Design and Experimental Development of a Pneumatic Stiffness Adjustable Foot System for Biped Robots Adaptable to Bumps on the Ground

Abstract

:1. Introduction

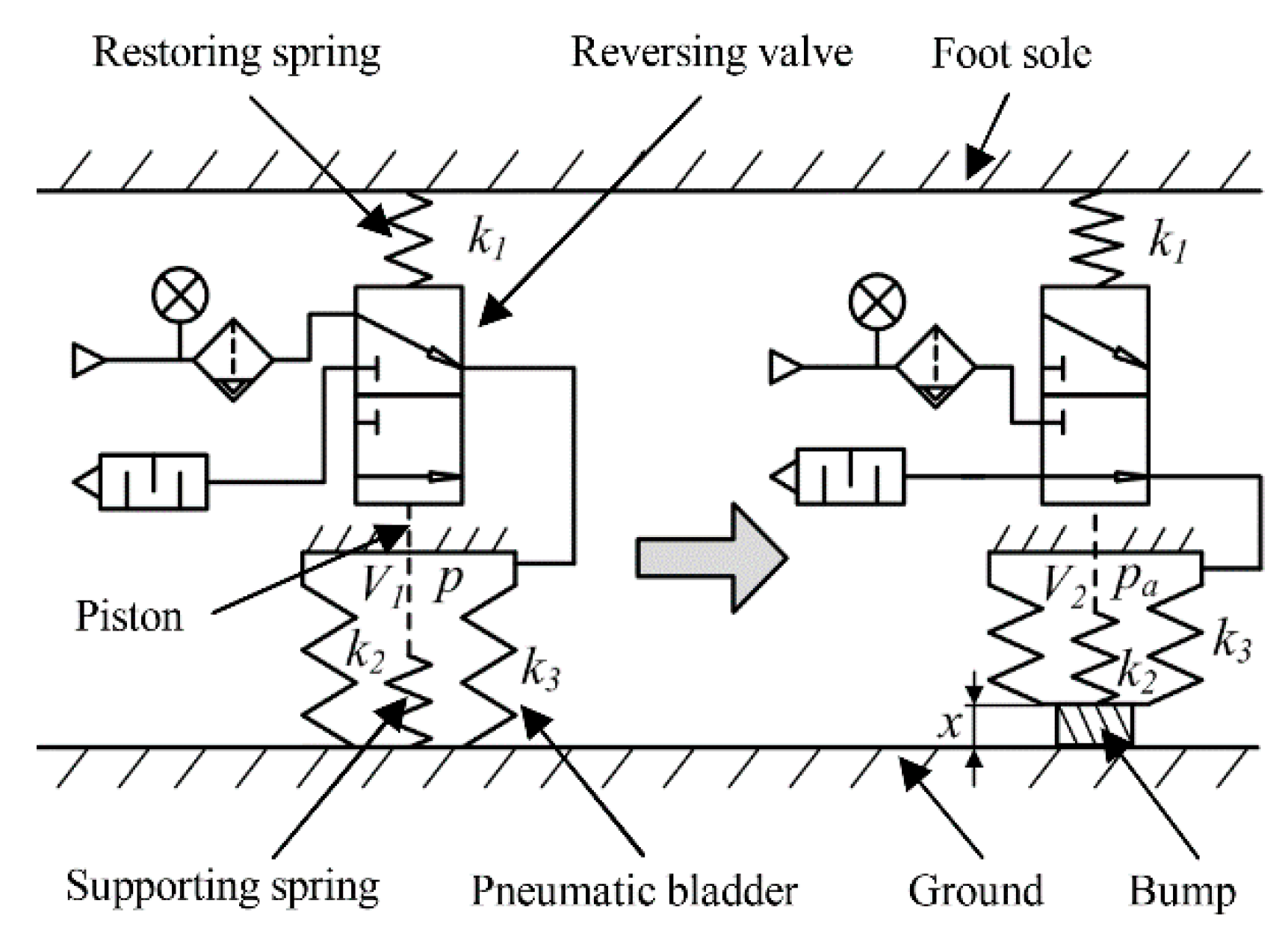

2. Working Mechanism of the Stiffness-Adjustable Foot System

2.1. Overview of the Stiffness-Adjustable Foot System

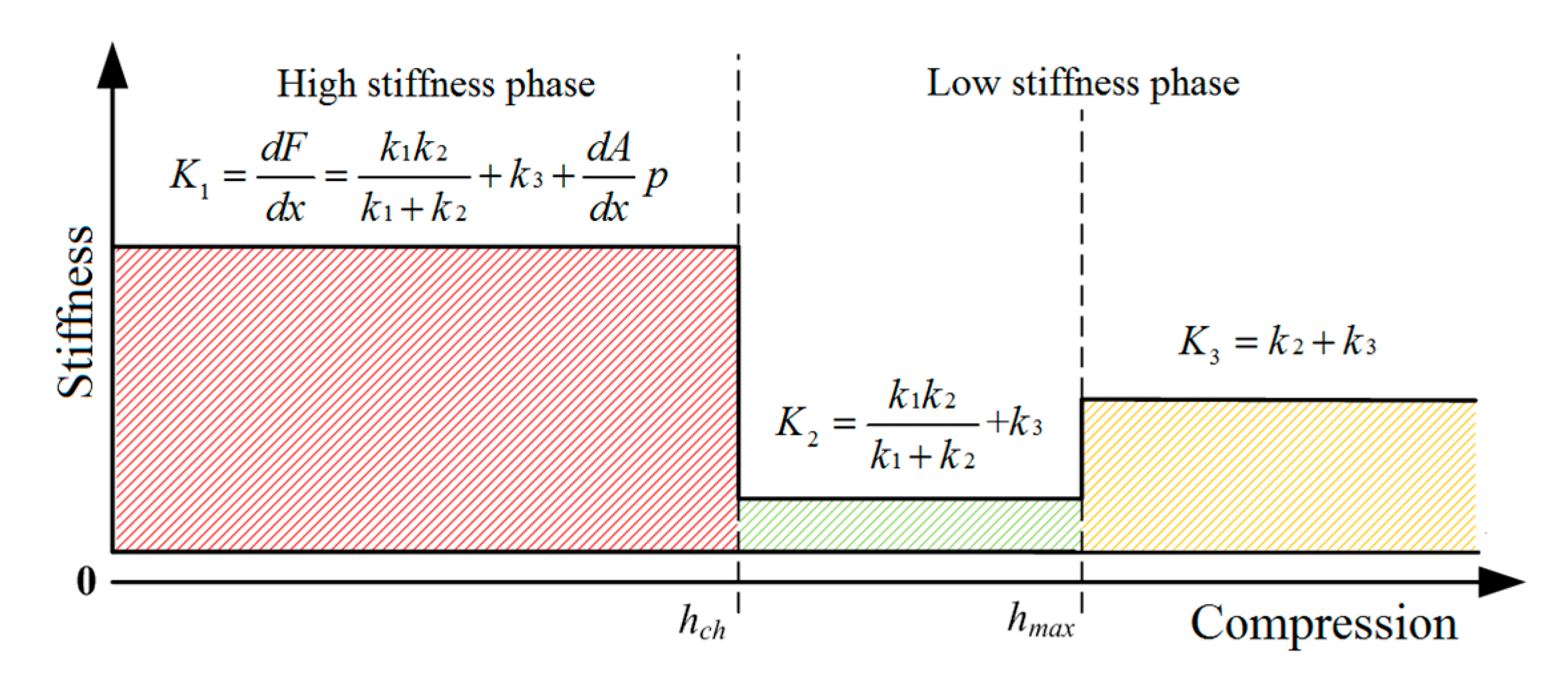

2.2. Theoretical Analysis of the Variable Stiffness Mechanism

3. Development of the Stiffness Adjustable Foot System

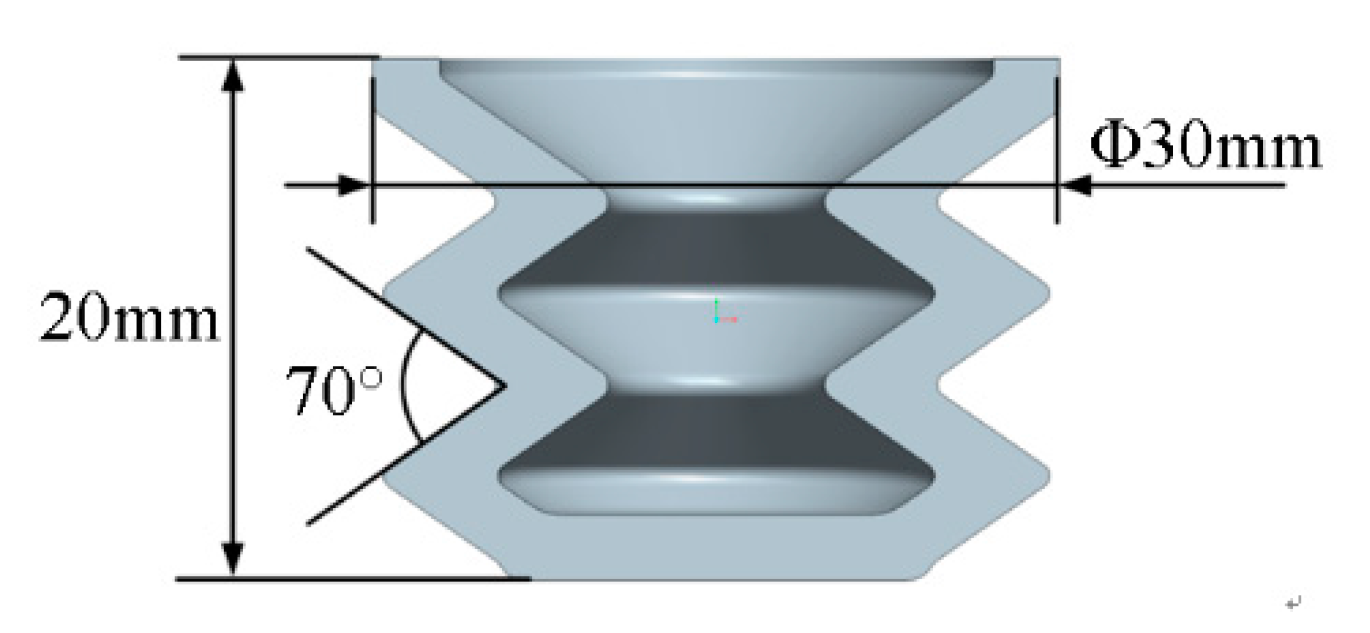

3.1. Design of the Pneumatic Bladder

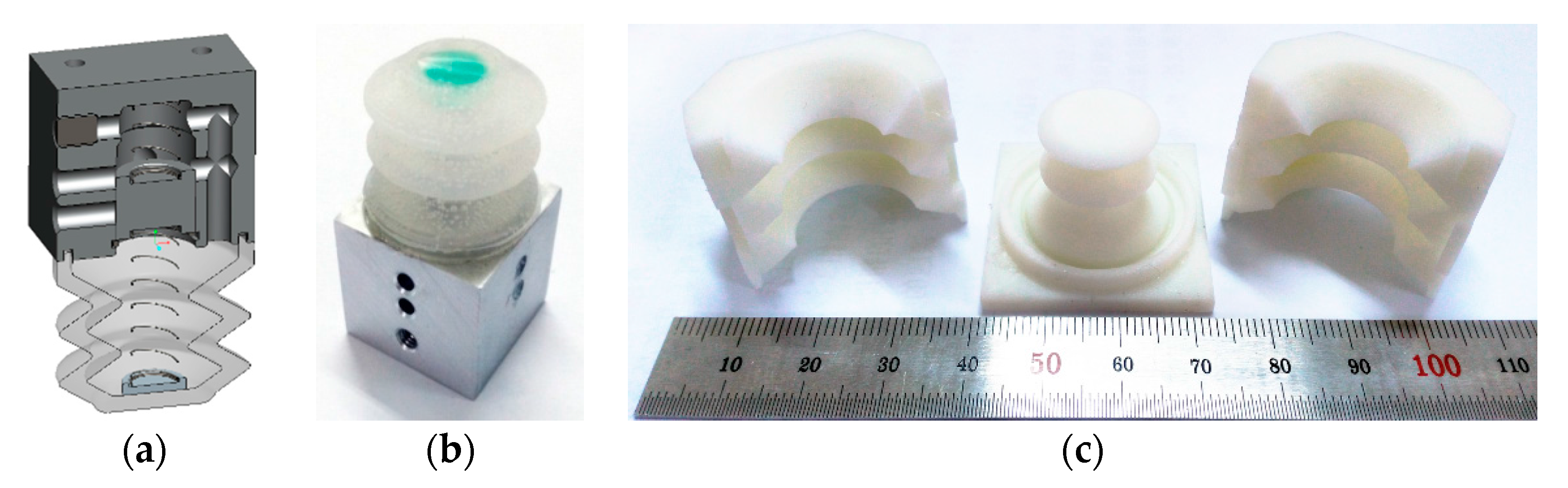

3.2. Design of the PVSU

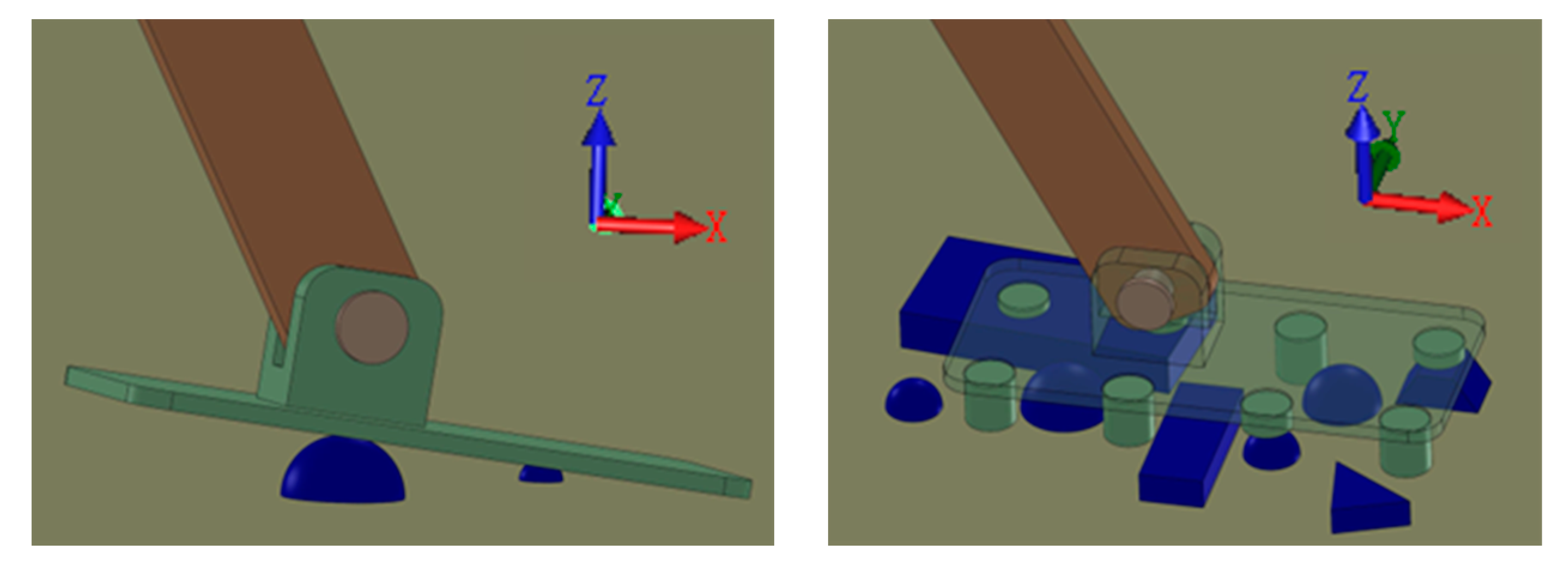

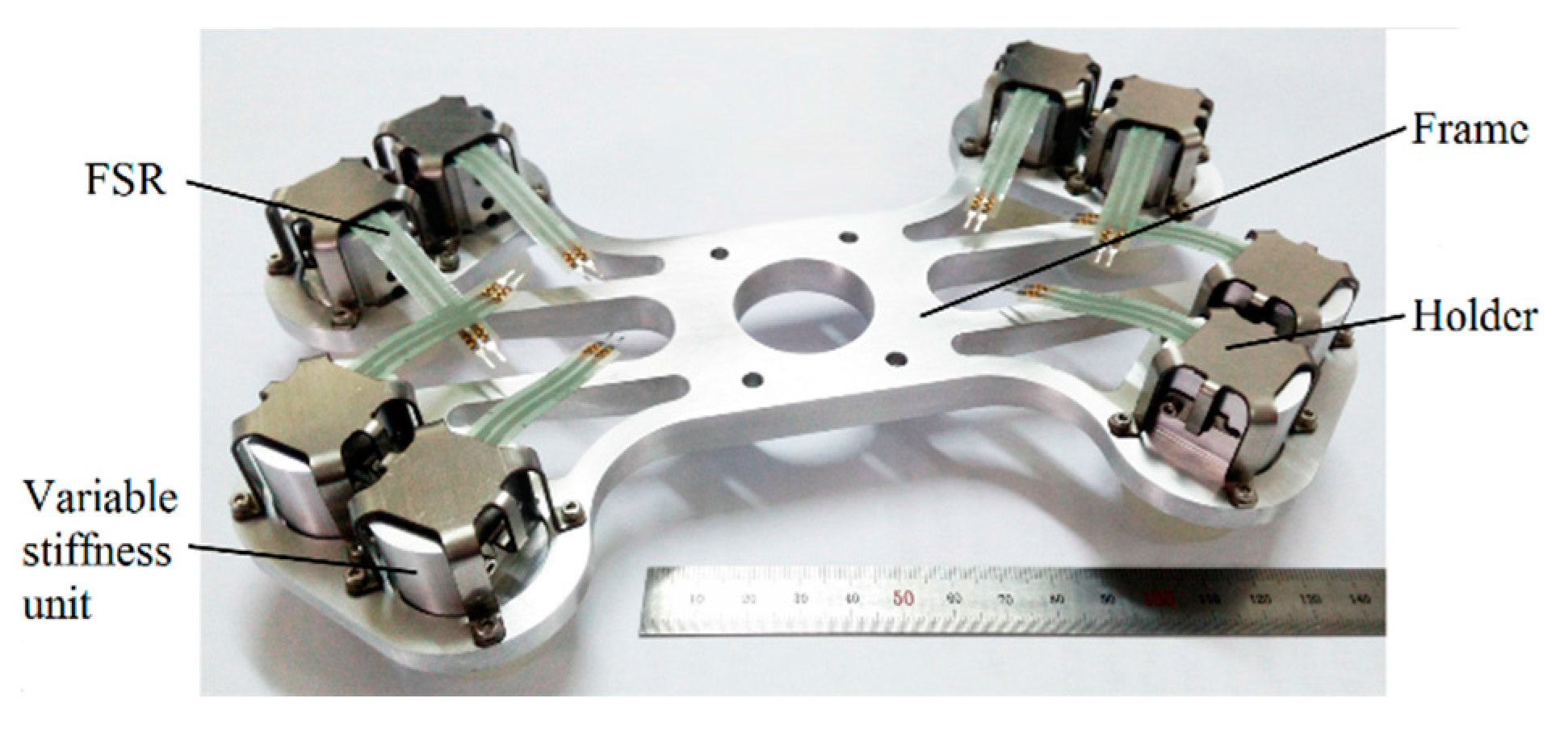

3.3. Design of the Foot System

4. Experiments

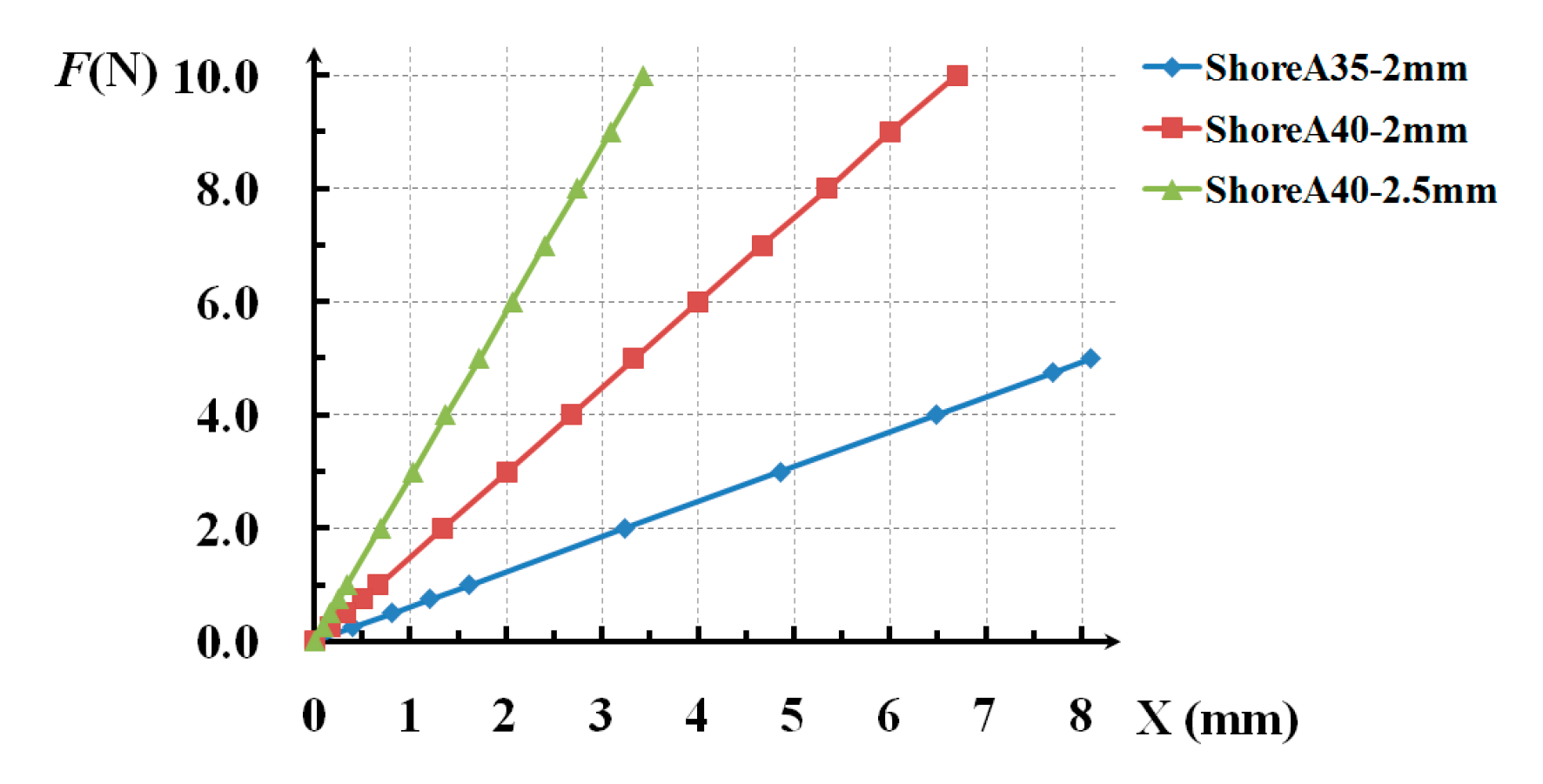

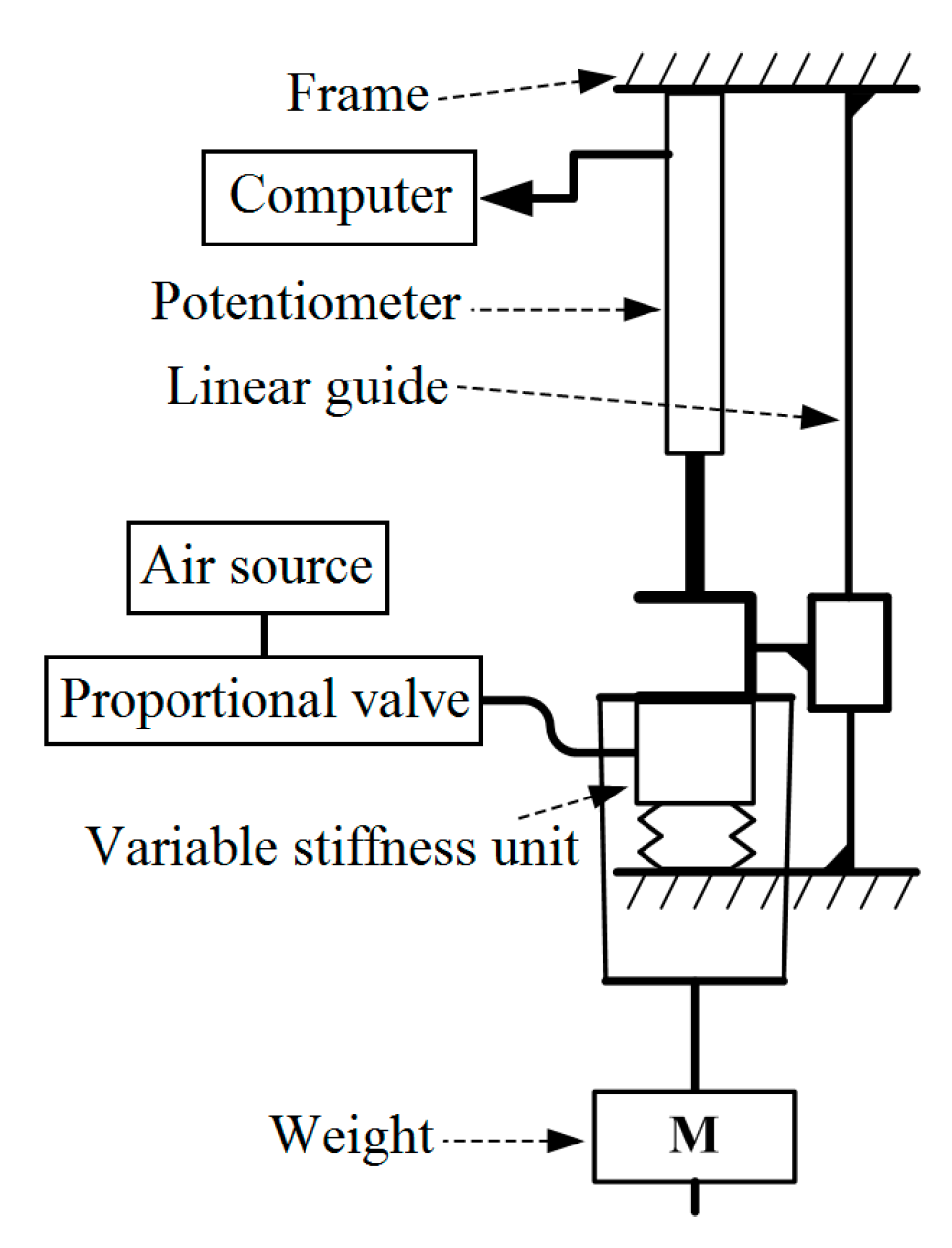

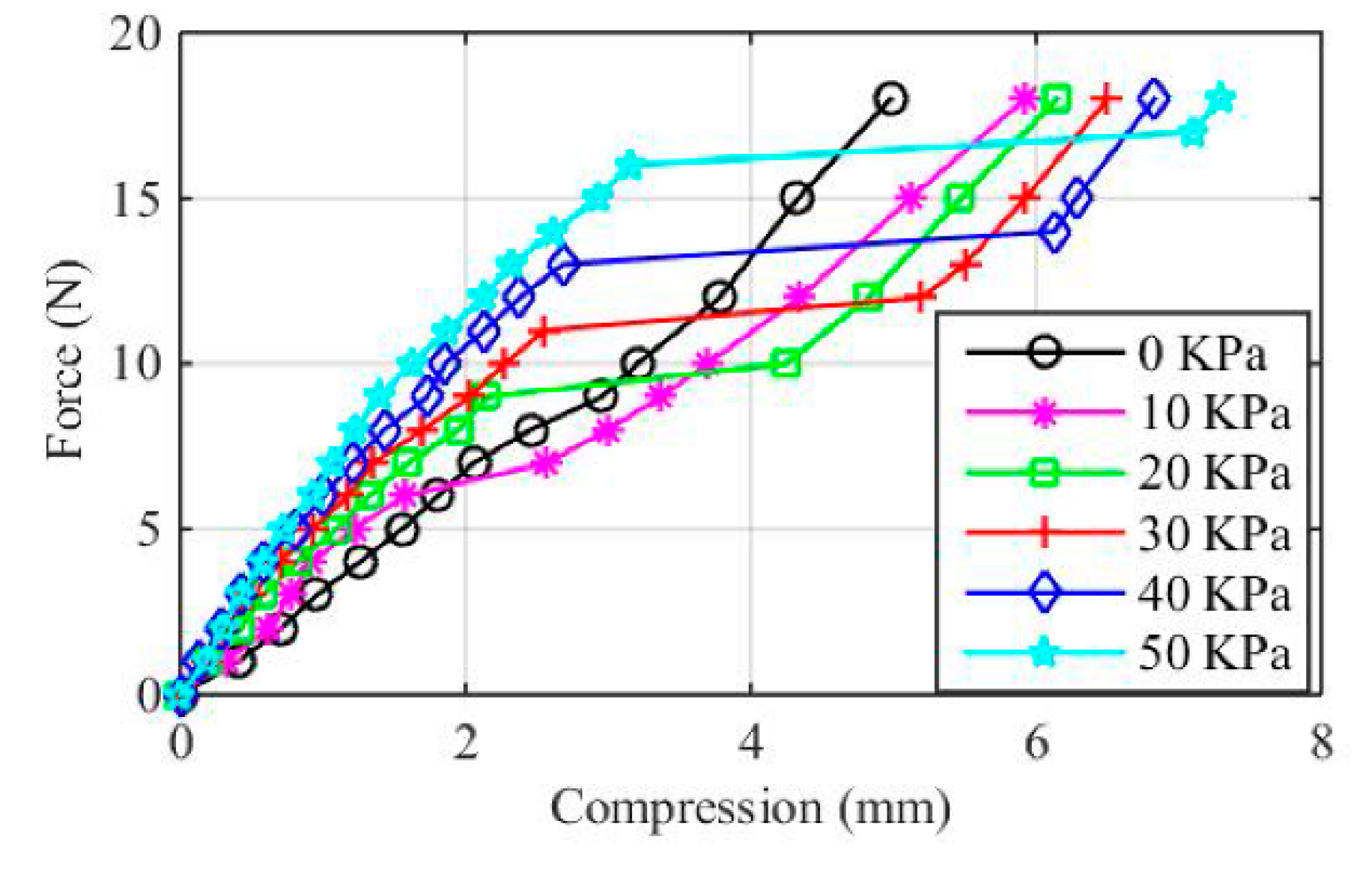

4.1. Experiment on the PVSU

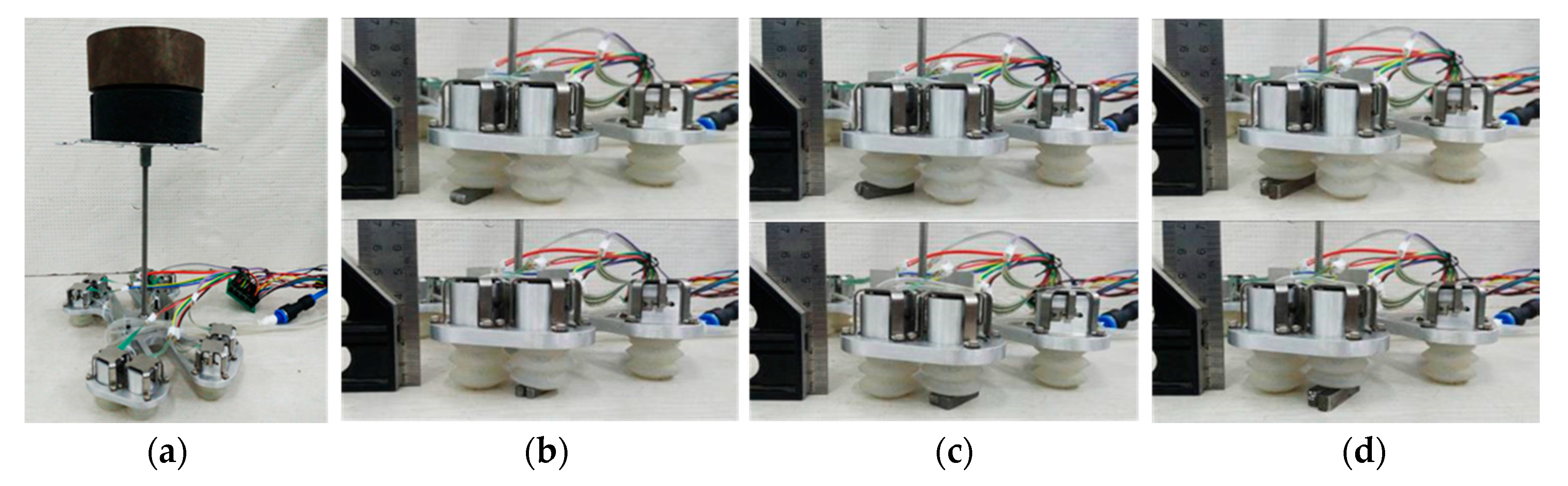

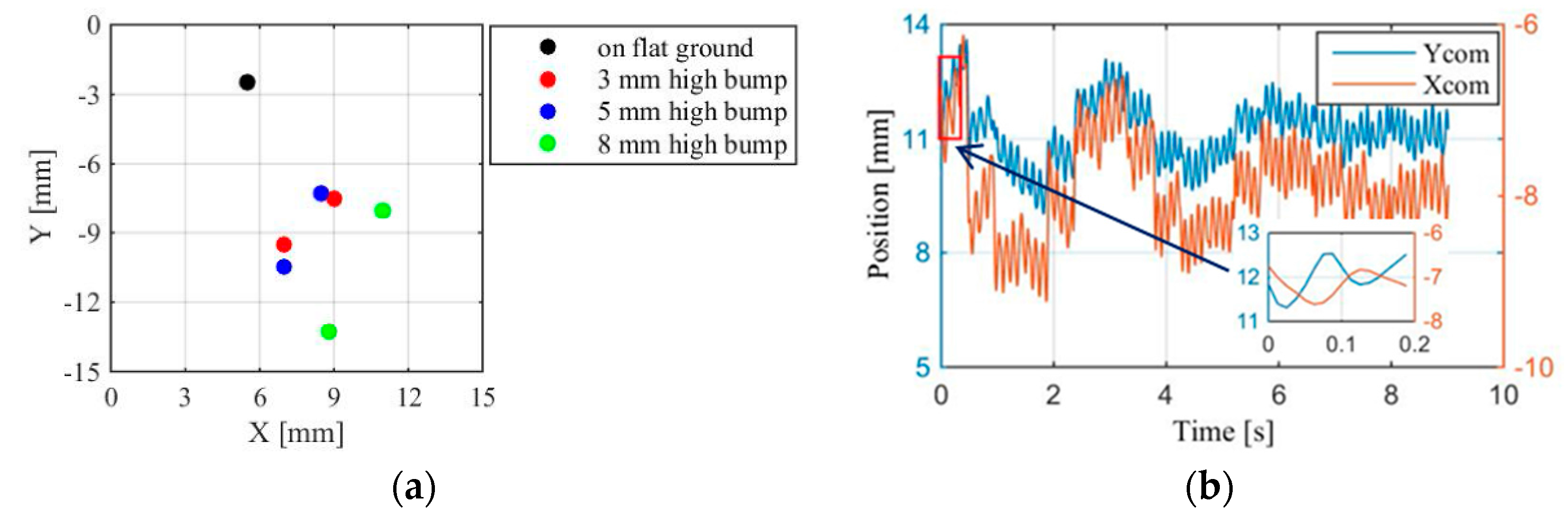

4.2. Experiment on the Foot System

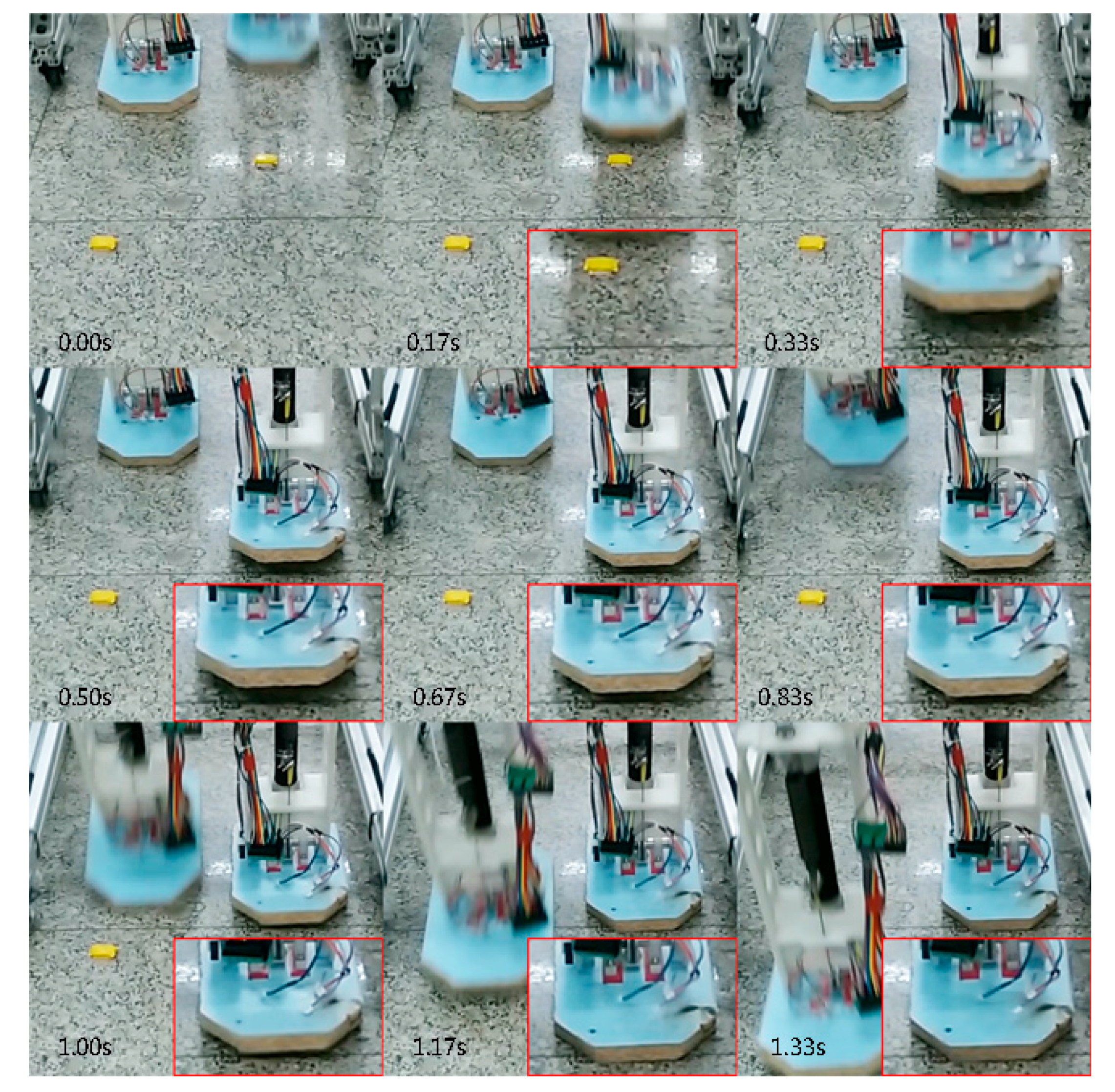

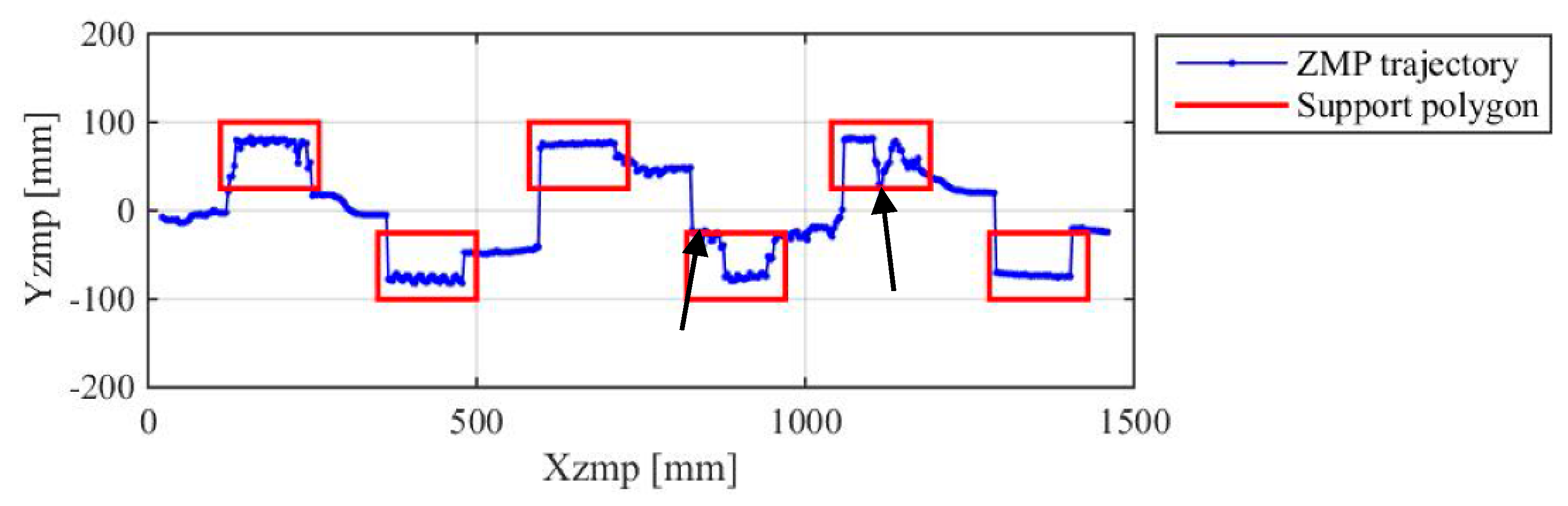

4.3. Experiment on a Biped Robot

5. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hirai, K. Current and future perspective of Honda humanoid robot. In Proceedings of the 1997 IEEE/RSJ International Conference on Intelligent Robots and Systems, Grenoble, France, 11 September 1997; pp. 500–508. [Google Scholar]

- Hirai, K.; Hirose, M.; Hikawa, Y.; Takenaka, T. The development of Honda humanoid robot. In Proceedings of the 1998 IEEE International Conference on Robotics and Automation, Leuven, Belgium, 16–20 May 1998; pp. 1321–1326. [Google Scholar]

- Kajita, S.; Kanehiro, F.; Kaneko, K.; Yokoi, K.; Hirukawa, H. The 3D linear inverted pendulum mode: A simple modeling for a biped walking pattern generation. In Proceedings of the 2001 IEEE/RSJ International Conference on Intelligent Robots and Systems, Maui, HI, USA, 29 October–3 November 2001; pp. 239–246. [Google Scholar]

- Okumura, Y.; Tawara, T.; Endo, K.; Furuta, T.; Shimizu, M. Realtime ZMP compensation for biped walking robot using adaptive inertia force control. In Proceedings of the 2003 IEEE/RSJ International Conference on Intelligent Robots and Systems, Las Vegas, NV, USA, 27–31 October 2003; pp. 335–339. [Google Scholar]

- Sugahara, Y.; Hosobata, T.; Mikuriya, Y.; Sunazuka, H.; Lim, H.O.; Takanishi, A. Realization of dynamic human-carrying walking by a biped locomotor. In Proceedings of the 2004 IEEE/RSJ International Conference on Robotics and Automation, New Orleans, LA, USA, 26 April–1 May 2004; pp. 3055–3060. [Google Scholar]

- Sakagami, Y.; Watanabe, R.; Aoyama, C.; Matsunaga, S.; Higaki, N.; Fujimura, K. The intelligent Asimo: System overview and integration. In Proceedings of the 2002 IEEE/RSJ International Conference on Intelligent Robots and Systems, Lausanne, Switzerland, 30 September–4 October 2002; pp. 2478–2483. [Google Scholar]

- Ogura, Y.; Aikawa, H.; Shimomura, K.; Kondo, H.; Morishima, A.; Lim, H.; Takanishi, A. Development of a new humanoid robot WABIAN-2. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation, Orlando, FL, USA, 15–19 May 2006; pp. 76–81. [Google Scholar]

- Nugroho, S.; Prihatmanto, A.; Rohman, A. Design and implementation of kinematics model and trajectory planning for NAO humanoid robot in a tic-tac-toe board game. In Proceedings of the 2014 IEEE 4th International Conference on System Engineering and Technology, Bandung, Indonesia, 24–25 November 2014; pp. 1–7. [Google Scholar]

- Tsagarakis, N.; Metta, G.; Sandini, G.; Vernon, D.; Beira, R.; Becchi, F.; Righetti, L.; Santos-Victor, J.; Ijspeert, A.; Carrozza, M.; et al. iCub: The design and realization of an open humanoid platform for cognitive and neuroscience research. Adv. Robot. 2007, 21, 1151–1175. [Google Scholar] [CrossRef]

- Vukobratovic, M. Zero-Moment Point—Thirty five years of its life. Int. J. Humanoid Robot. 2001, 1, 157–173. [Google Scholar] [CrossRef]

- Braun, D.J.; Mitchell, J.E.; Goldfarb, M. Actuated dynamic walking in a seven-link biped robot. IEEE/ASME Trans. Mechatron. 2012, 17, 147–156. [Google Scholar] [CrossRef]

- Shin, H.; Kim, B.K. Energy-efficient gait planning and control for biped robots utilizing the allowable ZMP region. IEEE Trans. Robot. 2014, 30, 986–993. [Google Scholar] [CrossRef]

- Hashimoto, K.; Hosobata, T.; Sugahara, Y.; Mikuriya, Y.; Sunazuka, H.; Kawase, M.; Lim, H.; Takanishi, A. Development of foot system of biped walking robot capable of maintaining four-point contact. In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems, Edmonton, AB, Canada, 2–6 August 2005; pp. 1464–1469. [Google Scholar]

- Wei, H.; Shuai, M.; Wang, Z. Dynamically adapt to uneven terrain walking control for humanoid robot. Chin. J. Mech. Eng. 2012, 25, 214–222. [Google Scholar] [CrossRef]

- Nishiwaki, K.; Chestnutt, J.; Kagami, S. Autonomous navigation of a humanoid robot over unknown rough terrain using a laser range sensor. Int. J. Robot. Res. 2012, 31, 1251–1262. [Google Scholar] [CrossRef]

- Stumpf, A.; Kohlbrecher, S.; Conner, D.C.; von Stryk, O. Supervised footstep planning for humanoid robots in rough terrain tasks using a black box walking controller. In Proceedings of the 2014 14th IEEE-RAS International Conference on Humanoid Robots, Madrid, Spain, 18–20 November 2014; pp. 287–294. [Google Scholar]

- Khadiv, M.; Moosavian, S.; Ali, A.; Yousefi-Koma, A.; Maleki, H.; Sadedel, M. Online adaptation for humanoids walking on uncertain surfaces. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2017, 231, 245–258. [Google Scholar] [CrossRef]

- Nishiwaki, K.; Chestnutt, J.; Kagami, S. Autonomous navigation of a humanoid robot over unknown rough terrain. In Robotics Research, Springer Tracts in Advanced Robotics; Christensen, H., Khatib, O., Eds.; Springer: Cham, Switzerland, 2017; Volume 100, pp. 619–636. [Google Scholar]

- Lukac, D.; Siedel, T.; Benckendorff, C. Designing the test feet of the humanoid robot M-Series. In Proceedings of the XXII International Symposium on Information, Communication and Automation Technologies, Bosnia, Serbia, 29–31 October 2009; pp. 1–6. [Google Scholar]

- Hashimoto, K.; Sugahar, Y.; Hayash, A.; Kondo, H.; Takashima, T.; Lim, H.; Takanishi, A. Development of new biped foot mechanism mimicking human’s foot arch structure. In ROMANSY 18 Robot Design, Dynamics and Control, Proceedings of the Eighteenth CISM-IFToMM Symposium; Parenti, C.V., Schiehlen, W., Eds.; Springer: Vienna, Austria, 2010; Volume 524, pp. 249–256. [Google Scholar]

- Buschmann, T.; Lobmeier, S.; Ulbrich, H. Humanoid robot LOLA: Design and walking control. J. Physiol. Paris 2009, 103, 141–148. [Google Scholar] [CrossRef] [PubMed]

- Fondahl, K.; Kuehn, D.; Beinersdorf, F.; Bernhardy, F.; Grimminger, F.; Schillingy, M.; Starky, T.; Kirchneret, F. An adaptive sensor foot for a bipedal and quadrupedal robot. In Proceedings of the Fourth IEEE RAS/EMBS International Conference on Biomedical Robotics and Biomechatronics, Rome, Italy, 24–27 June 2012; pp. 270–275. [Google Scholar]

- Yamamoto, K.; Sugihara, T.; Nakamura, Y. Toe joint mechanism using parallel four-bar linkage enabling humanlike multiple support at toe pad and toe tip. In Proceedings of the 2007 IEEE International Conference on Humanoid Robots, Pittsburgh, PA, USA, 29 November–1 December 2007; pp. 410–415. [Google Scholar]

- Kang, H.; Hashimoto, K.; Kondo, H.; Hattori, K.; Nishikawa, K.; Hama, Y.; Lim, H.; Takanishi, A.; Suga, K.; Kato, K. Realization of biped walking on uneven terrain by new foot mechanism capable of detecting ground surface. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010; pp. 5167–5172. [Google Scholar]

- Yang, H.; Shuai, M.; Qiu, Z.; Wei, H.; Zheng, Q. A novel design of flexible foot system for humanoid robot. In Proceedings of the 2008 IEEE Conference on Robotics, Automation and Mechatronics, Chengdu, China, 21–24 September 2008; pp. 824–828. [Google Scholar]

- Piazza, C.; Santina, C.D.; Gasparri, G.M.; Catalano, M.G.; Grioli, G.; Garabini, M.; Bicchi, A. Toward an adaptive foot for natural walking. In Proceedings of the 2016 IEEE-RAS 16th International Conference on Humanoid Robots, Cancun, Mexico, 15–17 November 2016; pp. 1204–1210. [Google Scholar]

- Nagarajaiah, S.; Sahasrabudhe, S. Seismic response control of smart sliding isolated buildings using variable stiffness systems: An experimental and numerical study. Earthq. Eng. Struct. Dyn. 2006, 35, 177–197. [Google Scholar] [CrossRef]

- Huang, Y.; Vanderborght, B.; Ham, R.V.; Wang, Q.; Damme, M.V.; Xie, G.; Lefeber, D. Step length and velocity control of a dynamic bipedal walking robot with adaptable compliant joints. IEEE/ASME Trans. Mechatron. 2013, 18, 598–611. [Google Scholar] [CrossRef]

- Wang, R.J.; Huang, H.P. AVSER—Active variable stiffness exoskeleton robot system: Design and application for safe active-passive elbow rehabilitation. In Proceedings of the 2012 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Kachsiung, Taiwan, 11–14 July 2012; pp. 220–225. [Google Scholar]

- Wu, Y.S.; Lan, C.C. Design of a linear variable-stiffness mechanism using preloaded bistable beams. In Proceedings of the 2014 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Besacon, France, 8–11 July 2014; pp. 605–610. [Google Scholar]

- Kuder, I.K.; Arrieta, A.F.; Raither, W.E.; Ermanni, P. Variable stiffness material and structural concepts for morphing applications. Prog. Aerosp. Sci. 2013, 63, 33–55. [Google Scholar] [CrossRef]

- Kind, R.J. Pneumatic stiffness and damping in air-supported structures. J. Wind Eng. Ind. Aerodyn. 1984, 17, 295–304. [Google Scholar] [CrossRef]

- Pan, P.; Liao, G.; Yan, G.; Zhao, Y. Calculation of elastic deformation for the sealing gasket. J. Harbin Inst. Technol. 1996, 28, 130–134. [Google Scholar]

- Liu, H.; Lee, J.C. Model development and experimental research on an air spring with auxiliary reservoir. Int. J. Automot. Technol. 2011, 12, 839–847. [Google Scholar] [CrossRef]

- Wickramatunge, K.C.; Leephakpreeda, T. Empirical modeling of dynamic behaviors of pneumatic artificial muscle actuators. ISA Trans. 2013, 52, 825–834. [Google Scholar] [CrossRef] [PubMed]

- Chou, C.P.; Hannaford, B. Static and dynamic characteristics of McKibben pneumatic artificial muscles. In Proceedings of the 1994 IEEE International Conference on Robotics and Automation, San Diego, CA, USA, 8–13 May 1994; pp. 281–286. [Google Scholar]

- Carbone, G. Stiffness analysis and experimental validation of robotic systems. Front. Mech. Eng. 2011, 6, 182–196. [Google Scholar]

- Liu, Y.; Zang, X.; Liu, X.; Wang, L. Design of a biped robot actuated by pneumatic artificial muscles. Bio-Med. Mater. Eng. 2015, 26, 757–766. [Google Scholar] [CrossRef] [PubMed]

- Klein, T.; Lewis, M.A. A neurorobotic model of bipedal locomotion based on principles of human neuromuscular architecture. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012; pp. 1450–1455. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zang, X.; Liu, Y.; Li, W.; Lin, Z.; Zhao, J. Design and Experimental Development of a Pneumatic Stiffness Adjustable Foot System for Biped Robots Adaptable to Bumps on the Ground. Appl. Sci. 2017, 7, 1005. https://doi.org/10.3390/app7101005

Zang X, Liu Y, Li W, Lin Z, Zhao J. Design and Experimental Development of a Pneumatic Stiffness Adjustable Foot System for Biped Robots Adaptable to Bumps on the Ground. Applied Sciences. 2017; 7(10):1005. https://doi.org/10.3390/app7101005

Chicago/Turabian StyleZang, Xizhe, Yixiang Liu, Wenyuan Li, Zhenkun Lin, and Jie Zhao. 2017. "Design and Experimental Development of a Pneumatic Stiffness Adjustable Foot System for Biped Robots Adaptable to Bumps on the Ground" Applied Sciences 7, no. 10: 1005. https://doi.org/10.3390/app7101005