1. Introduction

In the previous decades, with the change in the power sector, there has been a tremendous development in load utilization, because of the overwhelming upkeep and types of gear. Now and again, the demand required is high, because of various consumers requesting power in the same time period [

1]. Because of this issue, the Generation Companies (GENCO’s) are infrequently not able to meet their client requests, subsequently making them unsatisfied, or to end their agreements. A portion of the developing issues related with power system operation incorporate constrained supply of system assets that thus drives the administrators to operate their systems at their most extreme limit, bringing about consistent price hikes in the power market [

2]. All the previously mentioned constraints made us explore and investigate and examine novel ways to build proficient usage of assets in power operations. The author proposed an idea of about power system planning studies, with consideration of Optimal Power Flow (OPF) constraints [

3]. On the premise of investigating new ways, demand response (DR) has, as of late, turned into a noteworthy asset in power system operation [

4,

5].

The utilization of demand response administration in power systems empowers the administrator to productively use their assets, and in addition, enhance the power system’s operation. The utilization of Demand Response Program (DRP) in power system operation builds the benefit of clients and the administrators [

6]. Also, consumers who participate in this program are rewarded with incentives for shaving off some of their demand power during peak hours [

7,

8].

The Federal Energy Regulatory Commission (FERC) report on DR implementation in US utilities and electricity markets in 2006 has classified demand response program in two major categories, namely, Time Based Rate Demand Response Program (TBRDRP), and Incentive Based Demand Response Program (IBDRP) [

4]. TBDRP involves changes in price over a day, in accordance with load demand. The higher the demand, the more the price rate, whereas prices decrease in hours where the demand is lower [

9]. Here, the consumers are neither penalized nor rewarded, as done in IBDRP. IBDRP involves paying customers a certain amount in the form of incentives, in order for them to shift or curtail their loads during peak hours. Here, the customers are penalized if they fail to curtail the load based on the contract they maintain with the GENCOs. Demand response, when considered theoretically, is satisfying, but when implemented in practical cases, various criteria and constraints need to be checked [

10].

Demand response (DR) gives an opportunity in the integration of distributed energy resources as demand side resources (DSR), and encourages them to participate in power system services. The DR program gives support and infrastructure for DSR to produce or consume power with some operating constraints [

11]. The main objective of the DR program is balancing the supply and demand power, and maintaining the system without congestion occurring with various demand side resources [

12,

13]. The proposed work is focused on realizing the unprepared demand response services with real-time control strategies. The main issue associated with implementing demand response in the power systems’ operation network is the load kickback effect [

14]. Load kickback effect can be described as the sudden rise in demand during the non-peak hours that is caused by the overuse of power by the consumers after their reduction of power during peak hours [

15].

In load kickback effect, the load demand may go beyond the level during the steady state operation before the outage during the system restoration [

16]. It is observed that load kickback effect is produced in demand response programs after the load elasticity from DSRs is activated [

17]. It may lead to cancellation of the contract, and produce more congestion problems. Controlling the home and commercial loads, like water heater and coolers in peak hours, may reduce the original peak load, but another kickback load is produced, even larger than the original peak load value, after the peak hours [

18].This paper discusses the load kickback issue associated with Demand Response while implementing in the power systems. The research outcome provides us with a few solutions to avoid it.

Load kickback effect can be controlled by two methods. The first involves direct load control of electronic devices by the GENCOs. In this method, heavy power consuming devices, like heaters, pumps, and air conditioners, can be directly controlled from the supply station. When the need arises, these devices can be shut directly, to avoid overloading of the system. The second method involves GENCOs with some more incentive rewards to consumers who agree to maintain their loads at a minimum, to avoid overloading of the system after a DR event. The consumers are subsequently rewarded for minimizing their loads.

2. Demand Response Unit Commitment Program

The Traditional Unit Commitment (TUC) is a process of scheduling the power generation, within the system and unit operational limits. Minimizing the generation cost, along with fuel cost and startup cost, is the prime objective of the traditional unit commitment problem [

19]. The primary objective of the demand response unit commitment problem is to maximize the profits of the GENCOs using time based demand response program (TBDRP).

PR—is the total profit of the GENCOs and DRSP combined

TRV—is the total revenue calculated from GENCOs and DRSP

TOCOST—is the total operating cost of GENCOs and DRSP combined

Total operating cost varies for GENCOs and consumers:

Total operating cost for GENCOs is represented as

The following section illustrates the various equations associated with demand response unit commitment.

Equality Constraint: The equality constraint gives the power balance between generation and load, (i.e., total generated power should be equal to the demanded power)

Inequality Constraint: The power generation limit should be within the specified generation limits of that unit.

Ramp up Rate: It is the specified limit above which the maximum power generation value cannot be increased for a unit in the next hour.

Ramp down Rate: It is the specified limit below which the minimum power generation value cannot be decreased for a unit in the next hour.

Minimum up time: Once a unit is committed, then for some specific number of hours, it cannot be decommitted.

Minimum down time: Once a unit is decommitted, then for some specific number of hours it cannot be recommitted.

Reserve Constraints: A specified amount of power that is generated by the unit at a particular hour may be used in cases of emergencies, for which it is kept reserved.

Spinning Reserve: The difference between the amount of power generated from all the units synchronized to the system with its present load supplies and losses incurred in the system is called spinning reserve.

Startup Cost of Units: Startup cost can be classified into two different types, namely, hot start cost and cold start cost. Hot start cost is the one where the generator is maintained at minimum temperature, without being shut down. Cold start cost is the one when the generator is shut down, and is started back up once again [

20].

3. Cat Swarm Optimization (CSO)

Cat Swarm Optimization is developed by Chu, Tsai, and Pan in 2006, and it can be used to many complex and nonlinear problems [

21]. CSO has been successfully applied to a number of power system optimization problems, such as transmission congestion management problems [

22], power system stability [

23], and reconfiguration problems [

24] like optimal placement of Distributed Generator (DG) and Phasor Measurement Unit (PMU) [

25]. The constraints impacted by parameters and stagnation issue of Particle Swarm Optimization (PSO) and Differential Evolution (DE) are met by CSO. CSO is a meta-heuristic transformative optimization approach that imitates the characteristic conduct of felines [

26]. The main significance of the feline group is that it has a solid interest towards articles that move, and that of the cat group is that it has prevalent chasing aptitudes. Despite the fact that they are dependable and appear to move gradually, they are constantly prepared and attentive towards their environment. On detecting the pray, they chase it rapidly in this manner, spending a lot of vitality [

21,

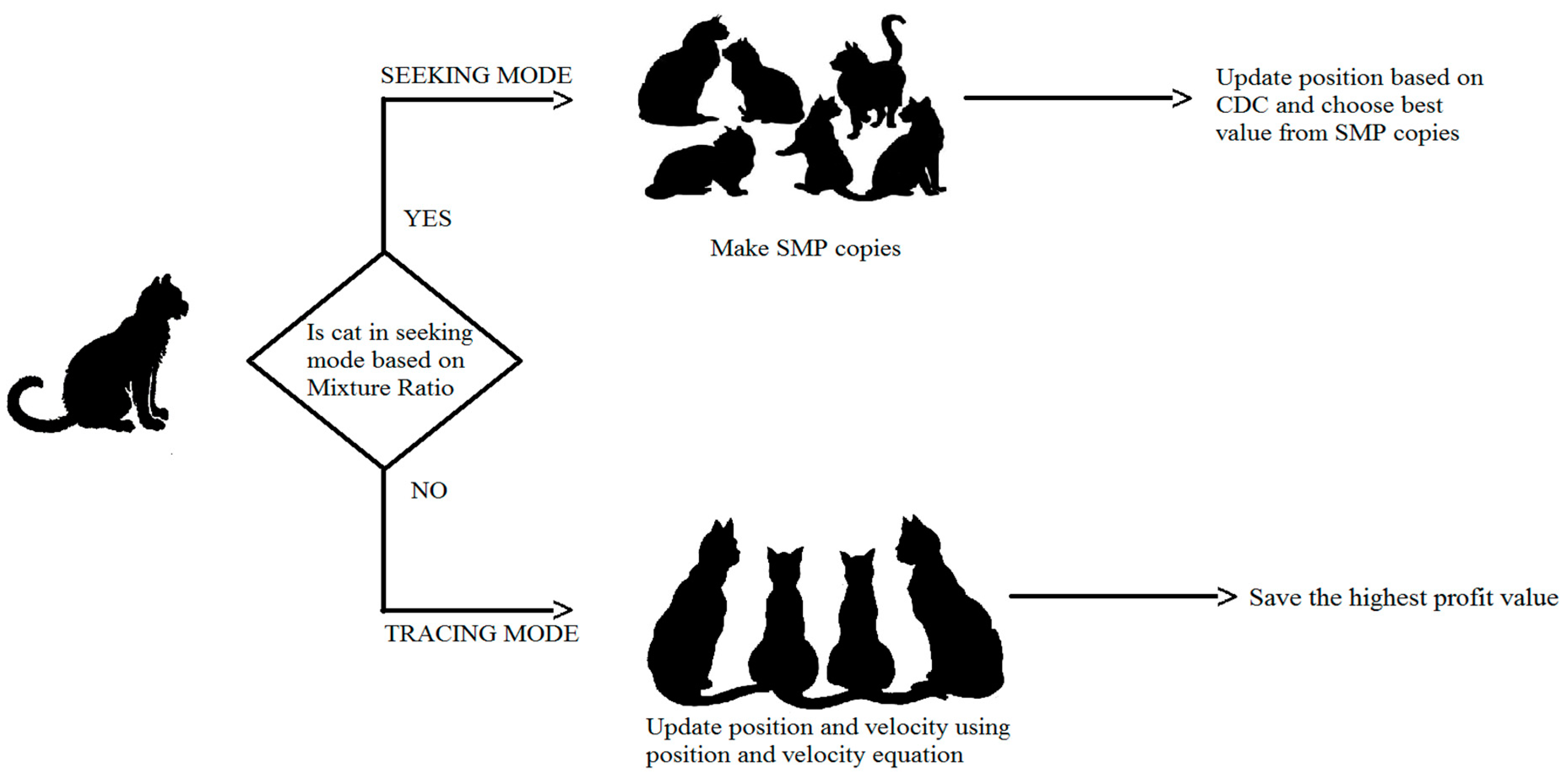

27]. These two attributes, that is, the moderate development resting and sudden rapid chasing, are depicted as looking for and following modes. Each of these mode is independently modeled. The pictorial representation of CSO is explained in

Figure 1.

3.1. Seeking Mode

There are fouressential factors used in seeking, and these factors are described as [

7]

- (a)

Seeking Memory Pool (SMP): number of cat copies produced.

- (b)

Seeking Range of selected Dimension (SRD): discrepancy between the new and old in the dimension selected for mutation.

- (c)

Counts of Dimensions to Change (CDC): number of dimensions to be mutated.

- (d)

Mixture Ratio (MR): the ratio of the time spent by the cats is resting to observing.

Steps executed in seeking mode:

- (1)

Randomly choose MR fraction of population seeking cats: rest are declared as tracing cats.

- (2)

SMP copies of the ith seeking cat are created.

- (3)

Position of each copy is updated based on CDC, by randomly adding or subtracting SRD fraction.

- (4)

Error fitness values of copies are evaluated.

- (5)

Best candidate is picked form all copies and assigned as ith seeking cat.

- (6)

Repeat step 2 until all seeking cats are involved.

3.2. Tracing Mode

This sub model is modeled when cat is tracing its targets.

In tracing mode, the cats will move in accordance with its own velocity for every dimension. This mode is carried out in 3 steps:

3.3. Algorithm for Proposed Method

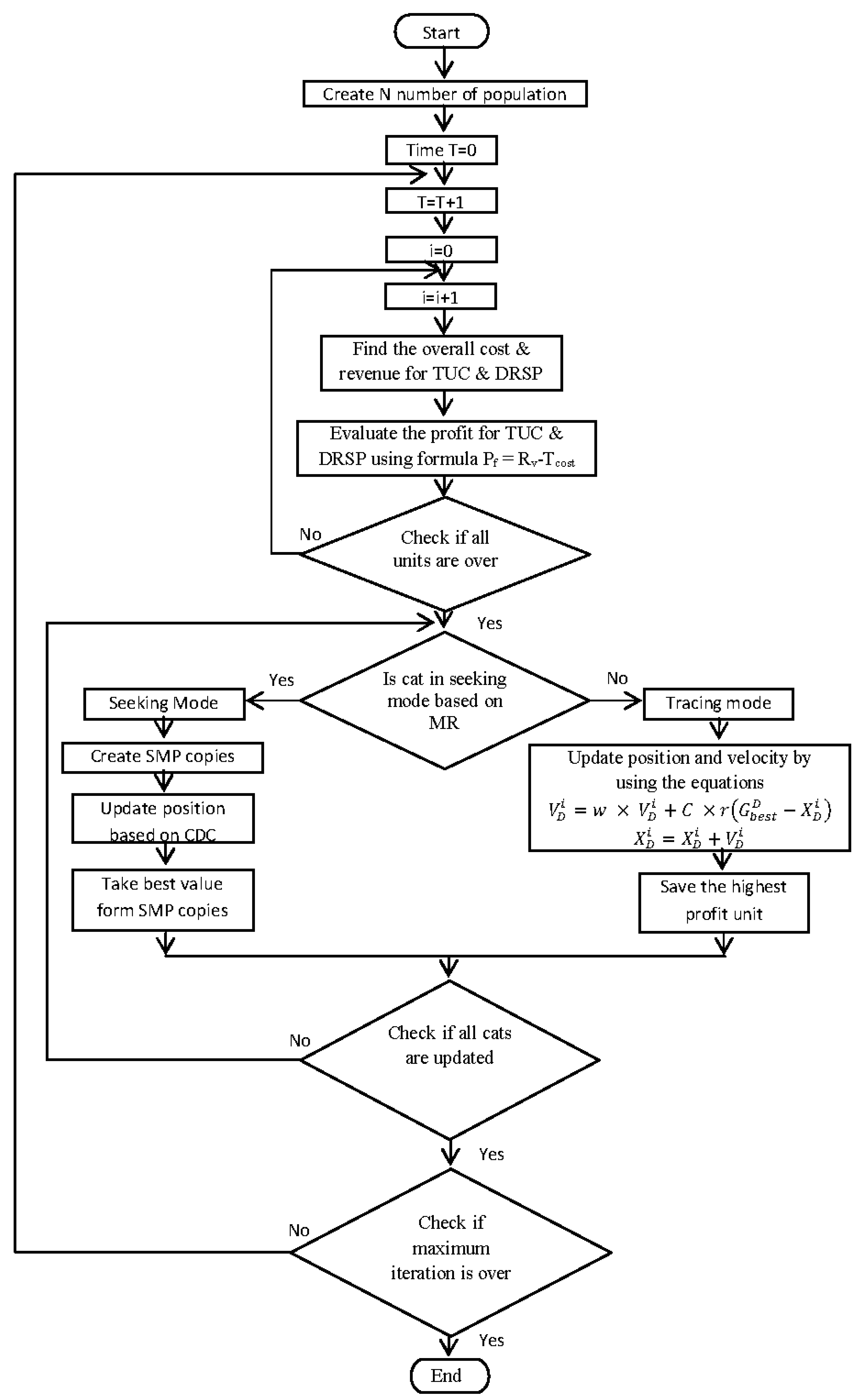

The algorithm for the proposed method solution is discussed below, and the flowchart is explained in

Figure 2.

Step 1: Generate N number of population.

Step 2: Initialize time t = 0 and i = 0.

Step 3: Find the overall cost andrevenue for Traditional Unit Commitment (TUC) and Demand Response Service Providers (DRSP)from the data provided, using iterations, and store the values andevaluate the profit for TUC andDRSP using formula Pf = Rv − Tcost.

Step 4: Check if all units are over andwhether the cat is in seeking mode based on MR value?

Step 5: If yes, Seeking Mode.

Create SMP copies, and update position based on CDC, then take best value from SMP copies.

Step 6: If no, then Tracing mode.

Step 7: Update position and velocity by using the equation and , save the highest profit unit.

Step 8: Check if all cats are updated, if yes, then proceed or else go back to step 4.

Step 9: Check if maximum iteration is over, if yes, then stop and display the result, else, go back to step 2.

4. Results and Discussion

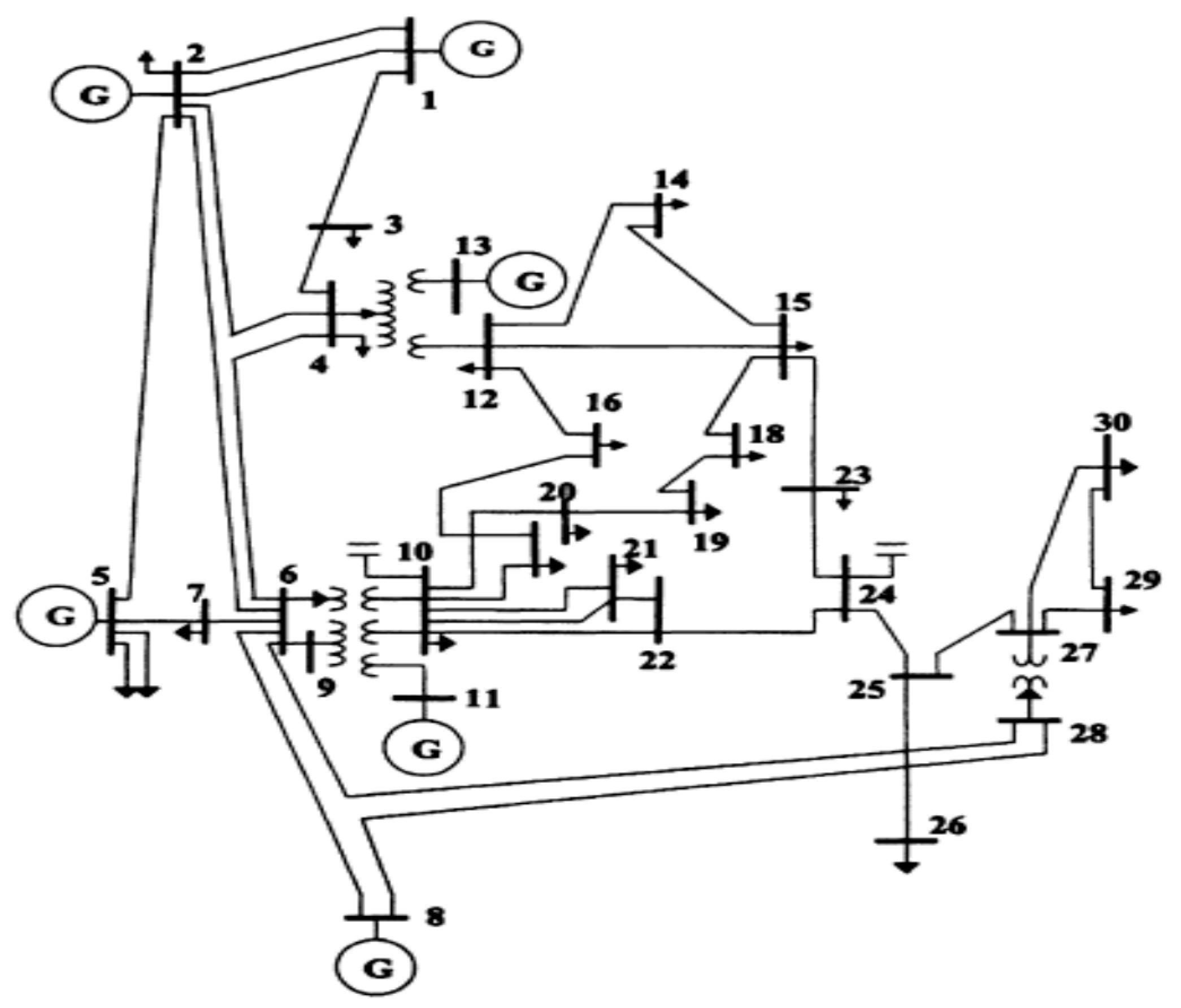

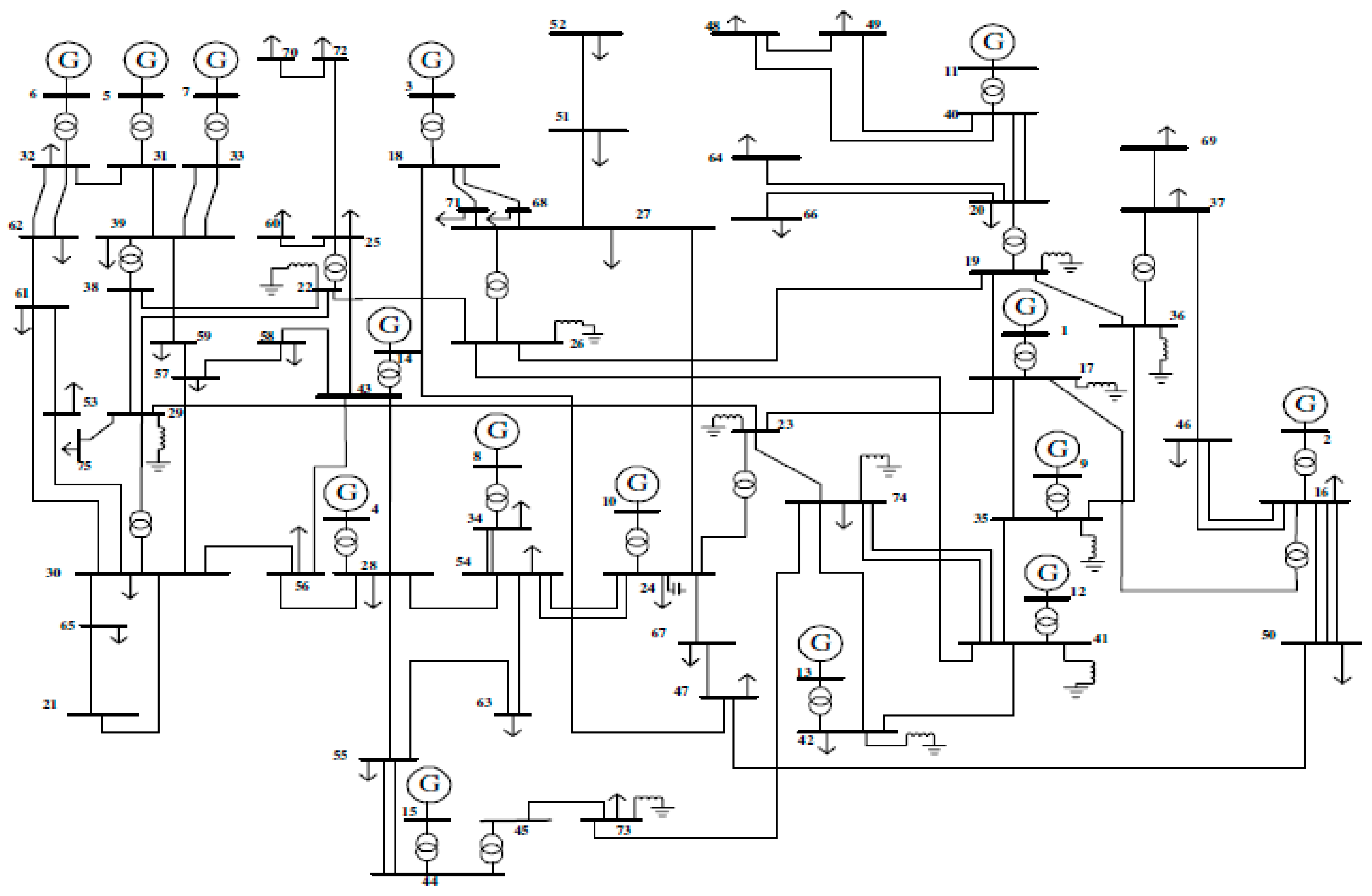

The optimization has been done on two systems, the first being IEEE 30 bus system with 6 generating units, and the second being 75 bus Indian utility system with 15 generating units. The single diagram of the IEEE 30 bus and 75 bus Indian utility systems are given in

Figure 3 and

Figure 4. The operator data for 30 bus system is given in

Table 1 and the fuel and emission cost data is given in

Table 2. The operator data for 75 buses Indian utility system is given in

Table 3, and the fuel and emission cost data in

Table 4.

The optimization algorithm has been implemented on both IEEE 30 bus and 75 bus Indian utility system, and the results have been obtained. The costs of 30 bus system for various cases involving demand response, kickback load, and controlled kickback load are discussed in

Table 5. From the table, it can be seen that the profit is high while controlled kickback load is implemented. Same thing has been observed for 75 bus system shown in

Table 5, where the various costs have been shown. Here too, it is observed that when controlled kickback load is implemented, there is high rise in profit. Even though the profit is more in a DR regulated environment, it is not taken into consideration, due to the kickback effect.

The plots involving various costs and loads have been plotted.

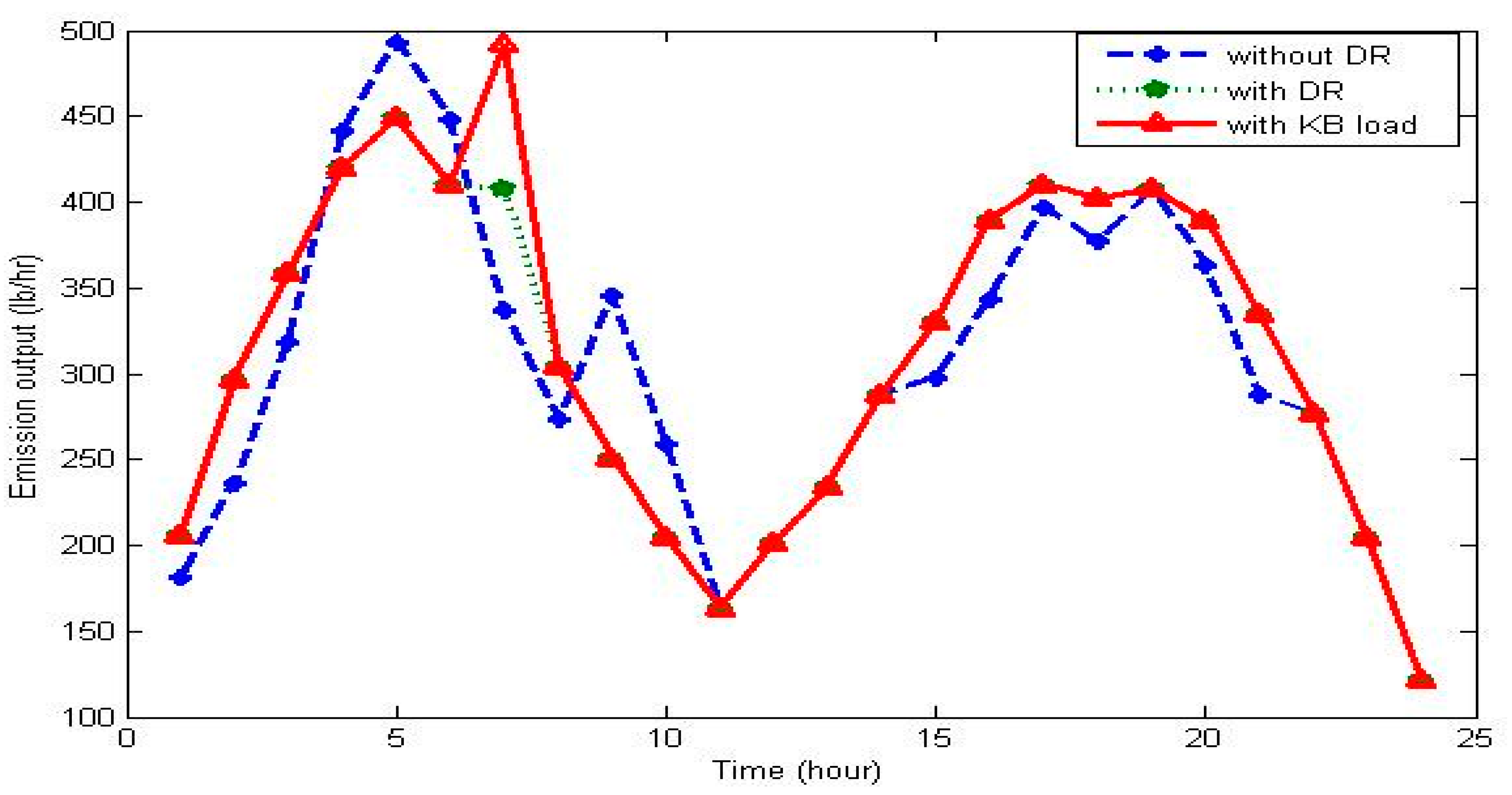

Figure 5 shows the plot for emission output versus time for cases involving DR, excluding DR, and with kickback load for 30 bus system. In

Figure 5, the emission output for 30 bus system with kickback load hours and off-peak hours, is more compared to without demand response case. However, the total emission output for 30 bus and 75 bus system for 24 h scheduling horizon is less, and is given in

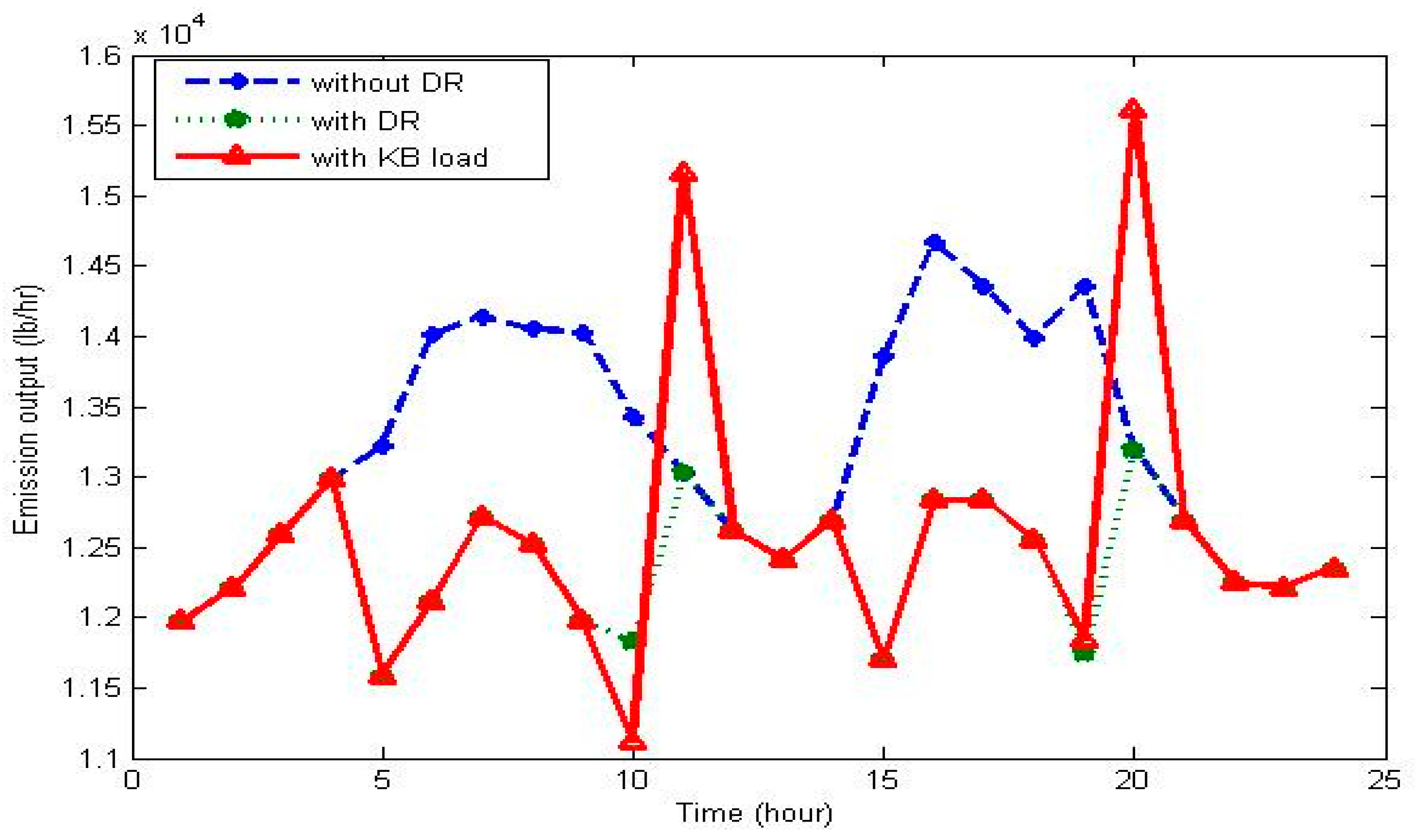

Table 6. The emission output has been plotted for 75 bus system in

Figure 6. It shows that without demand response case, the emission is more in most of the hours, compared to the other two cases. The load demand versus time with DR, without DR, and with kickback load for 30 bus system has been plotted in

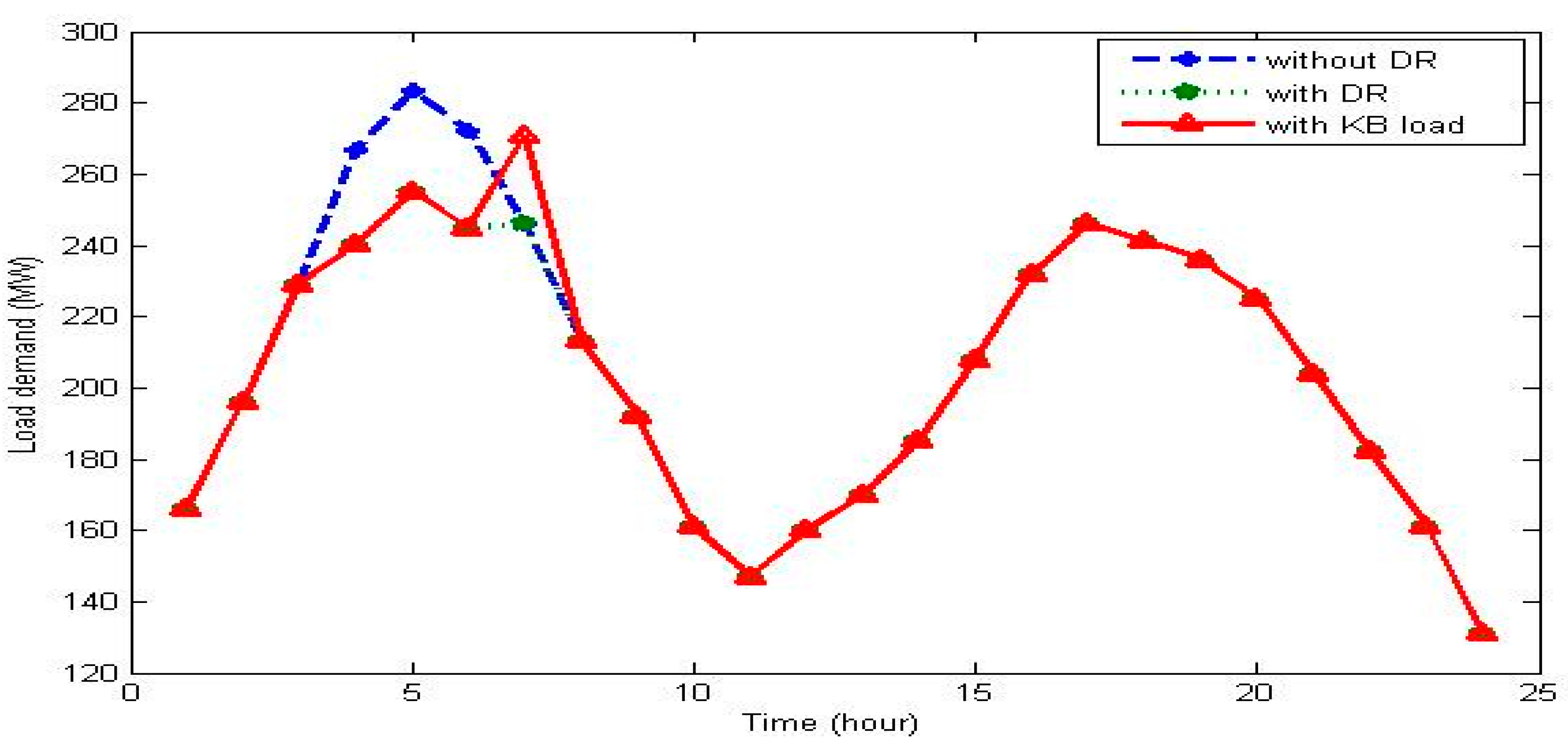

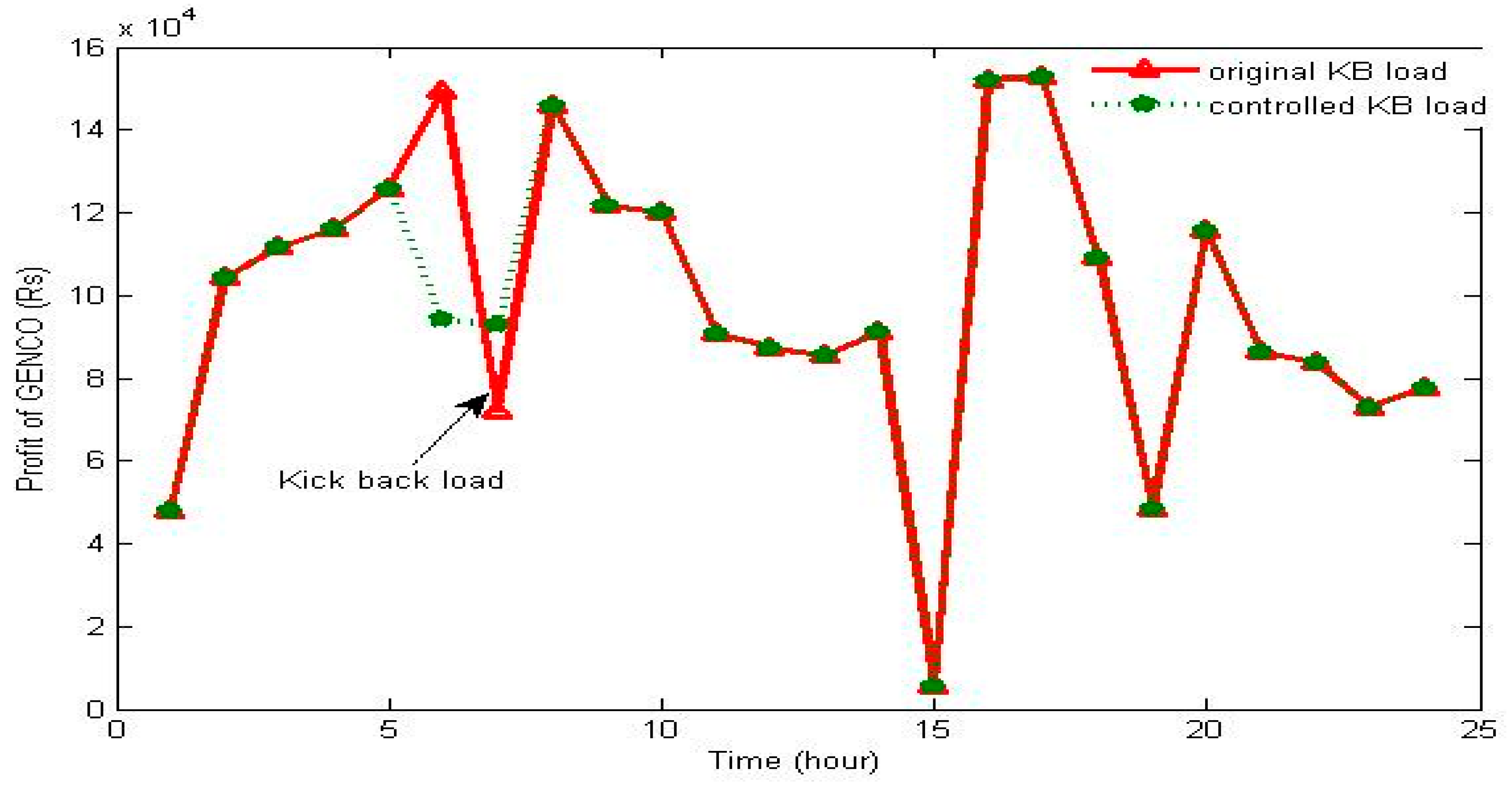

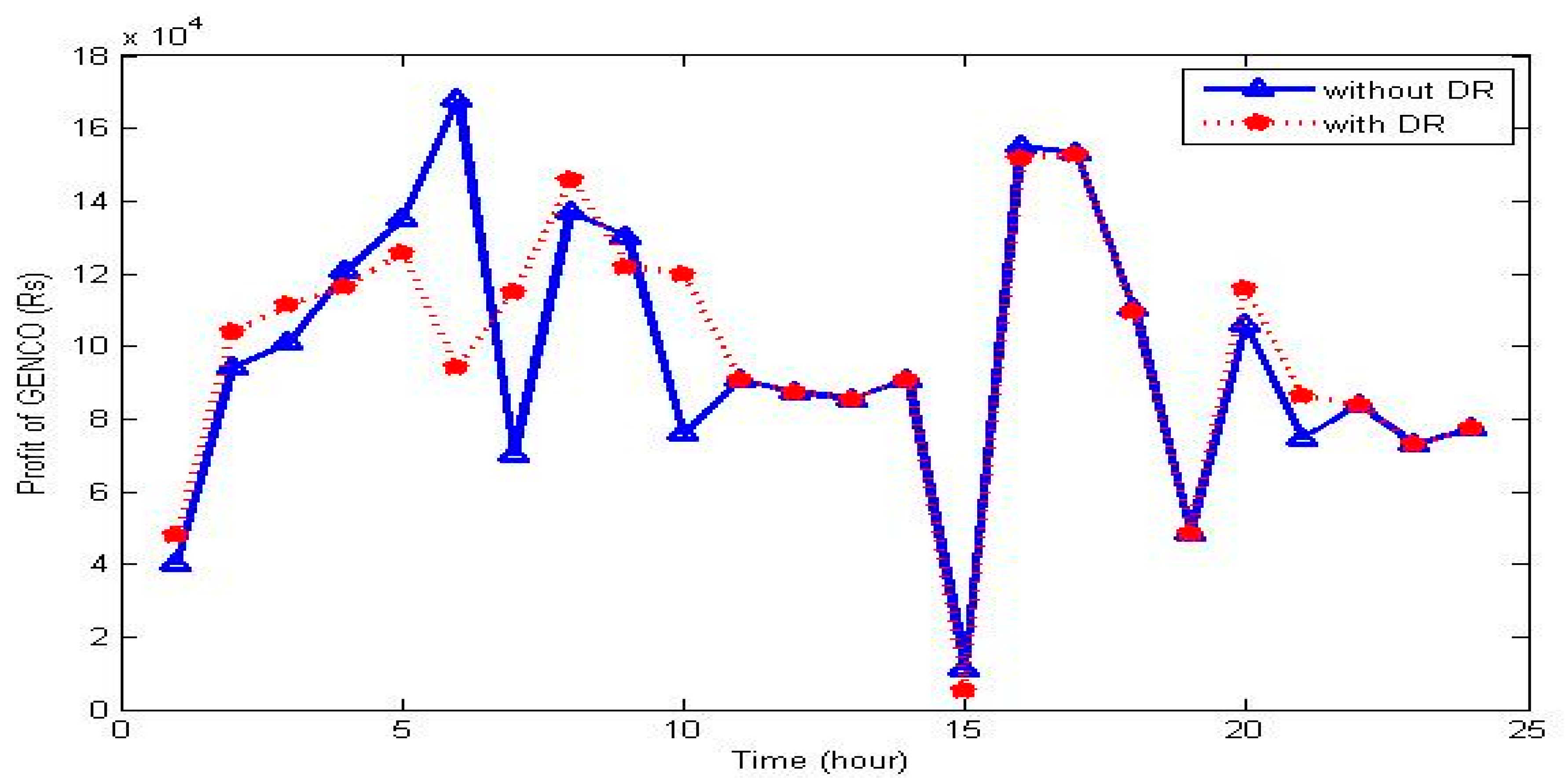

Figure 7. The total profit of GENCOs versus time for original kickback load and controlled kickback load for 30 bus system and 75 bus system has been plotted in

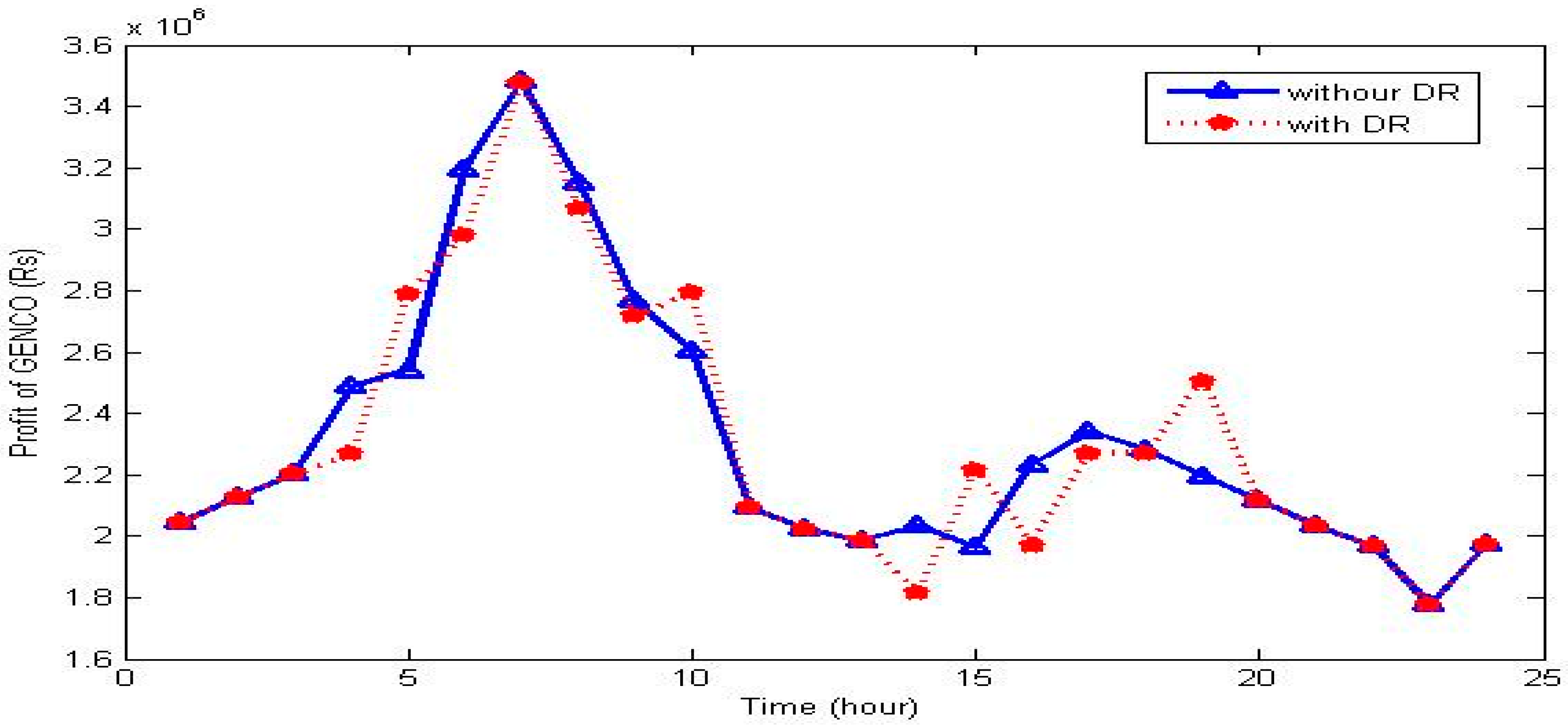

Figure 8 and

Figure 9, respectively.

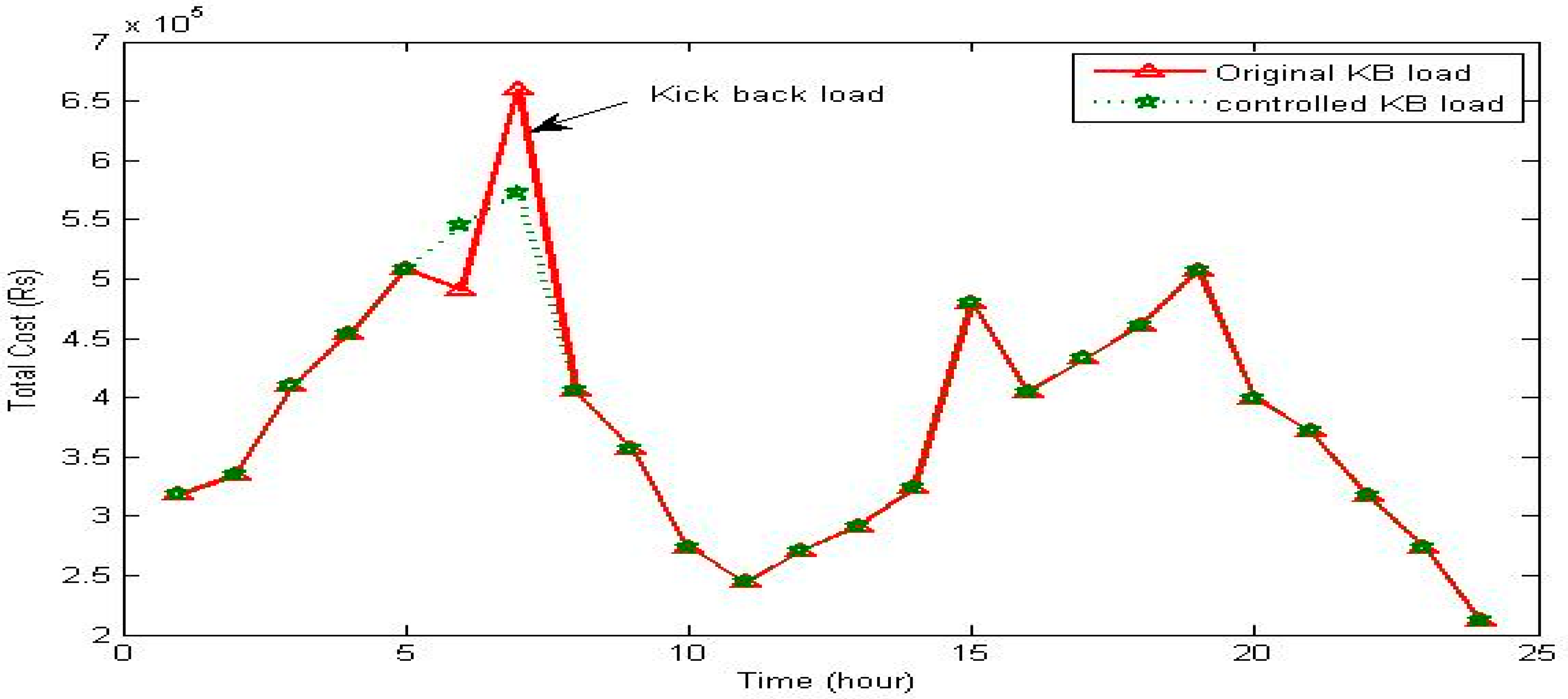

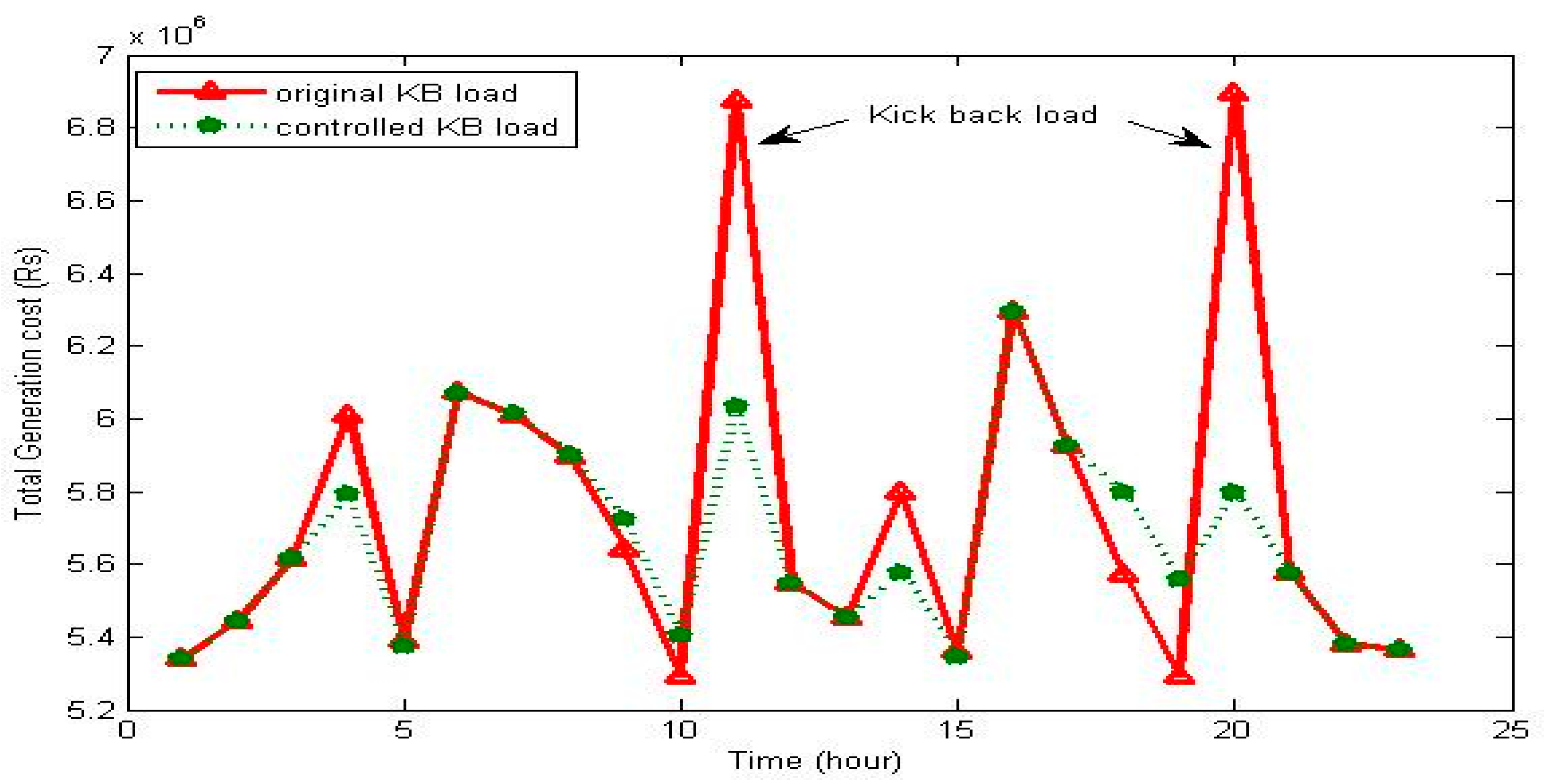

The total cost versus time for original kickback load and controlled kickback load for 30 bus system and 75 bus system has been plotted in

Figure 10 and

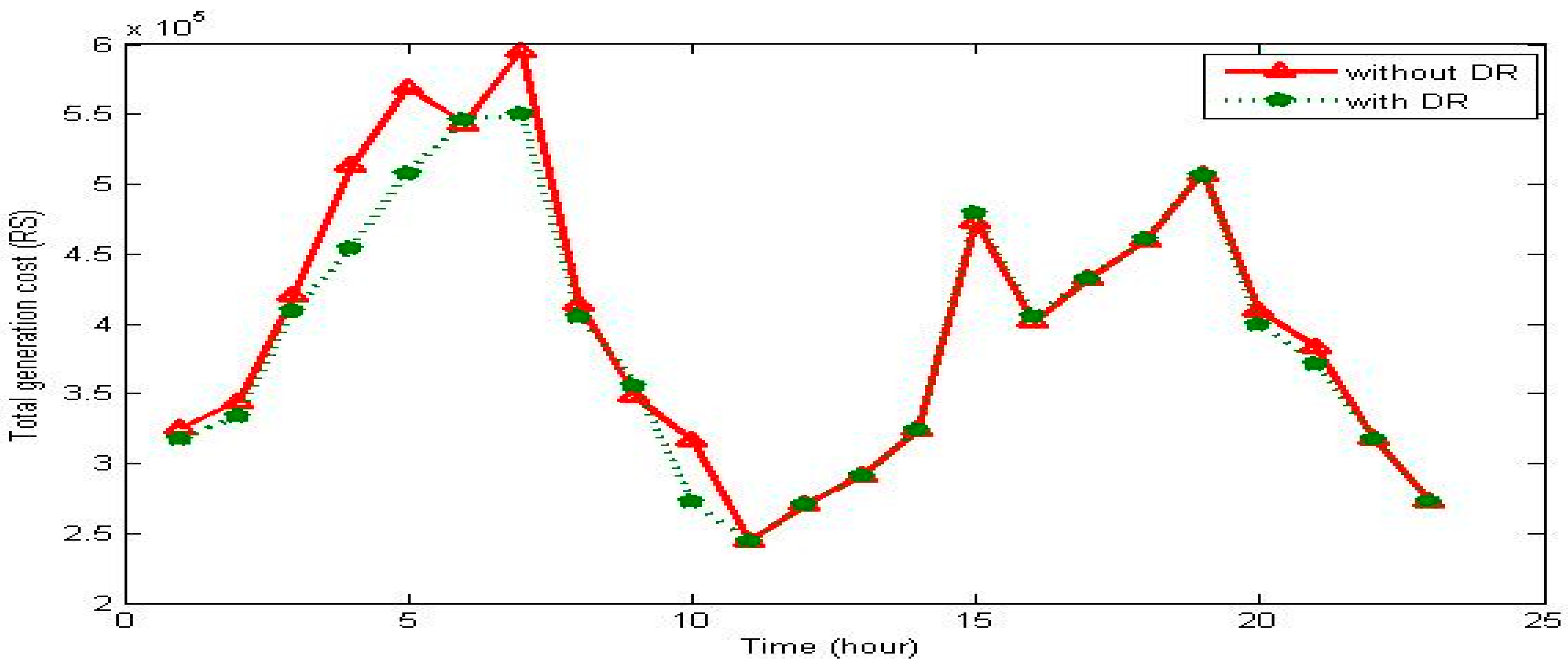

Figure 11. The total generation cost versus time for 30 bus system involving DR and without DR has been shown in

Figure 12. The total profit of GENCOs versus time with DR and without DR for 30 bus system and 75 bus system has been shown in

Figure 13 and

Figure 14.

Figure 13 and

Figure 14 clearly show the profit is more in most of the hours, except the kickback load-occurring hours in both 30 bus and 75 bus systems.

The total generation cost of GENCOs versus time for original kickback load and controlled kickback load for 75 bus systems has been plotted in

Figure 15. The original kickback load total generation cost at 11th and 20th hours is comparatively very high, compared to the proposed controlled kickback load case.