1. Introduction

The interface of composite materials is the heart of composite materials. There is a significant difference between the physical and chemical properties or the mechanical properties of the reinforcing fibers and the matrix resin itself [

1]. Therefore when the materials are combined, the nature of the interface between the dissimilar materials can have a profound impact on the mechanical properties of the composite material. The physical properties of composite materials are often described by the rule of mixtures, which represent the average physical properties of the reinforcement and the matrix resin. However, in practical applications, situations arise when the rule of mixtures is not followed. This is because when an external energy is applied to the composite material, it is transferred from the matrix to the reinforcement, affecting the final physical properties of the interface between them rather than the intrinsic properties of both the reinforcement and the matrix. In addition, each matrix or reinforcement forms strong internal chemical bonds, and their interface forms weak physical bonds. Because of this, a force delivered from outside is dependent on the extent of the physical bonding [

2,

3].

In general, composite materials, which do not have any surface treatment of carbon fibers, are known to show a low degree of interlaminar shear strength (ILSS) or critical stress intensity factor (K

IC). This is due to the fact that carbon fiber, which is used as reinforcement, has a low wettability level with the matrix and the surface itself is smooth, and thus the interfacial bonding strength is weak [

4]. Therefore, the interfacial bonding strength of carbon fiber-reinforced composite material can be improved by two methods. (i) first removing impurities on the surface of the carbon fiber with surface treatment methods such as vapor phase oxidation, liquid phase oxidation, anodic oxidation, and plasma treatment. After that the number of functional groups (carboxyl, carbonyl, and hydroxyl) enhancing the bonding force with the matrix, is increased [

5]; (ii) the interfacial bonding strength can be improved be adding trace amounts of other materials such as SiC [

6] and TiO

2 [

1] between the carbon fibers and the matrix.

In this research, carbon fiber-reinforced composite materials were produced by dispersing HNTs and expected to enhance the interfacial bonding strength between the carbon fibers and the matrix, and epoxy resin using an ultrasonic homogenizer. In order to analyze the mechanical behavior in the presence of added HNTs to carbon fibers and the matrix, first the mechanical behavior of the HNT/matrix-based composites was observed by dispersing HNTs in the matrix. Based on this, the mechanical properties were evaluated in accordance with the interfacial bonding strength according to the addition of particles with varying HNT content.

Also, mode II interlaminar fracture toughness was measured and evaluated to investigate the fracture phenomenon at the interface of carbon fiber reinforced composite with nanoparticles. In order to investigate the interfacial reinforcement effect of HNTs, nanoparticles were dispersed only in epoxy resins, and mechanical properties were evaluated to compare the reinforcing effect in the resin and the theoretical and experimental properties of the layered composite material.

3. Results and Discussion

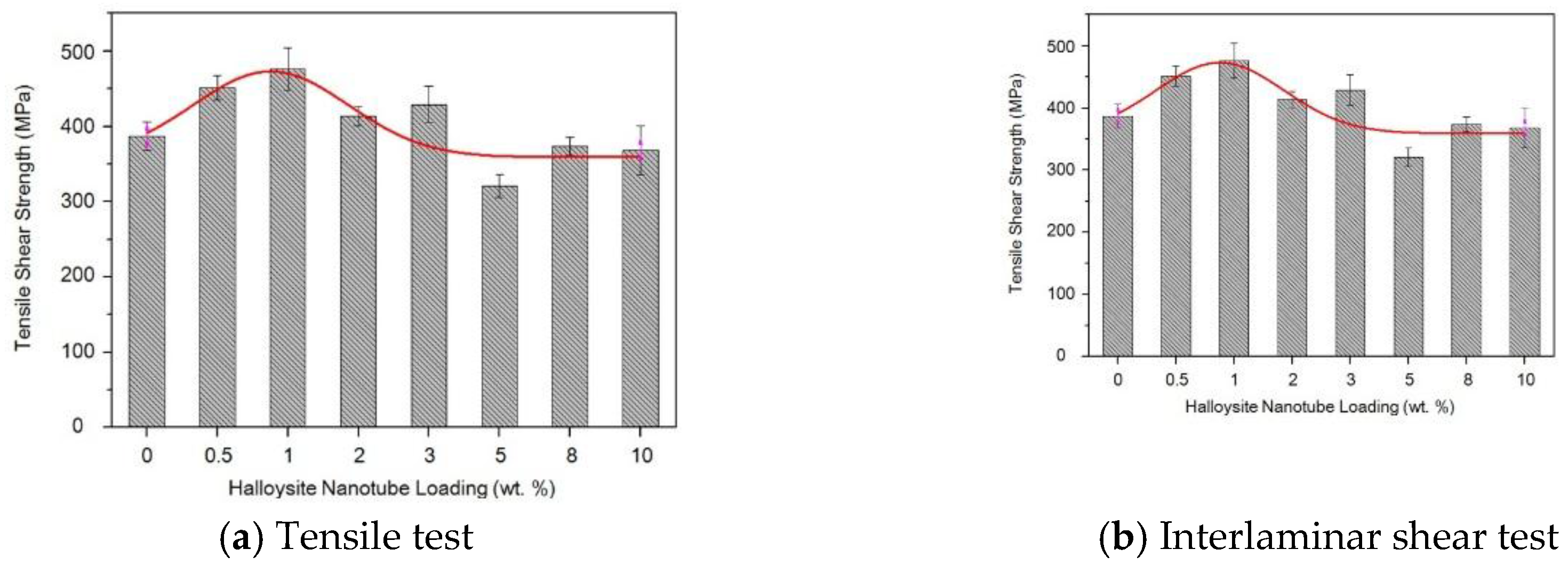

Tensile strength was investigated to evaluate the effect of HNTs on the tensile strength of carbon fiber-reinforced composite material. The respective mean value of the eight sets was calculated excluding the minimum and maximum values. These results are shown in

Figure 2a. The tensile strength of the test specimens increased in accordance with the added amount of HNT content up until 1 wt %. However, the tensile strength tended to decrease after 1 wt % HNT content. In particular, the specimen with an HNT content of >5 wt % had a smaller tensile strength than the specimens with no added HNT. In the case where the content of the HNT increased beyond a certain level, it is believed that by increasing the cohesion of the HNT, the tensile strength decreased according to the stress concentration in the agglomerated HNT.

The interlaminar shear test was carried out to evaluate the interfacial properties of carbon fiber/epoxy composite with added HNTs. The ILSS with varying amount of HNTs is shown in

Figure 2b. The ILSS of carbon fiber-reinforced epoxy composite without any added HNT was ~26.29 MPa, which was even lower than the test specimen with 10 wt % HNT showing the smallest strengthening effect with the addition of HNTs. The ILSS improved by adding HNTs. In addition, when the added HNT content was up to 3 wt %, the ILSS increased with added amount, and starting at 3 wt %, as the content was increased, the ILSS decreased. When more than a certain amount of HNTs was added, the effect of the addition was found to be small. In the case where a comparatively high amount was added to the epoxy resin, even when dispersed, the HNTs clumped together and were not uniformly dispersed by visual observation. It was surmised that stress concentration due to such agglomeration decreased the strength.

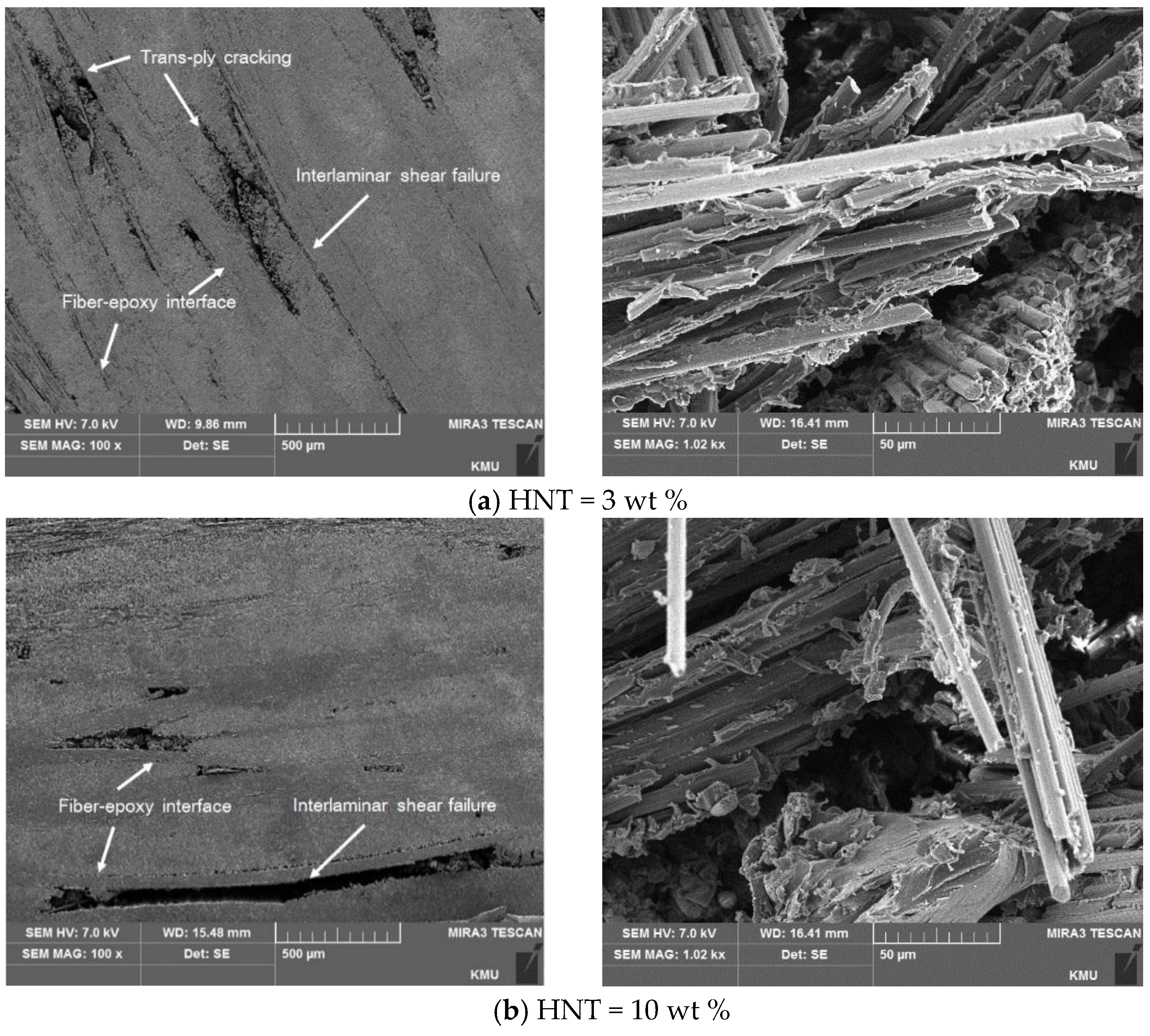

The left side in

Figure 3 shows the SEM image of a test specimen with a fracture cut from the front side after the interlaminar shear test of the carbon fiber-reinforced composite with added HNTs. A test specimen with an HNT content of 10 wt %, compared to the test specimen with 3 wt % HNT content, had the maximum shear strength value, forming a significant interlaminar shear fracture, and the damaged side of the fractured surface was seen to be smooth.

An image of the fractured surface, which was taken to evaluate the fracture’s shape is shown in the right side of

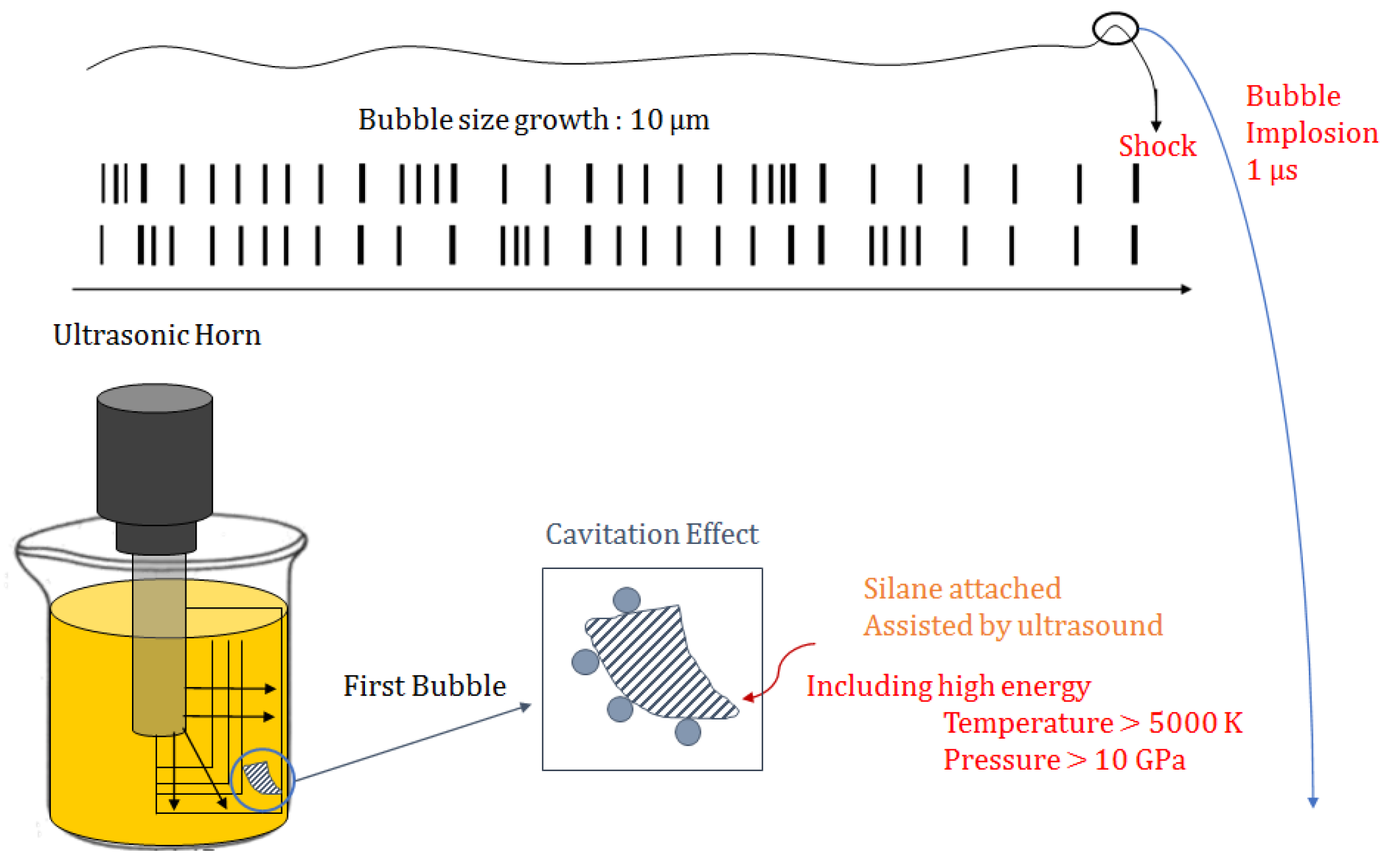

Figure 3. With an HNT content of 3 wt %, the pull-out phenomenon was relatively small in the entire fractured surface, and the epoxy resin was also observed to be adhering well to the surface of the carbon fiber. In addition, at an HNT content of 10 wt %, the pull-out phenomenon such as the white part in the SEM image of the test specimen appeared in every aspect of the fiber, and in particular, delamination appeared near or at the fiber-resin interface. It is believed that the reason delamination appears locally is because of the stress concentration from the agglomeration of the HNTs. In order to prevent the agglomeration of the epoxy resin and the HNT nanoparticles, it was dispersed using an ultrasonic dispersion device. An ultrasonic dispersion device was used to incorporate the cavitation effect into the composite material.

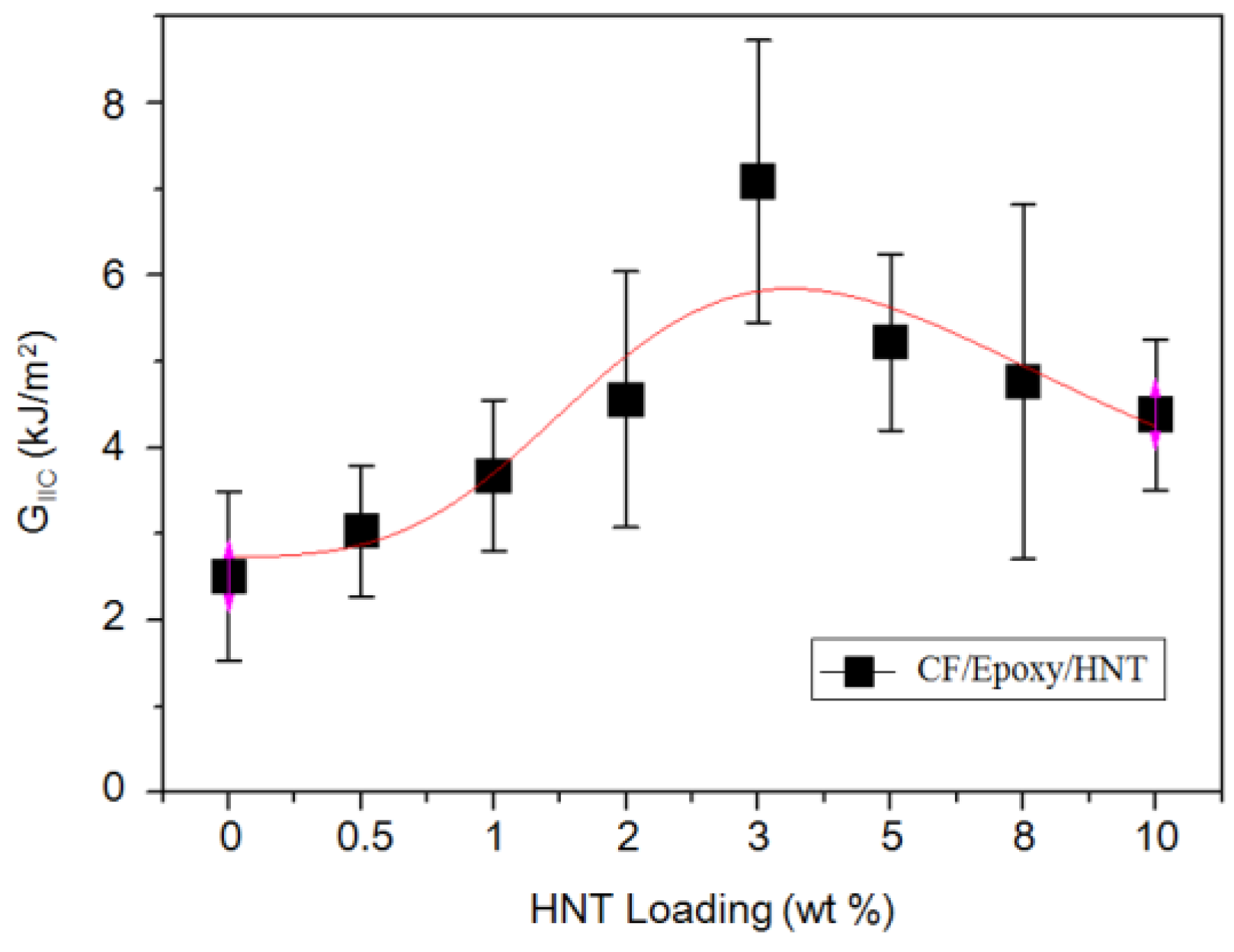

Figure 4 shows the graph of mode II shear modulus with varying HNT content to evaluate mode II interlaminar fracture toughness of carbon fiber reinforced composite with HNT. The interfacial bond energy increased up to 3 wt % of HNT, but decreased at ≥5 wt % HNT content. The binding energy of HNT increased for 3 wt % at the interface, but at ≥5 wt %, the binding energy of HNT was concentrated due to the concentration of HNT. To evaluate the interfacial bond energy of HNT—reinforced carbon fiber reinforced composites and the strengthening effect of HNT addition, HNT was added to the epoxy resin to evaluate the strengthening effect of epoxy resin by HNT.

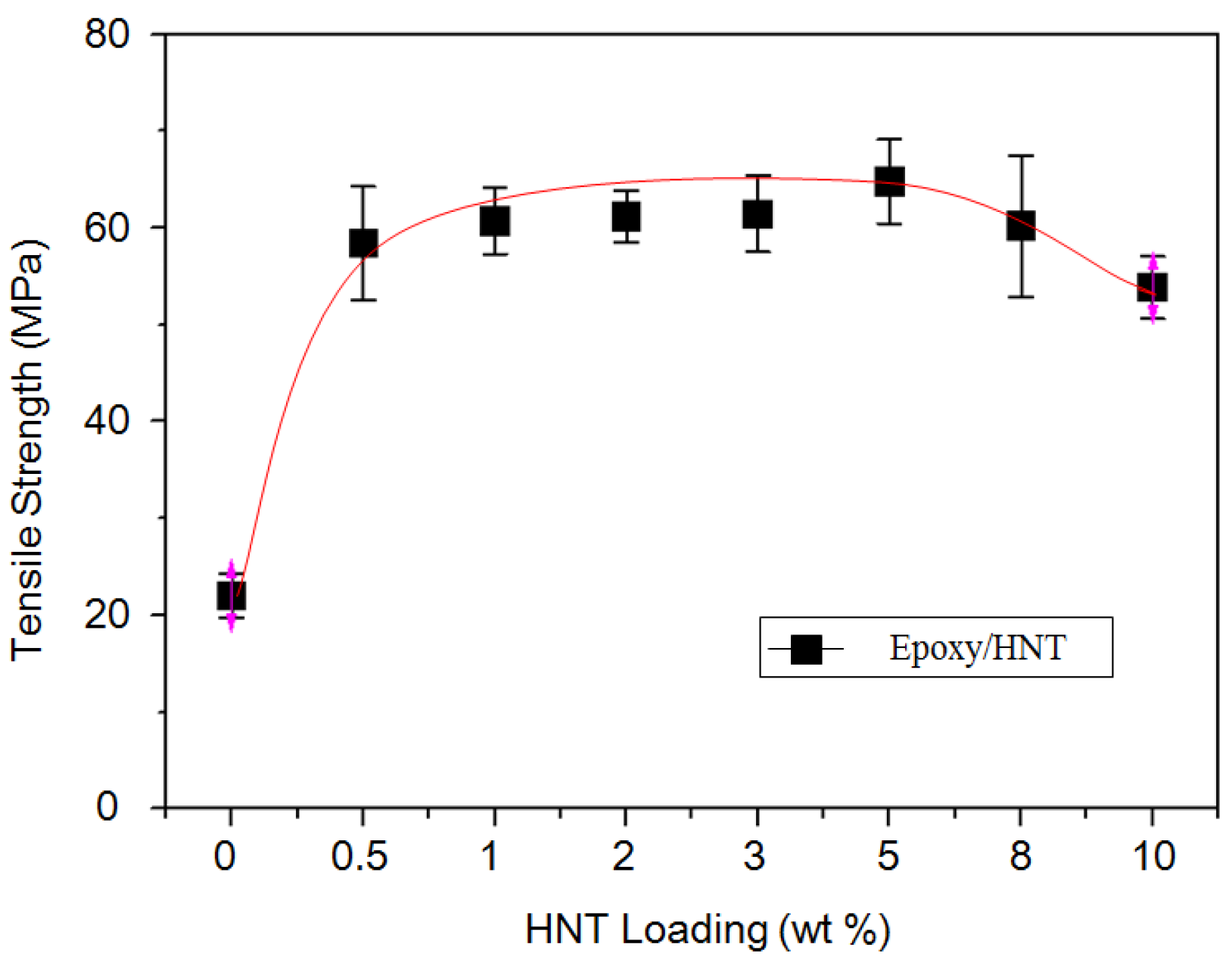

Figure 5 shows the result of the tensile strength by adding HNT to the epoxy resin. The strength of the epoxy resin without HNT was 22 MPa, and the addition of HNT strengthened the effect by two to three times, confirming remarkable epoxy resin strengthening effect by the addition of HNT, and the increase in the tensile strength by addition increased the content of HNT to 5 wt %. In ≥5 wt % of test specimens, the strengthening effect gradually decreased with addition.

In order to investigate the correlation between the strengthening effect of HNT in epoxy resin and the mechanical properties of carbon fiber reinforced composite material by the addition of HNT by the improvement of interfacial bonding energy based on the results obtained above, the strength characteristic value of the epoxy resin reinforced with HNT, and the strength characteristics of carbon fiber were obtained by the theoretical strength of the composite material.

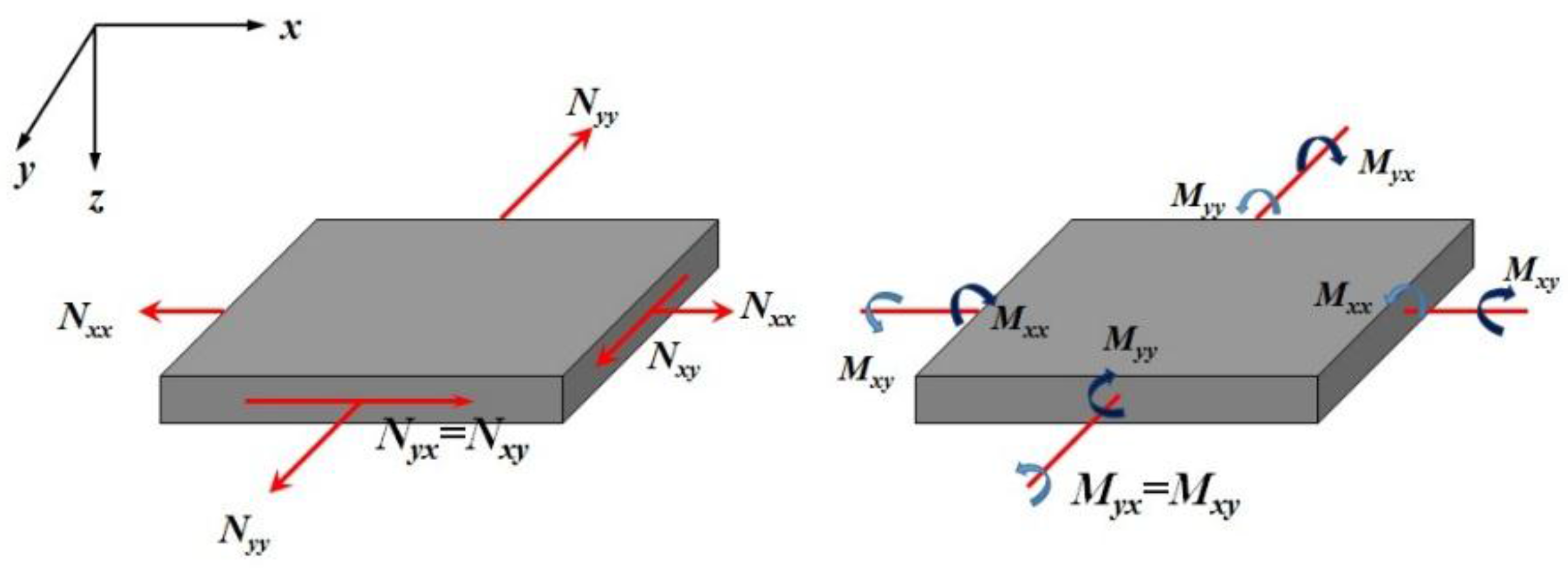

The displacement and the strain of the composite laminate under load are different from those of the single layer composites, because of the interaction between the layers. In the composite laminate, the lamination angles are different for each layer, so the stiffness and strength are different for the same external force. The force and moment applied to the laminate can be obtained by integrating different forces and moments for each layer depending on the laminate thickness. Assuming the planar stress state of the laminates, the forces and moments applied to the laminates are as follows.

where

Nij is the applied force per unit length of the laminate and

Mij is the applied force per unit length of the laminate.

Figure 6 is the moment applied per unit length of the laminates.

Here, the average stress of the composite material is given by the following equation, and t is the total thickness of the composite laminate.

To compare the strength of the theoretically strengthened composite with the actual strength, the fiber volume fraction was calculated to investigate the strength of the theoretical composite material. The fiber contents of composite specimens were tested in accordance with ASTM D 3171, and determined using the following formula.

where

m1,

m2,

m3 are the initial mass (g) of the dried container only, the mass of the container (g) containing the dried test specimen, and the mass of fiber (g), respectively. The volume content of the fibers measured by each method was ~62%, and the weight of the added HNT was calculated by assuming that the HNT was dispersed in the epoxy resin.

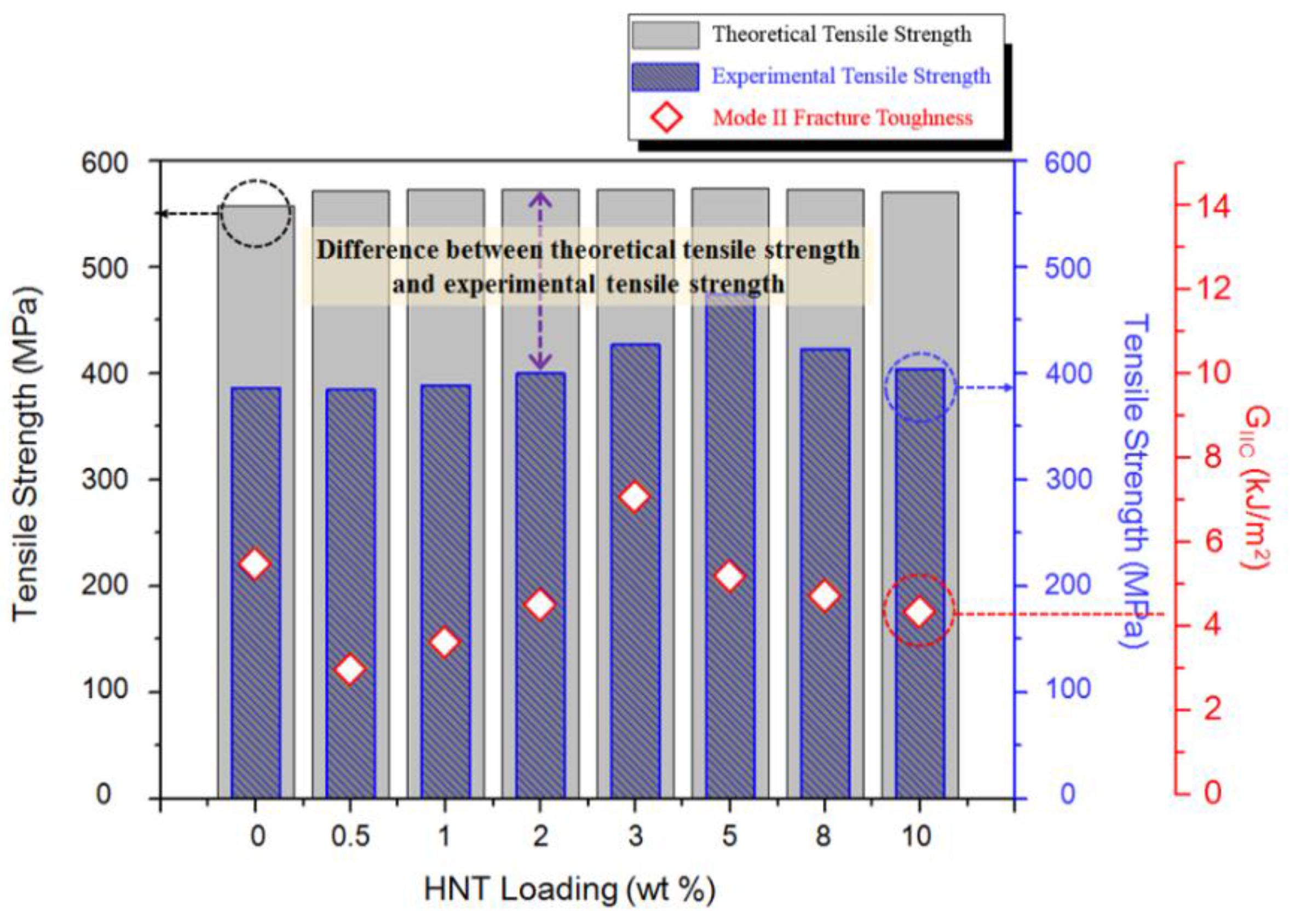

Figure 7 shows the graph comparing the theoretical strength obtained by calculation with the carbon fiber reinforced composite material and interlaminar fracture toughness energy added with HNT. The theoretically calculated values were ~20 MPa higher than the test specimens without HNT. The difference in the strengthening effect due to the additive content was insufficient in the theoretical calculation. Theoretically, the calculation of the strength of a composite material does not seem to have any effect on the theoretically calculated value because it is dominated by fiber, which is a reinforcing material, rather than a known resin. However, the measured value of HNT was the highest at 5 wt % HNT, because the binding force at the interface increased with increasing amount of added HNT. Moreover, it is considered that the addition of HNT which is not calculated theoretically is due to the interfacial adhesion strengthening effect.

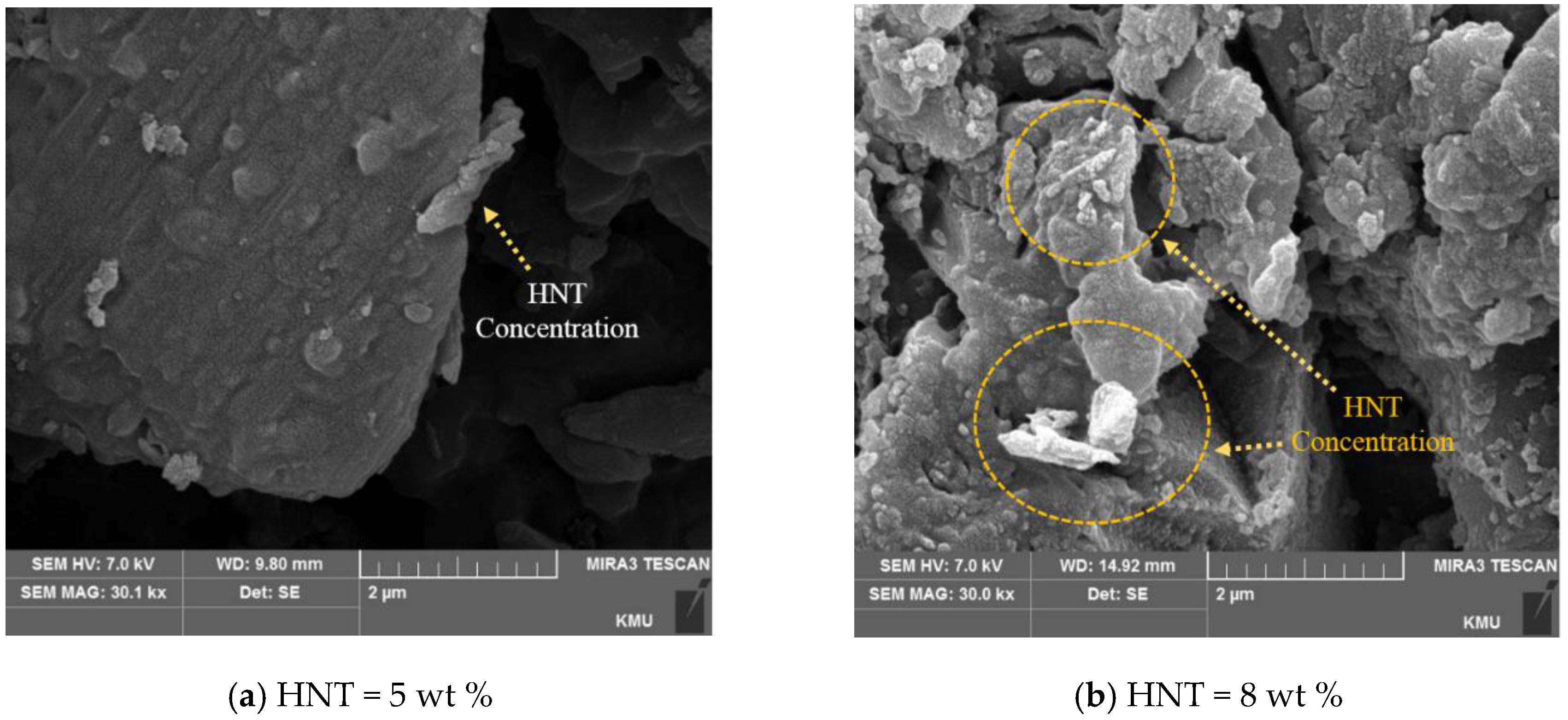

The cohesion of the HNT in the carbon fiber reinforced composite material was investigated by SEM.

Figure 8 shows the photograph of specimens taken at 5 wt % HNT having the highest tensile strength value, and at 8 wt %, the tensile strength decreases with increasing content. The photograph of the sample with 8 wt % HNT shows a considerable amount of agglomerated HNTs.