High Power Fiber Laser Welding of Single Sided T-Joint on Shipbuilding Steel with Different Processing Setups

Abstract

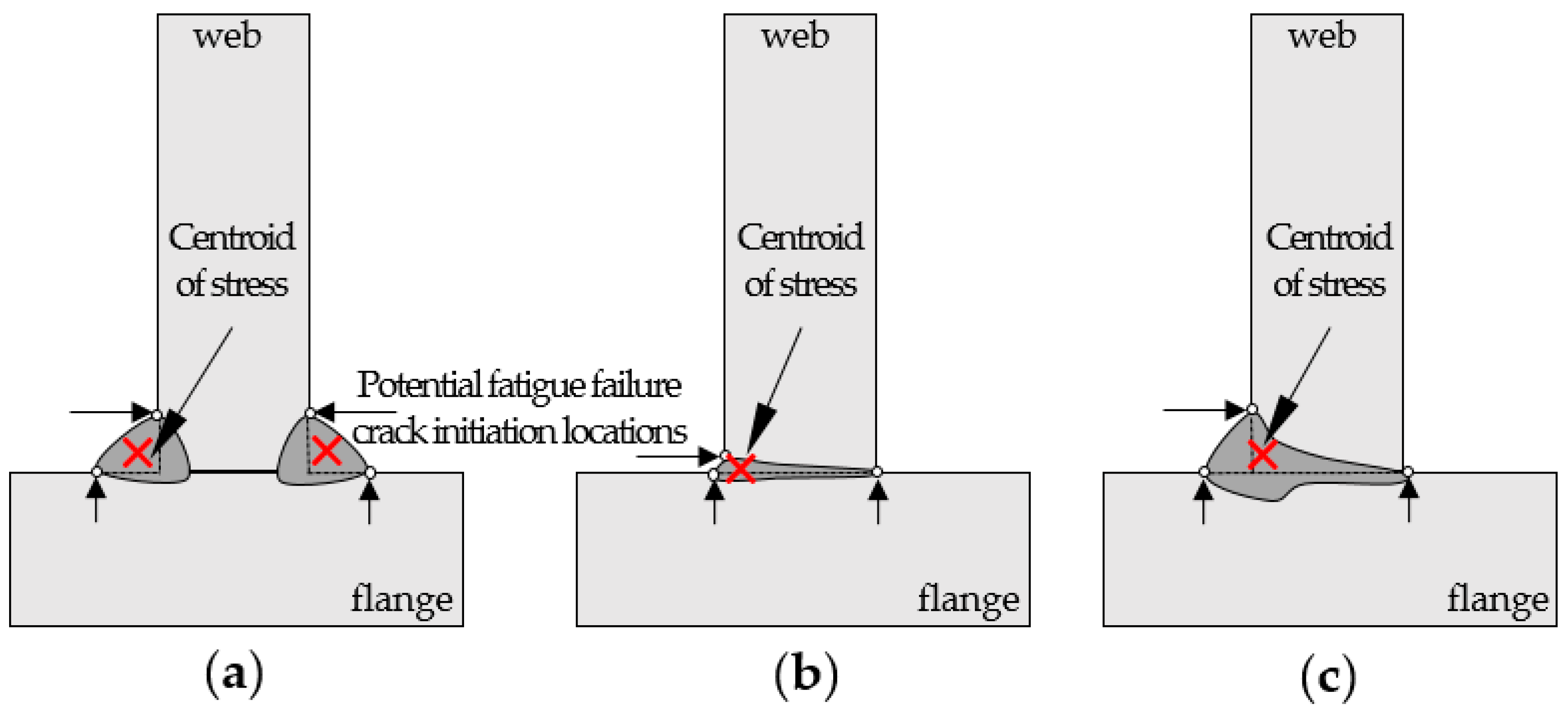

:1. Introduction

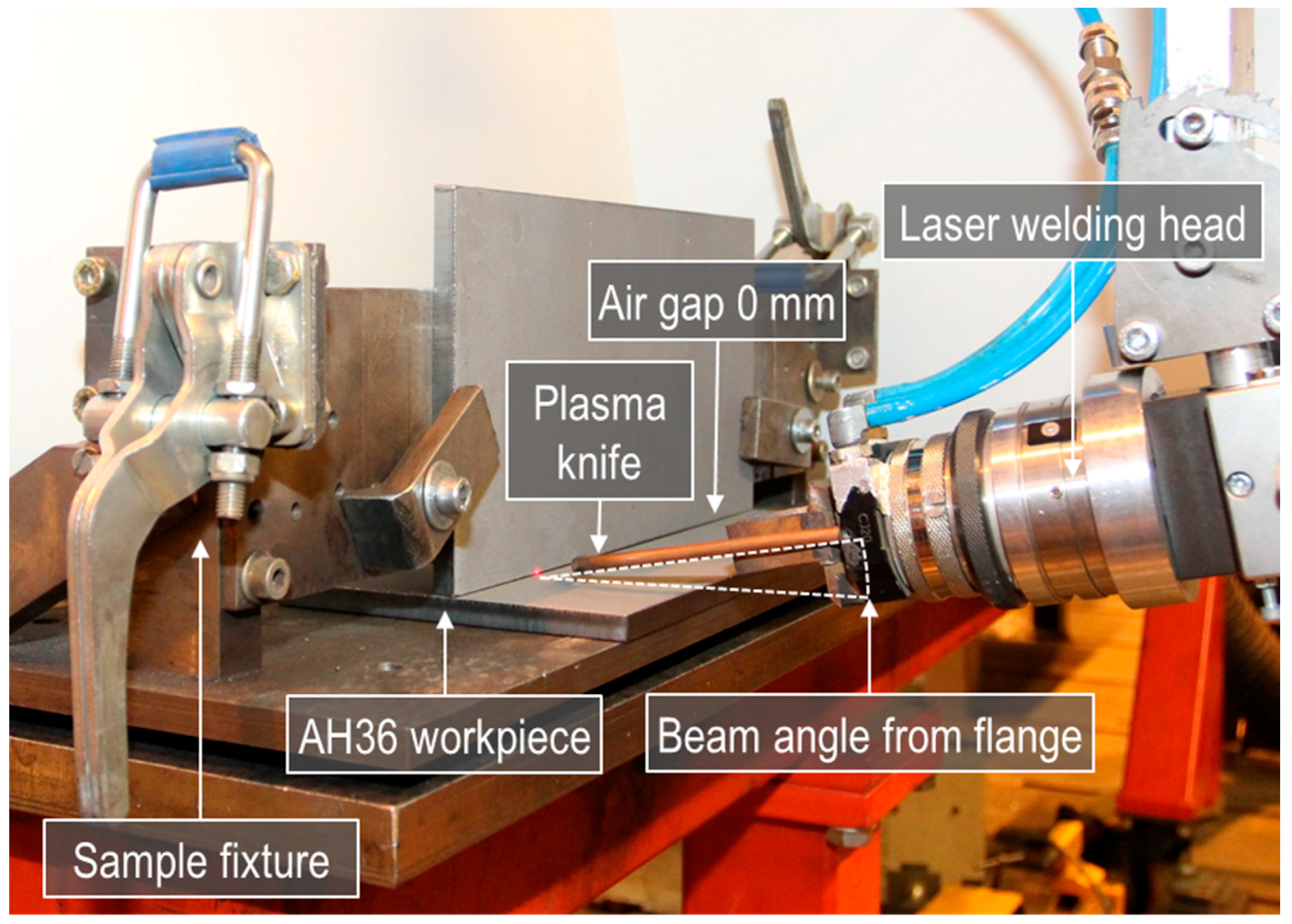

2. Materials and Methods

3. Results

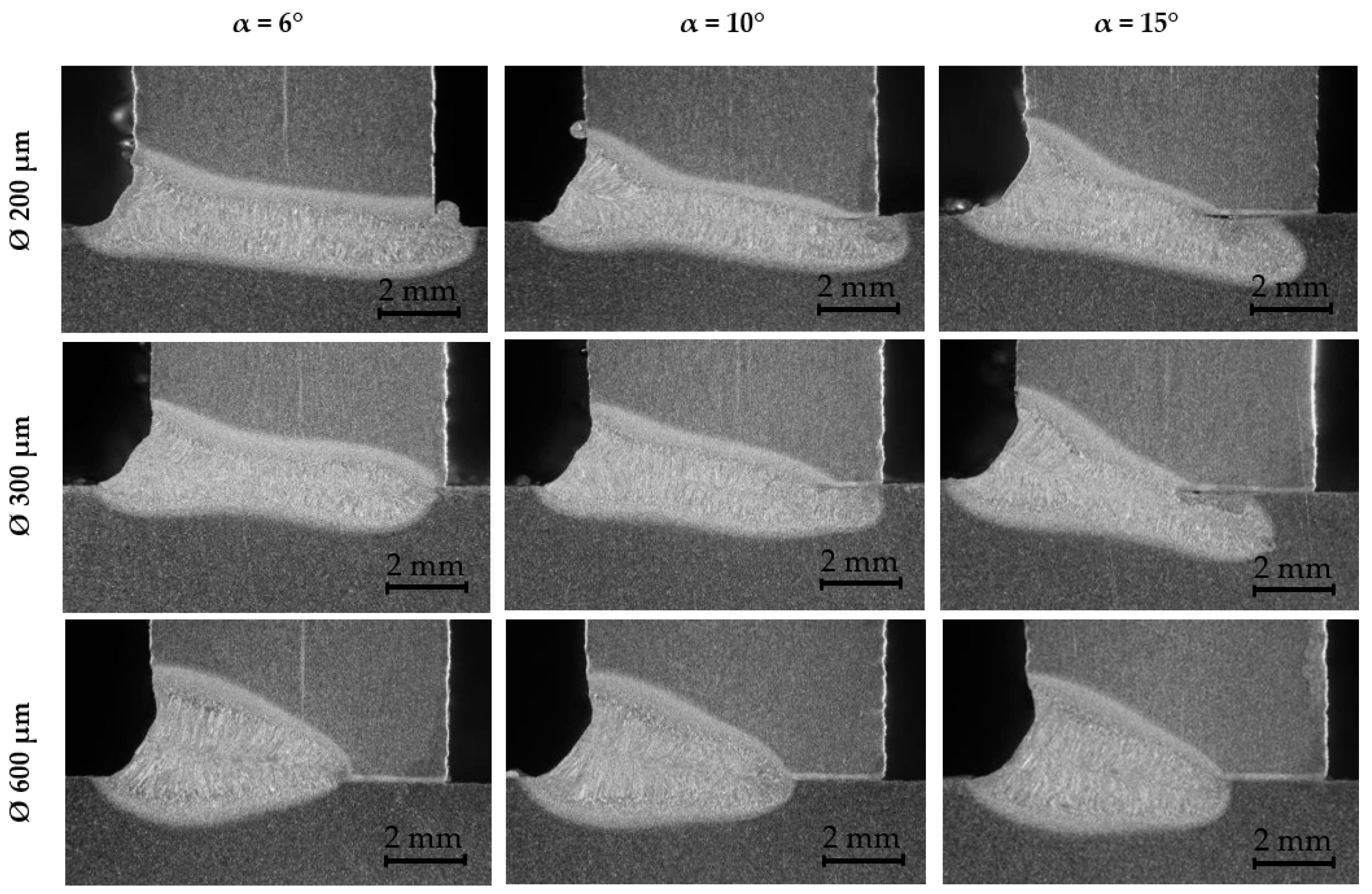

3.1. Effect of Beam Inclination Angle α

3.2. Effect of Beam Offset from the Flange

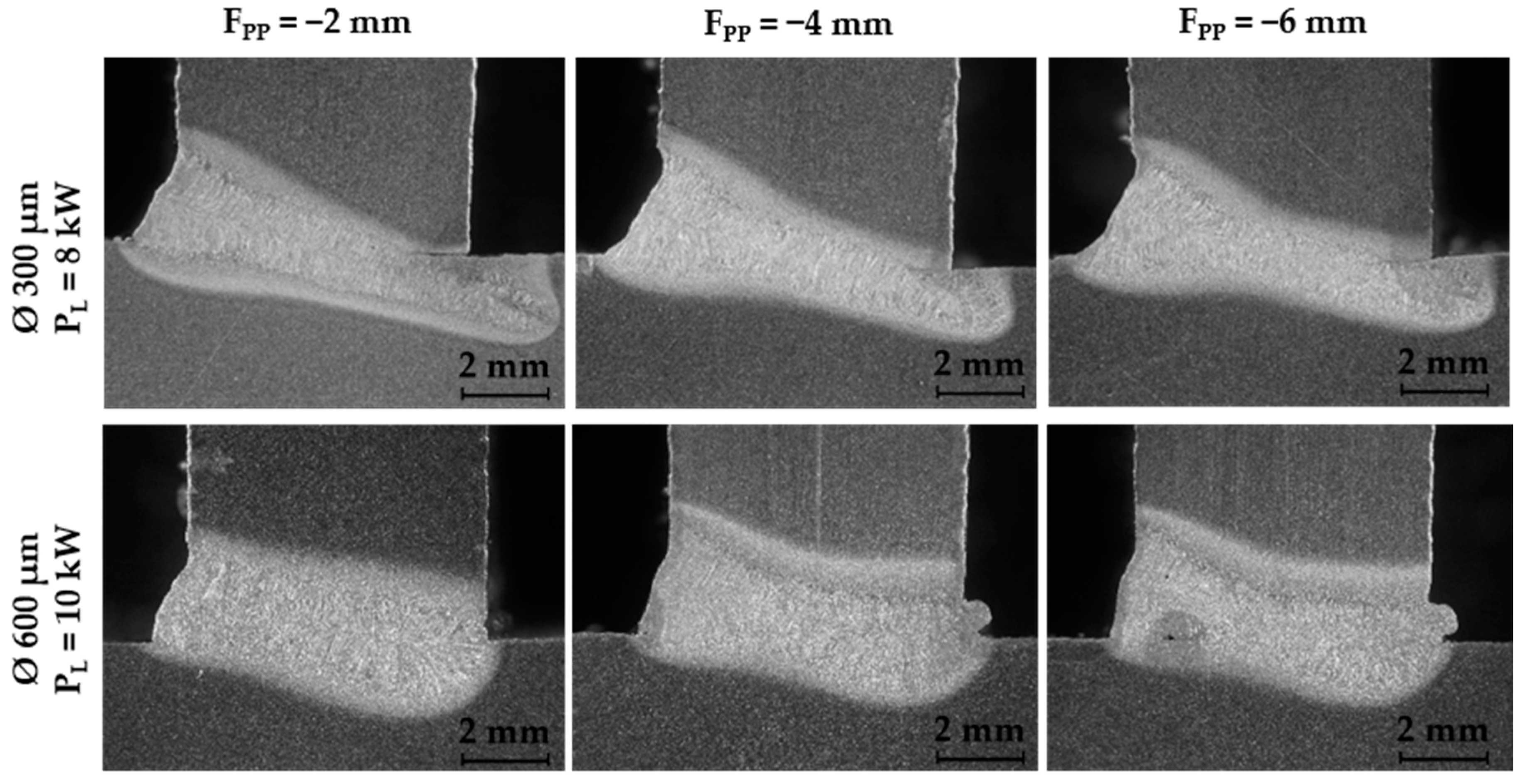

3.3. Effect of Focal Point Position

4. Discussion

4.1. Geometry of the Welds

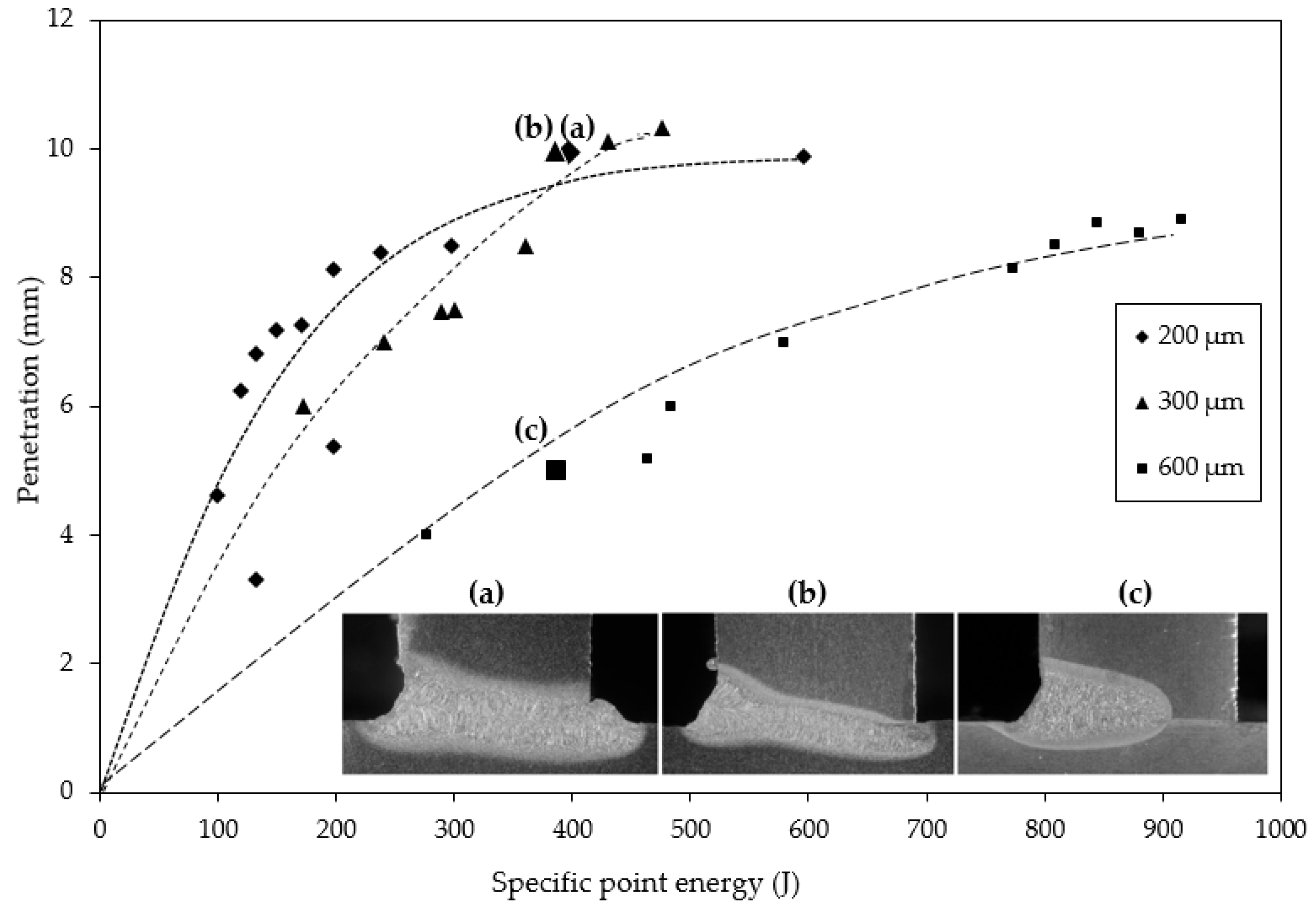

4.2. Application of Specific Point Energy to Welding of T-Joints

4.3. Optimal Welding Conditions for T-Joint

5. Conclusions

- (1)

- Full fusion in one welding pass was produced with all three process fibers studied.

- (2)

- Penetration depth and width of the weld both primarily depend on the beam diameter. The parameter with the greatest influence on the depth of the weld is the power density of the beam, while the width of the weld is determined by the diameter of the focused beam. The width of the weld bead only has a minor correlation to the diameter of the beam on the surface.

- (3)

- Smaller spot sizes provide an advantage in penetration depth at the same welding speed and power but are prone to producing undercuts. Due to the narrowness of the weld, the positioning of the beam has to be extremely accurate to avoid the weld missing the root of the joint.

- (4)

- Welds produced with 600 µm process fiber were less prone to undercut formation and had more favorable shape of the weld toe than welds produced with 200 µm and 300 µm process fibers.

- (5)

- Process fiber with core diameter 600 µm produced welds with the highest quality and was least sensitive to changes in beam positioning.

- (6)

- Using beam delivery fibers with larger core diameters has a favorable effect on achieving full fusion in T-joints. Reduced energy density on surface increases the width of the weld throughout the penetration and produces smoother junctions of weld bead and base material.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Grupp, M.; Klinker, K.; Cattaneo, S. Welding of high thicknesses using a fibre optic laser up to 30 kW. Weld. Int. 2013, 27, 109–112. [Google Scholar] [CrossRef]

- Belforte, D. Laser Market Results Confound the Experts. Available online: http://www.industrial-lasers.com/articles/2017/01/laser-market-results-confound-the-experts.html (accessed on 16 August 2017).

- Thoss, A.F. Four laser companies to exceed $1 billion revenue in 2016. Adv. Opt. Technol. 2017, 6, 13–16. [Google Scholar] [CrossRef]

- Enz, J.; Khomenko, V.; Riekehr, S.; Ventzke, V.; Huber, N.; Kashaev, N. Single-sided laser beam welding of a dissimilar AA2024–AA7050 T-joint. Mater. Des. 2015, 76, 110–116. [Google Scholar] [CrossRef]

- Liu, S.; Mi, G.; Yan, F.; Wang, C.; Jiang, P. Correlation of high power laser welding parameters with real weld geometry and microstructure. Opt. Laser Technol. 2017, 94, 59–67. [Google Scholar] [CrossRef]

- Sokolov, M.; Salminen, A. Improving laser beam welding efficiency. Engineering 2014, 6, 559–571. [Google Scholar] [CrossRef]

- Kuryntsev, S.V.; Gilmutdinov, A.K. Welding of stainless steel using defocused laser beam. J. Constr. Steel Res. 2015, 114, 305–313. [Google Scholar] [CrossRef]

- Hobbacher, A. Recommendations for Fatigue Design of Welded Joints and Components; Springer: Berlin, Germany, 2015. [Google Scholar]

- Det Norske Veritas. Fatigue Design of Offshore steel Structures, Recommended Practice; DNV-RP-C203; DNV GL: Oslo, Norway, 2008. [Google Scholar]

- Matsumoto, N.; Kawahito, Y.; Nishimoto, K.; Katayama, S. Effects of laser focusing properties on weldability in high-power fiber laser welding of thick high-strength steel plate. J. Laser Appl. 2017, 29, 012003. [Google Scholar] [CrossRef]

- Grajcar, A.; Morawiec, M.; Różański, M.; Stano, S. Twin-spot laser welding of advanced high-strength multiphase microstructure steel. Opt. Laser Technol. 2017, 92, 52–61. [Google Scholar] [CrossRef]

- Morawiec, M.; Różański, M.; Grajcar, A.; Stano, S. Effect of dual beam laser welding on microstructure–property relationships of hot-rolled complex phase steel sheets. Arch. Civ. Mech. Eng. 2017, 17, 145–153. [Google Scholar] [CrossRef]

- Shen, J.; Li, B.; Hu, S.; Zhang, H.; Bu, X. Comparison of single-beam and dual-beam laser welding of Ti–22Al–25Nb/TA15 dissimilar titanium alloys. Opt. Laser Technol. 2017, 93, 118–126. [Google Scholar] [CrossRef]

- Vänskä, M. Defining the Keyhole Modes—The Effects on the Weld Geometry and the Molten Pool Behaviour in High Power Laser Welding of Stainless Steels. Ph.D. Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2014. [Google Scholar]

- Müller, A.; Goecke, S.F.; Sievi, P.; Albert, F.; Rethmeier, M. Laser beam oscillation strategies for fillet welds in lap joints. Phys. Proc. 2014, 56, 458–466. [Google Scholar] [CrossRef]

- Wang, L.; Gao, M.; Zhang, C.; Zeng, X. Effect of beam oscillating pattern on weld characterization of laser welding of AA6061-T6 aluminum alloy. Mater. Des. 2016, 108, 707–717. [Google Scholar] [CrossRef]

- Hao, K.; Li, G.; Gao, M.; Zeng, X. Weld formation mechanism of fiber laser oscillating welding of austenitic stainless steel. J. Mater. Process. Technol. 2015, 225, 77–83. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, G.; Zhou, Y.; Liao, S. Optimization of deep penetration laser welding of thick stainless steel with a 10 kW fiber laser. Mater. Des. 2014, 53, 568–576. [Google Scholar] [CrossRef]

- Ion, J. Laser Processing of Engineering Materials: Principles, Procedure and Industrial Application; Butterworth-Heinemann: Oxford, UK, 2005; p. 179. ISBN 0-7506-6079-1. [Google Scholar]

- Zou, J.L.; He, Y.; Wu, S.K.; Huang, T.; Xiao, R.S. Experimental and theoretical characterization of deep penetration welding threshold induced by 1-μm laser. Appl. Surf. Sci. 2015, 57, 1522–1527. [Google Scholar] [CrossRef]

- Courtois, M.; Carin, M.; Le Masson, P.; Gaied, S.; Balabane, M. A new approach to compute multi-reflections of laser beam in a keyhole for heat transfer and fluid flow modelling in laser welding. J. Phys. D Appl. Phys. 2013, 46, 505305. [Google Scholar] [CrossRef]

- Suder, W.J.; Williams, S.W. Investigation of the effects of basic laser material interaction parameters in laser welding. J. Laser Appl. 2012, 24, 032009. [Google Scholar] [CrossRef]

- Suder, W.J.; Williams, S. Power factor model for selection of welding parameters in CW laser welding. Opt. Laser Technol. 2014, 56, 223–229. [Google Scholar] [CrossRef]

- Ayoola, W.A.; Suder, W.J.; Williams, S.W. Parameters controlling weld bead profile in conduction laser welding. J. Mater. Process. Technol. 2017, 249, 522–530. [Google Scholar] [CrossRef]

- Nikhare, N.B.; Arakerimath, R.R. Parametric analysis and heat transfer enhancement of laser welding for different material. Int. J. Eng. Manag. Res. 2015, ICRAME-2015, 92–96. [Google Scholar]

- Hashemzadeh, M.; Suder, W.; Williams, S.; Powell, J.; Kaplan, A.F.H.; Voisey, K.T. The application of specific point energy analysis to laser cutting with 1 μm laser radiation. Phys. Proc. 2014, 56, 909–918. [Google Scholar] [CrossRef]

- Verhaeghe, G. The effect of spot size and laser quality on welding performance when using high-power continuous wave solid-state lasers. In Proceedings of the ICALEO’2005 Conference, Miami, FL, USA, 31 October–3 November 2005; pp. 264–271. [Google Scholar]

- Kawahito, Y.; Mizutani, M.; Katayama, S. Investigation of high-power fiber laser welding phenomena of stainless steel. Trans. JWRI 2007, 36, 11–15. [Google Scholar]

- Bhargava, P.; Paul, C.P.; Mundra, G.; Premsingh, C.H.; Mishra, S.K.; Nagpure, D.; Kumar, A.; Kukreja, L.M. Study on weld bead surface profile and angular distortion in 6 mm thick butt weld joints of SS304 using fiber laser. Opt. Laser Eng. 2014, 53, 152–157. [Google Scholar] [CrossRef]

- Katayama, S.; Kawahito, Y.; Mizutani, M. Elucidation of laser welding phenomena and factors affecting weld penetration and welding defects. Phys. Proc. 2010, 5, 9–17. [Google Scholar] [CrossRef]

- International Organization for Standardization. EN ISO 13919-1: Welding—Electron and Laser-Beam Welded Joints—Guidance on Quality Levels for Imperfection—Part 1: Steel; ISO: Geneva, Switzerland, 1996; 9p. [Google Scholar]

- International Organization for Standardization. EN ISO 17639 Destructive Tests on Welds in Metallic Materials—Macroscopic and Microscopic Examination of Welds; ISO: Geneva, Switzerland, 2003. [Google Scholar]

| Material | C | Si | Mn | P | S | Cr | Mo | Ni | Cu | Al | V |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AH36 | 0.111 | 0.149 | 0.711 | 0.035 | 0.150 | 0.051 | 0.01 | 0.041 | 0.031 | 0.030 | 0.008 |

| Parameter | Unit | Parameter Range |

|---|---|---|

| Fiber diameter | [µm] | 200; 300; 600 |

| Laser power, PL | [kW] | 6.0; 8.0; 10.0 |

| Welding speed, vw | [m/min] | 0.75; 1.0; 1.25; 1.5; 1.75 |

| Focal point position, FPP | [mm] | −2.0; −4.0; −6.0 |

| Beam angle from flange α | [°] | 6; 10; 15 |

| Beam offset from flange | [mm] | 0.5; 1.0; 1.2; 1.5; 2.0 |

| Delivery Fiber Diameter (μm) | 200 | 300 | 600 |

|---|---|---|---|

| Beam profile |  |  |  |

| Nominal beam waist (mm) | 0.50 | 0.75 | 1.50 |

| Measured beam waist (86% pts) (mm) | 0.710 | 0.882 | 1.460 |

| BPP (mm∙mrad) | 9.079 | 12.000 | 23.800 |

| Rayleigh length (mm) | 13.86 | 16.18 | 22.38 |

| PL at workpiece (kW) | 6.0 | 6.0 | 6.0 |

| Beam area at surface (mm2) | 0.396 | 0.611 | 1.674 |

| Fiber Diameter [µm] | Penetration Depth [mm] | Bead Width [mm] | Fusion Zone [mm2] | HAZ Area [mm2] | Depth to Width Ratio | Max Hardness HV5 [FZ 1/HAZ] |

|---|---|---|---|---|---|---|

| 200 | 8.7 | 2.3 | 13.2 | 6.5 | 4.0 | 386/373 |

| 300 | 7.8 | 2.4 | 12.6 | 6.0 | 3.3 | 392/359 |

| 600 | 5.6 | 2.7 | 12.0 | 5.5 | 2.0 | 393/365 |

| Parameter | 200 µm Process Fiber | 300 µm Process Fiber | 600 µm Process Fiber |

|---|---|---|---|

| α | 6° | 6° | 6°; 10° |

| Beam offset | 1 mm | 1 mm | 1−1.5 mm |

| FPP | −4 mm | −4 mm | −2–−6 mm |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Unt, A.; Poutiainen, I.; Grünenwald, S.; Sokolov, M.; Salminen, A. High Power Fiber Laser Welding of Single Sided T-Joint on Shipbuilding Steel with Different Processing Setups. Appl. Sci. 2017, 7, 1276. https://doi.org/10.3390/app7121276

Unt A, Poutiainen I, Grünenwald S, Sokolov M, Salminen A. High Power Fiber Laser Welding of Single Sided T-Joint on Shipbuilding Steel with Different Processing Setups. Applied Sciences. 2017; 7(12):1276. https://doi.org/10.3390/app7121276

Chicago/Turabian StyleUnt, Anna, Ilkka Poutiainen, Stefan Grünenwald, Mikhail Sokolov, and Antti Salminen. 2017. "High Power Fiber Laser Welding of Single Sided T-Joint on Shipbuilding Steel with Different Processing Setups" Applied Sciences 7, no. 12: 1276. https://doi.org/10.3390/app7121276