1. Introduction

Determining the compressive strengths at different curing ages of ordinary concrete in situ is of primary importance for ensuring safety in construction. The compressive strength estimated on the 28th day has been widely used as a vital indication of the strength development of cementitious materials in industry [

1]. Over the past few decades, nondestructive detecting and monitoring techniques have become popular in structure health monitoring (SHM) and evaluations as they offer many advantages over the conventional destructive techniques. As the microstructures of cement-based materials (CBMs), like pores and hydration compounds, govern their macroscale mechanical behavior, great efforts and various techniques have been employed to study and evaluate the process and the mechanism of microstructure during hydration in order to establish the strength prediction. Conventional thermal-based monitoring of heat generation leading to temperature increases during the hydration process was used in bridge and dam construction [

2], whereas the compressive strength of CBMs in relation to the reflection loss of ultrasonic waves was investigated in [

3]. An ultrasound technique was used to evaluate the compressive strength of CBM with added mineral admixtures, where compressive strength and ultrasonic pulse velocity were measured and correlated for days 3, 7, 28 and 120 of the curing period [

4]. The relationship between pulse velocity and compressive strength was, hence, found to fall within the trend of exponential functions. A novel technique that made use of a fuzzy logic system to correlate the early-age CBM strength with harmonic amplitudes using smart aggregate was presented in [

5]. Crack detection, hydration monitoring and energy harvesting using similar embedded piezoelectric transducers were reported in [

6,

7,

8]. Recently, good correlation between acoustic emission energy at low frequency (25–100 kHz) and plastic strain energy of reinforced concrete specimens was established in [

9,

10]. An active acoustic method at a lower frequency of around 6 kHz was also employed [

11] to monitor setting and hardening in concrete at early ages, wherein the P-wave velocity and attenuation coefficient were used to characterize the development of calcium silicate hydrate (C-S-H) gel inside the concrete and, hence, predict strength growth during early ages. However, the aforementioned detecting techniques require in situ embedded sensors to be set up and or non-real time signal post-processing. For example, they need wired sensor pair matches, sensor locations and alignments, and so on. All of these require prior precise arrangement and calibration, and therefore will be high-cost and time-consuming, as they were applied to large-scale CBM’s monitoring.

Conversely, simple, direct detection of intrinsic electrical properties, e.g., direct current (dc) resistivity, of CBM during hydration was proposed [

12,

13]. The four-probe (Wenner method) resistivity measurement used a simple setup, where no embedded sensors and alignment were required. However, the simple method suffers from accuracy problems due to the contact resistance between electrodes and CBM specimens being tested, as well as due to the possible shrinkage gap. To combat such problems, Li et al. introduced a non-contact measurement approach to monitor the hydration process of early-age concrete through electrical resistivity using alternative current (ac) transformer method [

14]. It was found that non-contact resistivity measurement was appropriate for precise monitoring of CBM at very early-age period since the technique was sensitive to the ionic concentrations and mobility in the liquid or pore solution [

15]. However, the transformer-based method has its limitations in terms of operating frequency because the accuracy of measured resistivity is a function of frequency [

16]. The actual measured value is the complex impedance rather than the pure resistance, and thus could not truly reflect the hydration process, especially at higher frequency beyond 30 kHz. This is attributed to the high magnetization reactance and high core loss of the transformer at high frequencies.

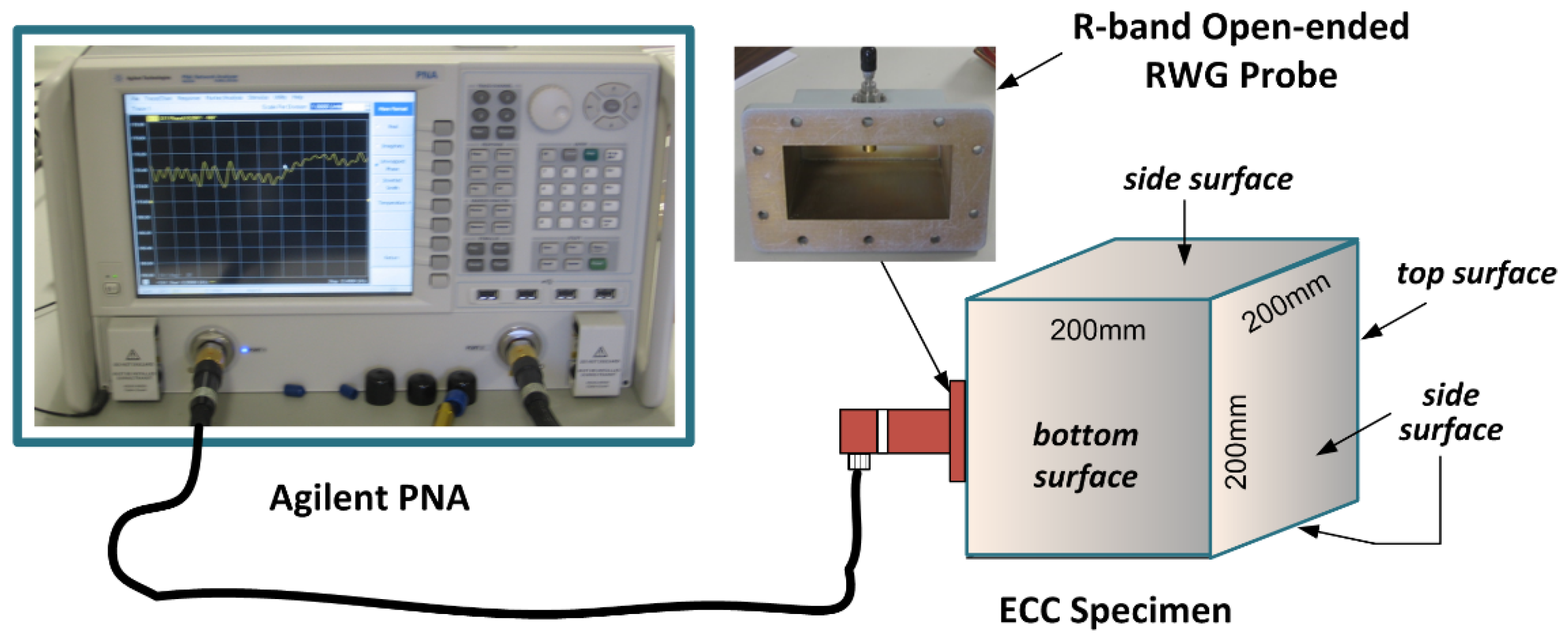

In this paper, the authors propose a microwave near-field detecting approach to monitor the development of microstructure of CBM via the change of effective conductance during early-age hydration, where the degree of hydration relates to concrete’s temperature response [

17]. Moreover, the changes in the conductivity of hardening CBM are known to be the outcomes of microstructure development in the hydrating CBM. The CBM can be considered as a homogenous dielectric slab with an effective complex permittivity (ε

c = ε’ −

jε”). Dispersion in CBM is mainly due to the presence of liquid phase, which is actually a water solution of salts and chemical compounds sourcing from the cement components. According to the extended Debye model of dielectric materials, the imaginary part takes account of the energy losses due to the dielectric relaxation and the effective electrical conductivity (σ

eff) of CBM, and is given by [

18]

where σ

dc is the dc conductivity, and

Δε = ε

dc −

ε∞ is the difference between values of the real part of the complex relative permittivity at very low and very high frequency, respectively, and τ is the relaxation time in second (s) whereas ω is the angular frequency in s

−1.

From (1), it is known that the four-probe direct resistivity measurement method may only account for part of bulk conductivity, namely, the dc conductivity of CBM during hydration. Moreover, the losses due to dielectric relaxation and dipole polarization are not to be included in the transformer non-contact measurement method because a low frequency (10 kHz) was used [

14,

15]. Nondestructive microwave near-field detecting techniques have remarkable applications, such as estimating compressive strength [

19] and cure-state monitoring of CBM [

20,

21]. The chosen microwave frequency allows electromagnetic (EM) energy to penetrate deeper into the specimen [

21,

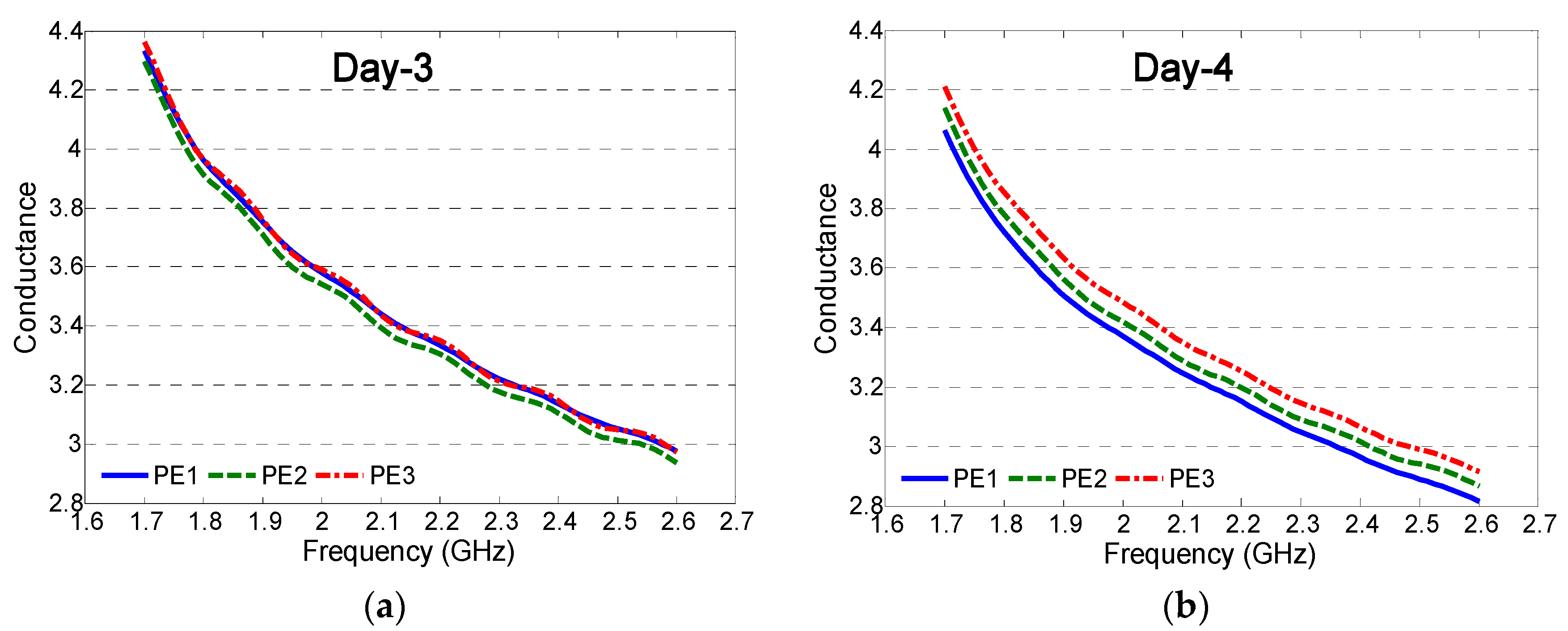

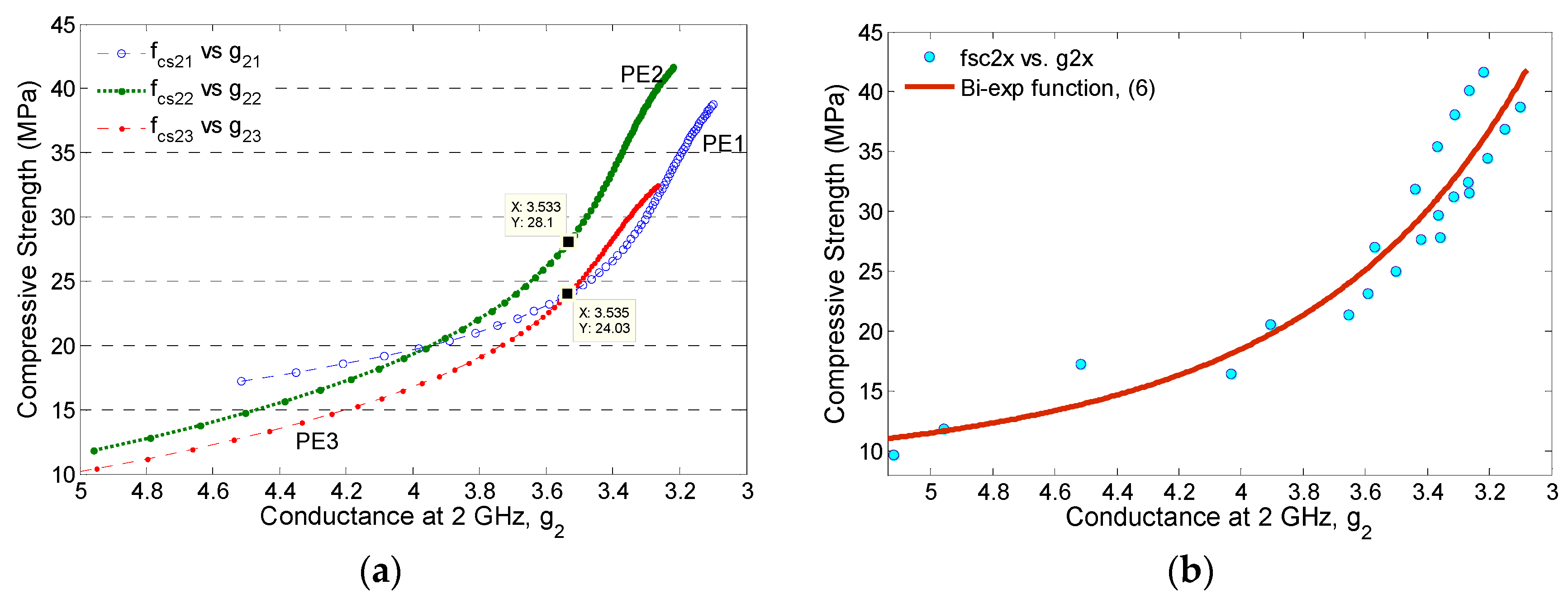

22], and hence a near-field technique at a microwave frequency of 2 GHz was used in this study. The goal was to measure the bulk effective conductance that accounted for all types of loss in order to monitor the development of microstructure of CBMs under the influence of various water-to-cement ratios [

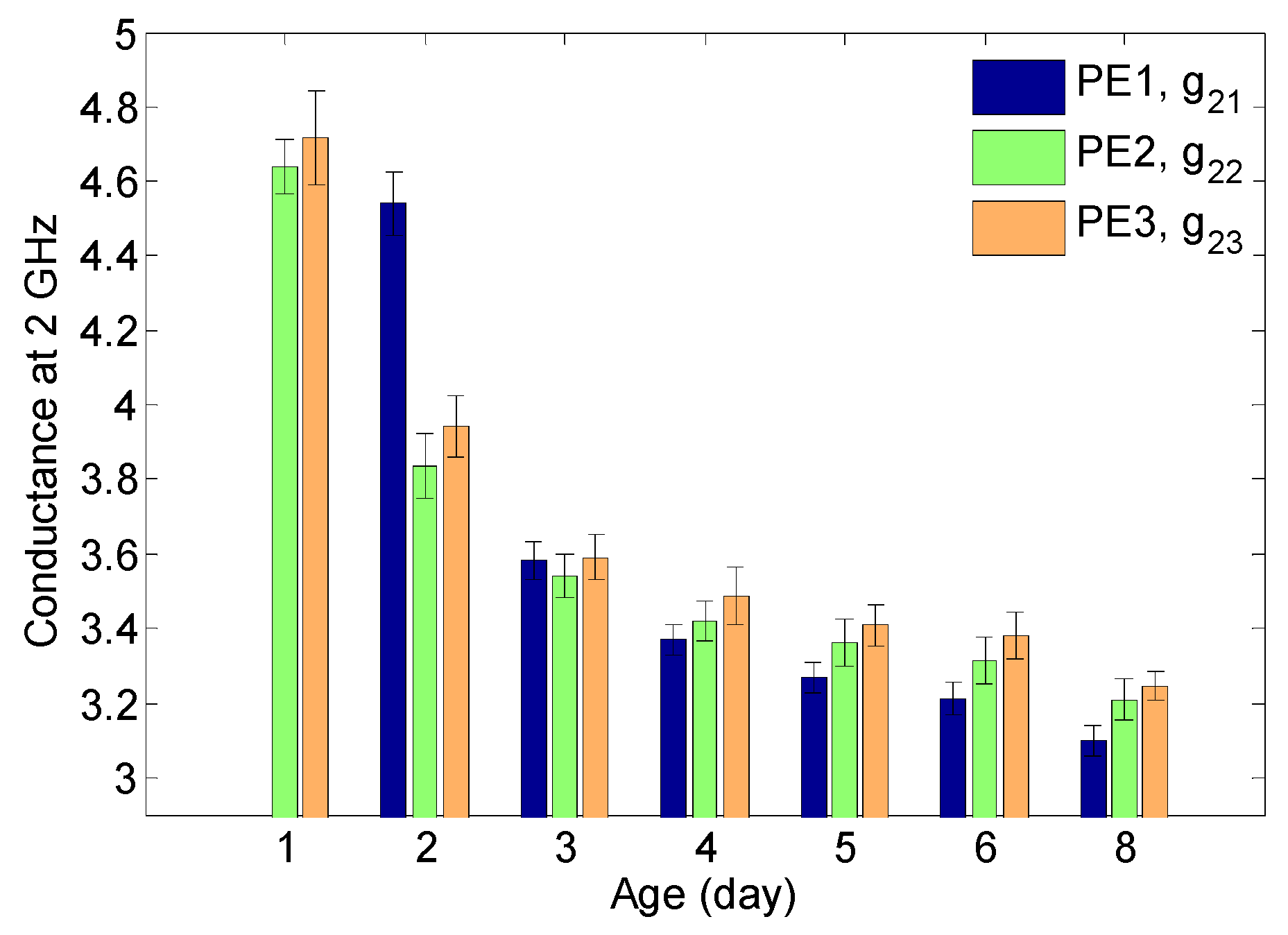

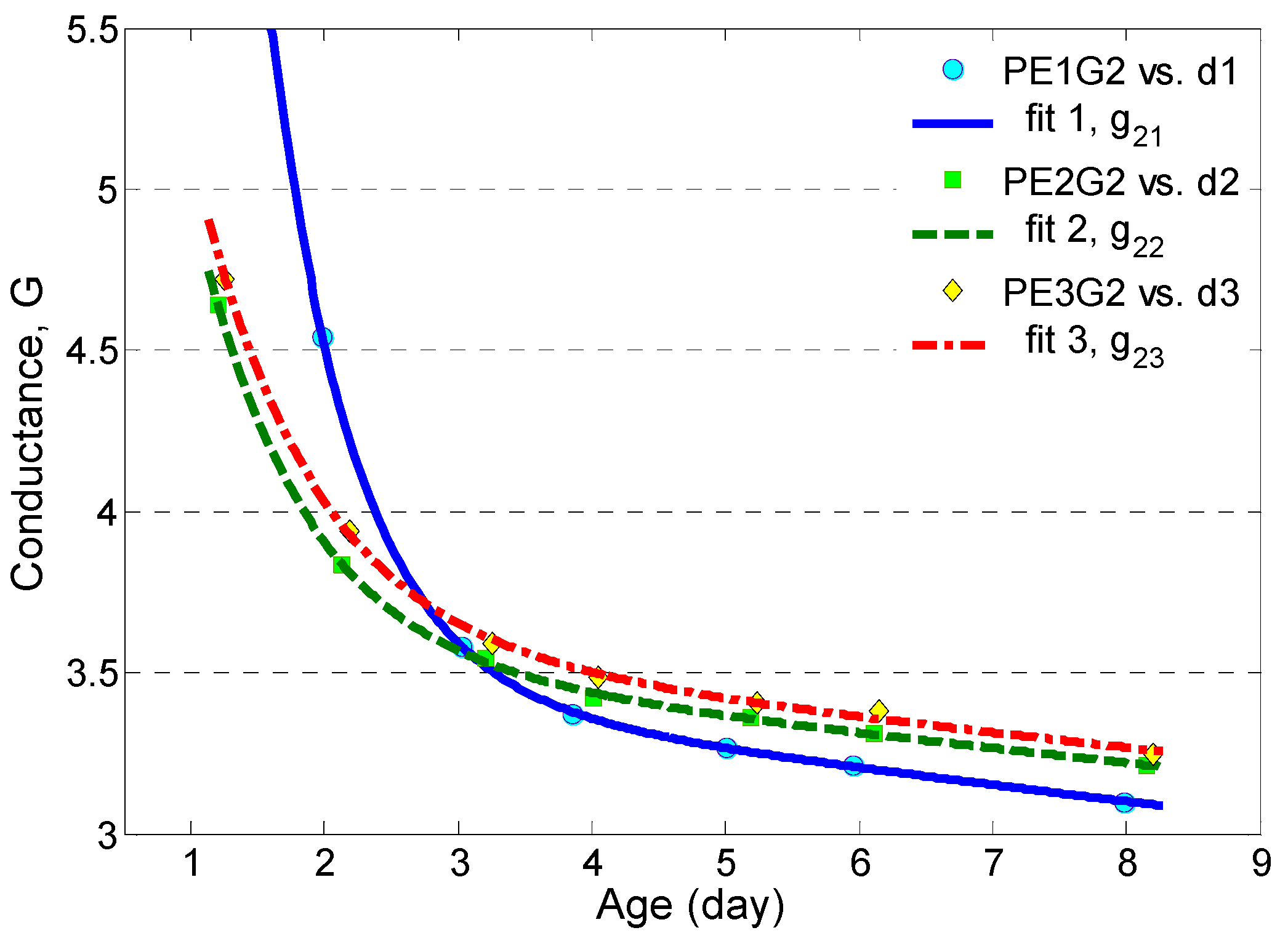

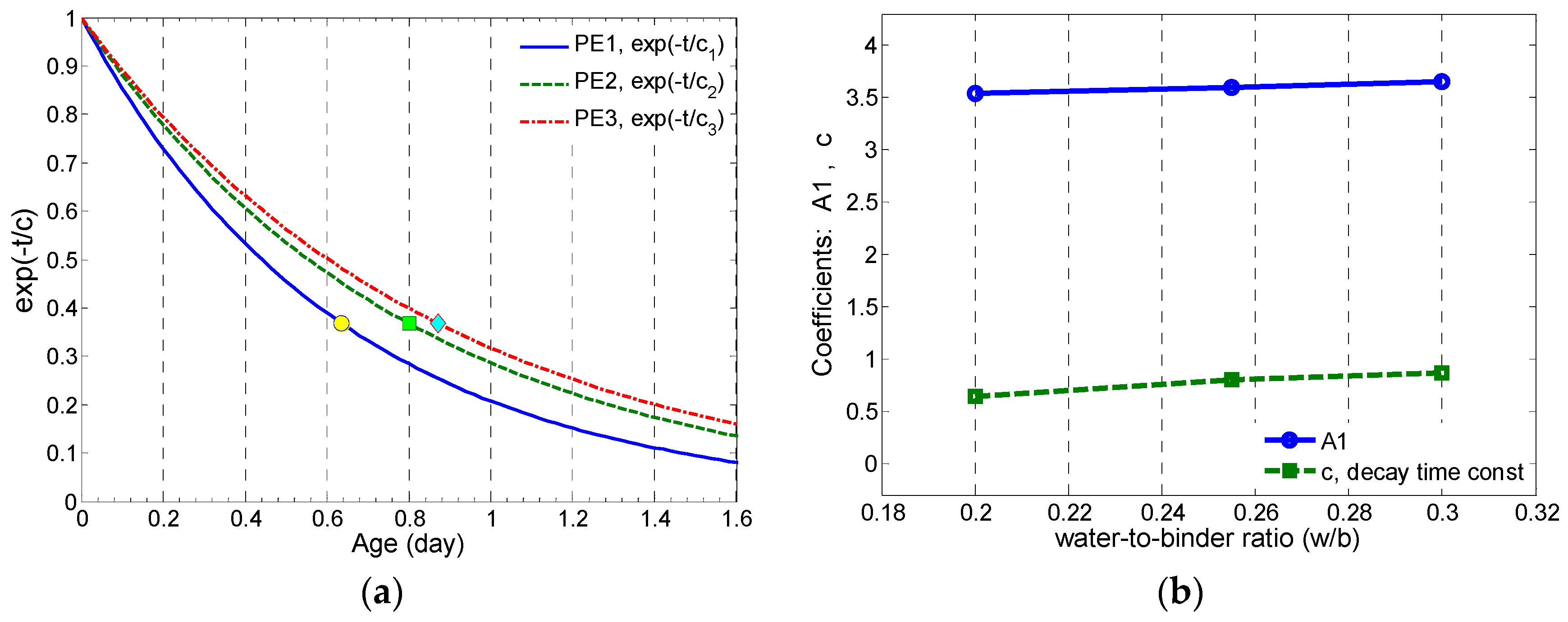

21,

23].

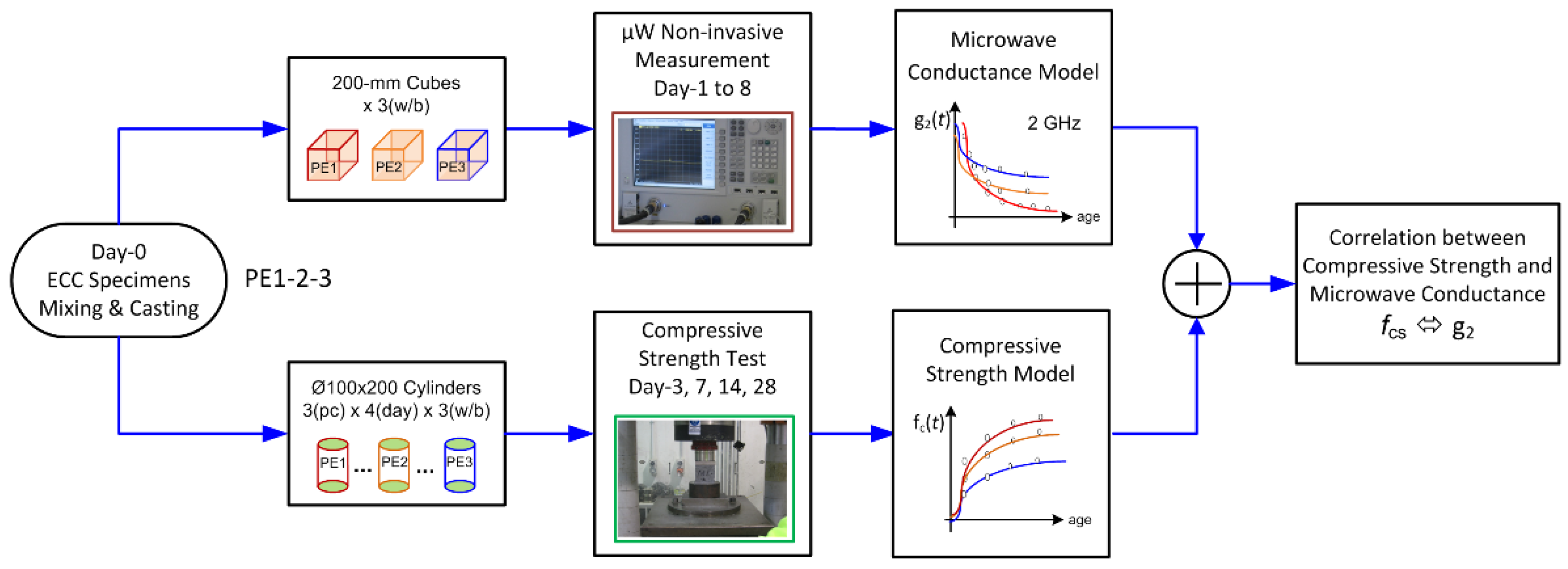

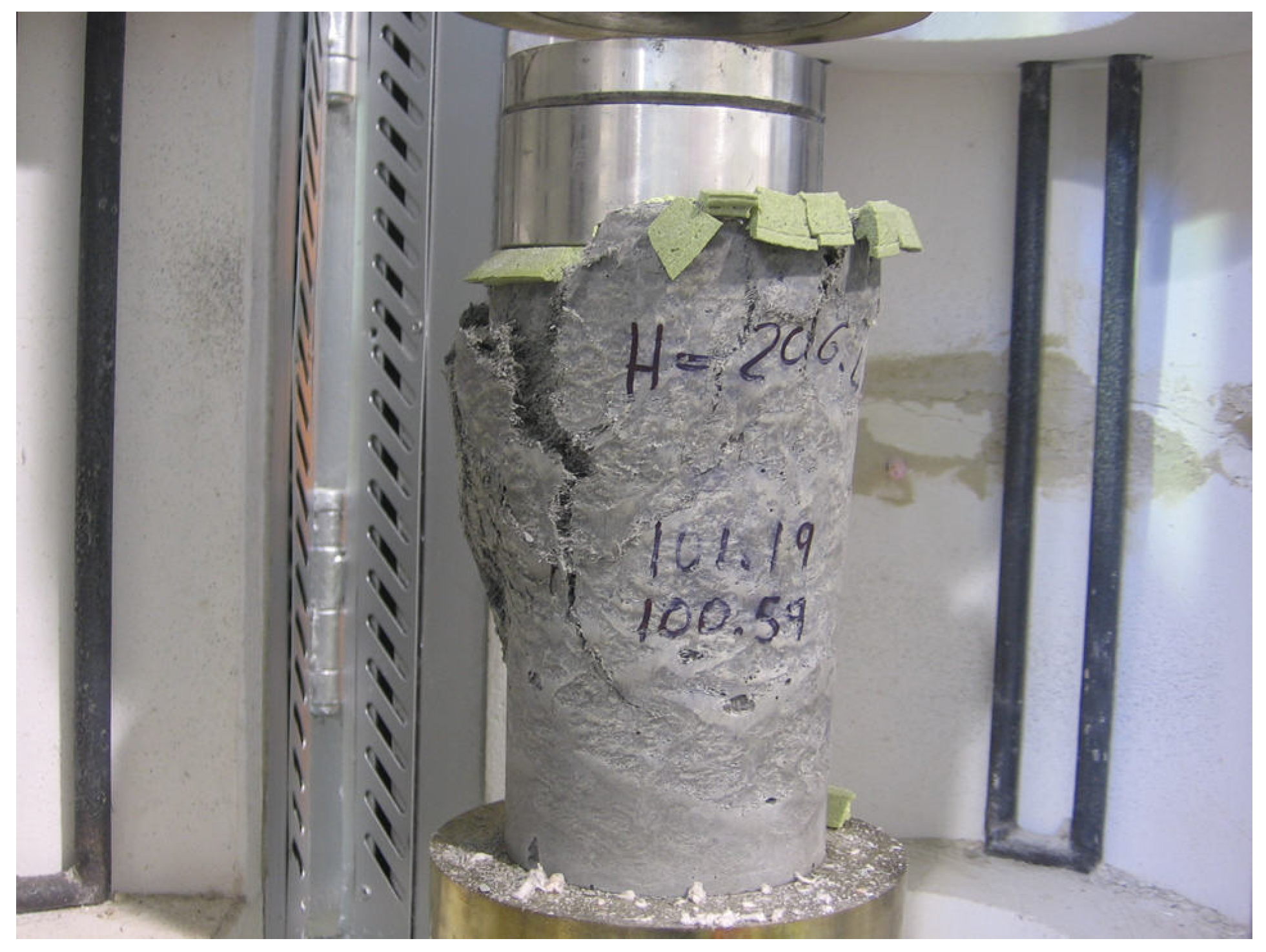

The objectives and applications of the aforementioned studies were to make compressive strength of CBM predictable and improve monitoring efficiency at early ages of the materials. However, these studies were largely focused on the traditional materials like concrete, mortar, and or cement paste, with less attention on the new type of cement composites. With the advent of ultra-ductile fiber-reinforced composites like engineered cementitious composite (ECC) [

24,

25], substantial developments in commercialization and research of ECC technologies have materialized both in the academic and industrial communities [

26,

27,

28]. ECC uses moderate amount of polyvinyl alcohol (PVA) fiber in volume fraction of 2%, but offers tensile ductility several hundred times higher than the conventional CBMs [

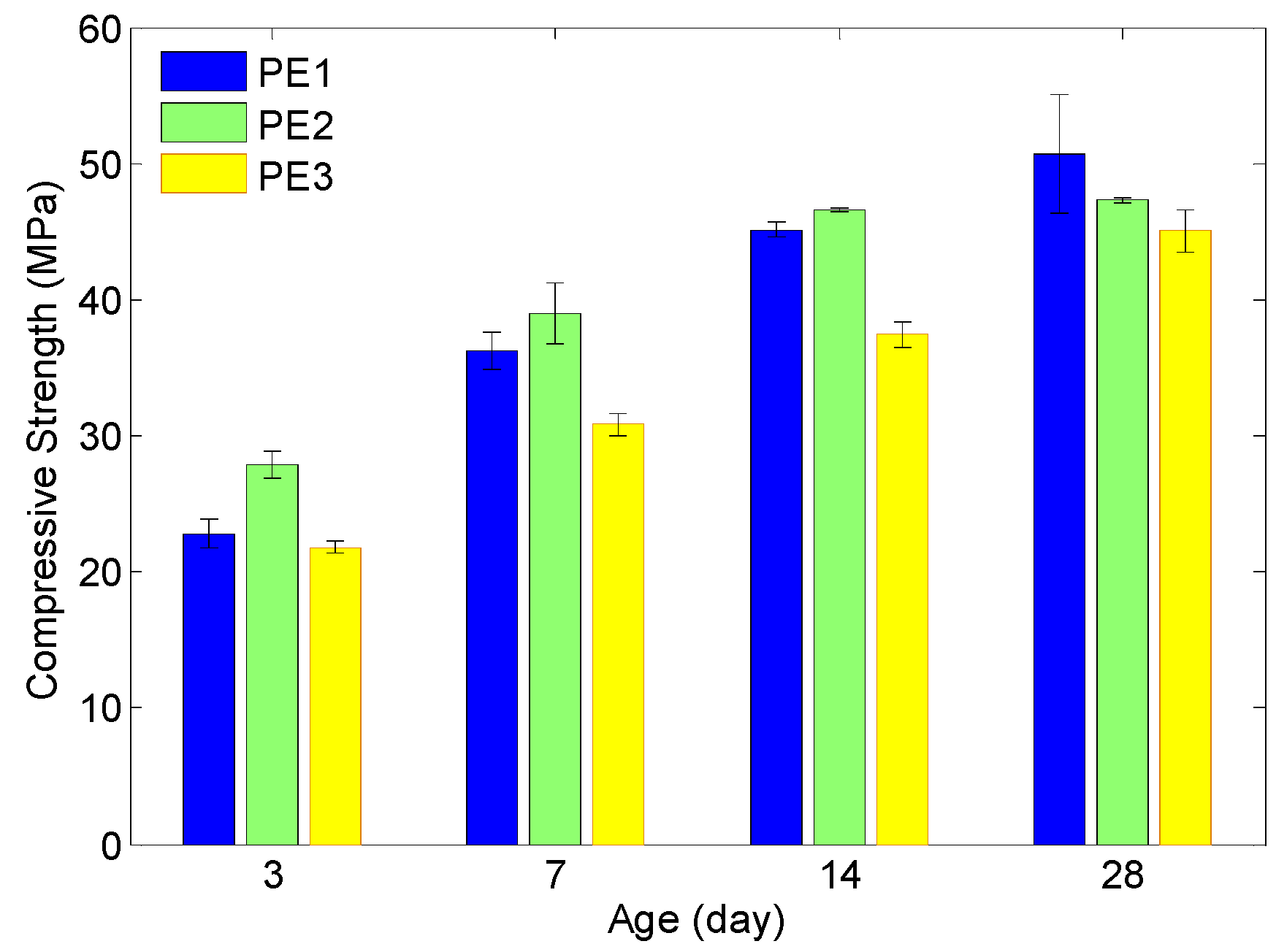

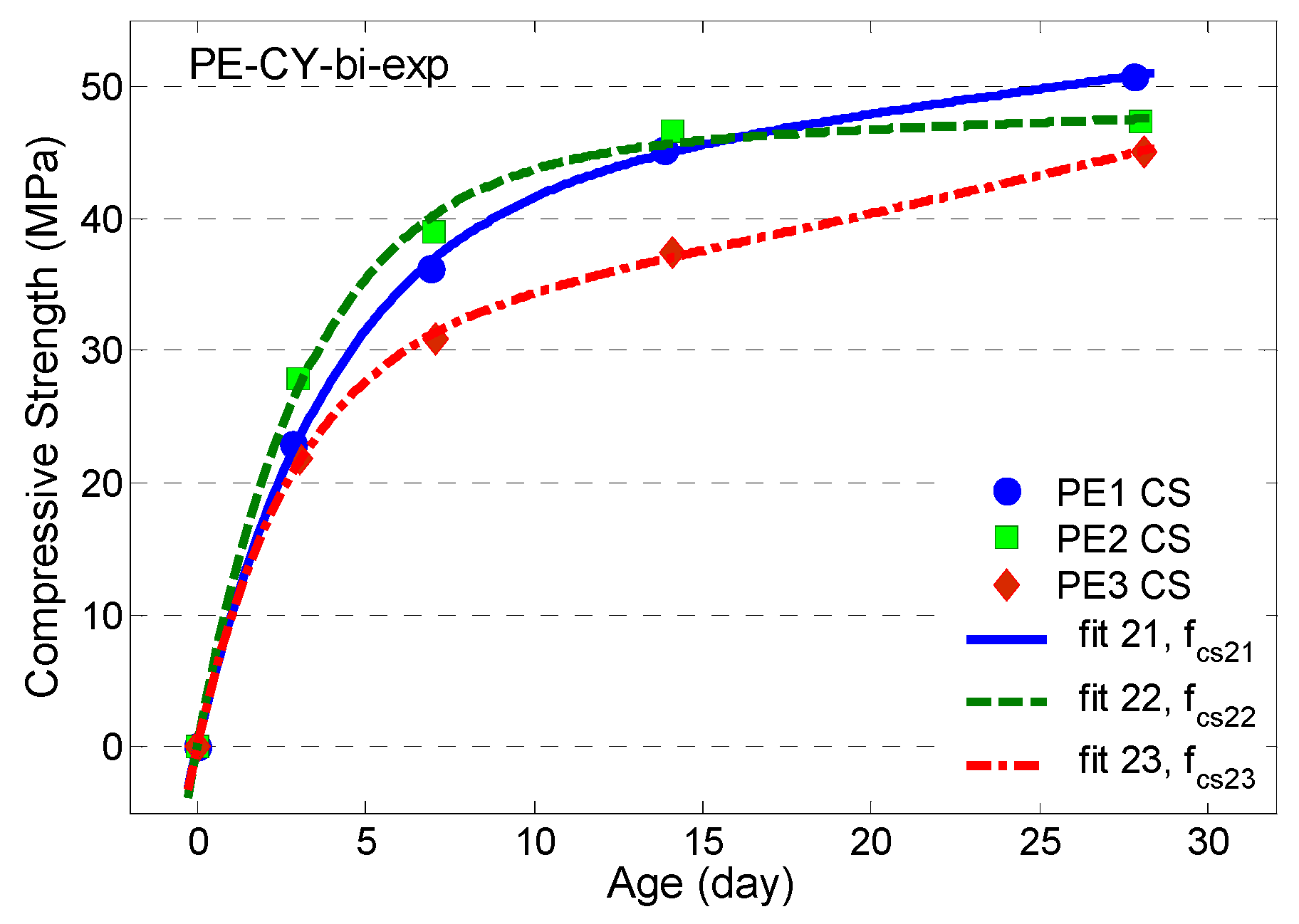

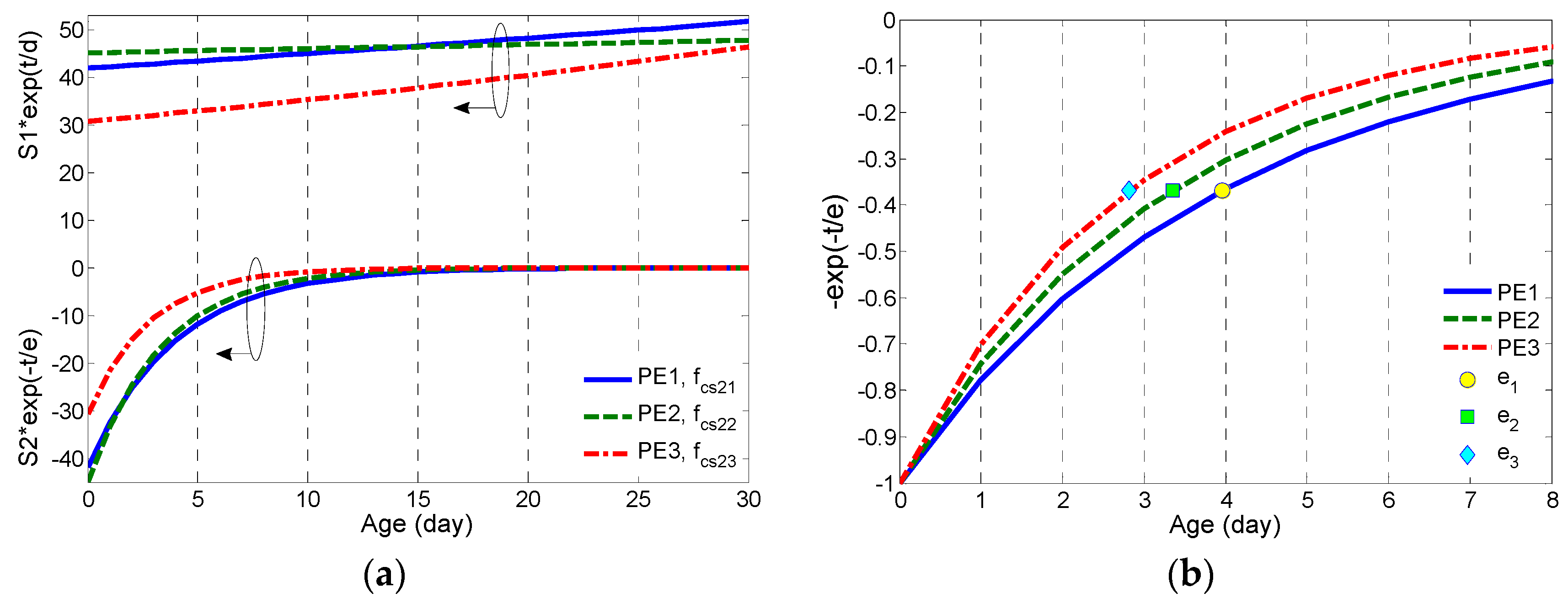

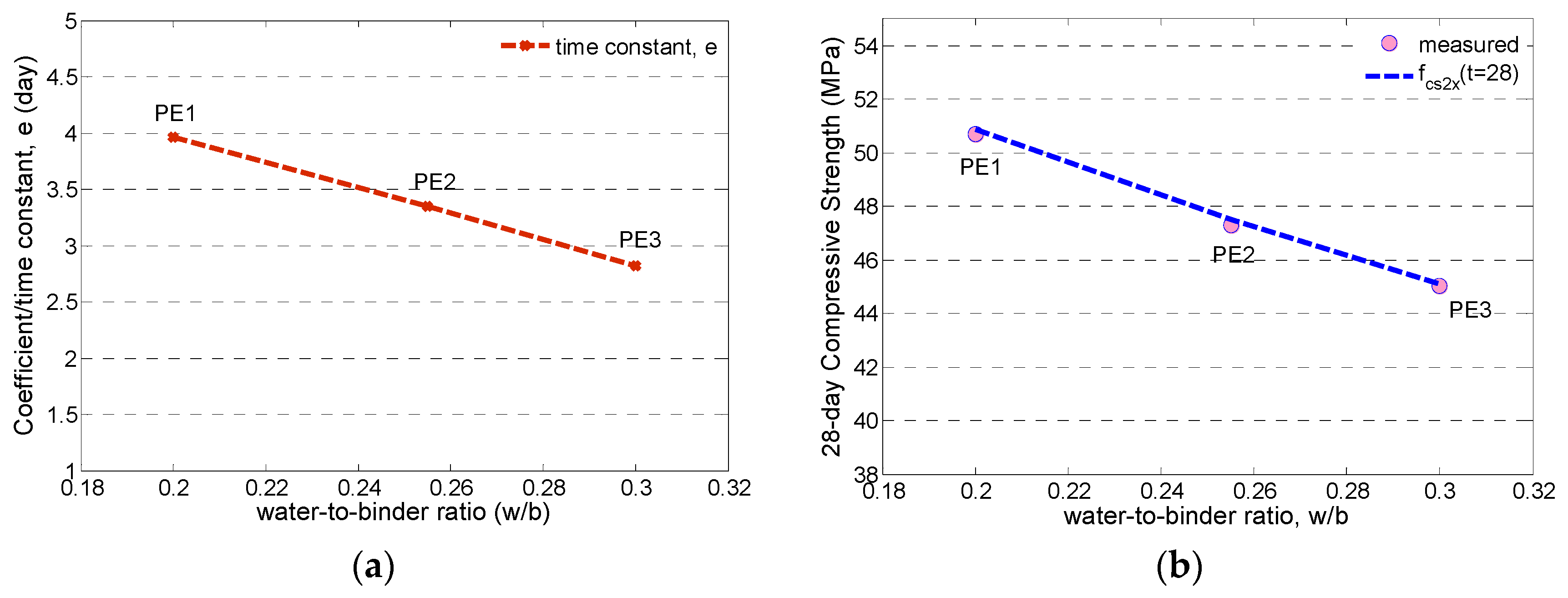

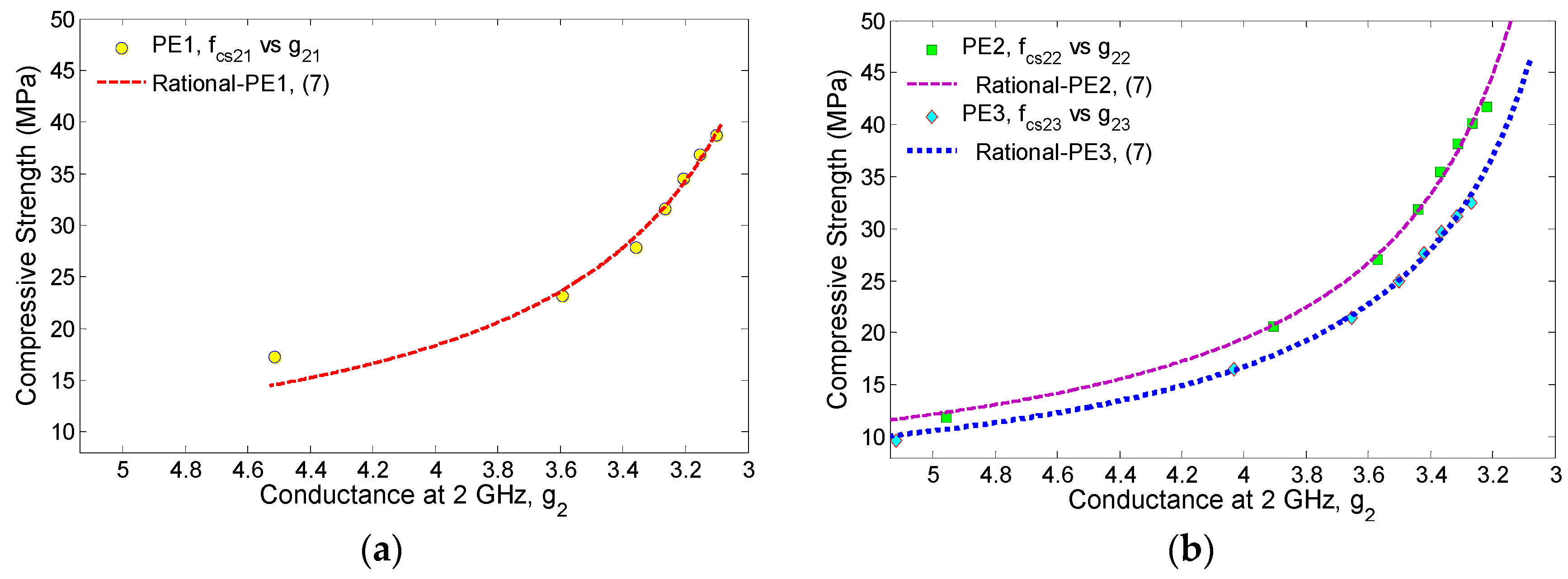

25]. The present study developed two correlation models between compressive strength and effective electrical conductance measured at early ages. The goal was to monitor the strength evolution by means of early-age conductance and hence to predict the final compressive strength under influence of initial water-to-binder (

w/

b) ratios. It is known that compressive and flexural strengths of ECC are sensitive to initial water content at all ages. However, PVA fibers are hydrophilic material so they absorb water and provide a strong interfacial bond with the cementitious matrix and thereby have a favorable effect on strength development. Furthermore, commercially available PVA fiber, in general, has unknown water absorption characteristics. Therefore, one of the objectives in this study was to differentiate the effect of tight water contents inside PVA-ECC matrixes using effective electrical conductance.