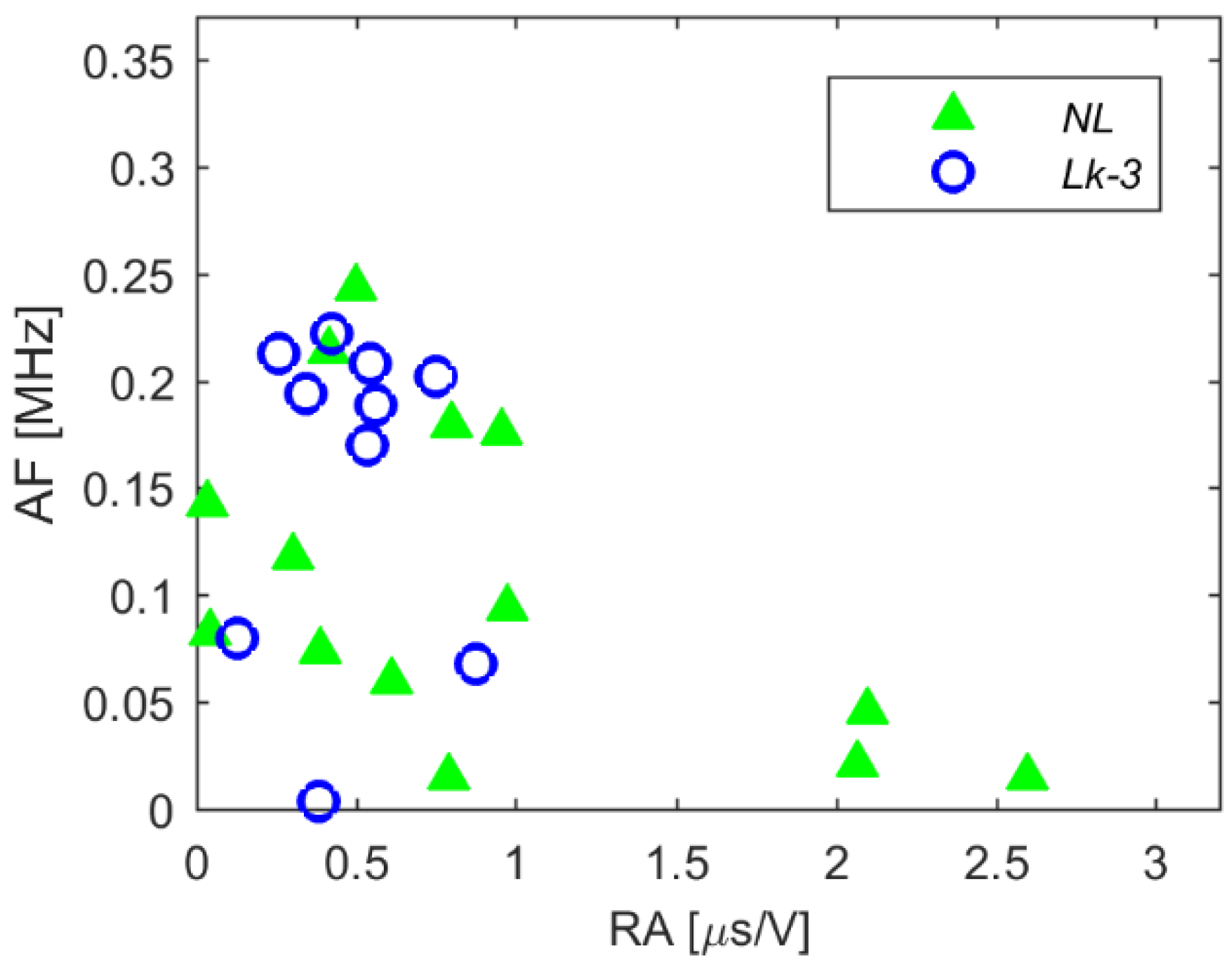

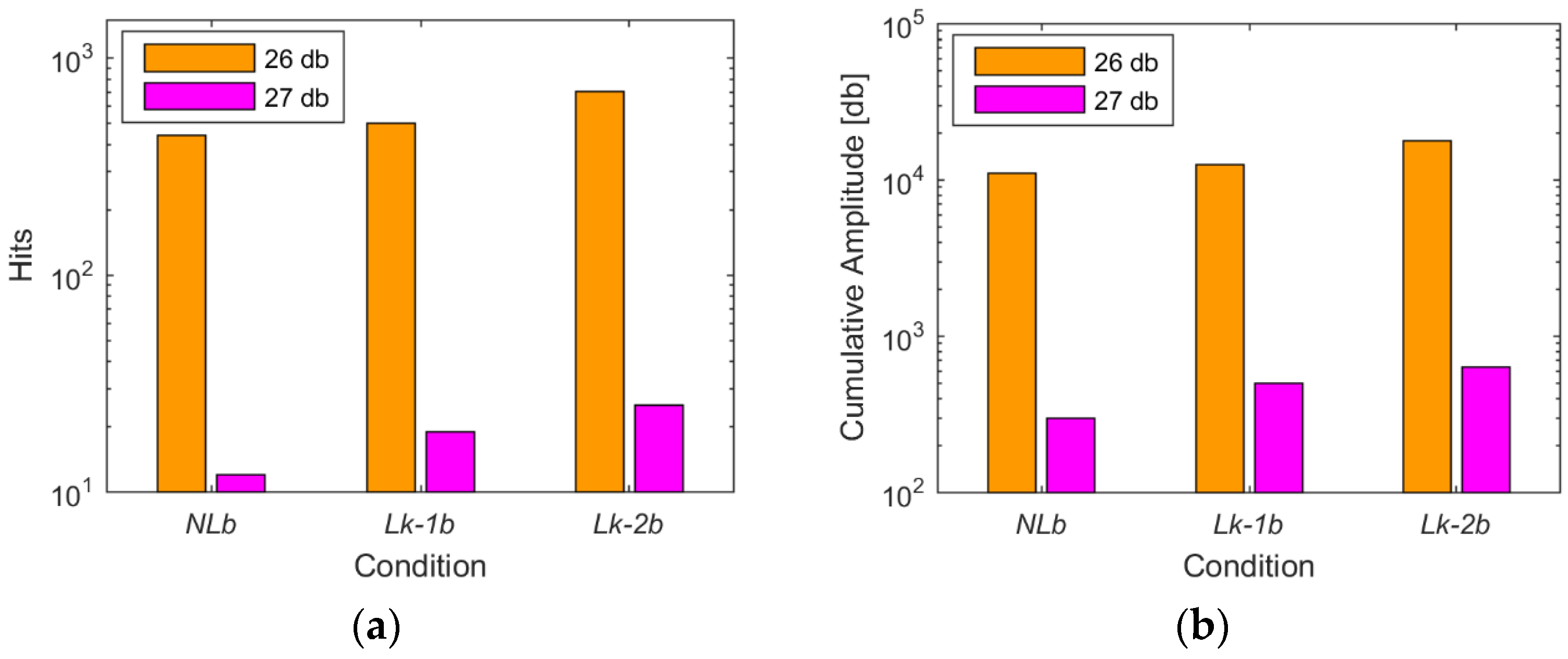

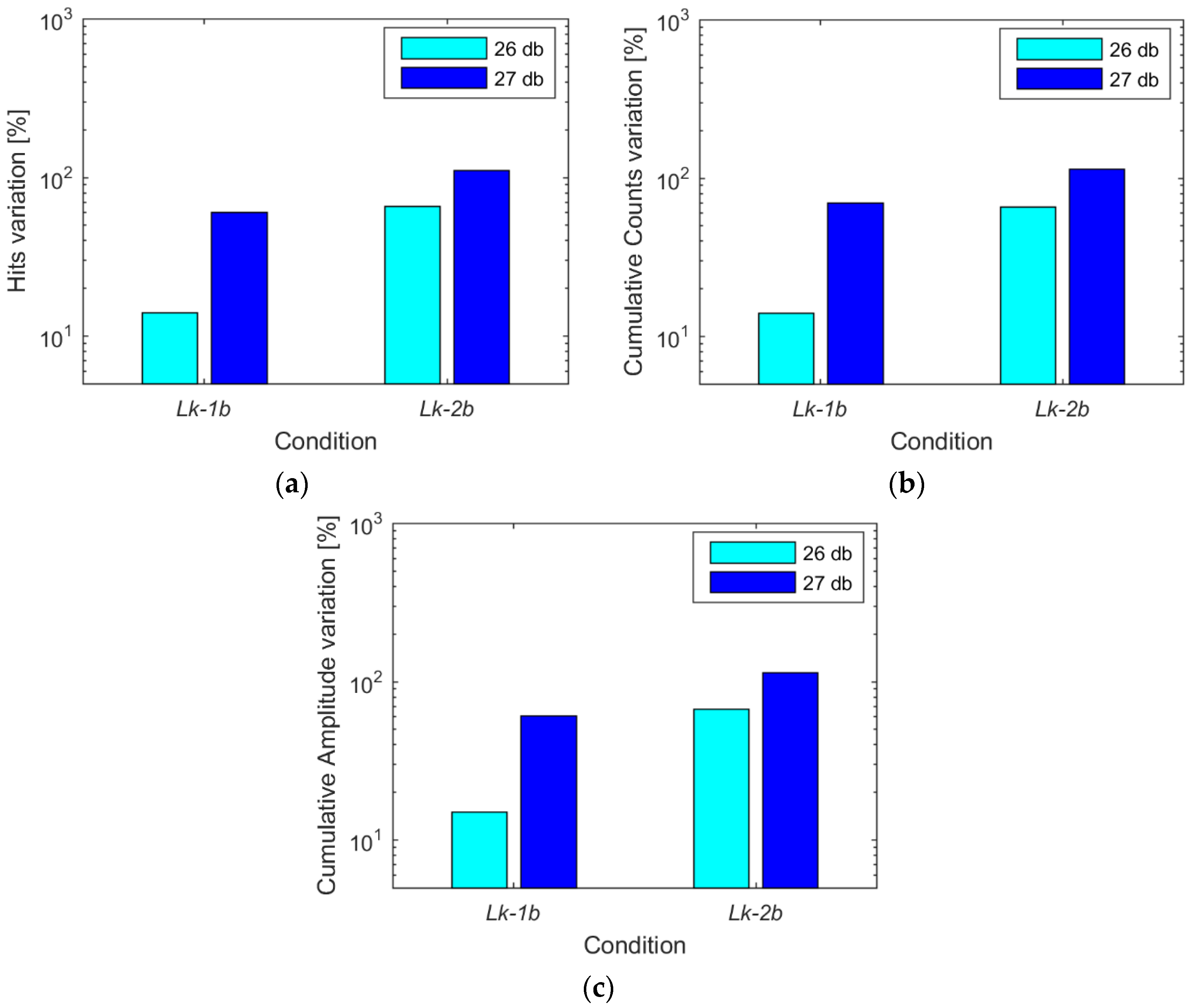

- trend of three AE parameters, namely Hits, Cumulative Counts, and Cumulative Amplitude;

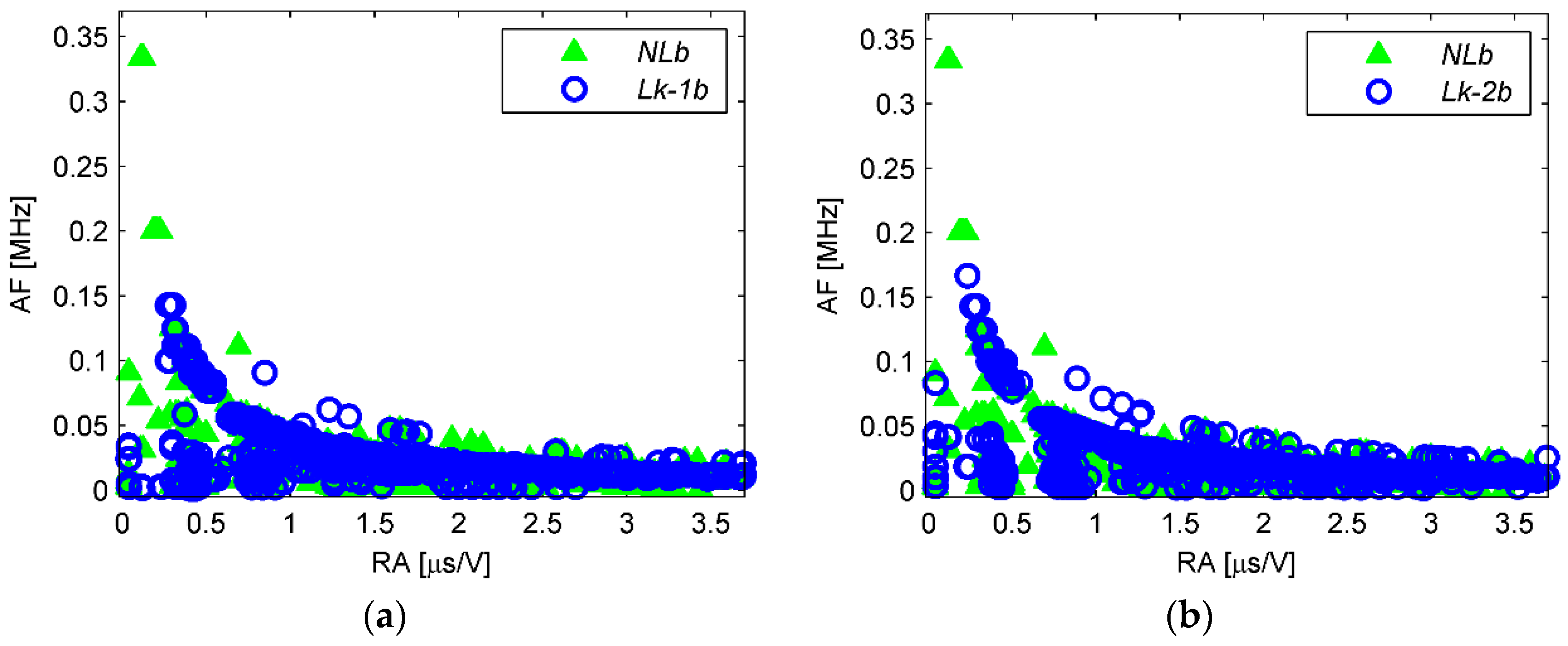

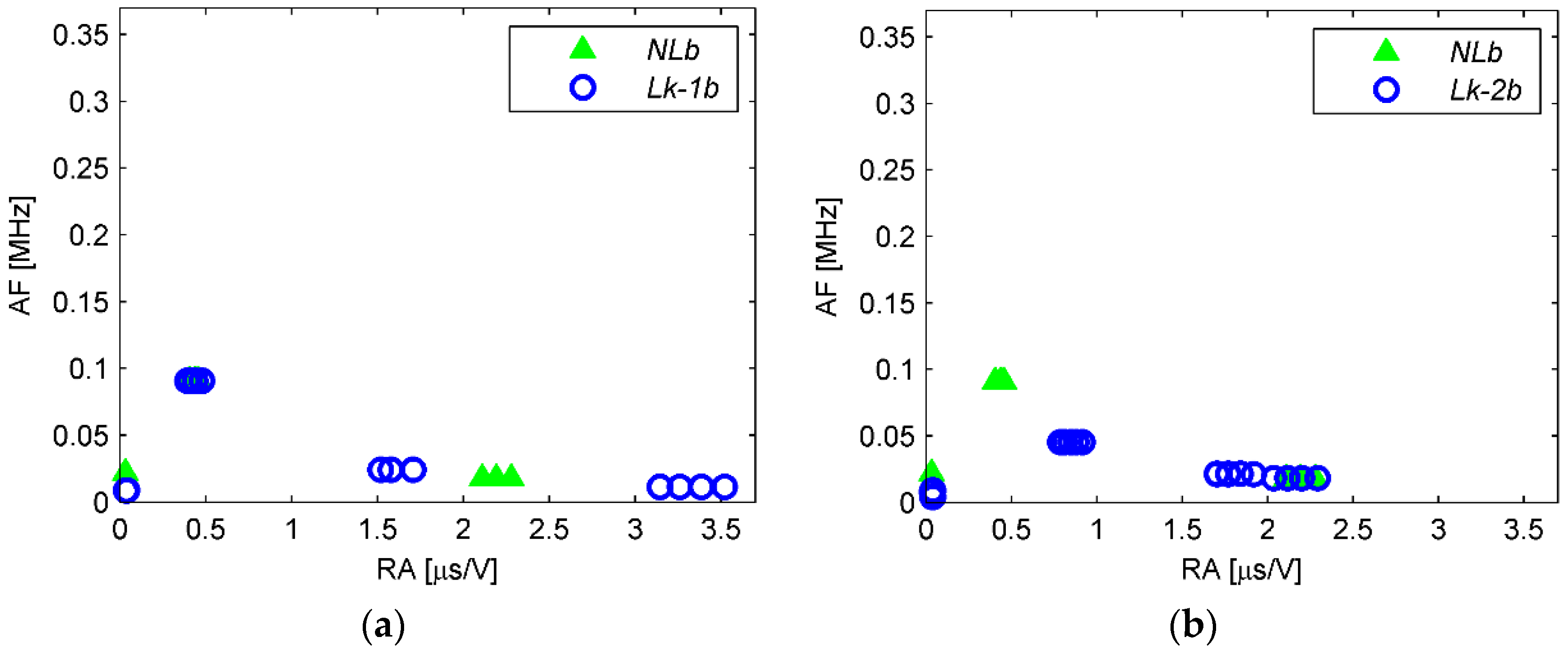

- distribution of AE events in an AF versus RA value diagram.

3.2. Results and Discussion

4. Conclusions

Author Contributions

Conflicts of Interest

References

- United States Environmental Protection Agency. Control and Mitigation of Drinking Water Losses in Distribution Systems; EPA 816-R-10-019 Report; United States Environmental Protection Agency: Washington, DC, USA, 2010.

- BDEW—German Association of Energy and Water Industries. VEWA Survey: Comparison of European Water and Waste Water Prices. 2010. Available online: www.bdew.de (accessed on 23 November 2016).

- Mutikanga, H.E.; Sharma, S.K.; Vairavamoorthy, K. Methods and tools for managing losses in water distribution systems. J. Water Resour. Plan. Manag. 2012, 139, 166–174. [Google Scholar] [CrossRef]

- Hunaidi, O.; Chu, W.; Wang, A.; Guan, W. Detecting leaks in plastic pipes. J. Am. Water Works Assoc. 2000, 92, 82–94. [Google Scholar]

- Gao, Y.; Brennan, M.J.; Joseph, P.F.; Muggleton, J.M.; Hunaidi, O. On the selection of acoustic/vibration sensors for leak detection in plastic water pipes. J. Sound Vib. 2005, 283, 927–941. [Google Scholar] [CrossRef]

- Metje, N.; Atkins, P.R.; Brennan, M.J.; Chapman, D.N.; Lim, H.M.; Machell, J.; Muggleton, J.M.; Pennock, S.; Ratcliffe, J.; Redfern, M.; et al. Mapping the Underworld—State-of-the-art review. Tunn. Undergr. Space Technol. 2007, 22, 568–586. [Google Scholar] [CrossRef]

- Fahmy, M.; Moselhi, O. Detecting and locating leaks in Underground Water Mains Using Thermography. In Proceedings of the 26th International Symposium on Automation and Robotics in Construction (ISARC 2009), Austin, TX, USA, 24–27 June 2009.

- Bimpas, M.; Amditis, A.; Uzunoglu, N. Detection of water leaks in supply pipes using continuous wave sensor operating at 2.45 GHz. J. Appl. Geophys. 2010, 70, 226–236. [Google Scholar] [CrossRef]

- Ghazali, M.F.; Beck, S.B.M.; Shucksmith, J.D.; Boxall, J.B.; Staszewski, W.J. Comparative study of instantaneous frequency based methods for leak detection in pipeline networks. Mech. Syst. Signal Proc. 2012, 29, 187–200. [Google Scholar] [CrossRef]

- Cataldo, A.; Persico, R.; Leucci, G.; De Benedetto, E.; Cannazza, G.; Matera, L.; De Giorgi, L. Time domain reflectometry, ground penetrating radar and electrical resistivity tomography: A comparative analysis of alternative approaches for leak detection in underground pipes. NDT&E Int. 2014, 62, 14–28. [Google Scholar]

- Martini, A.; Troncossi, M.; Rivola, A.; Nascetti, D. Preliminary investigations on automatic detection of leaks in water distribution networks by means of vibration monitoring. In Advances in Condition Monitoring of Machinery in Non-Stationary Operations (Lecture Notes in Mechanical Engineering); Springer: Heidelberg, Germany, 2014; Volume 5, pp. 535–544. [Google Scholar]

- Martini, A.; Troncossi, M.; Rivola, A. Automatic Leak Detection in Buried Plastic Pipes of Water Supply Networks by Means of Vibration Measurements. Shock Vib. 2015, 2015. [Google Scholar] [CrossRef]

- Yazdekhasti, S.; Piratla, K.R.; Atamturktur, S.; Khan, A. Novel vibration-based technique for detection of water pipeline leakage. Struct. Infrastruct. Eng. 2016, in press. [Google Scholar] [CrossRef]

- Miller, R.K.; Pollock, A.A.; Watts, D.J.; Carlyle, J.M.; Tafuri, A.N.; Yezzi, J.J., Jr. A reference standard for the development of acoustic emission pipeline leak detection techniques. NDT&E Int. 1999, 32, 1–8. [Google Scholar]

- ASTM E1316-16a. Standard Terminology for Nondestructive Examinations; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Vahaviolos, S.J.; Miller, R.K.; Watts, D.J.; Shemyakin, V.V.; Strizkov, S.A. Detection and Location of Cracks and Leaks in Buried Pipelines Using Acoustic Emission. J. Acoust. Emiss. 2001, 19, 172–183. [Google Scholar]

- Suzuki, T.; Ikeda, Y.; Tomoda, Y.; Ohtsu, M. Water-Leak Evaluation of Existing Pipeline by Acoustic Emission. J. Acoust. Emiss. 2005, 23, 272–276. [Google Scholar]

- Anastasopoulos, A.; Kourousis, D.; Bollas, K. Acoustic Emission leak detection of liquid filled buried pipeline. J. Acoust. Emiss. 2009, 27, 27–39. [Google Scholar]

- Ahadi, M.; Bakhtiar, M.S. Leak detection in water-filled plastic pipes through the application of tuned wavelet transforms to Acoustic Emission signals. Appl. Acoust. 2010, 71, 634–639. [Google Scholar] [CrossRef]

- Brunner, A.J.; Barbezat, M. Acoustic Emission Monitoring of Leaks in Pipes for Transport of Liquid and Gaseous Media: A Model Experiment. Adv. Mater. Res. 2006, 13–14, 351–356. [Google Scholar] [CrossRef]

- Leoni, G.; Anzalone, C.; Giunchi, D.; Nascetti, D. Method for Detecting the Presence of Leaks in a Water Distribution Network and Kit for Applying the Method. Patent EP2107357A1, 7 October 2009. [Google Scholar]

- MISTRAS Group Inc.—Products & Systems Division. USB-AE Node & AEwin for USB Software User’s Manual; MISTRAS Group Inc.: Princeton Junction, NJ, USA, 2010. [Google Scholar]

| Leak (Buried Pipe) | Distance (m) | Flow Rate (L/h) |

|---|---|---|

| # 1b | 3 | 200 |

| # 2b | 8 | 295 |

| # 3b | 13 | 200 |

| # 4b | 18 | 180 |

| # 5b | 26 | 4000 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martini, A.; Troncossi, M.; Rivola, A. Leak Detection in Water-Filled Small-Diameter Polyethylene Pipes by Means of Acoustic Emission Measurements. Appl. Sci. 2017, 7, 2. https://doi.org/10.3390/app7010002

Martini A, Troncossi M, Rivola A. Leak Detection in Water-Filled Small-Diameter Polyethylene Pipes by Means of Acoustic Emission Measurements. Applied Sciences. 2017; 7(1):2. https://doi.org/10.3390/app7010002

Chicago/Turabian StyleMartini, Alberto, Marco Troncossi, and Alessandro Rivola. 2017. "Leak Detection in Water-Filled Small-Diameter Polyethylene Pipes by Means of Acoustic Emission Measurements" Applied Sciences 7, no. 1: 2. https://doi.org/10.3390/app7010002