Technologies and Principles of Hot Recycling and Investigation of Preheated Reclaimed Asphalt Pavement Batching Process in an Asphalt Mixing Plant

Abstract

:1. Introduction

- Materials. It must be ensured that the reclaimed materials correspond to the requirements, they are homogeneous, with a low moisture content, and without contamination.

- Mix design should be performed according to best practices, depending on recycled asphalt content and its properties to ensure the reduction of stiffness of the aged binder, as well as the desired performance properties for the entire life-cycle of the pavement [6].

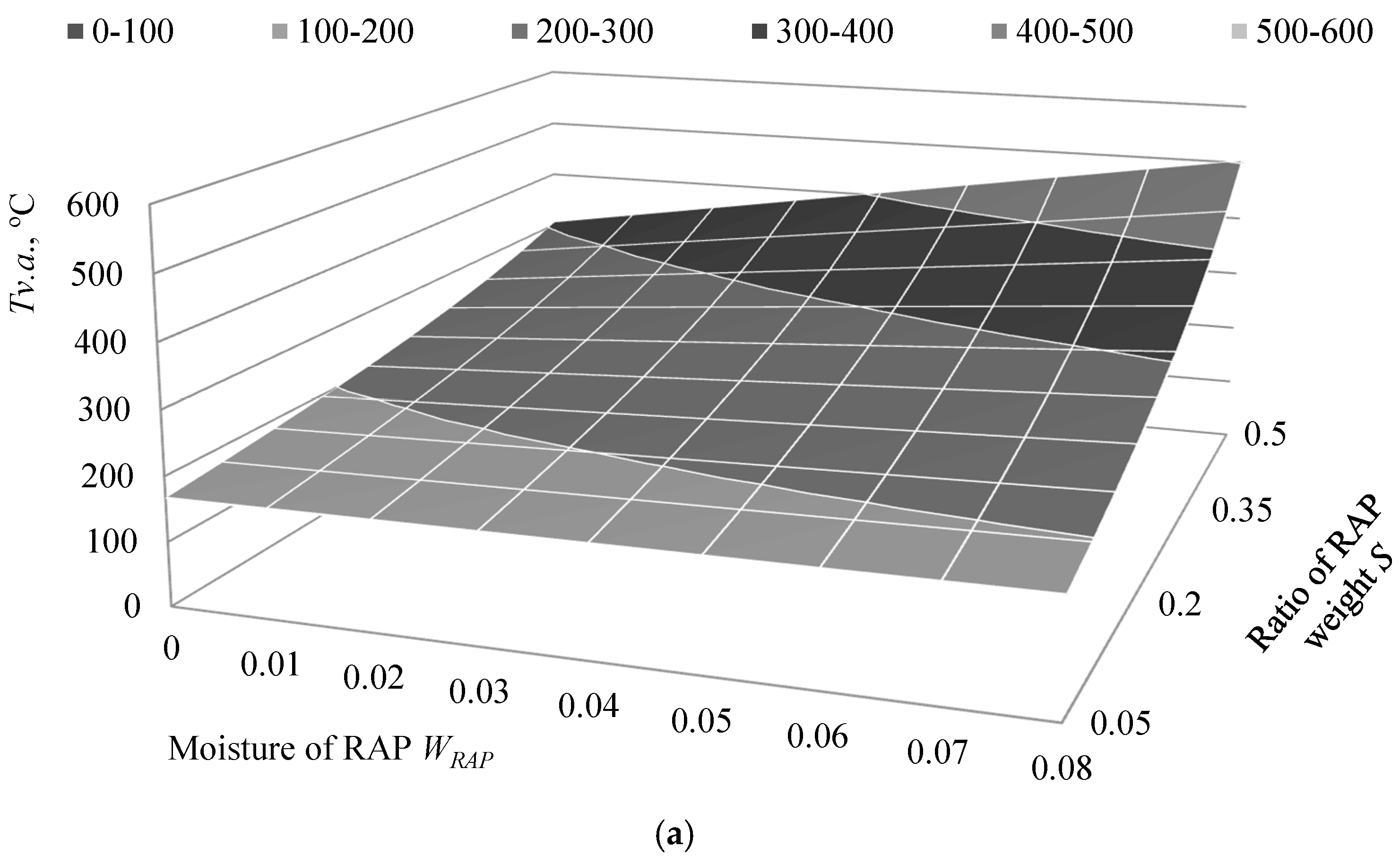

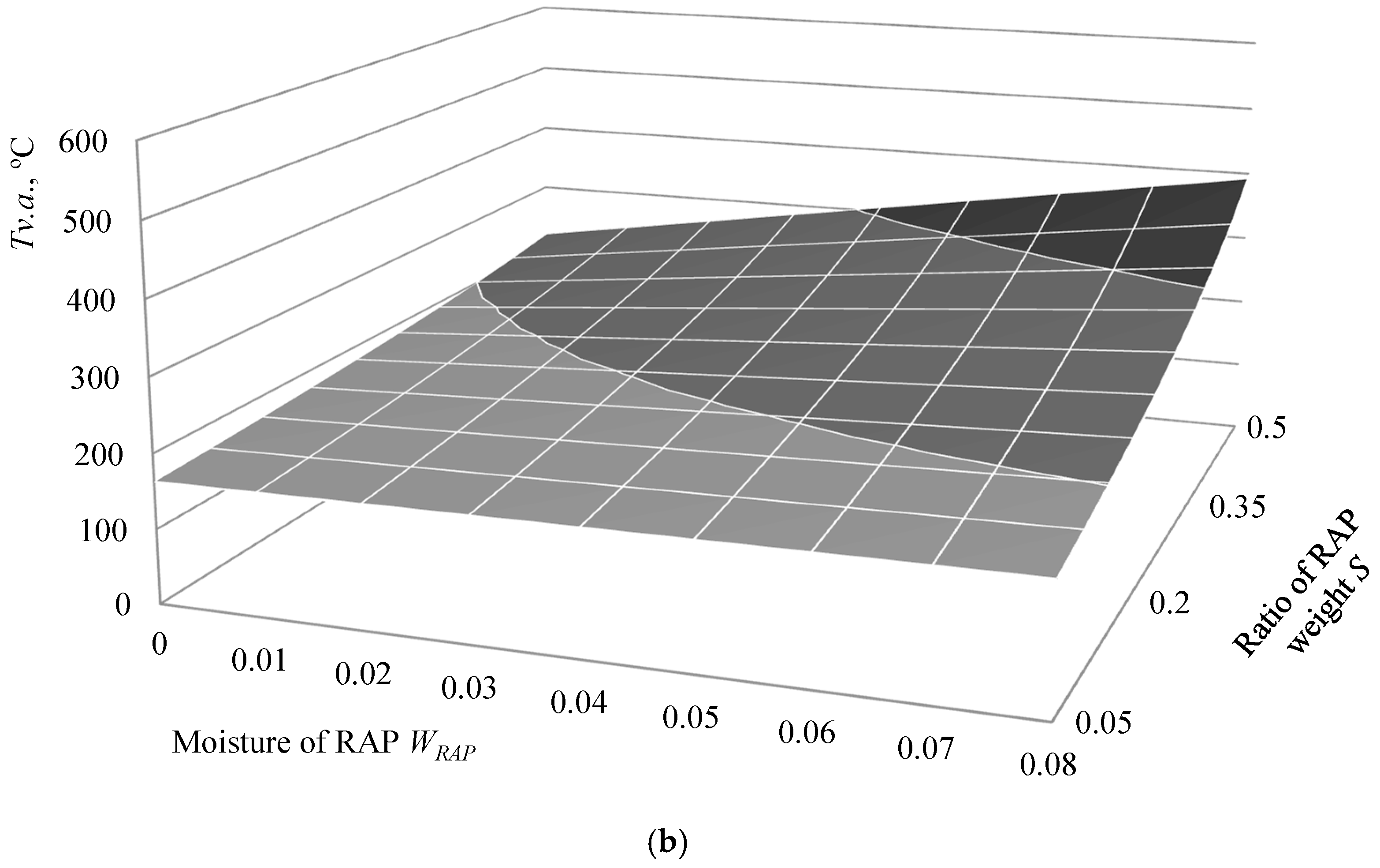

- The production technology must allow for incorporating the desired RAP content by heating it to the necessary temperature and ensuring homogeneous blending with virgin materials without creating emissions [7].

2. Theoretical Formulation of the Problem

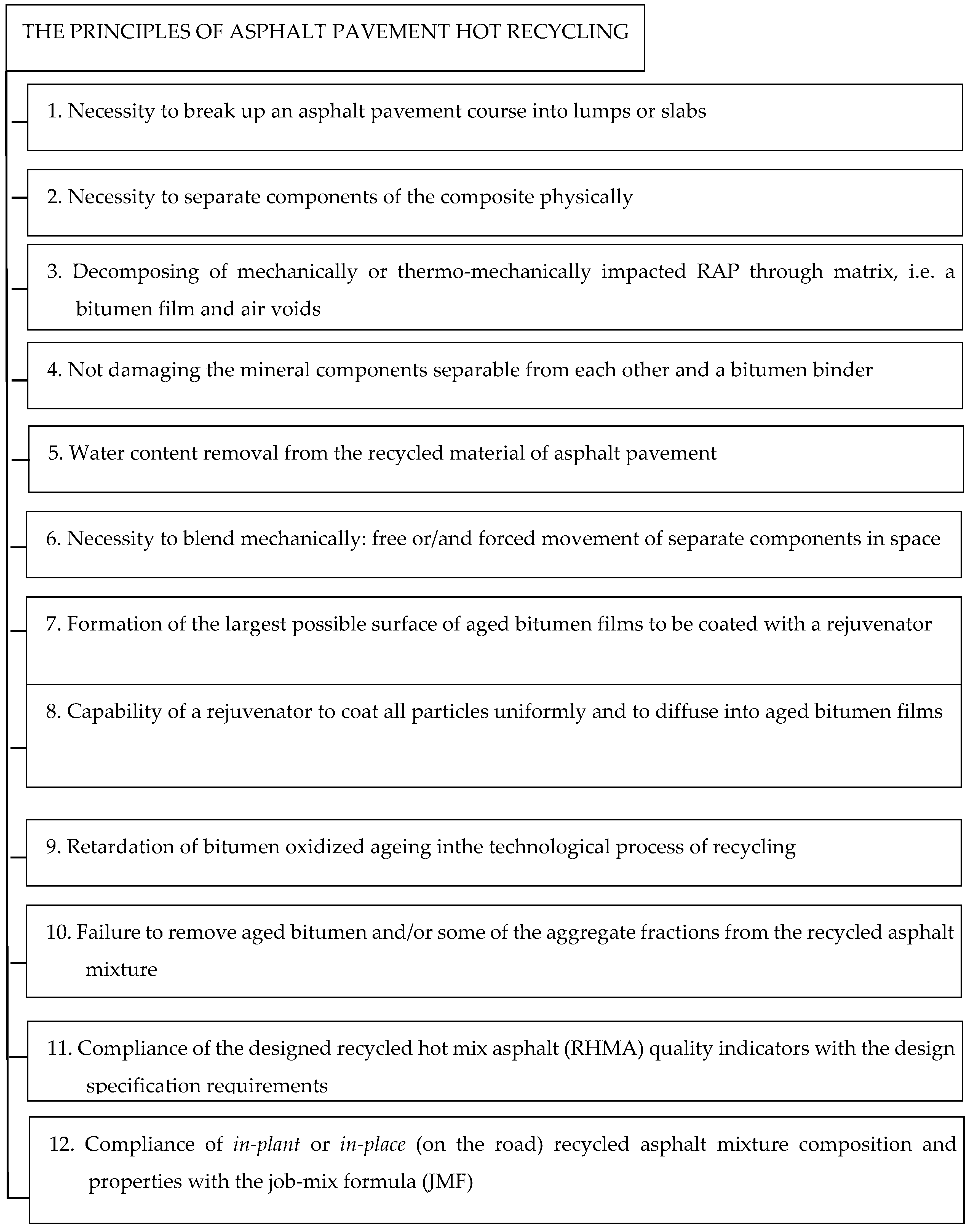

2.1. Principles of Asphalt Pavement Hot Recycling

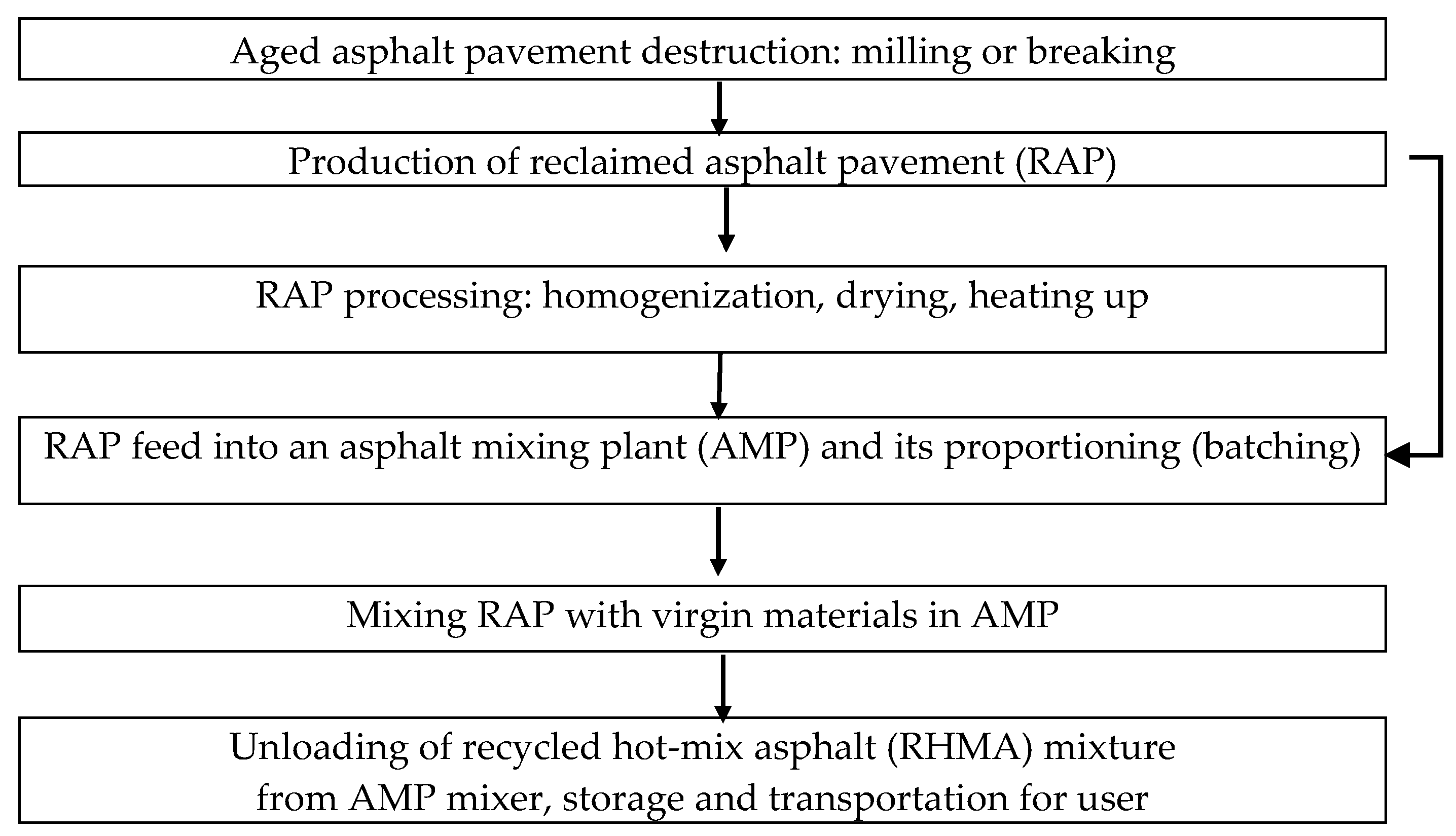

2.2. Model of Technologies of RAP Recycling

- the conformity of its gradation (content of mineral filler, fine aggregate and coarse aggregate and bituminous binder content with JMF; and,

- the conformity of the RHMA mixture temperature to the type of used bituminous binder grade.

3. RAP Batching Accuracy and Precision

3.1. Methods

3.2. Materials

4. Results and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tran, N.H.; Taylor, A.; Willis, R. Effect of Rejuvenator on Performance Properties of HMA Mixtures with High RAP and RAS Contents; Report Number 12-05; National Center for Asphalt Technology: Auburn, AL, USA, 2012. [Google Scholar]

- Zaumanis, M.; Mallick, R.B. Review of very high-content reclaimed asphalt use in plant-produced pavement: State of the art. Int. J. Pavement Eng. 2015, 16, 39–55. [Google Scholar] [CrossRef]

- Solaimanian, M.; Savory, E. Variability Analysis of Hot-Mix Asphalt Concrete Containing High Percentage of Reclaimed Asphalt Pavement. Transp. Res. Rec. 1996, 1543, 89–96. [Google Scholar] [CrossRef]

- Howard, I.L.; Cooley, L.A., Jr.; Doyle, J.D. Laboratory Testing and Economic Analysis of High RAP Warm Mixed Asphalt; Mississippi Department of Transportation: Jackson, MS, USA, 2009. [Google Scholar]

- Bloomquist, D.; Diamond, G.; Oden, M.; Ruth, B.; Tia, M. Engineering and Environmental Aspects of Recycled Materials for Highway Construction; Western Research Institute: Laramie, WY, USA, 1993. [Google Scholar]

- Apeagyei, A.K.; Clark, T.M.; Rorrer, T.M. Stiffnes of high-RAP asphalt mixtures: Virginia’s experience. J. Mater. Civ. Eng. 2013, 25, 747–754. [Google Scholar] [CrossRef]

- Rad, F.Y.; Sefidmazgi, N.R.; Bahia, H. Application of diffusion mechanism. Degree of Blending between fresh and recycled asphalt pavement binder in dynamic shear rheometer. Transp. Res. Rec. J. Transp. Res. Board. 2014, 2444, 71–77. [Google Scholar] [CrossRef]

- Miró, R.; Valdés, G.; Martínez, A.; Segura, P.; Rodriguez, C. Evaluation of high modulus mixture behaviour with high reclaimed asphalt pavement (RAP) percentages for sustainable road construction. Const. Build. Mater. 2011, 25, 3854–3862. [Google Scholar] [CrossRef]

- Mogawer, W.; Bennert, T.; Daniel, J.S.; Bonaquist, R.; Austerman, A.; Booshehrian, A. Performance characteristics of plant produced high RAP mixtures. Road Mater. Pavement Des. 2012, 13, 183–208. [Google Scholar] [CrossRef]

- Bražiūnas, J.; Sivilevičius, H. The bitumen batching system’s modernization and its effective at the asphalt mixing plant. Transport 2010, 25, 325–335. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% recycled hot mix asphalt: A review and analysis. Resour. Conserv. Recycl. 2014, 92, 230–245. [Google Scholar] [CrossRef]

- Santos, L.G.D.P.; Baptista, A.M.D.C.; Capitão, S.D. Assessment of the Use of Hot-Mix Recycled Asphalt Concrete in Plant. J. Transp. Eng. 2010, 136, 1159–1164. [Google Scholar] [CrossRef]

- Estakhri, C.; Spiegelman, C.; Gajewski, B.; Yang, G.; Little, D. Recycled Hot-Mix Asphalt Concrete in Florida: A Variability Study; International Center for Aggregates Research: Austin, TX, USA, 1999. [Google Scholar]

- West, R.; Willis, J.R.; Marasteanu, M. Improved Mix Design, Evaluation, and Materials Management Practices for Hot Mix Asphalt with High Reclaimed Asphalt Pavement Content; NCHRP Report 752; NCHRP: Washington, DC, USA, 2013. [Google Scholar]

- National Center for Asphalt Technology (NCAT). LTPP Data Shows RAP Mixes Perform as Well as Virgin Mixes. In Asphalt Technology News; NCAT: Auburn, AL, USA, 2009; Volume 21. [Google Scholar]

- Diefenderfer, S.; Nair, H. Evaluation of Production, Construction, and Properties of High Reclaimed Asphalt Pavement Mixture. Transp. Res. Rec. J. Transp. Res. Board. 2014, 2445, 75–82. [Google Scholar] [CrossRef]

- Bonaquist, R. Can I run more RAP? HMAT Hot Mix Asph. Technol. 2007, 12, 11–13. [Google Scholar]

- Mohammad, L.; Wu, Z.; Zhang, C.; Khattak, M.; Abadie, C. Variability of Air Voids and Mechanistic Properties of Plant-Produced Asphalt Mixtures. Transp. Res. Rec. J. Transp. Res. Board. 2004, 1891, 85–97. [Google Scholar] [CrossRef]

- Ali, H.; Grzybowski, K. Life cycle of hot in-place pavement recycling. Case study. Transp. Res. Rec. J. Transp. Res. Board. 2012, 2292, 29–35. [Google Scholar] [CrossRef]

- Tahmoorian, F.; Samali, B.; Tam, V.W.Y.; Yeaman, J. Evaluation of mechanical properties of recycled material for utilization in the asphalt mixtures. Appl. Sci. 2017, 7, 763. [Google Scholar] [CrossRef]

- Kriz, P.; Grant, D.L.; Veloza, B.A.; Gale, M.J.; Blahey, A.G.; Brownie, J.H.; Shirts, R.D. Blending and diffusion of reclaimed asphalt pavement and virgin asphalt binders. Road Mater. Pavement Des. 2014, 15, 78–112. [Google Scholar] [CrossRef]

- Le Guen, L.; Huchet, F.; Tamagny, P. Drying and heating modelling of granular flow: Application to the mix-asphalt process. J. Appl. Fluid Mech. 2011, 4, 71–80. [Google Scholar]

- Peinado, D.; de Vega, M.; Garcia-Hernando, N.; Marugan-Cruz, C. Energy and exergy analysis in an asphalt’s rotary dryer. Appl. Therm. Eng. 2011, 31, 1039–1049. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Hao, P.; Xue, L. Laboratory evaluation of microwave heating method for hot in-place recycling. J. Test. Eval. 2011, 39, 1070–1077. [Google Scholar]

- Carpenter, S.H.; Wolosick, J.R. Modifier influence in the characterization of hot-mix recycled material. Transp. Res. Rec. J. Transp. Res. Board. 1980, 777, 15–22. [Google Scholar]

- Nahar, S.N.; Mohajeri, M.; Schmets, A.J.M.; Scarpas, A.; van de Ven, M.F.C.; Schitter, G. First observation of blending-zone morphology at interface of reclaimed asphalt binder and virgin bitumen. Transp. Res. Rec. J. Transp. Res. Board. 2013, 2370, 1–9. [Google Scholar] [CrossRef]

- Willis, J.R.; Turner, O.; de Goes Padula, F.; Tran, N.; Julian, G. Effects of changing virgin binder grade and content on high reclaimed asphalt pavement mixture properties. Transp. Res. Rec. J. Transp. Res. Board. 2013, 2371, 66–73. [Google Scholar] [CrossRef]

- Dony, A.; Colin, J.; Bruneau, D.; Drouadainc, I.; Navaro, J. Reclaimed asphalt concretes with high recycling rates: Changes in reclaimed binder properties according to rejuvenating agent. Constr. Build. Mater. 2013, 41, 175–181. [Google Scholar] [CrossRef]

- Lin, J.; Guo, P.; Xie, J.; Wu, S.; Chen, M. Effect of rejuvenator scaler materials on the properties of aged asphalt binder. J. Mater. Civ. Eng. 2013, 25, 829–835. [Google Scholar] [CrossRef]

- Čygas, D.; Mučinis, D.; Sivilevičius, H.; Abukauskas, N. Dependence of the recycled asphalt mixture physical and mechanical properties on the grade and amount of rejuvenating bitumen. Balt. J. Road Bridge Eng. 2011, 6, 124–134. [Google Scholar] [CrossRef]

- Huang, S.-C.; Qin, Q.; Grimes, W.R.; Pauli, A.T.; Galer, R. Influence of Rejuvenators on the Physical Properties of RAP Binders. J. Test. Eval. 2015, 43, 594–603. [Google Scholar] [CrossRef]

- Shirodkar, P.; Mehta, Y.; Nolan, A.; Sonpal, K.; Norton, A.; Tomlison, C.; Dubois, E.; Sullivan, P.; Sauber, R. A study to determine the degree of partial blending of reclaimed asphalt pavement (RAP) binder for high RAP hot mix asphalt. Constr. Build. Mater. 2011, 25, 150–155. [Google Scholar] [CrossRef]

- Karlsson, R.; Isacsson, U. Material-related aspects of asphalt recycling—State-of-art. J. Mater. Civ. Eng. 2006, 18, 81–92. [Google Scholar] [CrossRef]

- Wang, F.; Wang, Z.; Li, C.; Xiao, Y.; Wu, S.; Pan, P. The rejuvenating effect in hot asphalt recycling by mortar transfer ratio and image analysis. Materials 2017, 10, 574. [Google Scholar] [CrossRef] [PubMed]

- Poulikakos, L.D.; dos Santos, S.; Bueno, M.; Kuentzel, S.; Hugener, M.; Partl, M.N. Influence of short and long-term aging on chemical, microstructural and macro-mechanical properties of recycled asphalt mixtures. Constr. Build. Mater. 2014, 51, 414–423. [Google Scholar] [CrossRef]

- Huang, B.; Li, G.; Vukosavljevic, D.; Shu, X.; Egan, B. Laboratory investigation of mixing hot-mix asphalt with reclaimed asphalt pavement. Transp. Res. Rec. J. Transp. Res. Board. 2005, 1929, 37–45. [Google Scholar] [CrossRef]

- Bražiūnas, J.; Sivilevičius, H.; Virbickas, R. Dependences of SMA mixture and its bituminous binder properties on bitumen batching system, mixing time and temperature on asphalt mixing plant. J. Civ. Eng. Manag. 2013, 19, 862–872. [Google Scholar] [CrossRef]

- Vislavičius, K.; Sivilevičius, H. Effect of reclaimed asphalt pavement gradation variation on the homogeneity of recycled hot-mix asphalt. Arch. Civ. Mech. Eng. 2013, 13, 345–353. [Google Scholar] [CrossRef]

- Aurangzeb, Q.; Al-Qadi, I.L.; Abuawad, I.M.; Pine, W.J.; Trepanier, J.S. Achieving desired volumetrics and performance for mixtures with high percentage of reclaimed asphalt pavement. Transp. Res. Rec. J. Transp. Res. Board. 2012, 2294, 34–42. [Google Scholar] [CrossRef]

- Sivilevičius, H.; Vislavičius, K.; Bražiūnas, J. Technological and economic design of asphalt mixture composition based on optimization methods. Technol. Econ. Dev. Econ. 2017, 23, 627–648. [Google Scholar] [CrossRef]

- Valdés, G.; Pérez-Jiménez, F.; Miró, R.; Martínez, A.; Botella, R. Experimental study of recycled asphalt mixtures with high percentages of reclaimed asphalt pavement (RAP). Constr. Build. Mater. 2011, 25, 1289–1297. [Google Scholar] [CrossRef] [Green Version]

- Mučinis, D.; Sivilevičius, H.; Oginskas, R. Factors determining the inhomogeneity of reclaimed asphalt pavement and estimation of its components content variation parameters. Balt. J. Road Bridge Eng. 2009, 4, 69–79. [Google Scholar] [CrossRef]

- Mogawer, W.S.; Austerman, A.J.; Bonaquist, R. Determining the influence of plant type and production parameters on performance of plant-produced reclaimed asphalt pavement mixtures. Transp. Res. Rec. J. Transp. Res. Board. 2012, 2268, 71–81. [Google Scholar] [CrossRef]

- Silva, H.M.R.D.; Oliveira, J.R.M.; Jesus, C.M.G. Are totally recycled hot mix asphalts a sustainable alternative for road paving? Resour. Conserv. Recycl. 2012, 60, 38–48. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X.; Woods, M.E. Quantitative Characterization of Binder Blending. Transp. Res. Rec. J. Transp. Res. Board. 2015, 2506, 72–80. [Google Scholar] [CrossRef]

- Babtista, A.M.; Picado-Santos, L.G.; Capitão, S.D. Design of hot-mix recycled asphalt concrete produced in plant without preheating the reclaimed material. Int. J. Pavement Eng. 2013, 14, 95–102. [Google Scholar] [CrossRef]

- DeDene, C.D.; Voller, V.R.; Marasteanu, M.O.; Dave, E.V. Calculation of particle heating times of reclaimed asphalt pavement material. Road Mater. Pavement Des. 2014, 15, 721–732. [Google Scholar] [CrossRef]

- National Cooperative Highway Research Program (NCHRP). A Manual for Design of Hot Mix Asphalt with Commentary. National Cooperative Highway Research Program. Transportation Research Board of the National Academics; NCHRP Report 673; NCHRP: Washington, DC, USA, 2011; p. 273. [Google Scholar]

- Ma, T.; Huang, X.; Zhao, Y.; Zhang, Y.; Wang, H. Influences of preheating temperature of RAP on properties of hot-mix recycled asphalt mixture. J. Test. Eval. 2016, 44, 762–769. [Google Scholar] [CrossRef]

- Baroux, R. Recyclage des enrobés bitumineux en centrale d’enrobage. Les problémes de matériel. Bulletin de Liaison des Ratoires des Ponts et Chaussées 1980, 105, 98–102. [Google Scholar]

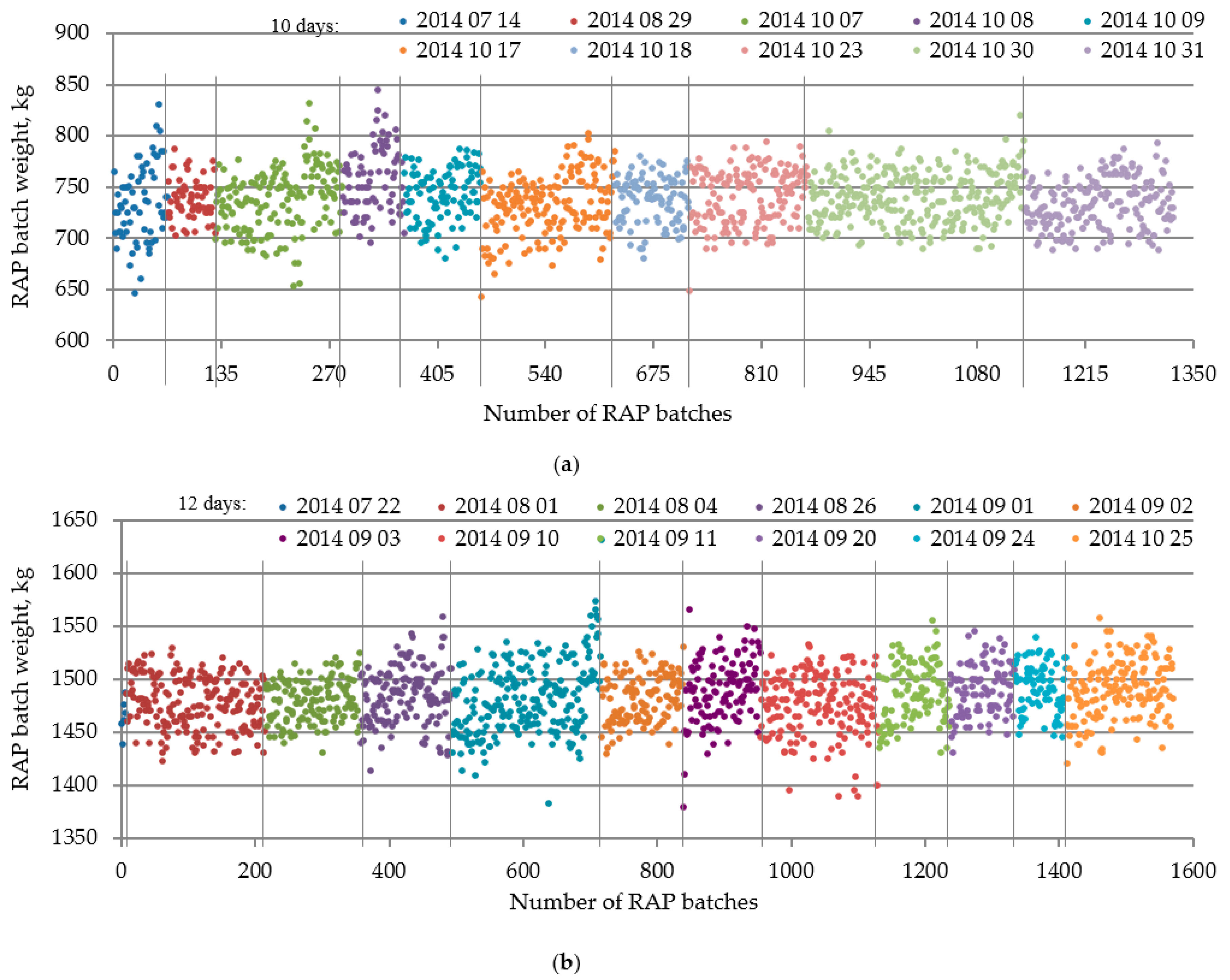

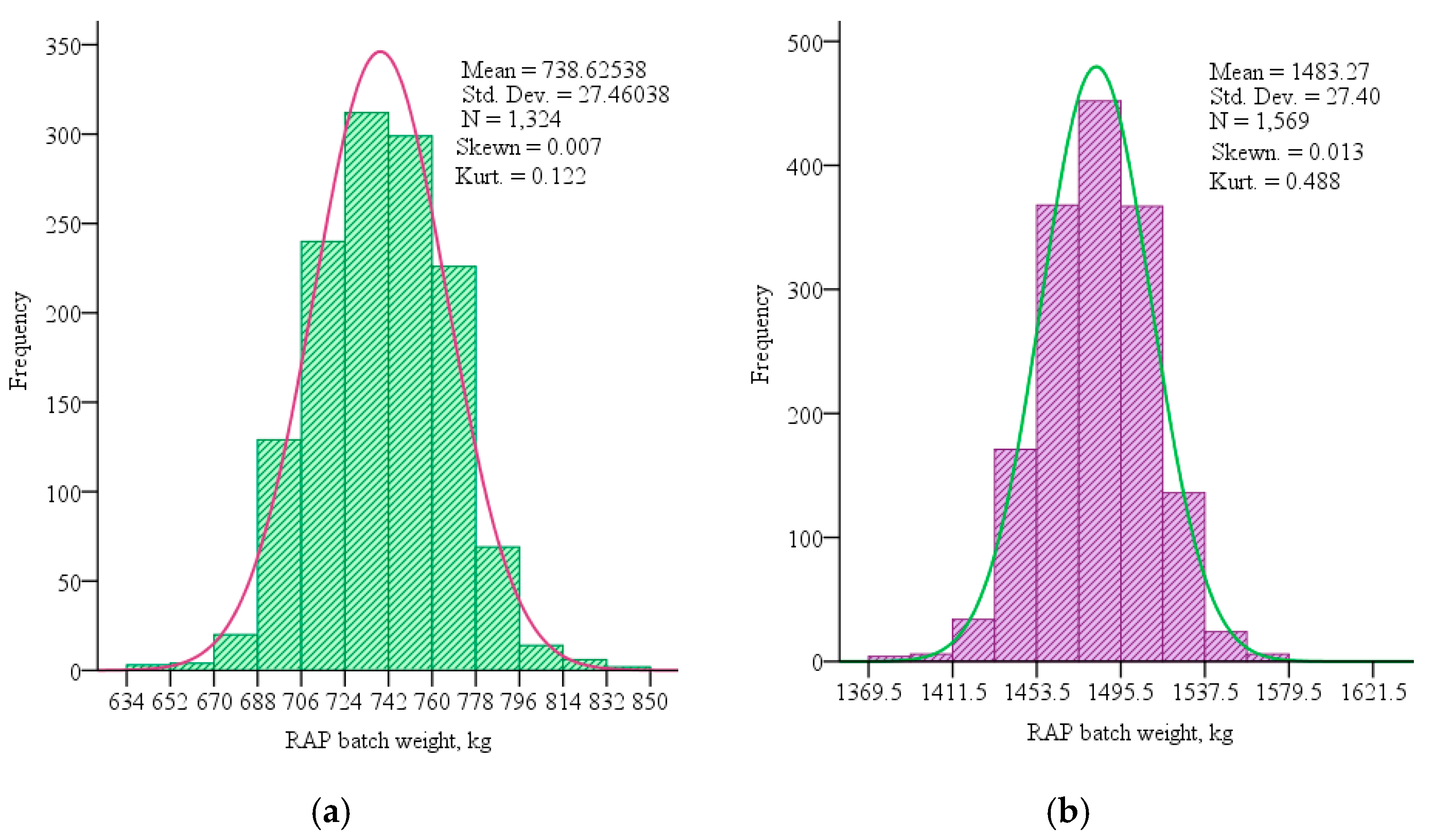

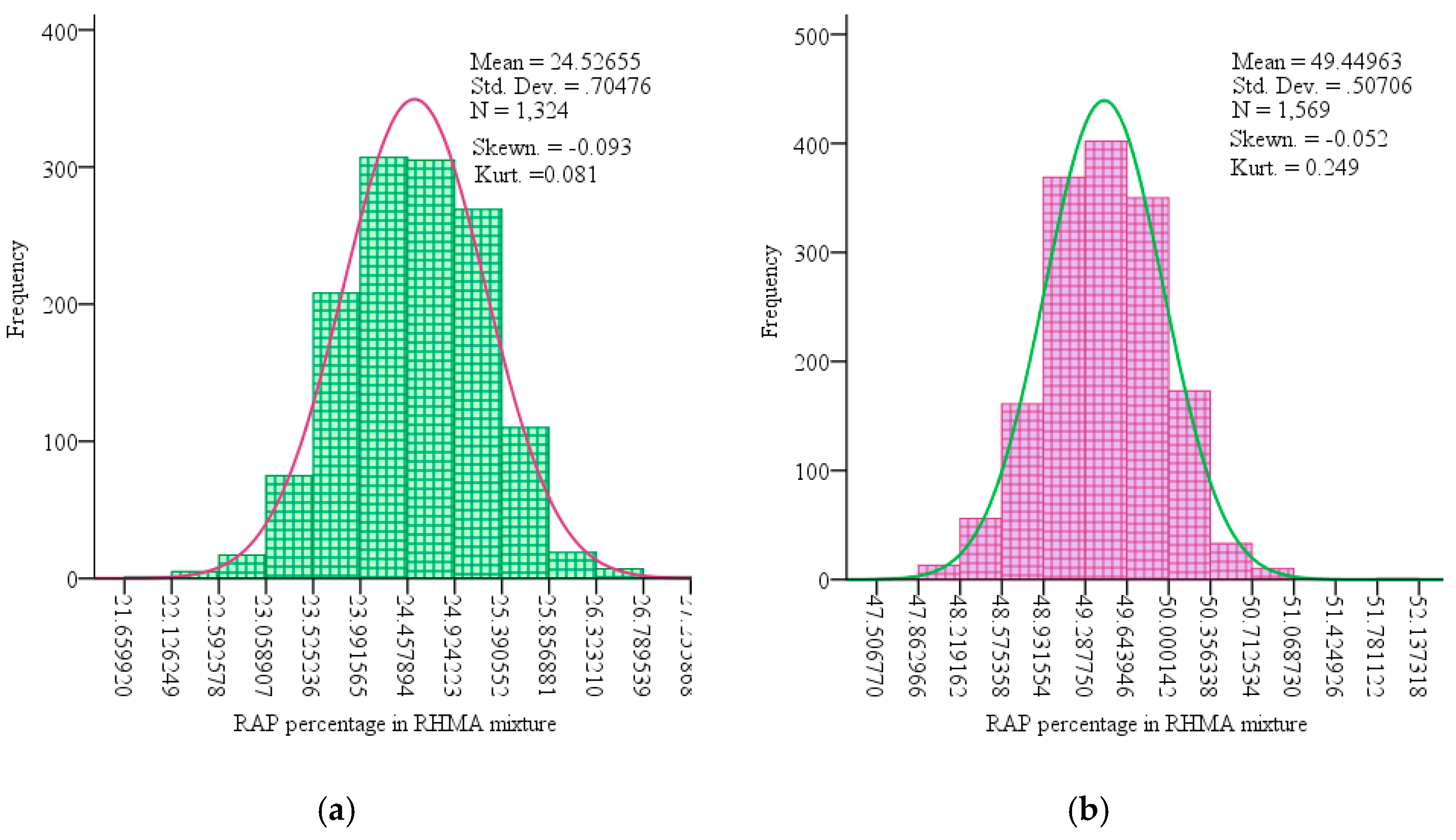

| Type of RHMA | Days | Total Sample Size | Sample Size Without Outliers |

|---|---|---|---|

| AC 16 PD | 10 | 1424 | 1324 |

| AC 22 PS | 12 | 1617 | 1569 |

| Particle Size, mm | Subsample Number | Average | ||||

|---|---|---|---|---|---|---|

| I | II | III | IV | V | ||

| >11.2 | 6.3 | 7.5 | 8.4 | 8.7 | 7.5 | 7.7 |

| >2 | 69.4 | 73.4 | 71.2 | 68.5 | 68.7 | 70.6 |

| 0.063–2 | 30.4 | 26.5 | 28.6 | 31.3 | 31.2 | 29.2 |

| <0.125 | 0.5 | 0.3 | 0.2 | 0.3 | 0.3 | 0.3 |

| <0.063 | 0.2 | 0.1 | 0.2 | 0.2 | 0.1 | 0.2 |

| Bitumen | 4.78 | 4.73 | 4.86 | 4.81 | 4.43 | 4.72 |

| RHMA Mixture Group | RAP | IF | RD | Hot Aggregate Fractions, mm | Virgin Bitumen | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0/2 | 2/5 | 5/8 | 8/11 | 11/16 | 11/32 | |||||

| AC 16 PD | 750 | 99 | 99 | 612 | 219 | 411 | 384 | 306 | - | 120 |

| AC 22 PS | 1500 | - | - | 141 | 87 | 297 | 144 | - | 780 | 51 |

| Materials | Total Batch Mass of a Paving Mix, % |

|---|---|

| Batch aggregate component | ±1.5 |

| Mineral filler | ±0.5 |

| Bituminous material | ±0.1 |

| Zero return (aggregate) | ±0.5 |

| Zero return (bituminous material) | ±0.1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sivilevičius, H.; Bražiūnas, J.; Prentkovskis, O. Technologies and Principles of Hot Recycling and Investigation of Preheated Reclaimed Asphalt Pavement Batching Process in an Asphalt Mixing Plant. Appl. Sci. 2017, 7, 1104. https://doi.org/10.3390/app7111104

Sivilevičius H, Bražiūnas J, Prentkovskis O. Technologies and Principles of Hot Recycling and Investigation of Preheated Reclaimed Asphalt Pavement Batching Process in an Asphalt Mixing Plant. Applied Sciences. 2017; 7(11):1104. https://doi.org/10.3390/app7111104

Chicago/Turabian StyleSivilevičius, Henrikas, Justas Bražiūnas, and Olegas Prentkovskis. 2017. "Technologies and Principles of Hot Recycling and Investigation of Preheated Reclaimed Asphalt Pavement Batching Process in an Asphalt Mixing Plant" Applied Sciences 7, no. 11: 1104. https://doi.org/10.3390/app7111104