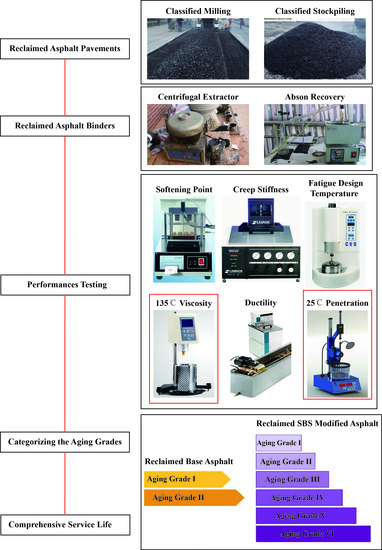

1. Introduction

The use of reclaimed asphalt pavement has contributed to saving a great amount of asphalt and aggregates and alleviating the problem of resource waste [

1], land occupation and secondary pollution, which allowed this technology to achieve rapid development in last two decades [

2]. As early as the end of last century, reclaimed asphalt pavement (RAP) was utilized for weaker pavement layers such as the base or sub base [

3]. Generally, RAP contents from 10% to 30% by mass of the mixture are considered to be adequate to produce asphalt mixtures with performance similar to conventional mixtures [

4,

5,

6]. Rejuvenators, additives and warm mix asphalt technology are usually employed to improve the effective contribution of RAP binder towards the total binder of the mixture [

7,

8,

9]. However, the use of RAP is at a very low level in many developing countries, for there are no relevant and unified recycling guidelines. Since the key to recycling old asphalt pavement is the rejuvenation and remobilization of asphalt binder [

10,

11], it would be of great significance to establish a RAP evaluation guideline based on the condition of the reclaimed asphalt binder (RAB).

The classification of RAP materials is the basis of its efficient utilization. Today however, arbitrary stockpiling of RAP is still a common practice from the lack of standards or specifications [

12,

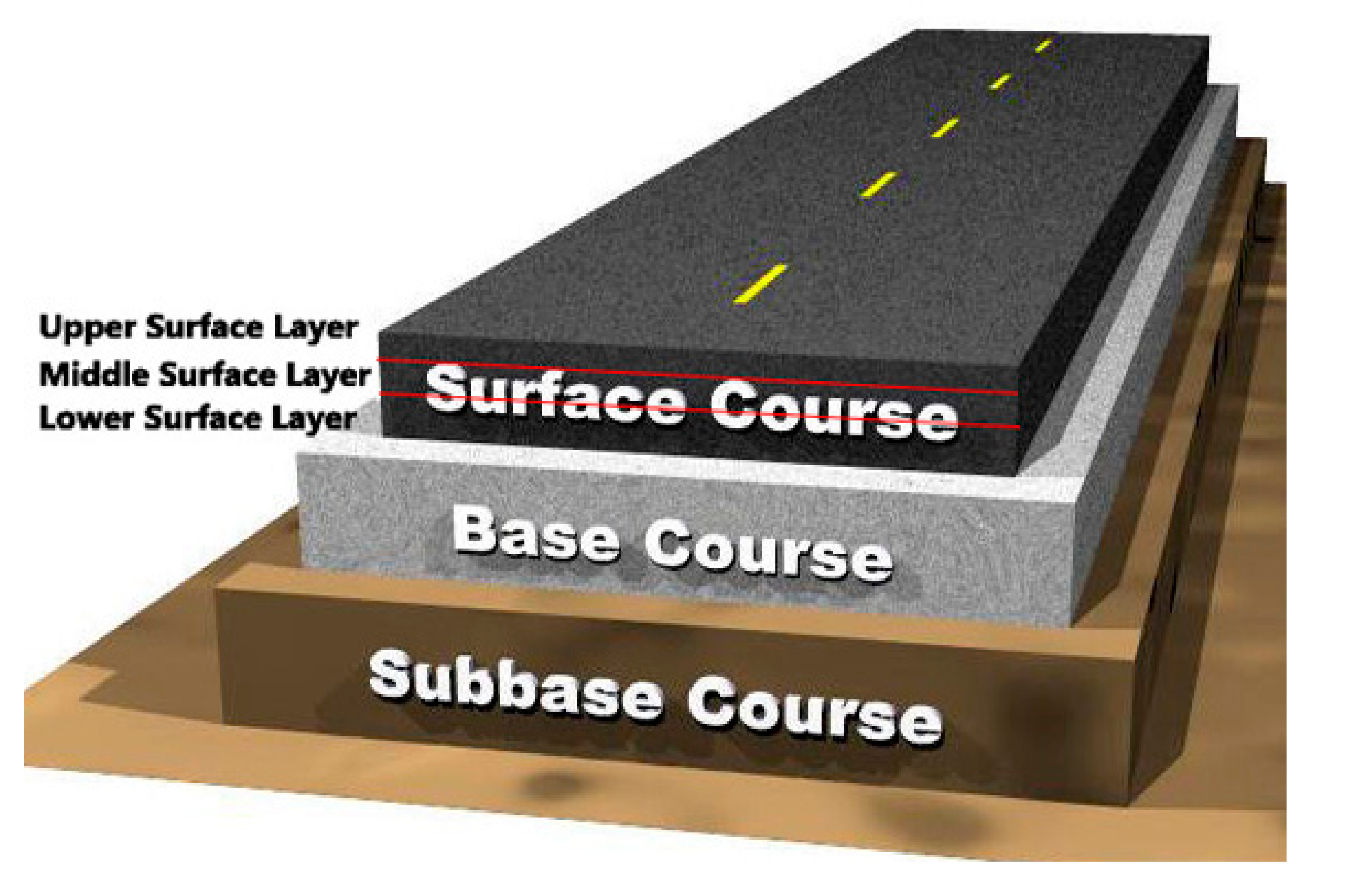

13], especially in Asia and Africa. Different pavement layers are paved with different asphalt binders, such as conventional base asphalt, lake or rock asphalt, polymer modified asphalt (PMA), fiber asphalt and so on [

14]. Recycling of unclassified RAP may lead to many difficulties, depending on the aging characteristics of different RAP binders. The types of binders, pavement layers, service life and position of lanes should be taken into account in milling and recycling.

The aging of asphalt binder is a long-term oxidation process. According to SARA (saturate, aromatic, resin and asphaltene) analysis for binder aging [

15,

16], oxidative polymerization reaction causes mutual transformation of different components. The lighter aromatics in the binder are transformed into colloids while the polar aromatics into asphaltenes. This chemical process finally leads to a stiffer asphalt binder [

17,

18]. Most researchers have used accelerated laboratory aging to study the composition and property changes of asphalt binder during aging process. Ji et al. proposed critical aging viscosity as the aging grade index. They divided aging grades according to the relationship between the viscosity of the aged binder and the critical aging viscosity [

19]. Kuang divided aging asphalt into three grades by penetration, namely, mild aging, moderate aging and severe aging [

20]. It was also found that the penetration of asphalt with severe aging could be restored by adding a rejuvenator and modified asphalt, moderately aged asphalt by adding just a rejuvenator and mildly aged asphalt by only adding some virgin asphalt. F. Mazzotta et al. put forward that the short-term aging simulation should conducted at the equiviscous temperature instead of the standard temperature of 163 °C to overcome the non-homogeneous distribution of the binder on the glass [

21].

A number of studies have been conducted to evaluate the aging degree of recycled virgin asphalt and modified asphalt, including SARA analysis, softening point, penetration, ductility, Brookfield viscosity and so on. However, this work has not been put towards developing of quantitative aging grades of RAP binder. Most studies have simulated aging virgin asphalt binder, but not field sourced reclaimed asphalt binder (RAB). In China, as in most other places, there are no uniform standards for using RAP. PMA has been widely used in asphalt pavement [

22,

23,

24], but scholars mainly focused on the study of aging base asphalt RAP. The purpose of this study is to develop a guide for RAP binder aging and grading evaluation for base and polymer-modified asphalt, based on performance tests and analysis of real reclaimed asphalt pavement materials from sixteen different field sections.

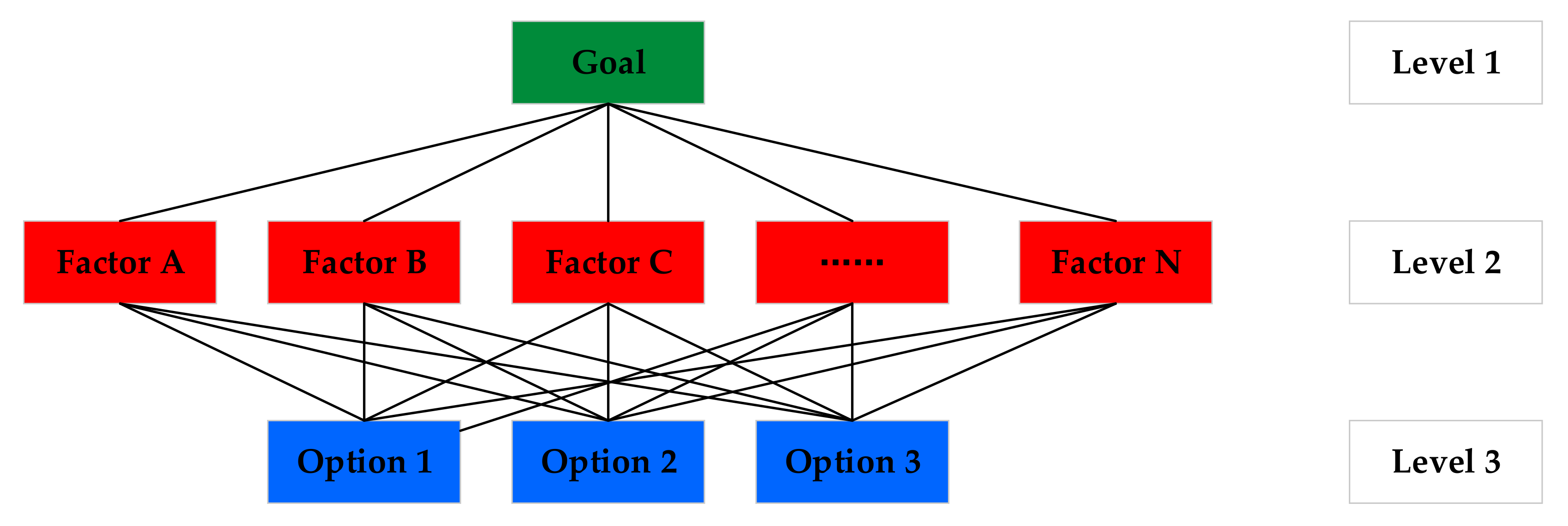

Some studies have attempted to find a comprehensive evaluation method by using investigated data and engineering experience, which could also to some extent decrease laboratory work. In this context, the analytic hierarchy process (AHP) was initially developed, making the most use of field data, laboratory results and experts’ experience, for applications in multicriteria decision making, planning and resource allocation and in conflict resolution [

25,

26]. In the present time, the AHP has been widely used in the fields of social studies, education, manufacturing and civil engineering due to the process simplifying complex decisions into a series of one-on-one comparisons [

27]. It was applied to infrastructure management earlier by S. L. Tighe for comparing seven maintenance, rehabilitation, and reconstruction strategies for asphalt pavements [

28]. Guo, Zhang developed a comprehensive evaluation system on the basis of the AHP, by which ratings for asphalt pavement construction quality were generated. The advantage of this system is that it allows experts to assign relative importance between any related pairs of indices [

29,

30]. Other publications also focused on the application of AHP in determining the reliability index of asphalt pavement construction, the comprehensive performance grades of warm mix asphalt (WMA), and the damage condition of asphalt pavement [

31,

32,

33]. As for the reclaimed asphalt binders, a comprehensive index incorporating the key influencing factors of aging and engineering experience would help divide the RABs into different grades, and help save on laboratory testing work.

3. Results

3.1. High Temperature Performance: Softening Point and Viscosity

In general, softening point and viscosity have positive correlation to service years, as found in previous studies of RAP binder [

1]. This indicates that service years influence high temperature performance much more than milling depth and some other factors. It was assumed that the RABs were subject to similar temperature histories because they had the same source material and were collected from similar climactic conditions in Southern China.

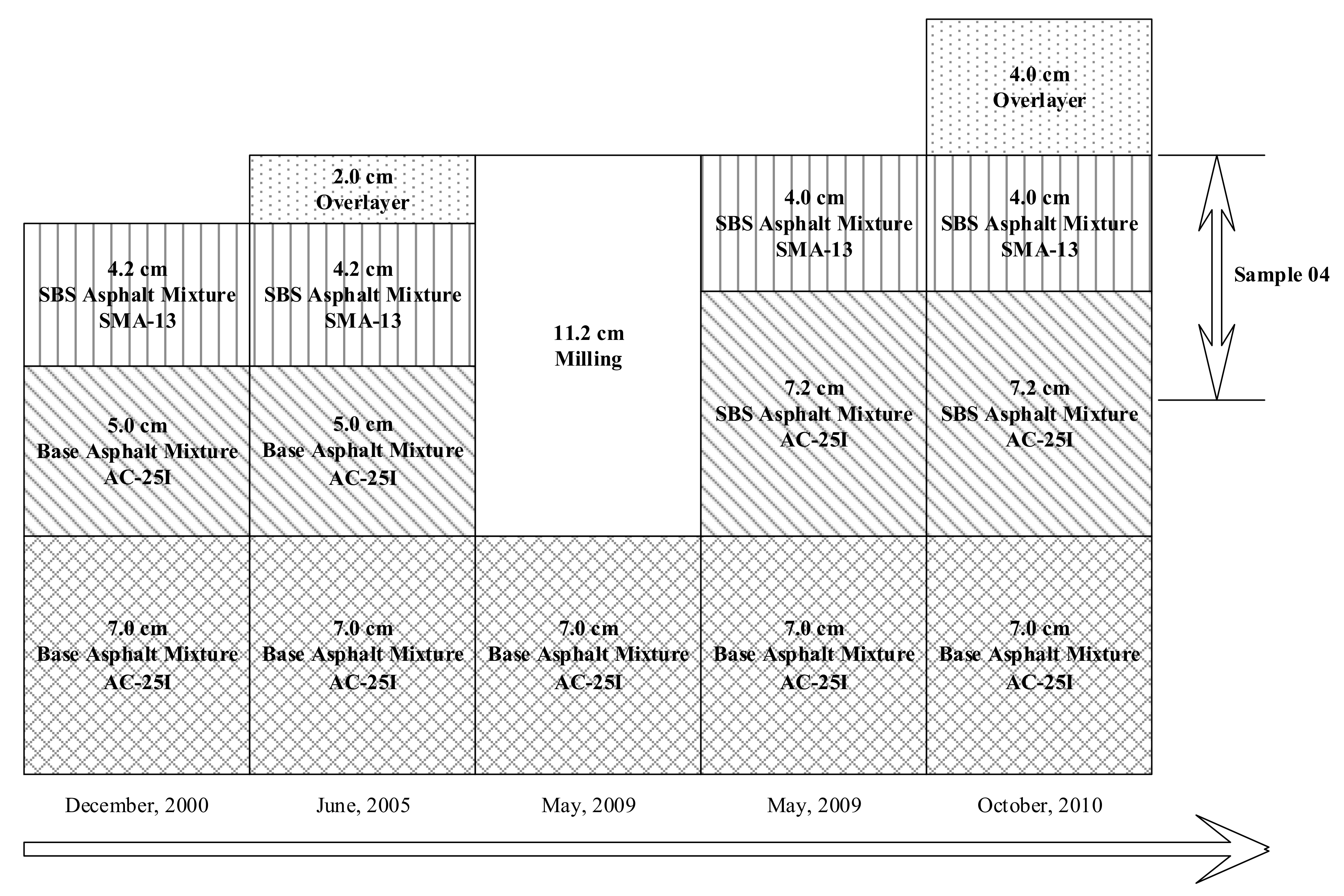

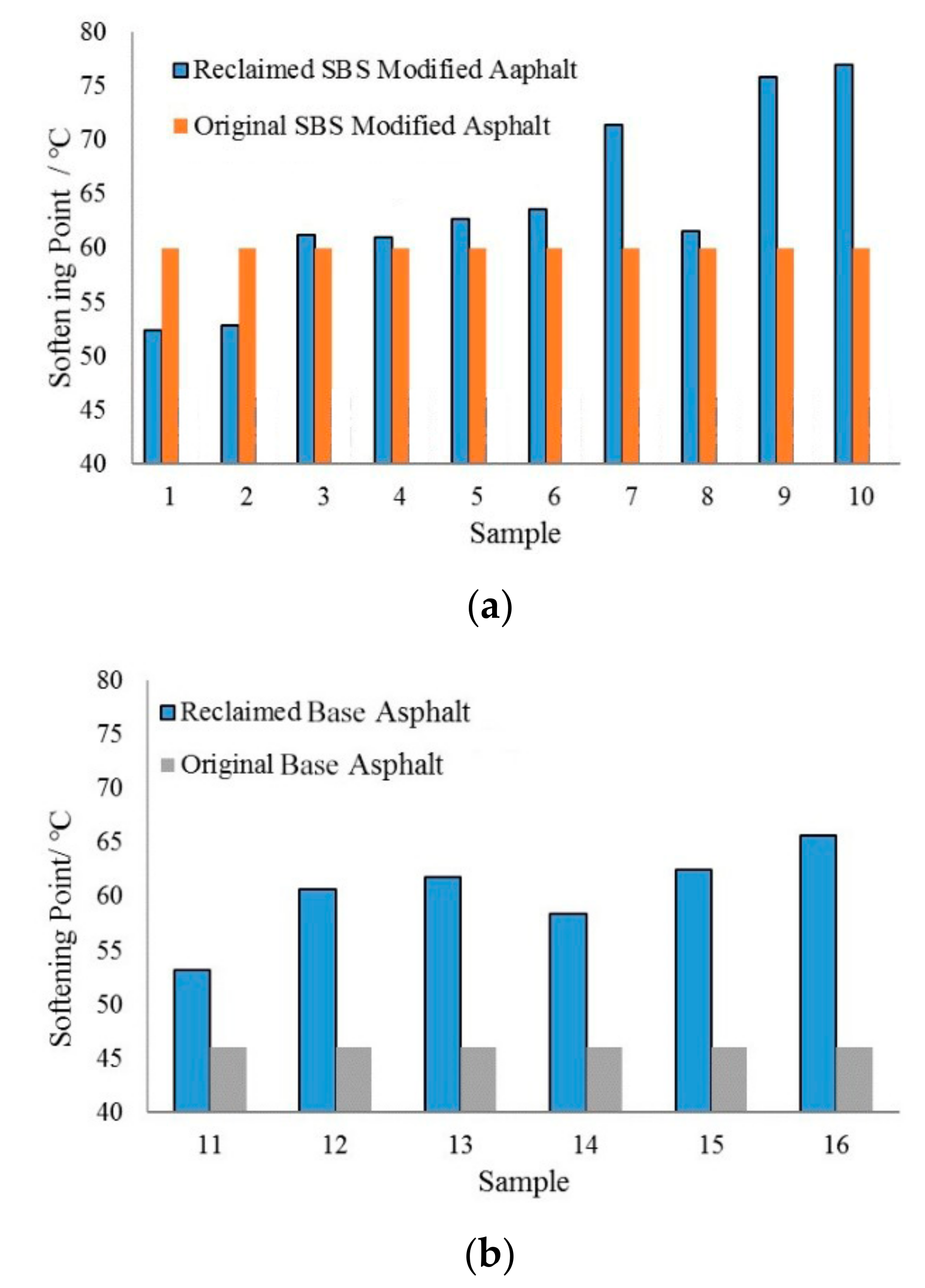

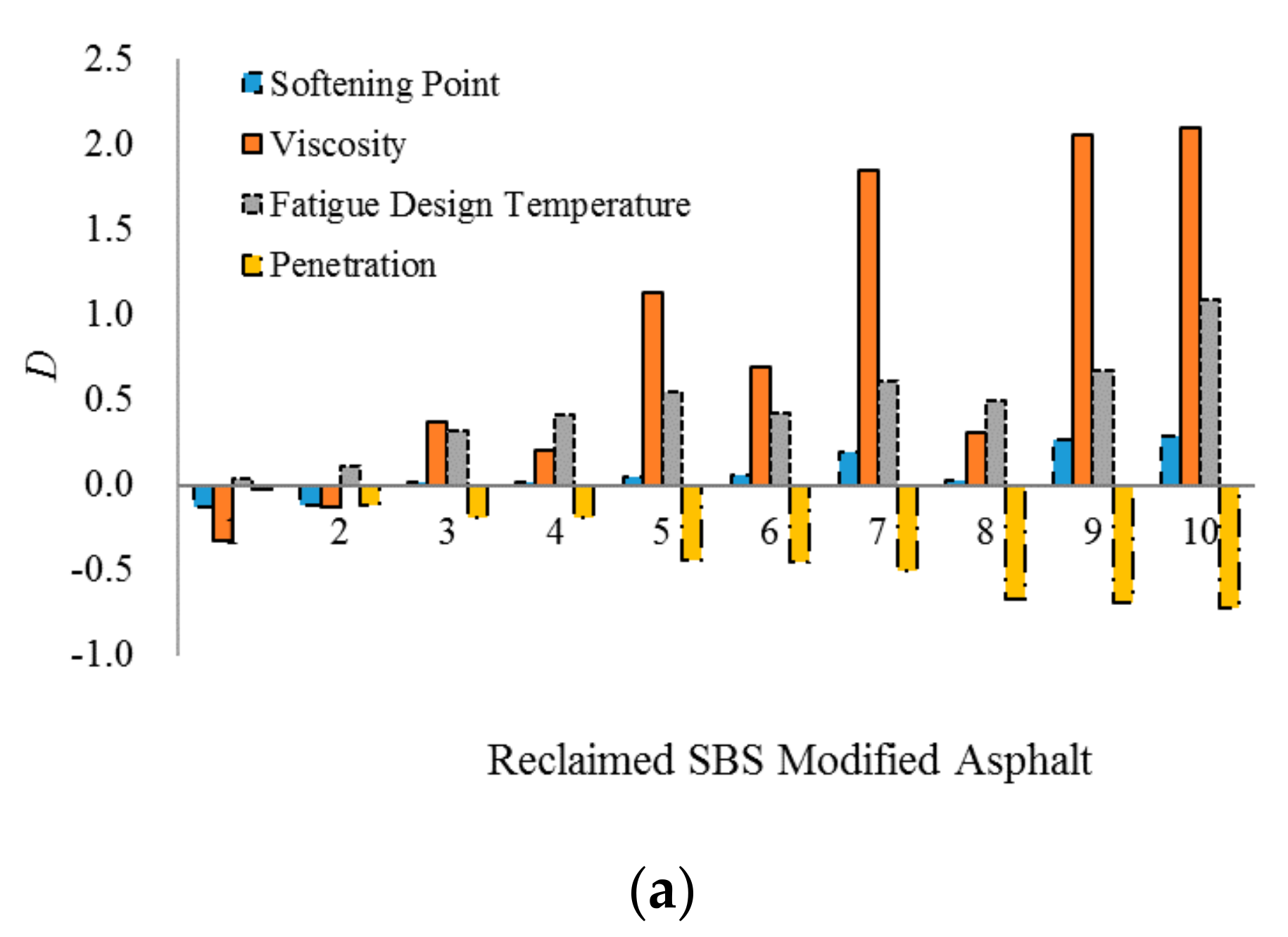

Due to differences in traffic volume, surface layer and mixture gradation, the increase in softening point and viscosity for sample 8 was lower than the other samples as shown in

Figure 6 and

Figure 7. The aging process makes asphalt binders become harder, but sample 8 only consisted of middle and lower surface layers, giving it less exposure to the aging experienced by the upper layers. However, softening point and viscosity of samples 1 and 2 became lower than original SBS modified asphalt due to the presence of base asphalt in one of the component layers.

A comparison between sample 1 and 2 shows that the latter has slightly high softening point and viscosity because it covers an upper surface layer, more prone to aging than middle and lower surface layers. The service year and the thickness of the upper layer of sample 3, 5 and 7 are the same, so the longer service time of the middle layer results in a more serious aging degree. Sample 11 and 12 have the same service years and thickness but were located in different layers, showing again that upper layers are more subject to aging. The effect of service year on aging degree can also be seen in samples 12 to 16.

3.2. Low Temperature Performance: Ductility and Creep Stiffness

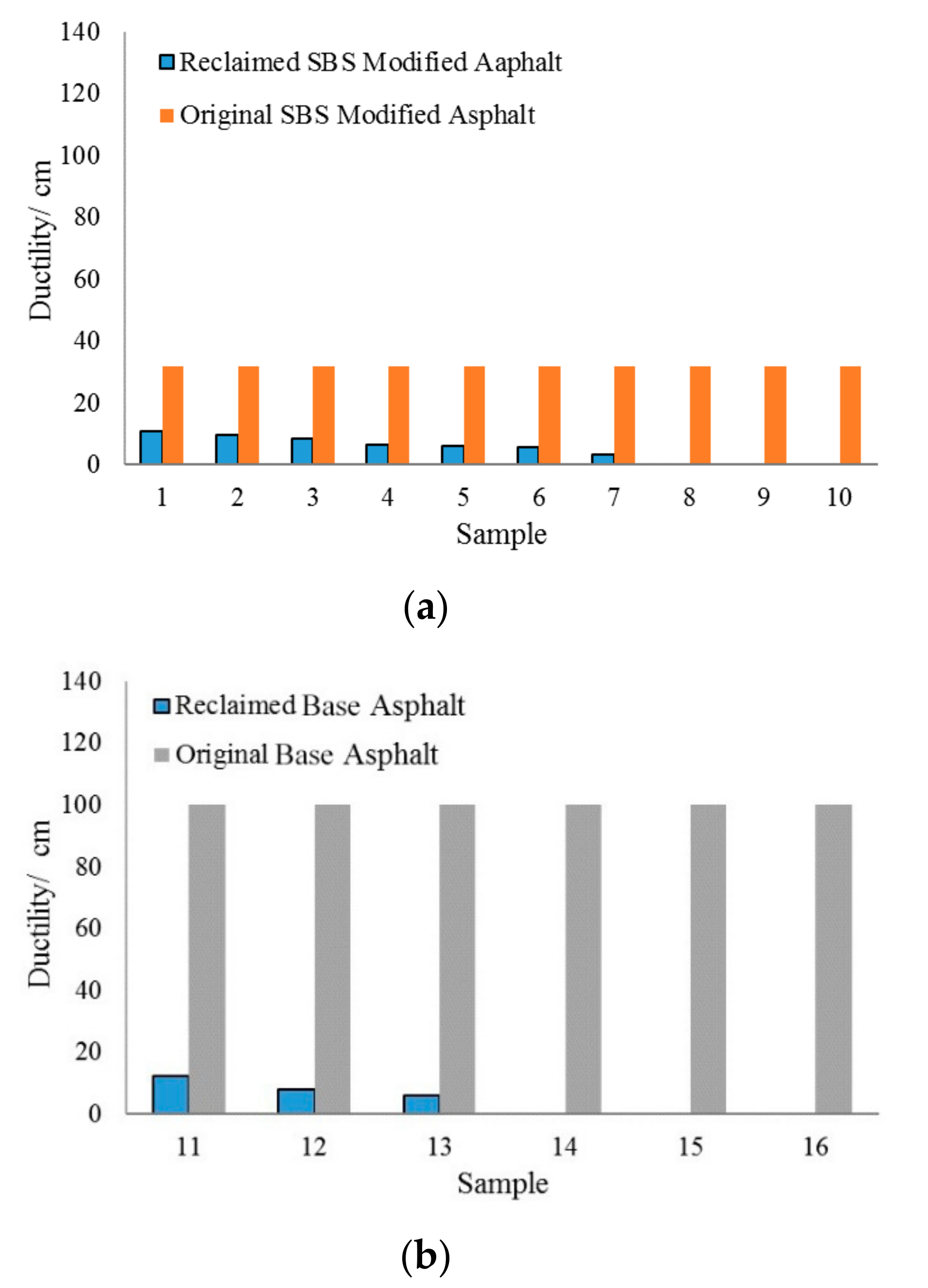

The ductility of the ten reclaimed SBS modified asphalts was tested at 5 °C while the ductility of the six reclaimed base asphalts was conducted at 15 °C due to their decreased performance in ductility compared to SBS binders.

From

Figure 8, it is evident that the ductility of RAB decrease sharply compared with the original binder with the extension of service years, as observed elsewhere [

42]. The SBS additive improves the ductility of the binder compared to virgin asphalt considerably [

43,

44]. The deterioration of the SBS molecular structure by long term aging [

45] makes the deterioration of reclaimed SBS modified asphalt more significant than base asphalt, which could be also reflected by the sharp of creep stiffness for the SBS samples.

Unfortunately, ductility and creep stiffness are unavailable for a part of the samples, due to some of the samples being too brittle to be tested. It is for this reason that these two indexes are not suitable for categorizing the aging grades of more brittle RABs.

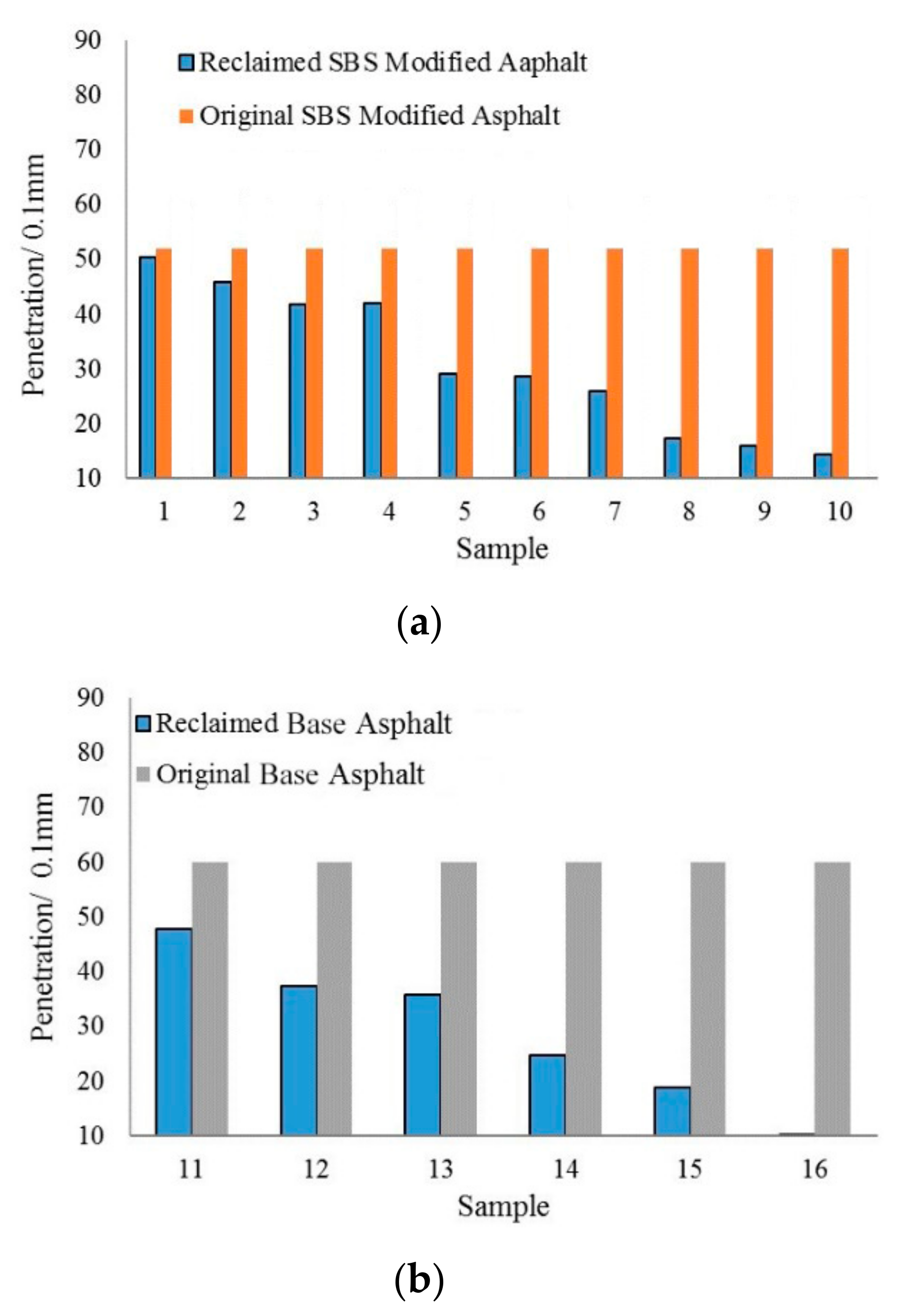

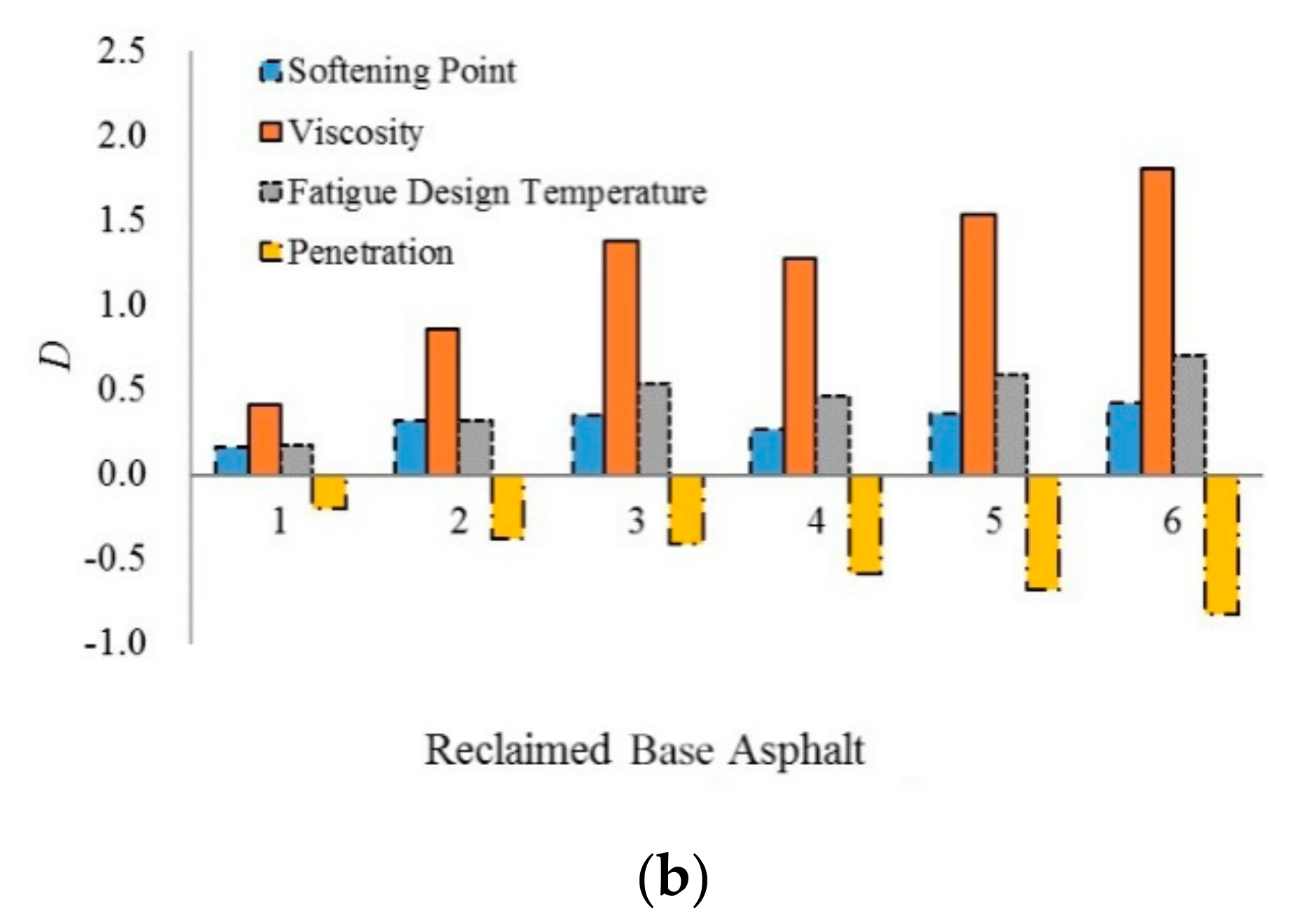

3.3. Average Temperature Performance: Penetration and Fatigue Design Temperature

With the extension of sample service years, the penetration of the RABs declined while the fatigue design temperature increased. The increase of penetration indicates that aging makes asphalt binders stiffer. Fatigue design temperature stands for the critical temperature below which the fatigue factor is more than the required value (5000 kPa). A higher fatigue design temperature represents a weaker fatigue cracking resistance.

Generally, the changing trend of the average temperature performance of RABs caused by aging is as similar as that of high temperature performance. Due to the longer service life of the middle layer, the performance decline of sample 5 and 7 are steeper than that of sample 2 to 4. Both sample 8 and sample 9 consist of middle and lower layers but sample 9 had a longer life, which made it stiffer and reduced the fatigue cracking resistance.

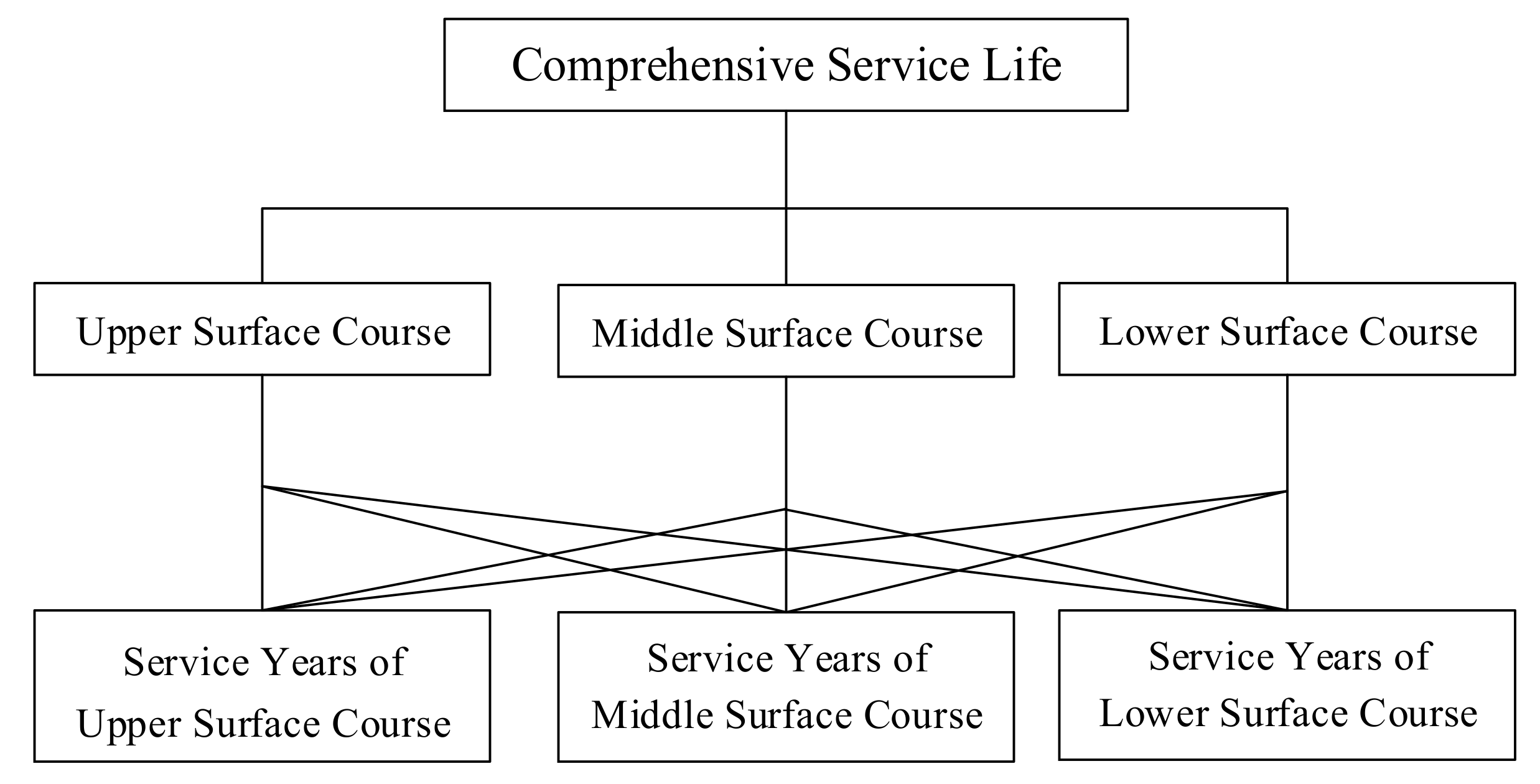

5. Conclusions

Through investigation and analysis on factors such as surface layers, types of asphalt, service years and milling depth, this study aimed to establish a method to evaluate the aging grades of RABs in order to their recycling. For this purpose, performance tests at high, average and low temperatures were conducted on the various reclaimed asphalt binders collected from sixteen different sites. The penetration and viscosity were found to be more consistent in distinguishing aged binders for both base asphalt and polymer modified asphalt. By these two indexes, the reclaimed base asphalts were classified into two aging grades and reclaimed SBS modified asphalt into six aging grades. Contractors or agents can rejuvenate the old asphalt binders recycled from RAPs according to their aging grades. Another convenient way to determine the aging grades is to find a comprehensive evaluation index which can take the binder type, milling depth, surface layers and service years into account. All these factors have a strong influence on the aging degree of RABs. Finally, the concept, comprehensive service life is found to be a feasible index to classify RAB aging grades that may help save testing time. However, its calculation should incorporate more engineering properties in the future.