Increasing the Performance of Vacuum Membrane Distillation Using Micro-Structured Hydrophobic Aluminum Hollow Fiber Membranes

Abstract

:1. Introduction

2. Experimental

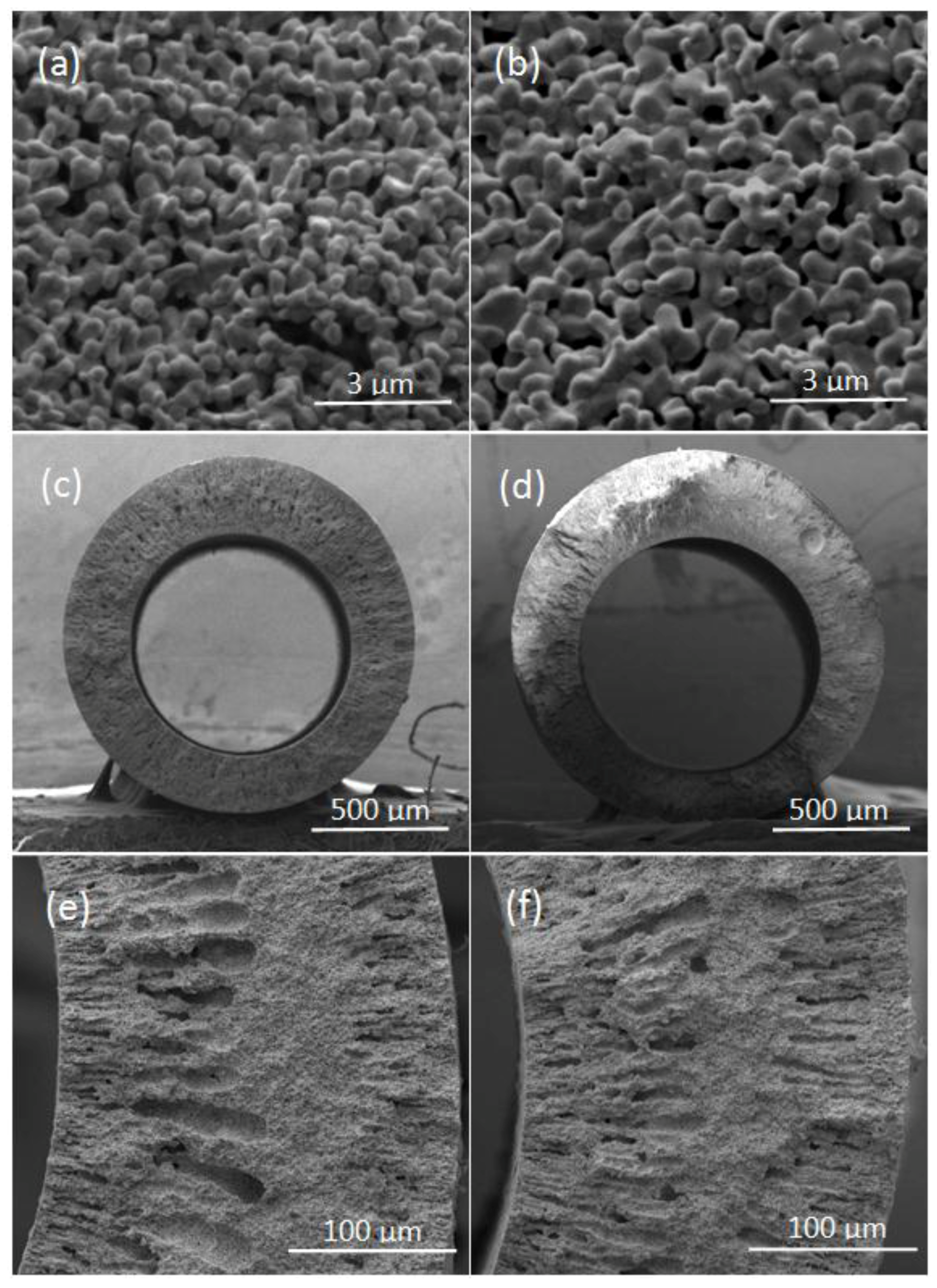

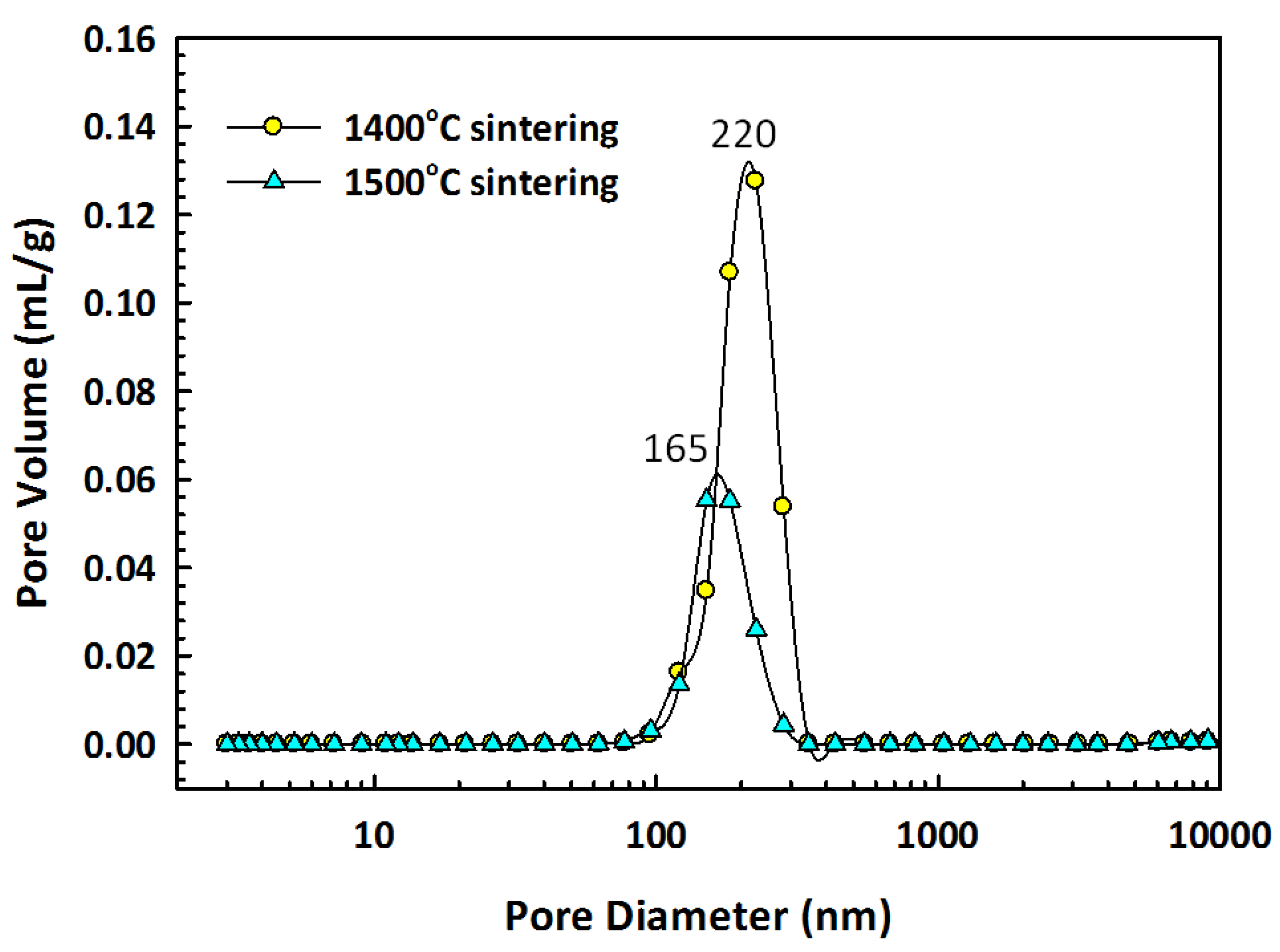

2.1. Fabrication of Alumina Hollow Fiber Membranes

2.2. Fiber Hydrophobization

2.3. Characterization

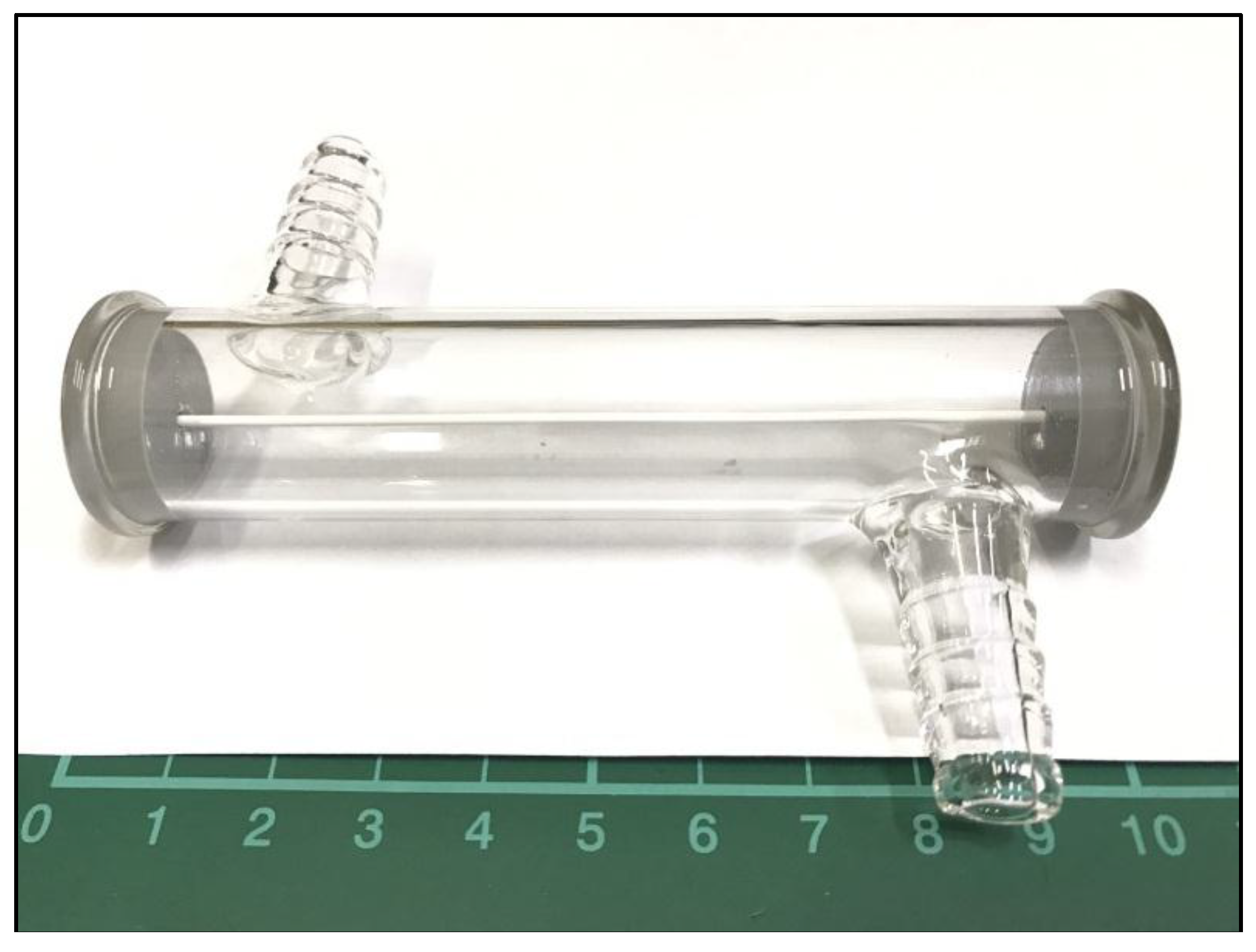

2.4. Fiber Module

2.5. Membrane Distillation

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shirazi, M.M.; Kargari, A.; Shirazi, M.J. Direct contact membrane distillation for seawater desalination. Desalin. Water Treat. 2012, 49, 368–372. [Google Scholar] [CrossRef]

- Shiklomanov, I. World fresh water resources. In Water in Crisis: A Guide to the World’s Fresh Water Resources; Gleick, P.H., Ed.; Oxford University Press, Inc.: New York, NY, USA, 1993. [Google Scholar]

- Drioli, E.; Ali, A.; Macedonio, F. Membrane distillation: Recent developments and perspectives. Desalination 2015, 356, 56–84. [Google Scholar] [CrossRef]

- Drioli, E.; Criscuoli, A.; Curcio, E. Membrane Contactors: Fundamentals, Applications and Potentialities; Elsevier Science: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Noble, R.D.; Stern, S.A. Membrane Separations Technology: Principle and Applications; Elsevier Science: Amsterdam, The Netherlands, 1995. [Google Scholar]

- Alkhudhiri, A.; Darwish, N.; Hilal, N. Membrane distillation: A comprehensive review. Desalination 2012, 287, 2–18. [Google Scholar] [CrossRef]

- Ma, Z.; Hong, L.; Su, M. Superhydrophobic membranes with ordered arrays of nanospiked microchannels for water desalination. Langmuir 2009, 25, 5446–5450. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.Q.; Ren, C.L.; Zong, X.; Chen, C.S.; Winnubst, L. Preparation of alumina membranes comprising a thin separation layer and a support with straight open pores for water desalination. Ceram. Int. 2016, 42, 12427–12434. [Google Scholar] [CrossRef]

- Manawi, Y.M.; Khraisheh, M.A.M.M.; Fard, A.K.; Benyahia, F.; Adham, S. A predictive model for the assessment of the temperature polarization effect in direct contact membrane distillation desalination of high salinity feed. Desalination 2014, 341, 38–49. [Google Scholar] [CrossRef]

- Lawson, K.W.; Loyd, D.R. Membrane distillation. J. Membr. Sci. 1997, 124, 1–25. [Google Scholar] [CrossRef]

- Khayet, M. Membranes and theoretical modeling of membrane distillation: A review. Adv. Colloid Interface Sci. 2011, 164, 56–88. [Google Scholar] [CrossRef] [PubMed]

- Srisurichan, S.; Jiraratananon, R.; Fane, A.G. Humic acid fouling in the membrane distillation process. Desalination 2005, 174, 63–72. [Google Scholar] [CrossRef]

- Ding, Z.; Ma, R.; Fane, A.G. A new model for mass transfer in direct contact membrane distillation. Desalination 2003, 155, 205. [Google Scholar] [CrossRef]

- Boubakri, A.; Hafiane, A.; Bouguecha, S.A.T. Nitrate removal from aqueous solution by direct contact membrane distillation using two different commercial membranes. Desalin. Water Treat. 2015, 26, 2723–2730. [Google Scholar] [CrossRef]

- Sommer, S.; Melin, T. Performance evaluation of microporous inorganic membranes in the dehydration of industrial solvents. Chem. Eng. Process. 2005, 44, 1138–1156. [Google Scholar] [CrossRef]

- Lin, Y.F.; Chen, C.H.; Tung, K.L.; Wei, T.Y.; Lu, S.Y.; Chang, K.S. Mesoporous fluorocarbon-modified silica aerogel membranes enabling long-term continuous CO2 capture with large absorption flux enhancements. ChemSusChem 2013, 6, 437–442. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.F.; Wang, C.S.; Ko, C.C.; Chen, C.H.; Chang, K.S.; Tung, K.L.; Lee, K.R. Polyvinylidene fluoride/siloxane nanofibrous membranes for long-term continuous CO2-capture with large absorption-flux enhancement. ChemSusChem 2014, 7, 604–609. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.F.; Ko, C.C.; Chen, C.H.; Tung, K.L.; Chang, K.S. Reusable methyltrimethoxysilane-based mesoporous water-repellent silica aerogel membranes for CO2 capture. RSC Adv. 2014, 4, 1456–1459. [Google Scholar] [CrossRef]

- Lin, Y.F.; Ko, C.C.; Chen, C.H.; Tung, K.L.; Chang, K.S.; Chung, T.W. Sol-gel preparation of polymethylsilsesquioxane aerogel membranes for CO2 absorption fluxes in membrane contactors. Appl. Energy 2014, 128, 25–31. [Google Scholar] [CrossRef]

- Li, K. Ceramic Membranes for Separation and Reaction; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar]

- Lee, M.; Wu, Z.; Wang, R.; Li, K. Micro-structured alumina hollow fiber membranes—Potential applications in wastewater treatment. J. Membr. Sci. 2014, 461, 39–48. [Google Scholar] [CrossRef]

- Tan, X.; Liu, N.; Meng, B.; Liu, S. Morphology control of the perovskite hollow fiber membranes for oxygen separation using different bore fluids. J. Membr. Sci. 2011, 378, 308–318. [Google Scholar] [CrossRef]

- Krajewski, S.R.; Kujawski, W.; Bukowska, M.; Picard, C.; Larbot, A. Application of fluoroalkylsilanes (FAS) grafted ceramic membranes in membrane distillation process of NaCl solutions. J. Membr. Sci. 2006, 281, 253–259. [Google Scholar] [CrossRef]

- Gazagnes, L.; Cerneaux, S.; Persin, M.; Prouzet, E.; Larbot, A. Desalination of sodium chloride solutions and seawater with hydrophobic ceramic membranes. Desalination 2007, 217, 260–266. [Google Scholar] [CrossRef]

- Khemakhem, M.; Khemakhem, S.; Amar, R.B. Emulsion separation using hydrophobic grafted ceramic membranes by. Colloids Surf. A Physicochem. Eng. Asp. 2013, 436, 402–407. [Google Scholar] [CrossRef]

- Kujawa, J.; Cerneaux, S.; Koter, S.; Kujawski, W. Highly efficient hydrophobic titania ceramic membranes for water desalination. Appl. Mater. Interfaces 2014, 6, 14223–14230. [Google Scholar] [CrossRef] [PubMed]

- Hendren, Z.D.; Brant, J.; Wiesner, M.R. Surface modification of nanostructured ceramic membranes for direct contact membrane distillation. J. Membr. Sci. 2009, 31, 1–10. [Google Scholar] [CrossRef]

- Ren, C.L.; Fang, H.; Gu, J.Q.; Winnubst, L.; Chen, C.S. Preparation and characterization of hydrophobic alumina planar membranes for water desalination. J. Eur. Ceram. Soc. 2015, 35, 723–730. [Google Scholar] [CrossRef]

- Larbot, A.; Gazagnes, L.; Krajewski, S.; Bukowska, M.; Kujawski, W. Water desalination using ceramic membrane distillation. Desalination 2004, 168, 367–372. [Google Scholar] [CrossRef]

- Zhang, J.W.; Fang, H.; Wang, J.W.; Hao, L.Y.; Xu, X.; Chen, C.S. Preparation and characterization of silicon nitride hollow fiber membranes for seawater desalination. J. Membr. Sci. 2014, 450, 197–206. [Google Scholar] [CrossRef]

- Wang, J.W.; Li, L.; Zhang, J.W.; Xu, X.; Chen, C.S. β-Sialon ceramic hollow fiber membranes with high strength and low thermal conductivity for membrane distillation. J. Eur. Ceram. Soc. 2016, 36, 59–65. [Google Scholar] [CrossRef]

- Fang, H.; Gao, J.F.; Wang, H.T.; Chen, C.S. Hydrophobic porous alumina hollow fiber for water desalination via membrane distillation process. J. Membr. Sci. 2012, 403–404, 41–46. [Google Scholar] [CrossRef]

- Garofalo, A.; Donato, L.; Drioli, E.; Criscuoli, A.; Carnevale, M.C.; Alharbi, O.; Aljlil, S.A.; Algieri, C. Supported MFI zeolite membranes by cross flow filtration for water treatment. Sep. Purif. Technol. 2014, 137, 28–35. [Google Scholar] [CrossRef]

- Cerneaux, S.; Strużyńska, I.; Kujawski, W.M.; Persin, M.; Larbot, A. Comparison of various membrane distillation methods for desalination using hydrophobic ceramic membranes. J. Membr. Sci. 2009, 337, 55–60. [Google Scholar] [CrossRef]

- Zhang, J.-W.; Fang, H.; Hao, L.-Y.; Xu, X.; Chen, C.-S. Preparation of silicon nitride hollow fibre membrane for desalination. Mater. Lett. 2012, 68, 457–459. [Google Scholar] [CrossRef]

- Wang, J.-W.; Li, L.; Gu, J.-Q.; Yang, M.-Y.; Xu, X.; Chen, C.-S.; Wang, H.-T.; Agathopoulos, S. Highly stable hydrophobic SiNCO nanoparticle-modified silicon nitride membrane for zero-discharge water desalination. AIChE J. 2017, 63, 1272–1277. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Ko, C.-C.; Chen, L.-H.; Huang, C.-T.; Tung, K.-L.; Liao, Y.-C. A simple coating method to prepare superhydrophobic layers on ceramic alumina for vacuum membrane distillation. Sep. Purif. Technol. 2016. [Google Scholar] [CrossRef]

- Fan, Y.; Chen, S.; Zhao, H.; Liu, Y. Distillation membrane constructed by TiO2 nanofiber followed by fluorination for excellent water desalination performance. Desalination 2017, 405, 51–58. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Suspension flow rate (mL/min) | 15 |

| Bore fluid flow rate (mL/min) | 10 |

| Air gap (cm) | 20 |

| Configuration | Membrane Material | Membrane Morphology | NaCl Feed Solution | Hot Side Temp (°C) | MD Permeate Flux (Lm−2h−1) | Ref. |

|---|---|---|---|---|---|---|

| SGMD | Al2O3 | Disk | 4.0 wt% | 70 °C (80 °C) [90 °C] | 9.9 (13.1) [19.8] | [8] |

| AGMD | ZrO2/Al2O3 | Tubular | 1.0 [M] | 65 °C (80 °C) [95 °C] | 1.0 (2.9) [6.9] | [23] |

| AGMD | Al2O3/ZrO2 | Tubular | 1.0 [M] | 75 °C (85 °C ) [95 °C] | 1.7 (2.9) [5.0] | [24] |

| AGMD | ZrO2 | Tubular | 0.9 wt% | 50 °C (60 °C) [70 °C] | 2.3 (3.9) [7.0] | [25] |

| AGMD | Titania | Tubular | 0.8 [M] | 70 °C (80 °C) [90 °C] | 0.8 (1.5) [2.8] | [26] |

| DCMD | Titania | Tubular | 0.8 [M] | 70 °C (80 °C) [90 °C] | 0.6 (1.0) [2.5] | [26] |

| DCMD | Al2O3 | Planar | 0.5 [M] | 53 °C | 9.0 | [27] |

| VMD | ZrO2/Ti | Tubular | 0.1 [M] | 40 °C | 10.8 | [27] |

| AGMD | ZrO2/Ti | Tubular | 0.5 [M] | 75 °C (85 °C) [95 °C] | 2.7 (3.3) [4.7] | [27] |

| DCMD | Al2O3 | Planar | 4.0 wt% | 60 °C (70 °C) [80 °C] | 7.1 (11.5) [17.0] | [28] |

| DCMD | Al2O3/ZrO2 | Tubular | 1.0 [M] | 60 °C (95 °C) | 1.1 (6.9) | [29] |

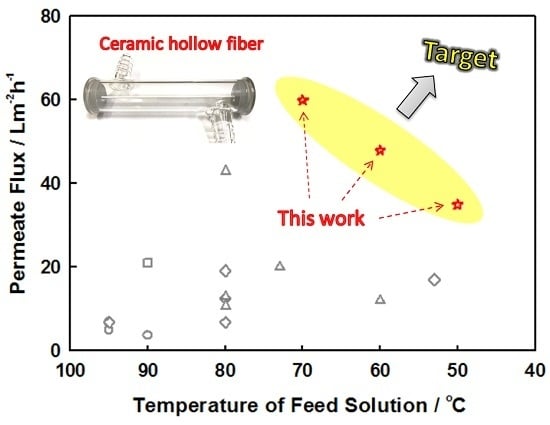

| VMD | Si3N4 | Hollow fiber | 4.0 wt% | 60 °C (70 °C) [80 °C] | 14.6 (22.9) [27.5] | [30] |

| DCMD | Si3N4 | Hollow fiber | 4.0 wt% | 60 °C (70 °C) [80 °C] | 5.4 (7.5) [10.4] | [30] |

| VMD | Al2O3 | Planar | 4.0 wt% | 60 °C (70 °C) [80 °C] | 5.8 (7.9) [10.4] | [31] |

| DCMD | β-Sialon | Hollow fiber | 4.0 wt% | 60 °C (70 °C) [80 °C] | 3.8 (5.4) [6.7] | [31] |

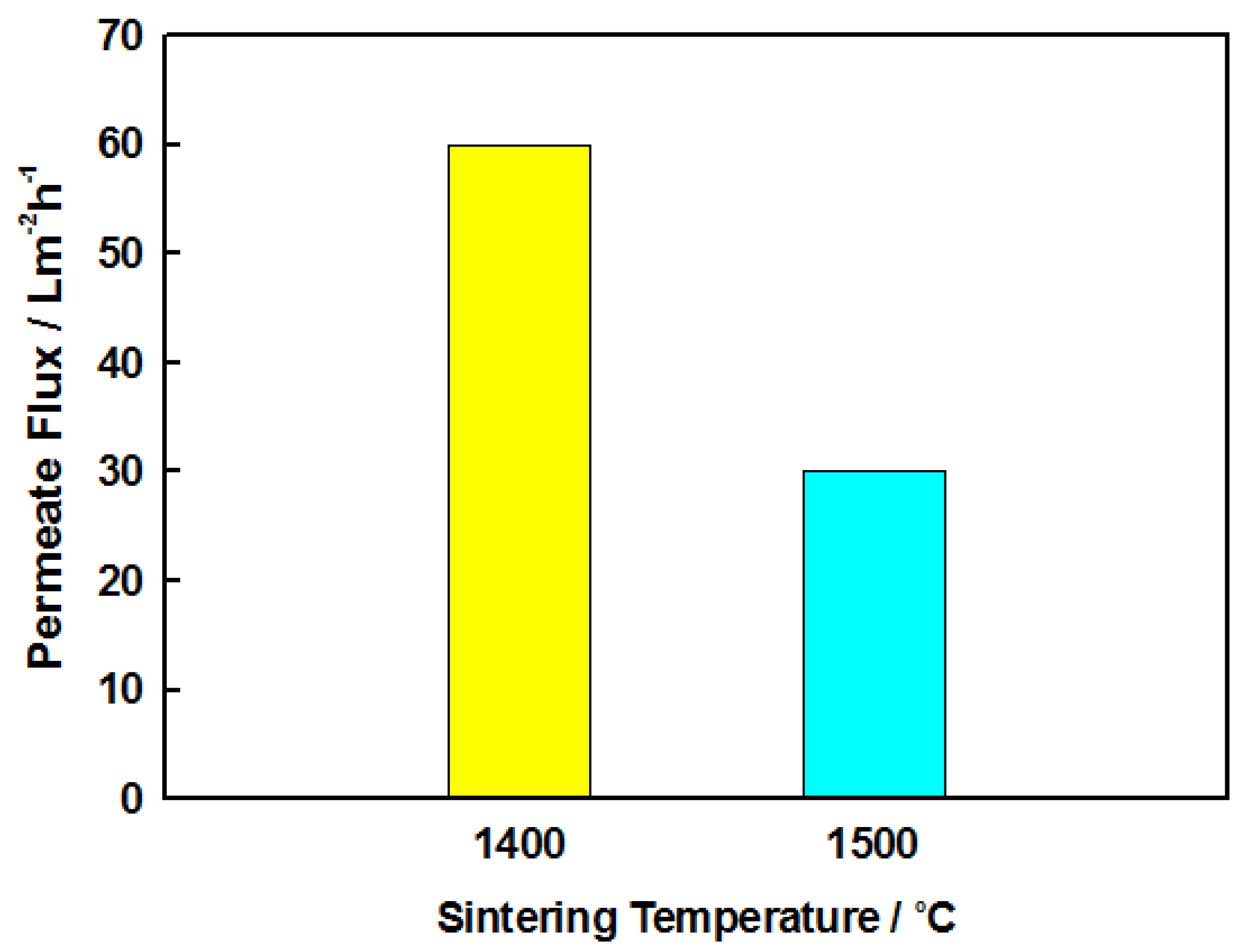

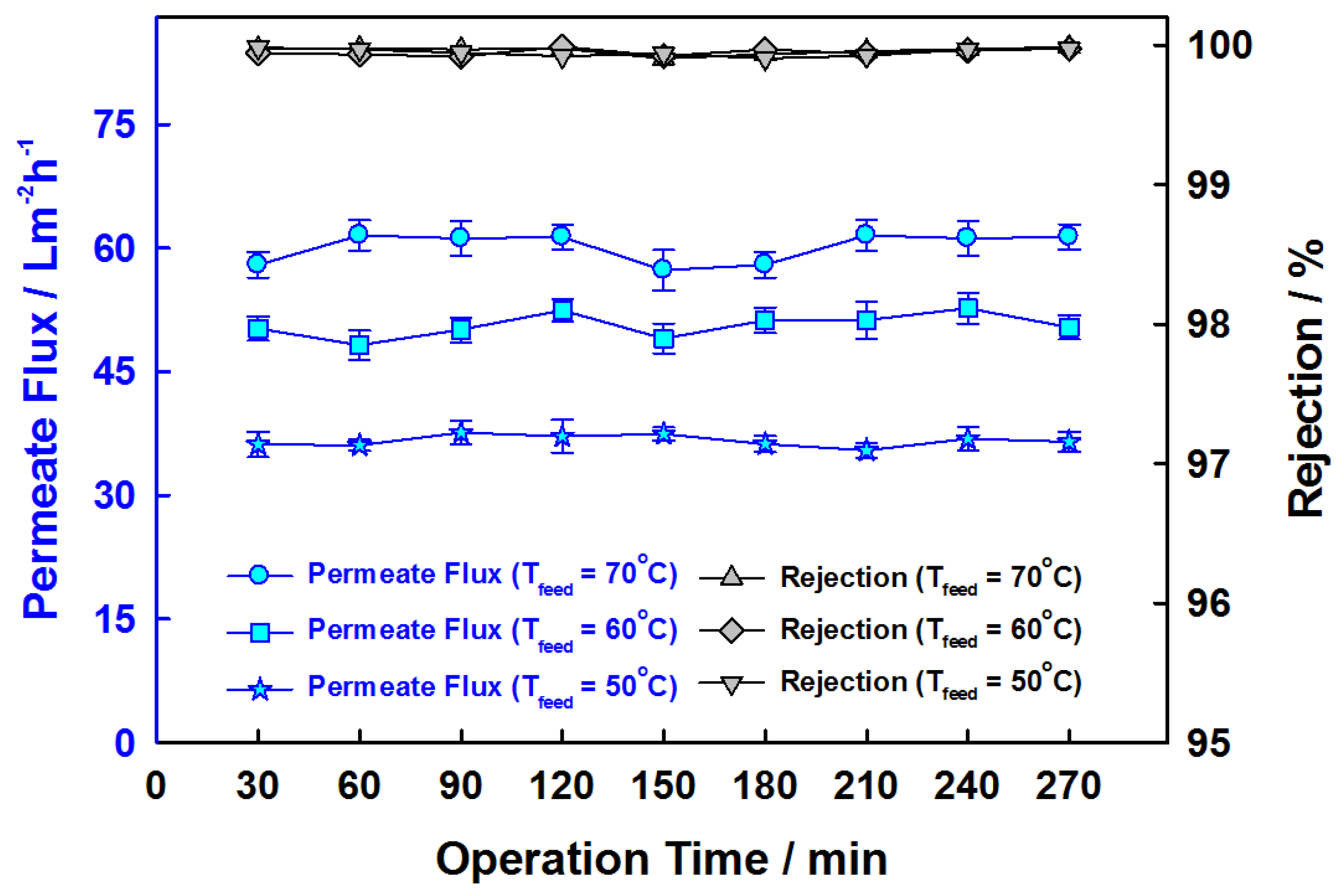

| VMD | Al2O3 | Hollow fiber | 4.0 wt% | 60 °C (70 °C) [80 °C] | 19.0 (32.0) [42.9] | [32] |

| VMD | Zeolite/Al2O3 | Tubular | 3.5 wt% | 60 °C | 12.0 | [33] |

| DCMD | ZrO2/Ti | Tubular | 0.5 [M] | 75 °C (85 °C) [95 °C] | 1.7 (2.5) [3.8] | [34] |

| VMD | Si3N4 | Hollow fiber | 4.0 wt% | 50 °C (60 °C) [70 °C] | 9.6 (14.6) [22.2] | [35] |

| SGMD | Si3N4 | Planar | 4.0 wt% | 75 °C | 6.7 | [36] |

| VMD | Al2O3 | Disk | 3.5 wt% | 70 °C | 37.1 | [37] |

| DCMD | TiO2 | Nanofiber | 3.5 wt% | 60 °C (70 °C) [80 °C] | 7.1 (9.2) [11.9] | [38] |

| VMD | Al2O3 | Hollow fiber | 3.5 wt% | 50 °C (60 °C) [70 °C] | 35.0 (47.0) [60.0] | This work |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ko, C.-C.; Chen, C.-H.; Chen, Y.-R.; Wu, Y.-H.; Lu, S.-C.; Hu, F.-C.; Li, C.-L.; Tung, K.-L. Increasing the Performance of Vacuum Membrane Distillation Using Micro-Structured Hydrophobic Aluminum Hollow Fiber Membranes. Appl. Sci. 2017, 7, 357. https://doi.org/10.3390/app7040357

Ko C-C, Chen C-H, Chen Y-R, Wu Y-H, Lu S-C, Hu F-C, Li C-L, Tung K-L. Increasing the Performance of Vacuum Membrane Distillation Using Micro-Structured Hydrophobic Aluminum Hollow Fiber Membranes. Applied Sciences. 2017; 7(4):357. https://doi.org/10.3390/app7040357

Chicago/Turabian StyleKo, Chia-Chieh, Chien-Hua Chen, Yi-Rui Chen, Yu-Hsun Wu, Soon-Chien Lu, Fa-Chun Hu, Chia-Ling Li, and Kuo-Lun Tung. 2017. "Increasing the Performance of Vacuum Membrane Distillation Using Micro-Structured Hydrophobic Aluminum Hollow Fiber Membranes" Applied Sciences 7, no. 4: 357. https://doi.org/10.3390/app7040357