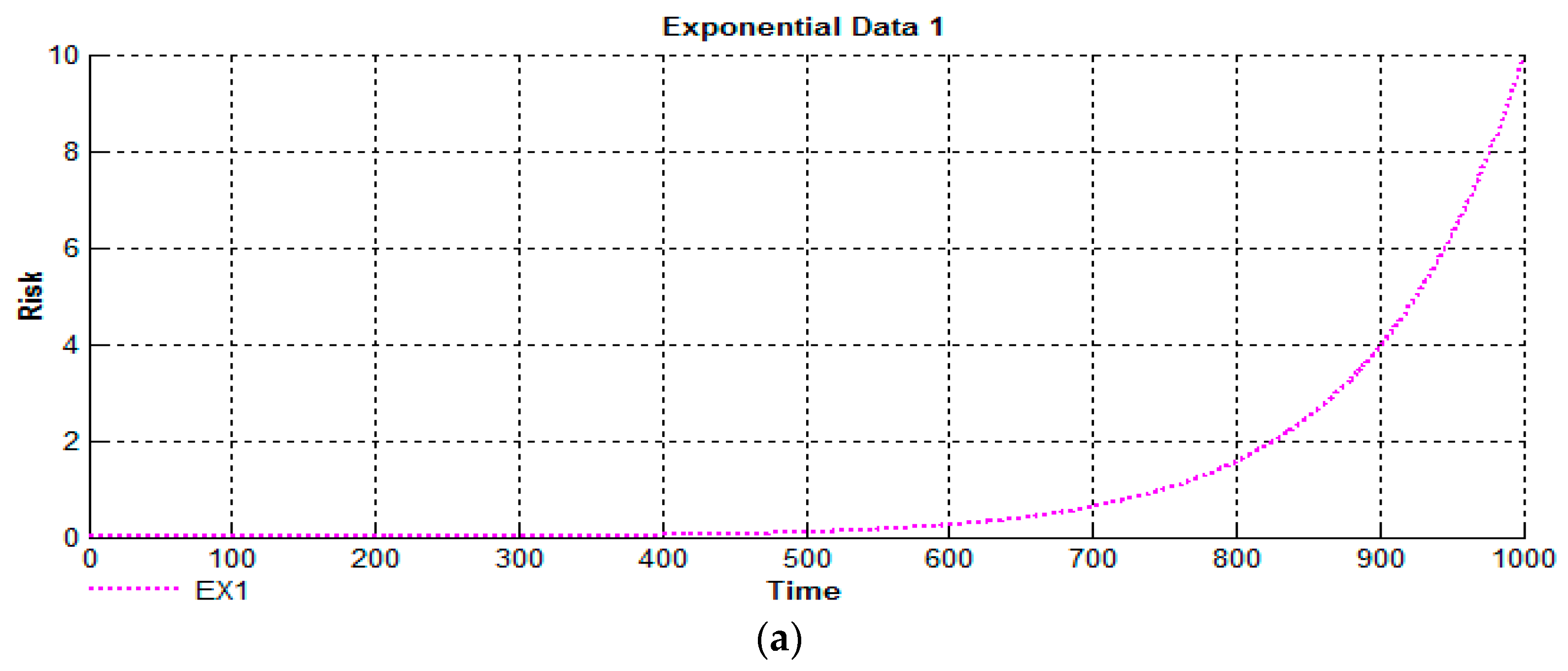

The main challenge of the hierarchical fuzzy inference system is to design a full architecture with minimum rules. In this work, we have to take into account 8 parameters; if conventional fuzzy logic is designed for such system, its computational complexity will be high, because computation complexity increases exponentially as new perimeters enter into the system. In this work, we have designed a model named integrated risk index model, which is based on the hierarchical fuzzy model. Due to the hierarchical decomposition, the proposed fuzzy system is called hierarchical fuzzy system. Rendering to their roles, the rules are grouped into the modules in the system. Each module performs the computation of partial solution, and these fractional solutions are used in next succeeding modules to calculate the concluding output of the system. Though calculation in modules is achieved through fuzzy rules, the decomposition of the flat and large rule base into numerous small rule bases (each with only a few variables) shrinks the complete number of rules.

The

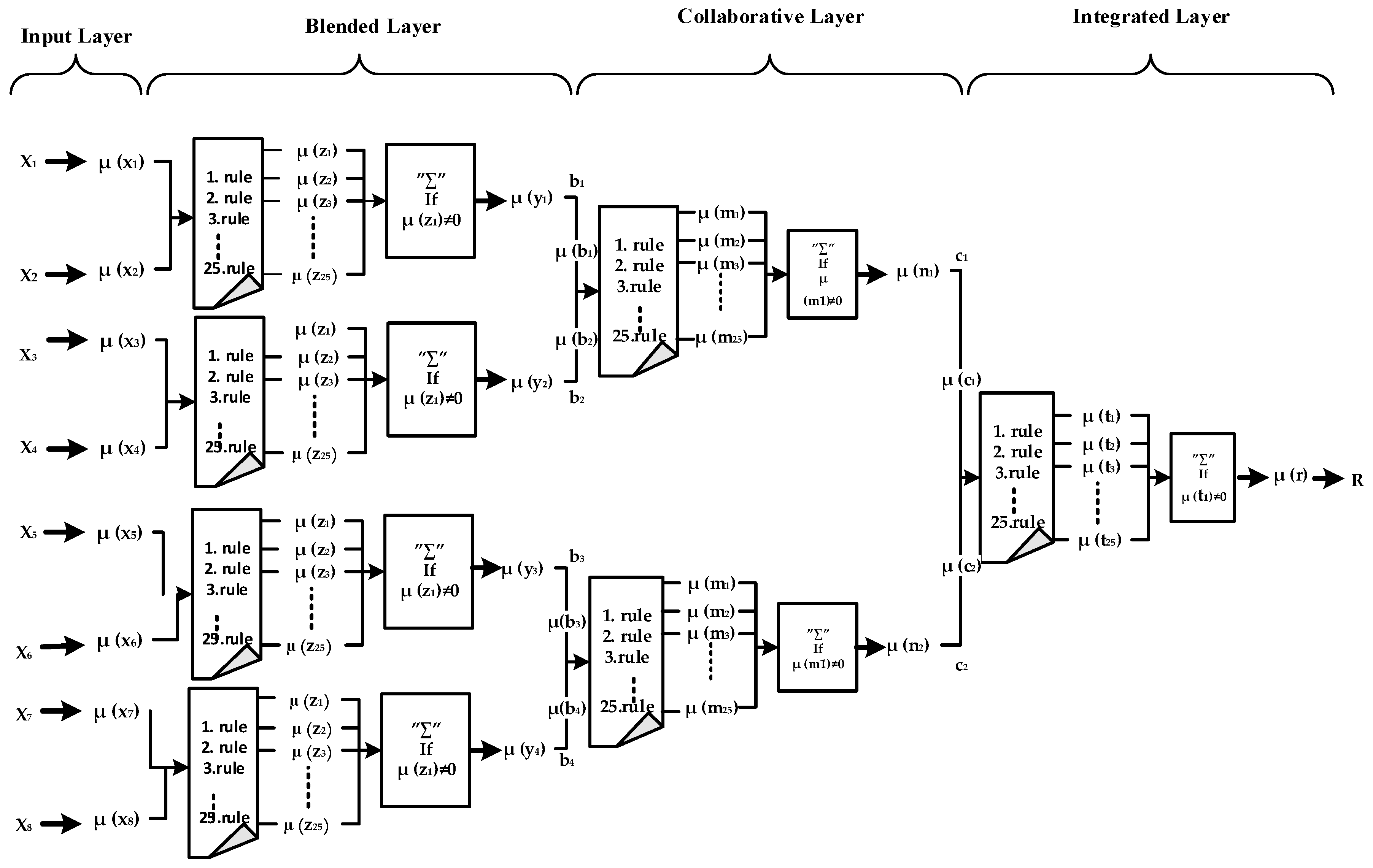

Figure 1 illustrates the hierarchical fuzzy logic architecture for the risk assessment for the UGS system. Four hierarchical levels are present in the proposed architecture for underground risk assessment: input layer (level-3), Blended Layer (layer-2), Collaborative layer (Level-1), and Integrated Risk layer (Layer-0). Total of 7 sub fuzzy logics have been used in this model; the input layer has eight input parameters, namely, water supply risk probability (X

1), water supply risk severity (X

2), sewerage supply risk probability (X

3), sewerage supply risk severity (X

4), metro structure risk probability (X

5), metro structure risk severity (X

6), Geo-environmental risk probability (X

7), and Geo-environmental risk severity (X

8). The blended layer has four fuzzy inference systems: M1_FIS, M2_FIS, M

3_FIS, and G_FIS, which are abbreviated for water supply pipeline risk index (M

1) fuzzy logic, sewerage supply pipeline risk index (M

2) fuzzy logic, metro structure risk index (M

3) fuzzy logic, and Geo-environmental risk index (G) fuzzy logic, respectively. The collaborative layer has two fuzzy logics, namely, collaborative risk index 1 fuzzy logic (CR

1_FIS) and collaborative risk 2 fuzzy logic (CR

2_FIS). Similarly, the integrated layer has integrated risk fuzzy logic (FIS_IR); this is the final output of the proposed hierarchical fuzzy inference system architecture. Water supply risk probability and water supply risk severity are inputs to FIS_M1. Inputs to FIS_M

2 are sewerage risk probability and sewerage risk severity. The metro structure risk probability and metro structure risk severity are inputs to the FIS_M

3; similarly, the FIS_G takes Geo-environmental risk probability and Geo-environmental risk severity as inputs. Further, the output of FIS_M

1 and FIS_M

2 are inputted to FIS_CR

1; FIS_CR

2_FIS takes the output of M3_FIS and G_FIS as inputs. The purpose of the proposed model is to take into account all the parameters to calculate a centric risk value using fuzzy logic, hence an integrated risk fuzzy logic (FIS_IR) is used. The output of IR_FIS is the final risk value of hierarchical fuzzy logic for underground risk. The structure diagram for the proposed model is given in

Figure 1, and the structure diagram of the conventional logic has the same number of input parameters as given in

Figure 2.

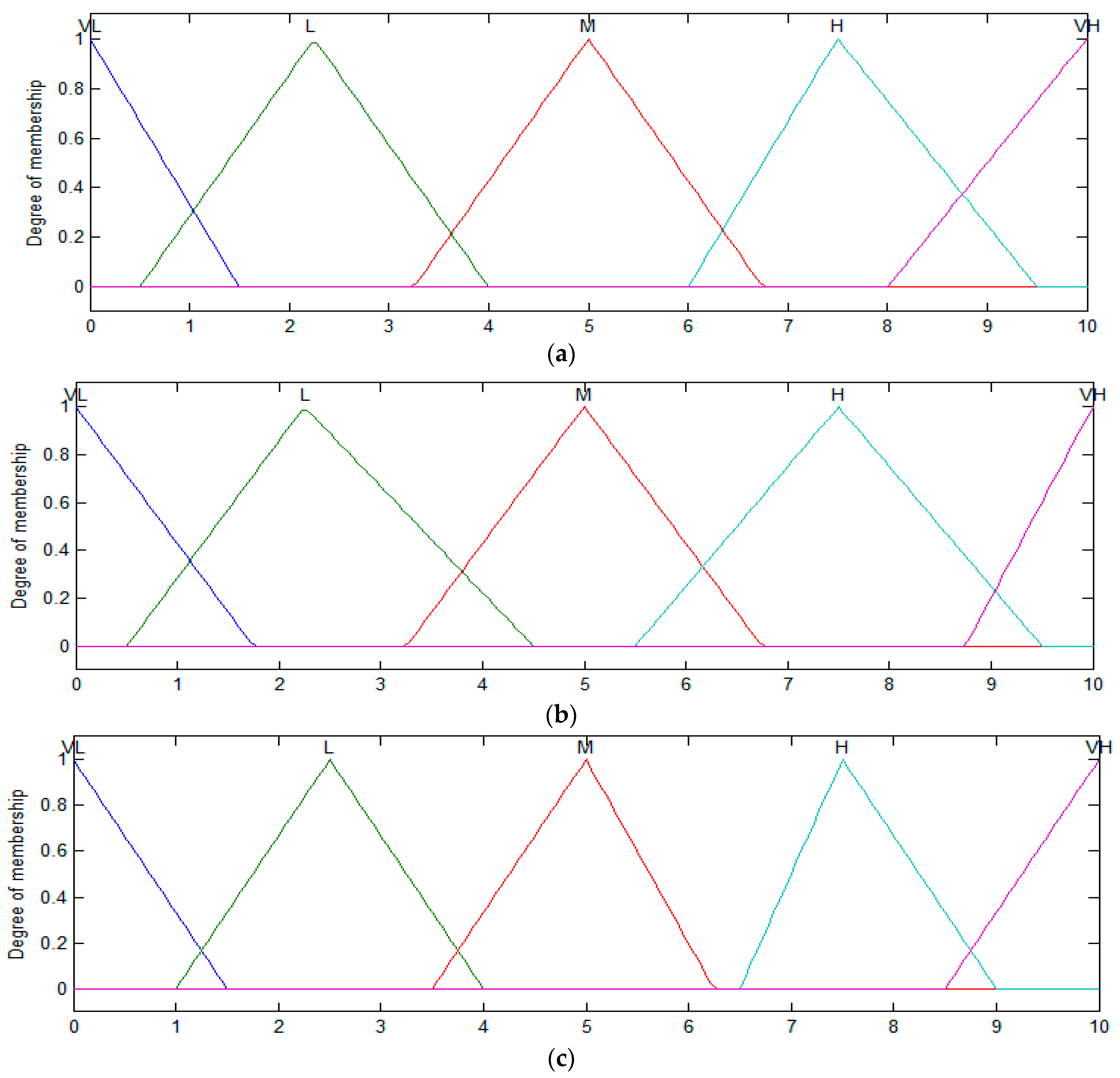

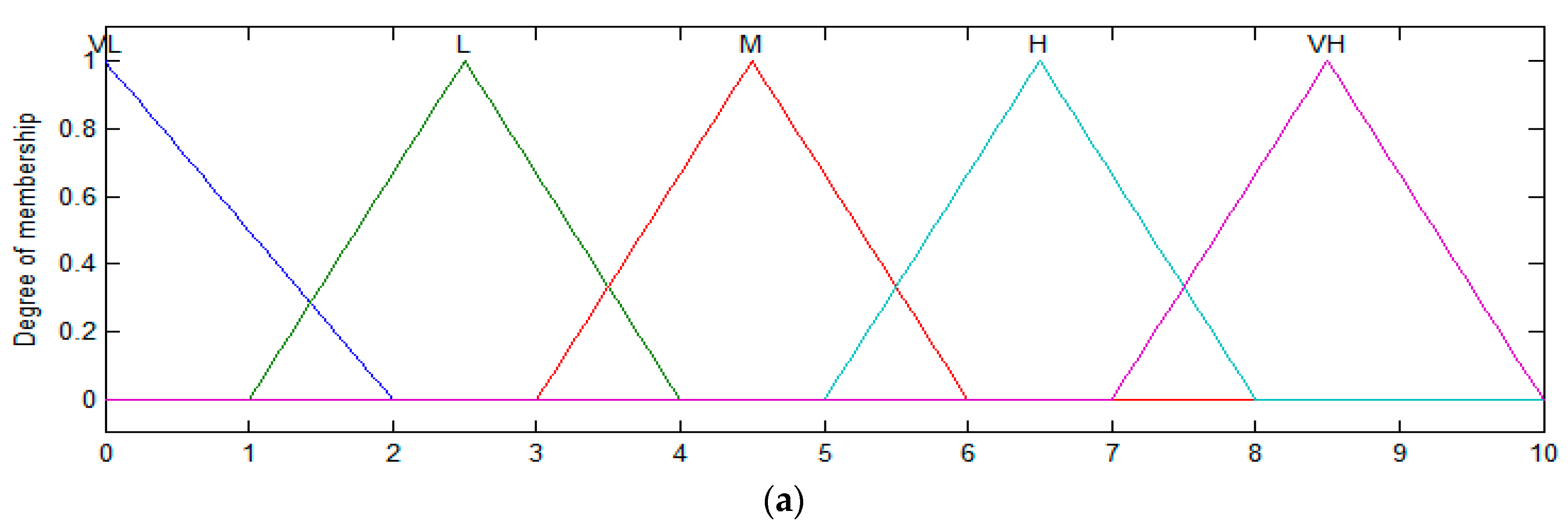

Mamdani fuzzy logic has been used in the proposed hierarchical model. Mamdani fuzzy rules are too simple and more useful as compared to the Takagi-Sugeno-Kang method. Mamdani fuzzy logic is comprised of the fuzzifier, knowledge base, inference engine, and defuzzifier modules. The fuzzifier takes crisp values as input and generates fuzzy values using membership functions. After each rule evaluation inside the knowledge base, the aggregation of each consequent membership function values is carried out using maximum operation. The defuzzification method converts the fuzzy consequents into crisp value [

24]. Membership functions play a very vital role in fuzzy logic construction and operations; there are many types of membership functions, such as triangular, Gaussian, Bell-shaped, and Sigmoid (right, left, difference, etc.). In the proposed approach we have used the triangular membership function which is the most common and effective membership function used in fuzzy logic [

25]. The fuzzy logic consisted of input and output variables and many membership functions can be defined for each input/output variable. In the proposed approach, five membership functions have been defined for each input/output variable; for consistency, we have defined the same number of membership functions for each variable in all fuzzy logics. The labelling has also been carried out in the same manner and identical labels (linguistic terms) are assigned to the membership functions of all variables of the proposed model. The linguistic terms that are defined for membership functions are VL, L, M, H, and VH, which are abbreviations for very low, low, medium, high, and very high.

3.1. Detailed Structure Diagram of the Proposed Model

The detailed structure diagram given in

Figure 3 exhibits the working of each module of the proposed model. The terms used in the detail structure diagram of the proposed approach are: pipeline risk probability (X

1), pipeline risk severity (X

2), sewerage risk probability (X

3), sewerage risk severity (X

4), metro structure risk probability (X

5), metro structure severity (X

6), geo-environmental risk probability (X

7), and geo-environmental risk severity (X

8). BL ( ): represents the blended layer that takes inputs from the input layer. The µ (x

i) returns fuzzy value, where i = 1, 2…8. The µ (z

j) returns implicated fuzzy value, where j = 1, 2…25. The µ (y

k) returns the final output of fuzzy logic, where k = 1, 2, 3, and 4 in the blended layer of the proposed model. Similarly, CL ( ) represents the collaborative layer. The input to the CL ( ) is the output of BL ( ). The µ (m

j) returns implicated fuzzy value, and µ (nr) returns the output of fuzzy logic, where r = 1 and 2 in the collaborative layer. The IL ( ) represents the integrated layer, and µ (ti) returns the implicated fuzzy value. The µ (r) returns the output of IR ( ), which is the final risk index of the proposed model for underground risk assessment. The R represents the final risk index value. Agg ( ) return aggregation, arrow symbol “ ← ”, has been used for the assignment.

3.2. Pseudo Code with Structure Diagram

The pseudo code with the structure diagram of each layer is provided for better elaboration of the proposed approach in terms of input and output parameters and detailed processing of integrated hierarchal model. The symbols and terminologies are inherited from

Section 3.1. The pseudo code with structure diagram for the blended layer is provided in

Section 3.2.1, for the collaborative layer in

Section 3.2.2 and for the integrated layer in

Section 3.2.3.

3.2.1. Blended Layer

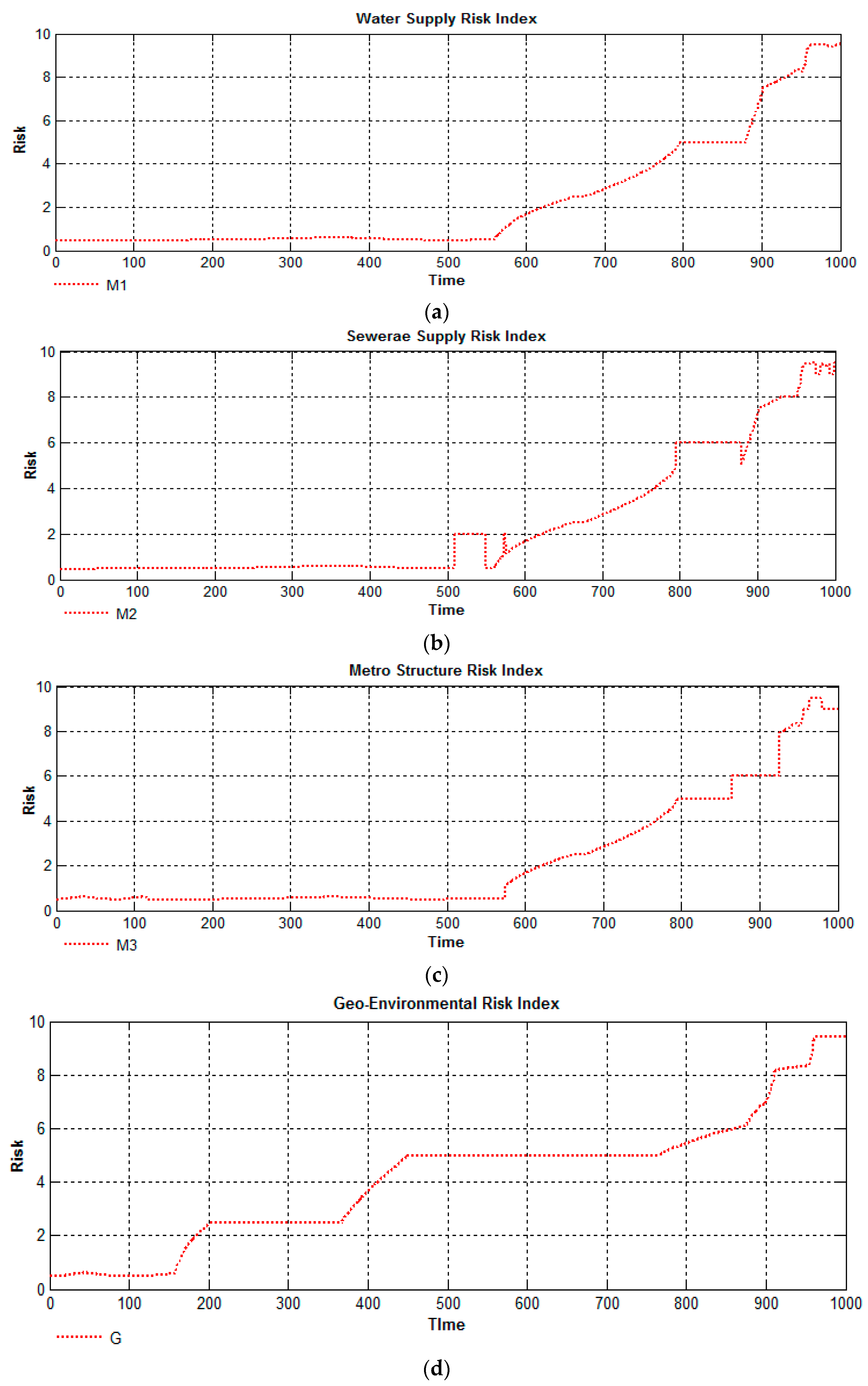

The blended layer is the most important layer of the proposed model; this layer consists of four modules, namely, water supply risk index fuzzy logic (M1_FIS), sewerage supply risk index fuzzy logic (M2_FIS), metro structure risk index fuzzy logic (M3_FIS), and Geo-environmental risk index fuzzy (G_FIS) logic. Inputs to the water supply risk index fuzzy logic are water supply risk probability and water supply risk severity, and the output is water supply pipeline risk index; sewerage supply pipeline risk index takes sewerage supply risk index probability and sewerage supply risk severity as inputs and provides sewerage supply risk index as output; metro structure fuzzy logic inputs are metro structure risk probability and metro structure risk severity, and the output is metro structure risk index. Similarly, inputs to Geo-environmental risk index fuzzy logic are Geo-environmental risk index probability and Geo-environmental risk severity, and the output is Geo-environmental risk index.

| Pseudo code for Blended Layer |

| Input (X1, X2, X3, X4, X5, X6, X7, X8) |

| Output: Risks |

| Begin: |

| 1. R ← ∅; |

| 2. BL(X1, X2, X3 ,X4, X5, X6 ,X7, X8) { |

| i. M1_FIS(X1, X2) { |

| ● µ (X1) // convert the crisp input X1 to fuzzy value |

| ● µ (X2) // convert the crisp input X2 to fuzzy value |

| For j ← 1 to 25 do |

| ▪ Rule inferencing |

| ▪ µ (zj) // Rule implication |

| od |

| ● µ (y1) ← Agg ( ): // Apply aggregation |

| ● b1 ← µ (y1) |

| ● return b1 |

| } |

| ii. M2_FIS(X3, X4) do |

| ● µ (X3) // convert the crisp input X3 to fuzzy value |

| ● µ (X4) // convert the crisp input X4 to fuzzy value |

| For j ← 1 to 25 do |

| ▪ Rule inferencing |

| ▪ µ (zj) // Rule implication |

| od |

| ● µ (y2) ← Agg ( ): // Apply aggregation |

| ● b2 ← µ (y2) |

| ● return b2 |

| iii. M3_FIS(X5, X6) { |

| ● µ (X1) // convert the crisp input X5 to fuzzy value |

| ● µ (X2) // convert the crisp input X6 to fuzzy value |

| For j ← 1 to 25 do |

| ▪ Rule inferencing |

| ▪ µ (zj) // Rule implication |

| od |

| ● µ (y3) ← Agg ( ): // Apply aggregation |

| ● b3 ← µ (y3) |

| ● return b3 |

| } |

| vi. G_FIS(X7, X8) do |

| ● µ (X3) // convert the crisp input X7 to fuzzy value |

| ● µ (X4) // convert the crisp input X8 to fuzzy value |

| For j ← 1 to 25 do |

| ▪ Rule inferencing |

| ▪ µ (zj) // Rule implication |

| od |

| ● µ (y4) ← Agg ( ): // Apply aggregation |

| ● b4 ← µ (y4) |

| ● return b4 |

| } [b1, b2, b3, b4] ← BL(X1, X2, X3, X4, X5, X6, X7 ,X8) |

| End |

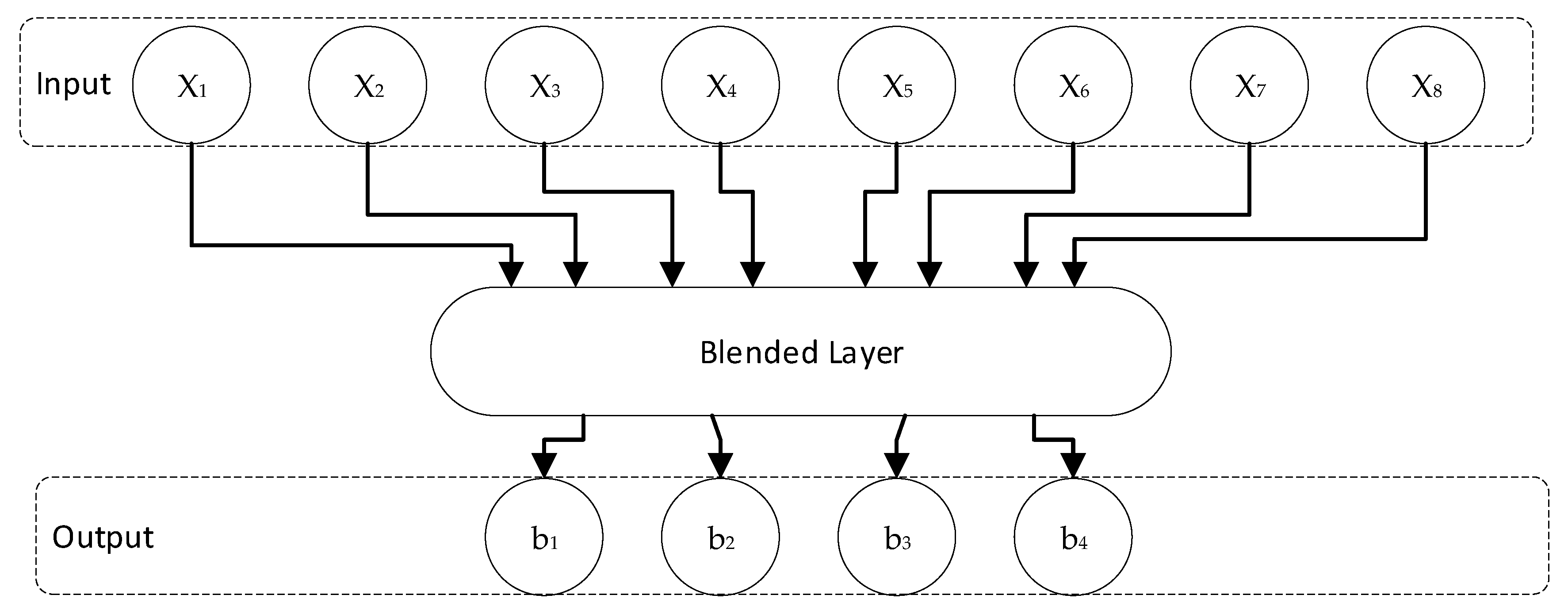

The structure diagram of the blended layer of the proposed model with eight inputs and four outputs is illustrated in

Figure 4 for better elaboration of the working mechanism of the blended layer.

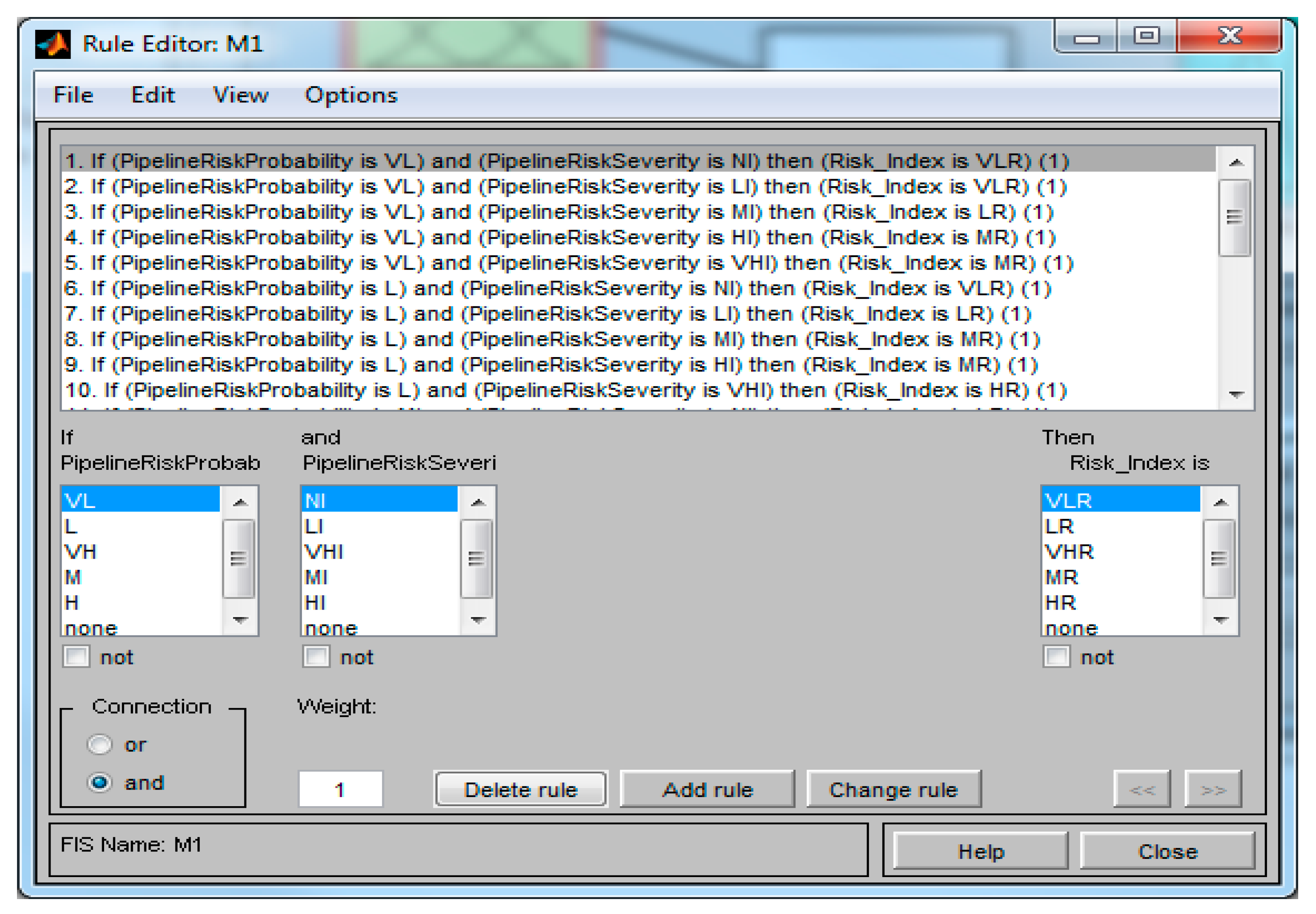

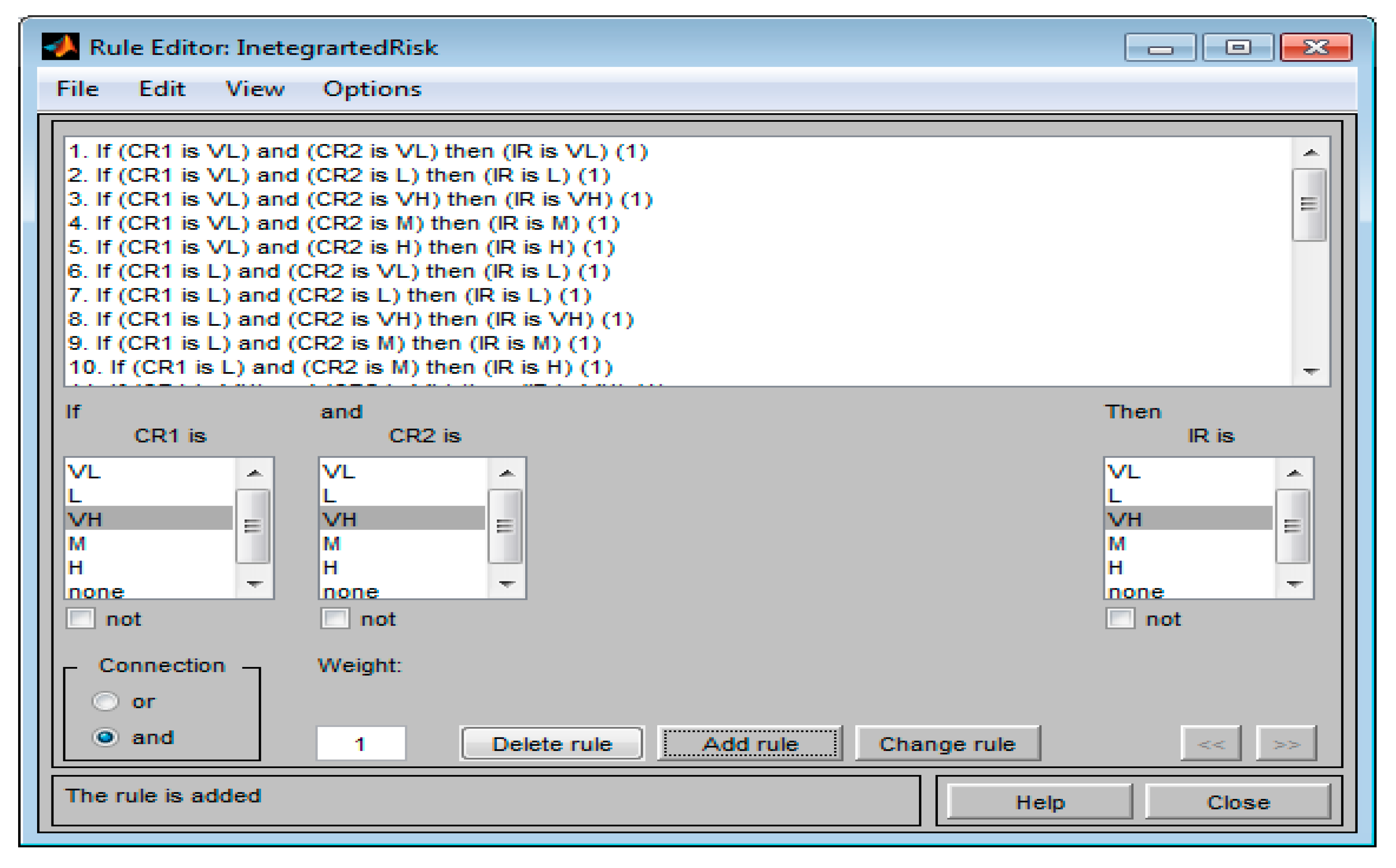

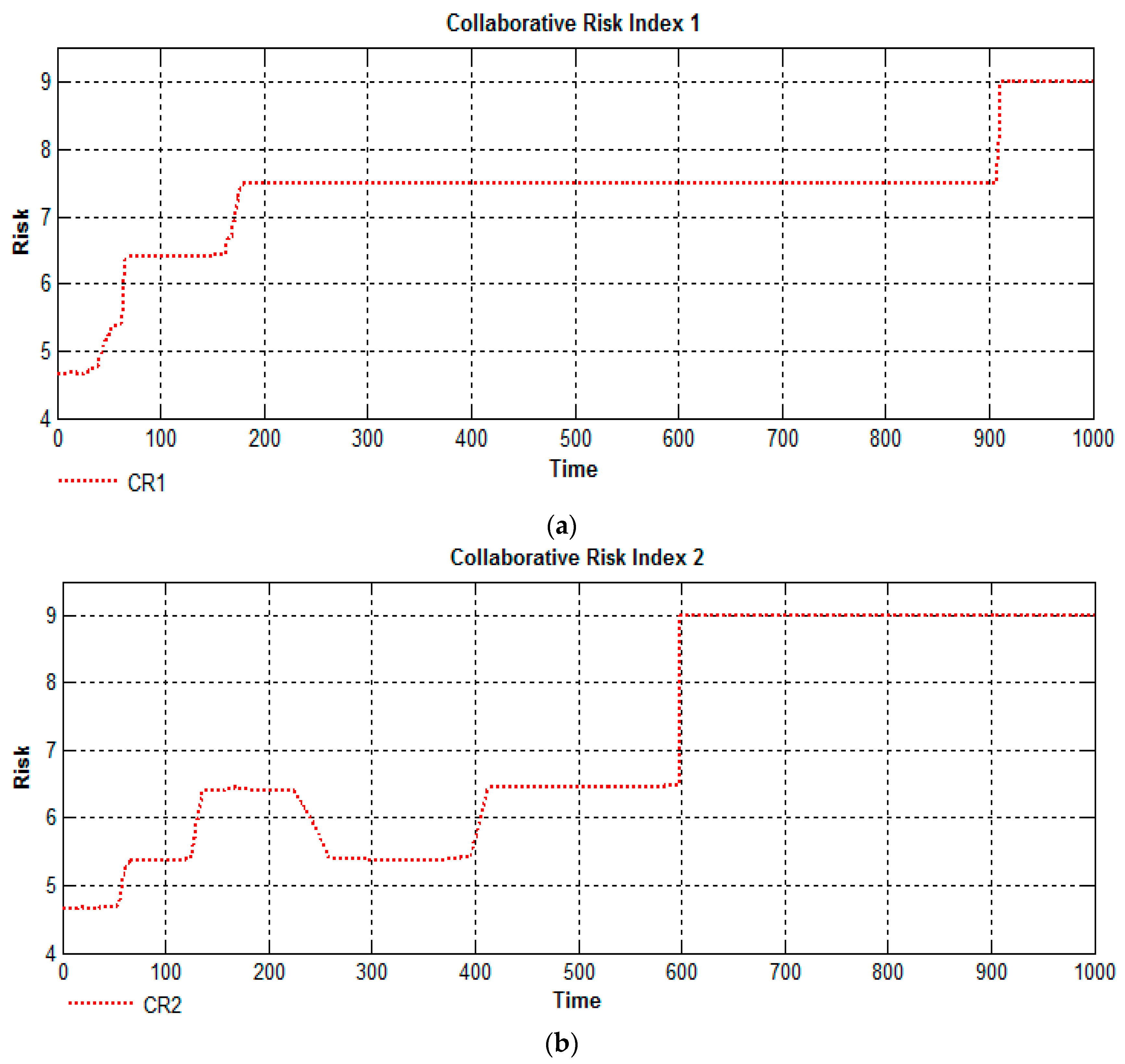

3.2.2. Collaborative Layer

The collaborative layer of the proposed model is comprised of two modules: namely, collaborative risk index (CR1_FIS) and collaborative risk index 2(CR2_FIS). The outputs of the blended layer are inputs to this layer, such as CR1_FIS; inputs are b1 and b2, which are outputs of M1_FIS and M2_FIS respectively and CR2_FIS inputs are b3 and b4, which are the outputs of M3_FIS and G_FIS, respectively.

| Pseudo Code for Collaborative layer |

| Input (b1, b2, b3, b4) |

| Output: Risks |

| Begin: |

| 3. CL(b1, b2, b3, b4) { |

| i. CR1_FIS (b1, b2) { |

| µ(b1) // convert the crisp input b1 to fuzzy value |

| µ(b2) // convert the crisp input b2 to fuzzy value |

| For j ← 1 to 25 do |

| ▪ Rule inferencing |

| ▪ µ(mj) // Rule implication |

| od |

| ● µ(n1) ← Agg(): // Apply aggregation |

| ● c1 ← µ(n1) |

| } |

| ii. CR2_FIS (b3, b4) do |

| µ(b3) // convert the crisp input b3 to fuzzy value |

| µ(b4) // convert the crisp input b4 to fuzzy value |

| For j ← 1 to 25 do { |

| ▪ Rule inferencing |

| ▪ µ (mj) // Rule implication |

| ● µ(n1) ← Agg ( ): // Apply aggregation |

| ● c1 ← µ(n1) |

| } return c1, c2 |

| End |

The collaborative layer of the proposed model having four inputs and two outputs is given in

Figure 5, which elaborates the working of the collaborative layer of the model.

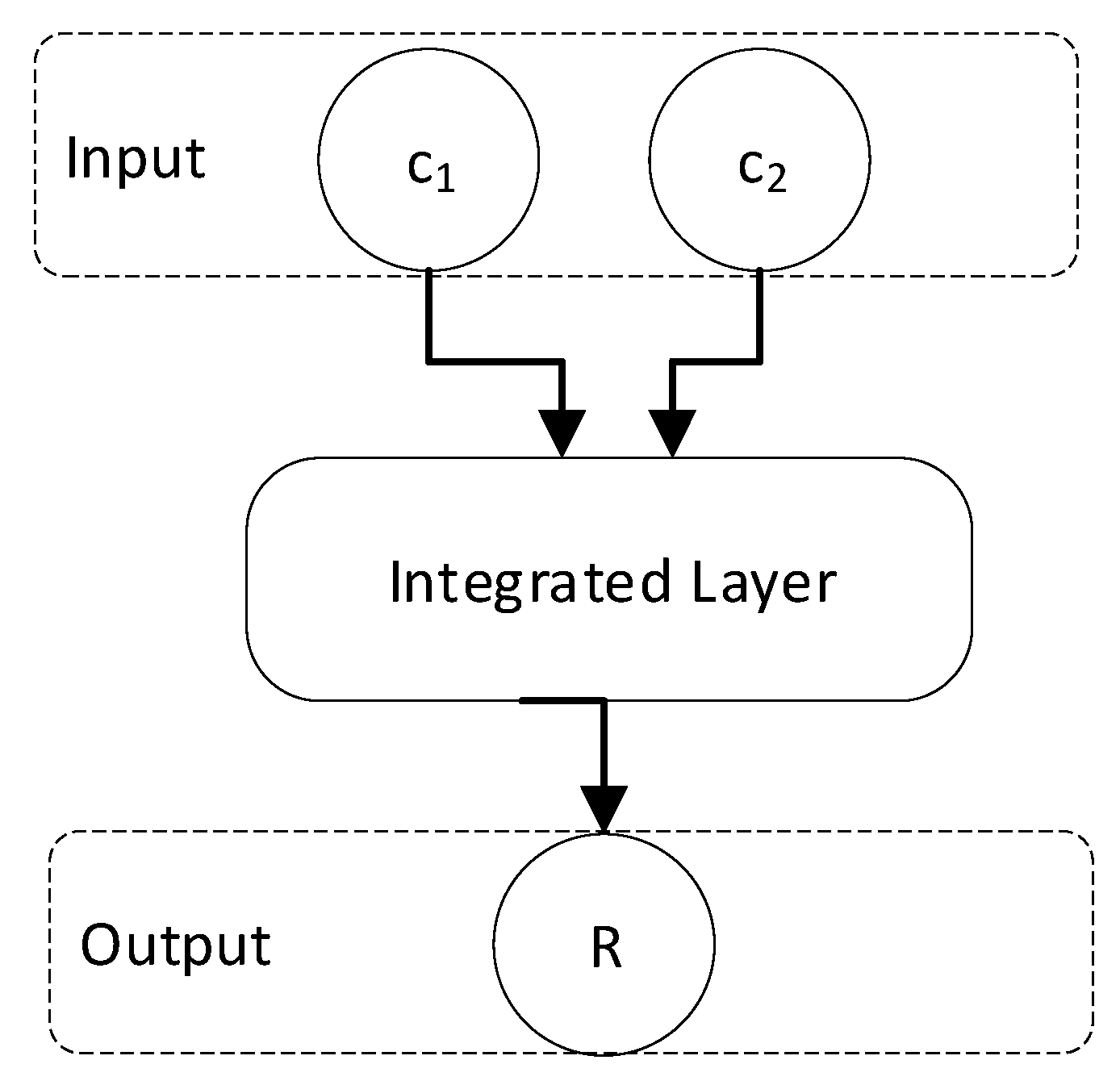

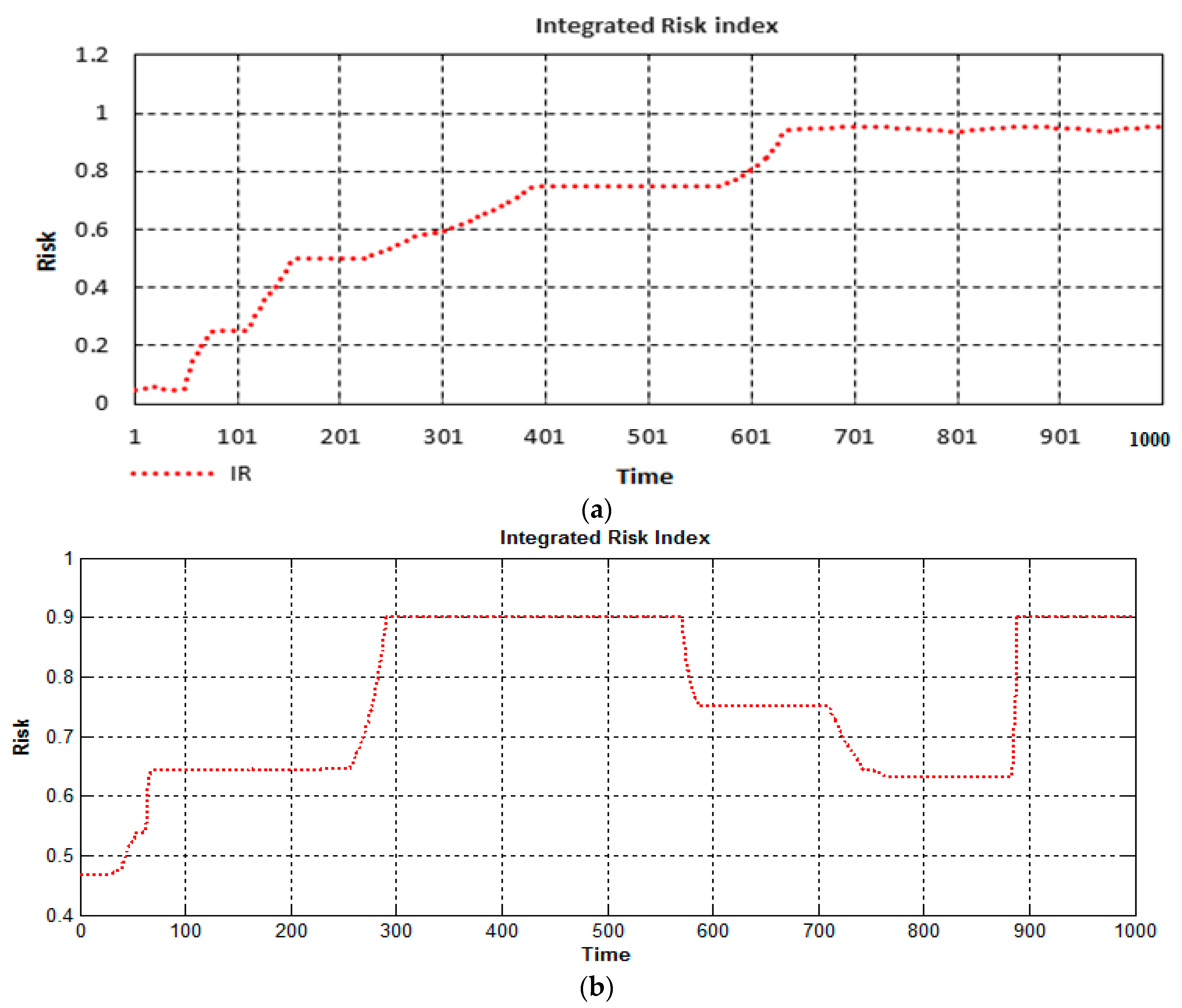

3.2.3. Integrated Layer

The integrated layer consists of one module named integrated fuzzy logic risk index (IR_FIS)). Inputs to integrated layer are the outputs of the collaborative layer. IR_FIS take CR1 and CR2 outputs as inputs and generate index value. The output of the integrated layer is the final output of the proposed model and further measurements are taken on the basis of risk value. The pseudo code of the integrated layer is as under:

| Pseudo Code for Integrated layer |

| Input (b1, b2, b3, b4) |

| Output: Risks |

| Begin: |

| Output: Risk Index |

| 4. IL() { |

| i. IR_FIS (c1, c2) { |

| F1 = µ(c1) // convert the crisp input X5 to fuzzy value |

| F2 = µ(c2) // convert the crisp input X6 to fuzzy value |

| For j ← 1 to 25 do |

| ▪ Rule inferencing |

| ▪ µ(tj) // Rule implication |

| od |

| ● µ(r) ← Agg ( ): // Apply aggregation |

| ● R ← µ(r) |

| } |

| } return R |

| Risk Index ← R |

| End |

Similarly, for better elaboration of the integrated layer of the proposed model, the structure diagram is illustrated in

Figure 6.

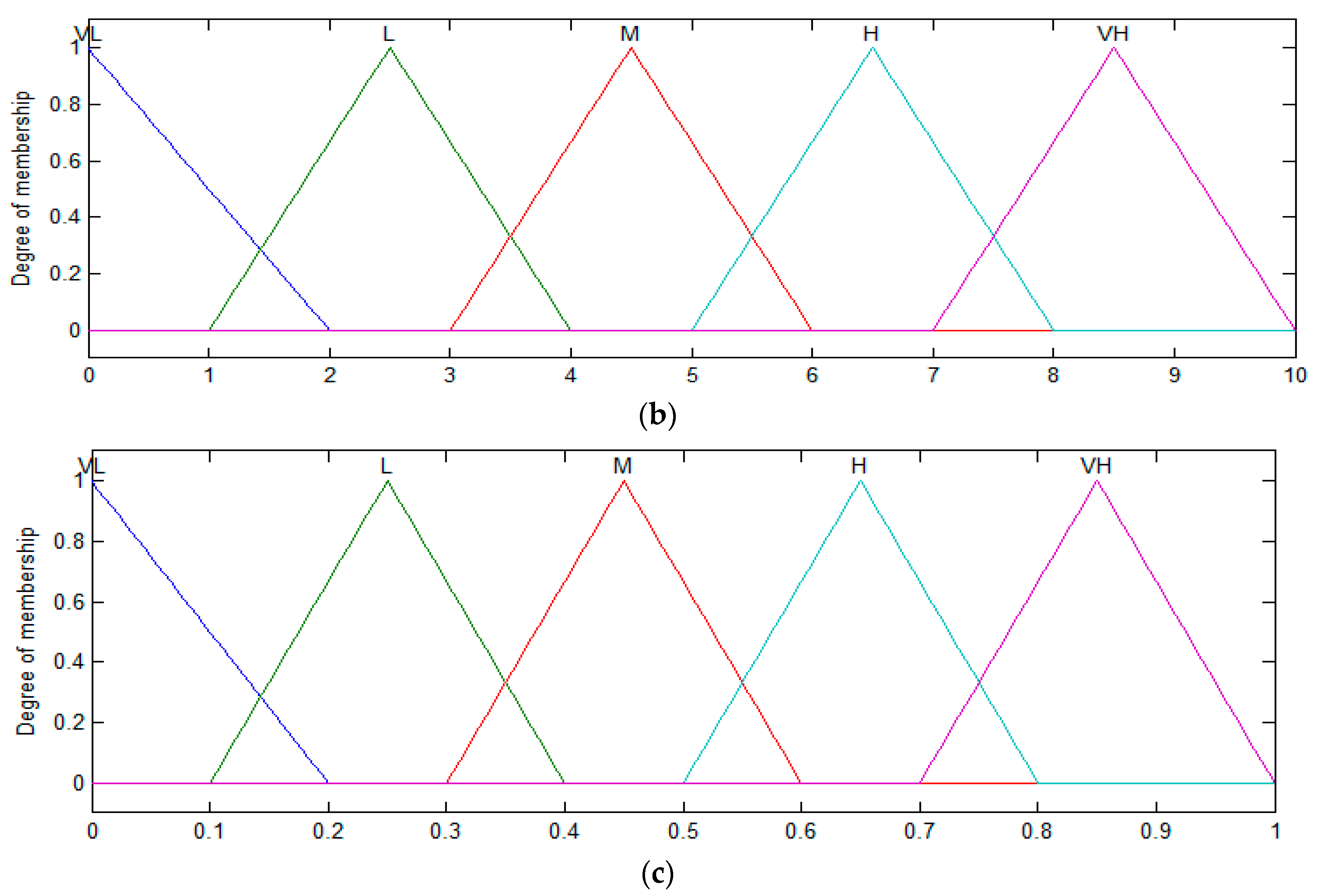

3.4. Rule Specification

For the rule specification, we have designed two different schemes: namely, average rule-based and maximum rule-based. In the average rule-based, first the weights are assigned to each membership function (MF), as shown in the

Table 1.

The formulas for specifying average rule-based and maximum rule-based rules are given in Equations (3) and (4), respectively.

For the rule specification using the average rule-based method, first the weights of membership functions are put in the Equation (3) and the output of rules are specified accordingly. Each output of the rule is specified as:

Table 2 indicates the fuzzy logic rules on the average rule-based method for M

1_FIS. It is a 5 × 5 matrix and each entry in

Table 2 is the water supply pipeline risk index.

For the rule specification by using the maximum rule-based method, first the membership function weights are put in the Equation (3), and the output of rules specification is carried out accordingly. The output of each rule is specified as:

Table 3 indicates the fuzzy logic rules based on the maximum rule-based method for water supply pipeline risk index fuzzy logic. It is a 5 × 5 matrix and each entry in

Table 3 is the water supply pipeline risk index.