1. Introduction

Corrosion is one of the primary factors for durability and security of structures. Compared with uniform corrosion, pitting corrosion is prone to impose more adverse impacts on the mechanical properties of structures [

1]. Since the generation and development of pitting corrosion are stochastic, the prediction of its influence is inaccurately implemented using the mathematical models [

1,

2,

3]. However, towards the pitting corrosion diagnosis, beyond that realizing the approximate prediction, one has to assess the current corrosion state, which drives a requirement to non-destructive evaluation techniques, and even has to complete more specific predetermination according to the updated destructive data to reduce the uncertainty [

4].

Guided waves based techniques are proven as accurate and efficient in local damage detection and structural health assessment of aerospace and civil infrastructures. When the dispersion equation was solved by numerical methods, the researchers had been practically applying ultrasonic guided waves in rods for length measurement and defects recognition conveniently [

5]. Combining with intelligent algorithms, Wu et al. detected a flaw of different positions and depths on the surface of a steel bar.

mode was selected considering its particular sensitivity to superficial defects [

6]. Reference-free algorithms were proposed to estimate the cross-section loss based on the differential time-of-flight of propagating guided waves in rod-like waveguides [

7,

8]. Pavlakovich and Beard extensively studied the attenuation properties of guided waves determined by the material properties, propagation distance, frequency et al. in an imbedded bar, and then applied it to the anchor structures detection [

9,

10,

11,

12]. Surface and core seeking guided waves were excited and respectively used to monitor reinforced-concrete beams suffering from damages with different corrosion mechanisms, such as delamination and pitting corrosion on steels [

13,

14].

For guided waves in either cylinders or plates, numerous vibrating modes propagate simultaneously at one single excitation frequency, and with its growth the number of modes also increase, that is multimode nature of guided waves. Multipath nature denotes that guided waves propagate along numerous possible paths between the transducers. As a result of the two native characteristics along with dispersion, the response signals are sometimes difficult to interpret definitely and then give rise to troubles for defect detection. In order to overcome the stringent constraints, lots of research was carried out to enhance resolution of signals, such as optimizing excitation mode, signal processing and loading compensation [

15,

16]. However, the characteristics of guided waves mentioned above have their strengths in damage detection. A refined method, considering the multimode nature and multipath nature with rich defect information, is able to improve the flexibility in selecting appropriate modes based on NAPFD distribution, and hence increase the quality of damage identification.

TRM is a testing technique that signals captured by transducers are inverted in time domain and then reemitted by the same transducers. The identical modes traveling in the same forward and backward propagation paths will arrive simultaneously at the trigger point of excitation, so the discrepancy due to multimode and multipath in time domain can be eliminated. Furthermore, the effect of the within-mode dispersion can be completely compensated. Numerous works relating to TRM have been done in damage detection with guided waves mainly including waveform reconstruction and signal focus [

17,

18,

19]. Wang and Rose et al. established the theoretical basis of the Lamb wave focus and reconstruction in plate using the simplified Mindlin plate theory [

20]; Park et al. improved the time reversal theory of Lamb wave with multimode and applied it to damage identification in composite plate [

21,

22]. A method to bring about higher focusing energy in pipe, by controlling the delay time of each element in the piezoelectric transducer array and adjusting the amplitude coefficient of each excitation channel, was introduced elaborately in Ref. [

23,

24,

25]. In a thick-walled pipe with large diameter, Liu et al. utilized the multichannel time reversal focusing method (MTRF) to focus the circumferential Lamb wave from independent channels, and located the defect by the aid of direct waves which were partially compensated [

26]. Up to now, time reversal technique is conducted extensively in plates and pipes, whereas the application in rod-shaped waveguide is rarely reported. Zhou et al. excited a single-mode of longitudinal guided waves in a steel rod to identify a notch, and used TRM to eliminate the dispersion to increase the resolution of the defect echo signal [

27]. Mustapha et al. came up with a reference-free method to detect the delamination in a rebar-reinforcement concrete beam. A damage index was also defined based on the correlation coefficient between the actuated and reconstructed signals which were derived from TRM [

28]. Both previous literatures mentioned above limited TRM in a single mode in rod-shaped waveguides, and only dealt with removing the within-mode dispersion.

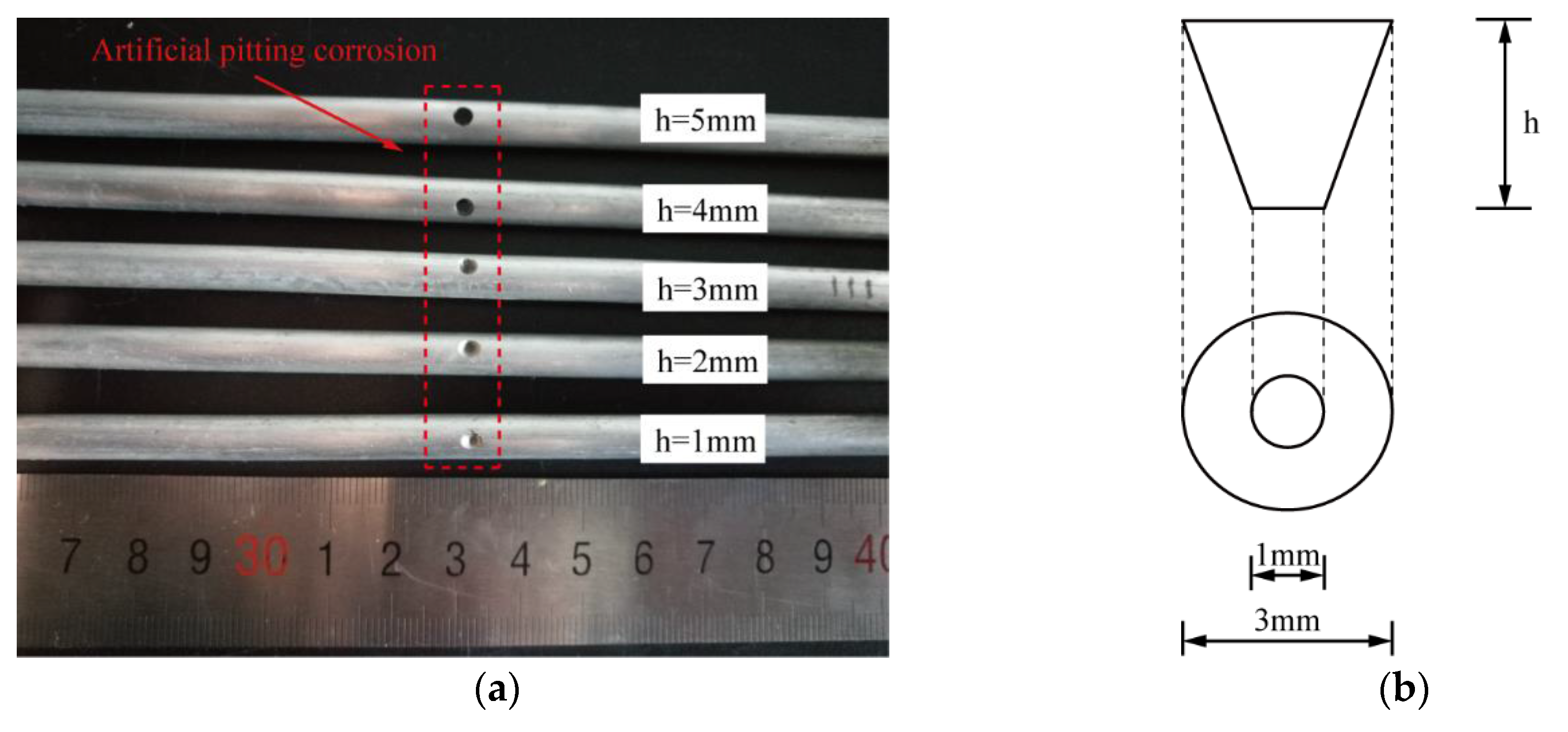

In this paper, ultrasonic guided waves with multiple modes are excited intentionally in differently damaged galvanized steel wires used in bridge cables, and the coupling defect signals attributed to multimode and multipath natures are focused by TRM. Compared with the conventional method for damage detection, not only is the proposed method with higher resolution to the variation of the damage degree, but is proved to supply the entire historical information of the pitting corrosion development.

2. Multimode and Multipath Time Reversal in a Rod

Supposing that a rod is separated into parts by defects, mode reflection or conversion occurs at boundaries or structural defects, and so guided waves will transmit through various routes in different modes from an actuator to a sensor, which results in multimode and multipath natures of guided waves propagation in a rod.

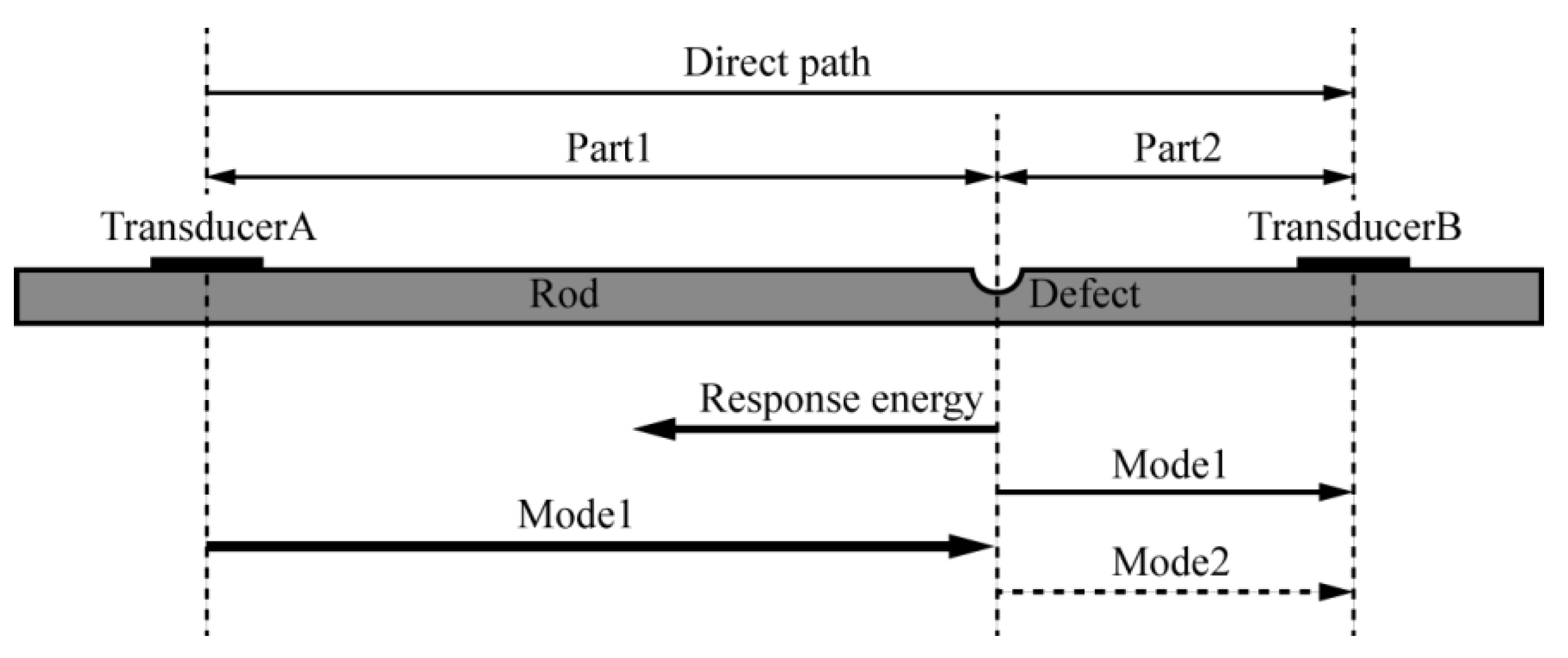

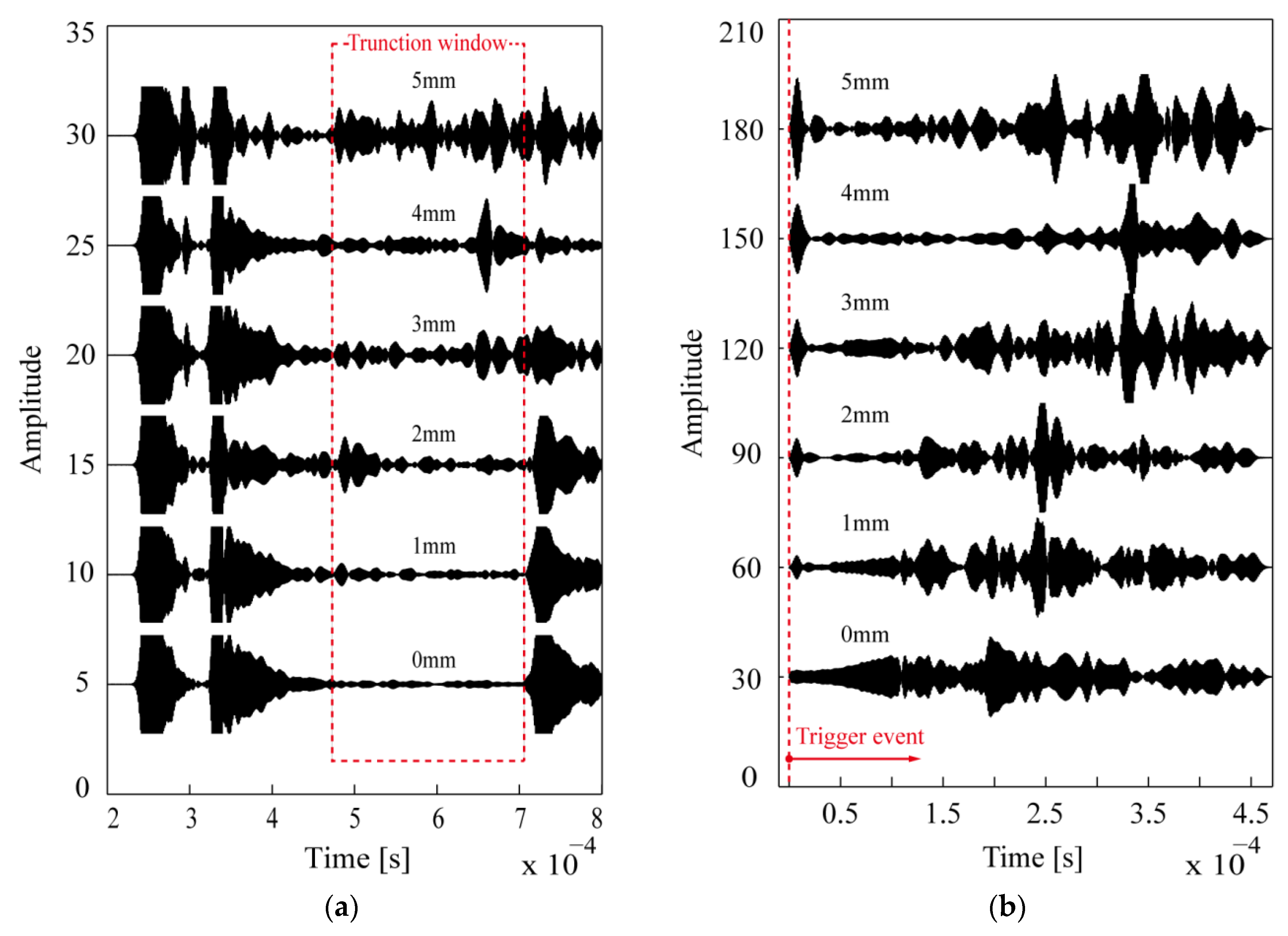

As to a specified transmission route from an actuator to a sensor, the response signal is a composition of modes with their individual propagating process defined specially for the aims of this study. The explanation to the multiple propagating ways is schematically shown in

Figure 1. For brevity, assume that a rod is divided into two transmission parts by one defect, and the direct path among multiple transmission routes is the only one considered here. Mode 1 is excited by transducer A and then propagates right through the Part 1. Supposing that the energy of Mode 1 is separated into sections at the defect, one will still transmit through the Part 2 as Mode 1, but another one converts to Mode 2 and propagates along the remaining path. Therefore, the response signals captured by transducer B on the other side are composed of Mode 1 and Mode 2 which derive from the identical direct path but with different propagating processes.

In general, as to a rod with multiple defects, the transfer function

of the

propagating process in a specified transmission route can be expressed in the frequency domain as follows:

where,

is the angular frequency,

is the number of disturbance due to discontinuities (including defects and boundaries),

is the amplitude dispersion function after the

disturbance,

and

denote the wave number of the mode after the

disturbance and length of transmission part between the

and the

disturbance respectively. For simplified expression,

is the total length of the specified transmission route,

and

indicate the equivalent amplitude dispersion function and the equivalent wave number of the

propagating process respectively.

When an excitation signal

is applied to the actuator, the response signal

at the sensor can be represented in the frequency domain as follows:

and

are the electro-mechanical efficiency coefficients of the actuator and the sensor respectively, and

can be defined as the total number of propagating processes in the specified transmission route.

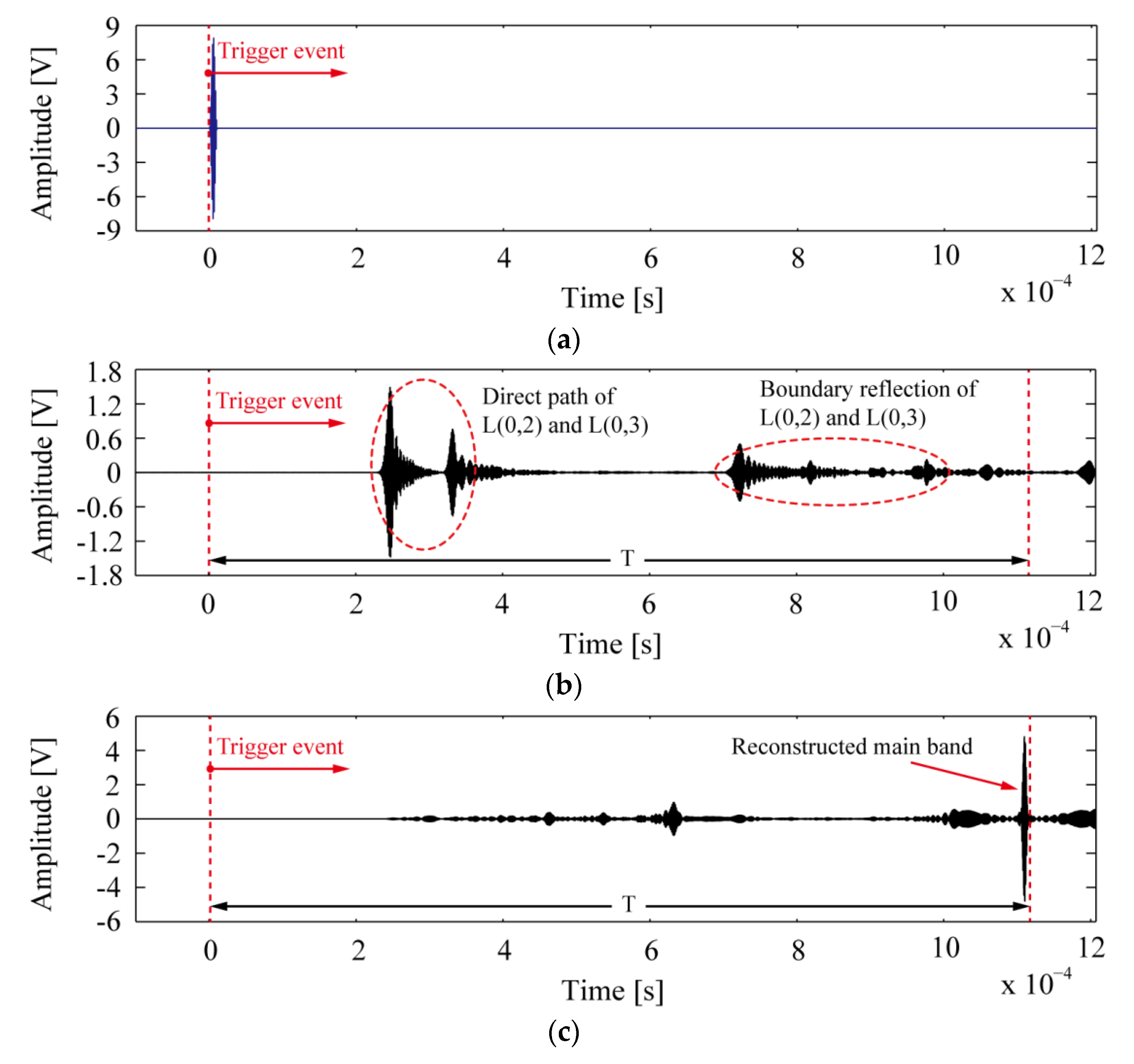

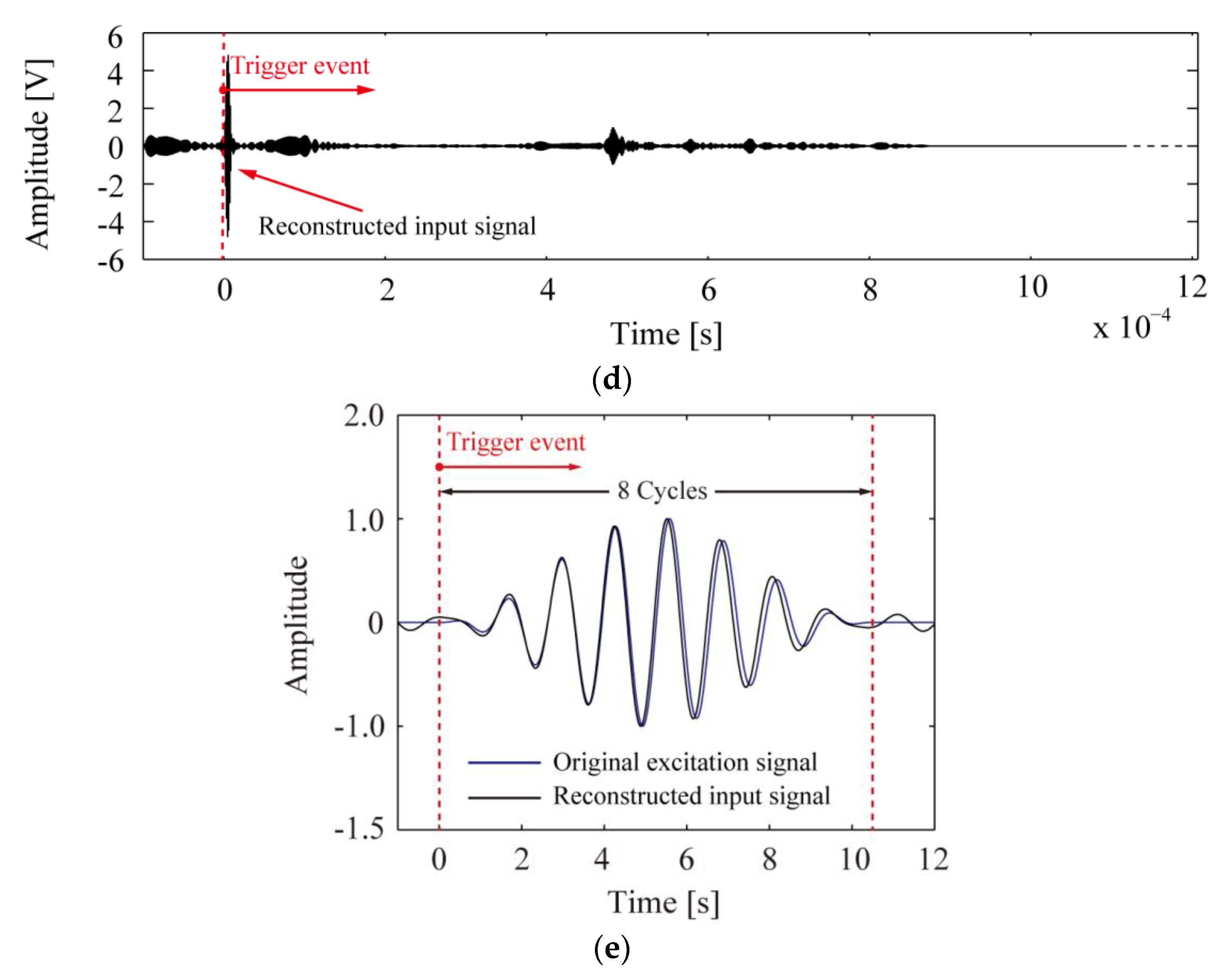

We truncate

at time

, reverse the acquired signal in the time domain, and then reload it to the sensor rather than the actuator. Noticing that reversion in time domain is equivalent to taking a complex conjugate of the signal in frequency domain, the reconstructed signal

captured by the transducer which is acted previously as an actuator is shown below:

where,

,

and

.

The reconstructed signal in the time domain

can be obtained by taking the inverse Fourier transform to

:

when an original input signal is a narrowband tone burst with a center frequency

, then

when

,

in Equation (4) can be rewritten as follows:

reverse

in Equation (6) in time domain, then the reconstructed input signal

is represented as follows:

when

, the

in Equation (4) can be rewritten alternatively as follows:

is expanded using a Taylor series near the center frequency

up to the first order term [

21]

By using the relationships among the equivalent wave number

, the equivalent group velocity

, and the equivalent phase velocity

of the

propagating process, Equation (10) is expressed as follows:

take Equation (10) into Equation (9), then

where,

,

.

Using Equation (11), Equation (8) is expressed as follows:

then, the reconstructed input signal

is represented as follows:

when

, that means the propagating processes are identical in both forward and backward of the specified transmission route. The scaling factor

in Equation (7) is a real number, which indicates that multiple modes are fully compensated and converge to a reconstructed main band. Alternatively, when

, that means the propagating processes are different in both forward and backward of the specified transmission route. The scaling factor

in Equation (13) is no longer a real number because of the item

representing phase shift. As a result, multiple modes are partially compensated and form side bands which are shifted from

by

in time domain.

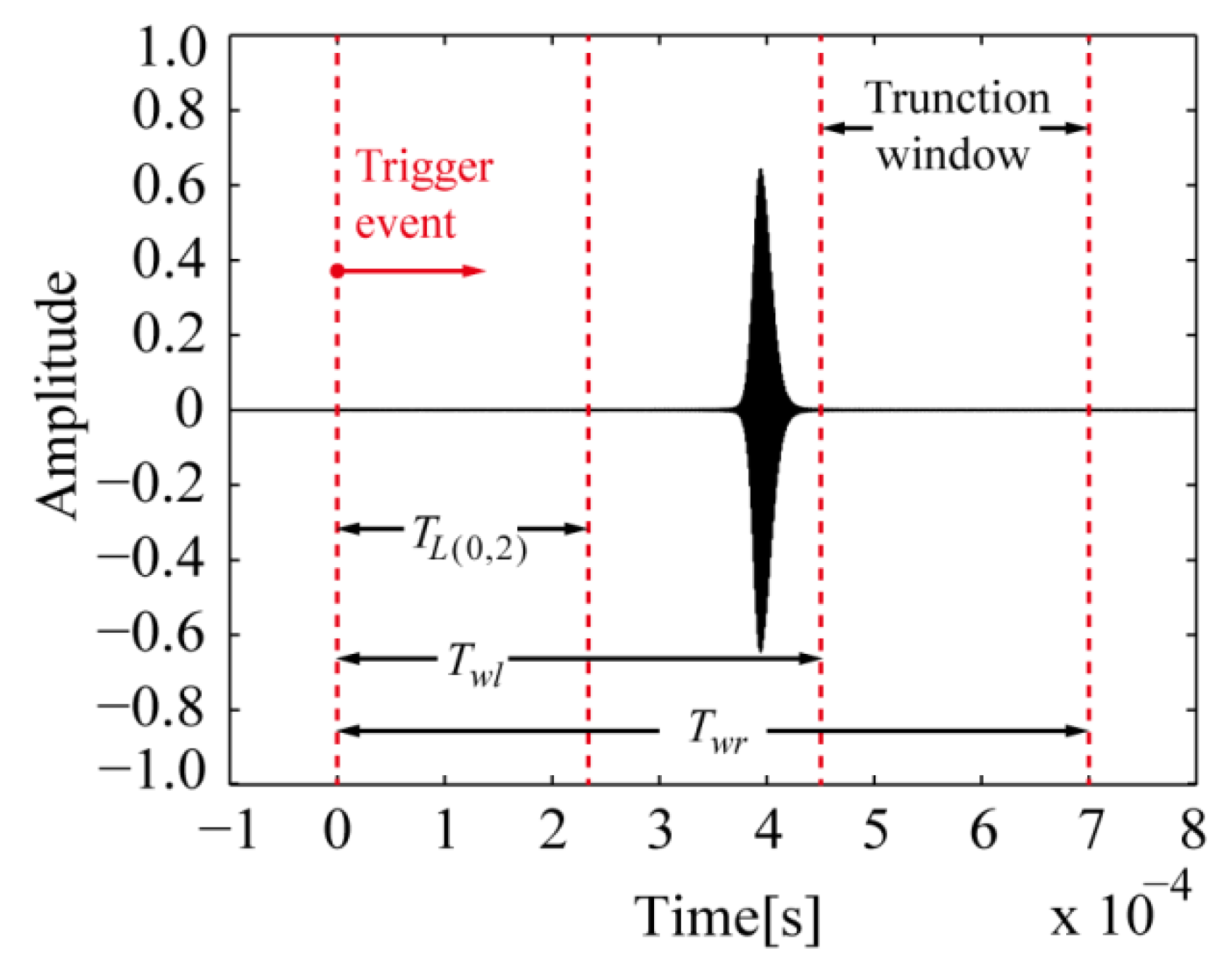

According to another transmission route from the actuator to the sensor, the time reversal process can be validated in a similar manner. Only a sufficiently large truncation window is required to acquire all the captured signals originating from multiple transmission routes, can the response signals of multimode and multipath be spatially and temporally focused and converge to be a main band as a reconstructed input signal.

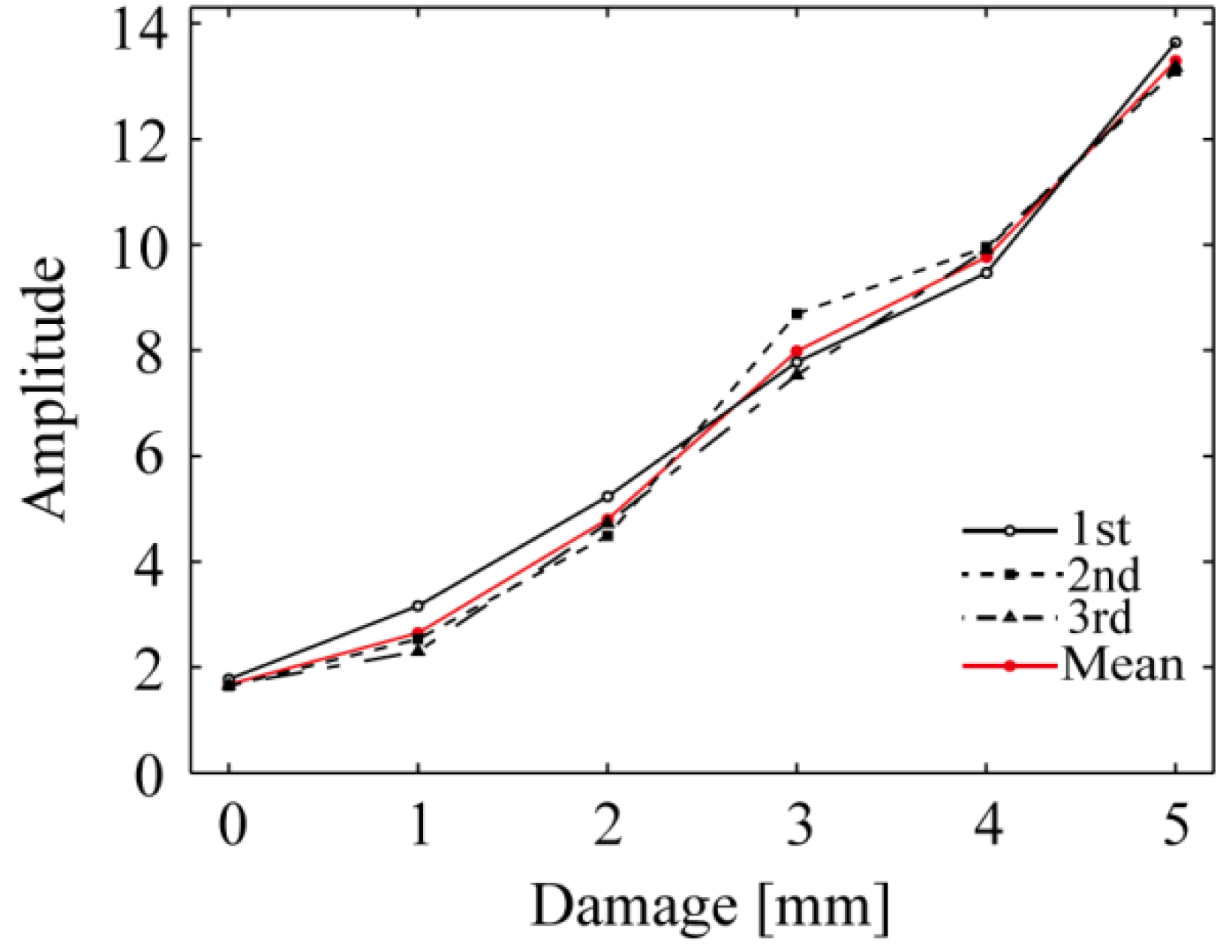

5. Comparison of Conventional Testing Method and TRM

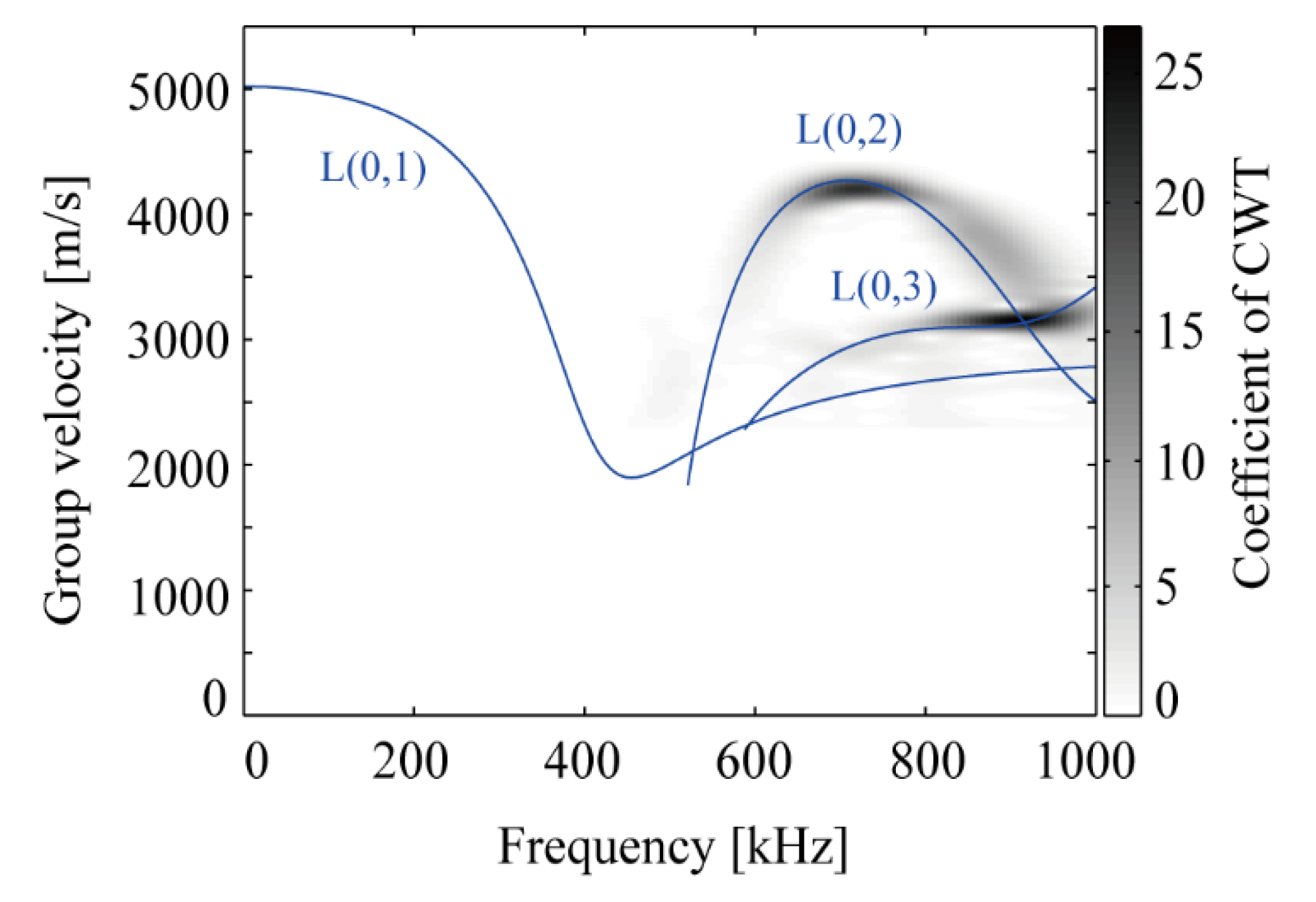

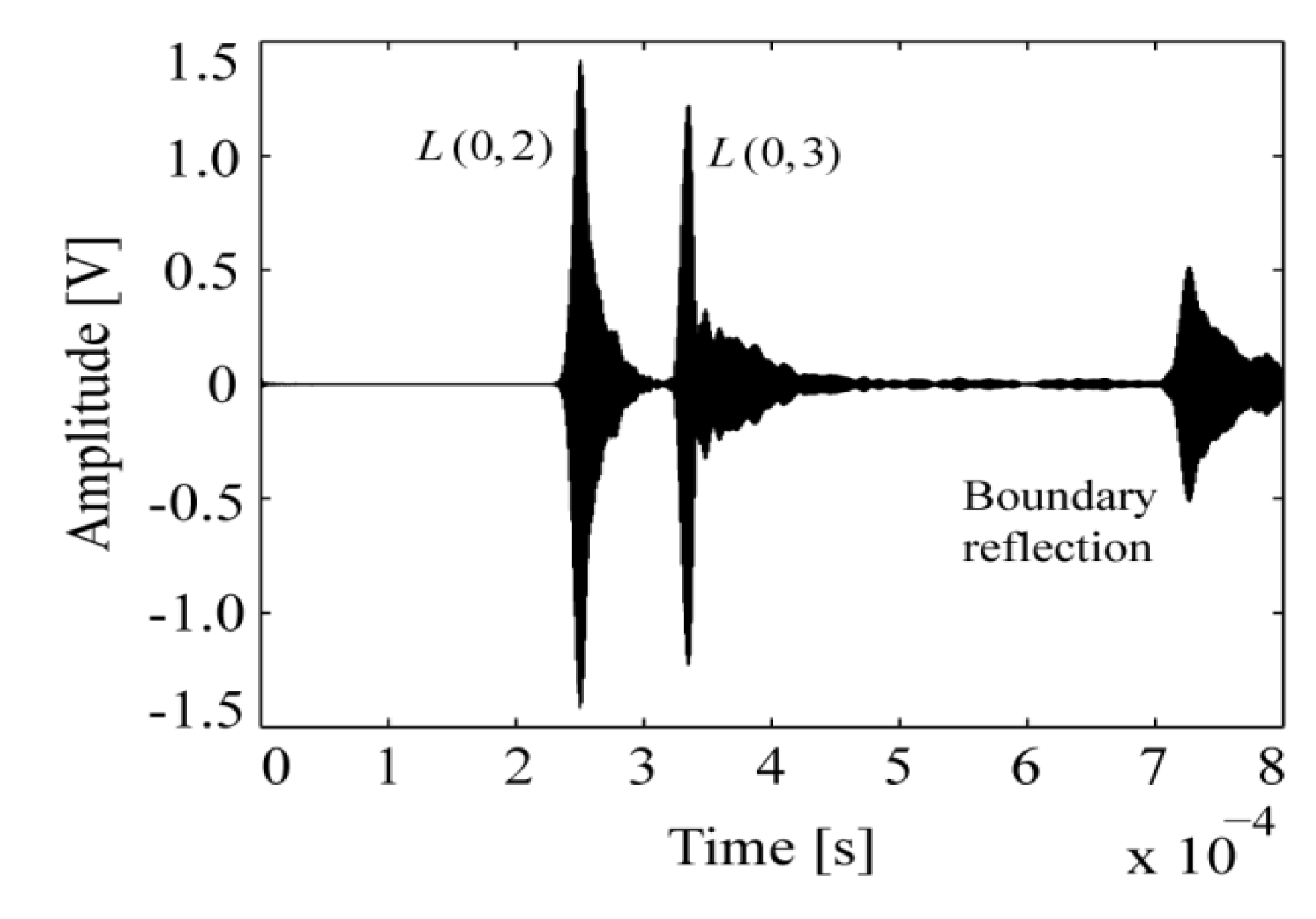

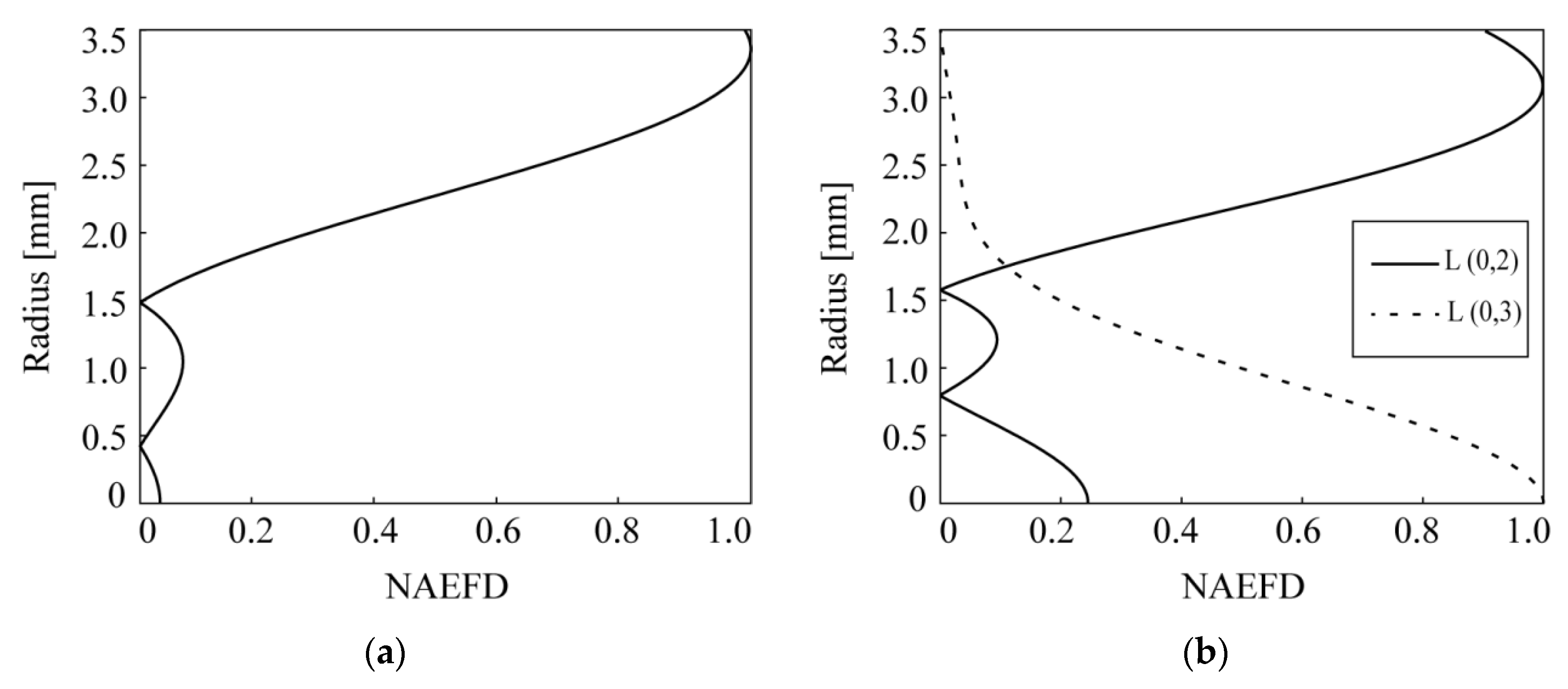

The dispersive behaviors of different modes are represented by dispersion curves like the ones shown in

Figure 4. Mode

, the only one which can be generated and received by the testing system in the frequency range between 0–200 kHz, is preferred as a candidate for damage detection because it is unnoticeably dispersed and apparently identified without disturbance from other modes. The point of minimum dispersion in mode

at 700 kHz is at the point of maximum group velocity, which leads to the wave packet of mode

easily separated from others to make accurate interpretation. For the foregoing reasons, modes

and

are generated at the central frequencies of 150 kHz and 700 kHz respectively under an excitation of 8 V, and then the normalized amplitudes of their defect echoes are applied to evaluate the damages as the conventional testing method in Ref. [

5,

6,

27]. The results towards different depths are shown in

Figure 10.

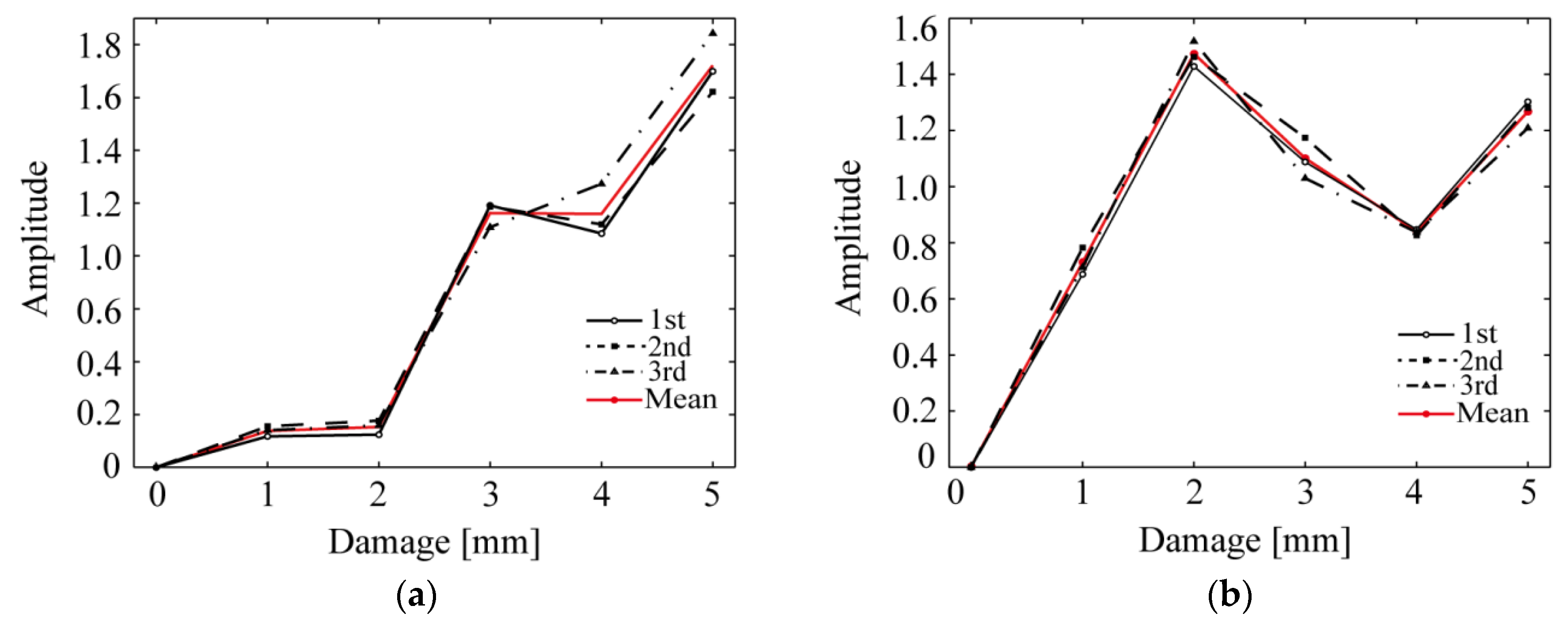

Regarding the results of mode

shown in

Figure 10a, the amplitudes corresponding to the aggravating damages rise with immensely different rates. Distinct increases occur at depths of 3 and 5 mm, but subtle changes occur at other points. It is reasonably deduced that only when the damage accumulates to some extent can feedback be given by mode

, but the sensitivity is not sufficiently high to identify tiny variations for its excessively large wavelength at 150 kHz. With regard to the results of mode

shown in

Figure 10b, the amplitudes can properly indicate the damage increase within the depth of 2 mm. When the depth goes up to 3 mm, the amplitudes turn around to decrease unexpectedly, and then bounce up at 5 mm. The wavelength of mode

at 700 kHz is much shorter; other than that, the NAPFD which is defined to describe the spatial distribution and transmitting direction of the wave energy has a significant surface distribution with respect to mode

at 700 kHz, as illustrated in

Figure 11a.

Both the characteristics demonstrate that mode

is sensitive to superficial damage. However, with the continuous development of pitting, the interaction of the guided waves and the defect becomes increasingly complex, therefore mode

is no longer the only component of the defect echoes. Other modes, which should have been suppressed, are aroused as well, and share the energy with mode

. On the other hand,

Figure 11a shows that the NAPFD of mode

has a negligible component at the core area of the wire, which means that the energy increment contributing to the defect echo is bound to be minimal. As can be seen from

Figure 12, when the damage depths are within 2 mm, the defect echoes of mode

are evident while the other modes are suppressed well. Due to the increasingly remarkable multimode nature of guided waves at 3 mm depth, the amplitudes of defect echoes can not keep growing any more. When pitting reaches 4 mm, the defect echo of mode

is hardly distinguished from the others, for it is no longer a dominant signal. To sum up, the amplitude of defect echo of mode

at 700 kHz can not be utilized to indicate the entire historical development of corrosion damage.

Refer to the damage qualification using TRM presented in

Section 4.3, mode

is simultaneously generated with a large amplitude approximately equal to mode

to indicate different damages universally. Notably, the NAPFD of mode

, which concentrates in the core area of a wire, is strongly complementary with that of mode

at 790 kHz, as illustrated in

Figure 11b. Therefore, besides mode

maintained for superficial damage detection, when the pitting further penetrates into the core area of the wire, a dramatical energy increment of the defect scattered signals is still ensured by mode

. Attributing to the application of TRM, the highly dispersed energy resulting from multimode, multipath and dispersion of guided waves is utilized efficiently. An accurate interpretation towards pitting corrosion can be made based on the normalized amplitudes of wave packets focusing at the trigger point.

6. Conclusions

In this paper, a high-resolution monitoring method is proposed for the depth development diagnosis of pitting corrosion in rod-like waveguide. According to the multimode and multipath natures of guided waves propagation, two modes with a complementary radial distribution of the NAPFD are excited simultaneously to identify the defect development. The energy of the defect scattered signal is focused by TRM, which effectively overcomes the problem that the damage is inconclusively evaluated rooting in the hard interpreted signal originating from multimode, multipath and dispersion of guided waves propagation.

The method is verified to evaluate the 1 mm to 5 mm artificial pitting corrosion in the middle positions of galvanized steel wires. Mode , with the NAPFD profile concentrating on the surface of a wire, is suitable for seeking the tiny superficial defect in early time. Mode whose radial distribution of the NAPFD is centered in the core area of a wire is turned out to track the defect deep inside instead of Mode . The time-frequency representation of the swept signals at 790 kHz shows that modes and can be excited simultaneously and they are of approximately the same energy. The defect scattered signals were extracted by a truncation window determined by the proposed method to eliminate the direct signals that may cause erroneous judgment towards defect. In consideration of the inevitable discrepancies due to the different coupling conditions between the specimen and transducers, the amplitudes of the reconstructed signals are normalized by the RMS of the signals captured before the reflected wave packet of mode from the boundary. It is demonstrated that the amplitudes of the normalized reconstructed signals focused at the trigger point exhibit almost linearly increasing trend in line with the growing depth of pitting corrosion.

The conventional method of straight forward detection through the differential amplitudes of single mode echo from different defects is also applied to corrosion assessment. By contrast, the proposed approach integrating multimode excitation with TRM is proved to be able to potentially supply more definite entire historical information of pitting corrosion.