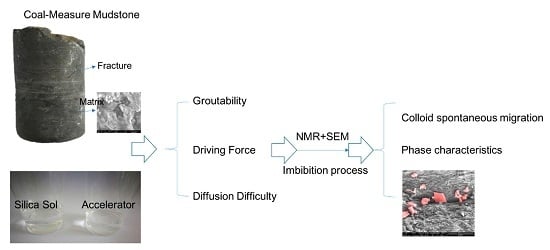

Experimental Study of Imbibition Characteristics of Silica Sol in Coal-Measure Mudstone Matrix

Abstract

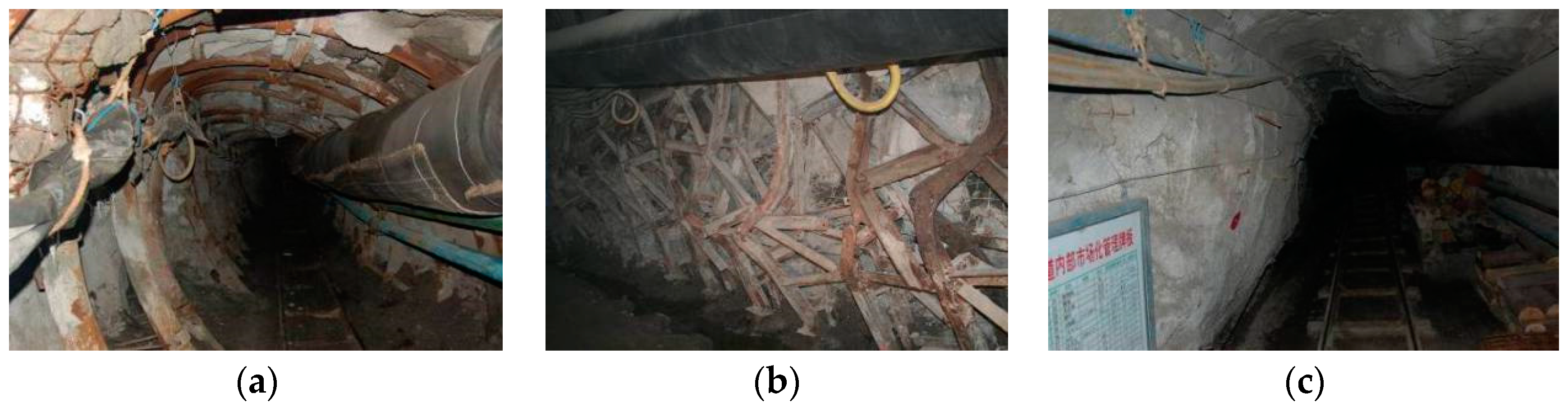

:1. Introduction

2. Theory of Grout Transport in Dual-Porosity Media

3. Basic Characteristics of Coal-Measure Mudstone and Silica Sol

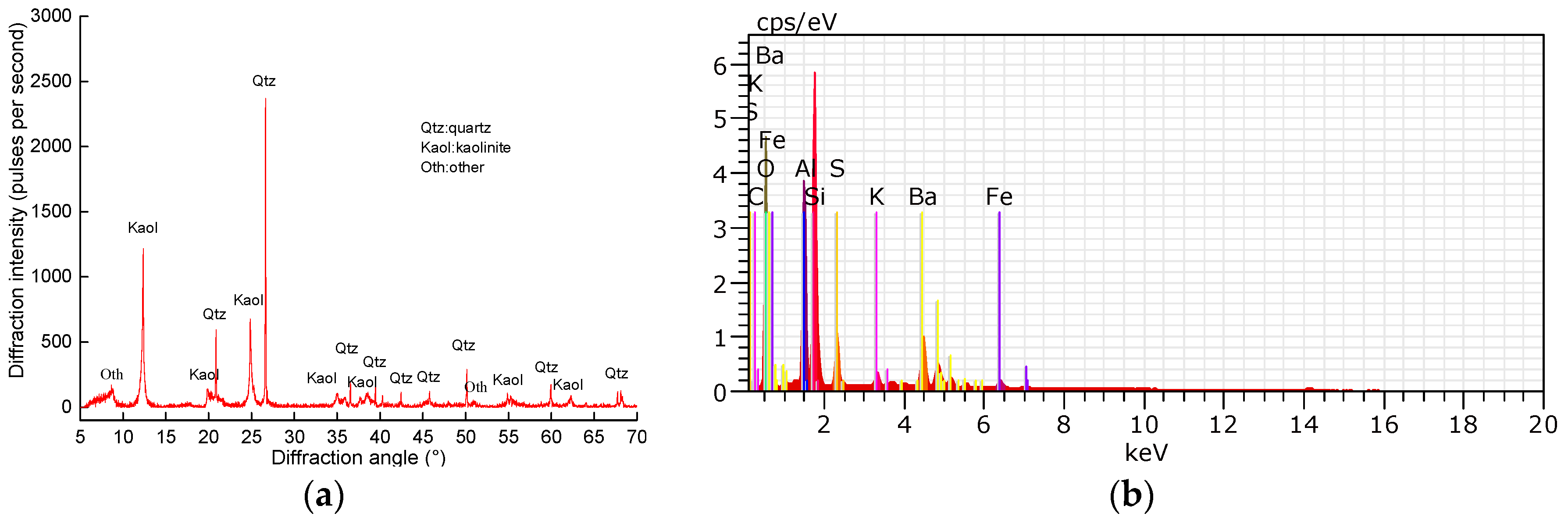

3.1. Coal-Measure Mudstone

3.2. Silica Sol

4. Test Analysis of Key Factors Affecting Imbibition Effect

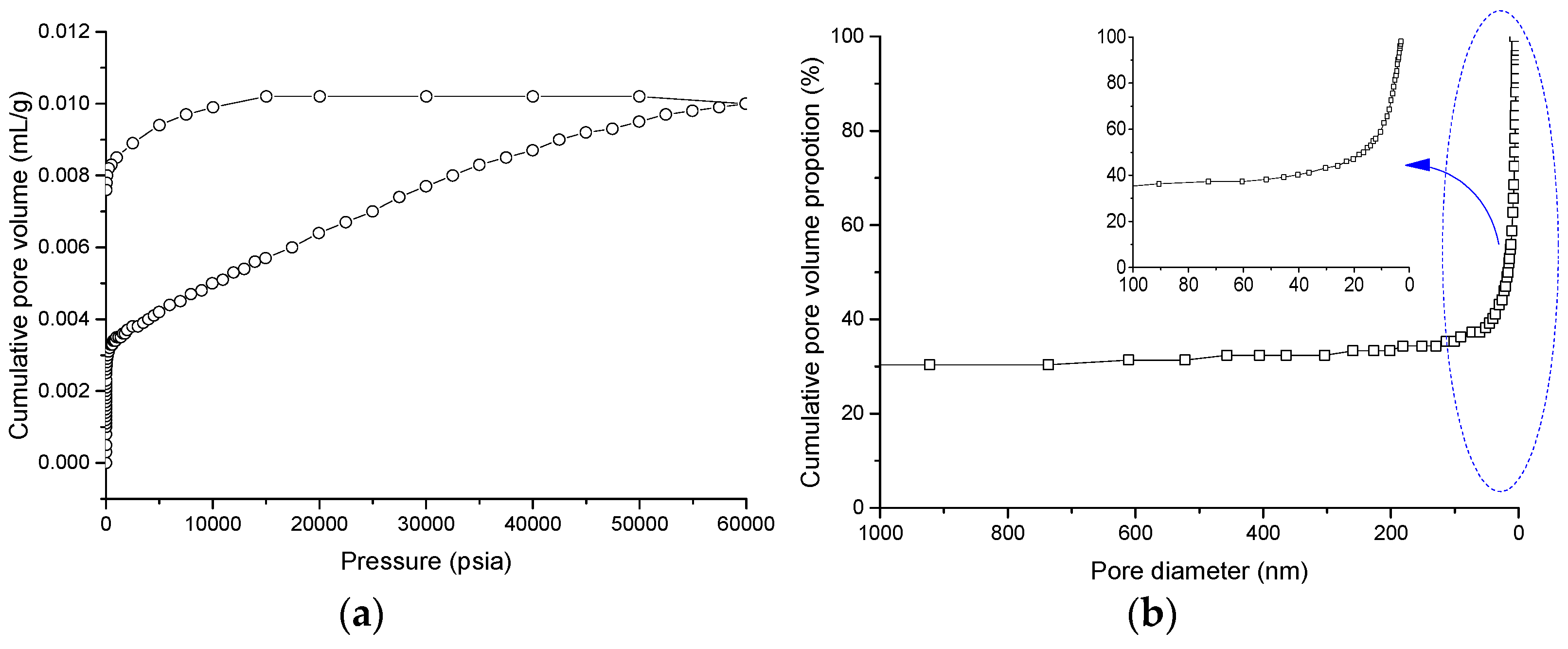

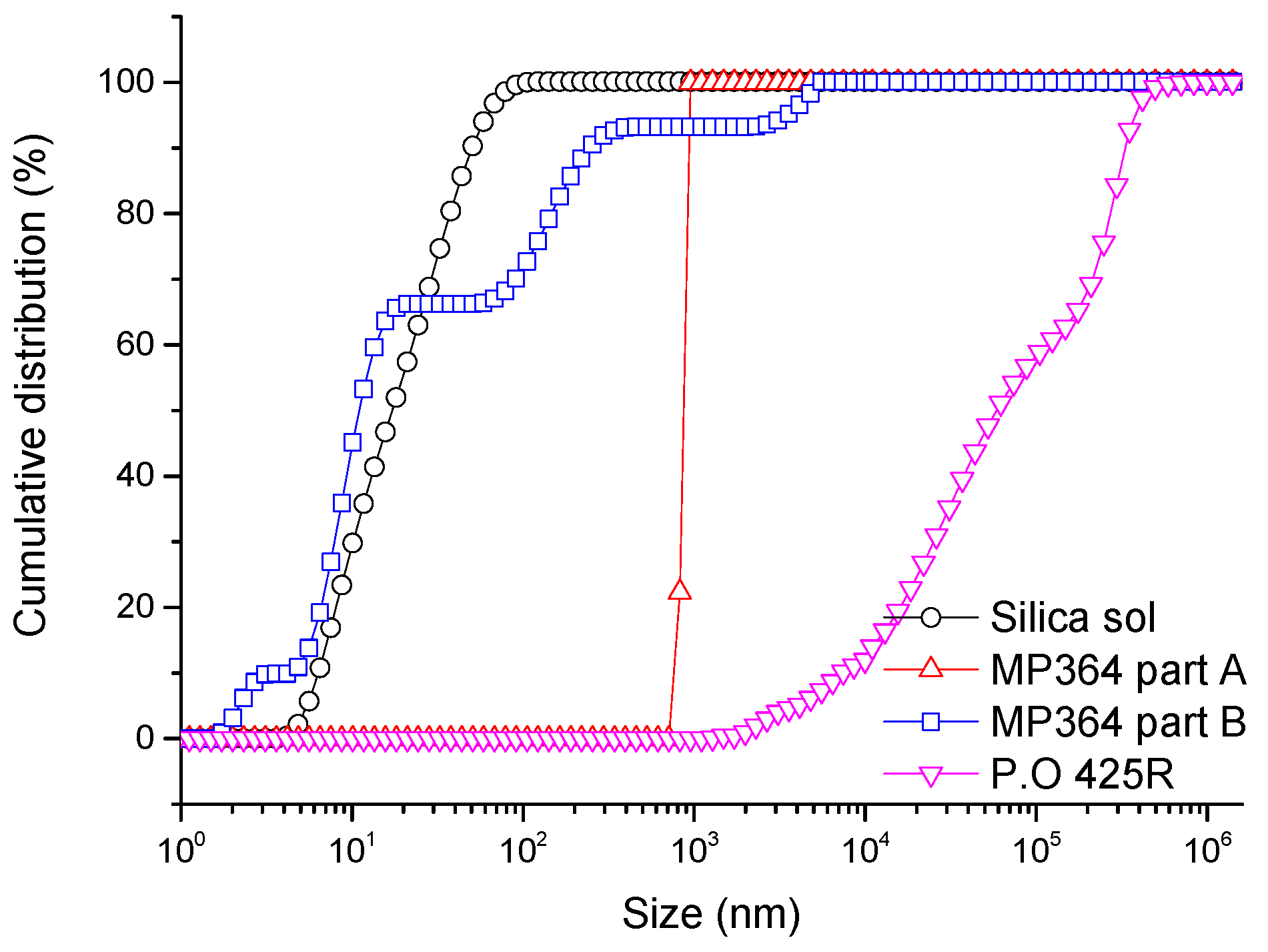

4.1. Groutability

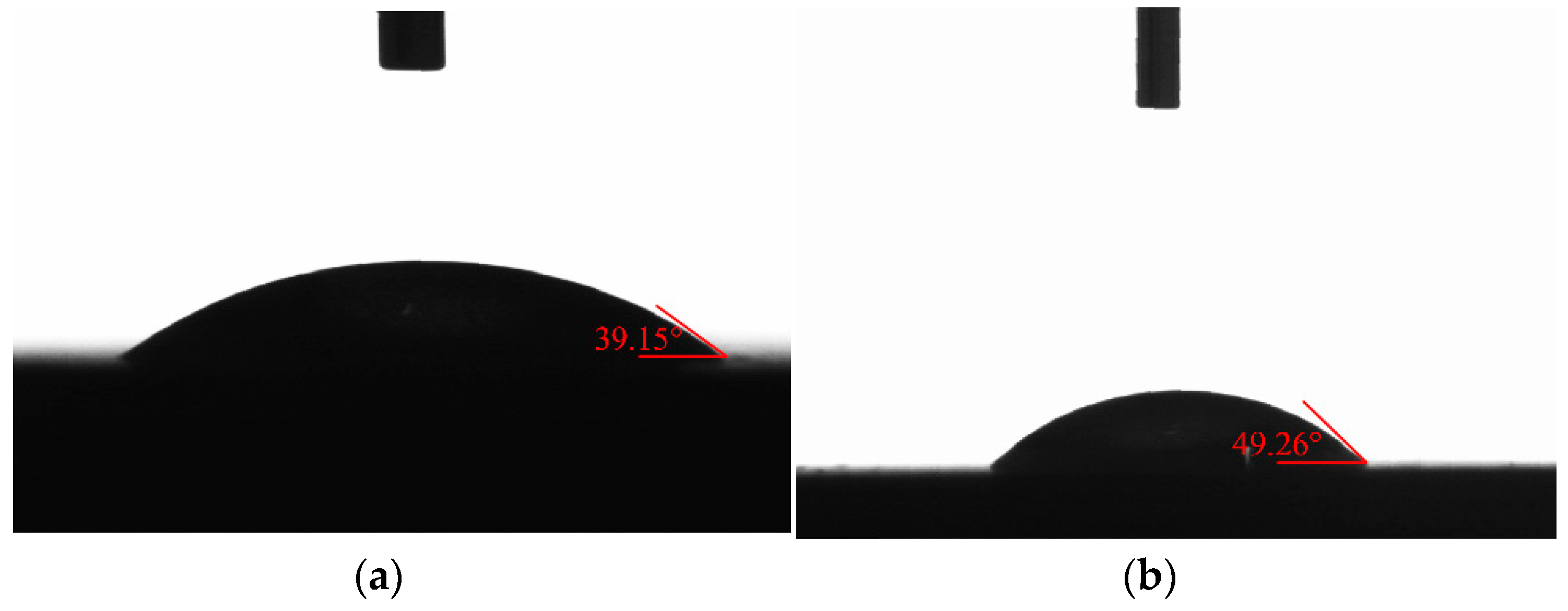

4.2. Driving Force

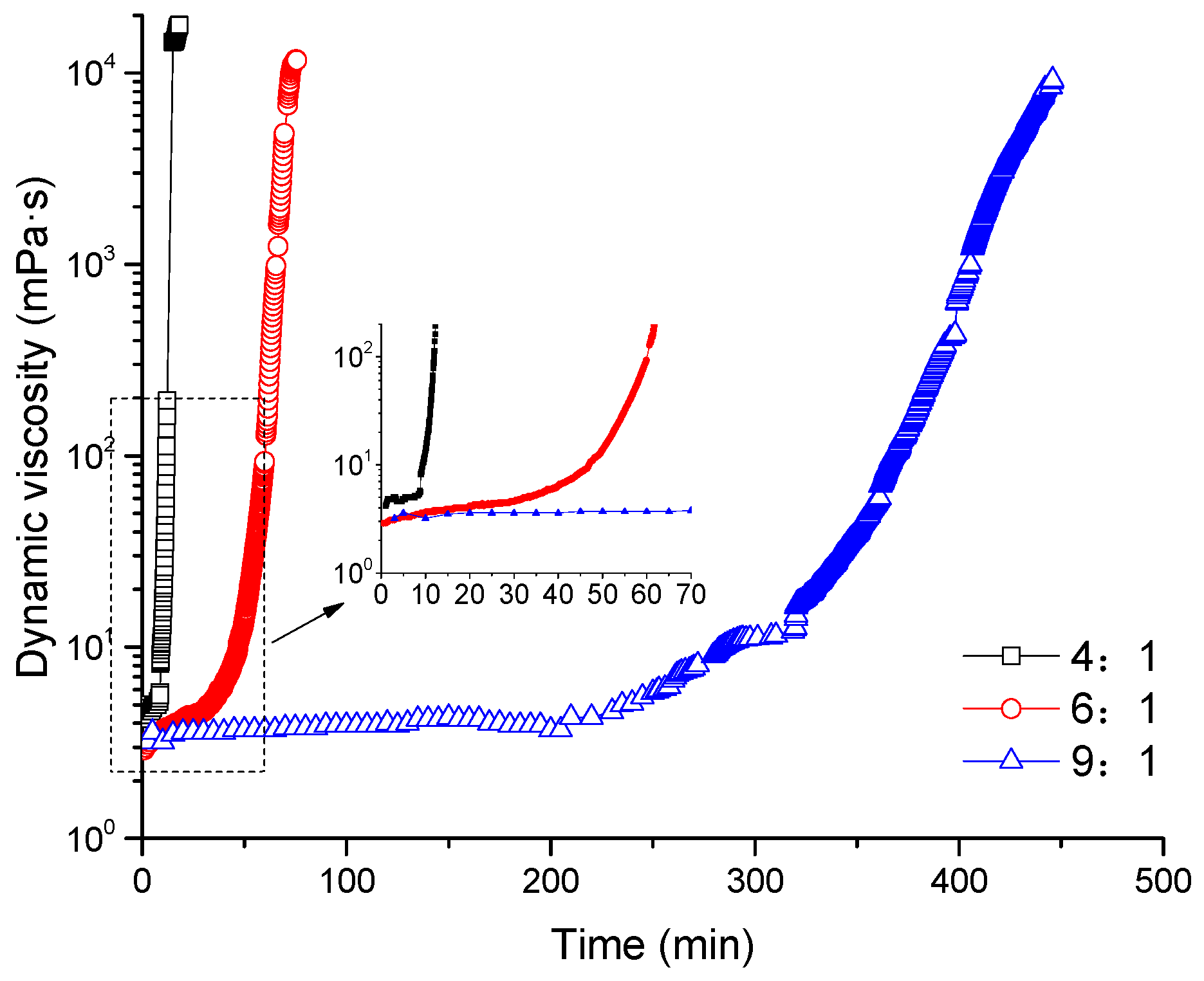

4.3. Diffusion Difficulty

5. Pressureless Imbibition Experiment

5.1. Sample Pretreatment

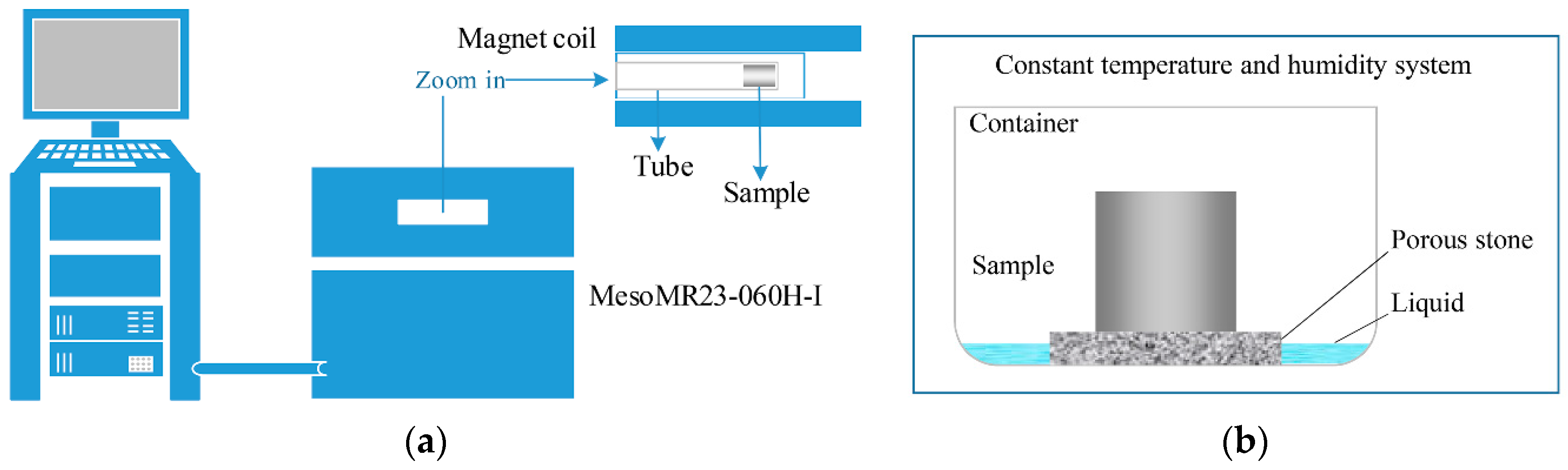

5.2. Experimental Principle and Process

5.3. Results and Analysis

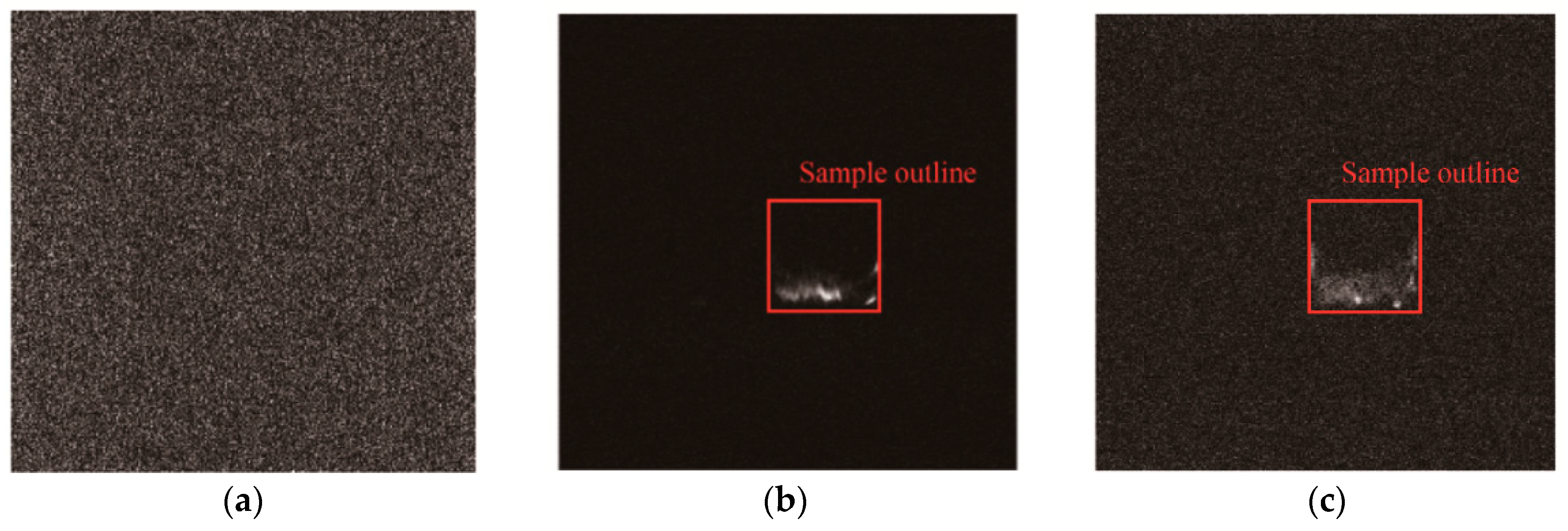

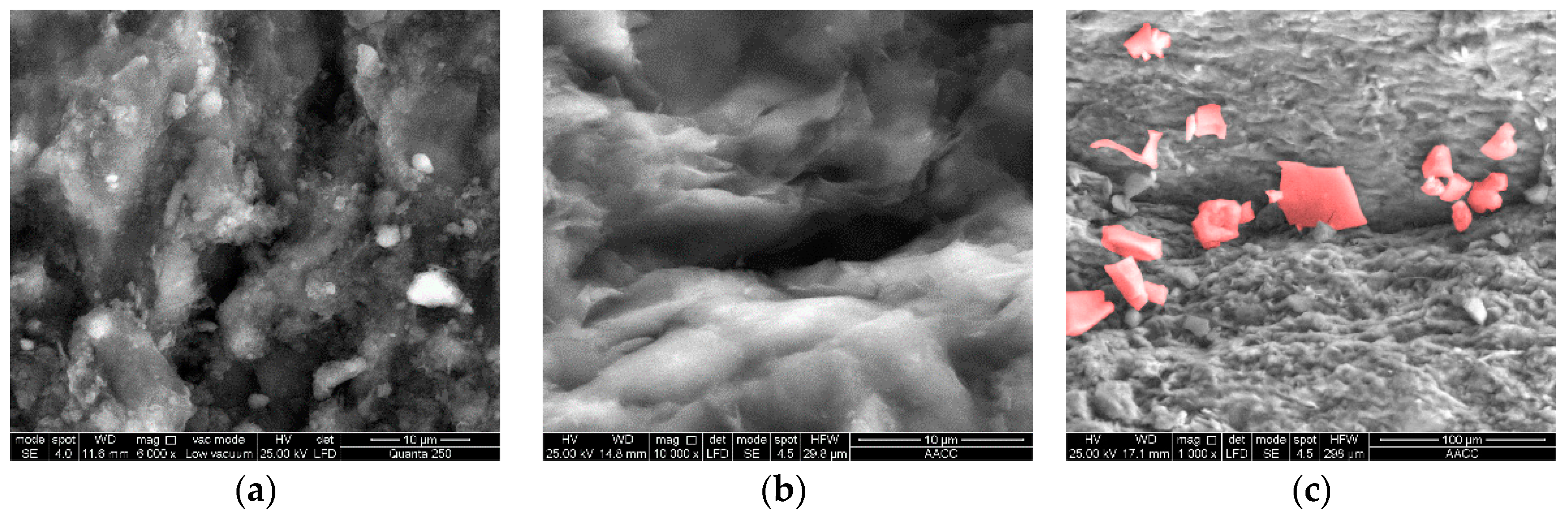

5.3.1. NMR-Imaging and SEM-Imaging Characteristics

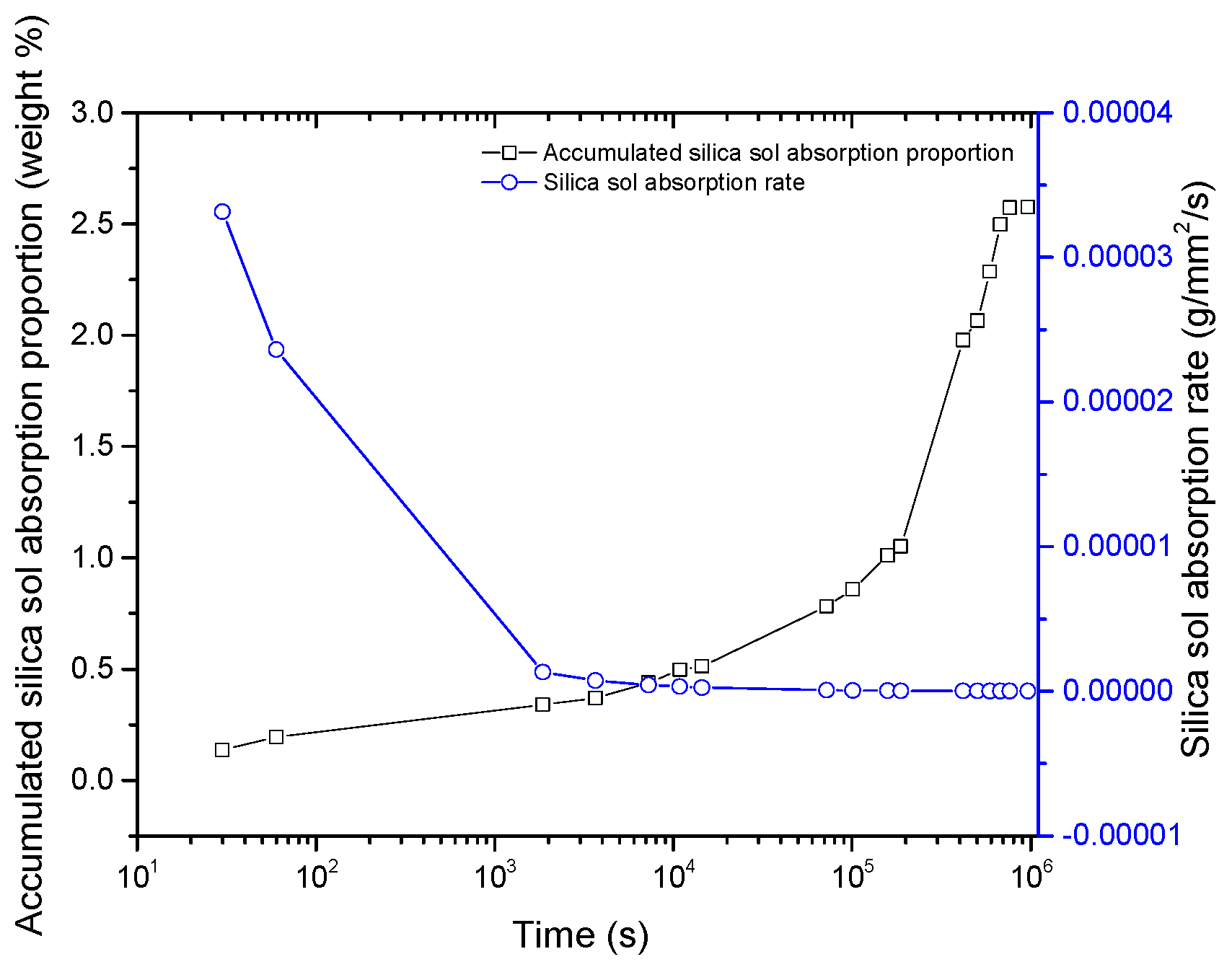

5.3.2. Staged Characteristics of Imbibition

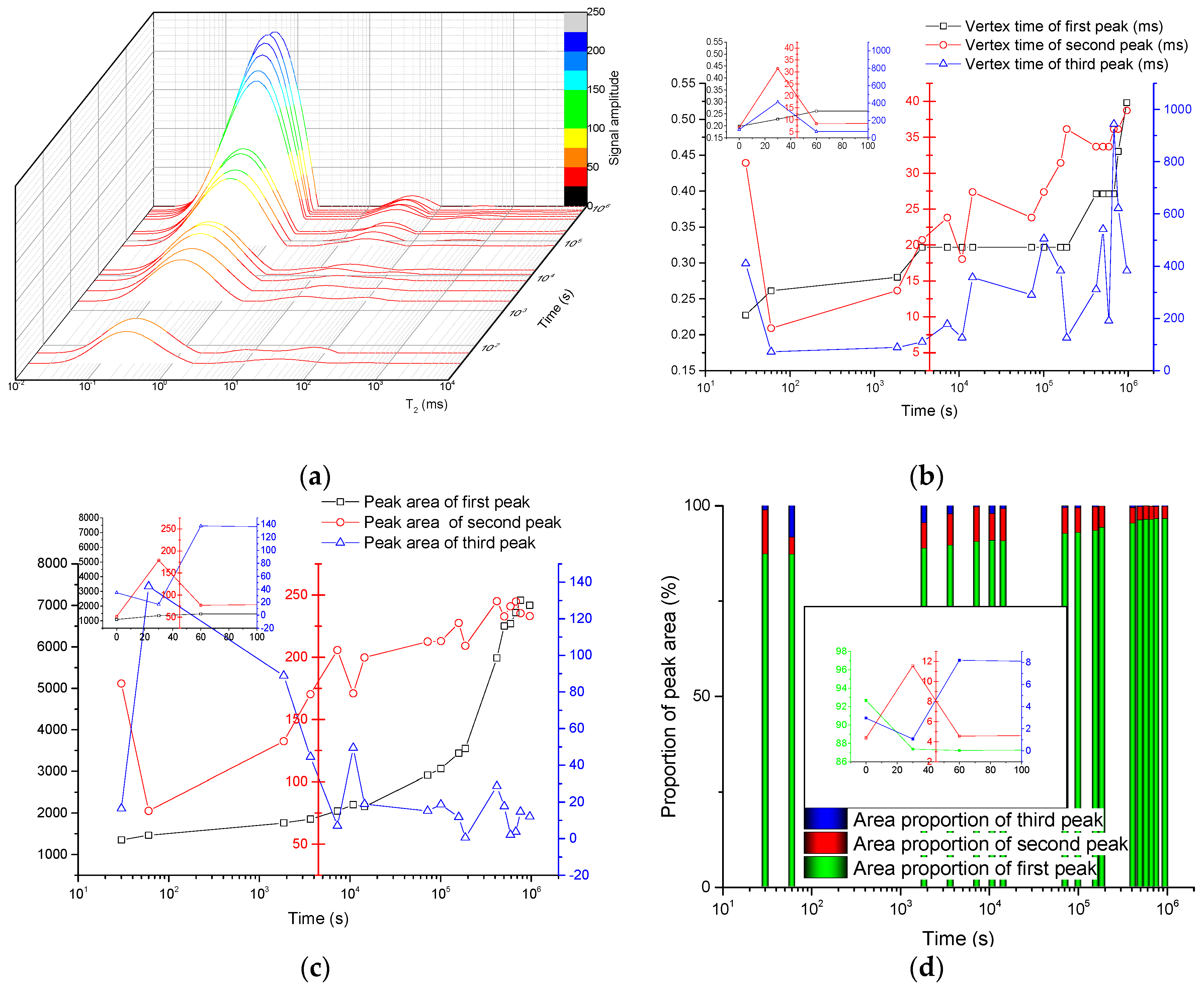

5.3.3. Spectrogram Characteristics of T2

5.4. Comparative Experiment

6. Conclusions

- (1)

- This paper reveals the silica sol grouting mechanism by two-phase displacement theory in dual-porosity media and confirms that grouting in a matrix system is dominantly controlled by the imbibition effect for silica sol.

- (2)

- Tests of key factors affecting imbibition show that the theoretical groutability ratio of silica sol is optimum compared with MP364 and P.O 425R. The imbibition potential of silica sol is quite significant, which is slightly lower than water. Moreover, silica sol has a low viscosity and a strong diffusivity.

- (3)

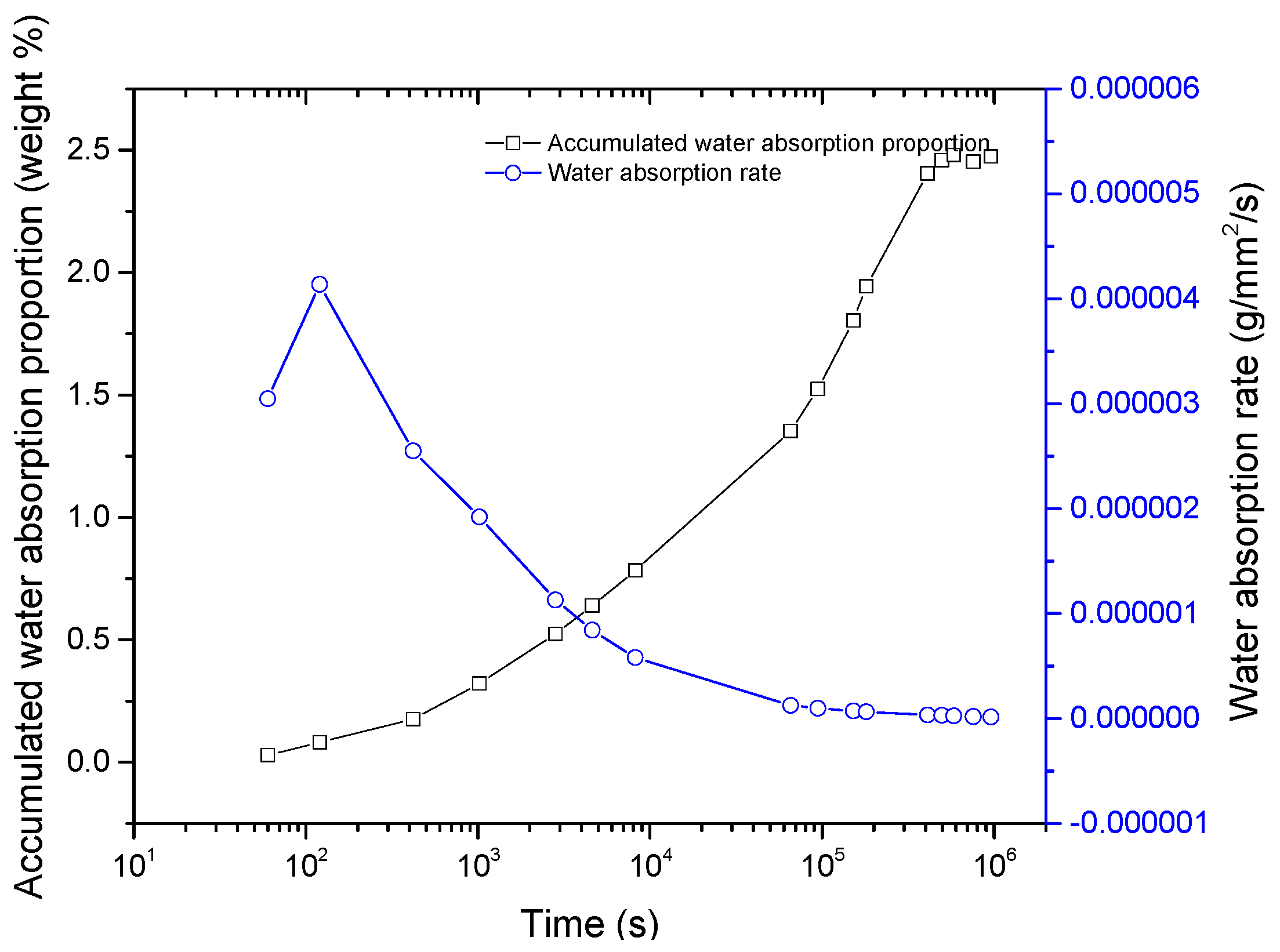

- The pressureless imbibition experiment shows that the silica sol absorption rate follows a power function. Colloid spontaneous migration features and phase characteristics were analyzed by the tests of time-varying spectrograms of T2.

- (4)

- The water absorption experiment, NMR imaging, and SEM imaging show the correctness of the pressureless imbibition experiment.

- (5)

- The silica sol groutability in coal-measure mudstone is extremely powerful. The paper lays a theoretical and experimental foundation for field grouting in the coal mine.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, G.C.; Jiang, Z.H.; Lv, C.X.; Huang, C.; Chen, G.; Li, M. Instability mechanism and control technology of soft rock roadway affected by mining and high confined water. Int. J. Min. Sci. Technol. 2015, 25, 573–580. [Google Scholar] [CrossRef]

- Xu, X.L.; Zhang, N. Study of Control Process Deformation Behavior and of Soft Rock Drift under Rich Water Condition. J. China Univ. Min. Technol. 2007, 36, 298–302. [Google Scholar]

- Zhang, C.L. Experimental evidence for self-sealing of fractures in claystone. Phys. Chem. Earth 2011, 36, 1972–1980. [Google Scholar] [CrossRef]

- Zhang, N.; Pan, D.J.; Xie, Z.Z. Reinforcement Method with Silica Sol by Slow-Penetration for Argillaceous Soft Rock. Patent CN105201528A, 30 December 2015. [Google Scholar]

- BASF Corporation. Underground Construction Solutions. Available online: http://www.master-builders-solutions.basf.us/en-us/products/masterroc (accessed on 29 August 2016).

- BASF Corporation. Solvent-Free, Low Viscosity, Hydrophilic Grout for Rock Injection and Consolidation of Sand and Silt Strata. Available online: http://assets.master-builders-solutions.basf.com/Shared%20Documents/EB%20Construction%20Chemcials%20-%20US/Admixture%20Systems/Data%20Sheets/MasterRoc/basf-masterroc-MP-325-tds.pdf (accessed on 29 August 2016).

- Wilhelm, E. Physical Chemistry of the Silicate; The University of Chicago Publishing House: Chicago, IL, USA, 1954; p. 426. [Google Scholar]

- Jia, G.Y.; Deng, Y.X. Investigation on the gelation process of silica sol. Bull. Chin. Ceram. Soc. 2004, 6, 91–93. [Google Scholar]

- Bolisetti, T.; Balachandar, R.; Reitsma, S. Simulation of Colloidal Silica Grout Injection Using Shear Effects. In Proceedings of the Fourth International Conference on Grouting and Deep Mixing, Louisiana, NO, USA, 15–18 February 2012; American Society of Civil Engineers Geotechnical Special Publication: Washington, DC, USA, 2012; pp. 1045–1054. [Google Scholar]

- Hamderi, M.; Gallagher, P.M.; Lin, Y. Numerical Model for Colloidal Silica Injected Column Tests. Vadose Zone J. 2014, 13, 1–6. [Google Scholar] [CrossRef]

- Gallagher, P.M.; Lin, Y. Colloidal Silica Transport through Liquefiable Porous Media. J. Geotech. Geoenviron. 2009, 135, 1702–1712. [Google Scholar] [CrossRef]

- Funehag, J.; Gustafson, G. Design of grouting with silica sol in hard rock—New methods for calculation of penetration length, Part I. Tunn. Undergr. Space Technol. 2008, 23, 1–8. [Google Scholar] [CrossRef]

- Mei, J.Y.; Ren, K.C. Study and Practice of Epoxy Grout in Low-Permeability Saturated Weak Intercalations; China Environmental Science Press: Beijing, China, 2013; pp. 89–100. [Google Scholar]

- Zhang, L.H.; Xiong, H.J.; Zhang, Q. Analyses of the unsteady permeation process of grout. Chin. J. Rock Mech. Eng. 1997, 16, 564–570. [Google Scholar]

- Kuang, J.Z.; Zan, Y.W.; Wang, J.; Du, J.H. Grouting Theory and Engineering Examples of Rock and Soil; Science Press: Beijing, China, 2001; pp. 92–94. [Google Scholar]

- Wang, L.F.; Weng, X.Z.; Zhang, R.Y.; Yao, Z.H.; Gu, Q.K.; Li, W.; Li, Y. Permeating-chemical grouting treatment method of sulphate saline soil. J. Traffic Transp. Eng. 2015, 15, 10–16. [Google Scholar]

- Valfouskaya, A.; Adler, P.M.; Thovert, J.F.; Fleury, M. Nuclear magnetic resonance diffusion with surface relaxation in porous media. J. Colloid Interface Sci. 2006, 295, 188–201. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.M.; Guo, H.K.; Liu, X.W.; Zhang, Y.P.; Xiong, S.C. Characteristic Experimental Technique of Extra-Low and Super-Low Permeability Reservoirs; Petroleum Industry Press: Beijing, China, 2012; pp. 19–23. [Google Scholar]

- He, M.C.; Zhou, L.; Li, D.J.; Wang, C.G.; Nie, W. Experimental research on hydrophilic characteristics of mudstone in deep well. Chin. J. Rock Mech. Eng. 2008, 27, 1113–1120. [Google Scholar]

- Qian, Z.W.; Jiang, Z.Q.; Cao, L.W.; Sun, Q. Experiment study of penetration grouting model for weakly cemented porous media. Rock Soil Mech. 2013, 34, 139–142. [Google Scholar]

| Grout | Silica Sol | MP364 | P.O 425R | ||

|---|---|---|---|---|---|

| Index | Part A | Part B | |||

| 3 × dmax | 24–36 nm | 2865 nm | 24–36 nm | 747–1056 μm | |

| 3 × d95 | 186 nm | 3205 nm | 10,740 nm | 1150 μm | |

| 49.31% | 34.24% | 49.31% | 0 | ||

| 41.10% | 32.87% | 21.92% | 0 | ||

| Index | Contact Angle (°) | Surface Tension (mN/m) | Affinity (mN/m) | |

|---|---|---|---|---|

| Liquid | ||||

| Silica sol | 49.26 ± 0.06 | 73.2 | 47.77 | |

| Water | 39.15 ± 0.04 | 73.5 | 57.00 | |

| Ratios between Silica Sol and Accelerator | Fitting Formula | Related Coefficient R2 |

|---|---|---|

| 4:1 | 0.9335 | |

| 6:1 | 0.9668 | |

| 9:1 | 0.9962 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, D.; Zhang, N.; Han, C.; Yang, S.; Zhang, C.; Xie, Z. Experimental Study of Imbibition Characteristics of Silica Sol in Coal-Measure Mudstone Matrix. Appl. Sci. 2017, 7, 300. https://doi.org/10.3390/app7030300

Pan D, Zhang N, Han C, Yang S, Zhang C, Xie Z. Experimental Study of Imbibition Characteristics of Silica Sol in Coal-Measure Mudstone Matrix. Applied Sciences. 2017; 7(3):300. https://doi.org/10.3390/app7030300

Chicago/Turabian StylePan, Dongjiang, Nong Zhang, Changliang Han, Sen Yang, Chenghao Zhang, and Zhengzheng Xie. 2017. "Experimental Study of Imbibition Characteristics of Silica Sol in Coal-Measure Mudstone Matrix" Applied Sciences 7, no. 3: 300. https://doi.org/10.3390/app7030300