A Precise Positioning Method for a Puncture Robot Based on a PSO-Optimized BP Neural Network Algorithm

Abstract

:1. Introduction

2. Research and Methods

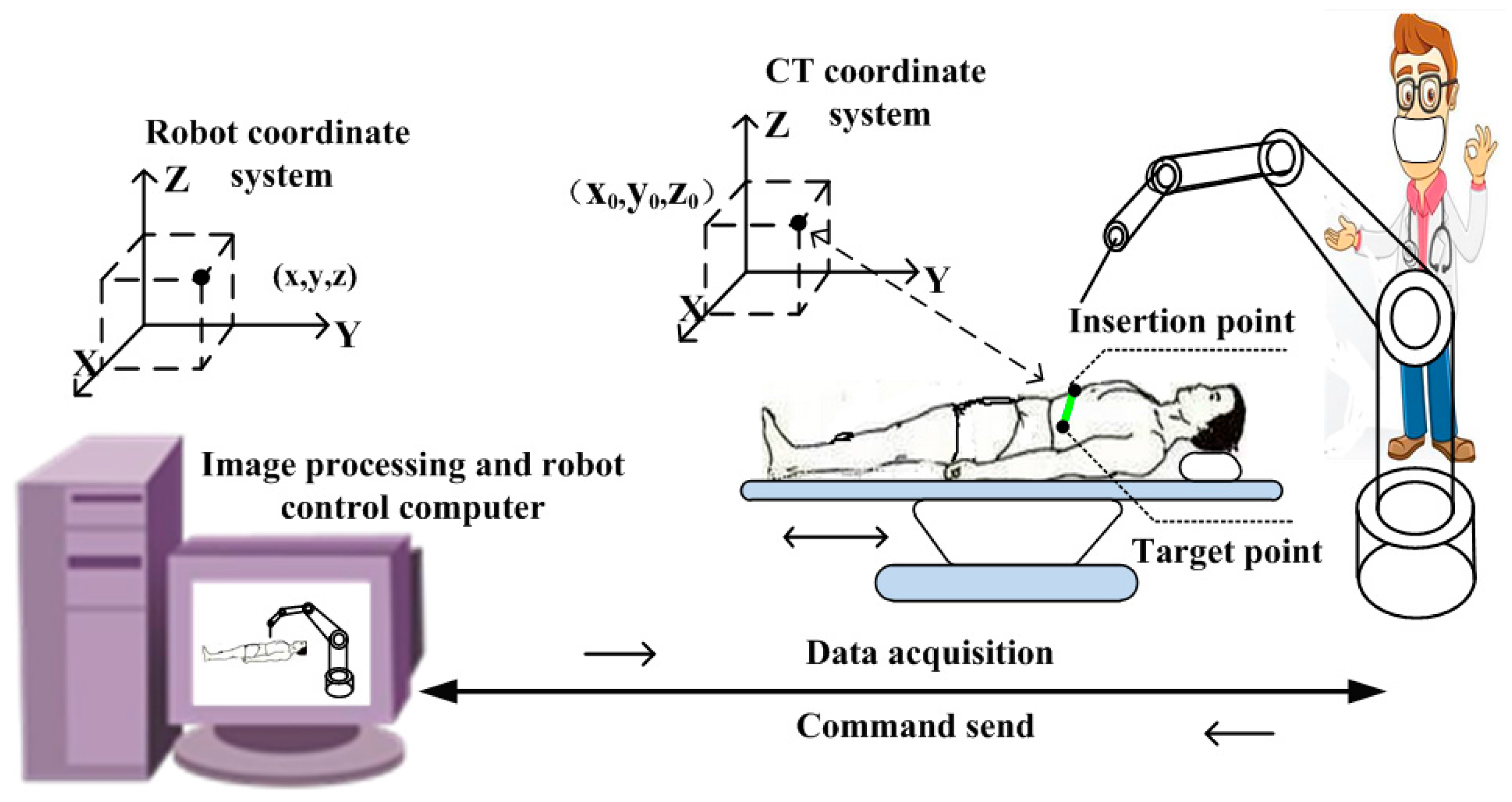

2.1. The Principle of Precision Positioning of a Puncture Robot

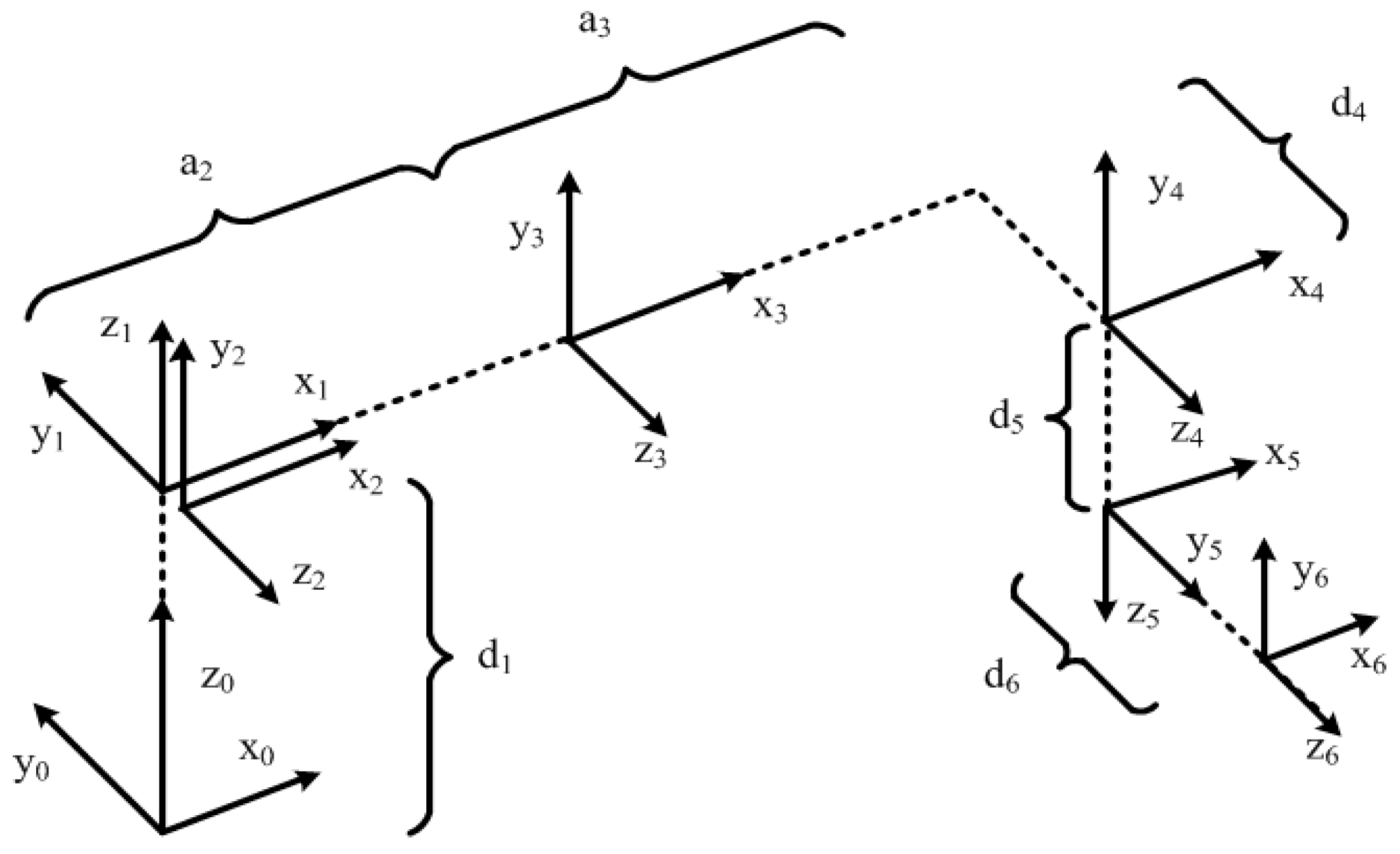

2.2. Analysis of the UR3 Manipulator

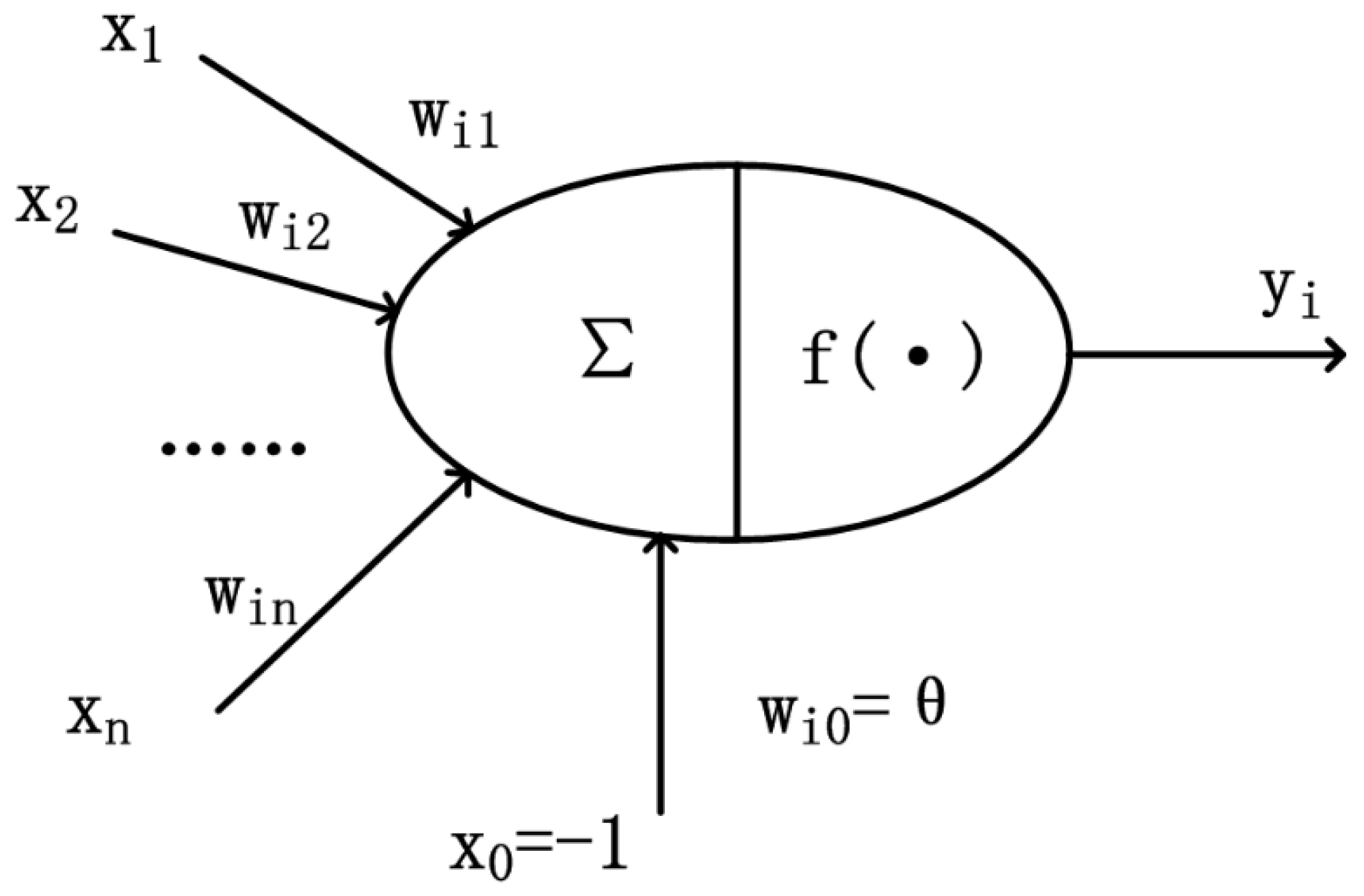

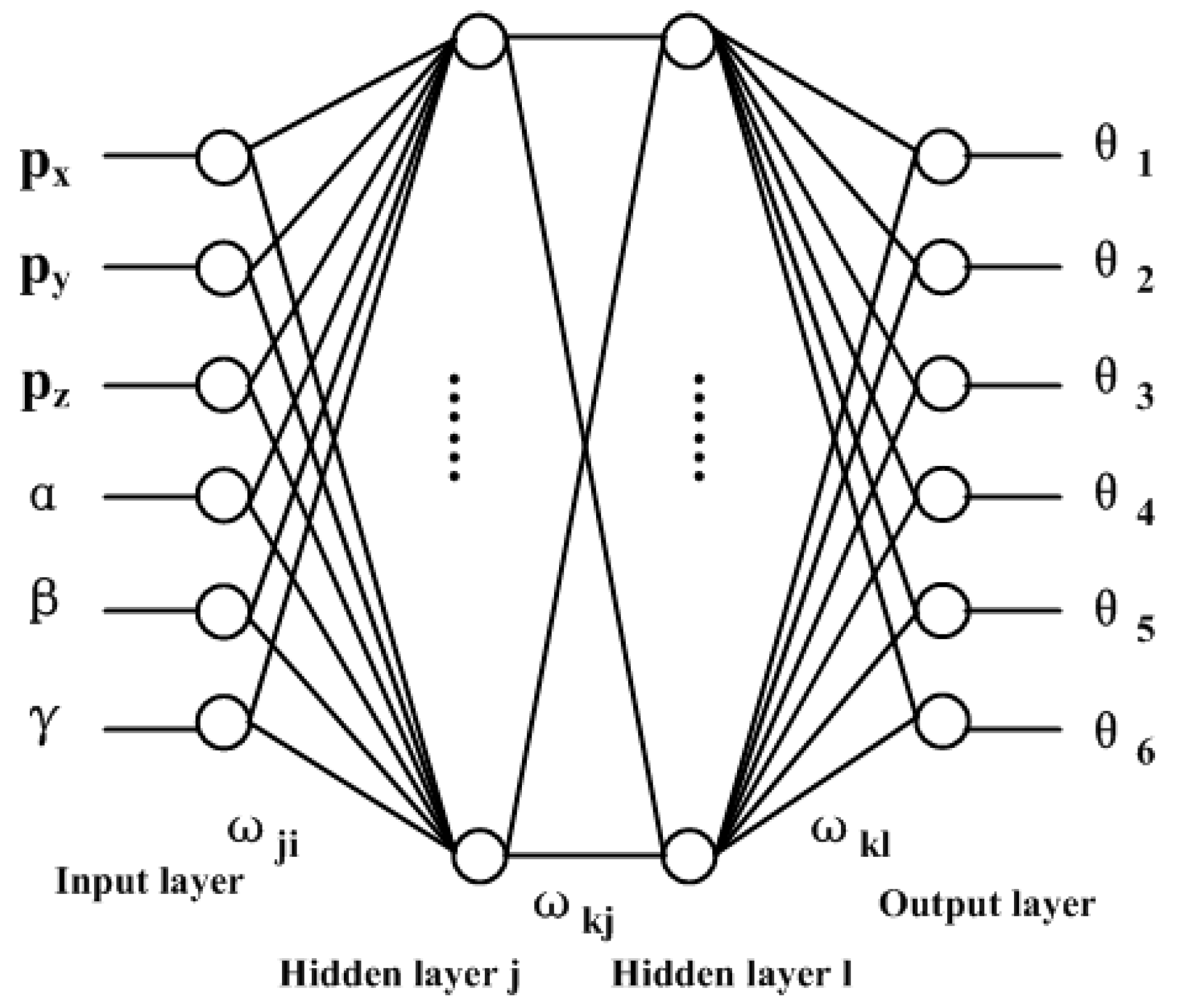

2.3. BP Neural Network

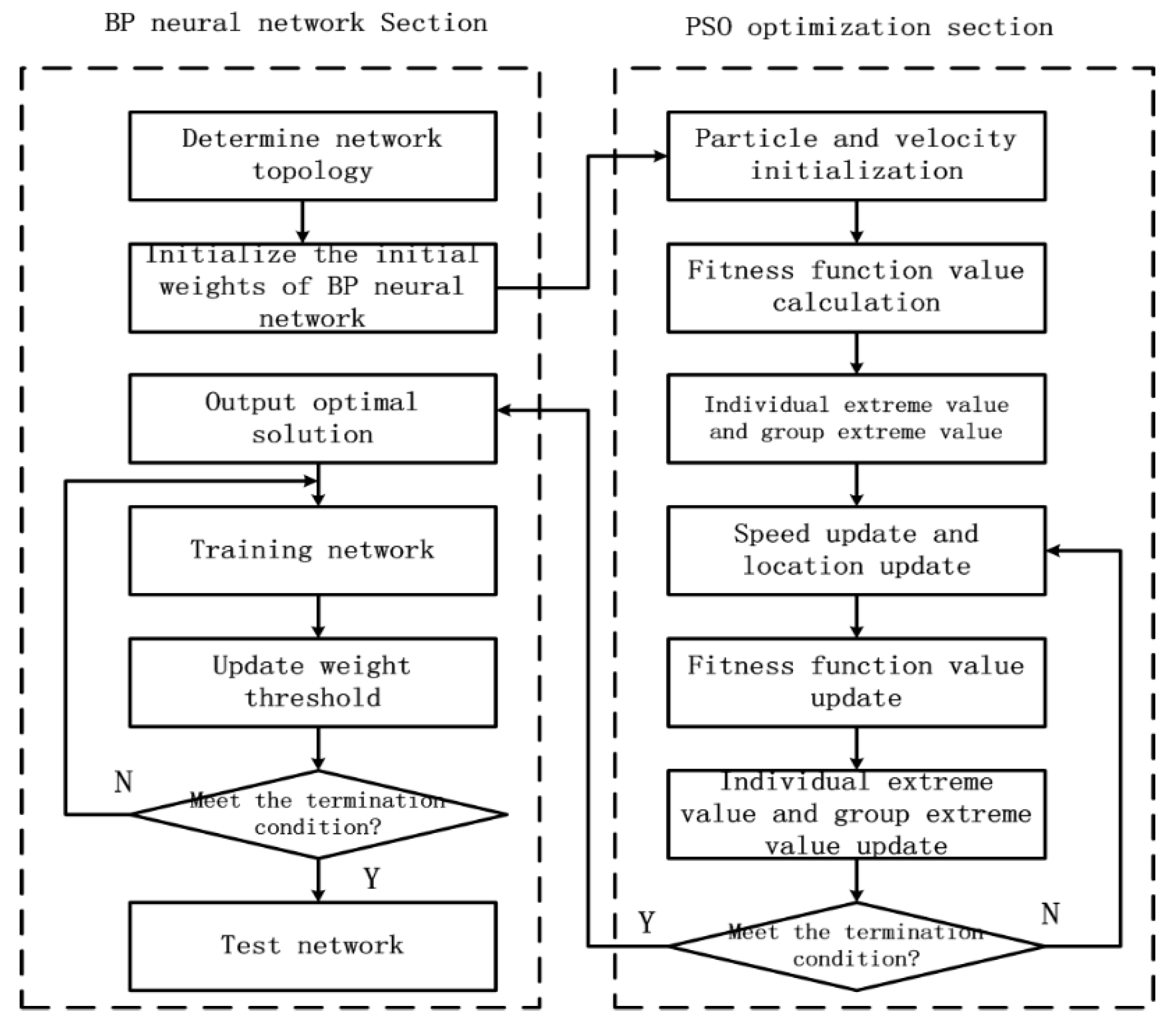

2.4. PSO Optimization Combined with the BP Neural Network

- Firstly, one needs to determine the topology of the neural network, initialize the BP neural network, and determine the initial value and threshold.

- In the PSO algorithm, one needs to initialize the particle velocity, calculate the corresponding fitness function, and create the individual extreme and extreme groups.

- Then update the particle’s velocity, position, and fitness function; update the individual extreme and extreme groups, and determine whether it meets the conditions. If the conditions are not satisfied, the parameter is updated again. If the conditions are satisfied, the optimal solution is obtained.

- Finally, the optimal solution of the PSO algorithm is given by the trained BP neural network, and then the weights and thresholds are updated to determine whether the training results meet the termination condition. If the condition is not satisfied, then the neural network is trained again; if it is satisfied, then finish the network testing and output the result.

3. Experimental Results and Validation

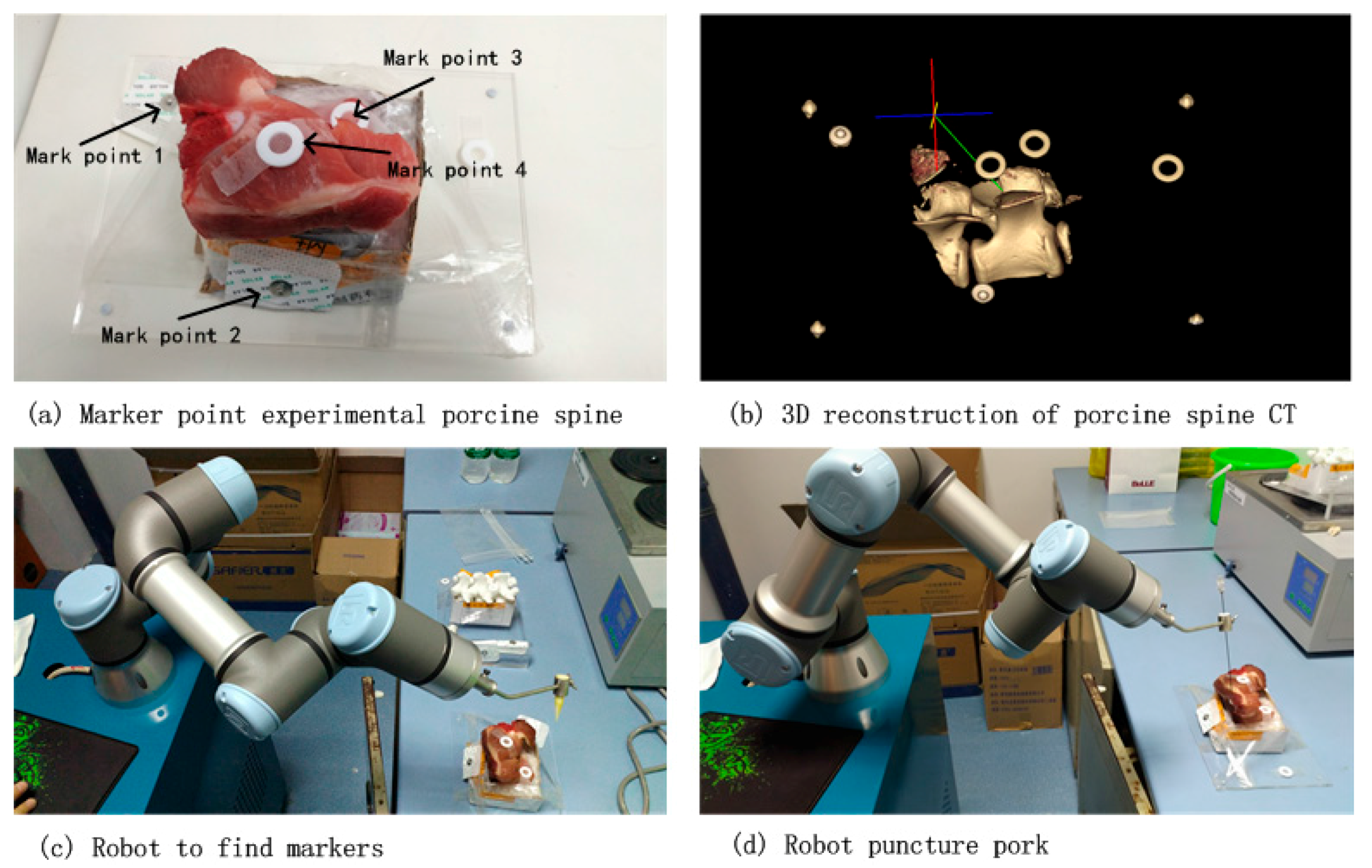

4. Application of the Puncture Robot

- (1)

- Firstly, a piece of porcine spine meat is affixed to some fixed marked points (Figure 14a), and then the DICOM (Digital Imaging and Communications in Medicine)image is obtained by CT scanning.

- (2)

- The CT image is copied to the image processing computer, and the 3D reconstruction is performed on the computer (Figure 14b). Then the coordinates of the marked points in the 3D model are selected.

- (3)

- We can then use, as a coordinate measuring arm, the mechanical measurement of spinal meat marked points on the robot with six degrees of freedom, combined with the coordinates of the marked points in the CT 3D model. Through the space registration conversion, we can obtain the position relationship between the spine meat in the CT 3D model coordinate system, and the robot coordinate system.

- (4)

- The coordinates of the target points and the coordinates of the needle insertion points are selected in the CT 3D model, which determines the route of the needle insertion. The position and rotation in the robot coordinate system are obtained according to the needle insertion route, such as the green line in Figure 14b.

- (5)

- Through the POS-BP neural network algorithm to train the data, we obtain the corresponding joint angles of the robot’s end puncture needle guide pipe when required to reach the specified position and rotation. After the command is sent, the robot moves to the position and ensures its rotation (Figure 14c).

- (6)

- The doctor confirms the positioning of the robot and inserts the needle into the porcine spine (Figure 14d). Once again, through the CT scan of the porcine spine meat, and the reconstruction of the three-dimensional image, a comparison of the needle in the three-dimensional model and the surgical planning of the needle route is conducted, so as to determine the success of the puncture operation.

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yang, G.L.; Kurbanhusen, S.; Yeo, S.H.; Lin, W.; Bin, W. Kinematic design of an anthropomimetic 7-DOF cable-driven robotic arm. Front. Mech. Eng. 2011, 6, 45–60. [Google Scholar] [CrossRef]

- Köker, R. A genetic algorithm approach to a neural-network-based inverse kinematics solution of robotic manipulators based on error minimization. Inf. Sci. 2013, 222, 528–543. [Google Scholar] [CrossRef]

- Bingul, Z.; Ertunc, H.M.; Oysu, C. Applying Neural Network to Inverse Kinematics Problem for 6R Robot Manipulator with Offset Wrist. Coimbra, Portugal, 2005; Springer: Vienna, Austria, 2005; pp. 112–115. [Google Scholar]

- Tabandeh, S.; Clark, C.; Melek, W. A genetic algorithm approach to solve for multiple solutions of inverse kinematics using adaptive niching and clustering. Comput. Sci. Softw. Eng. 2006, 63, 1815–1822. [Google Scholar]

- Hasan, A.T.; Ismail, N.; Hamouda, A.M.S.; Aris, I.; Marhaban, M.H.; Al-Assadi, H.M.A.A. Artificial neural network-based kinematics Jacobian solution for serial manipulator passing through singular configurations. Adv. Eng. Softw. 2010, 41, 359–367. [Google Scholar] [CrossRef]

- Boudjelaba, K.; Ros, F.; Chikouche, D. Potential of Particle Swarm Optimization and Genetic Algorithms for FIR Filter Design. Circuits Syst. Signal Process. 2014, 33, 3195–3222. [Google Scholar] [CrossRef]

- Kalra, P.; Mahapatra, P.B.; Aggarwal, D.K. An evolutionary approach for solving the multimodal inverse kinematics problem of industrial robots. Mech. Mach. Theory 2006, 41, 1213–1229. [Google Scholar] [CrossRef]

- Ayyıldız, M.; Cetinkaya, K. Comparison of four different heuristic optimization algorithms for the inverse kinematics solution of a real 4-DOF serial robot manipulator. Neural Comput. Appl. 2016, 27, 825–836. [Google Scholar] [CrossRef]

- Bernard, C.; Kang, H.; Singh, S.K.; Wen, J.T. Robotic system for collaborative control in minimally invasive surgery. Ind. Robot 1999, 26, 476–484. [Google Scholar] [CrossRef]

- Kebria, P.M.; Al-wais, S.; Abdi, H.; Nahavandi, S. Kinematic and Dynamic Modelling of UR5 Manipulator. In Proceedings of the 2016 IEEE International Conference on Systems, Man, and Cybernetics, Budapest, Hungary, 9–12 October 2016; IEEE: Washington, DC, USA, 2017; pp. 4229–4234. [Google Scholar]

- Hasan, A.T.; Hamouda, A.M.S.; Ismail, N.; Al-Assadi, H.M.A.A. An adaptive-learning algorithm to solve the inverse kinematics problem of a 6 DOF serial robot manipulator. Adv. Eng. Softw. 2006, 37, 432–438. [Google Scholar] [CrossRef]

- Rubio, J.J.; Aquino, V.; Figueroa, M. Inverse kinematics of a mobile robot. Neural Comput. Appl. 2013, 23, 187–194. [Google Scholar] [CrossRef]

- Duguleana, M.; Barbuceanu, F.G.; Teirelbar, A.; Mogan, G. Obstacle avoidance of redundant manipulators using neural networks based reinforcement learning. Robot. Comput. Intergr. Manuf. 2012, 28, 132–146. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, D.Q.; Sun, J.; Chang, L.; Ma, C.X.; Ge, Y.J.; Gao, L.F. Geometric Approach for Inverse Kinematics Analysis of 6-Dof Serial Robot. In Proceedings of the 2015 IEEE International Conference on Information and Automation, Lijiang, China, 8–10 August 2015; IEEE: Washington, DC, USA, 2015; pp. 852–855. [Google Scholar]

- Ma, C.; Zhang, Y.; Cheng, J.; Wang, B.; Zhao, Q.J. Inverse Kinematics Solution for 6R Serial Manipulator Based on RBF Neural Network. In Proceedings of the 2016 International Conference on Advanced Mechatronic Systems, Melbourne, VIC, Australia, 30 November–3 December 2016; IEEE: Washington, DC, USA, 2016; pp. 350–355. [Google Scholar]

- Mayorga, R.V.; Sanongboon, P. Inverse kinematics and geometrically bounded singularities prevention of redundant manipulators An Artificial Neural Network approach. Robot. Auton. Syst. 2005, 53, 164–176. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle Swarm Optimization. In Proceedings of the IEEE International Conference on Neural Networks IV, Perth, Australia, 27 November–1 December; IEEE: Piscataway, NJ, USA, 1995; pp. 1942–1948. [Google Scholar]

- Chen, C.C.; Li, J.S.; Luo, J.; Xie, S.R.; Li, H.Y. Seeker optimization algorithm for optimal control of manipulator. Ind. Robot 2016, 43, 677–686. [Google Scholar] [CrossRef]

- Si, L.; Wang, Z.W.; Liu, Z.; Liu, X.H.; Tan, C.; Xu, R.X. Health Condition Evaluation for a Shearer through the Integration of a Fuzzy Neural Network and Improved Particle Swarm Optimization Algorithm. Appl. Sci.-Basel 2016, 6, 171. [Google Scholar] [CrossRef]

- Falconi, R.; Grandi, R.; Melchiorri, C. Inverse Kinematics of Serial Manipulators in Cluttered Environments using a new Paradigm of Particle Swarm Optimization. IFAC Proc. Vol. 2014, 47, 8475–8480. [Google Scholar] [CrossRef]

- Kuo, P.H.; Liu, G.H.; Ho, Y.F.; Li, T.H.S. PSO and Neural Network based Intelligent Posture Calibration Method for Robot Arm. In Proceedings of the 2016 IEEE International Conference Systems, Man, and Cybernetics (SMC), Budapest, Hungary, 9–12 October 2016; IEEE: Washington, DC, USA, 2016; pp. 003095–003100. [Google Scholar]

| Link | θ (rad) | a (mm) | d (mm) | α (rad) |

|---|---|---|---|---|

| Joint 1 | 0 | 151.9 | π/2 | |

| Joint 2 | –243.65 | 0 | 0 | |

| Joint 3 | –213.25 | 0 | 0 | |

| Joint 4 | 0 | 112.35 | π/2 | |

| Joint 5 | 0 | 85.35 | –π/2 | |

| Joint 6 | 0 | 81.9 | 0 |

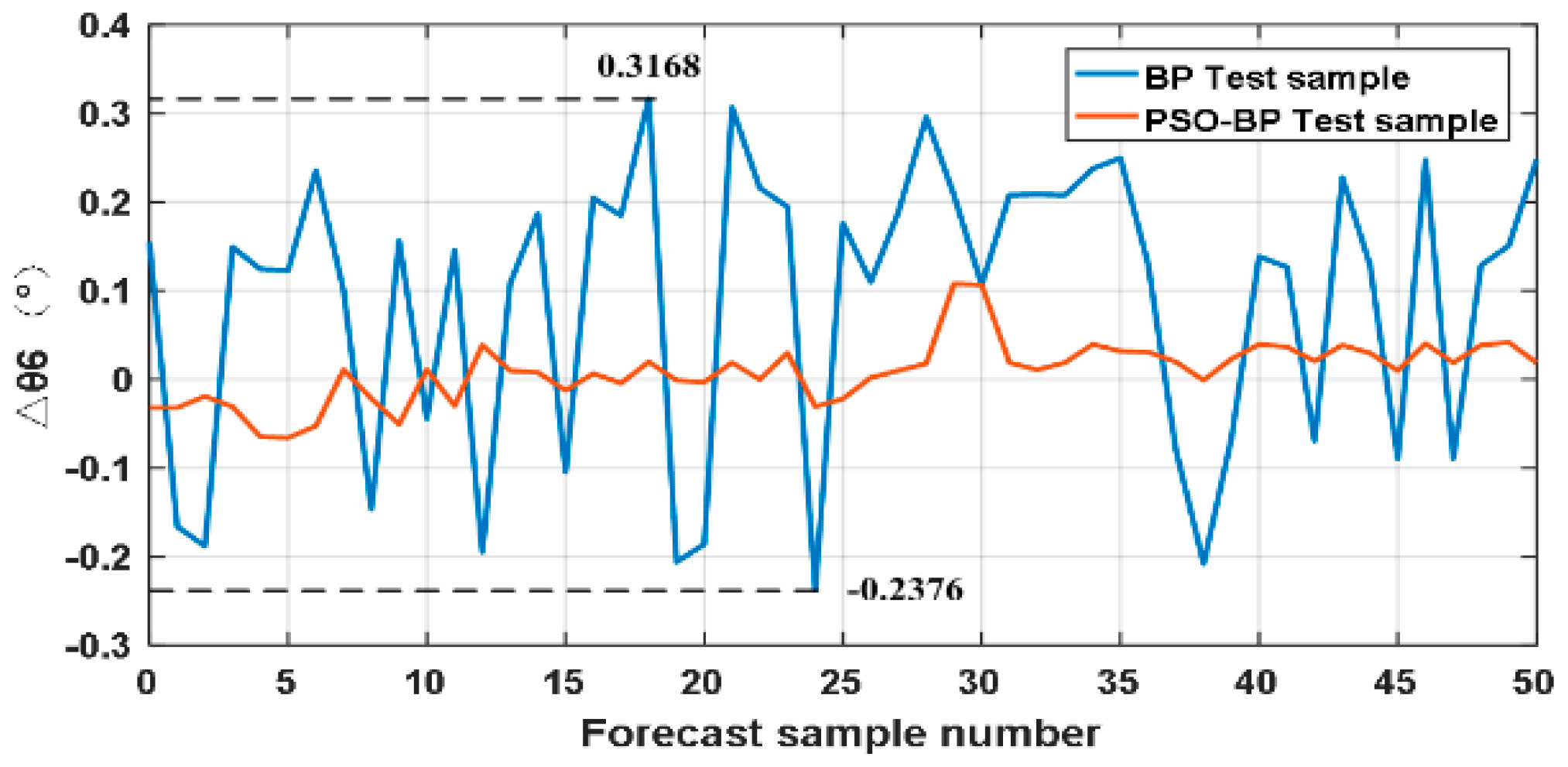

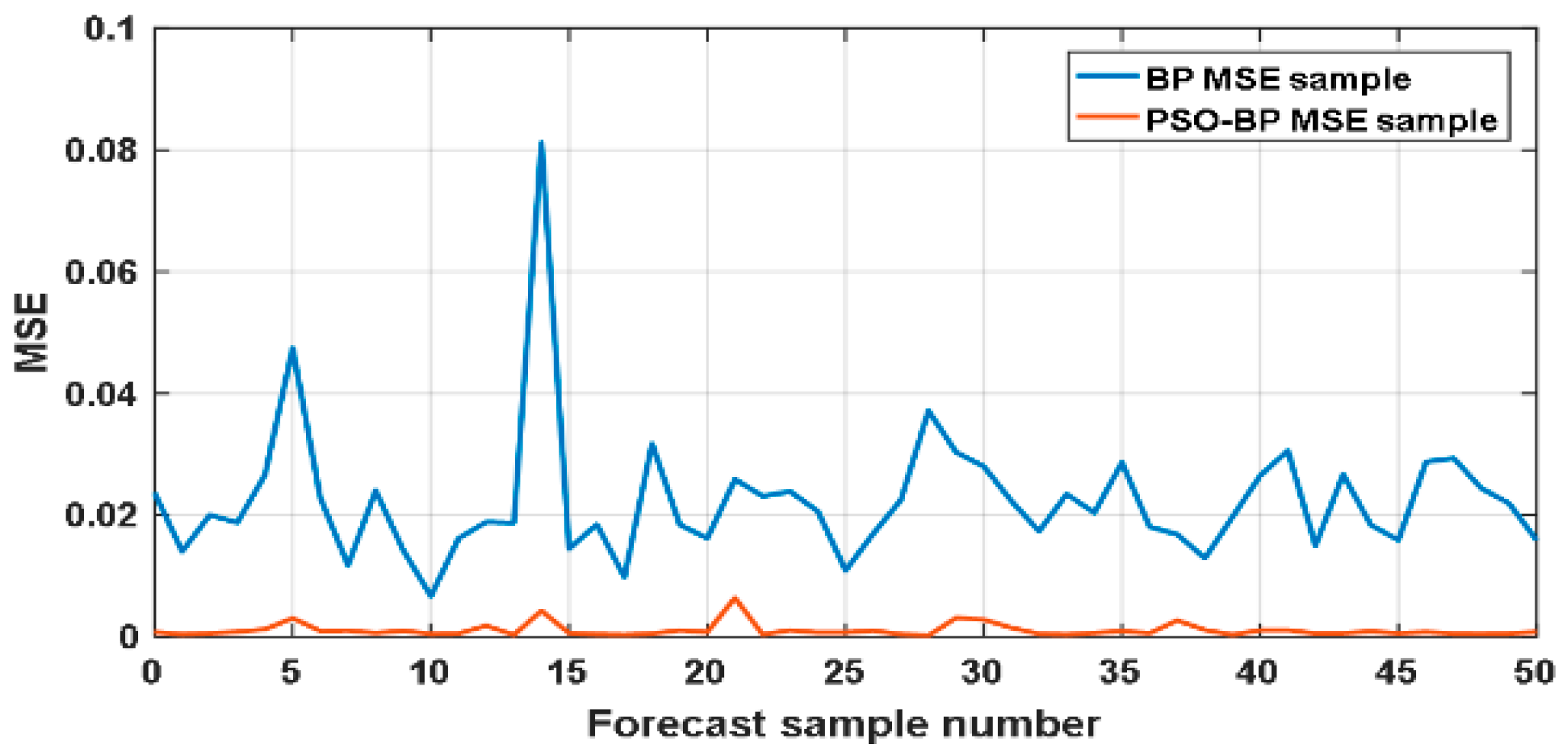

| Joint Angles and MSE (Mean Square Error) | BP (Back Propagation) Neural Network | PSO (Particle Swarm Optimization)-BP Neural Network |

|---|---|---|

| Δθ1 | −0.2005–0.4130 | −0.0534–0.065 |

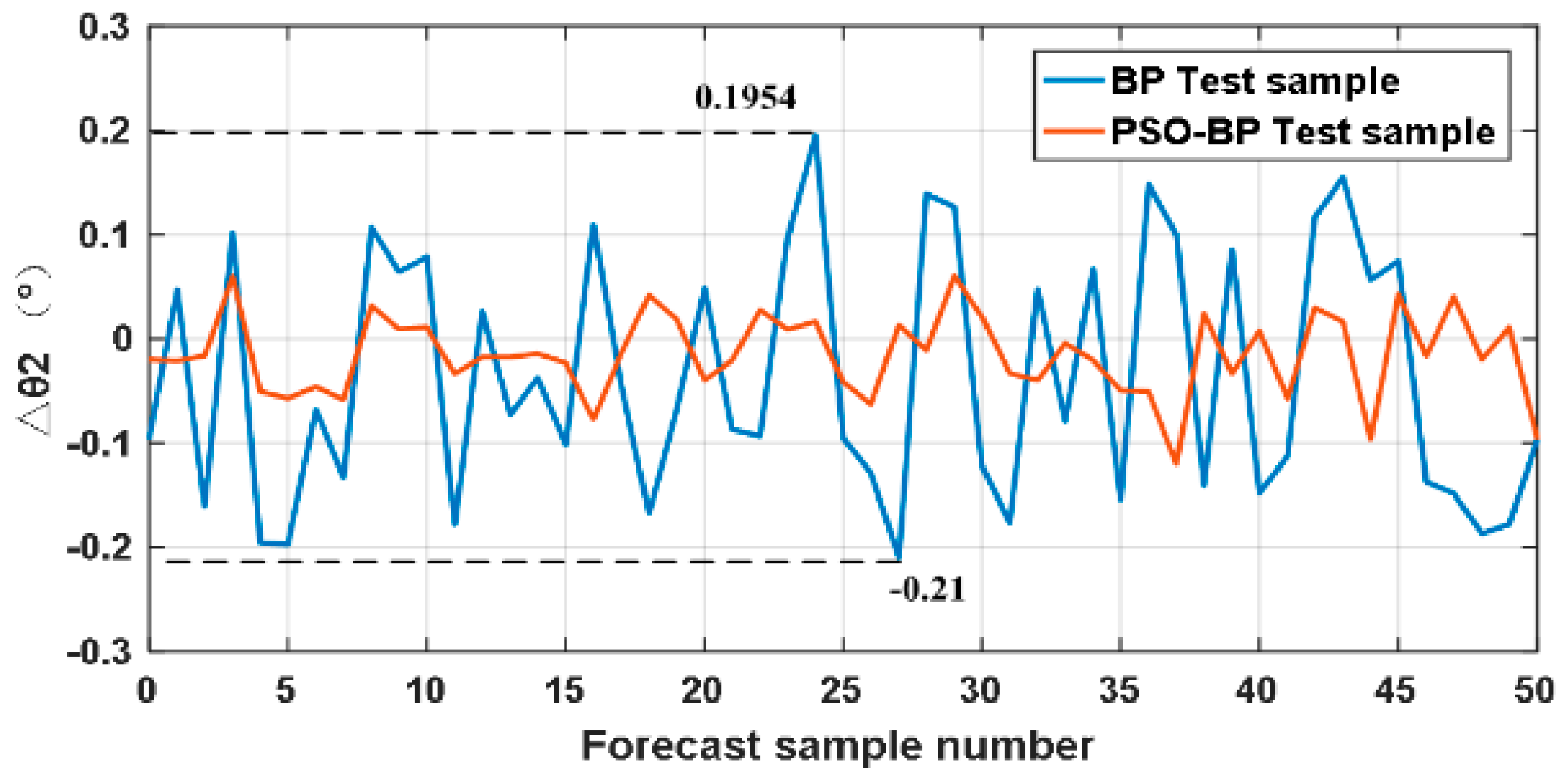

| Δθ2 | −0.2100–0.1954 | −0.1199–0.0605 |

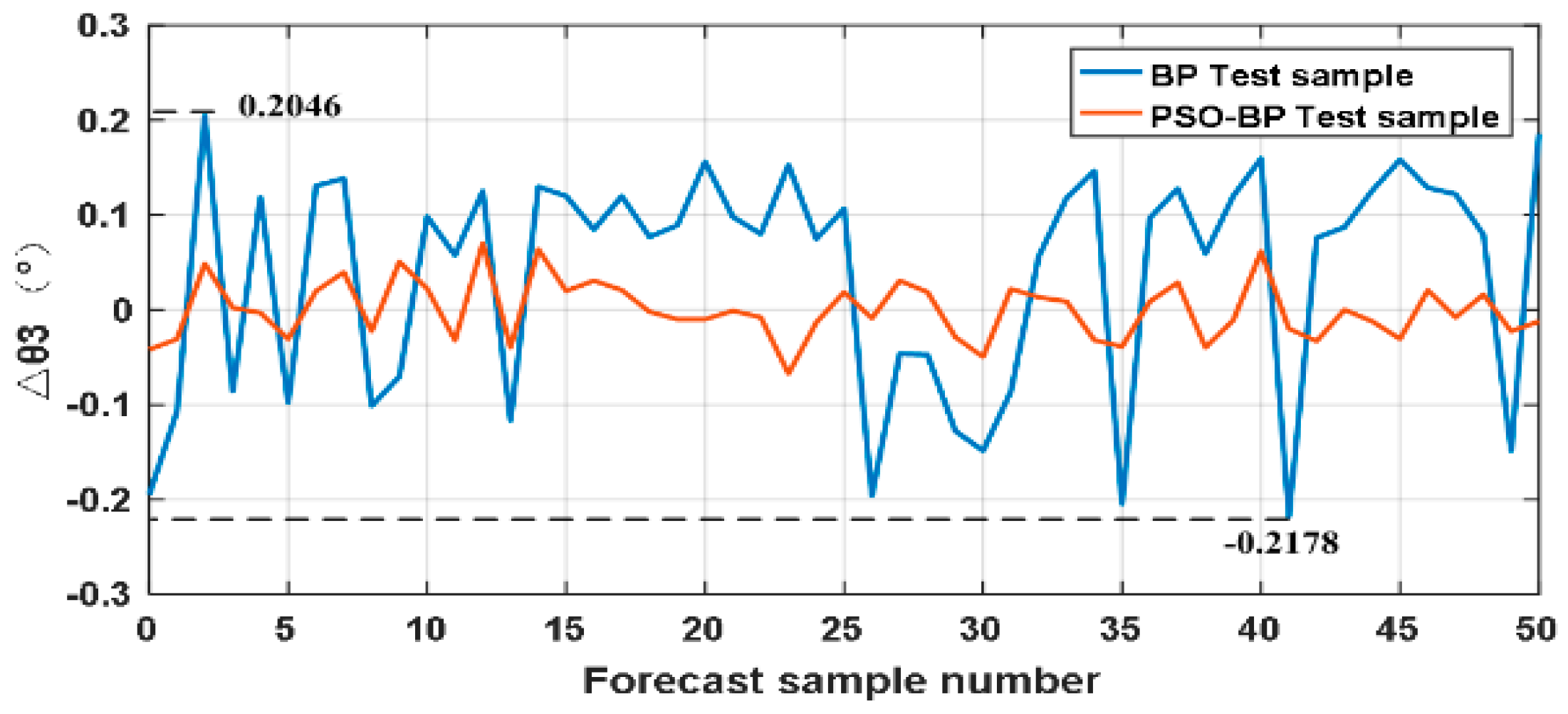

| Δθ3 | −0.2178–0.2046 | −0.0672–0.0704 |

| Δθ4 | −0.3059–0.2178 | −0.0486–0.0508 |

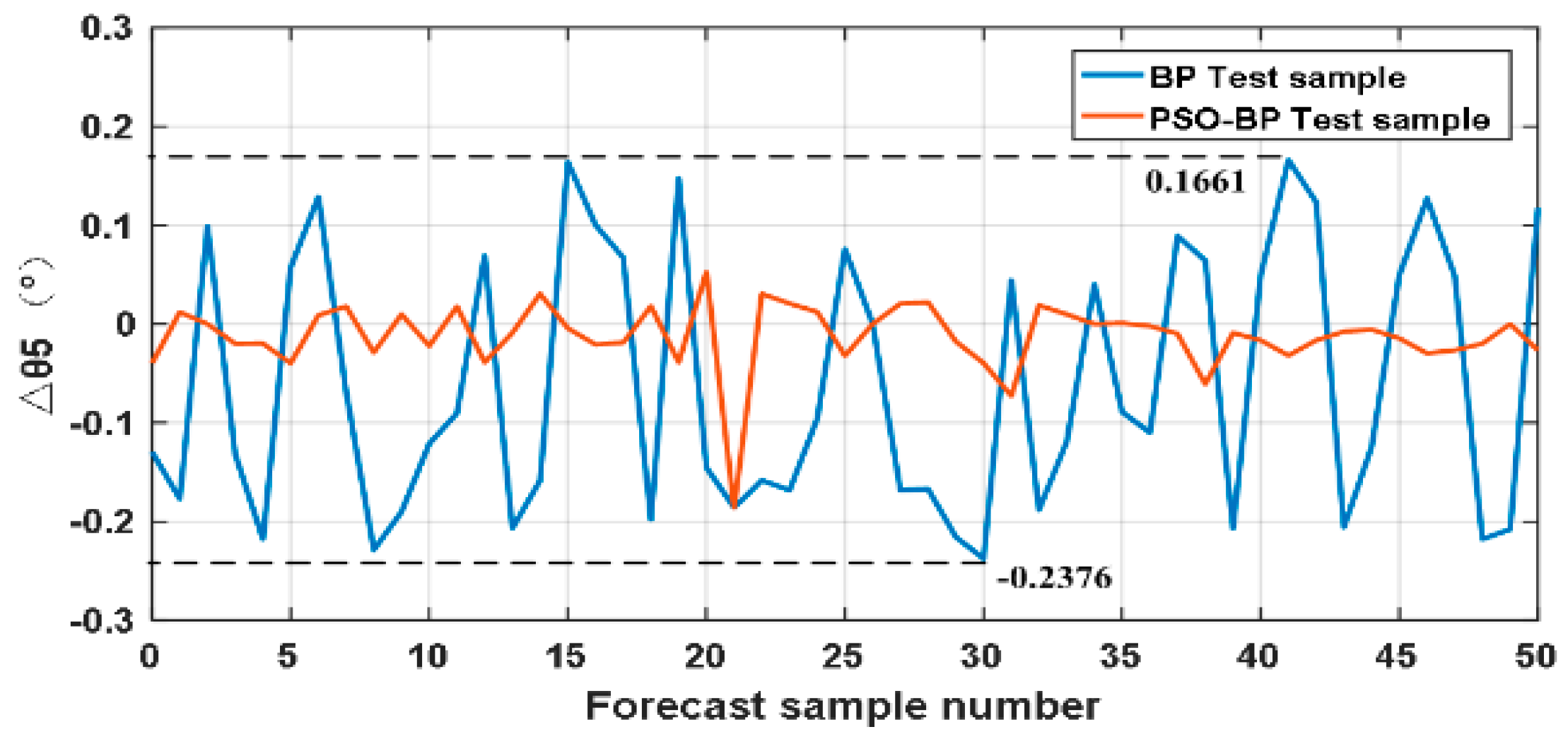

| Δθ5 | −0.2376–0.1661 | −0.1859–0.0526 |

| Δθ6 | −0.2376–0.3168 | −0.0658–0.1079 |

| MSE | 6.72 × 10−3–8.12 × 10−2 | 2.39 × 10−4–6.42 × 10−3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, G.; Luo, M.; Bai, K.; Chen, S. A Precise Positioning Method for a Puncture Robot Based on a PSO-Optimized BP Neural Network Algorithm. Appl. Sci. 2017, 7, 969. https://doi.org/10.3390/app7100969

Jiang G, Luo M, Bai K, Chen S. A Precise Positioning Method for a Puncture Robot Based on a PSO-Optimized BP Neural Network Algorithm. Applied Sciences. 2017; 7(10):969. https://doi.org/10.3390/app7100969

Chicago/Turabian StyleJiang, Guanwu, Minzhou Luo, Keqiang Bai, and Saixuan Chen. 2017. "A Precise Positioning Method for a Puncture Robot Based on a PSO-Optimized BP Neural Network Algorithm" Applied Sciences 7, no. 10: 969. https://doi.org/10.3390/app7100969