Parameters Sensitivity Analysis of Position-Based Impedance Control for Bionic Legged Robots’ HDU

Abstract

:1. Introduction

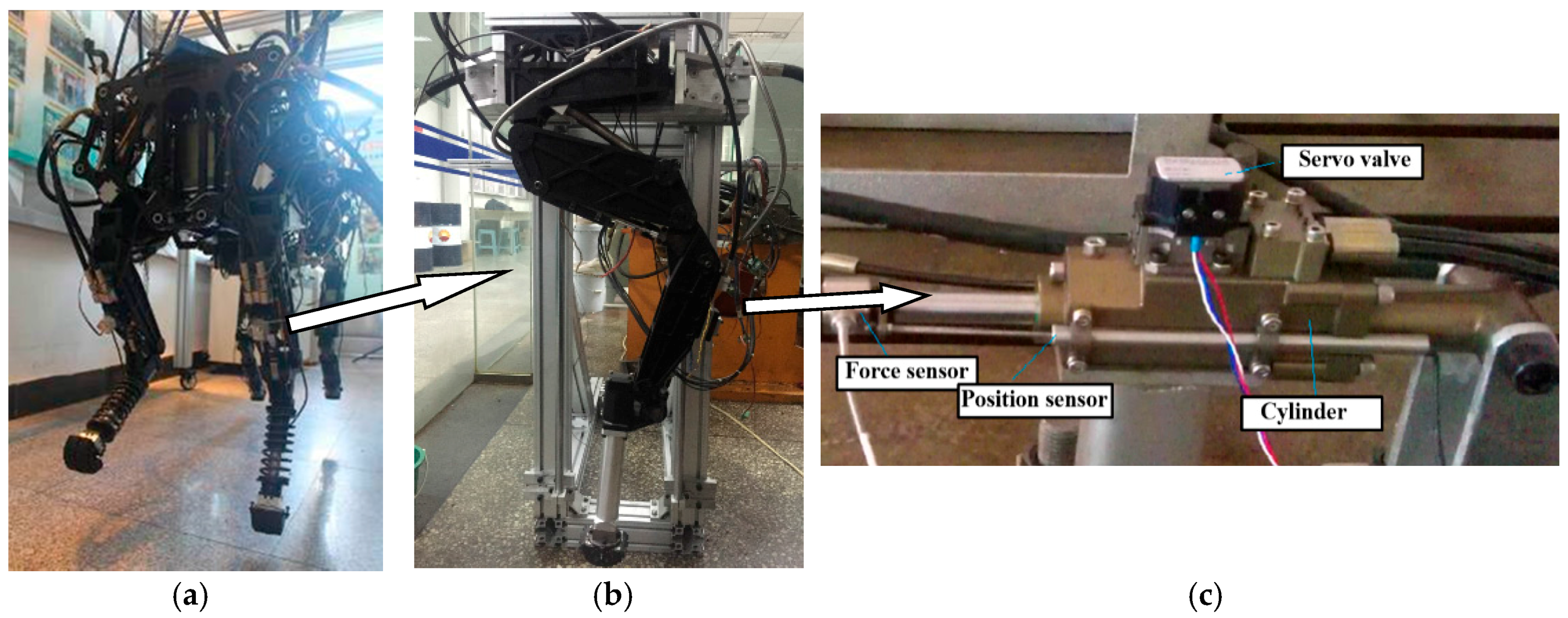

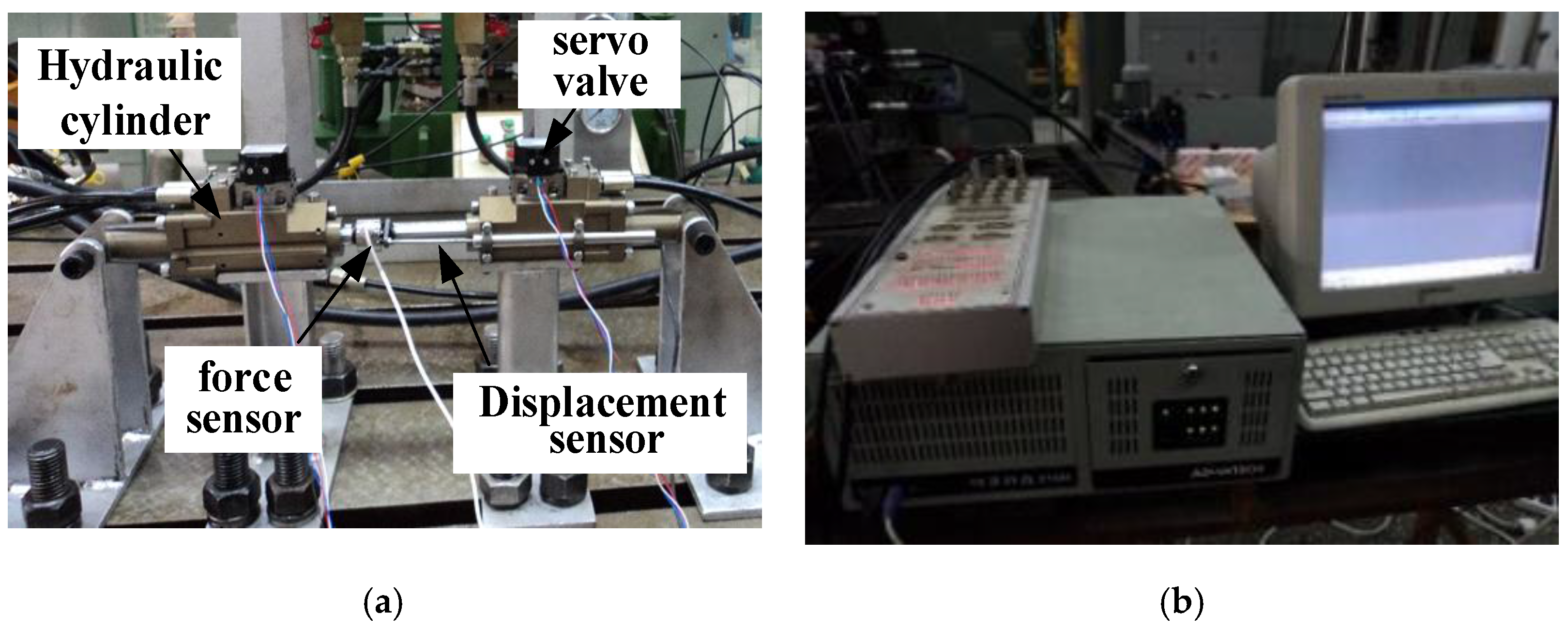

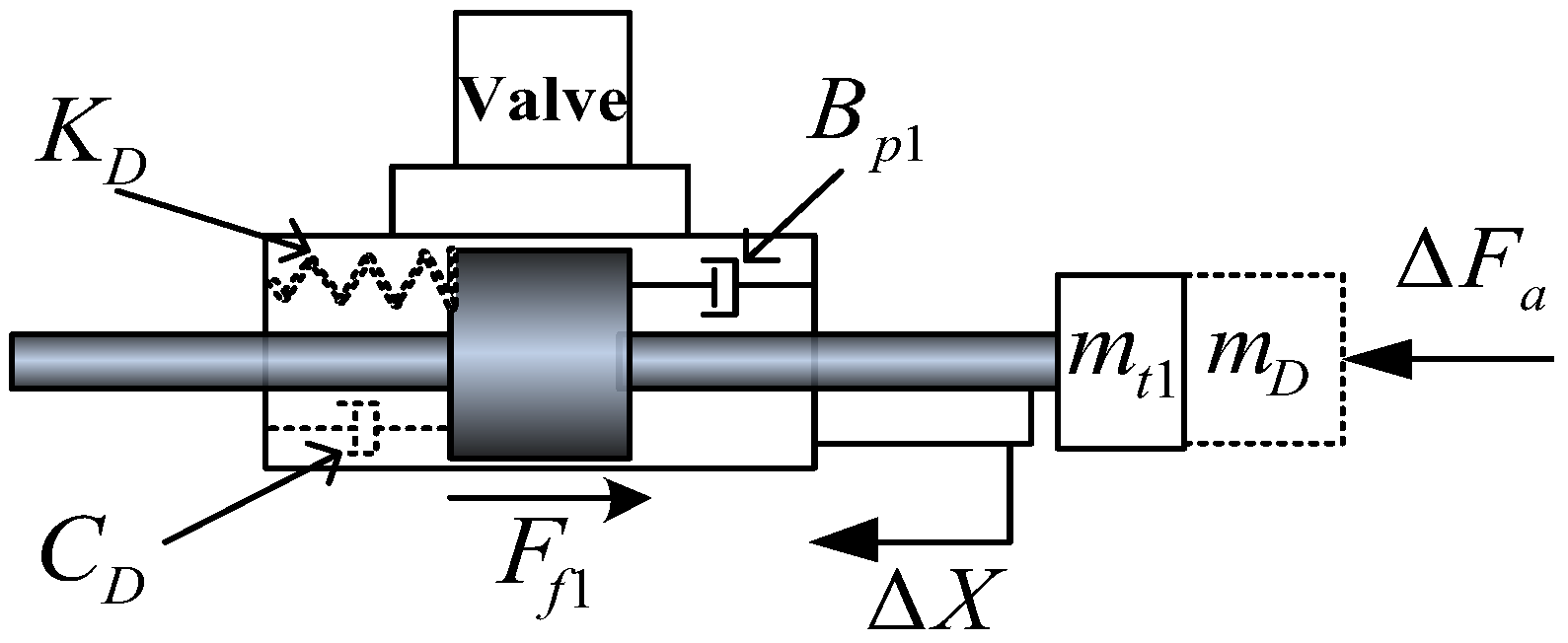

2. Introduction of the HDU and Its Performance Test Platform

3. HDU Position-Based Impedance Control

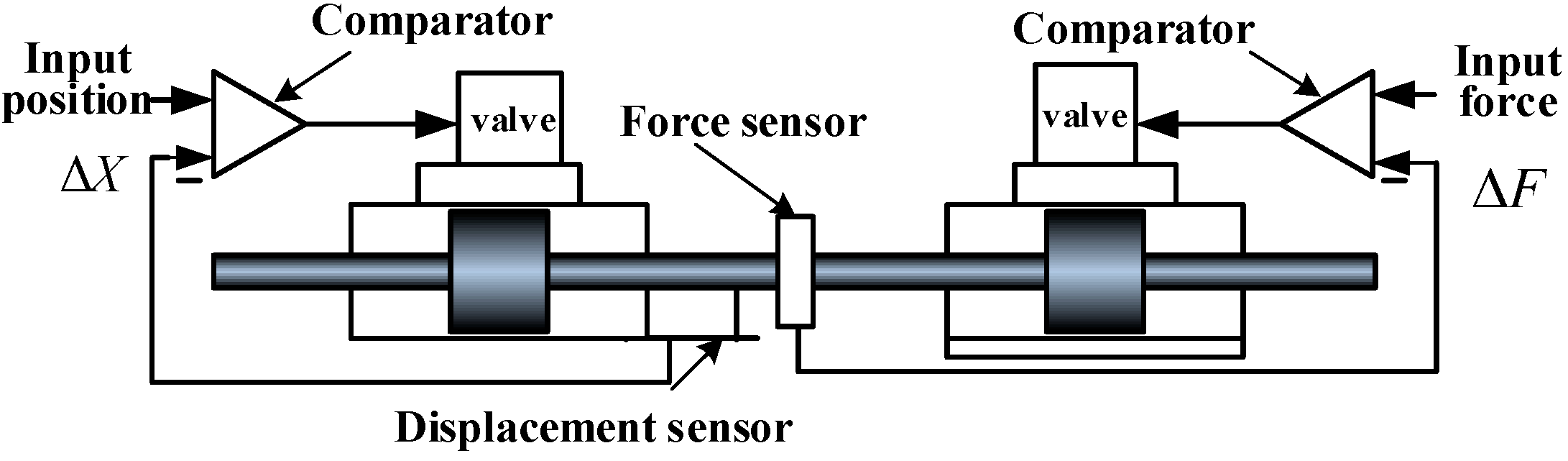

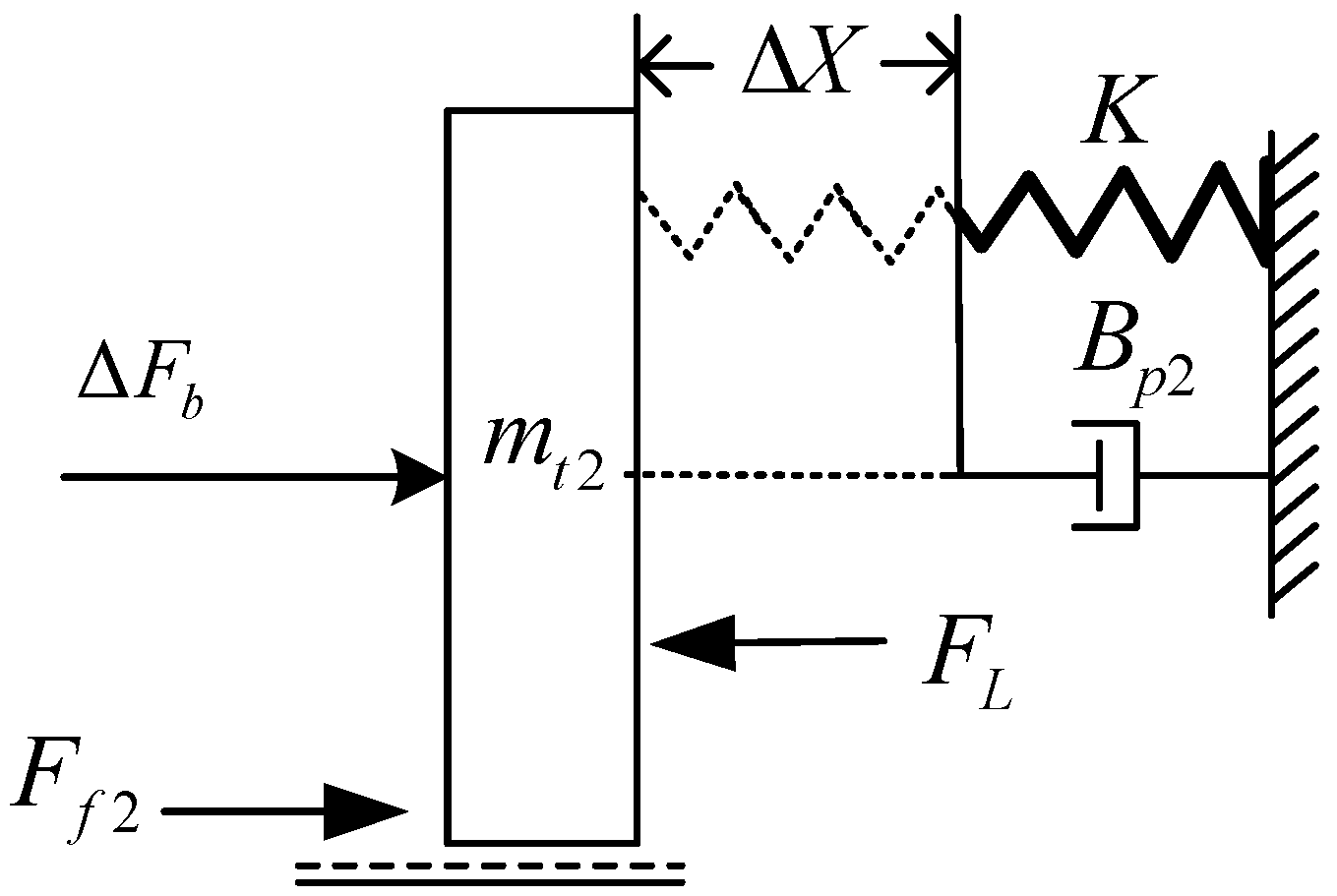

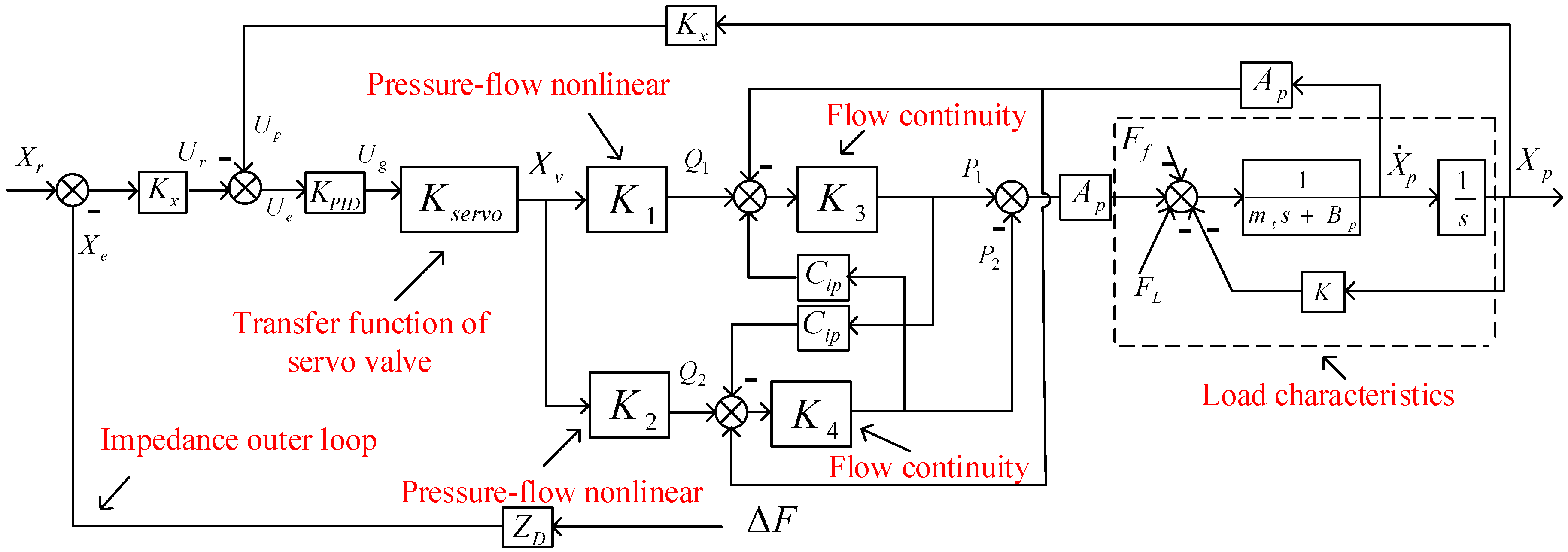

3.1. Mathematic Model of HDU Position-Based Impedance Control

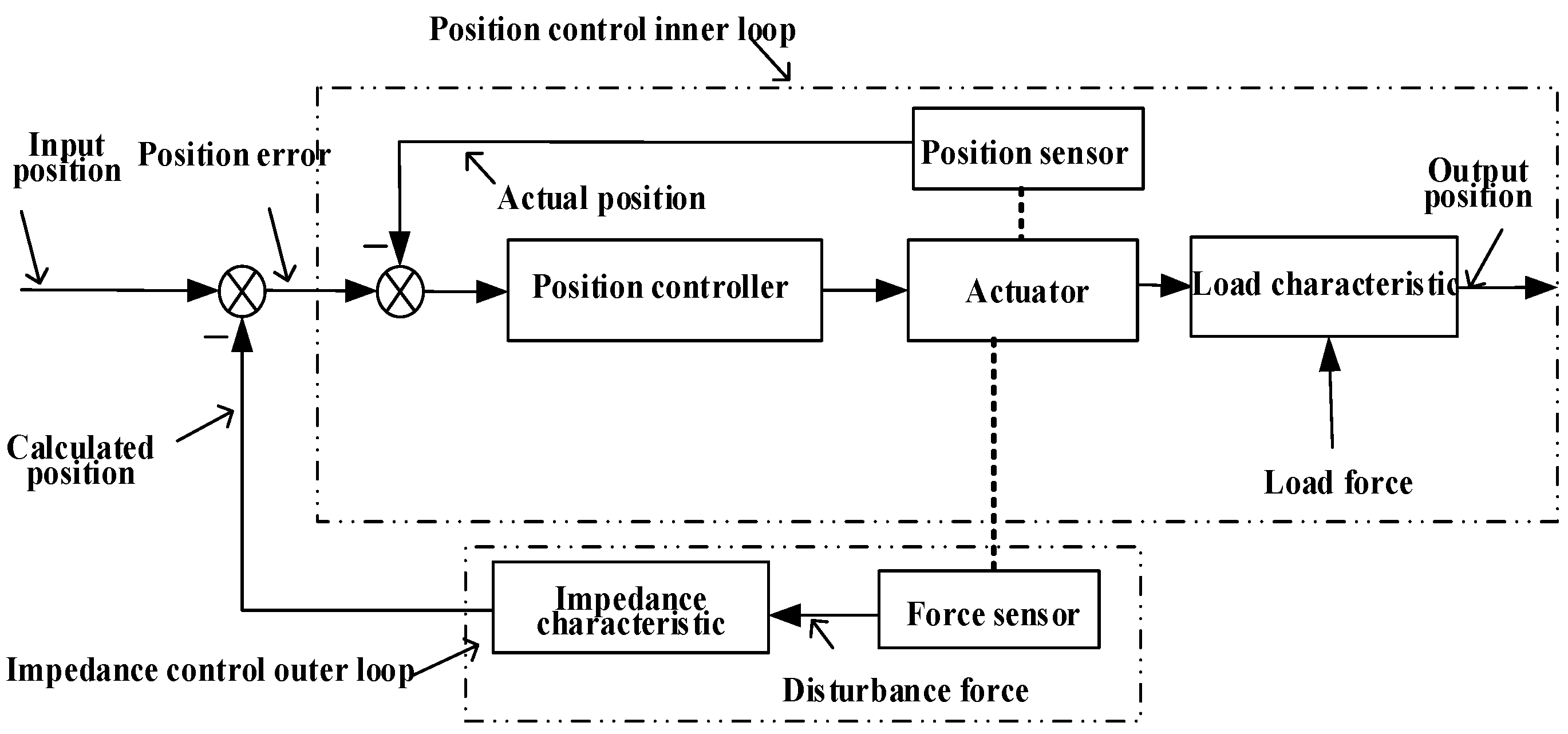

3.1.1. Principles of Impedance Control

3.1.2. The Block Diagram and State Space Presentation of Impedance Control System

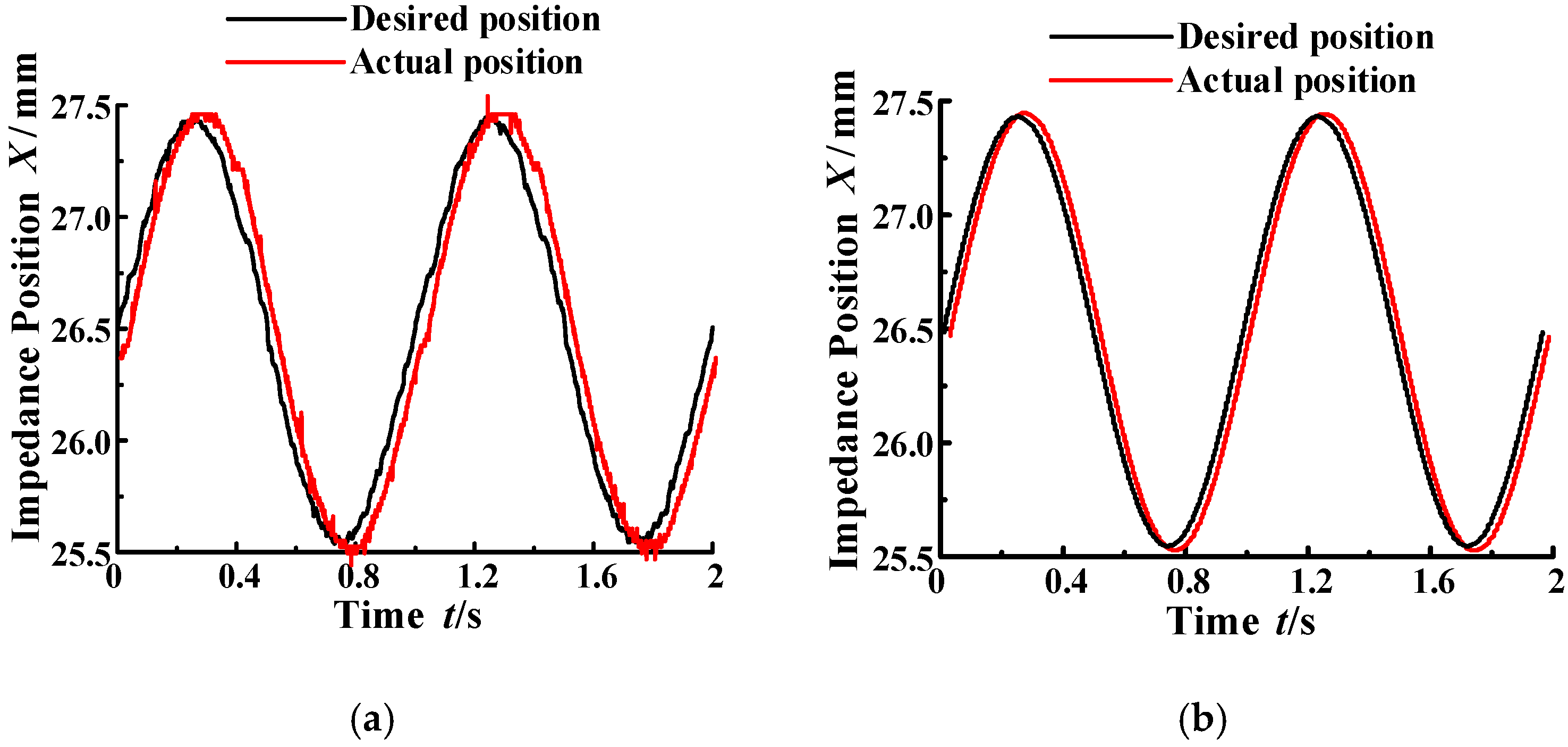

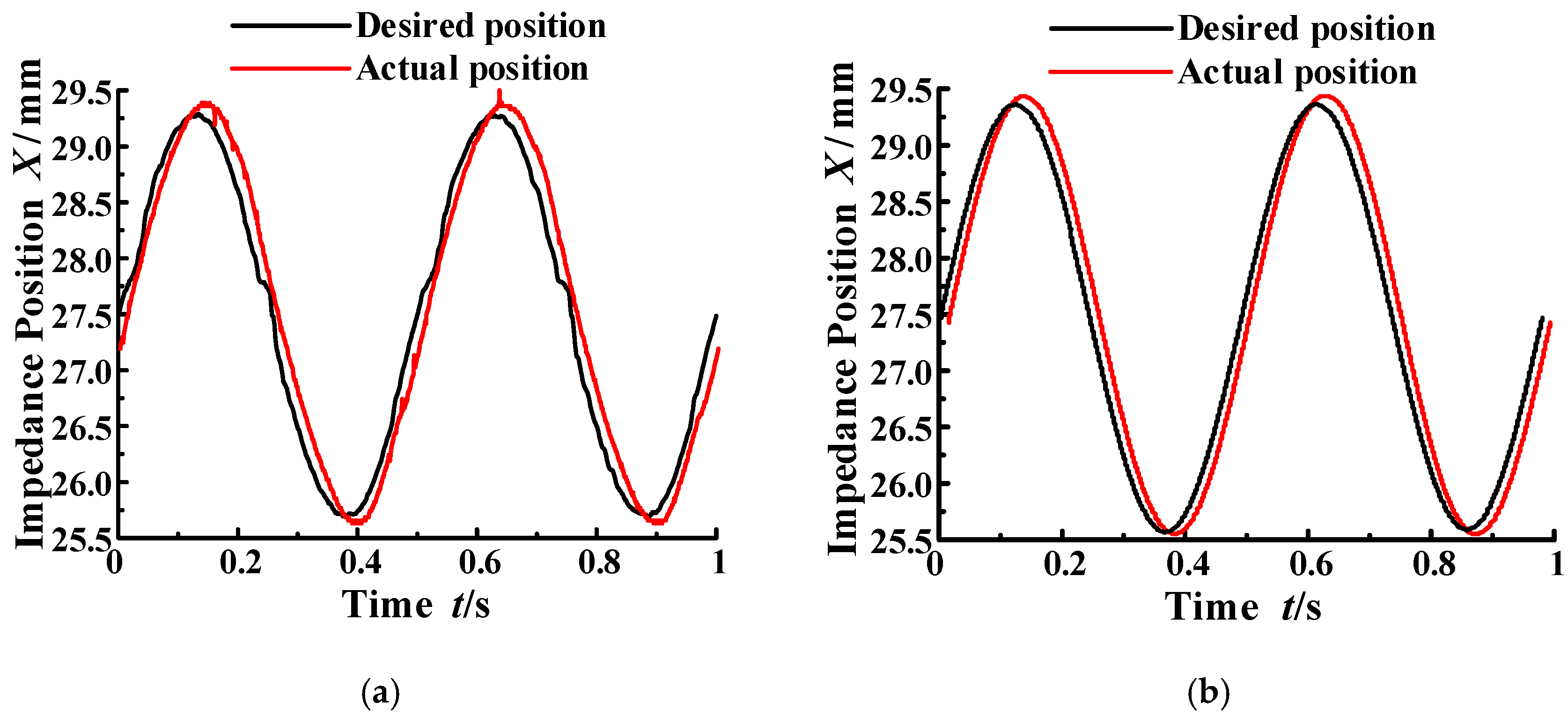

3.2. Experiment of Position-Based Impedance Control

4. Methods of Sensitivity Analysis

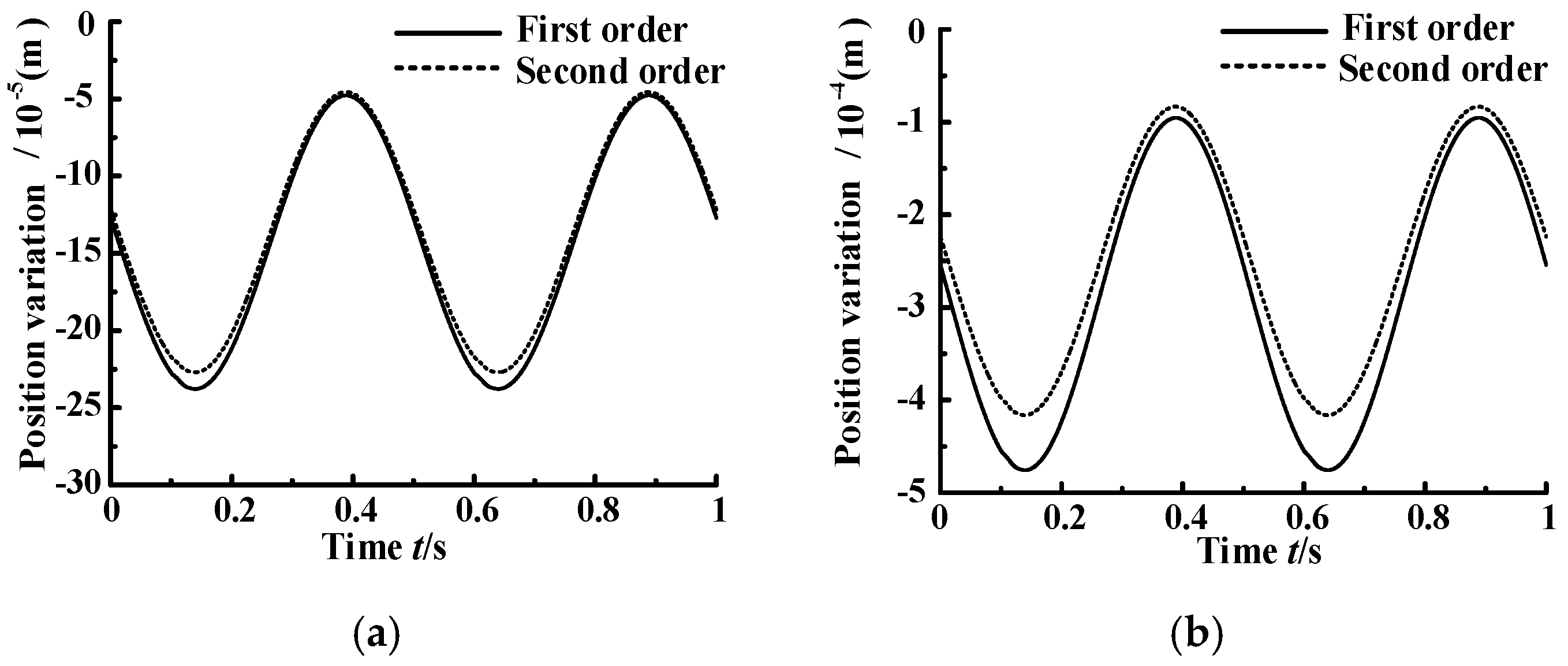

4.1. Contrast between First-Order and Second-Order Sensitivity Analysis

4.2. Deduction of First-Order Matrix Sensitivity Analysis Theory

5. Dynamic Sensitivity Analysis

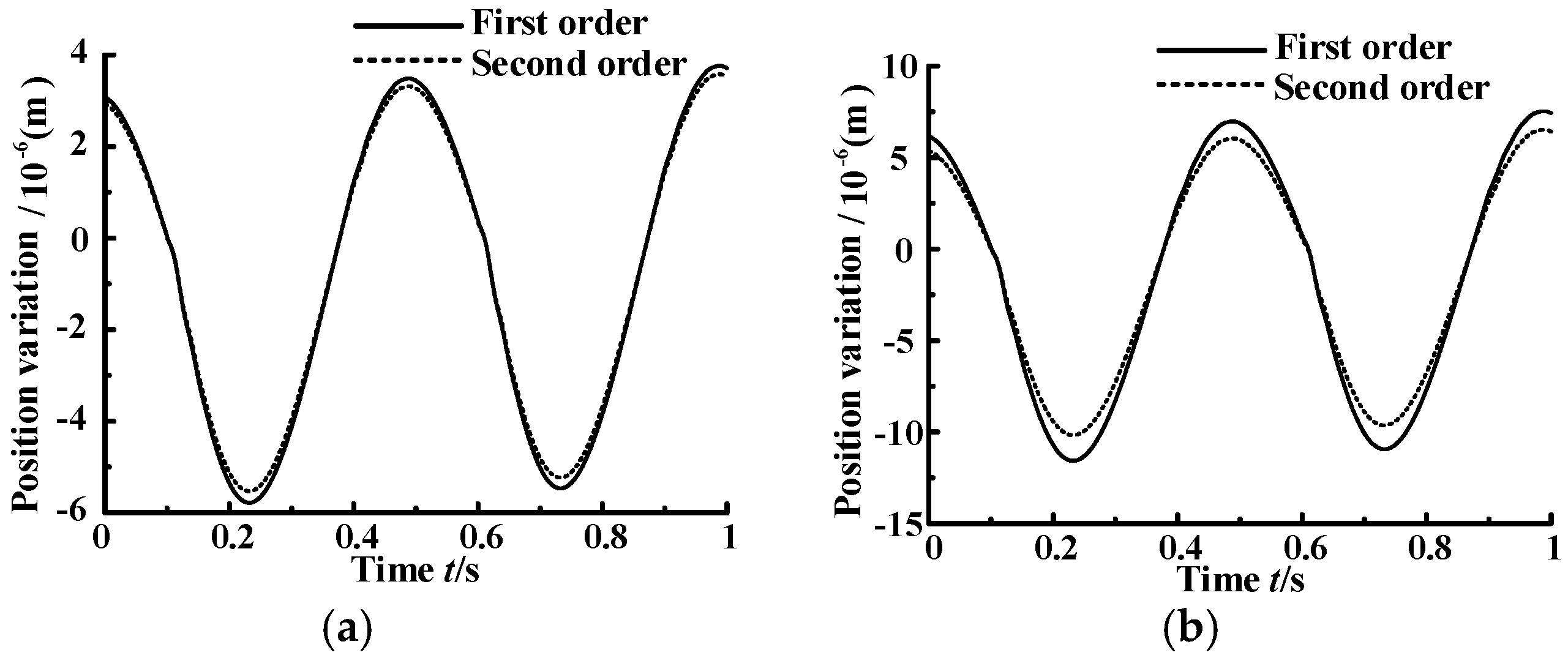

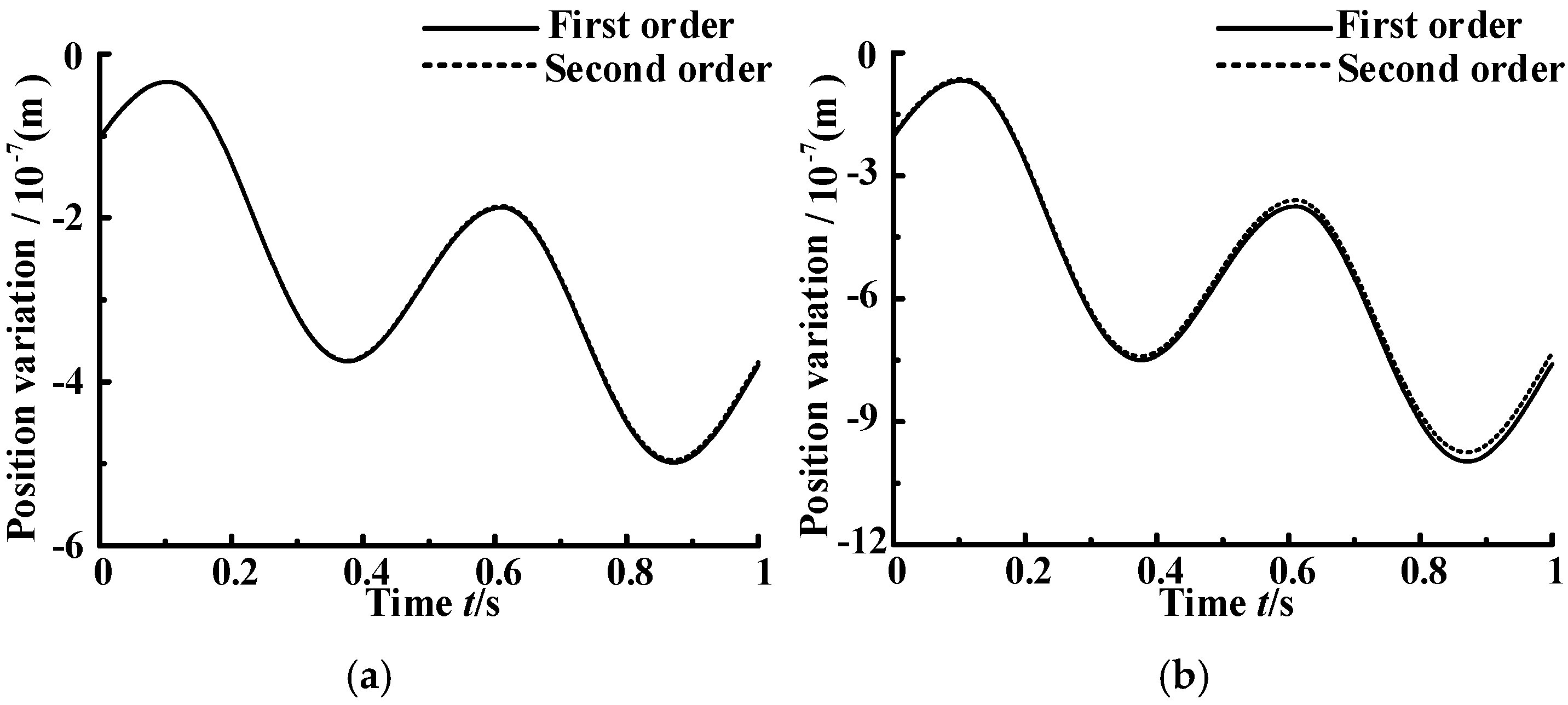

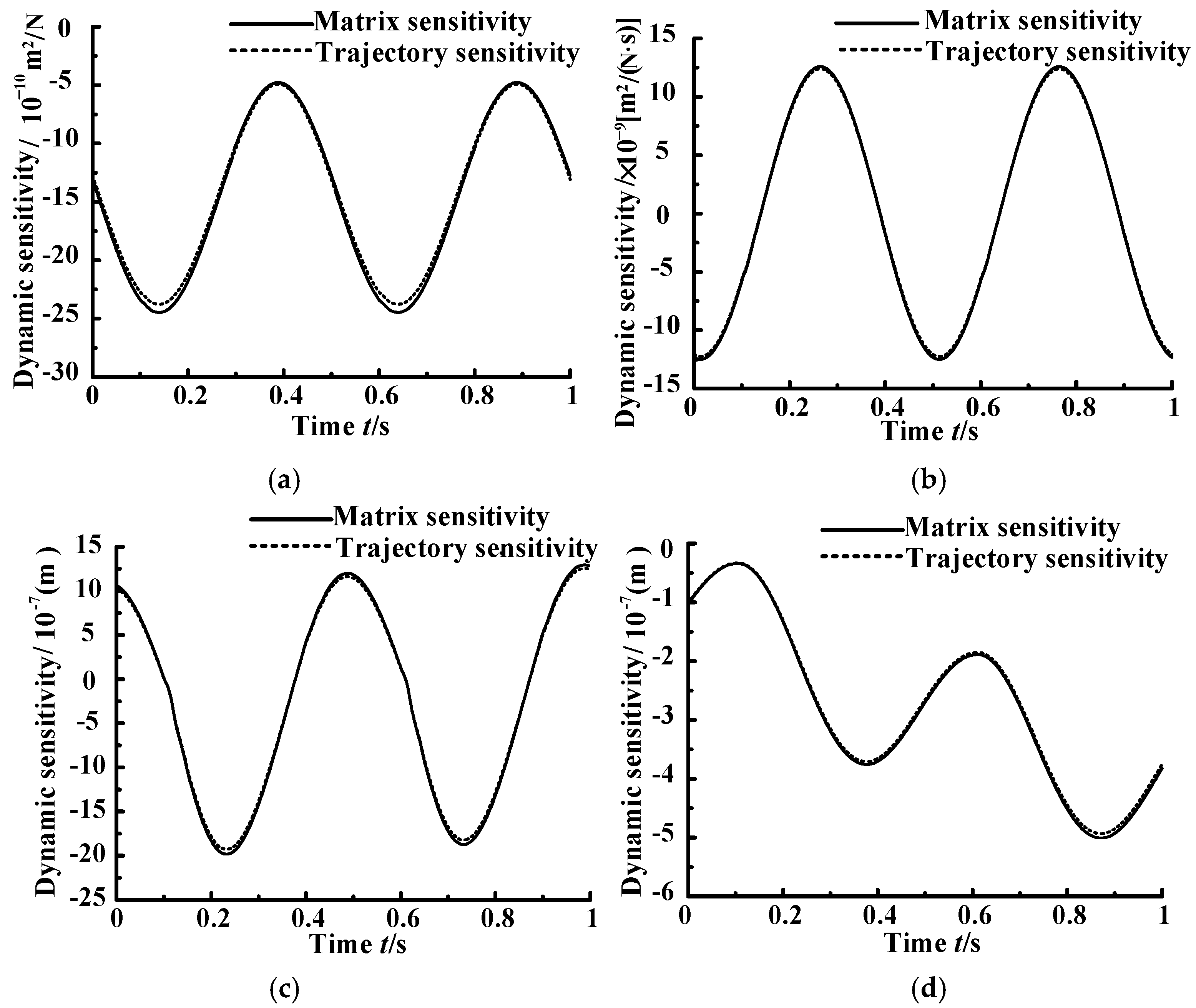

5.1. Contrast between Two Analysis Method of First-Order Sensitivity

5.2. Contrast of Dynamic Sensitivity Analysis in Each Working Condition

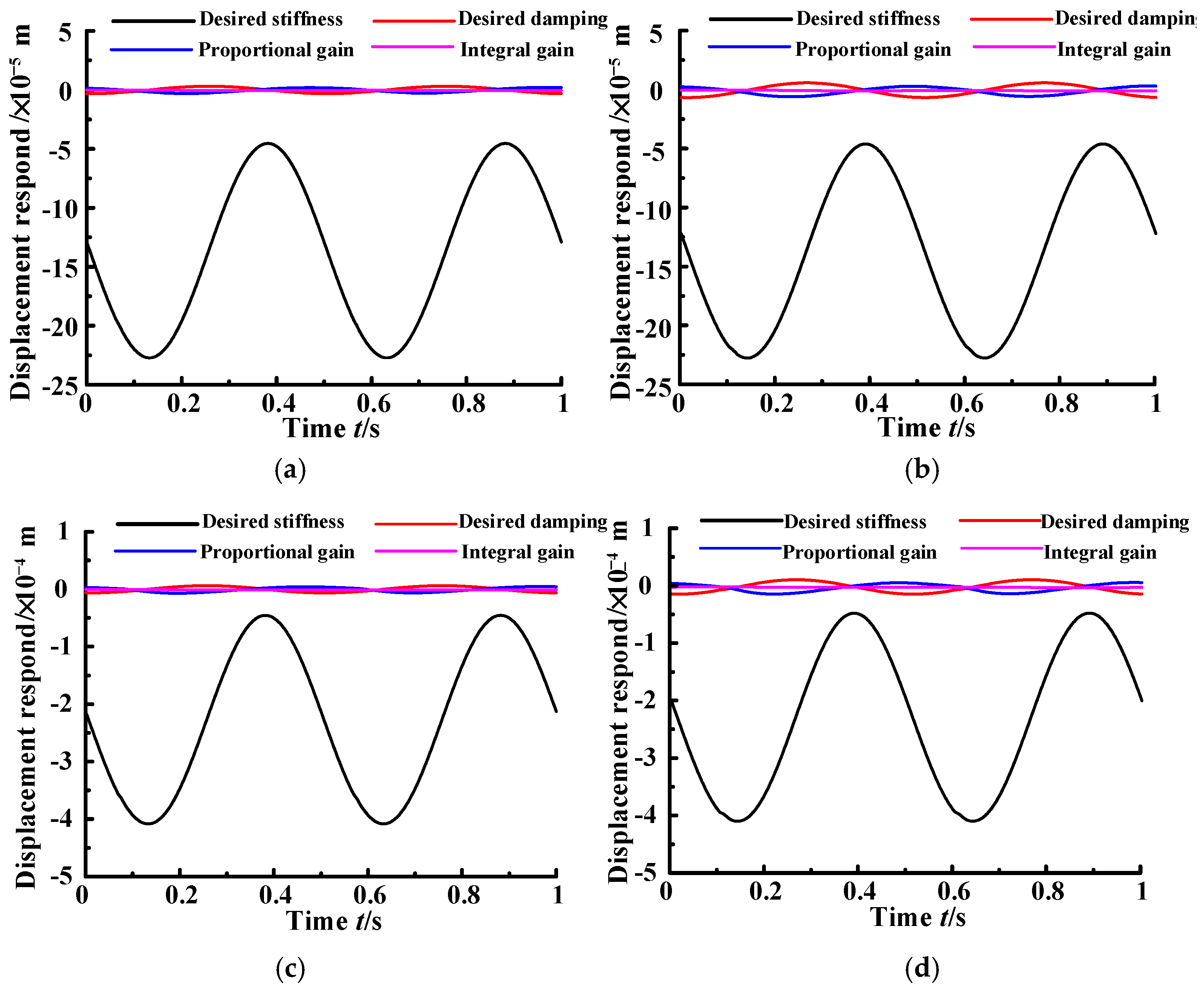

- The variation of each parameter affects impedance control position output. The position varies periodically with the sinusoidal disturbance force. Among the parameters, the desired stiffness affects the output position much more than the others. The influence from integral gain is the most irrelevant. Desired damping and proportional gain have similar influences on the output position. With the disturbance force in sinusoidal variation, varies by following the curve of minus cosine, and varies by following the curve of cosine.

- The order of magnitudes of output position increases with the increase of sinusoidal disturbance force. However, there isn’t an obvious relationship between the effects on output position and the frequency of the disturbance force.

6. Sensitivity Quantitative Analysis

6.1. Sensitivity Indexes

6.2. Sensitivity Histograms in Different Working Conditions

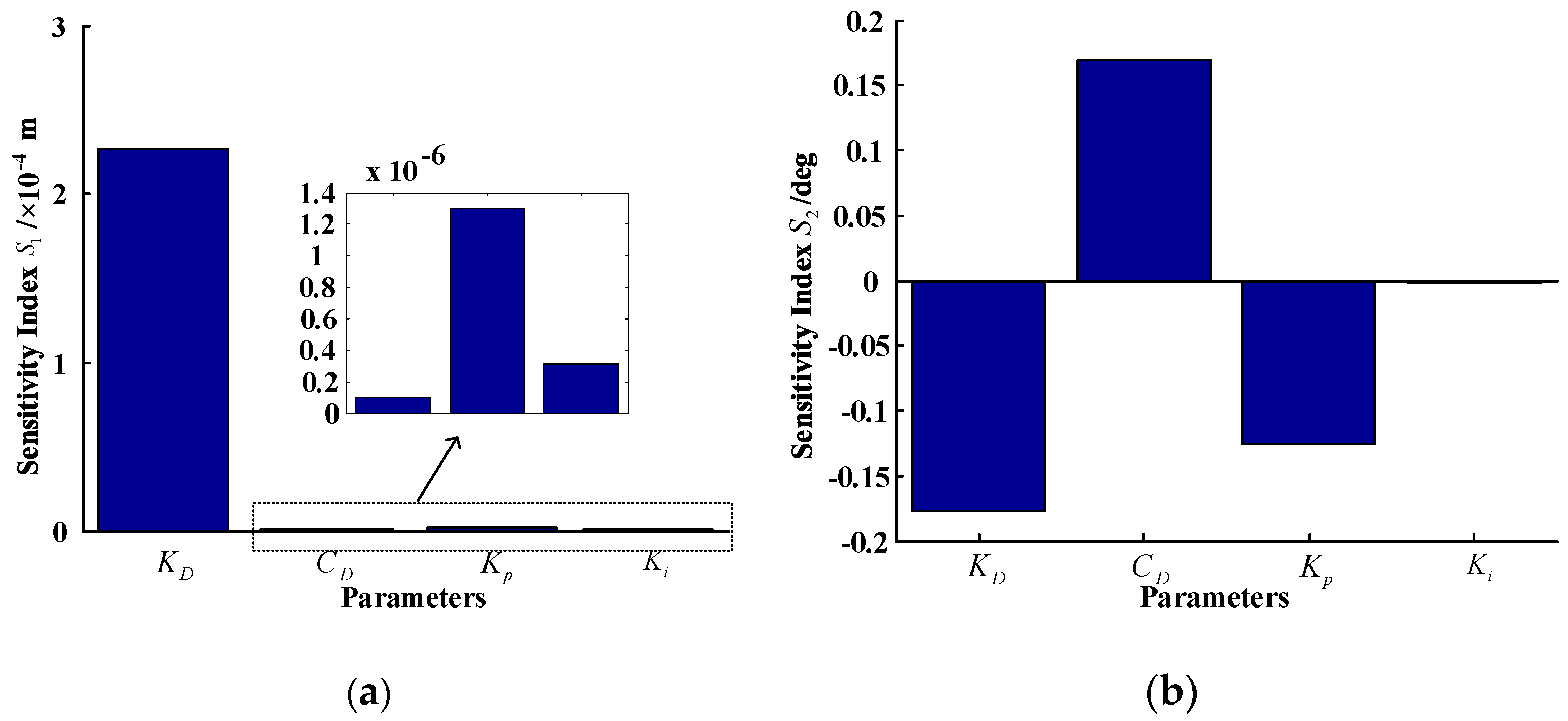

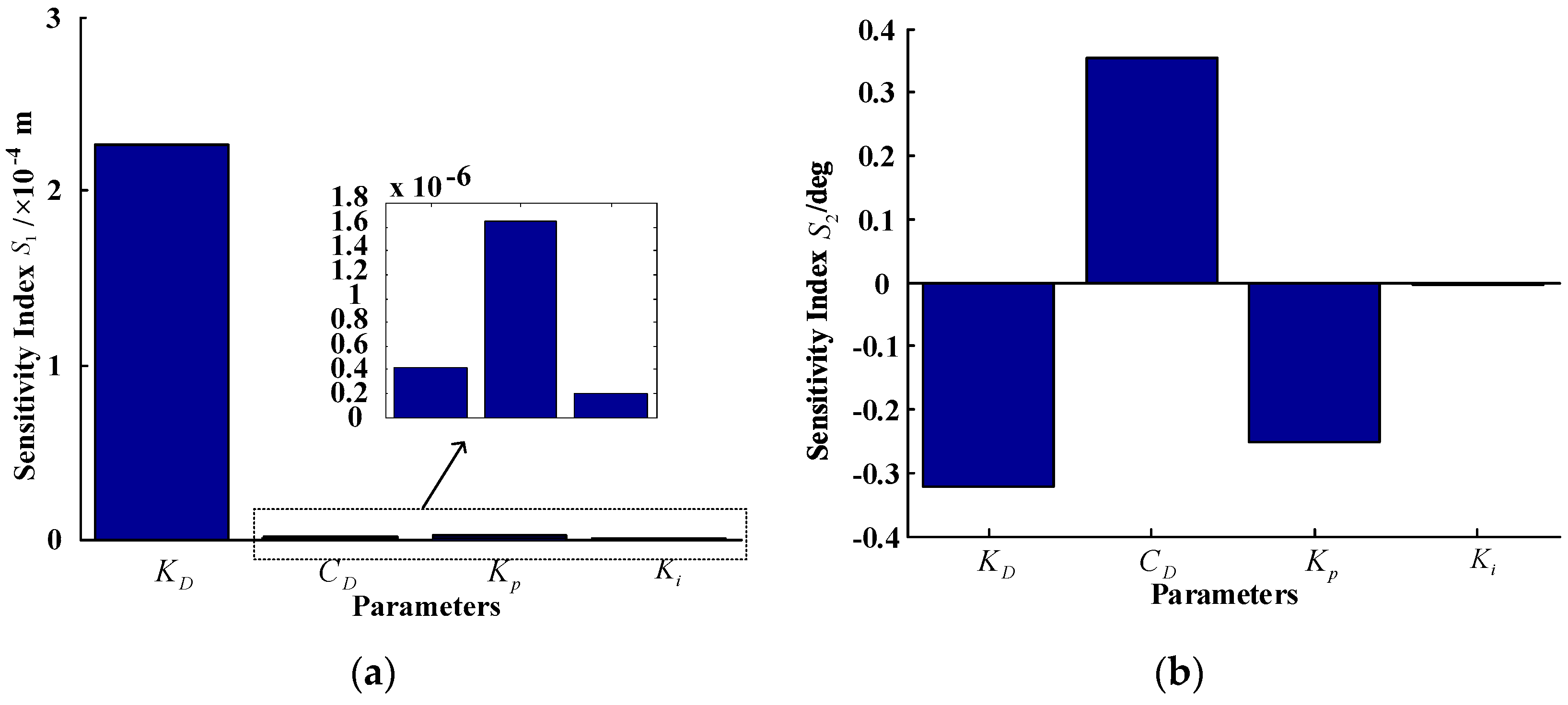

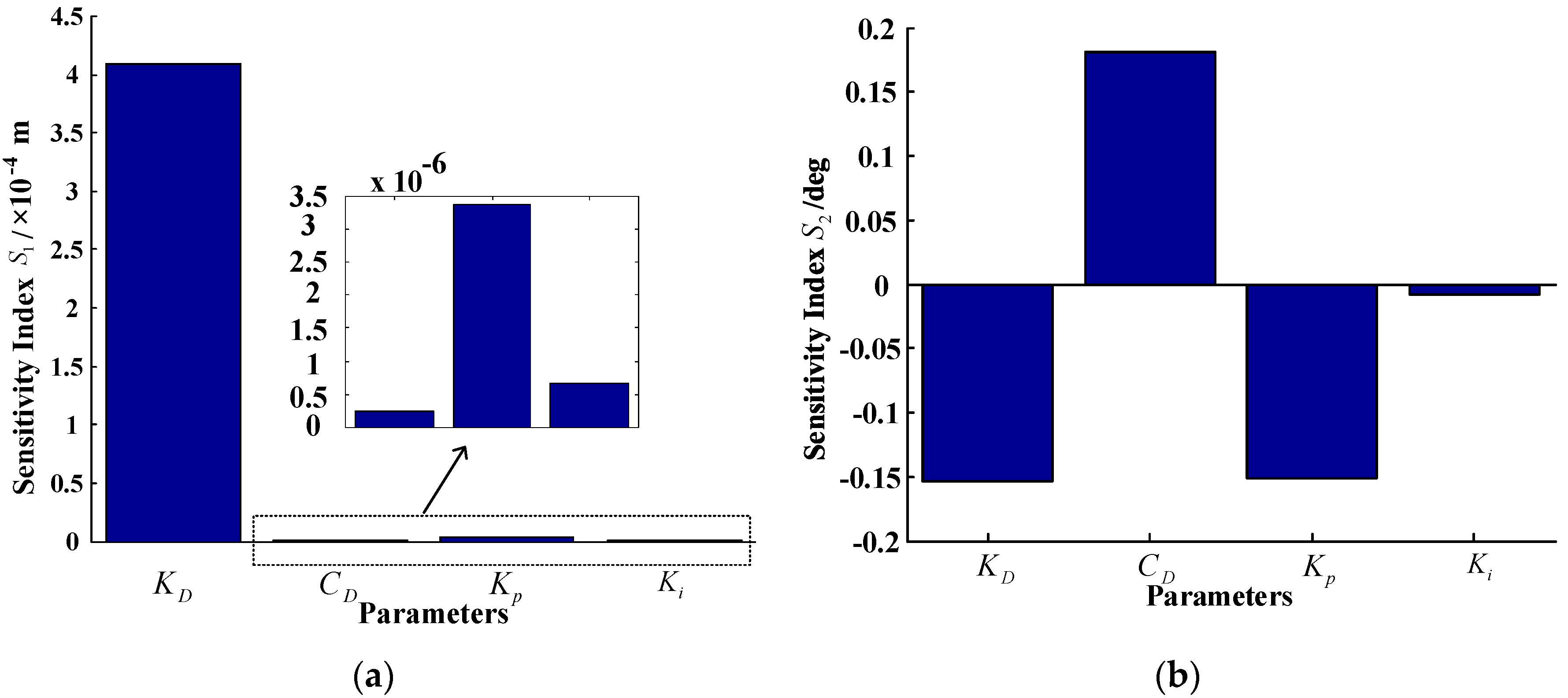

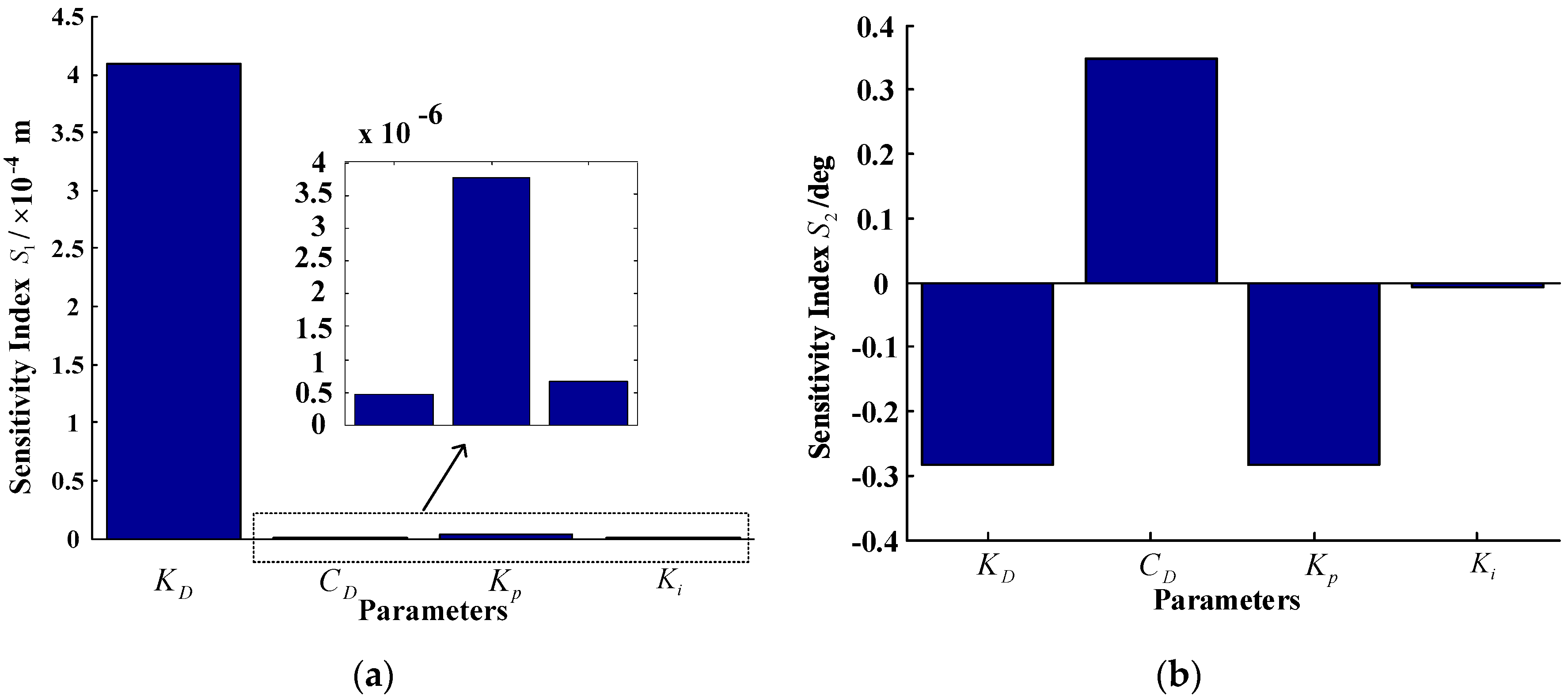

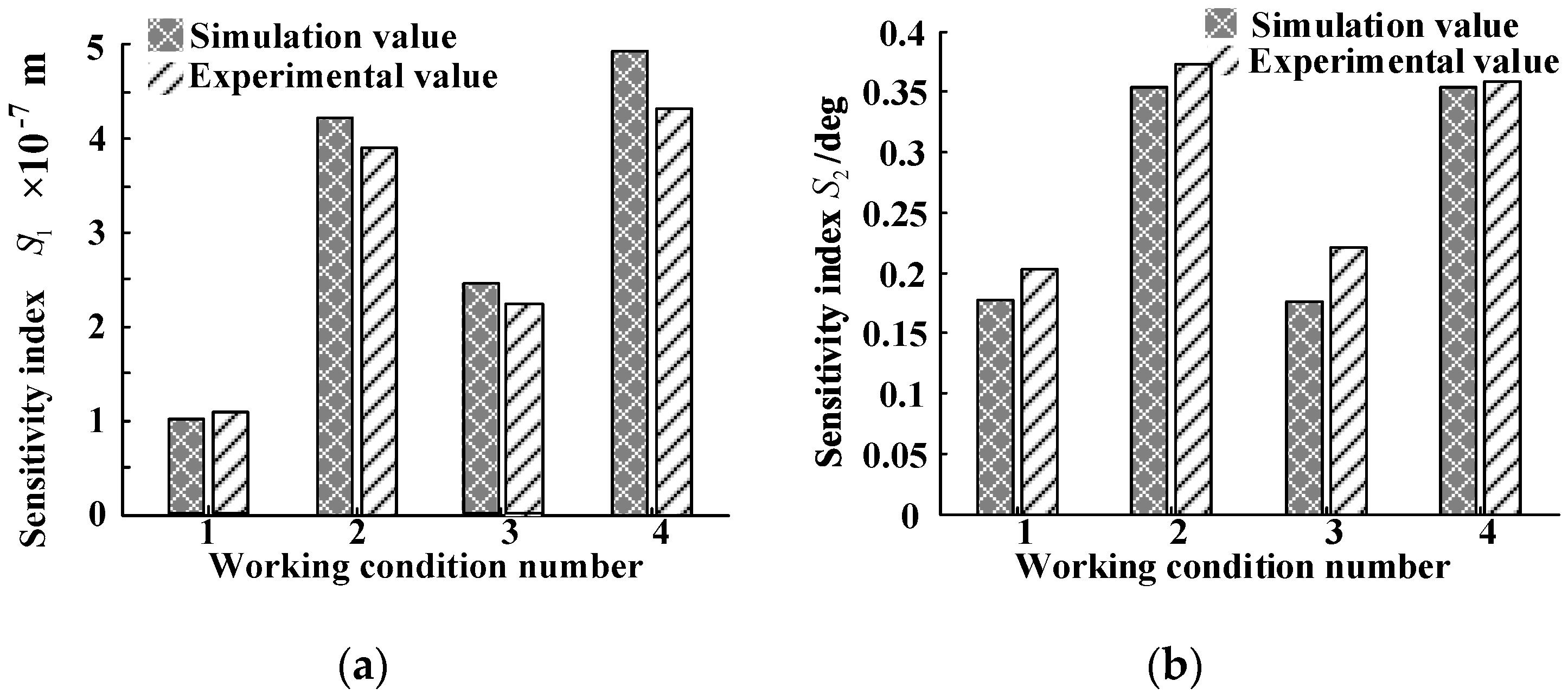

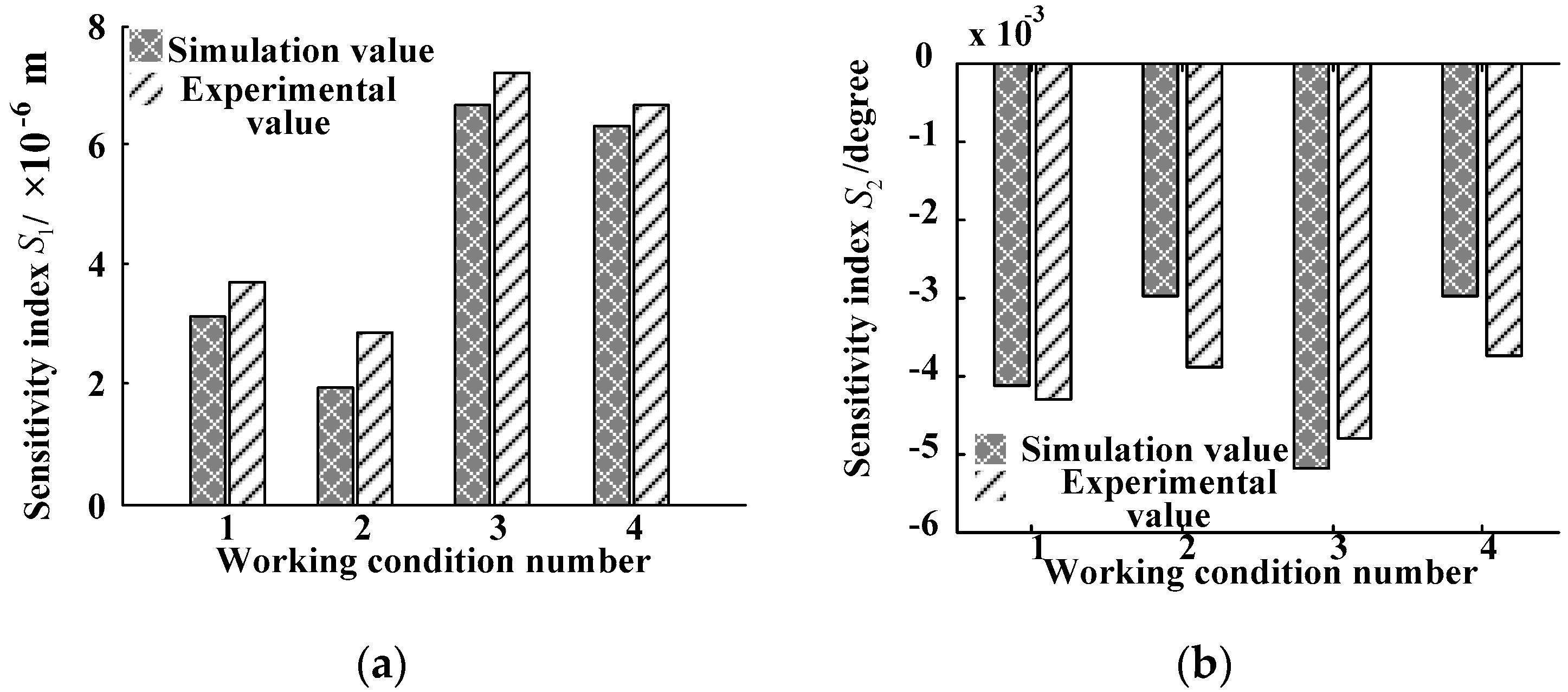

- In all conditions, is a positive value, so the increase of the four parameters will result in the reduction of the position amplitude attenuation. The of desired stiffness is much greater than the other parameters, which illustrates that the variation of has a remarkable influence on output position amplitude attenuation, and more relation with disturbance force amplitude than the disturbance force frequency. Under the first working condition, amplitude attenuation reduced about 0.2 mm when increased 10%. The of proportional gain is greater than that of and . The of and have some correlation with disturbance force amplitude, but have little correlation with disturbance force frequency.

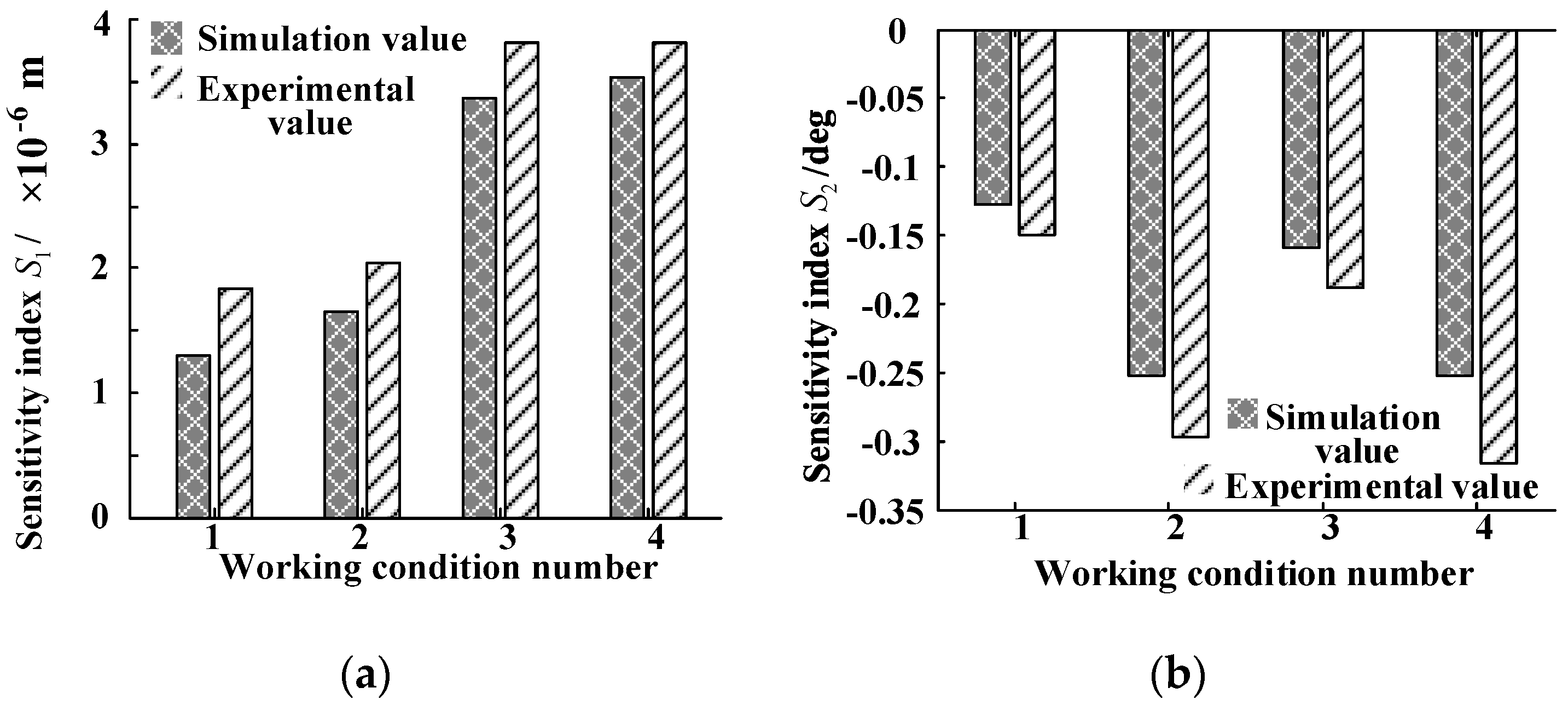

- The of the four control parameters has positive or negative values in different conditions. An increase of the parameters has different influences on the phase angle delay of the output position. Specifically, having more relation with disturbance force frequency than the amplitude, the of and have nearly the same absolute value, but an opposite sign. Their increase has totally different influences on phase angle delay. An approximate 10% increase of them generates about 0.18° of phase angle delay error. The of has correlation with both disturbance force amplitude and frequency. The larger the frequency, the more remarkable the influence on phase delay. The of is close to the of . The of is about 0.001° on magnitude order, much less than the other control parameters.

7. Experiment

8. Conclusions

- Sensitivity analysis method is used to analyze the four parameters, which are the proportional gain and integral gain of the inner loop PID controller, and the desired stiffness and desired damping of the impedance outer loop. The first-order and second-order effects on position are analyzed by the trajectory sensitivity analysis, when the four parameters increase no more than 20%. In spite of its higher accuracy, the second-order sensitivity analysis requires a complex solving process with lots of hard work. Considering that the largest error between the first-order and second-order sensitivity analysis methods is below 20% of the amplitude, this paper proposed the easier first-order matrix sensitivity analysis method. Compared with first-order trajectory sensitivity, the first-order matrix sensitivity method is simpler and more accurate in computing.

- The effects of parameter variation on output position varies periodically with sinusoidal disturbance force. Among the parameters, desired stiffness affects the output position much more than the other parameters. The influence of integral gain is the least. Desired damping and proportional gain have a similar influence on the output position.

- The of each parameter is a positive value, which shows that the increase of the four parameters will result in the reduction of the position amplitude attenuation. The of each parameter has positive or negative values in different conditions. Their increase has different influences on the phase angle delay of output positions.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Montes, H.; Armada, M. Force Control Strategies in Hydraulically Actuated Legged Robots. Int. J. Adv. Robot. Syst. 2016, 13, 50. [Google Scholar] [CrossRef]

- Nabulsi, S.; Sarria, J.; Montes, H.; Armada, M. High Resolution Indirect Feet-Ground Interactions Measurement for Hydraulic Legged Robots. J. IEEE Trans. Instrum. Meas. 2009, 58, 3396–3404. [Google Scholar] [CrossRef]

- Huang, Q.; Oka, K. Phased compliance control with virtual force for six-legged walking robot. Int. J. Innov. Comput. Inf. Control 2008, 4, 3359–3373. [Google Scholar]

- Kong, X.D.; Ba, K.X.; Yu, B.; Cao, Y.; Zhu, Q.; Zhao, H. Research on the force control compensation method with variable load stiffness and damping of the hydraulic drive unit force. Chin. J. Mech. Eng. (English Ed.) 2016, 29, 454–464. [Google Scholar] [CrossRef]

- Ba, K.X.; Yu, B.; Kong, X.D.; Zhao, H.-L.; Zhao, J.-S.; Zhu, Q.-X.; Li, C.-H. The dynamic compliance and its compensation control research of the highly integrated valve-controlled cylinder position control system. Int. J. Control Autom. Syst. 2017, 15, 1814–1825. [Google Scholar] [CrossRef]

- Li, M.T.; Jiang, Z.Y.; Wang, P.F.; Sun, L.N.; Ge, S.S. Control of a Quadruped Robot with Bionic Springy Legs in Trotting Gait. J. Bionic Eng. 2014, 11, 188–198. [Google Scholar] [CrossRef]

- Kimura, H.; Fukuoka, Y.; Cohen, A.H. Adaptive dynamic walking of a quadruped robot on natural ground based on biological concepts. Int. J. Robot. Res. 2007, 26, 475–490. [Google Scholar] [CrossRef]

- Poulakakis, I.; Smith, J.A.; Buehler, M. Modeling and experiments of untethered quadrupedal running with a bounding gait: The scout ii robot. Int. J. Robot. Res. 2005, 24, 239–256. [Google Scholar] [CrossRef]

- Seok, S.; Wang, A.; Meng, Y.C.; Otten, D. Design principles for highly efficient quadrupeds and implementation on the MIT Cheetah robot. In Proceedings of the IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 3307–3312. [Google Scholar]

- Playter, R.; Buehler, M.; Raibert, M. BigDog. In Unmanned Systems Technology VIII, Proceedings of SPIE; SPIE: Bellingham, WA, USA, 2006; Volume 6230, pp. 1–6. [Google Scholar]

- Semini, C.; Barasuol, V.; Boaventura, T.; Frigerio, M.; Focchi, M. Towards versatile legged robots through active impedance control. Int. J. Robot. Res. 2015, 34, 1003–1020. [Google Scholar] [CrossRef]

- Rong, X.; Li, Y.; Ruan, J.; Li, B. Design and simulation for a hydraulic actuated quadruped robot. J. Mech. Sci. Technol. 2012, 26, 1171–1177. [Google Scholar] [CrossRef]

- Vilenus, M. The Application of Sensitivity Analysis to Electrohydraulic Position Control Servos. J. Dyn. Syst. Meas. Control 1983, 105, 77–82. [Google Scholar] [CrossRef]

- Farasat, S.; Ajam, H. Sensitivity Analysis of Parameter Changes in Nonlinear Hydraulic Control Systems. Int. J. Eng. 2005, 18, 239–252. [Google Scholar]

- Kong, X.D.; Yu, B.; Quan, L.; Ba, K.; Wu, L. Nonlinear Mathematical Modeling and Sensitivity Analysis of Hydraulic Drive Unit. Chin. J. Mech. Eng. 2015, 28, 999–1011. [Google Scholar] [CrossRef]

- Kong, X.D.; Ba, K.X.; Yu, B.; Quan, L.; Wu, L. Trajectory Sensitivity Analysis of First Order and Second Order on Position Control System of Highly Integrated Valve−controlled Cylinder. J. Mech. Sci. Technol. 2015, 29, 4445–4464. [Google Scholar] [CrossRef]

- Kong, X.; Zhao, H.; Li, B.W.; Ba, K. Analysis of position-based impedance control method and the composition of system dynamic compliance. In Proceedings of the IEEE International Conference on Aircraft Utility Systems (AUS), Beijing, China, 10–12 October 2016; pp. 454–459. [Google Scholar]

| Parameter | Initial Value |

|---|---|

| Gain of servo valve / | 0.0225 |

| Natural frequency of servo valve / | 628 |

| Damping ratio of servo valve | 0.77 |

| Effective piston area Ap/m2 | 3.368 × 10−4 |

| Volume of inlet chamber /m3 | 6.2 × 10−7 |

| Volume of outlet chamber /m3 | 8.6 × 10−7 |

| Piston stroke L/m | 0.05 |

| Initial position of piston L0/m | 0.025 |

| Supply pressure Ps/Pa | 1 × 10−7 |

| Tank pressure P0/Pa | 0.5 × 106 |

| Gain of position sensor /() | 54.9 × 10−3 |

| Outer linkage coefficient of servo valve /(m3/(s·Pa)) | 0 |

| Inner linkage coefficient of servo valve /(m3/(s·Pa)) | 2.38 × 10−13 |

| Equivalent mass mt/kg | 1.1315 |

| Effective bulk modulus βe/Pa | 8 × 108 |

| Conversion coefficient Kd | 1.248 × 10−4 |

| Load stiffness K/(N/m) | 0 |

| Viscous damping coefficient Bp/() | 54.9 × 10−3 |

| proportional gain | 30 |

| differential gain | 10 |

| Desired stiffness /() | 1 × 106 |

| Desired damp /() | 5 × 104 |

| Desired mass /kg | 0 |

| No. | Working Conditions | |

|---|---|---|

| Frequency (Hz) | Bias, Amplitude (N) | |

| 1 | 1 | 1500, 1000 |

| 2 | 2 | 1500, 1000 |

| 3 | 1 | 2500, 2000 |

| 4 | 2 | 2500, 2000 |

| Performance Index | No. | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| Amplitude reduction (mm) | Experimental | −0.05 | −0.09 | −0.06 | −0.11 |

| Simulation | −0.03 | −0.06 | −0.03 | −0.06 | |

| Phase angle delay (°) | Experimental | 7.8 | 6.7 | 8.9 | 9.4 |

| Simulation | 5.2 | 5.3 | 7.1 | 7.5 | |

| Parameters | Max Error | Mean Error | Max Error | Mean Error |

|---|---|---|---|---|

| 19% | 12% | 20% | 16% | |

| 11% | 5% | 18% | 9% | |

| 31% | 16% | 15% | 10% | |

| 35% | 15% | 21% | 11% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ba, K.; Yu, B.; Gao, Z.; Li, W.; Ma, G.; Kong, X. Parameters Sensitivity Analysis of Position-Based Impedance Control for Bionic Legged Robots’ HDU. Appl. Sci. 2017, 7, 1035. https://doi.org/10.3390/app7101035

Ba K, Yu B, Gao Z, Li W, Ma G, Kong X. Parameters Sensitivity Analysis of Position-Based Impedance Control for Bionic Legged Robots’ HDU. Applied Sciences. 2017; 7(10):1035. https://doi.org/10.3390/app7101035

Chicago/Turabian StyleBa, Kaixian, Bin Yu, Zhengjie Gao, Wenfeng Li, Guoliang Ma, and Xiangdong Kong. 2017. "Parameters Sensitivity Analysis of Position-Based Impedance Control for Bionic Legged Robots’ HDU" Applied Sciences 7, no. 10: 1035. https://doi.org/10.3390/app7101035