1. Introduction

Durable road pavement is a necessary element for economic development in most countries. Recently, the application of renewable bio-origin resources for the construction of road pavement has become more popular as a result of both environment conservation and diminishing natural resources. Currently, there are known additions of bio-binders or bio-origin polymers for bitumen modification. Bio-derived oil is also used as a flux additive for bitumen or as a rejuvenator for reclaimed asphalt pavement (RAP). A growing demand for paving materials requires the application of recycling materials. Material from milled asphalt pavement is used for the construction of new pavement, in hot, warm, or cold technology. The recycling process can be accomplished on-site, in a remote location, or in an asphalt plant. The main reason for recycling milled asphalt mixtures is the decreased need for new material (aggregate and bitumen) in the production of new asphalt mixtures. It should be highlighted that reused bitumen serves as a fully functional, albeit aged, bitumen [

1,

2,

3,

4,

5,

6,

7].

The bio-derived materials are produced using various raw materials and are combined with a bituminous binder in a wide range of proportions [

8,

9,

10]. As studied earlier [

11], such materials may also change the binder and asphalt mixture stiffness, allowing for rejuvenating action. Advanced rheological methods can be accomplished to study rejuvenating effects [

12].

Gawel et al. [

13] proposed solutions to the oxidation conditions for rapeseed and linseed oils and the corresponding methyl esters in order to obtain environmentally friendly bitumen fluxes. A new generation of bituminous binders fluxed with rapeseed oil methyl esters with siccative exhibit lower consistency during the asphalt mixture production process and rebuild consistency during pavement operation, as a result of the polymerization reaction [

14].

A critical issue related to the application of the bio-derived additive fluxing bitumen is the final viscosity of the bitumen and stiffness of the mixture placed in the pavement. While fluxing is appreciated during mixture production, placement, and compaction, it is no longer desired once road is open to traffic [

15,

16].

This paper presents research on an asphalt mixture with RAP, modified with a bio-agent of rapeseed origin. The main idea of the conducted research was to apply more RAP content directly to the batch mix plant without extra RAP heating. The RAP used in this study was milled from a base asphalt layer; the addition of RAP stiffens the new asphalt mixture. A bio-agent, due to its fluxing action, was used to support the asphalt mixing process and to decrease over-stiffening of the mixture caused by RAP addition. During the study, a reference mixture and a mixture with 2.5% addition (based on bitumen weight) of bio-agent were tested. In order to assess the influence of RAP and the bio-agent on the asphalt mixture properties, low temperature behavior (Thermal Stress Restrained Specimen Test (TSRST)), stiffness, and fatigue resistance (four-point bending (4PB)) were studied.

The main objective of this research was to apply cold RAP during asphalt production without compromising the functional properties of the mixture. The research demonstrates that the bio-origin flux acts as a rejuvenator and allows for the application of 30% cold RAP. Thermal cracking resistance of the mixture with RAP and 2.5% bio-agent improved. The bio-agent removes unfavorable stiffening of the asphalt mixture with RAP and increases its fatigue resistance.

2. Materials and Methods

Road bitumen 35/50 (according to the European Specification EN) refined from Ural crude oil was used for the research. As a modifier, a bio-agent of fatty acid methyl esters (FAMEs) based on rapeseed oil (RME—rapeseed methyl esters) with a cobalt catalyst in the amount of 0.1% m/m as calculated for metal and with a reaction initiator of cumene hydroperoxide in the amount of 1% m/m was used. Details of the production process, composition, and chemical reaction connected to bio-agent processing are described elsewhere [

17]. The bio-modifier was produced by an application of an oxidation reaction promoter to the RME and then by allowing this mixture to be oxidized at a temperature of 20 ± 5 °C.

The bio-agent used in this study is a bi-functional material. During the first stage, after being added to the bitumen, it fluidized bitumen by lowering its viscosity. During the second stage, due to the presence of double unsaturated bonds and cobalt catalyzer in the RME, a slow polymerization process started in the bio-agent. Polymerization occurred in the presence of oxygen and partially recovered initial bitumen viscosity.

The research presented in this paper was conducted observing the bitumen specimens and the asphalt mixture samples.

The following samples were subjected to bitumen tests: clean unmodified bitumen 35/50 and bitumen modified with bio-modifier at the amounts of 1.25%, 2.5%, 3.75% and 5.0% of addition, in terms of bitumen weight. In addition, as reference points, unmodified bitumens 50/70 and 70/100 were also tested. Road bitumen 35/50 was mixed with a bio-modifier for one minute at a temperature of 150 °C. FAME demonstrated full blendability to the bitumen binder. In order to determine the characteristics of the polymerization process in time, bitumens modified with the bio-agent were conditions in the thin layer of 1 mm for up to 56 days at room temperature. The tests were conducted directly after modification (Day 0) and after 7, 14, 28, and 56 days of conditioning. Bitumens were tested in a dynamic shear rheometer (DSR) for complex modulus G* and for phase angle |δ|. Tests were accomplished with a constant frequency of 10 rad/s in the temperature range between 0 °C and 100 °C, using two parallel plates with a 25 mm diameter and a 1 mm gap.

For asphalt mixture tests, asphalt concrete (AC) with a 16 mm maximum aggregate sieve size was used. Two types of asphalt mixtures were tested: a reference AC with 30% RAP with 35/50 bitumen and AC with 30% RAP, 35/50 bitumen, and 2.5% bio-agent (bio-agent content was determined based on the bitumen testing as explained later in this paper).

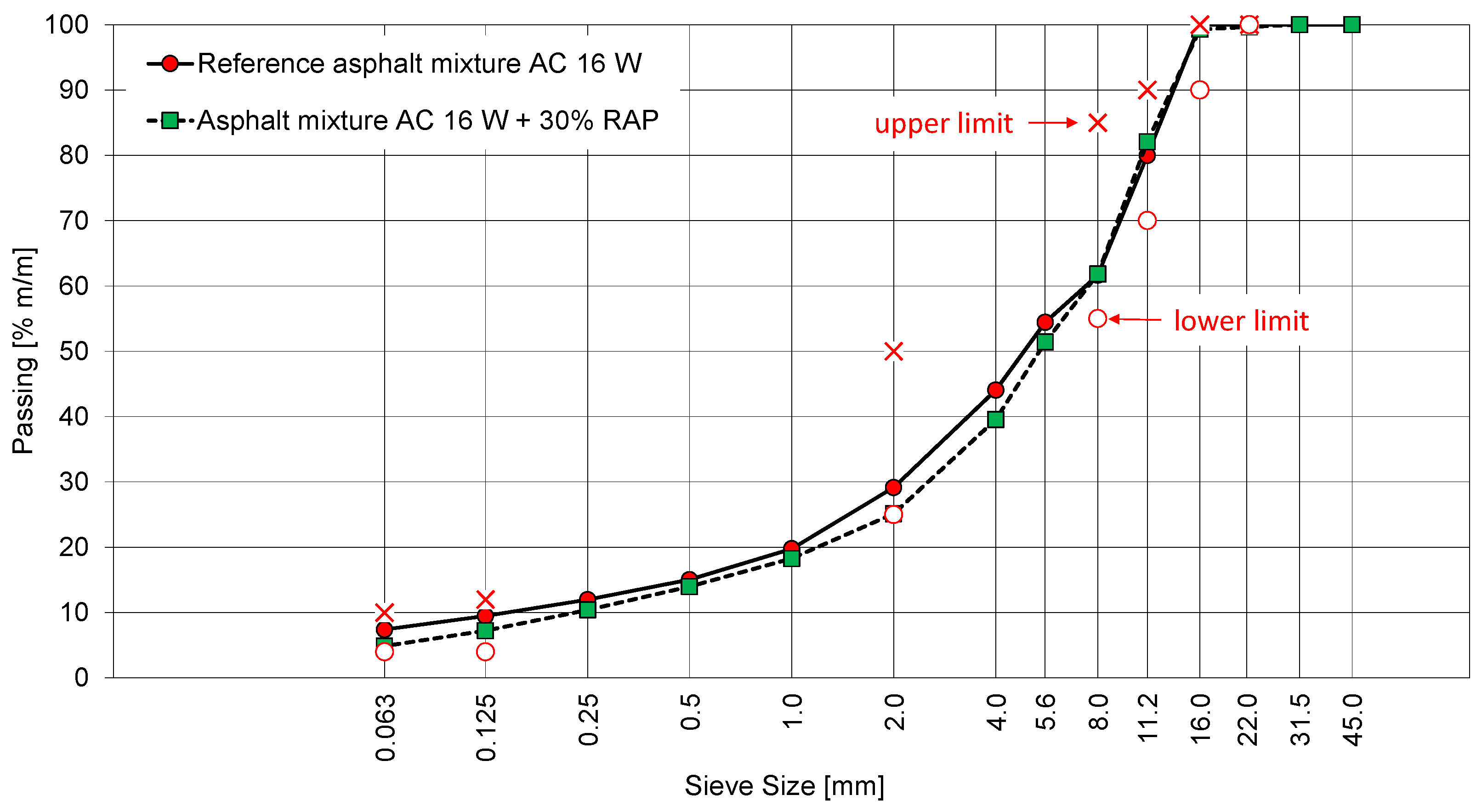

Figure 1 presents an aggregate blend gradation curve, while basic properties of asphalt concrete are shown in

Table 1. For air void determination, asphalt mixtures were compacted in a Marshall compactor with 2 × 75 blows for each sample, according to EN 12697-30 Bituminous mixtures. Test methods for hot mix asphalt. Specimen preparation by impact compactor. Compaction level was determined based on the air void determination according to EN 12697-8 Bituminous mixtures. Test methods for hot mix asphalt. Determination of void characteristics of bituminous specimens. During compaction, all samples demonstrated a temperature similar to 135 ± 5 °C. The reference mixture exhibited air void content of 4.6%. The bio-agent application resulted in better mixture compaction (3.2% air voids). The asphalt mixture with bio-agent was not optimized for air void content due to the Polish requirements for asphalt mix design. According to requirements WT-2 [

18], the mixture was designed for the required air void range. Once air void content is within the range (3%–6%), further optimization is not required. In addition, in this research, there was an attempt to determine the influence of bio-agent on the compactibility of asphalt mixture and those on its properties.

Asphalt mixtures were tested for 4PB stiffness and fatigue durability (resistance) as well as for low-temperature behavior. During the specimen preparation process, plate samples were compacted in the roller compactor according to EN 12697-33 Bituminous mixtures. Test methods for hot mix asphalt. Specimen prepared by roller compactor, reaching 98%–100% of the compaction index.

Stiffness and fatigue tests were conducted in the machine equipped with the 4PB bending module. Stiffness modulus |E*| was determined according to App. B of specification EN 12697-26 Bituminous mixtures. Test methods for hot mix asphalt. Stiffness. The test consisted of cyclic bending of beam with constant strain amplitude. While testing, load, beam deflection, phase angle, and cycle number are registered and stiffness modulus |E*| is calculated. The following test conditions were observed: a temperature of 10 °C, an amplitude of 1, 2, 5, 8, 10, and 15 Hz, and a strain of 50 mm/mm. A fatigue test was conducted in the same apparatus according to EN 12697-24 Bituminous mixtures. Test methods for hot mix asphalt. Resistance to fatigue. Tests were conducted with controlled strains, at temperature of 10 °C, and a 10 Hz amplitude. Six samples with three levels of deflection were tested. Based on the fatigue test results obtained for various strain levels, material fatigue characteristics were determined using linear regression, for which correlation coefficient r was calculated. The correlation r between fatigue and macrostrain was tested for statistical significance. The following was assumed: hypothesis H0: p = 0, meaning that a correlation does not exist and hypothesis H1: p ≠ 0, meaning that a correlation does exist. Once the correlation coefficient r was calculated, values of a Student t-test were determined. Then, the probability of a critical value transgression by variable t was calculated and compared with statistical significance at the level of α = 0.05. Once p < α, the correlation is significant; for p > α, the hypothesis (correlation between tested values) is not rejected.

To determine the low temperature cracking susceptibility of asphalt mixes, the TSRST was accomplished according to EN 12697-46:2012 Bituminous mixtures. Test methods for hot mix asphalt. Low temperature cracking and properties by uniaxial tension tests. Tests were conducted with the MTS test setup. The tested specimens were rectangular with dimensions of 50 × 50 × 250 mm. For each mixture, four rectangular specimens were prepared. The initial test temperature was 10 °C. This temperature decreased while testing with a rate of 10 °C/h. A special frame was used in order to position specimens in such way that any strain of the specimen is prohibited. In such a condition, inside tested sample thermal tensile stresses are induced. During the testing temperature, force and strain are registered. The end of the test is determined once the sample breaks. A test result is determined as a stress prior to sample breaking (cryogenic stress) and corresponding temperature (failure temperature).

3. Results

3.1. Binder Properties

The complex modulus |G*| and phase angle |δ| are good measures of the viscoelastic properties of bituminous binders. Once the temperature increases, the complex modulus decreases and the phase angle increases towards the viscous stage. A similar effect can be seen once the fluxing agent is added to the road bitumen, as a viscous part of the bitumen complex modulus increases. The bio-agent obtained from RME, as compared to regular oils, presents lower viscosity and good fluxing action in bitumen.

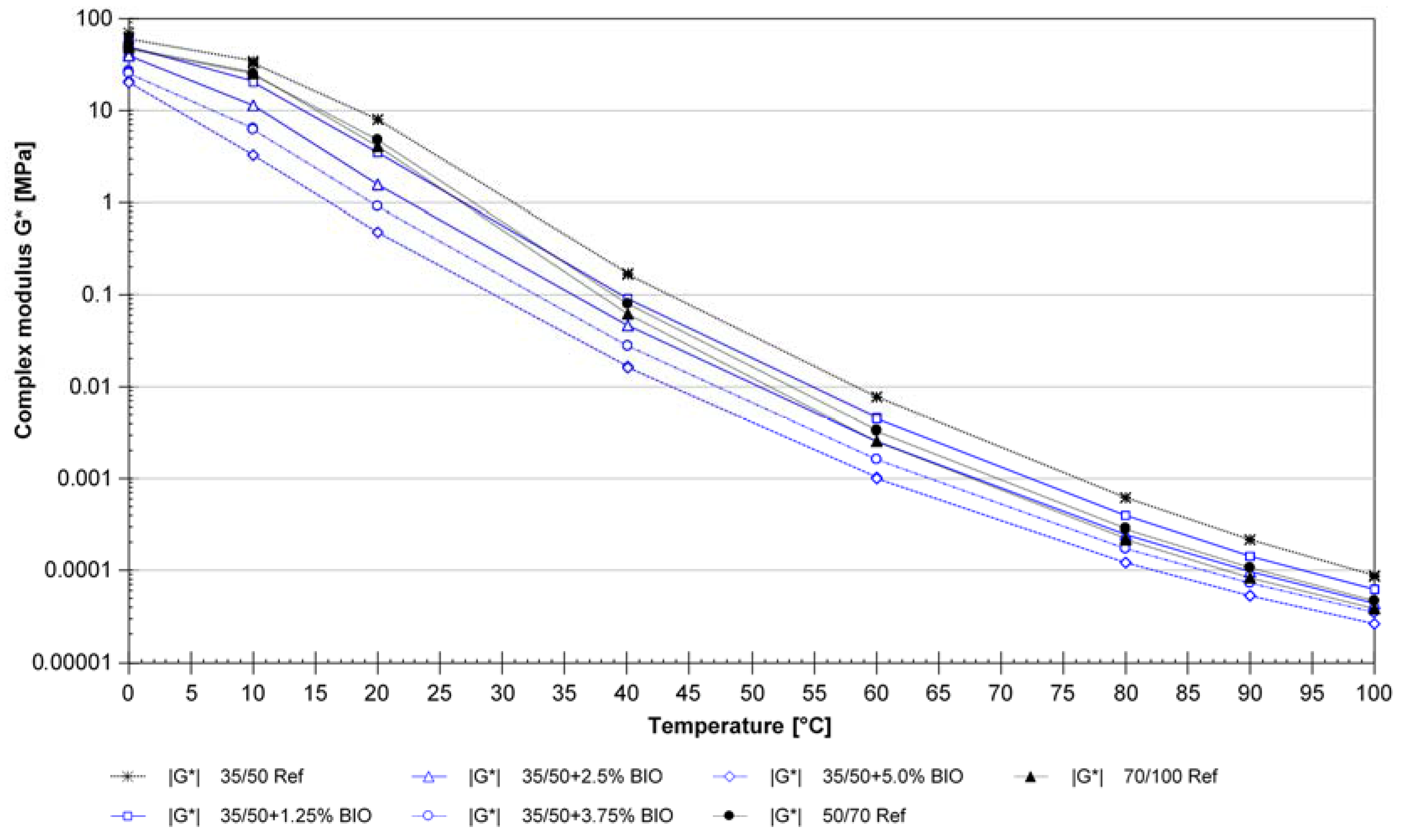

Figure 2 shows complex modulus curves with respect to temperature for reference binders and for binders with various amounts of bio-agent. Based on the curve location, the desired bio-agent content was determined for further tests on asphalt mixtures. It can be seen that, in all tested specimens in the temperature range, an unmodified binder shows the highest stiffness. Together with the bio-agent content increment (ranging from 1.25% to 5.0%), stiffness of the fluxed bitumen decreases (refer to

Figure 2). Comparison between bitumen modified with various amounts of bio-agent with reference 50/70 and 70/100 bitumens allows us to conclude that bitumen 35/50 with 2.5% bio-agent has similar viscoelastic properties to road bitumen 50/70.

Phase angle changes as a function of temperature are shown in

Figure 3 for reference binders and for binders with various amounts of bio-agent. It can be seen that, in the range of medium road operational temperature between 0 °C and 30 °C, bitumen 35/50 with bio-agent in the amount of 1.25% shows similar properties to reference bitumens 50/70 and 70/100. As the temperature increases above 40 °C, the behavior of reference bitumens 50/70 and 70/100 corresponds to properties of 35/50 road bitumen with bio-agent content above 2.5%. The influence of bio-agent is very positive due to the variable fluxing effect depending on the temperature. At a low temperature, bitumen 35/50 with 2.5% bio-agent shows higher flexibility than reference bitumens 50/70 and 70/100, which makes it more resistant to cracking, but at a high temperature presents lower flexibility, which is related to a higher resistance to permanent deformation (rutting). It can be concluded that bitumen 35/50 modified with 2.5% bio-agent demonstrates better visco-elastic properties than does non-modified 50/70 bitumen.

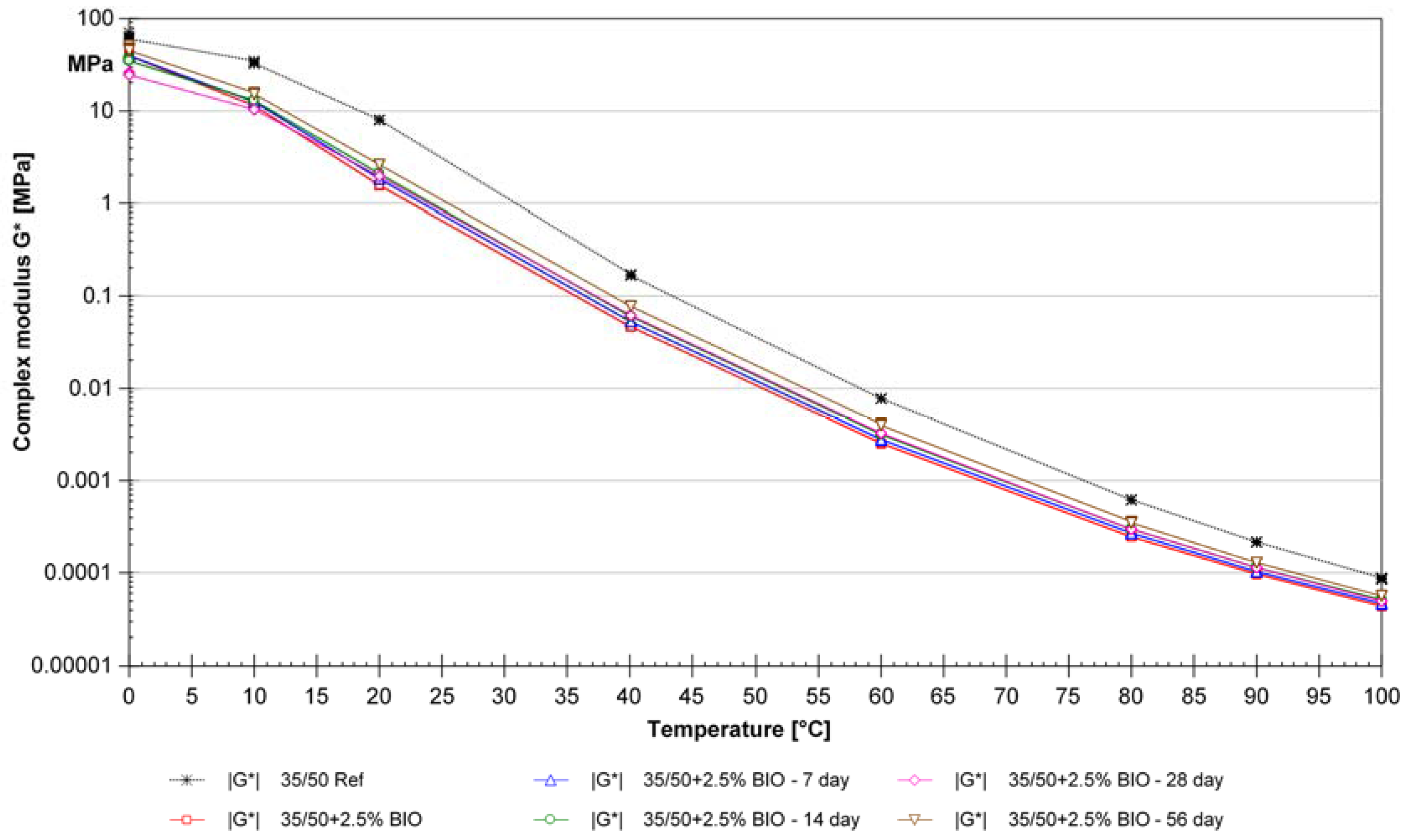

As was previously determined, modification of road bitumen with bio-agent may have a positive influence on the properties of hard bitumen and causes its fluxing during the technological processes of asphalt mixture production and placement. During the second stage of asphalt mixture life, once opened to traffic, as a result of bio-agent polymerization in bitumen, partial bitumen recovery to its properties before modification is expected. As shown in

Figure 4, curves of a complex modulus in the temperature function for bitumen 35/50 modified with 2.5% bio-agent, in time, demonstrate expected beneficial properties. It can be seen that the polymerization reaction of the bio-agent occurs in the bitumen in a permanent way and changes the bitumen stiffness at all temperatures. It also can be observed that the complex modulus curve for bitumen 35/50 shortly after its modification is the most shifted from the reference bitumen 35/50. In time, bitumen modified with the bio-agent increases in stiffness.

Figure 5 shows curves of the phase angle in a function of temperature for road bitumen 35/50 modified with 2.5% bio-agent in time. Based on the presented data, it can be seen that bitumen 35/50 after fluxidation presents higher flexibility as expressed by the higher phase angle value. This flexibility effect then decreases in time once polymerization occurs.

3.2. Asphalt Mixture Properties

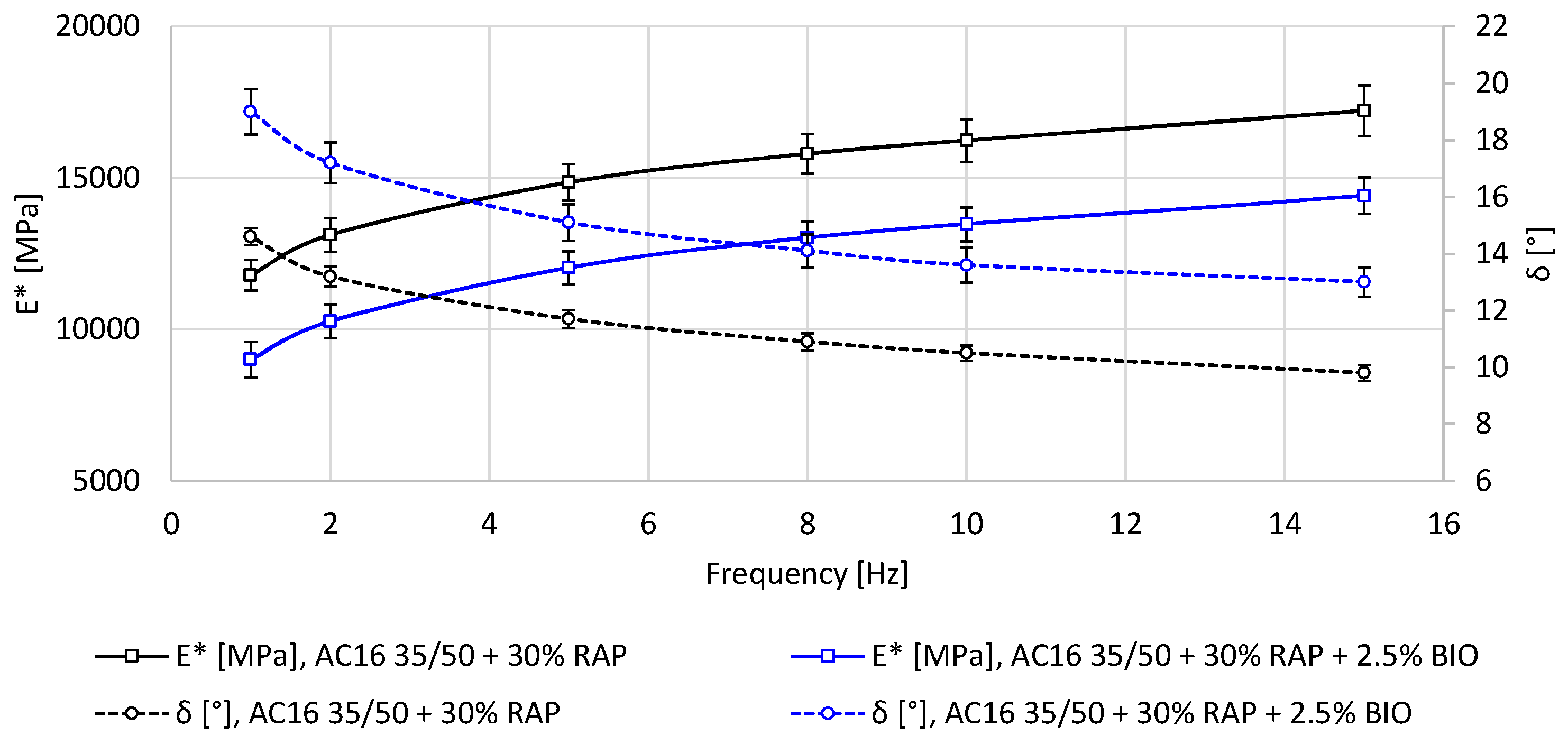

Complex modulus and phase angle test results are presented in

Figure 6 for 4PB tests in the frequency function for AC with bitumen 35/50 and bio-agent. Curves shown in

Figure 6 are an average from six measurements conducted for six different specimens of the same asphalt mixture. On plots, there are shown error bars as a value of standard deviation for the average of each repetition. Based on curve analysis, it can be concluded that the mixtures with the bio-agent demonstrate lower stiffness as compared to the mixture with unmodified binder. The aforementioned can be seen in all frequency range. The bio-agent presence in the asphalt mixture causes a higher value of phase angle, which is a beneficial phenomenon in the medium range of temperatures to which the road can be subjected.

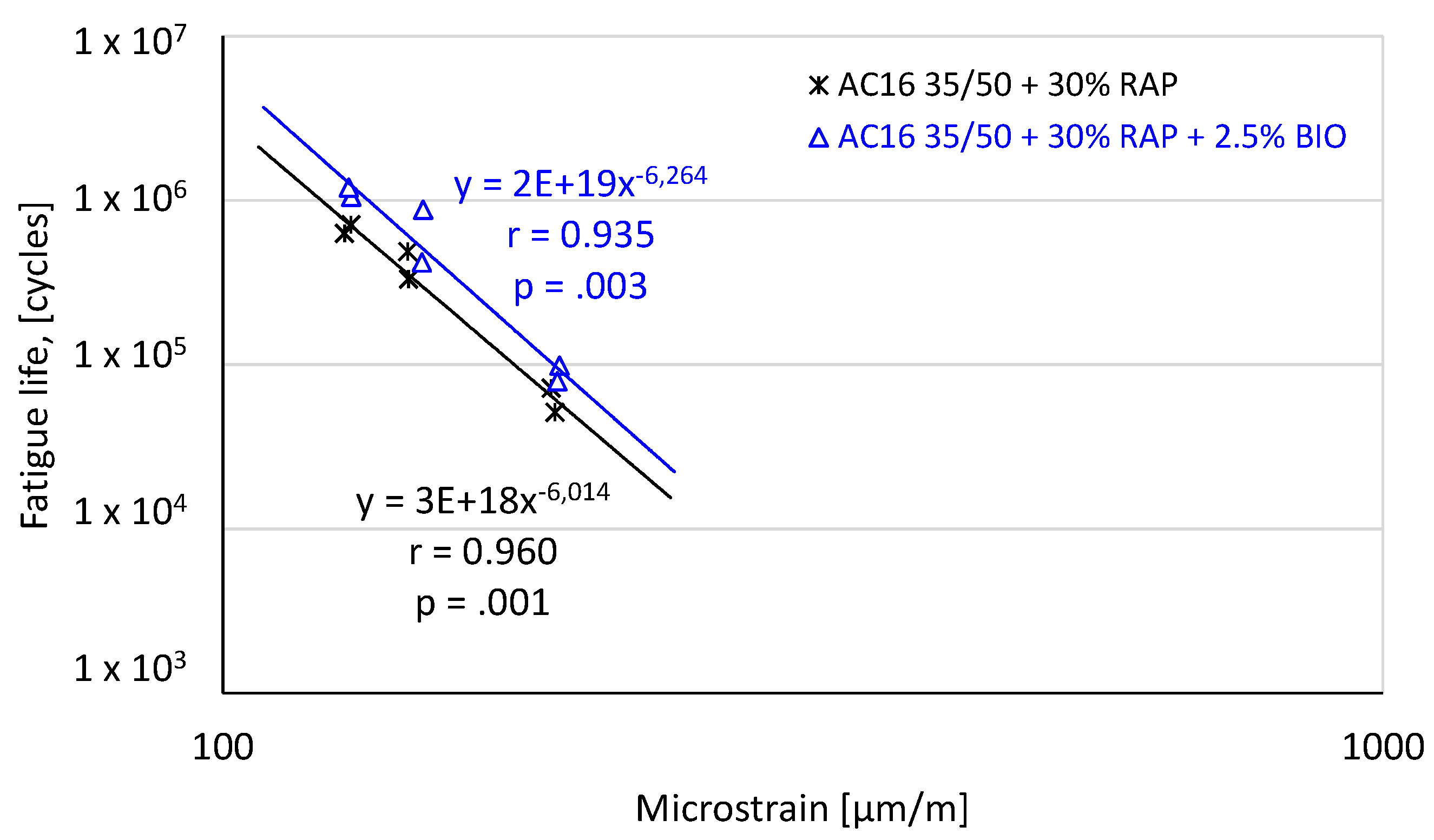

Fatigue characteristics of both asphalt mixtures are shown in

Figure 7. Based on a statistical analysis of correlation, it can be assumed that correlations describing fatigue characteristics of both asphalt mixture are true (

p < 0.05). Based on the location of both fatigue curves, it can be concluded that mixture with bio-agent demonstrates higher fatigue durability (resistance) as compared to the one without bio-agent. Curve for the mixture with bio-agent is parallel-shifted to the top as compared to the one with unmodified bitumen. Such shift is a sign of the fact that the mixture with comparable strain is more resistant to the fatigue and pavement will reach end-of-life in a longer timer period. On the other hand, based on the mixture properties at the same number of cycles, it can be found that mixture with bio-agent allows for an application of load with higher frequency strain. The asphalt mixture with RAP and bitumen without modification allows for a million cycles with a strain of 122 µm/m, while the mixture with RAP and bitumen modified with the bio-agent allows for a million cycles with a strain of about 10% higher (i.e., 134 µm/m).

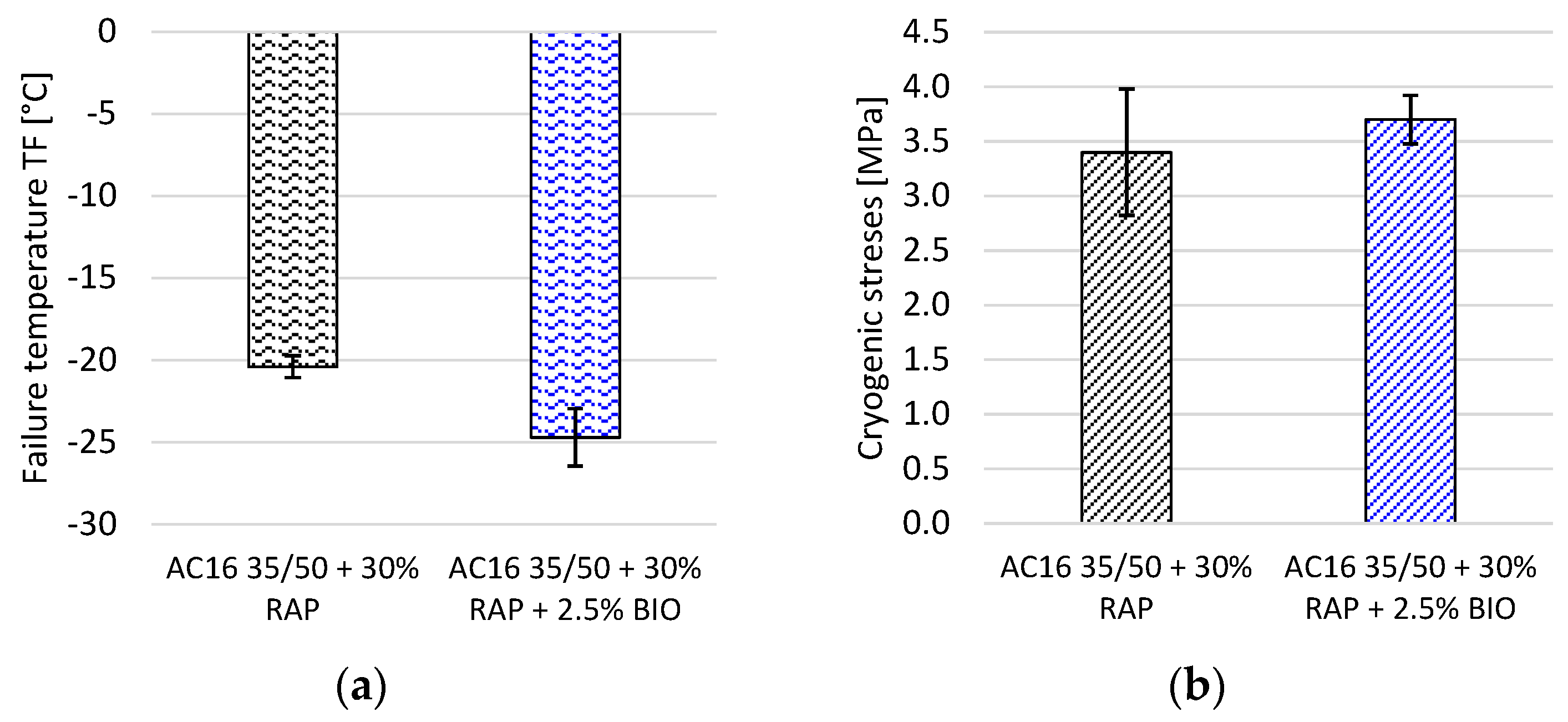

Figure 8 presents results of low temperature resistance according to the TSRST. On

Figure 8, there are shown error bars as a value of standard deviation for average from each of four repetitions. It can be seen that the mixture with the bio-agent added exhibited a 5 °C lower breaking temperature compared with the AC without the bio-agent (refer to

Figure 8a). Asphalt specimen destruction during the TSRST occurs as a result of thermal contraction once temperature decreases. As visible, the difference between test results of the mixes is higher than standard deviation, which implies the important influence of the bio-agent on low-temperature behavior. A comparison between cryogenic stresses suggests that the asphalt mixture with the bio-agent exhibits higher tensile strength occurring with low-temperature contraction (refer to

Figure 8b). Once taking into account the test results, including the error bars as a value of standard deviation, the differences in cryogenic stress between mixtures are not visible. From a statistical point of view, such a correlation is still possible and should be verified with a greater population.

4. Discussion and Conclusions

Bio-materials, allowing for the use of renewable resources, are increasingly applied in industry due to sustainability policy. Once used, they cannot detrimentally change properties of the material, instead they should make it more ecologically friendly. The effect of initial fluxidation of bitumen with the bio-agent and then the gradual polymerization suggests the potential of its application as a bi-functional additive in warm mix asphalt (WMA) technology or asphalt mixes with reclaimed asphalt pavement (RAP).

Asphalt mixture production is a sensitive process requiring high quality control. During application of RAP directly to the mixer there is a potential risk related to the mixture uniformity. Application of bio-agent with fluxing function lowers bitumen viscosity and helps to reach better homogeneity in the mixtures containing RAP. It also should be highlighted that, in asphalt mixtures containing RAP there are two types of bitumen binder: binder from RAP and virgin bitumen. It is commonly assumed that during asphalt mixture production both bitumens will mix resulting with blended bitumen. The tests conducted shows that even low rate of bio-agent (2.5%) beneficially changes bitumen properties in low temperature; moreover polymerization processes occurring in second stage of the process improves bitumen properties in high operational temperature. The testing of complex modulus |G*| and phase angle |δ| demonstrated that it is possible to select optimal bio-agent content depending on the desired consistency of bitumen. As mentioned earlier, bio-agent polymerization occurring during the second stage of the process partially recovers initial properties of the bitumen. Unrecovered parts of the fluxing effect compensate, in the blended RAP + virgin bitumen, the stiffening of the binder caused by the application of aged bitumen from RAP.

Due to the fact that bio-additive modifies visco-elastic properties of bitumen in a wide temperature range and has a fluxing effect, it also improves the compaction process of the asphalt mixture. As shown in this research, the bio-agent influences the amount of air voids in the compacted mixture. Based on the observed compaction of mixtures with RAP as well as with RAP and bio-agent, it can be concluded that the design process of such mixes should include an expected effect of fluxing in order to obtain the desired air void content and compaction level.

The fluxing effect of bitumen binder and the changes in its viscoelastic properties permanently influence the behavior of asphalt mixtures. Initially, before bio-agent polymerization, improvement in compactibility can be seen. Next, after polymerization, the mixture exhibits higher fatigue durability, accommodates higher strains, and shows improved low-temperature properties. Those effects are most likely caused by an improvement in both virgin binder properties and aged (RAP origin) binder properties. Asphalt mixtures with bio-agents added in the amount of 2.5% shows 10% higher fatigue durability (4PB) and a 5 °C lower failure temperature (TSRST).

As was demonstrated in another paper [

15] (more chemically oriented) produced based on this study, the polymerization process of the bio-agent occurs until the saturation of double unsaturated bonds, whose number is limited—typically, bio-agent polymerization occurs during the first month (with a complete stop after two months). For this reason, over-stiffening of the mixture during pavement in-service life is not expected.

The bio-agent used in this research is a material obtained from RME with an average polymerization potential due to the limited number of unsaturated bonds. In future studies, another vegetable-origin material such as tung oil, linseed oil, and sunflower oil can be applied in order to determine its applicability for road bitumen modification and to verify the relationship between the polymerization mechanism and the durability of asphalt mixtures.