Implementation of a Motor Diagnosis System for Rotor Failure Using Genetic Algorithm and Fuzzy Classification

Abstract

:1. Introduction

2. Problem Description

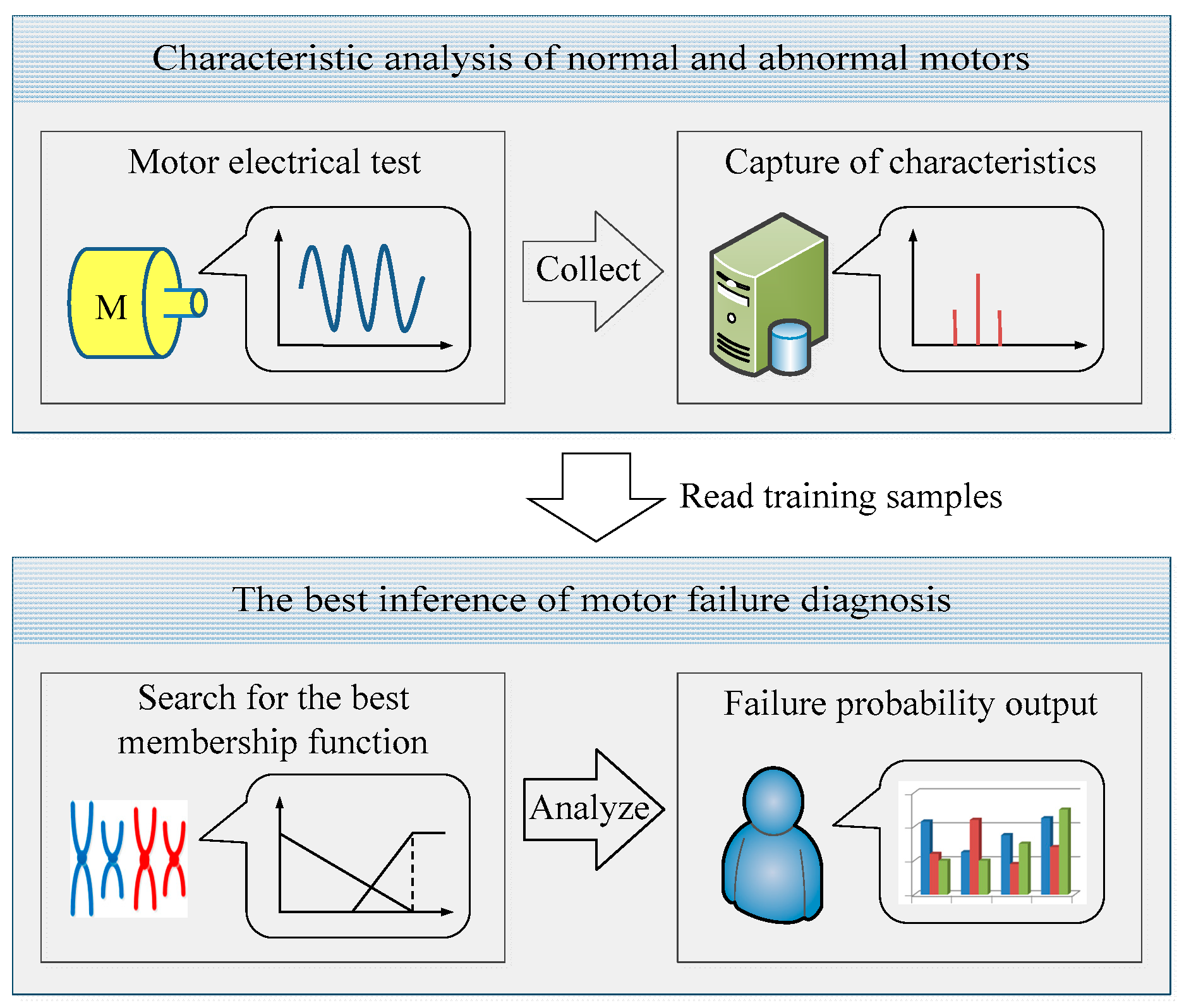

3. Technology Used for Diagnosis

3.1. Fast Fourier Transform

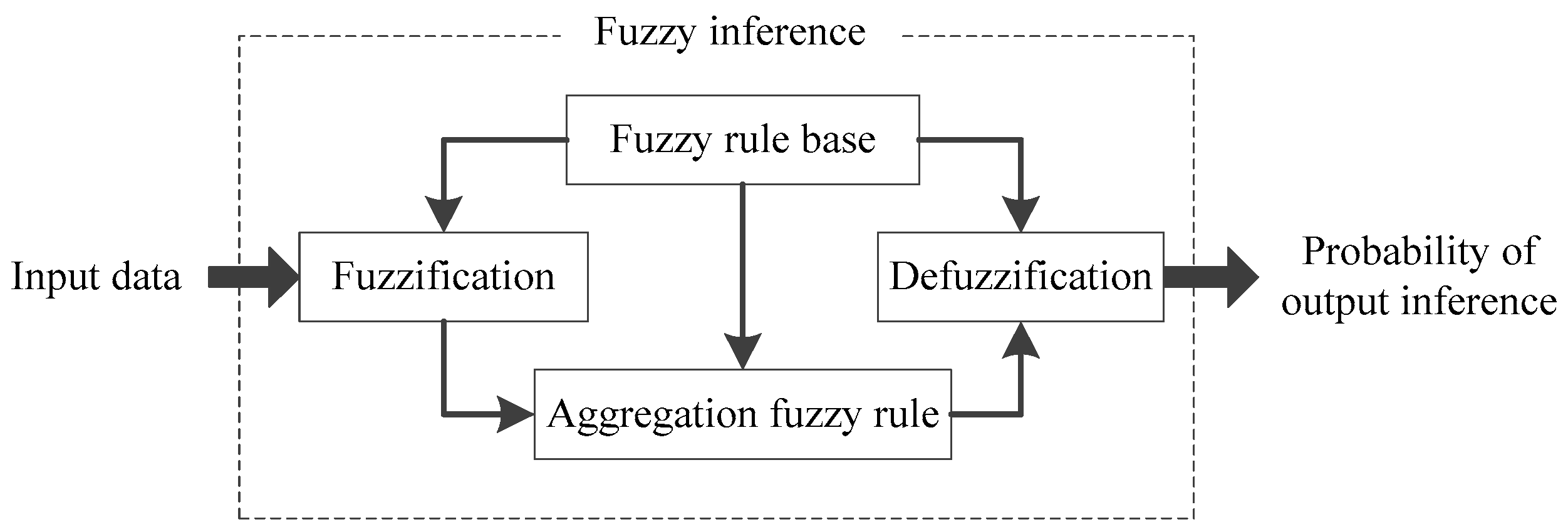

3.2. Fuzzy Theory

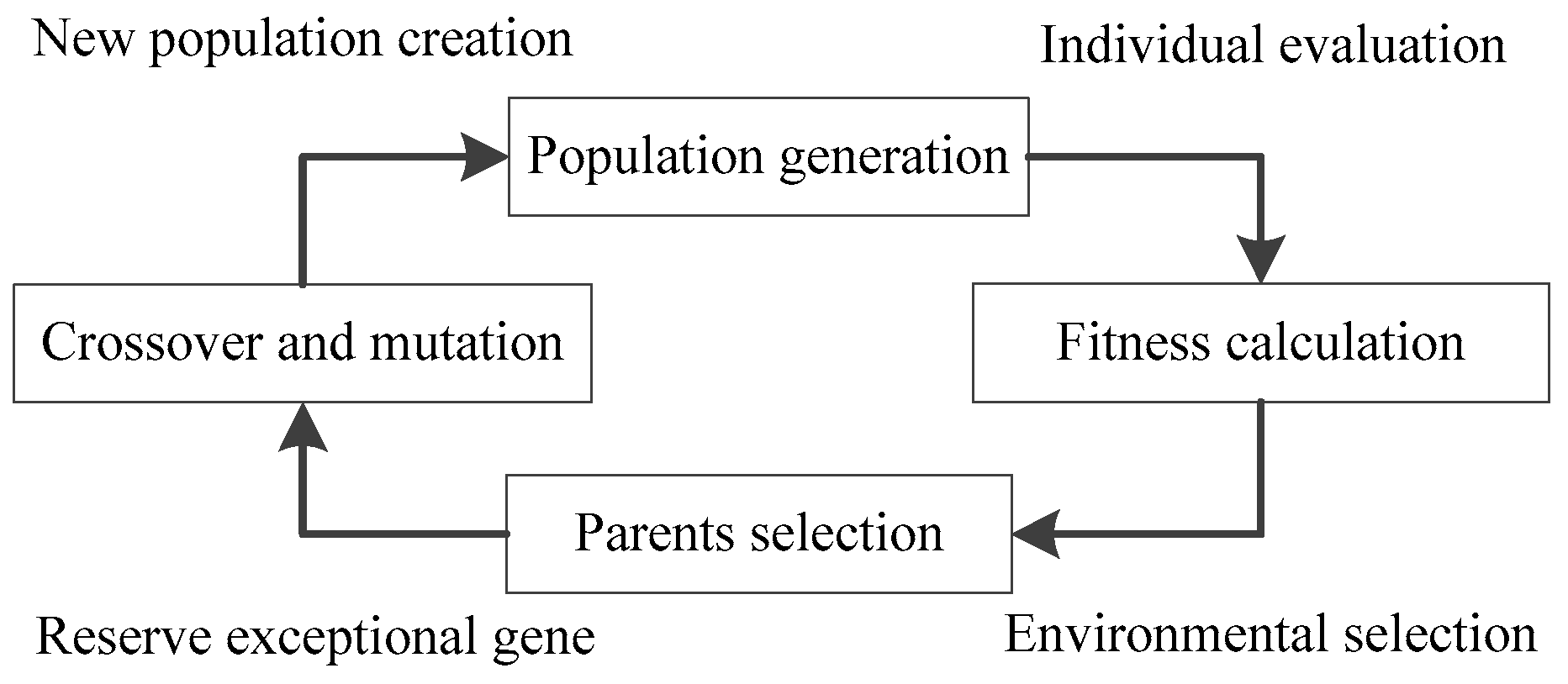

3.3. Genetic Algorithm

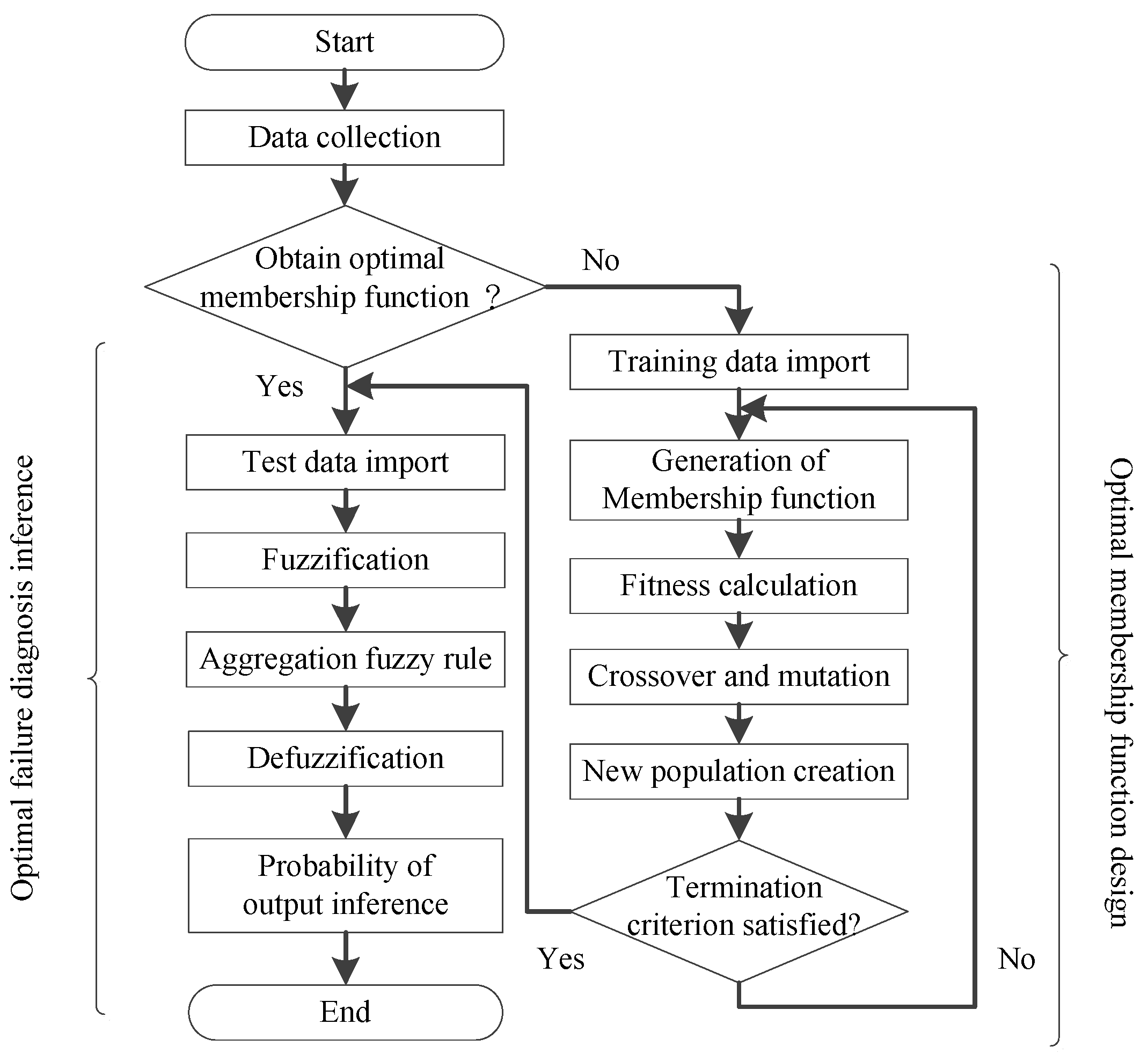

4. Optimal Design of Membership Function

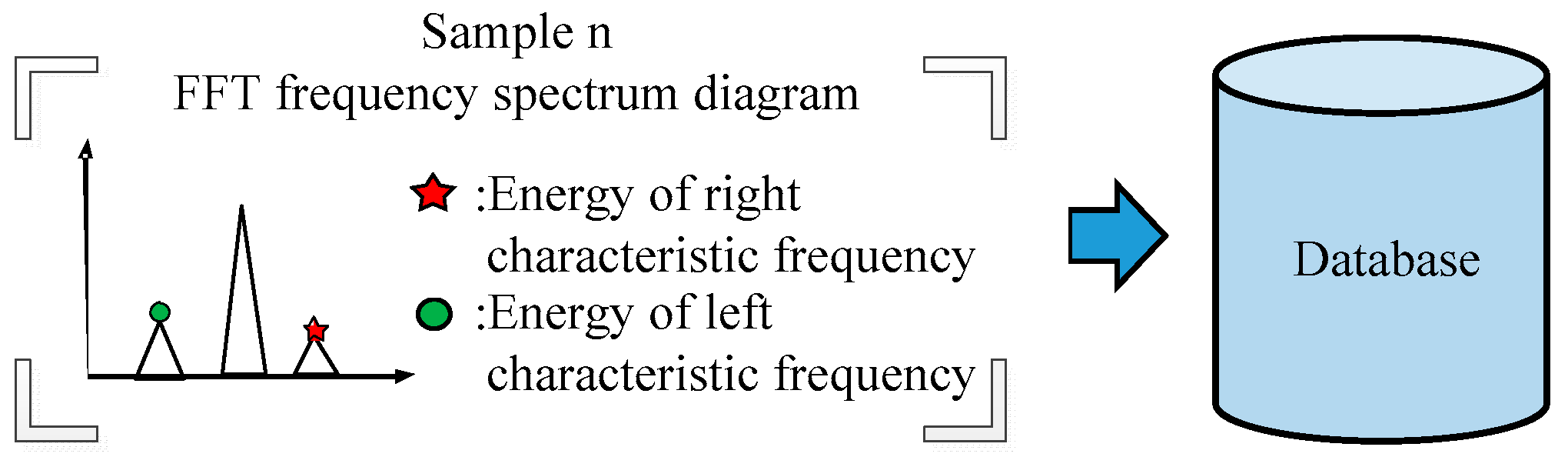

4.1. Data Collection

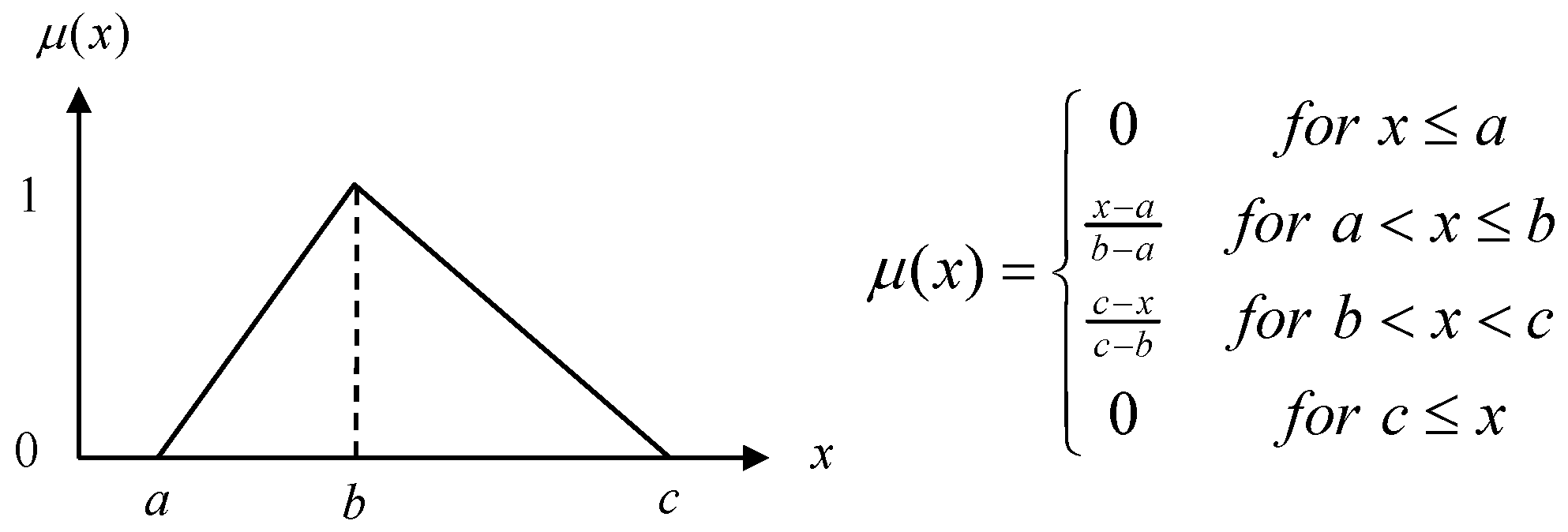

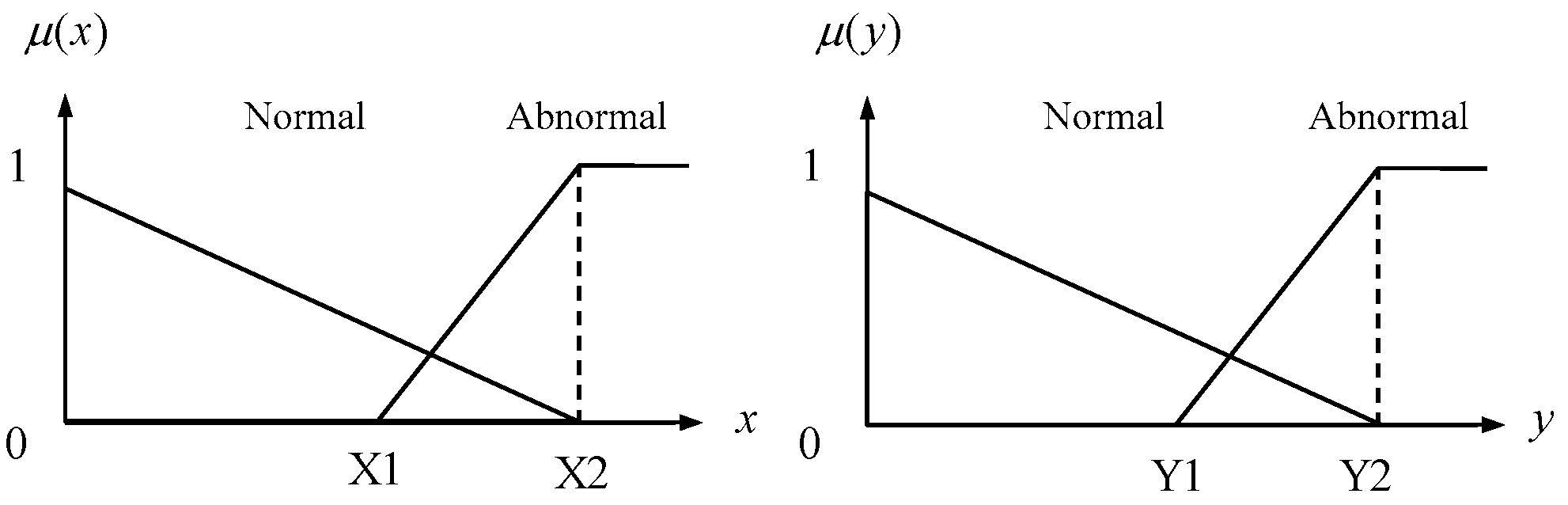

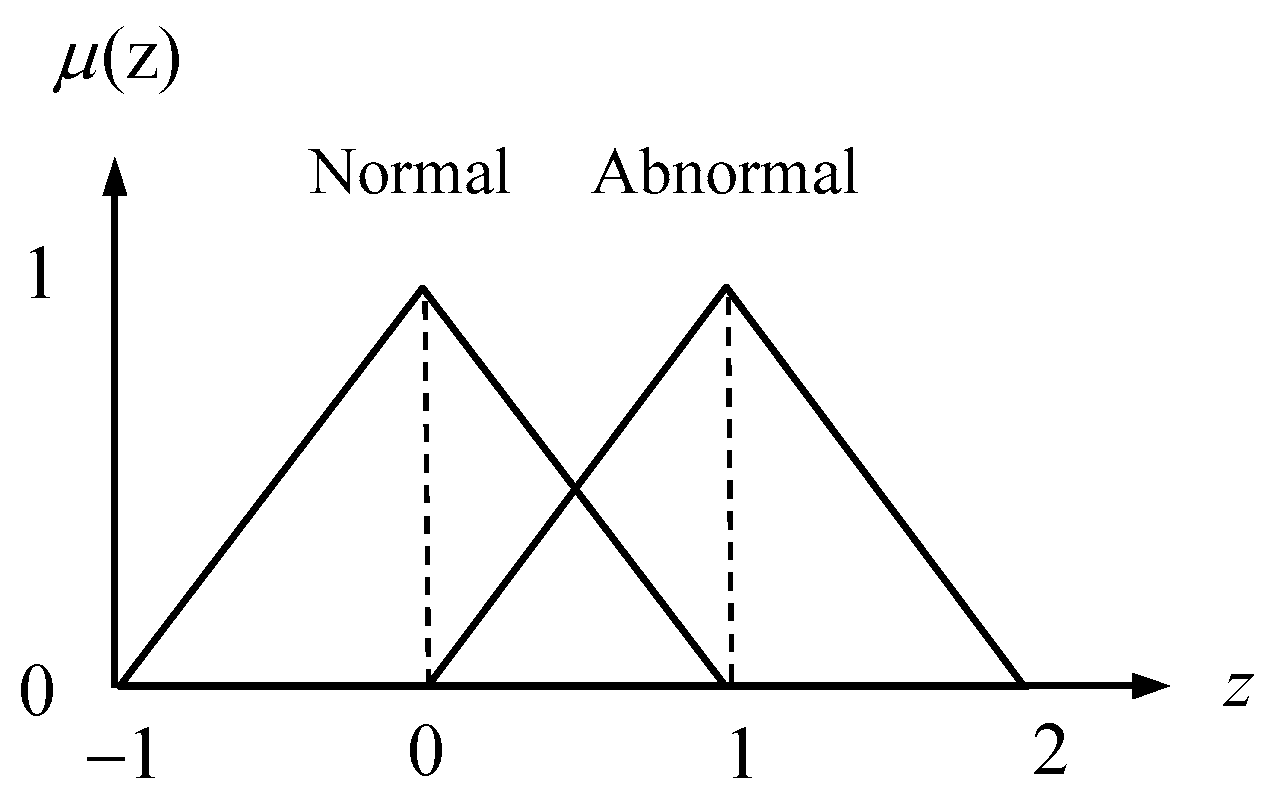

4.2. Generation of Membership Function

4.3. Fitness Evaluation

- (1)

- If the left characteristic frequency energy is “Normal”, then the state of the rotor is “Normal”.

- (2)

- If the left characteristic frequency energy is “Abnormal”, then the state of the rotor is “Abnormal”.

- (3)

- If the right characteristic frequency energy is “Normal”, then the state of the rotor is “Normal”.

- (4)

- If the right characteristic frequency energy is “Abnormal”, then the state of the rotor is “Abnormal”.

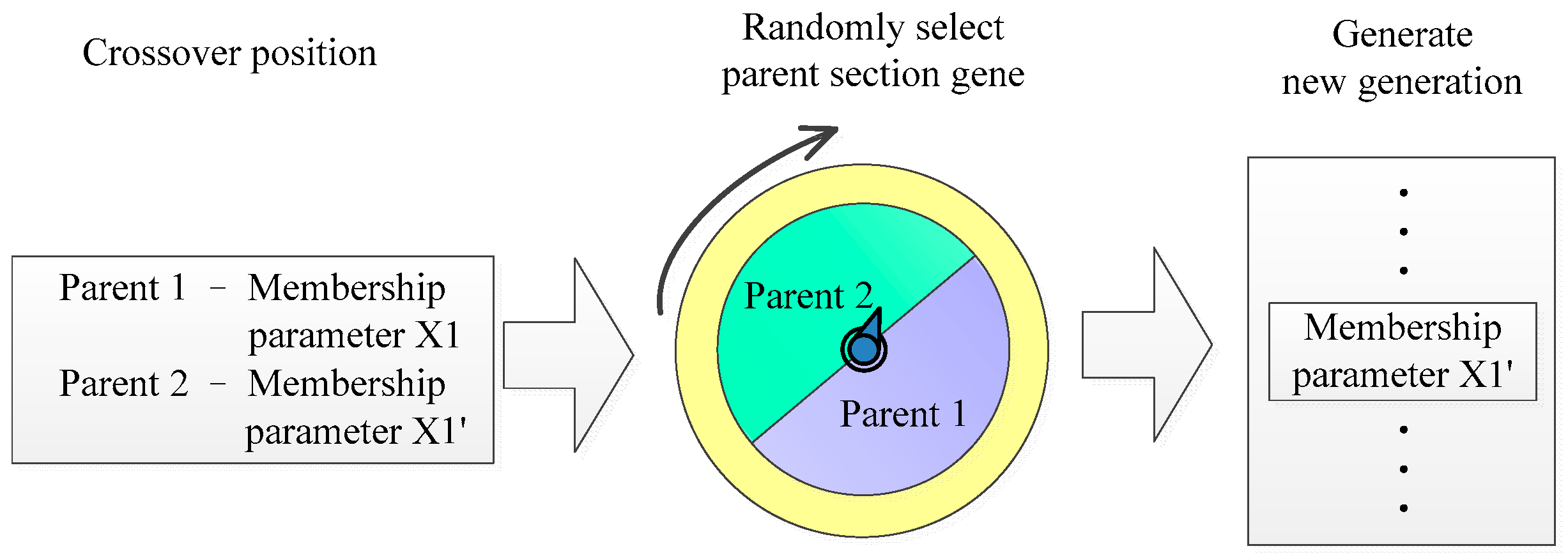

4.4. Crossover and Mutation

4.5. Termination and Conditions

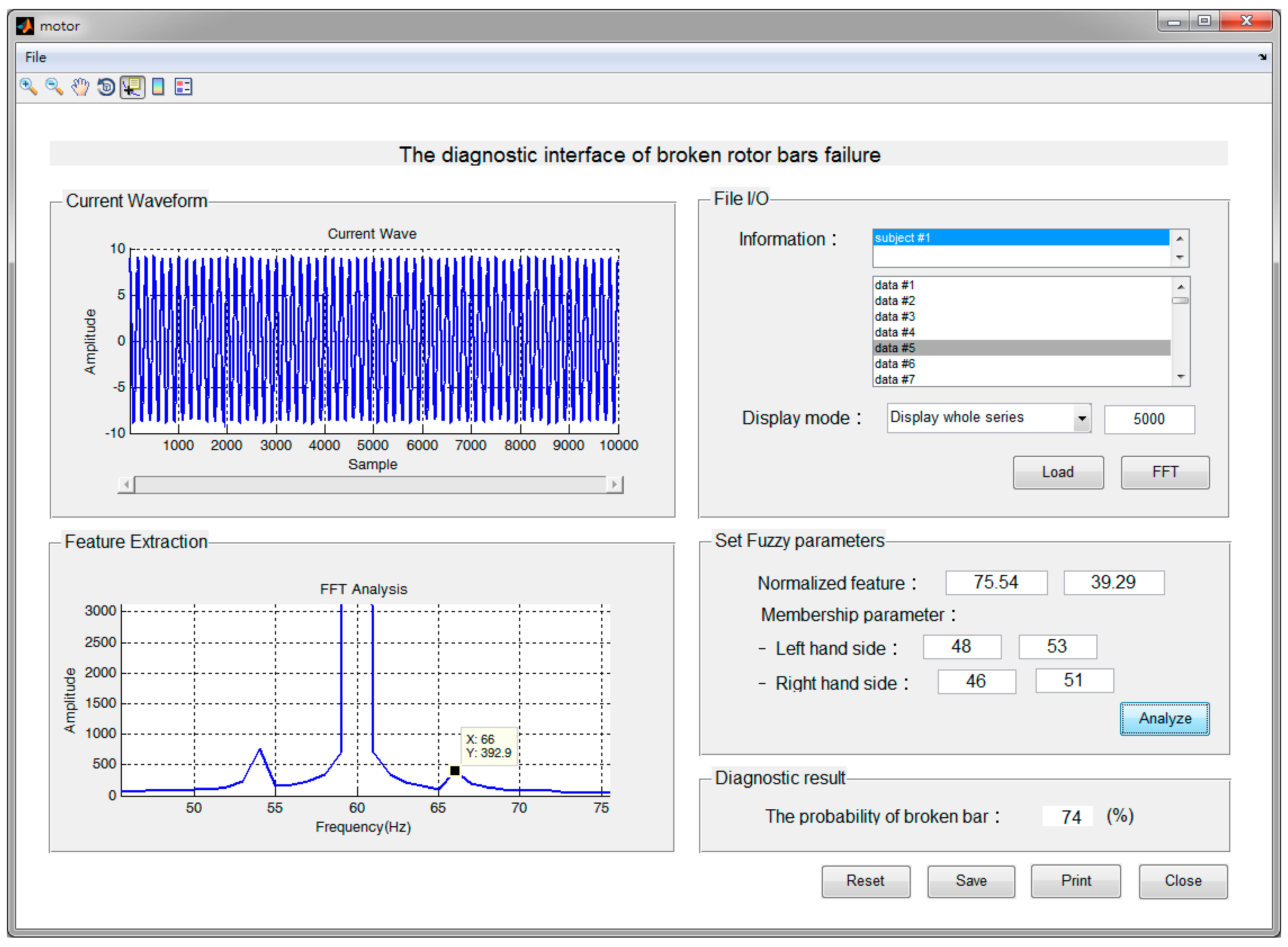

5. Test Case

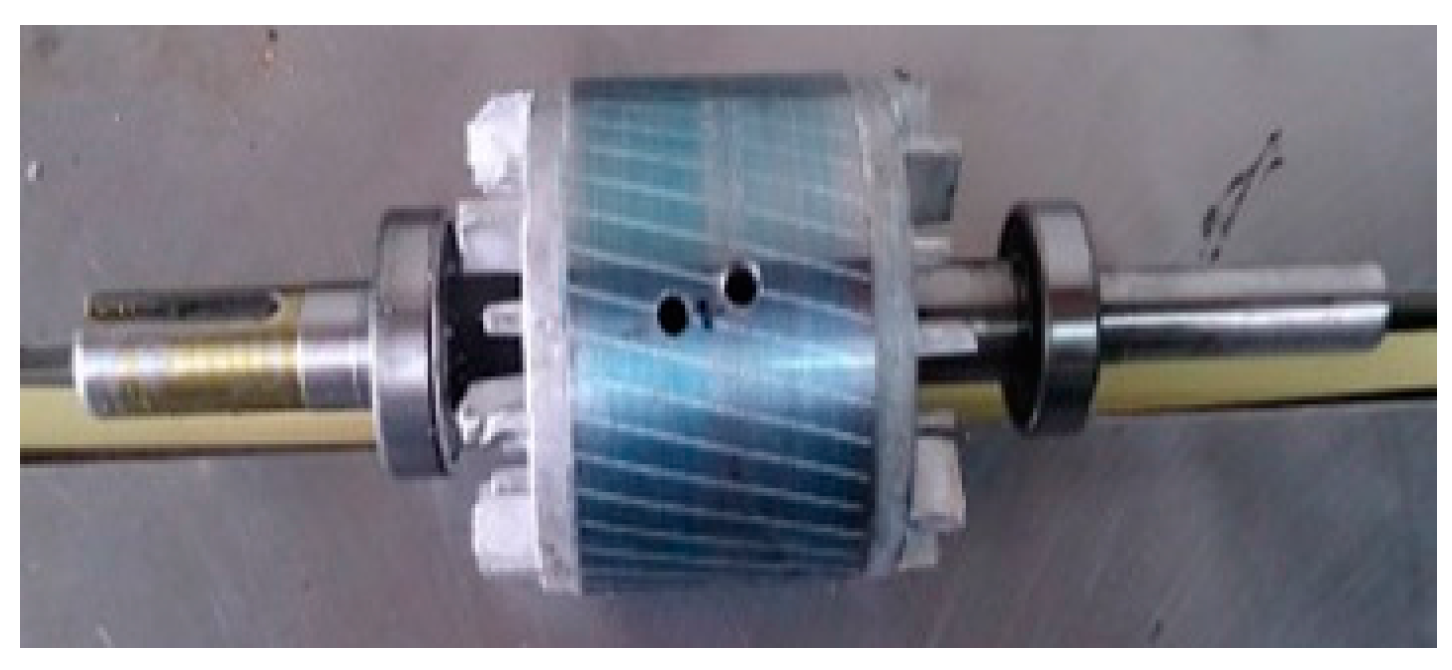

5.1. Experiment Model

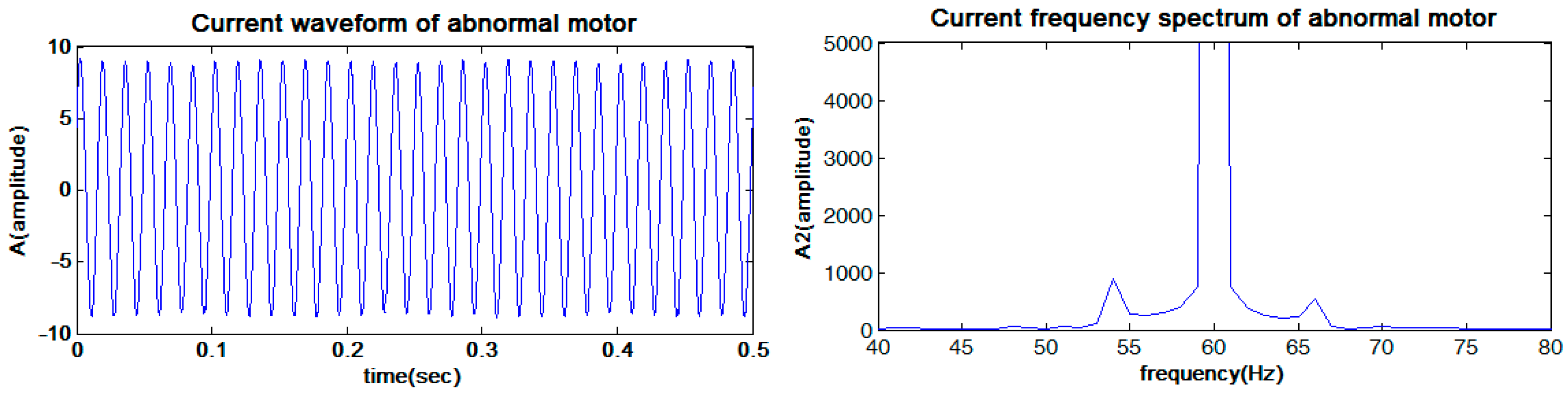

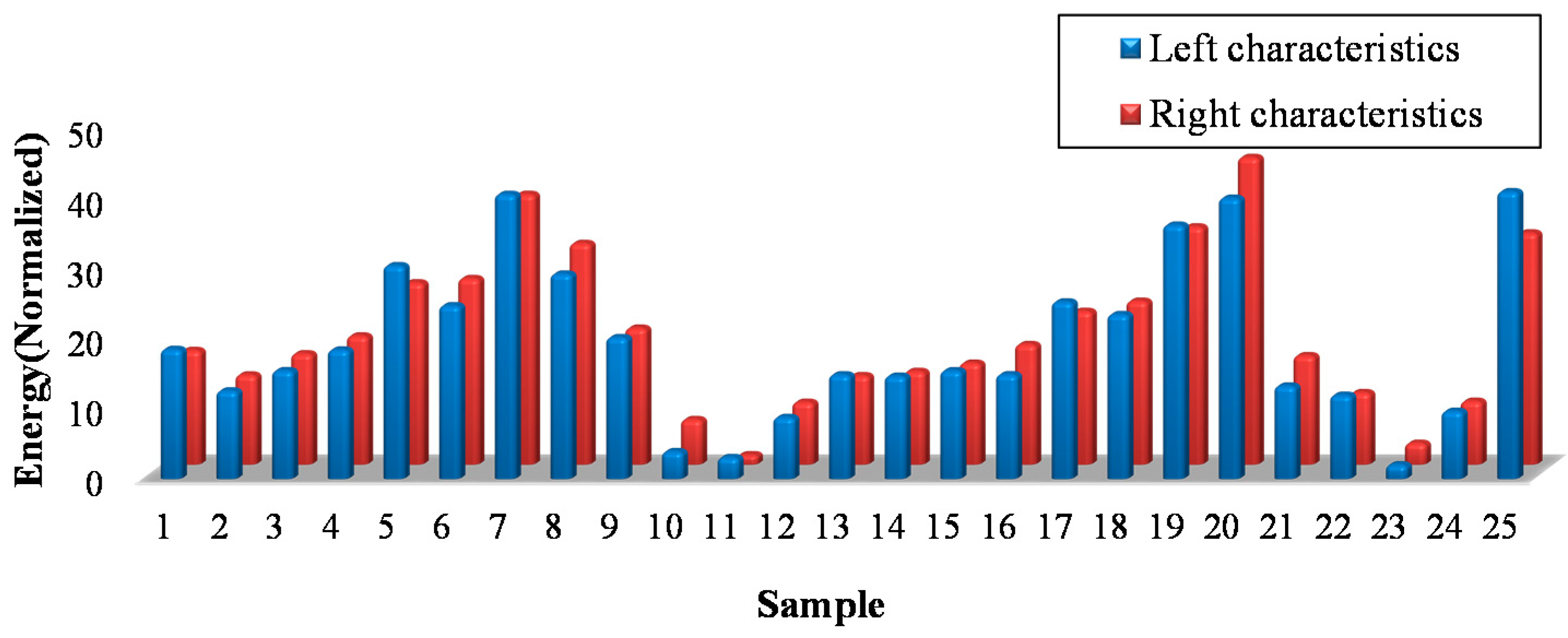

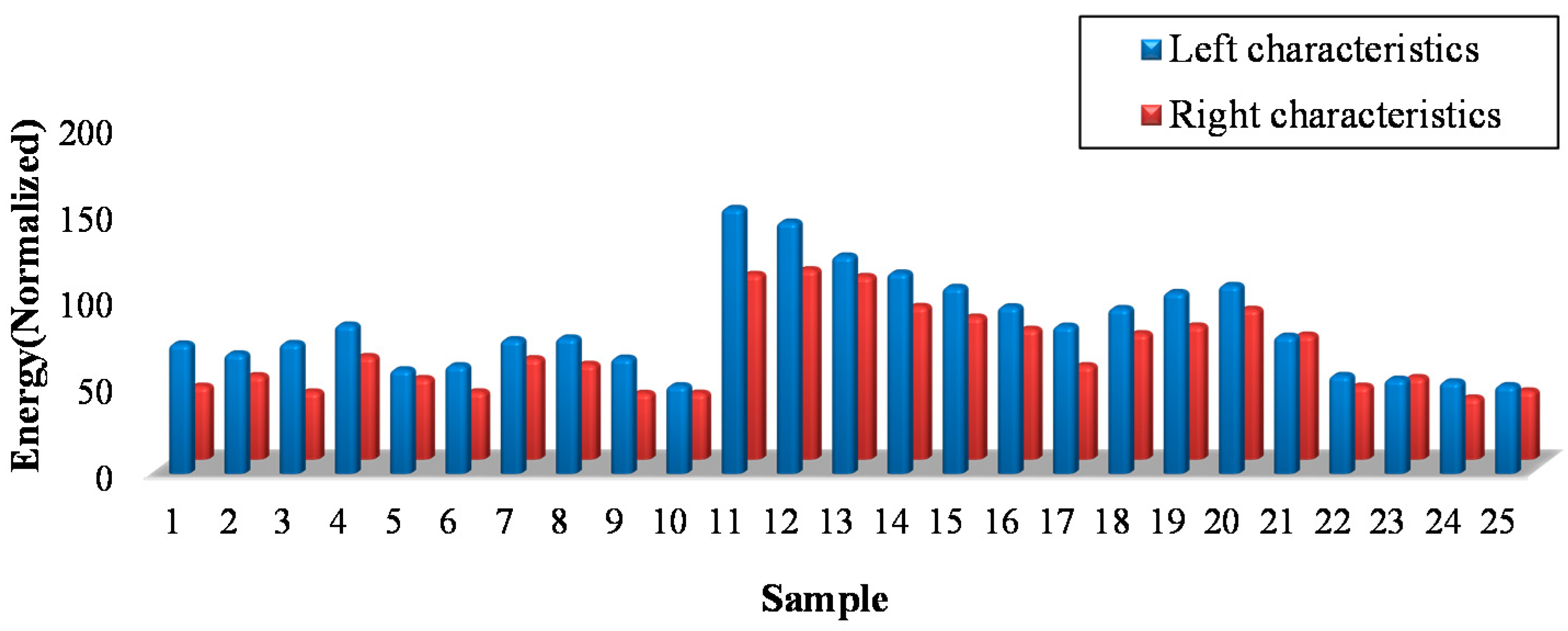

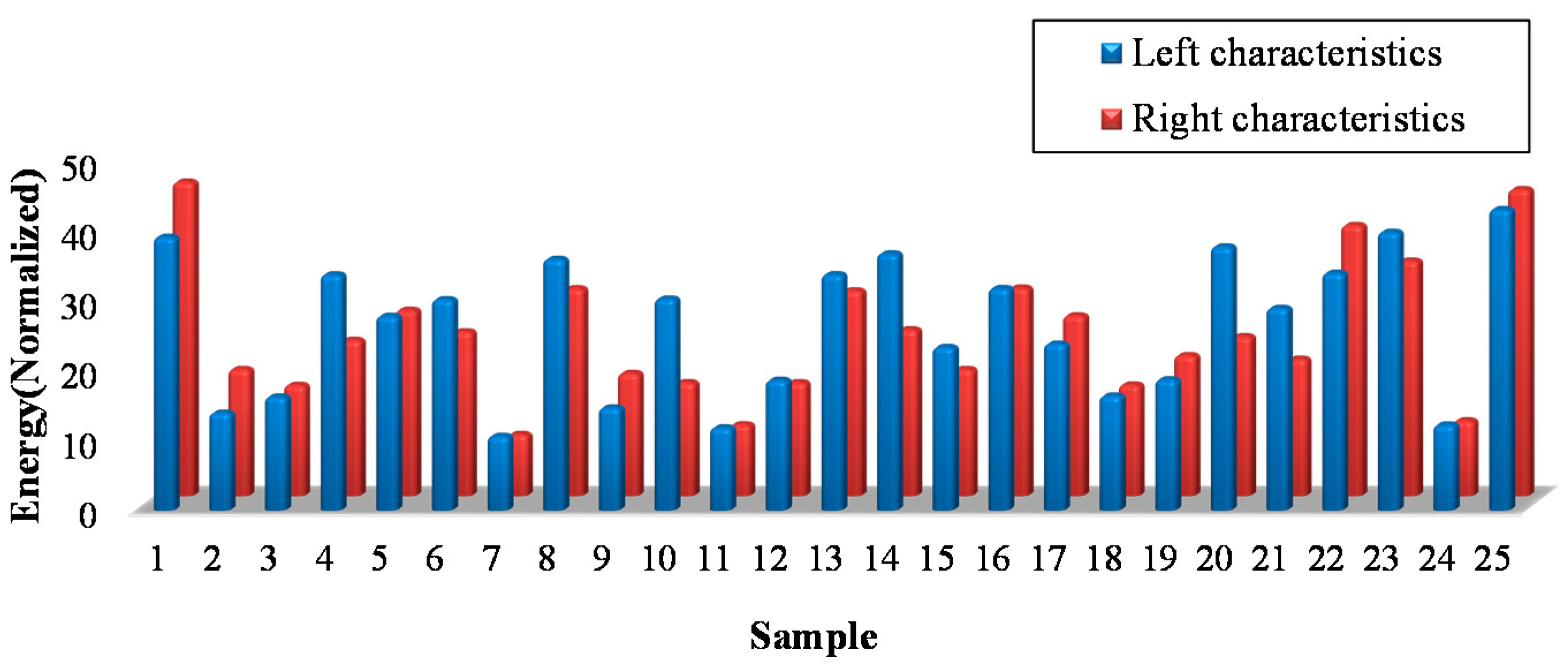

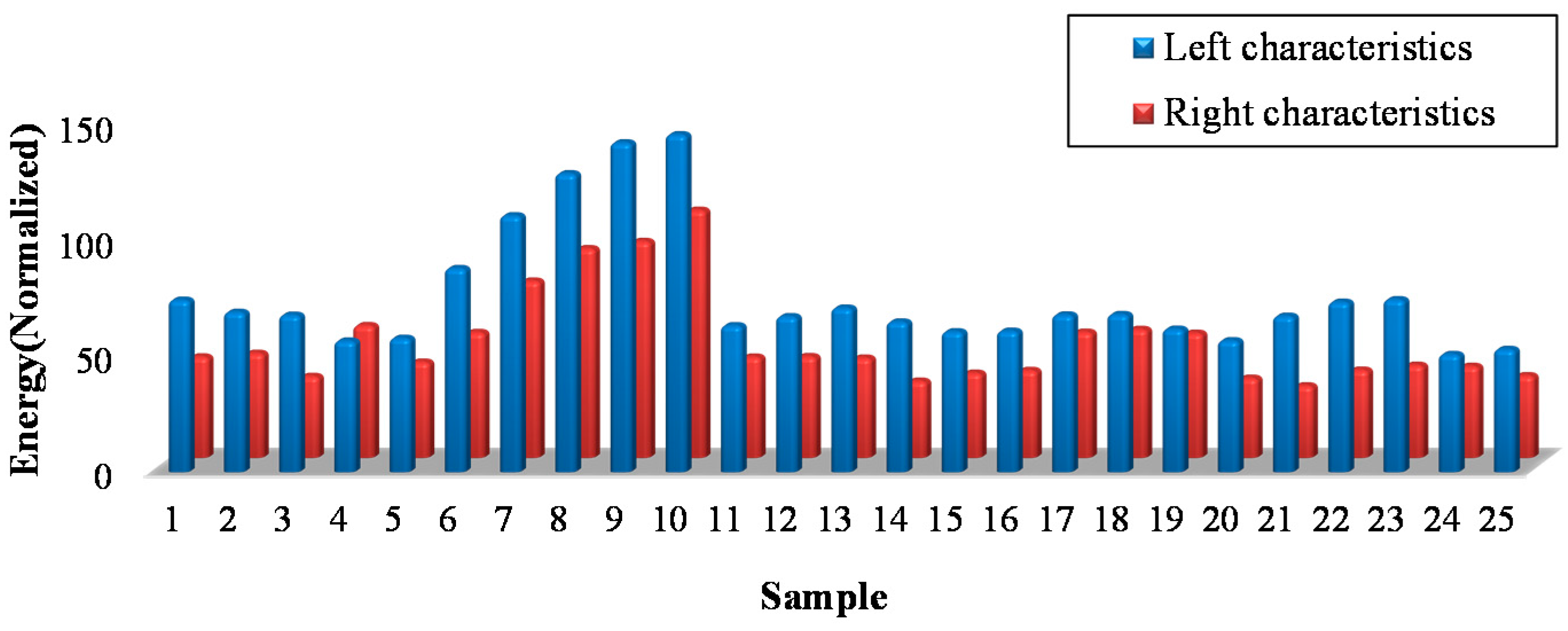

5.2. Establishment of Database

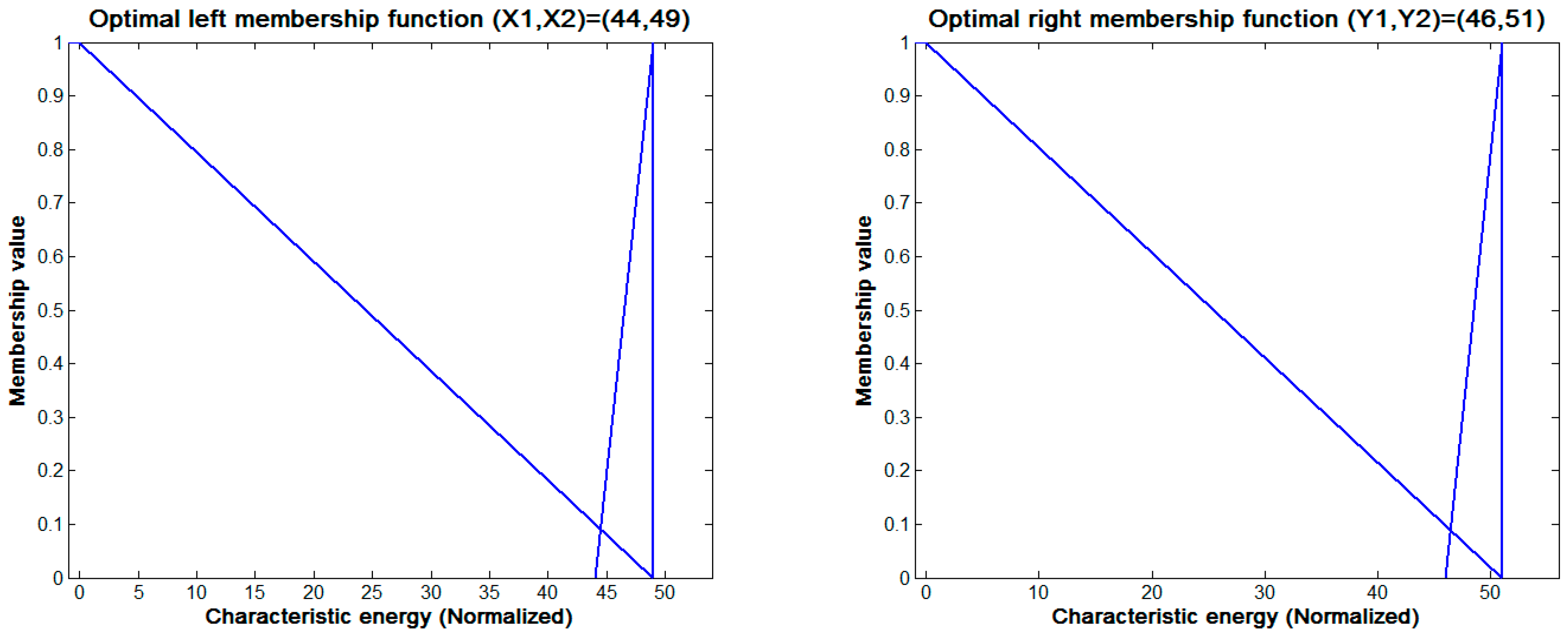

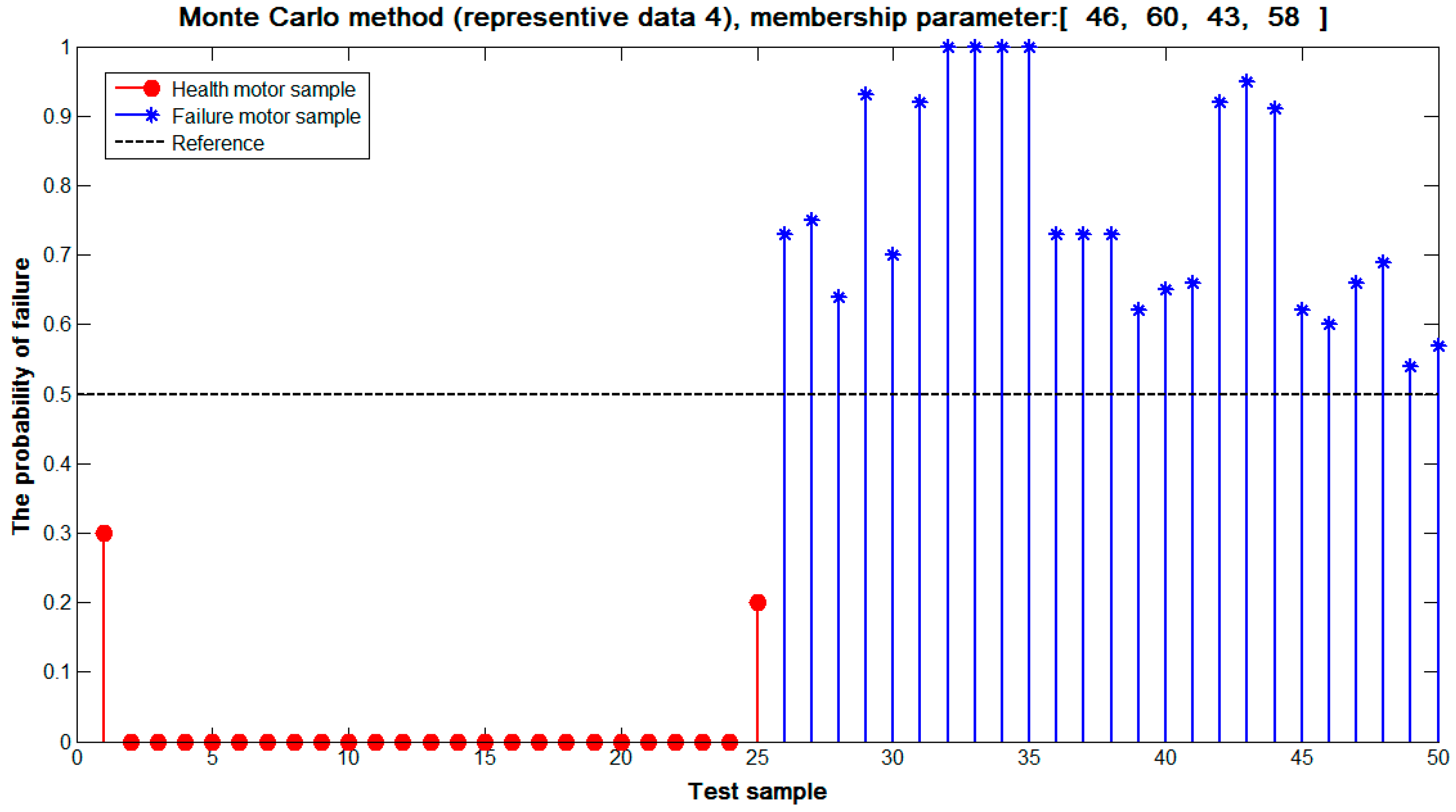

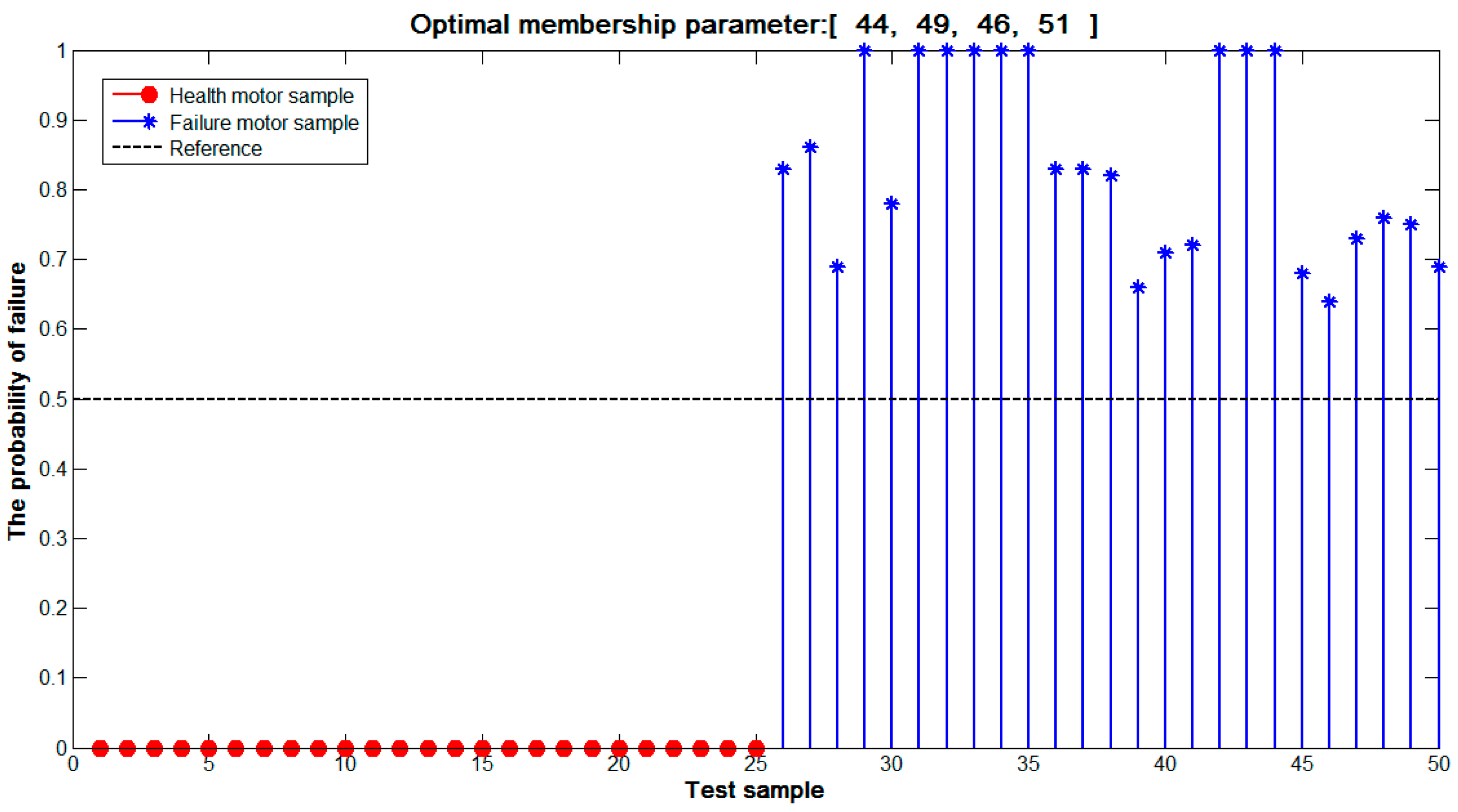

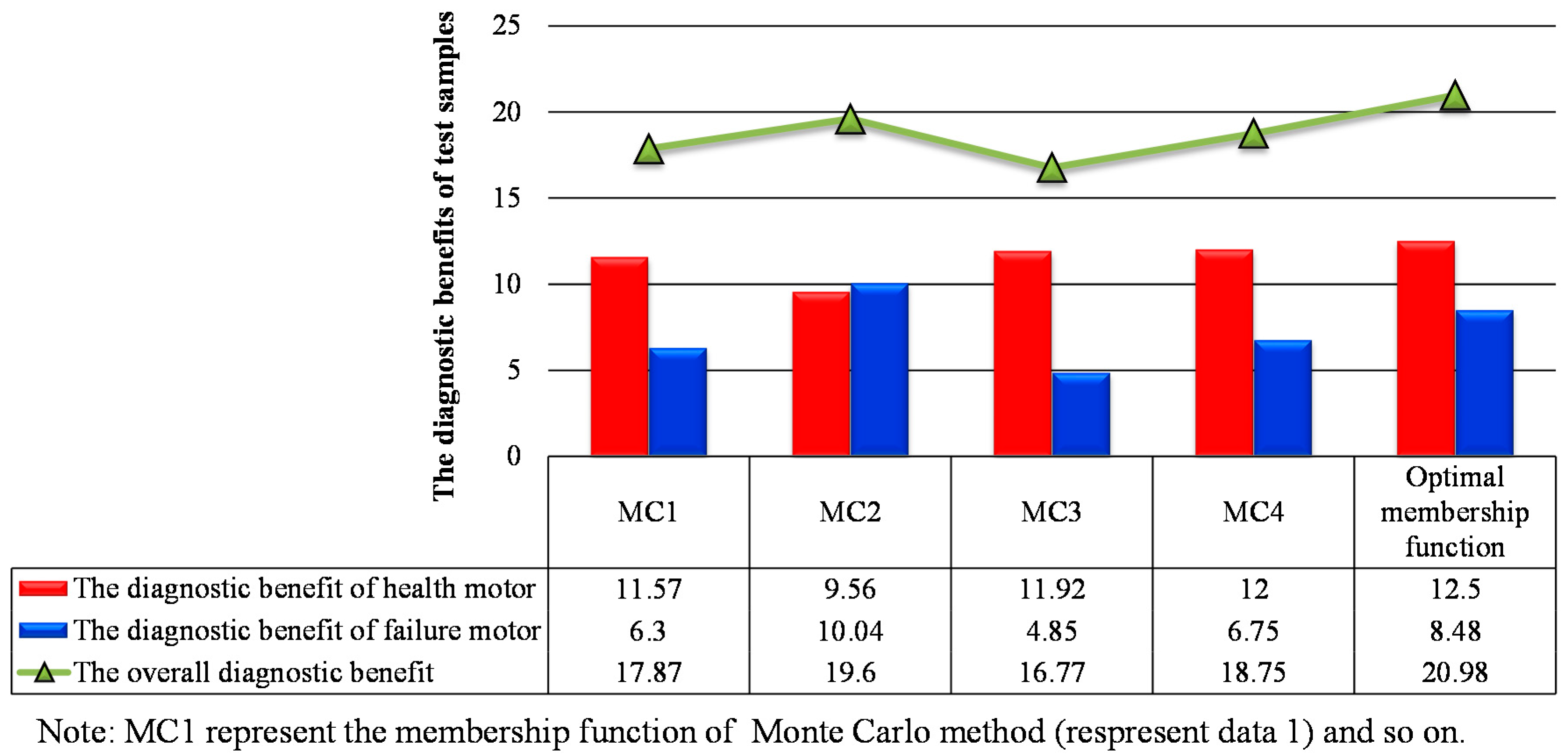

5.3. Optimization of Membership Function

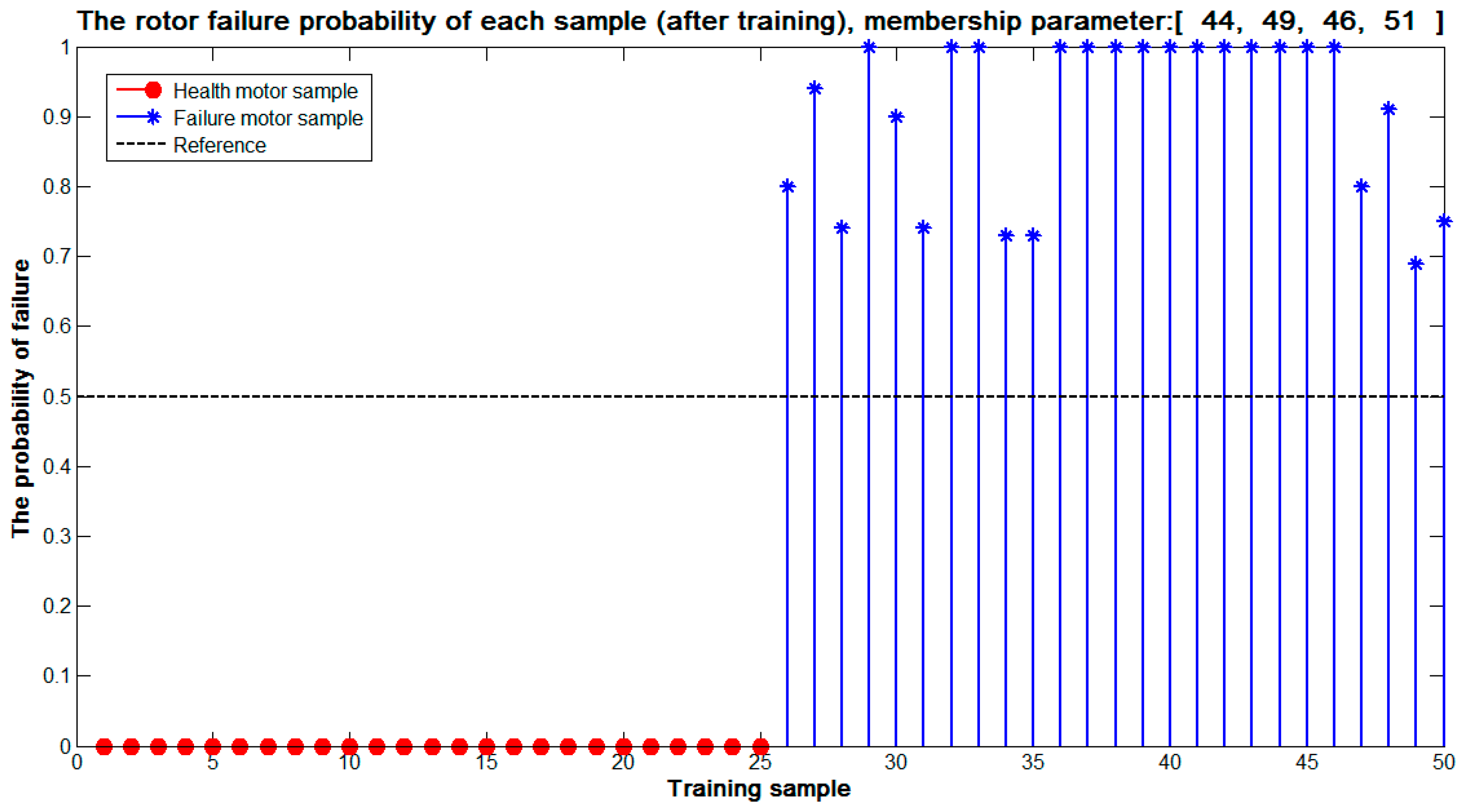

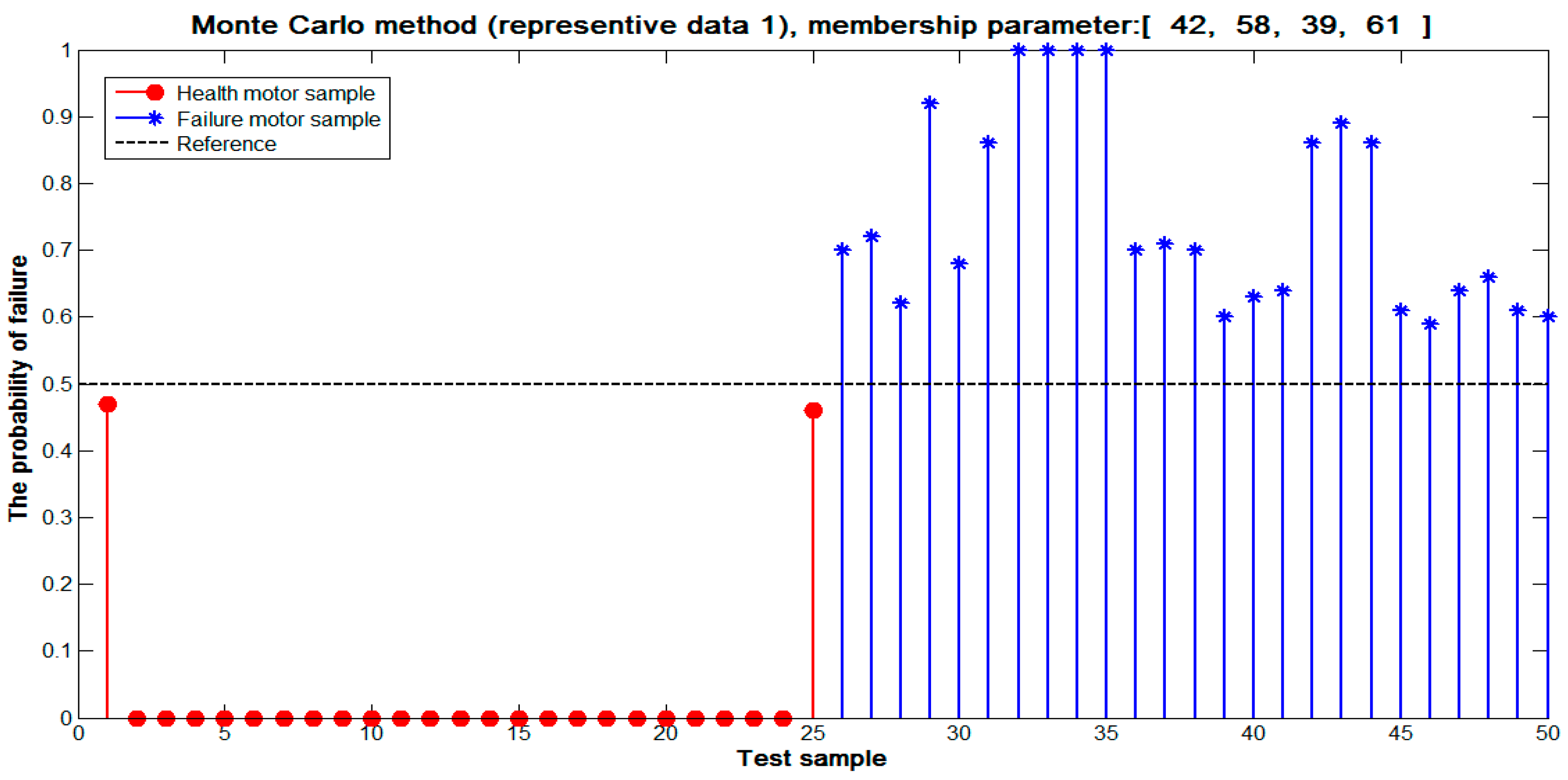

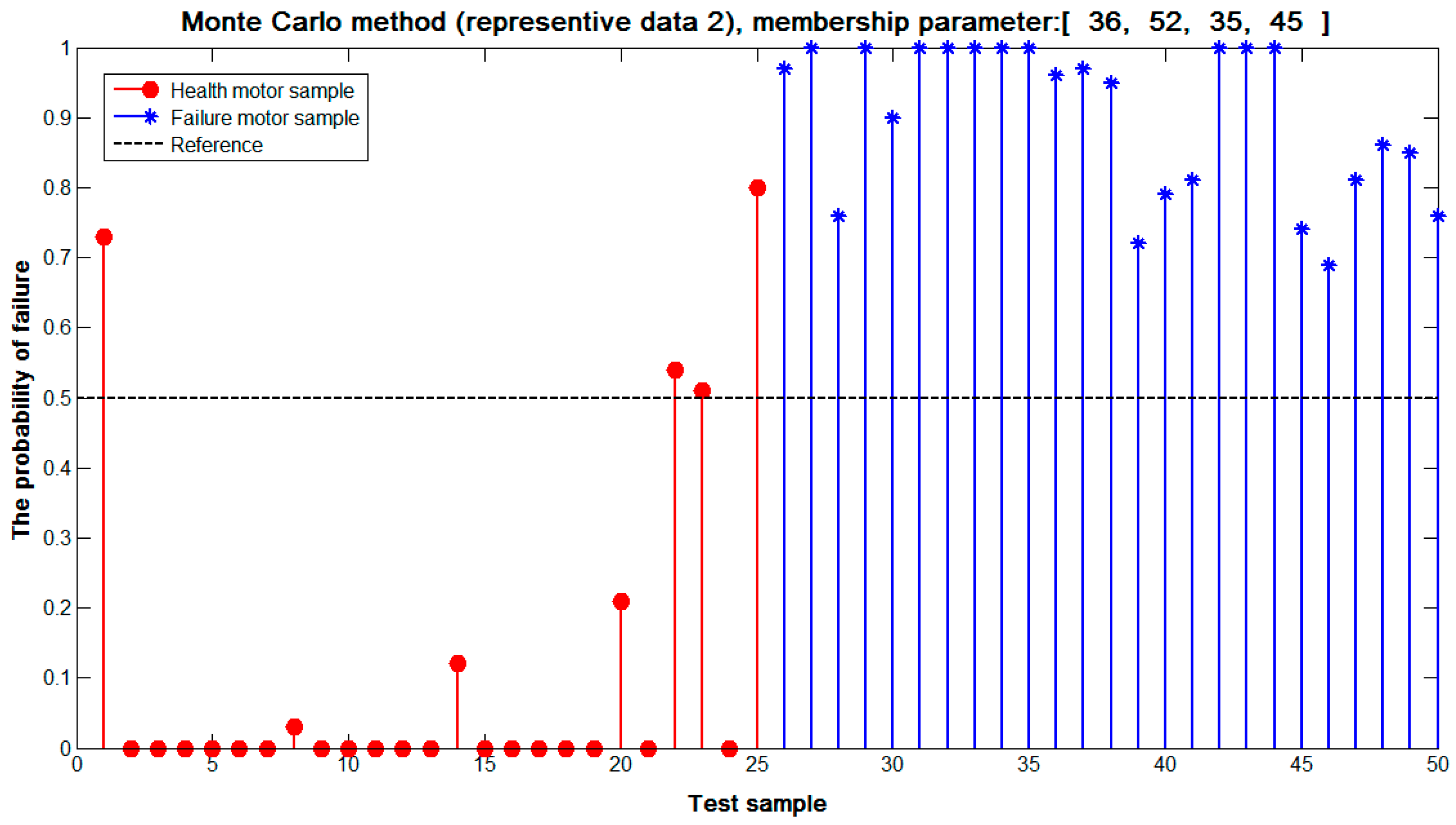

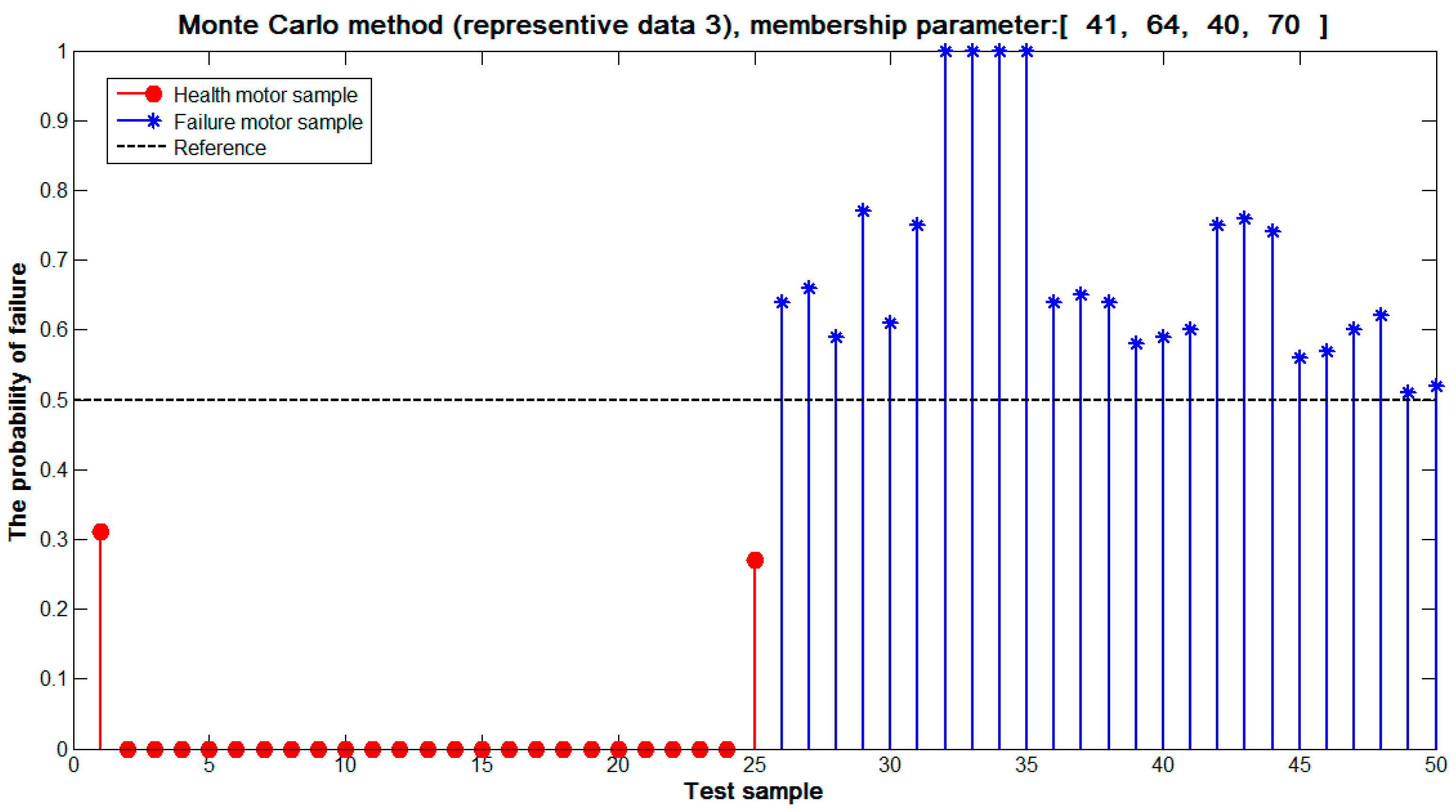

5.4. Rotor Failure Diagnosis Test

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Thomson, W.T.; Fenger, M. Current signature analysis to detect induction motor failures. IEEE Ind. Appl. Mag. 2001, 7, 26–34. [Google Scholar] [CrossRef]

- Jiang, L.; Fu, X.; Cui, J.; Li, Z. Rolling elemt bearing failure diagnosis using recursive wavelet and SOM neural network. In Proceedings of the Chinese Control and Decision Conference, Guiyang, China, 25–27 May 2013; pp. 4691–4696.

- Zidani, F.; Benbouzid, M.E.H.; Diallo, D.; Nait-Said, M.S. Induction motor stator failures diagnosis by a current Concordia pattern-based fuzzy decision system. IEEE Trans. Energy Convers. 2003, 18, 469–475. [Google Scholar] [CrossRef]

- Gao, X.Z.; Ovaska, S.J. Genetic Algorithm Training of Elman Neural Network in Motor Fault Detection. Neural Comput. Appl. 2002, 11, 37–44. [Google Scholar] [CrossRef]

- Goode, P.V.; Chow, M.Y. Using a neural/fuzzy system to extract heuristic knowledge of incipient failures in induction motors: Part II-Application. IEEE Trans. Ind. Electron. 1995, 42, 139–146. [Google Scholar] [CrossRef]

- Ghate, V.N.; Dudul, S.V. Cascade neural-network-based failure classifier for three-phase induction motor. IEEE Trans. Ind. Electron. 2011, 58, 1555–1563. [Google Scholar] [CrossRef]

- Gongora, W.S.; Silva, H.V.D.; Goedtel, A.; Godoy, W.F.; da Silva, S.A.O. Neural Approach for Bearing Failure Detection in three phase induction motors. In Proceedings of the 2013 9th IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives (SDEMPED), Valencia, Spain, 27–30 August 2013; pp. 566–572.

- Rauber, T.W.; de Assis Boldt, F. Heterogeneous feature models and feature selection applied to bearing failure diagnosis. IEEE Trans. Ind. Electron. 2015, 62, 637–646. [Google Scholar] [CrossRef]

- Antonino-Daviu, J.; Riera-Guasp, M.; Roger-Folch, J.; Martinez-Jimenez, F.; Peris, A. Application and optimization of the discrete wavelet transform for the detection of broken rotor bars in induction machines. Appl. Comput. Harmon. Anal. 2006, 21, 268–279. [Google Scholar] [CrossRef]

- Hernandez, J.; Antonino-Daviu, J.; Martinez-Jimenez, F.; Peris, A. Comparison of different wavelet families for broken bar detection in induction motors. In Proceedings of the 2015 IEEE International Conference on Industrial Technology (ICIT), Seville, Spain, 17–19 March 2015; pp. 3220–3225.

| Name of Specification | Data of Specification | Name of Specification | Data of Specification |

|---|---|---|---|

| Number of Poles | 4 Poles | Number of Stator Slot | 36 |

| Number of Phase | 3 Phase | Number of Rotor Slot | 44 |

| Rated Line Voltage | 220 V | Shaft diameter | 25 mm |

| Rated Current | 6.1 A | Outer diameter of Stator | 96 mm |

| Rated Speed | 1715 rpm | Inner diameter of Stator | 62 mm |

| Rated Output | 2 HP | Rotor Form | Single Squirrel-cage Type |

| Frequency | 60 Hz | Shape of Rotor Slot | Half-open Slot |

| Resampling | i = 1 | i = 2 | i = 3 | i = 4 | i = 5 | i = 6 | i = 7 | i = 8 | i = 9 | i = 10 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Record (the avg. of 10 times) | |||||||||||

| Optimal fitness value | 0.71 | 0.69 | 0.66 | 0.73 | 0.71 | 0.68 | 0.72 | 0.72 | 0.74 | 0.74 | |

| The benefit of health motor | 12.30 | 11.94 | 10.89 | 12.57 | 11.51 | 12.27 | 11.87 | 12.58 | 11.92 | 12.5 | |

| The benefit of failure motor | 8.52 | 7.82 | 8.34 | 8.69 | 8.86 | 7.05 | 6.92 | 8.69 | 7.88 | 8.48 | |

| The overall benefit | 20.82 | 19.76 | 19.23 | 21.26 | 20.37 | 19.32 | 18.79 | 21.27 | 19.80 | 20.98 | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuo, C.-C.; Liu, C.-H.; Chang, H.-C.; Lin, K.-J. Implementation of a Motor Diagnosis System for Rotor Failure Using Genetic Algorithm and Fuzzy Classification. Appl. Sci. 2017, 7, 31. https://doi.org/10.3390/app7010031

Kuo C-C, Liu C-H, Chang H-C, Lin K-J. Implementation of a Motor Diagnosis System for Rotor Failure Using Genetic Algorithm and Fuzzy Classification. Applied Sciences. 2017; 7(1):31. https://doi.org/10.3390/app7010031

Chicago/Turabian StyleKuo, Cheng-Chien, Chien-Hsun Liu, Hong-Chan Chang, and Kuan-Jung Lin. 2017. "Implementation of a Motor Diagnosis System for Rotor Failure Using Genetic Algorithm and Fuzzy Classification" Applied Sciences 7, no. 1: 31. https://doi.org/10.3390/app7010031