Use of the Genetic Algorithm-Based Fuzzy Logic Controller for Load-Frequency Control in a Two Area Interconnected Power System

Abstract

:1. Introduction

2. Materials and Methods

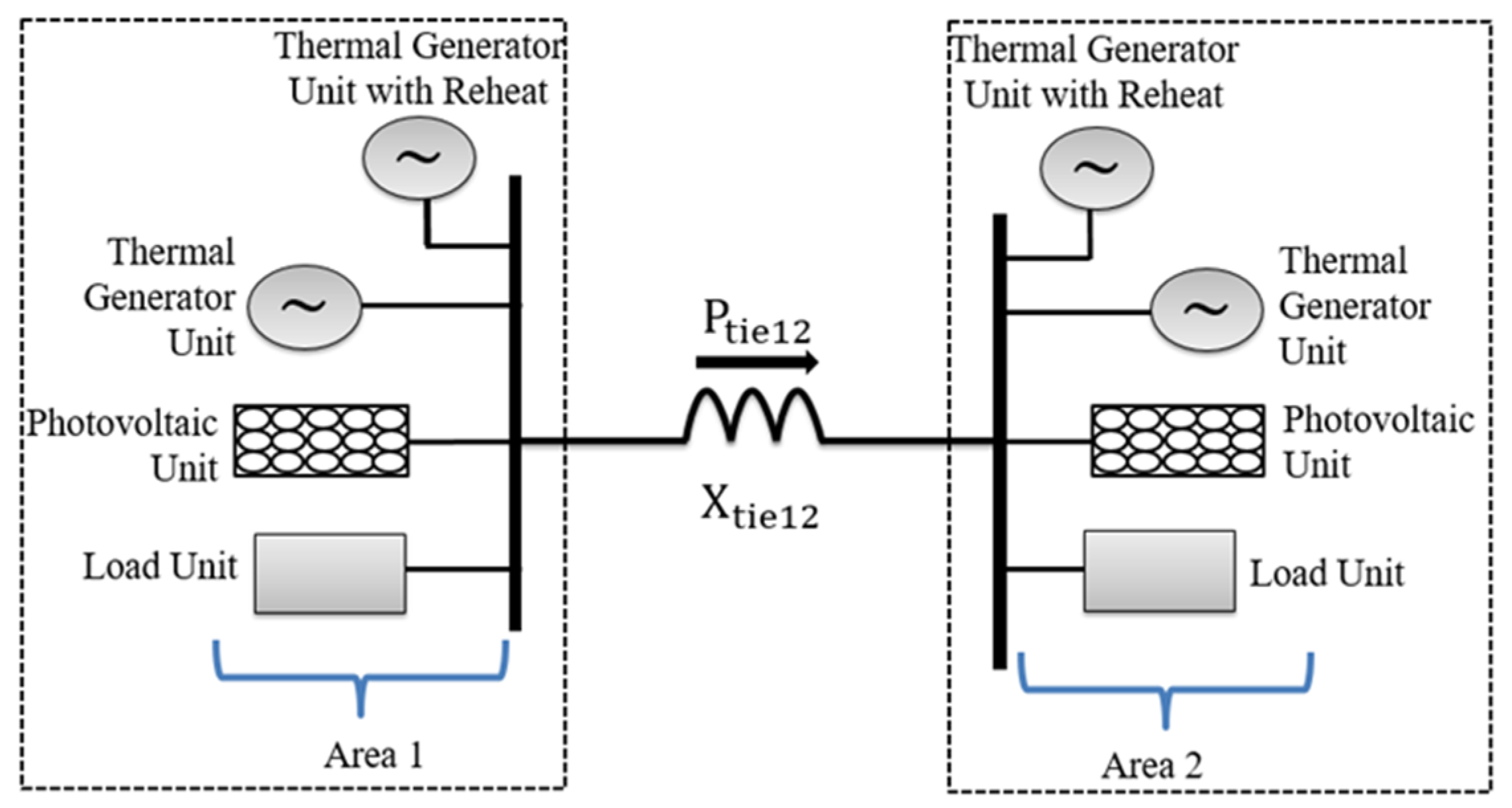

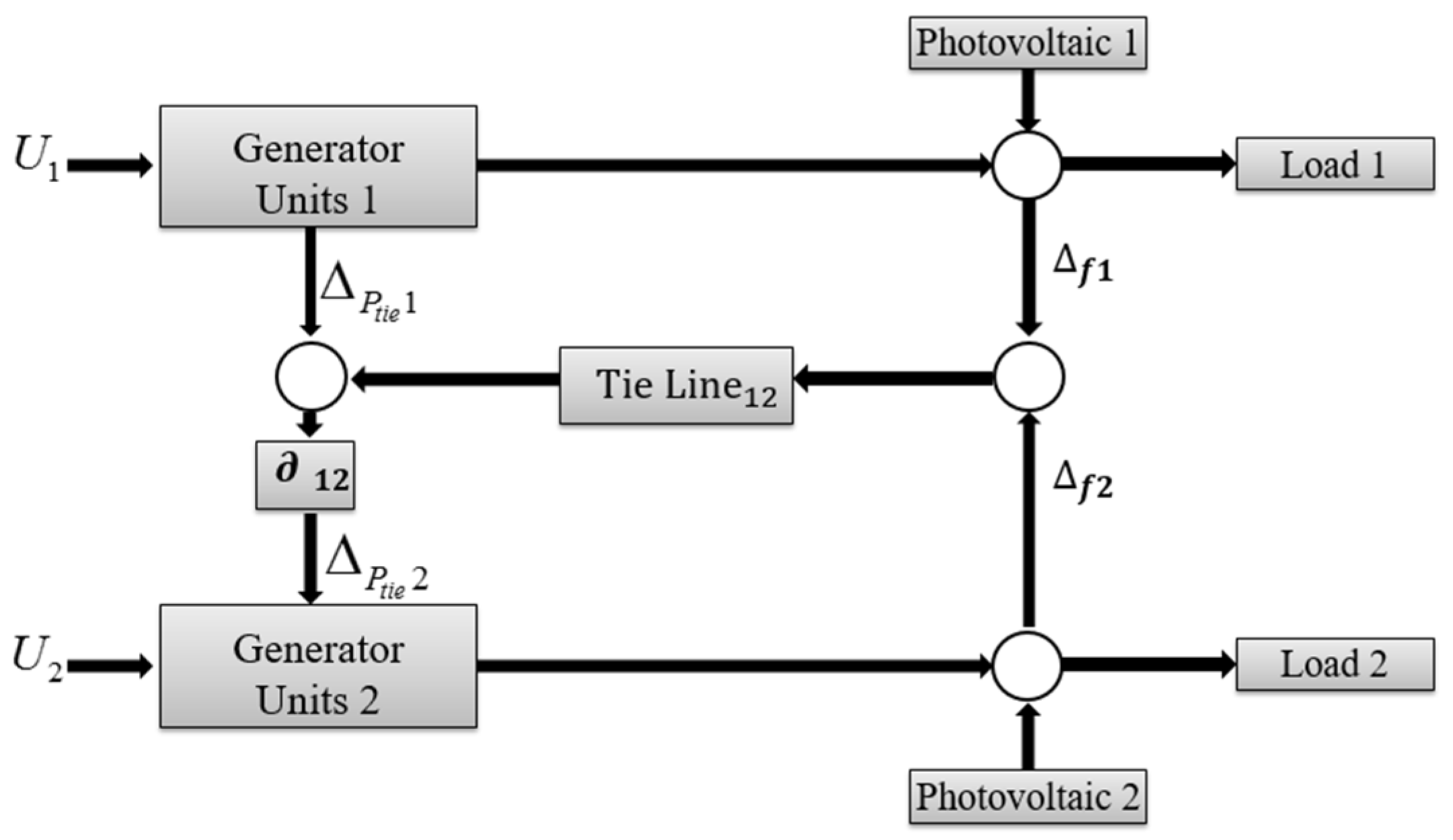

2.1. The Proposed Power System

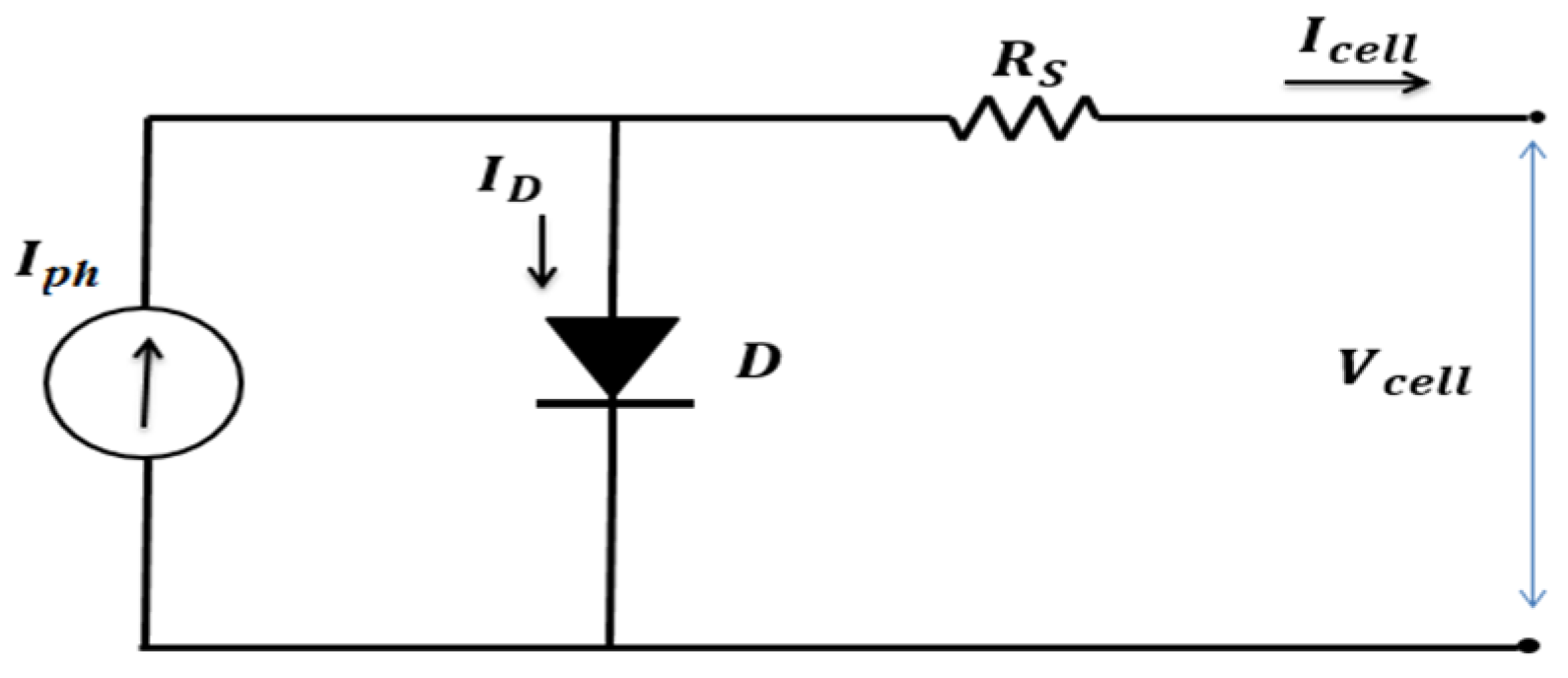

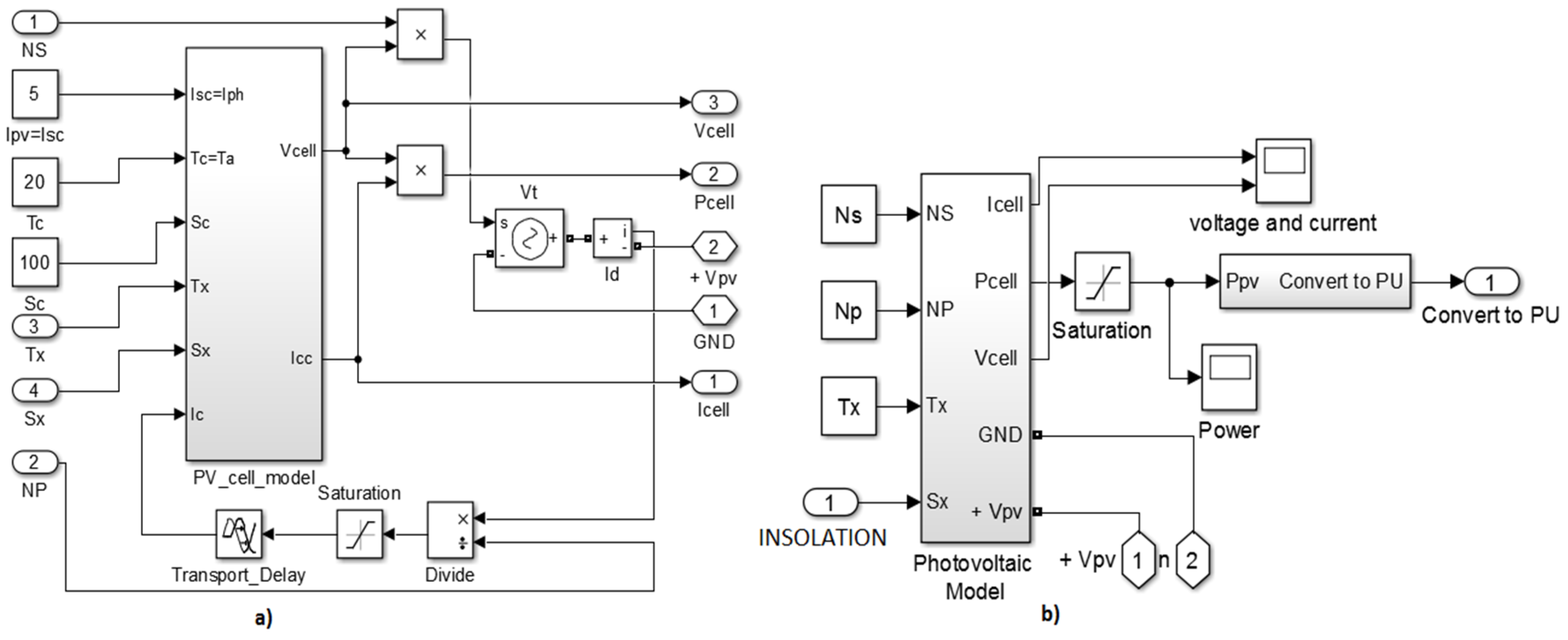

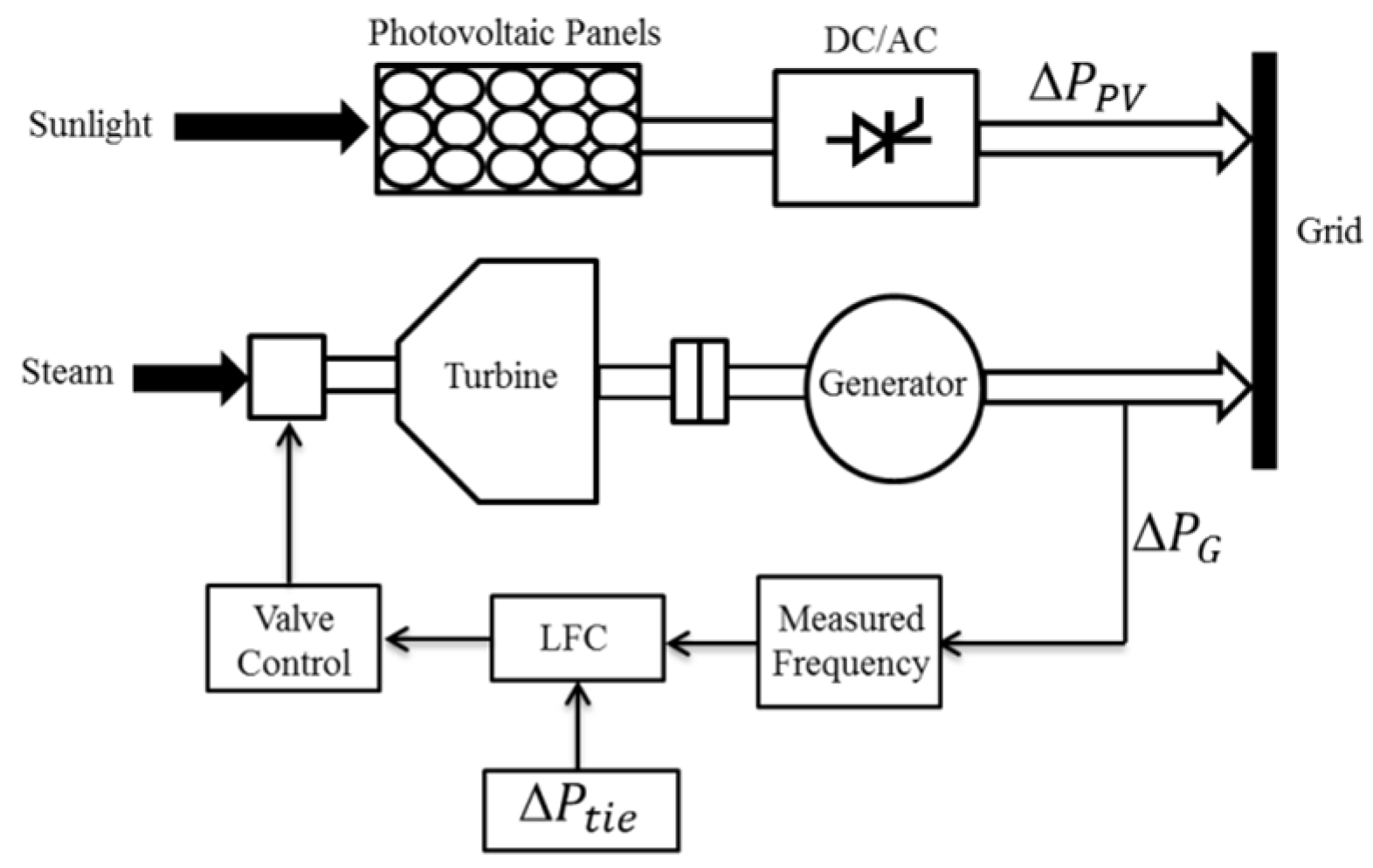

2.1.1. PV Power System

2.1.2. Single Area Interconnected Power System

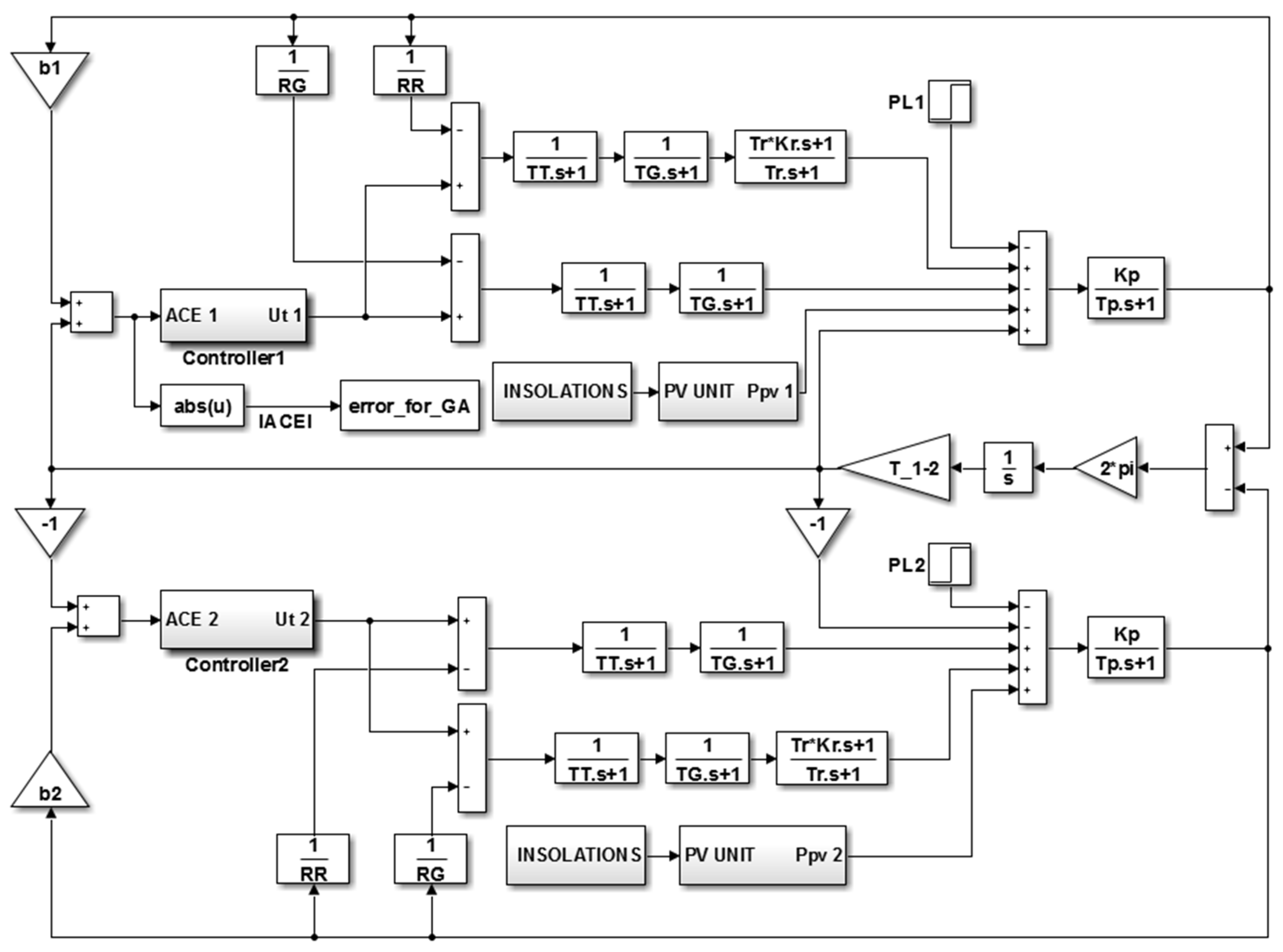

2.1.3. Two Area Interconnected Power System

2.2. Control Methods

2.2.1. Conventional Controllers

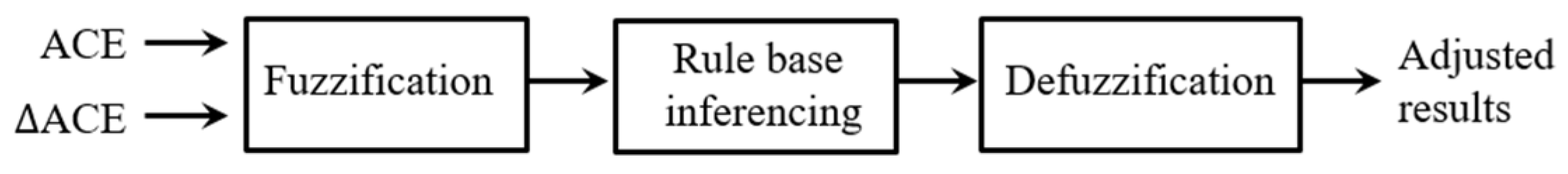

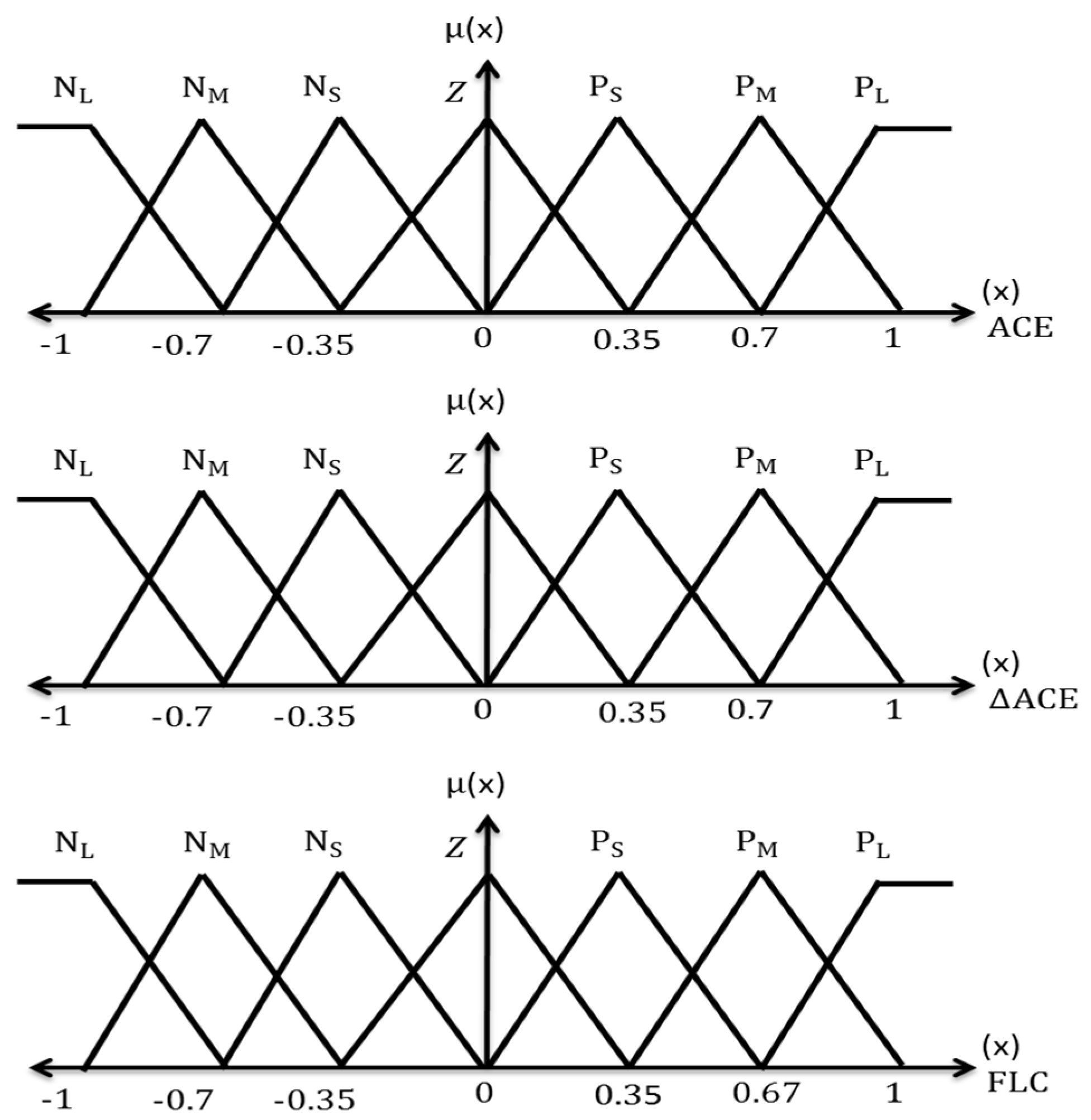

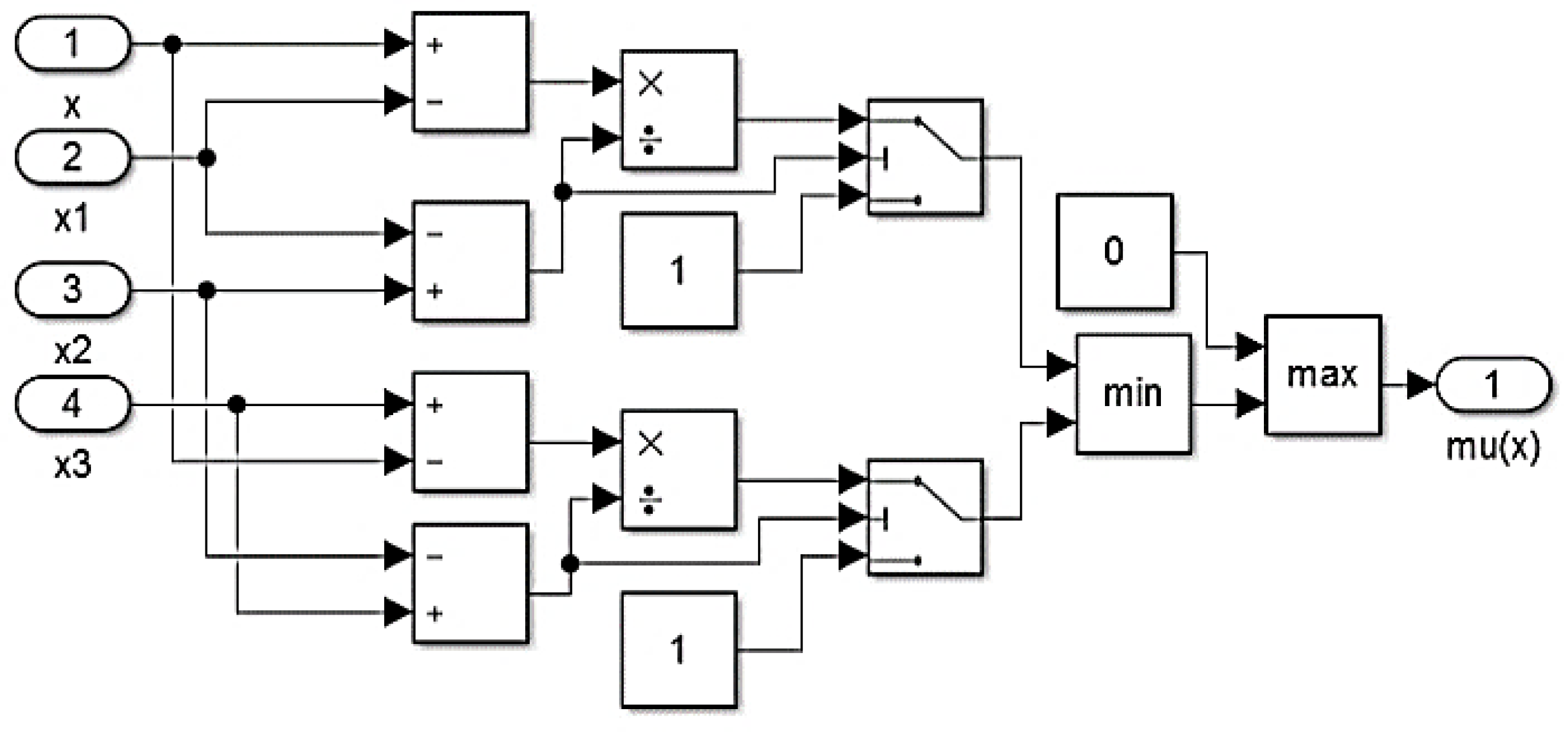

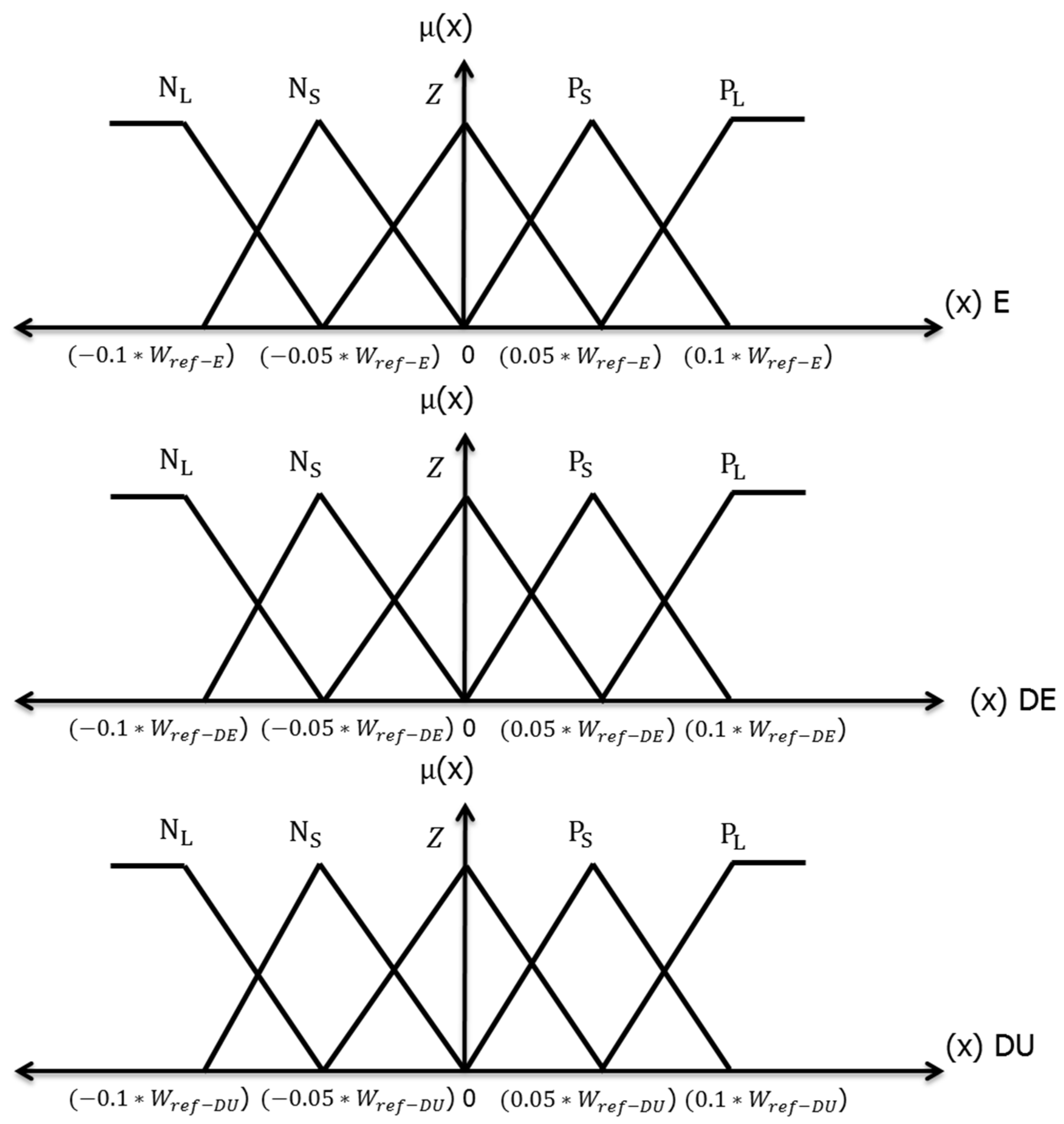

2.2.2. Fuzzy Logic Controller

2.2.3. Genetic Optimization

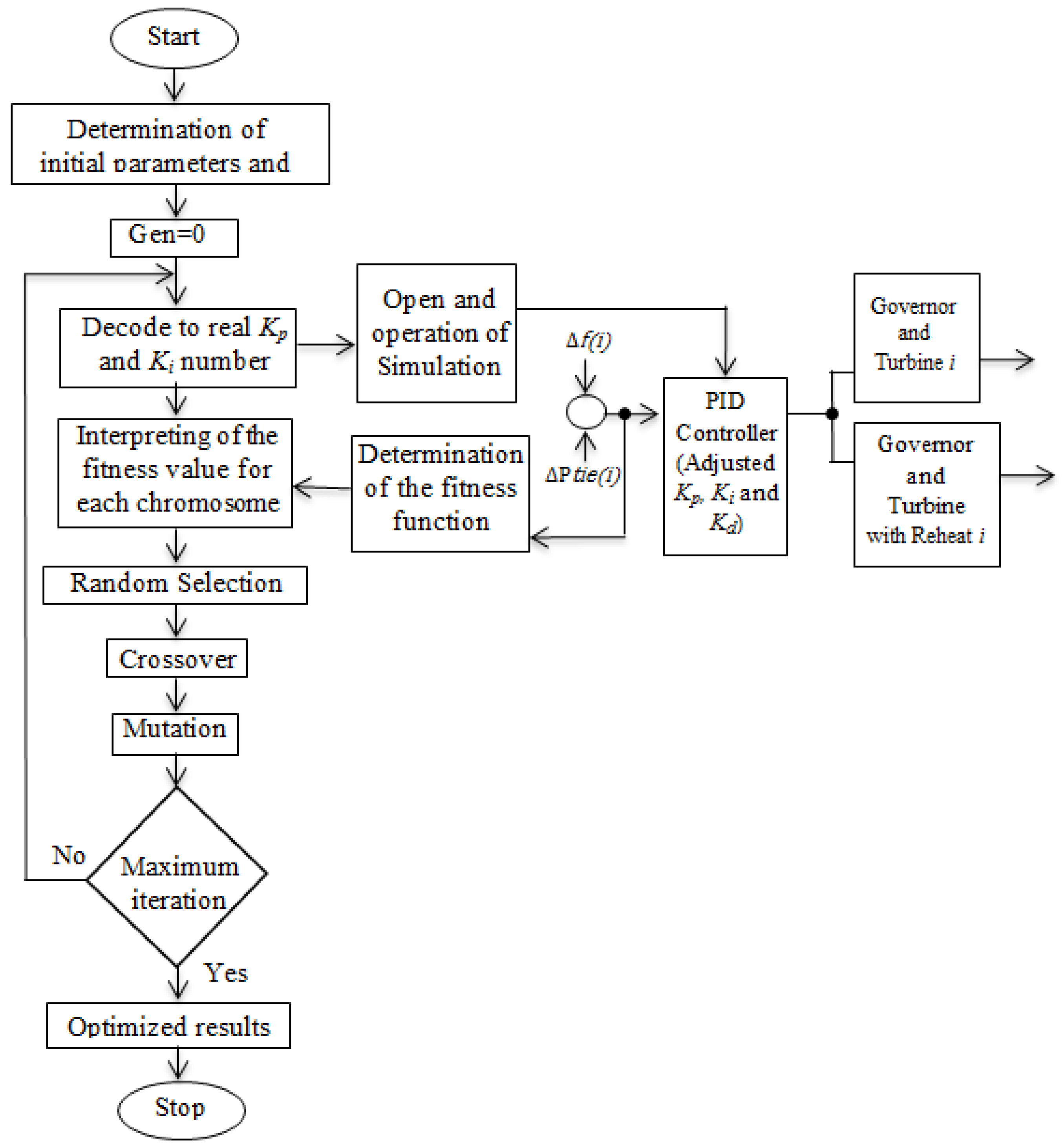

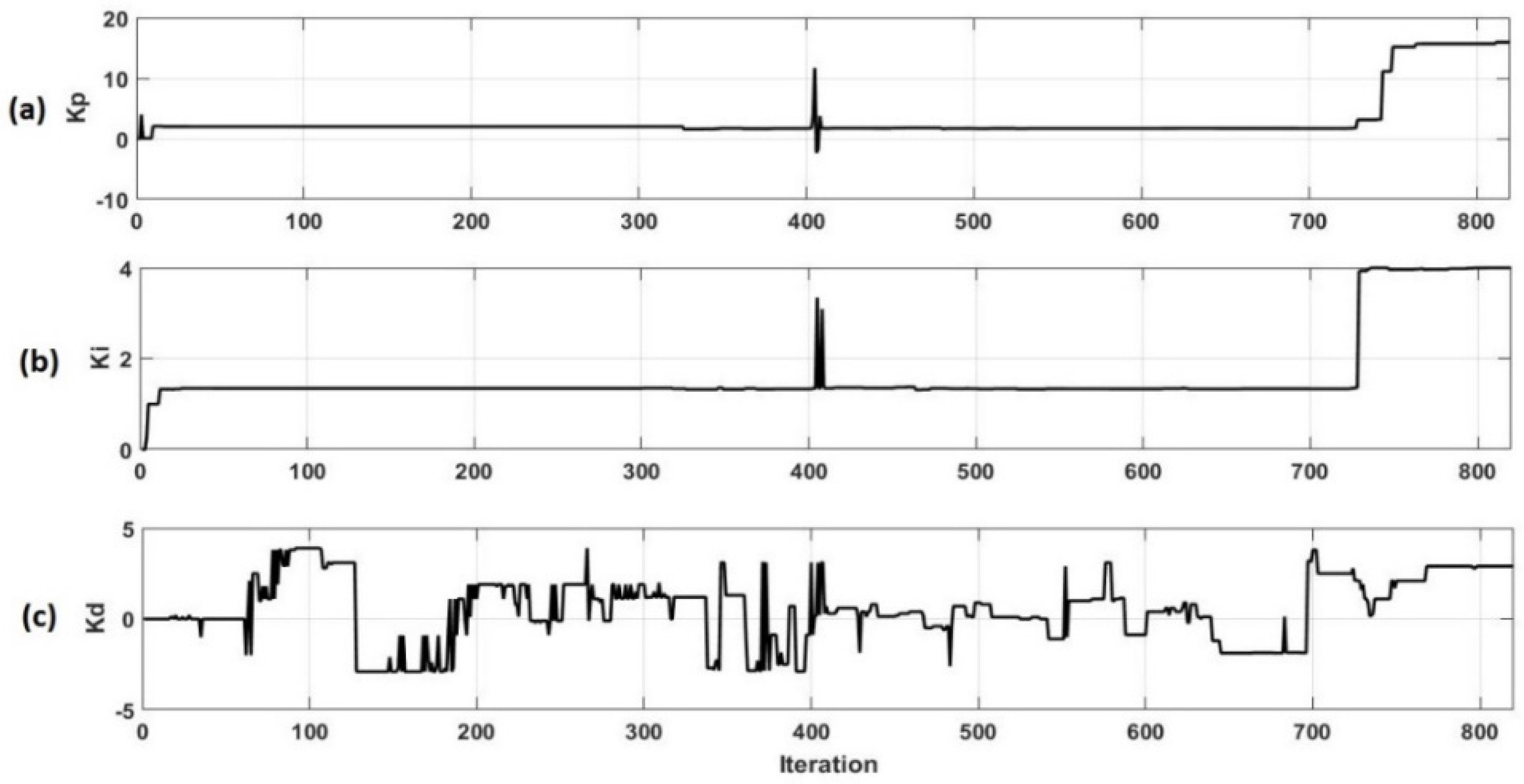

2.2.4. GA-PID Controller

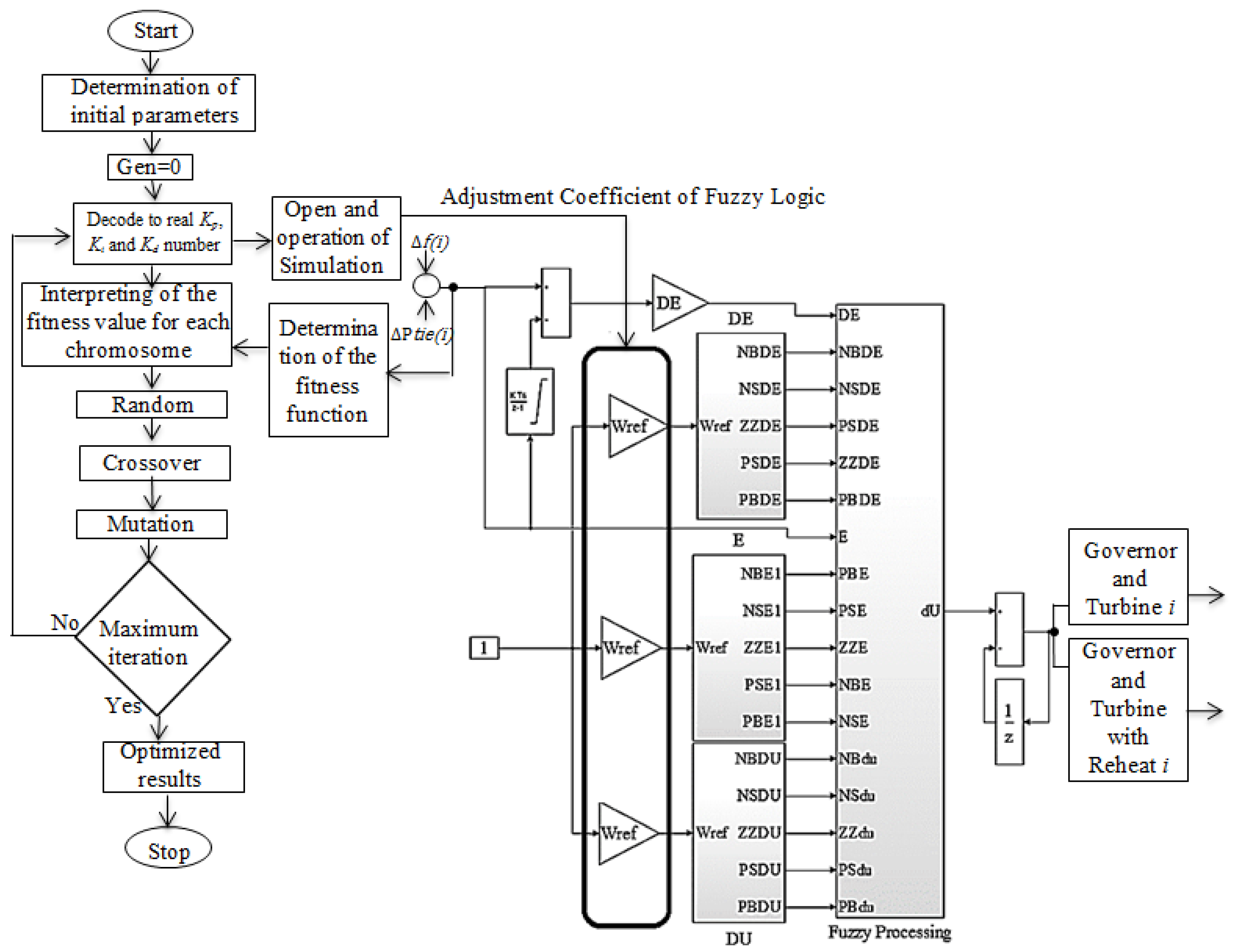

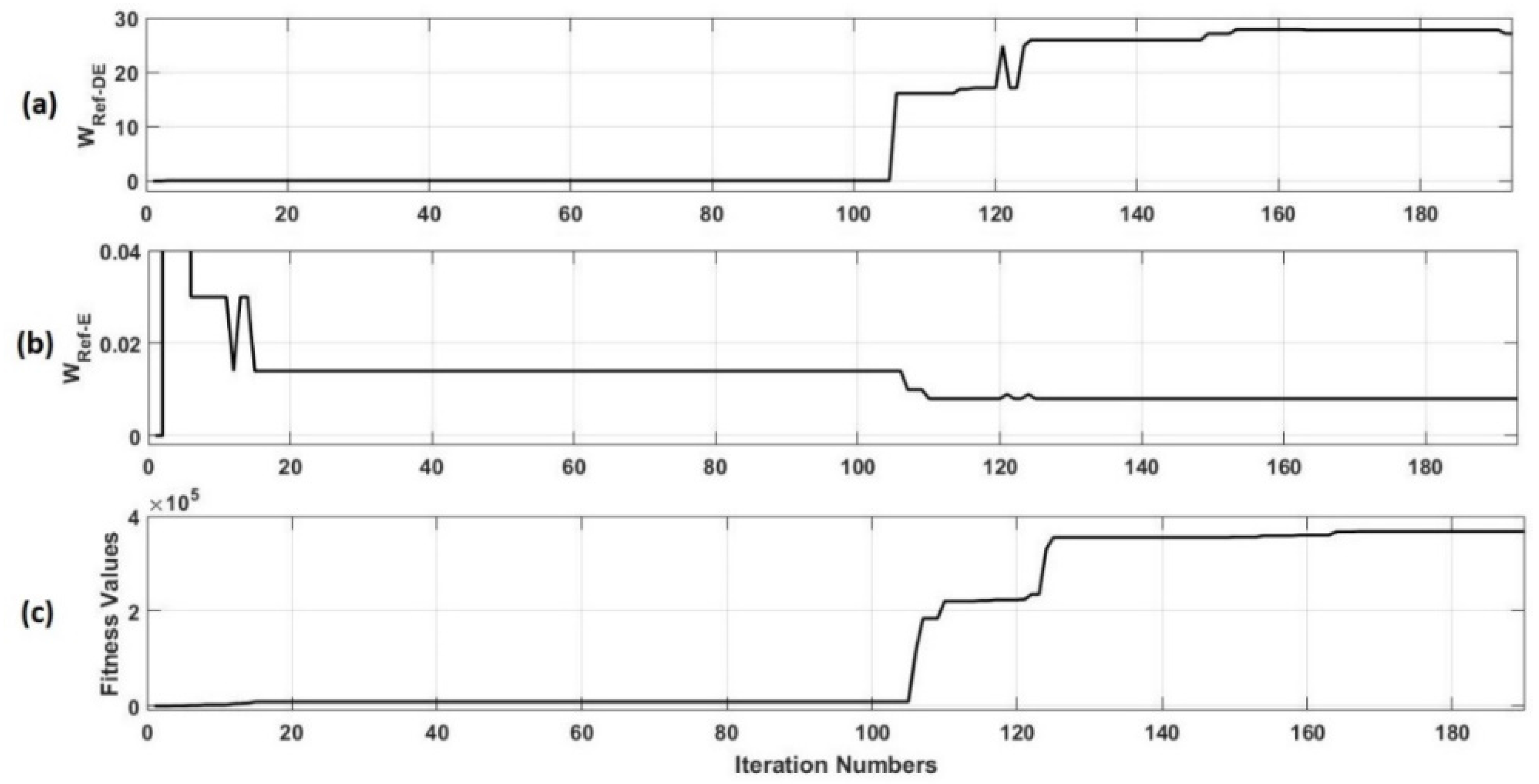

2.2.5. GA-FLC Controller

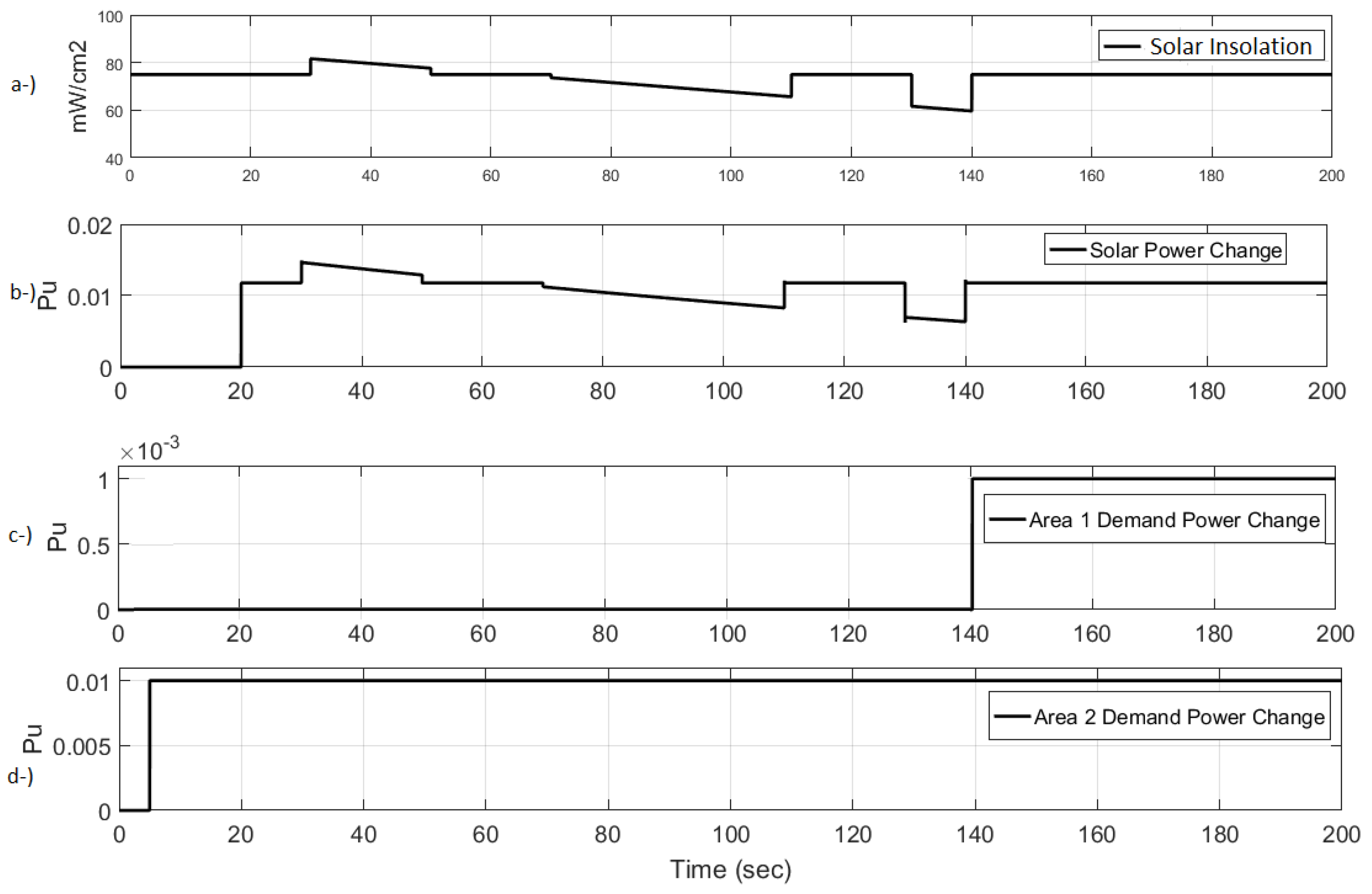

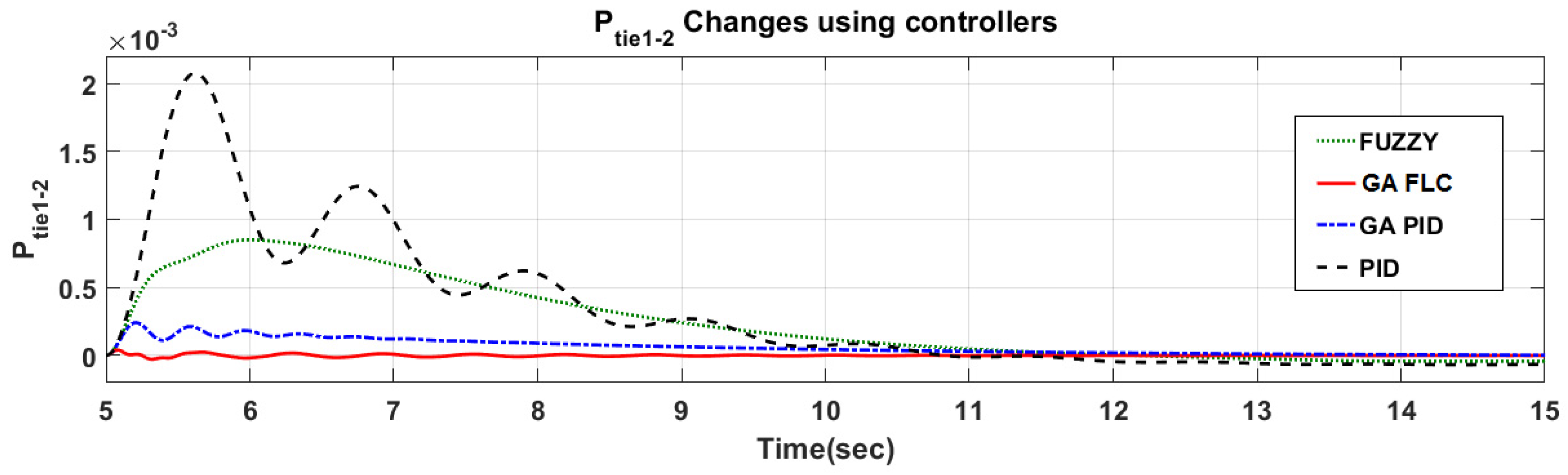

3. Results and Discussion

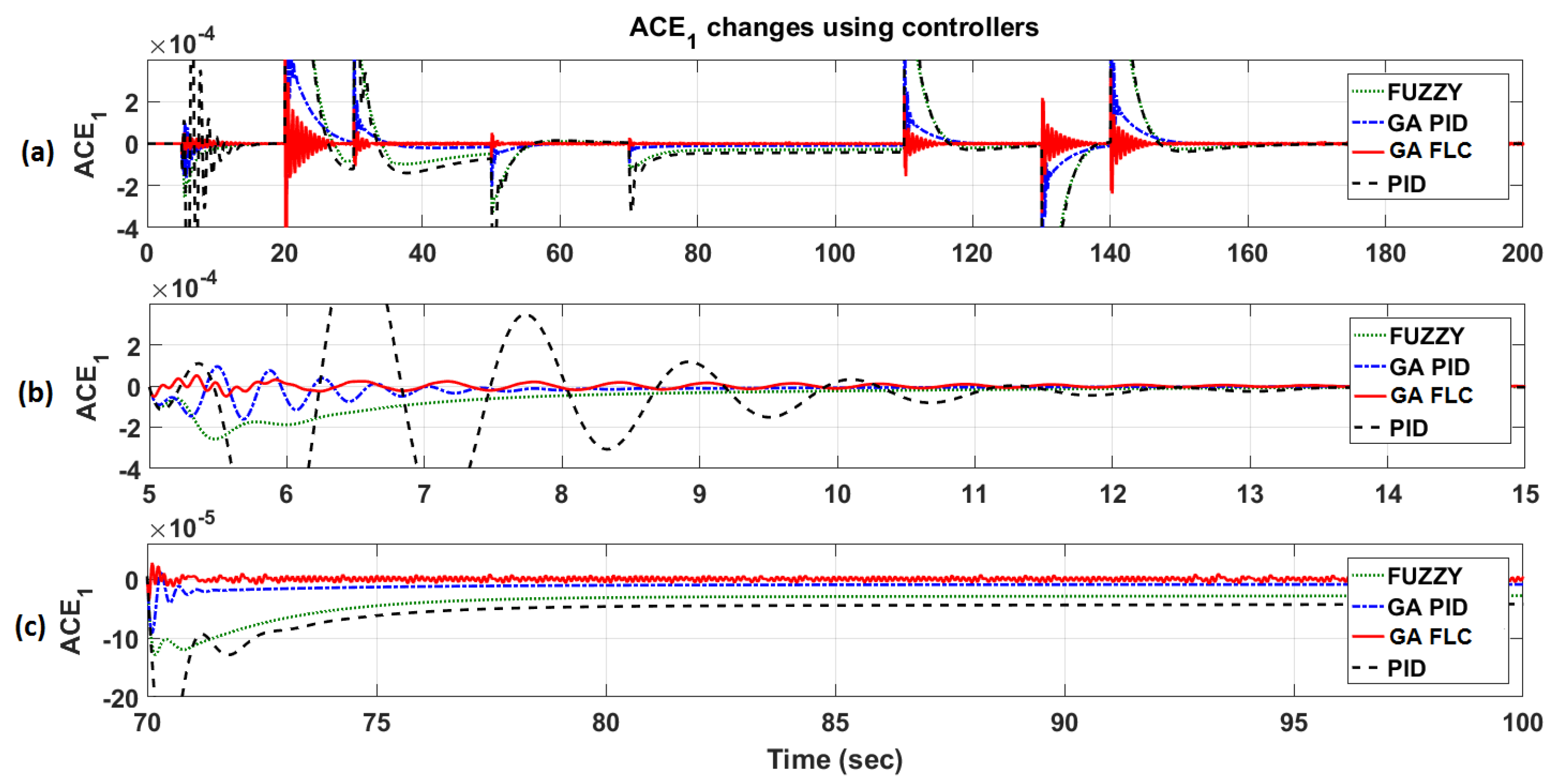

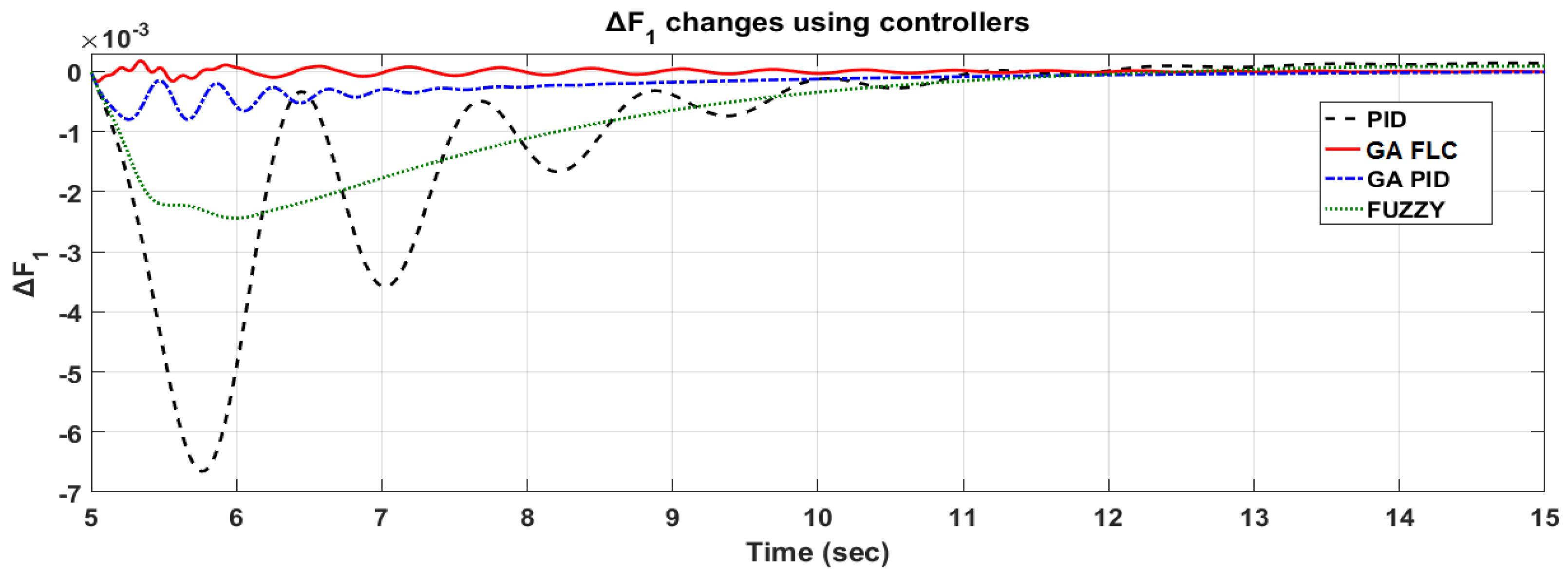

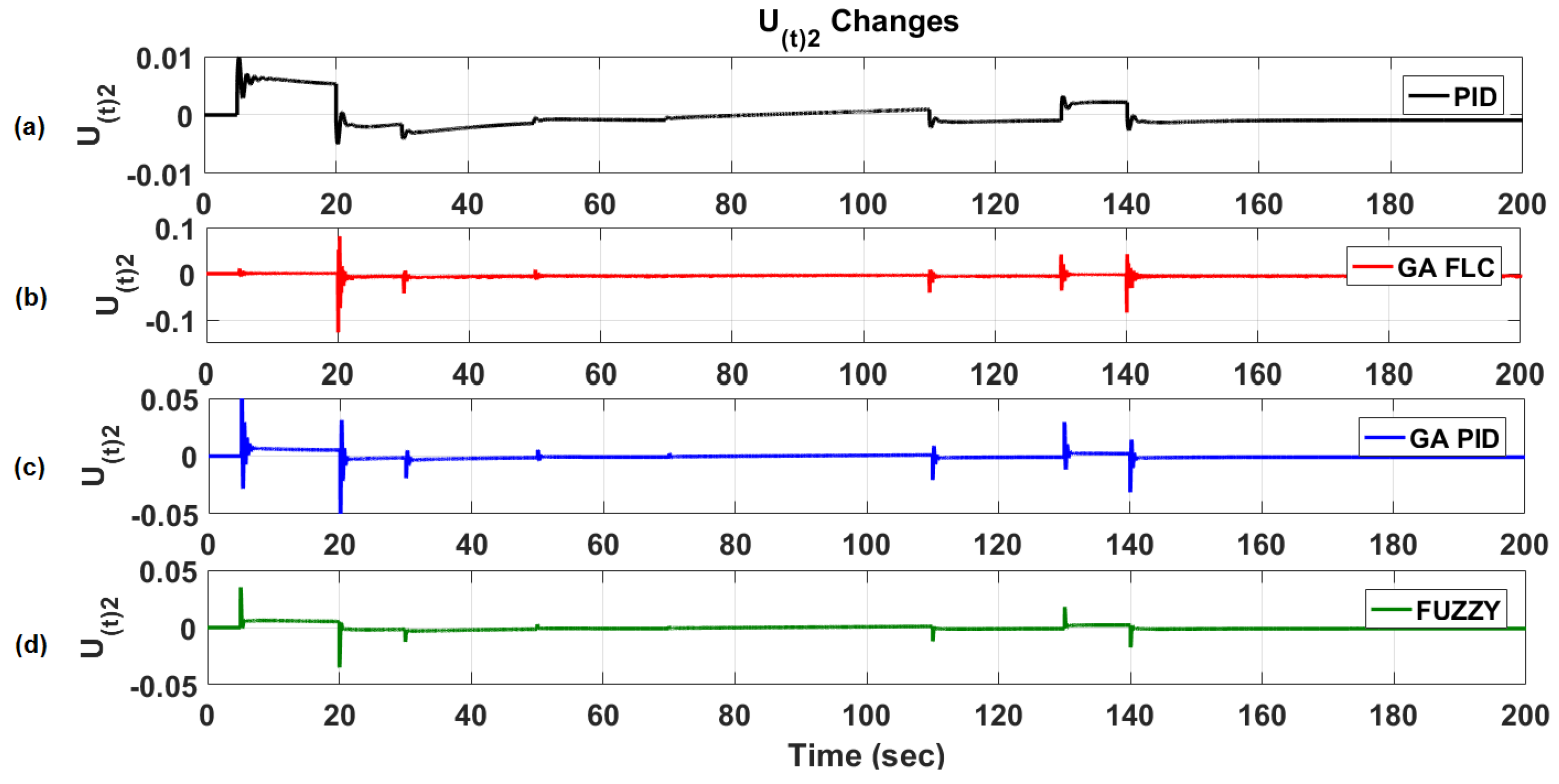

3.1. Results and Discussion for Area 1

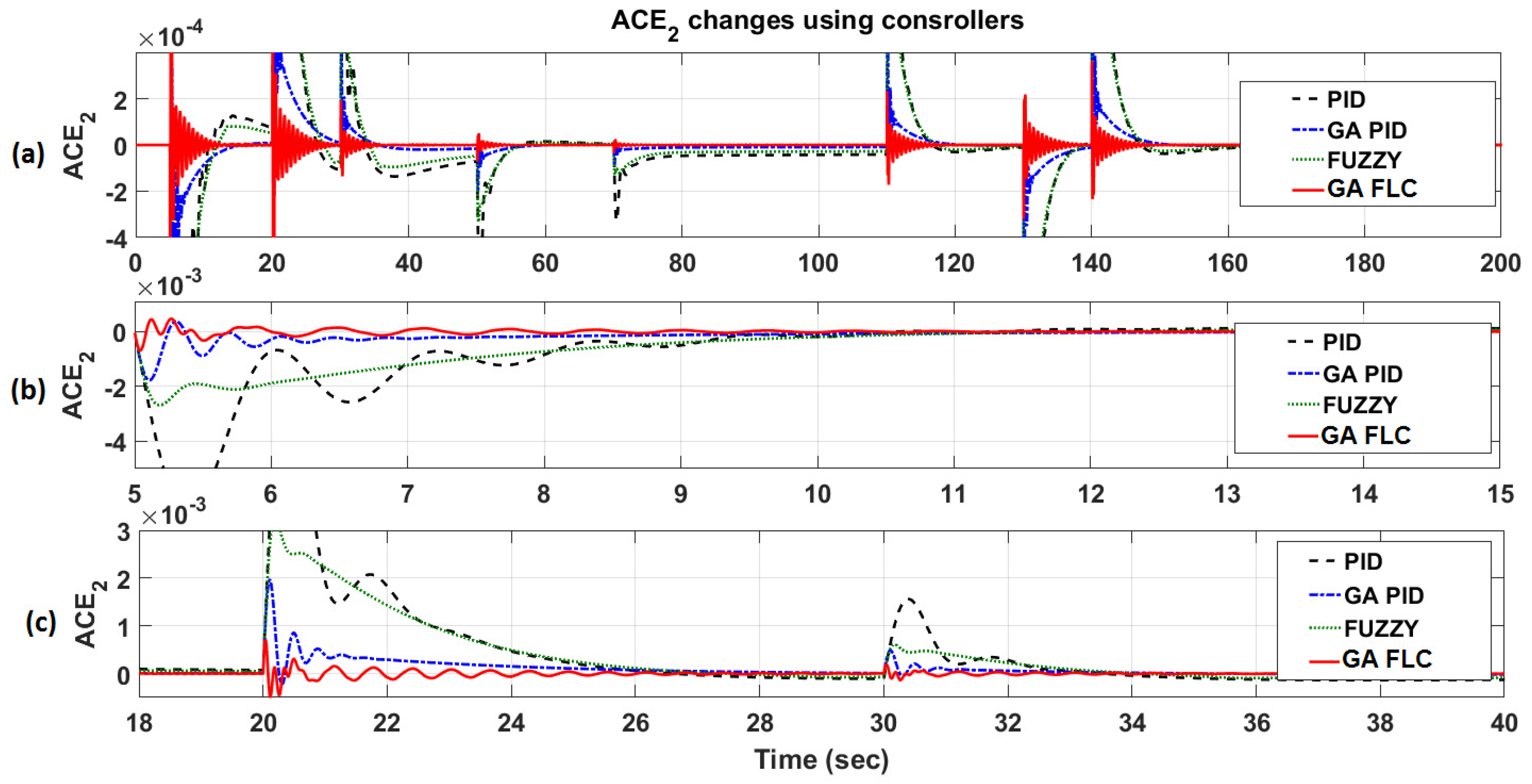

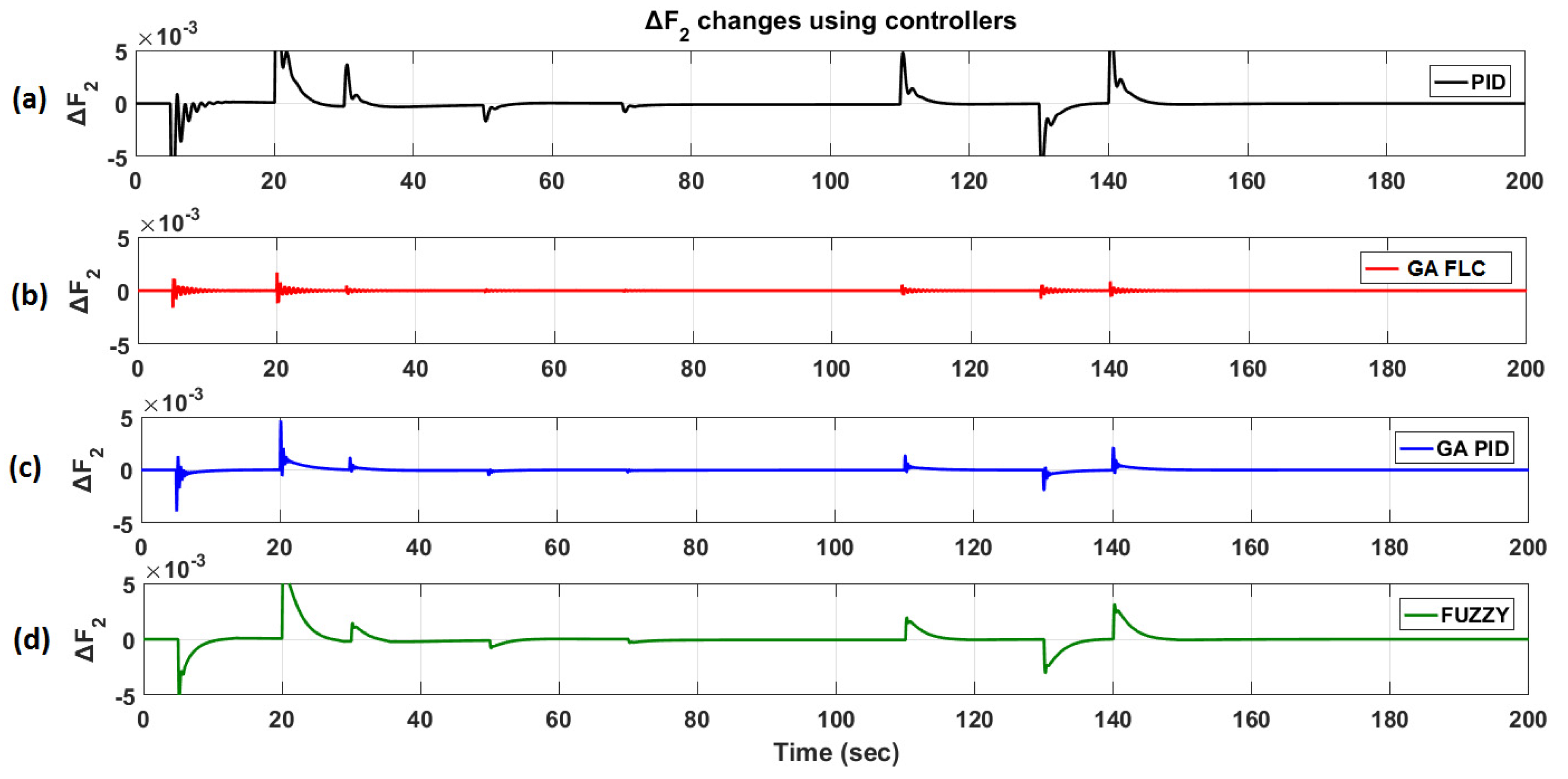

3.2. Results and Discussion for Area 2

4. Conclusions

Author Contributions

Conflicts of Interest

Abbreviations and Nomenclatures

| : Curve fitting factor | 1 and 2 areas power values derived from PV |

| : Area Control Error of i | : The balance of power i |

| : Frequency bias constant of area 1 and 2 | : The total power in the first region |

| : Electron charge | : Series resistance of cell (Ω) |

| : load changes disturbance vector | : Series resistance(Heat loses) |

| : The Loads transfer function | : Regulation constant |

| : The turbines transfer function | : Regulation constant with re-heat |

| : Re-heat turbine transfer function | : Benchmark reference solar irradiation |

| : Generator transfer function | : Synchronization constant |

| : The generators transfer function | : Speed governor time constant |

| : Turbine transfer function | : Control area time constant |

| : Reverse saturation current of diode (A) | : Re-heat time constant |

| : PV solar cell formed in the reverse saturation current | : Turbine time constant |

| : Photocurrent (A) | : Reference cell operating temperature |

| : Cell output current (A) | 1 and 2 areas controller outputs |

| : Boltzmann constant (J/°K) | : control vector |

| : Characteristic constant of the system frequency | : Cell output voltage (V) |

| : Control area gain | : state vector |

| : Re-heat gain | : system output vector |

| Changing demand power of area 1 and 2 | : Load increase |

| : The total power in the first region | 1 and 2 area frequency changes |

| : The power of generator power system | Change in tie-line power between two areas |

| : Refers to the change in load first region | : Frequency changes |

Appendix A

| Parameters of two-area power system with PV-SPP | |

| : 0.425 pu | : 10 |

| : 2.43 Hz/pu | : 0.3 |

| : 2.43 Hz/pu | : 120 |

| : 0.3 | : 20 |

| : 0.08 | : 20 °C |

| : 1.6021917 × (C) | : 0.086 |

| : 1.380622 × (J/°K) | : 0.0002 (A) |

| : 100 | : 0.0001 (Ω) |

| : 10 | : 5 (A) |

| : 7 | : 100 |

References

- Goksenli, N.; Akbaba, M. Development of a new microcontroller based mppt method for photovoltaic generators using akbaba model with implementation and simulation. Sol. Energy 2016, 136, 622–628. [Google Scholar] [CrossRef]

- Chandra Sekhar, G.T.; Sahu, R.K.; Baliarsingh, A.K.; Panda, S. Load frequency control of power system under deregulated environment using optimal firefly algorithm. Int. J. Electr. Power Energy Syst. 2016, 74, 195–211. [Google Scholar] [CrossRef]

- Sahu, B.K.; Pati, T.K.; Nayak, J.R.; Panda, S.; Kar, S.K. A novel hybrid lus–tlbo optimized fuzzy-pid controller for load frequency control of multi-source power system. Int. J. Electr. Power Energy Syst. 2016, 74, 58–69. [Google Scholar] [CrossRef]

- Rahmann, C.; Castillo, A. Fast frequency response capability of photovoltaic power plants: The necessity of new grid requirements and definitions. Energies 2014, 7, 6306–6322. [Google Scholar] [CrossRef]

- Khooban, M.H.; Niknam, T. A new intelligent online fuzzy tuning approach for multi-area load frequency control: Self adaptive modified bat algorithm. Int. J. Electr. Power Energy Syst. 2015, 71, 254–261. [Google Scholar] [CrossRef]

- Çam, E. Application of fuzzy logic for load frequency control of hydroelectrical power plants. Energy Convers. Manag. 2007, 48, 1281–1288. [Google Scholar] [CrossRef]

- Jagatheesan, K.; Anand, B.; Ebrahim, M. Stochastic particle swarm optimizaion for tuning of pid controller in load frequency control of single area reheat thermal power system. Int. J. Electr. Power Eng. 2014, 8, 33–40. [Google Scholar]

- Abdelaziz, A.Y.; Ali, E.S. Cuckoo search algorithm based load frequency controller design for nonlinear interconnected power system. Int. J. Electr. Power Energy Syst. 2015, 73, 632–643. [Google Scholar] [CrossRef]

- Çam, E.; Kocaarslan, İ. A fuzzy gain scheduling pi controller application for an interconnected electrical power system. Electr. Power Syst. Res. 2005, 73, 267–274. [Google Scholar] [CrossRef]

- Kocaarslan, İ.; Çam, E. Fuzzy logic controller in interconnected electrical power systems for load-frequency control. Int. J. Electr. Power Energy Syst. 2005, 27, 542–549. [Google Scholar] [CrossRef]

- Khalghani, M.R.; Khooban, M.H.; Mahboubi-Moghaddam, E.; Vafamand, N.; Goodarzi, M. A self-tuning load frequency control strategy for microgrids: Human brain emotional learning. Int. J. Electr. Power Energy Syst. 2016, 75, 311–319. [Google Scholar] [CrossRef]

- Sa-ngawong, N.; Ngamroo, I. Intelligent photovoltaic farms for robust frequency stabilization in multi-area interconnected power system based on pso-based optimal sugeno fuzzy logic control. Renew. Energy 2015, 74, 555–567. [Google Scholar] [CrossRef]

- Chowdhury, A.H.; Asaduz-Zaman, M. Load frequency control of multi-microgrid using energy storage system. In Proceedings of the 2014 International Conference on Electrical and Computer Engineering (ICECE), Dhaka, Banglades, 20–22 December 2014; pp. 548–551.

- Mamur, H. Design, application, and power performance analyses of a micro wind turbine. Turk. J. Electr. Eng. Comput. Sci. 2015, 23, 1619–1637. [Google Scholar] [CrossRef]

- Shankar, R.; Chatterjee, K.; Chatterjee, T.K. Genetic algorithm based controller for load-frequency control of interconnected systems. In Proceedings of the 2012 1st International Conference on Recent Advances in Information Technology (RAIT), Dhanbad, India, 15–17 March 2012; pp. 392–397.

- Rerkpreedapong, D.; Hasanovic, A.; Feliachi, A. Robust load frequency control using genetic algorithms and linear matrix inequalities. IEEE Trans. Power Syst. 2003, 18, 855–861. [Google Scholar] [CrossRef]

- Chia-Feng, J.; Chun-Feng, L. Power system load frequency control with fuzzy gain scheduling designed by new genetic algorithms. In Proceedings of the 2002 IEEE International Conference on Fuzzy Systems, Honolulu, HI, USA, 12–17 May 2002; pp. 64–68.

- Daneshfar, F.; Bevrani, H. Multiobjective design of load frequency control using genetic algorithms. Int. J. Electr. Power Energy Syst. 2012, 42, 257–263. [Google Scholar] [CrossRef]

- Demiroren, A.; Zeynelgil, H.L.; Sengor, N.S. The application of ann technique to load-frequency control for three-area power system. In Proceedings of the 2001 IEEE Porto Power Tech Proceedings, Porto, Portugal, 10–13 September 2001; Volume 2, p. 5.

- Ponnusamy, M.; Banakara, B.; Dash, S.S.; Veerasamy, M. Design of integral controller for load frequency control of static synchronous series compensator and capacitive energy source based multi area system consisting of diverse sources of generation employing imperialistic competition algorithm. Int. J. Electr. Power Energy Syst. 2015, 73, 863–871. [Google Scholar] [CrossRef]

- Kumar Sahu, R.; Panda, S.; Biswal, A.; Chandra Sekhar, G.T. Design and analysis of tilt integral derivative controller with filter for load frequency control of multi-area interconnected power systems. ISA Trans. 2016, 61, 251–264. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Nong, H.; Xi, K.; Yao, X. Robust distributed model predictive load frequency control of interconnected power system. Math. Probl. Eng. 2013, 2013, 468168. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Yan, Y. Model predictive control for load frequency control with wind turbines. J. Control Sci. Eng. 2015, 2015, 49. [Google Scholar] [CrossRef]

- Prakash, S.; Sinha, S. Load frequency control of three area interconnected hydro-thermal reheat power system using artificial intelligence and pi controllers. Int. J. Eng. Sci. Technol. 2011, 4, 23–37. [Google Scholar] [CrossRef]

- Altas, I.H.; Sharaf, A.M. A photovoltaic array simulation model for matlab-simulink gui environment. In Proceedings of the International Conference on Clean Electrical Power, ICCEP’07, Capril, Italy, 21–23 May 2007; pp. 341–345.

- Nikmanesh, E.; Hariri, O.; Shams, H.; Fasihozaman, M. Pareto design of load frequency control for interconnected power systems based on multi-objective uniform diversity genetic algorithm (muga). Int. J. Electr. Power Energy Syst. 2016, 80, 333–346. [Google Scholar] [CrossRef]

- Gozde, H.; Taplamacioglu, M.C.; Kocaarslan, I. A swarm optimization based load frequency control application in a two area thermal power system. In Proceedings of the International Conference on Electrical and Electronics Engineering, ELECO 2009, Bursa, Turkey, 5–8 November 2009; pp. I-124–I-128.

- Görel, G.; Çam, E.; Lüy, M.; Gürbüz, R. Operation of load frequency control with pid controller in single area renewable green photovoltaic energy systems. In Proceedings of the 1st International Conference on Environmental Science and Technology, Sarajevo, Bosnia and Herzegovina, 9–13 September 2015; pp. 312–316.

- Kocaarslan, İ.; Çam, E. An adaptive control application in a large thermal combined power plant. Energy Convers. Manag. 2007, 48, 174–183. [Google Scholar] [CrossRef]

- Valério, D.; da Costa, J.S. Tuning of fractional pid controllers with ziegler–nichols-type rules. Signal Process. 2006, 86, 2771–2784. [Google Scholar] [CrossRef]

- Ismail, M.S.; Moghavvemi, M.; Mahlia, T.M.I. Characterization of pv panel and global optimization of its model parameters using genetic algorithm. Energy Convers. Manag. 2013, 73, 10–25. [Google Scholar] [CrossRef]

- Civelek, Z.; Çam, E.; Lüy, M.; Mamur, H. Proportional-integral-derivative parameter optimisation of blade pitch controller in wind turbines by a new intelligent genetic algorithm. In IET Renewable Power Generatio; Institution of Engineering and Technology: Stevenage, UK, 2016; Volume 10, pp. 1220–1228. [Google Scholar]

- Kumar, A.; Kumar, A.; Chanana, S. Genetic fuzzy pid controller based on adaptive gain scheduling for load frequency control. In Proceedings of the 2010 Joint International Conference on Power Electronics, Drives and Energy Systems (PEDES) & 2010 Power India, New Delhi, India, 20–23 December 2010; pp. 1–8.

- Altas, I.H.; Sharaf, A.M. A generalized direct approach for designing fuzzy logic controllers in matlab/simulink gui environment. Int. J. Inf. Technol. Intell. Comput. 2007, 1, 1–27. [Google Scholar]

| Controller | |||

|---|---|---|---|

| PID |

| Fuzzy Logic Rules for FLC | |||||||

|---|---|---|---|---|---|---|---|

| ACE | |||||||

| NL | NM | NS | Z | PS | PM | PL | |

| NL | PL | PL | PL | PL | PM | PM | PS |

| NM | PL | PM | PM | PM | PS | PS | PS |

| NS | PM | PM | PS | PS | PS | PS | Z |

| Z | NS | NS | NS | Z | PS | PS | PS |

| PS | Z | NS | NS | NS | NS | NM | NM |

| PM | NS | NS | NM | NM | NM | NL | NL |

| PL | NS | NM | NL | NL | NL | NL | NL |

| The GA Parameters Type | Value |

|---|---|

| Population Size | 20 |

| Initial Population | 0 |

| Crossover Rate | 0.9 |

| Limit | 10 |

| Limit | 5 |

| Limit | 5 |

| Mutation | 8 |

| Iteration | for PID: 800 |

| for FLC: 190 |

| Fuzzy Logic Rules for GA-FLC (5) | |||||

|---|---|---|---|---|---|

| ACE | ∆ACE(k) | ||||

| NL | NS | Z | NS | NL | |

| Z | |||||

| Z | |||||

| Z | Z | ||||

| Z | |||||

| Z | |||||

| Controller | Controller Parameters | Min. | Mean | Median | Max. | Standart Deviations |

|---|---|---|---|---|---|---|

| GA-PID | 6.4295 | 13.6868 | 15.4255 | 15.9988 | 2.8714 | |

| 3.8590 | 7.5896 | 7.8589 | 7.9999 | 0.7833 | ||

| 0.4094 | 2.8252 | 2.4297 | 6.4565 | 1.2078 | ||

| GA-FLC | 0.1369 | 0.4931 | 0.4588 | 0.8591 | 0.1391 | |

| 0.0086 | 0.1761 | 0.1262 | 0.9371 | 0.1986 | ||

| 0.1000 | 1.2374 | 0.7393 | 5.3660 | 1.4304 |

| Parameters | Designs Controller | Area 1 Loads Increase (5th s) | Area 1 Solar Power Decrease (70th s) | Area 2 Loads Increase (5th s) | |||

|---|---|---|---|---|---|---|---|

| Overshoots | Settling Time | Overshoots | Settling Time | Overshoots | Settling Time | ||

| ACE | PID | −0.00114 | 13.1 | −0.00032 | 80.5 | −0.00655 | 8.9 |

| FL | −0.00025 | 8.6 | −0.00012 | 78.5 | −0.00267 | 8.4 | |

| GA-PID | −0.00016 | 6.8 | −0.00009 | 71.5 | −0.00177 | 5.8 | |

| GA-FLC | −0.00005 | 5.5 | −0.00003 | 70.6 | −0.00069 | 5.1 | |

| Δf | PID | −0.00665 | 9.6 | −0.00077 | 76.1 | −0.00128 | 9.6 |

| FL | −0.00244 | 9.1 | −0.00031 | 73.4 | −0.00381 | 8.3 | |

| GA-PID | −0.00078 | 6.7 | −0.00021 | 70.5 | −0.00556 | 5.9 | |

| GA-FLC | −0.00018 | 5.1 | −0.00008 | 70.1 | −0.01224 | 5.5 | |

| Δtie1−2 | PID | 0.00207 | - | - | - | - | - |

| FL | 0.00084 | - | - | - | - | - | |

| GA-PID | 0.00024 | - | - | - | - | - | |

| GA-FLC | 0.00002 | - | - | - | - | - | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cam, E.; Gorel, G.; Mamur, H. Use of the Genetic Algorithm-Based Fuzzy Logic Controller for Load-Frequency Control in a Two Area Interconnected Power System. Appl. Sci. 2017, 7, 308. https://doi.org/10.3390/app7030308

Cam E, Gorel G, Mamur H. Use of the Genetic Algorithm-Based Fuzzy Logic Controller for Load-Frequency Control in a Two Area Interconnected Power System. Applied Sciences. 2017; 7(3):308. https://doi.org/10.3390/app7030308

Chicago/Turabian StyleCam, Ertugrul, Goksu Gorel, and Hayati Mamur. 2017. "Use of the Genetic Algorithm-Based Fuzzy Logic Controller for Load-Frequency Control in a Two Area Interconnected Power System" Applied Sciences 7, no. 3: 308. https://doi.org/10.3390/app7030308