1. Introduction

Single-crystal sapphire optical fiber is frequently used in high temperature and corrosive environments for sensors monitoring properties such as temperature [

1,

2,

3] or gas concentration [

4]. While the resilience of sapphire in extreme environments is rivaled by very few optical materials, its large refractive index relative to air results in high modal volume at typical sensing wavelengths. This contributes to higher loss, increased modal dispersion, decreased distributed sensing resolution, and decreased detection sensitivity than can be achieved by silica-based counterparts [

5,

6] or preclude the application of some sensing schemes altogether [

7].

A cladding is employed in most optical fiber applications to regulate the index disparity between the core and its surroundings to reduce modal volume. To date, however, successful claddings have not been demonstrated for sapphire that will survive the extreme conditions in which it is typically utilized. At temperatures approaching or exceeding 2000 °C, many candidate claddings will delaminate due to thermal expansion mismatch or diffuse into the core, altering optical properties (not to mention those materials which would form an excellent sapphire cladding from an optics perspective but cannot survive hot and corrosive environments).

Ordered-array photonic crystal fibers (PCFs) have been demonstrated using sapphire [

8,

9] with reduced modal volume but still rely on commercially-available sapphire fiber, which are 50–70 µm in diameter at the smallest. Engineered cross-sectional geometries for the reduction of modal volume have also been theoretically proven recently [

10,

11], but practical fabrication methods for these designs have not yet been developed. Therefore, in lieu of a cladding or fabrication of PCFs and engineered fibers, one remaining method for producing sapphire optical fiber that will support only low order modes is to drastically reduce its diameter well below the minimum diameter commercially available.

We previously demonstrated a wet-acid etching method which was successfully applied to reduce the diameter of a sapphire optical fiber to less than 800 nm while maintaining a smooth, consistent surface [

12]. This method, which summarily prescribes the immersion of sapphire fiber into a mixture of sulfuric and phosphoric acids at temperatures exceeding 340 °C, was employed again in the work presented below to produce an air-clad sapphire optical fiber demonstrating support of only the fundamental LP

01 mode at wavelengths of 783 nm and greater.

2. Materials and Methods

2.1. Sample Production and Etching

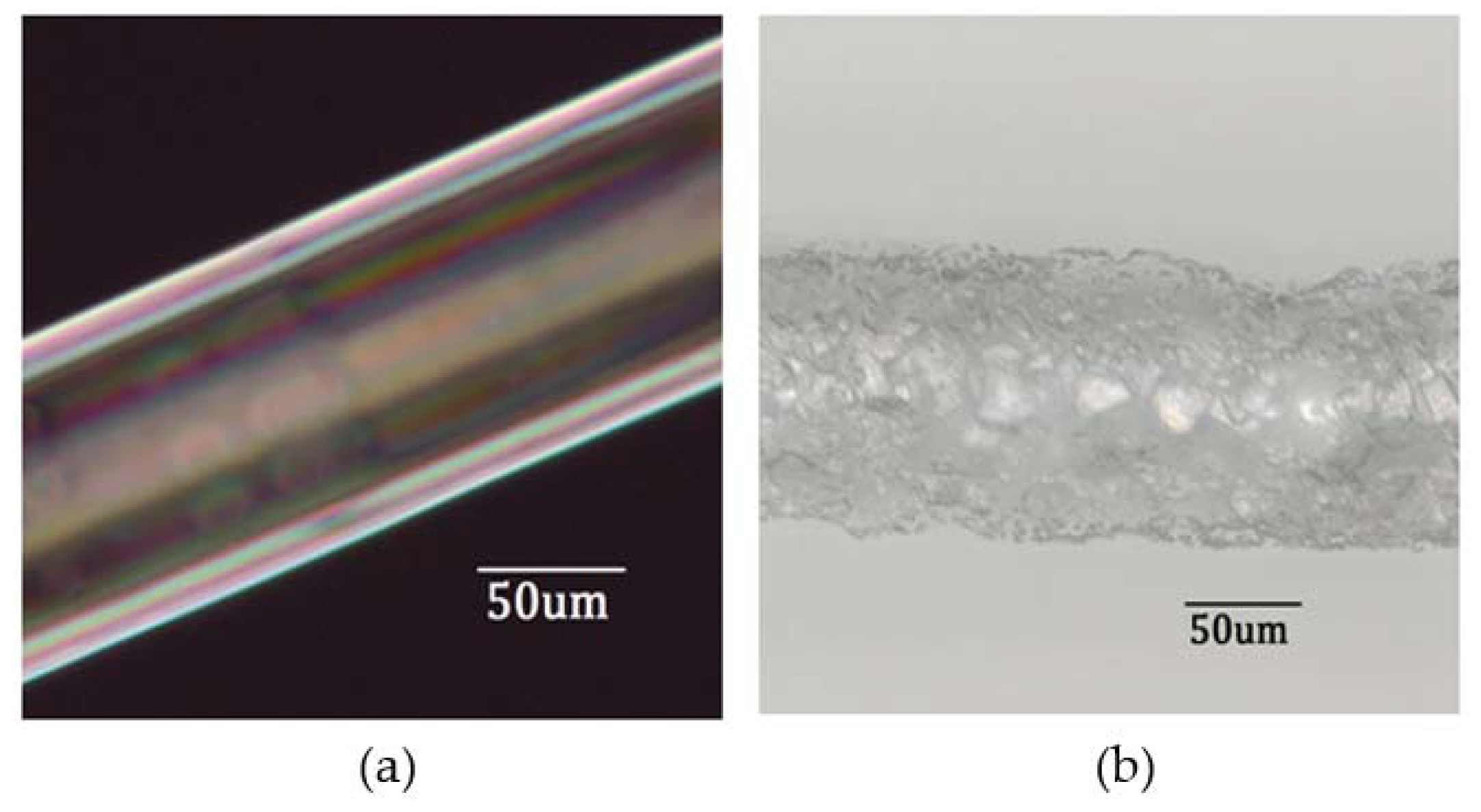

Approximately 15 cm of single crystal sapphire optical fiber (optical c-axis) with an original diameter of 125 µm was cut from a 100 cm segment from Micromaterials, Inc. (Tampa, FL, USA). Early experiments found signal-scattering deposits comprised of aluminum sulfate and aluminum phosphate would form and adhere strongly to the surface of an immersed sapphire fiber during etching, concentrated near the air-acid interface. To prevent adherence of these deposits at this region, a protective borosilicate glass tube with an internal diameter of 140 µm and length of around 5 cm was collapsed over one end of the sapphire fiber using an oxyhydrogen torch, leaving 10 cm of sapphire fiber to be etched. Less than 1 cm of the borosilicate tube was collapsed to reduce any “cladding” effect this region may have; with this seal formed, the acid solution would be prevented from wicking up along the fiber and producing deposits. Accordingly, the shielded 5 cm-length of the sapphire fiber retained its 125 µm diameter throughout, while etching reduced the diameter of the remaining 10 cm exposed length.

A ferrule connector/physical contact (FC/PC) connector was mounted, secured and polished on one end of the sapphire fiber which would remain outside the etching solution; attaching the connector before etching ensured that measurements could be taken between etching sessions without inadvertently altering input conditions.

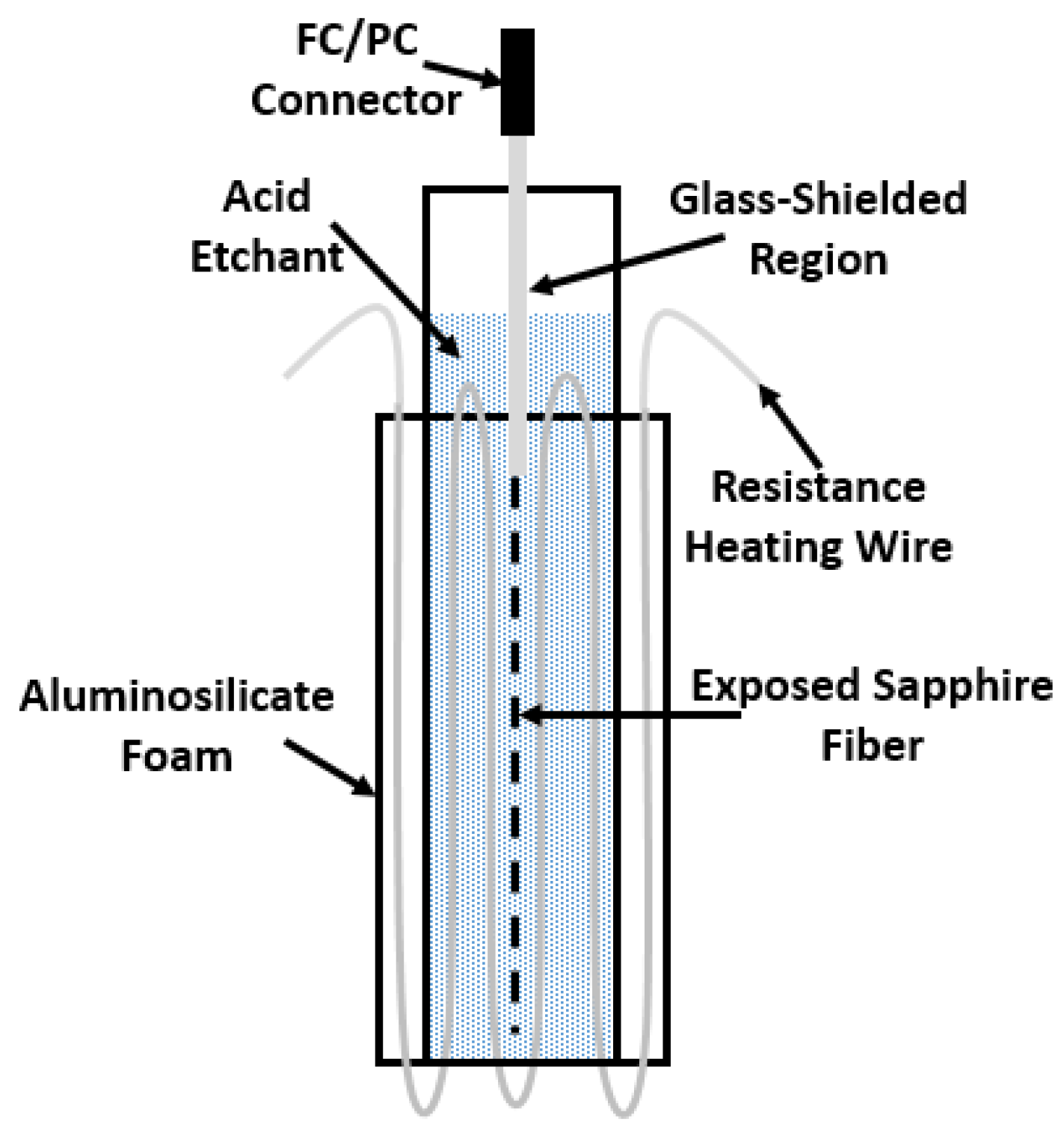

The etching solution was a 3:1 molar ratio mixture of sulfuric acid (98%, Sigma Aldrich, St. Louis, MO, USA) and phosphoric acid (85%, VWR). This solution was contained within a fused quartz tube with an inner diameter of 1.25′′. One end of this 8′′-long tube was collapsed using an oxyhydrogen torch, then placed within custom-made porous aluminosilicate rings to improve thermal distribution during heating. Holes were drilled longitudinally through these rings and resistance heating wire (80% nickel, 20% chromium, 20 gauge, OMEGA Engineering, Norwalk, CT, USA) was wound throughout. This resistance heating wire was connected to a variable transformer (Variac, Cleveland, UK, USA) so that the temperature could be controlled by adjusting to the proper voltage setting. These heating rings were finally enclosed in a polycrystalline alumina tube (Coorstek, Golden, CO, USA) and padded with alumina fiber insulation.

Figure 1 illustrates the etching apparatus in simplified form.

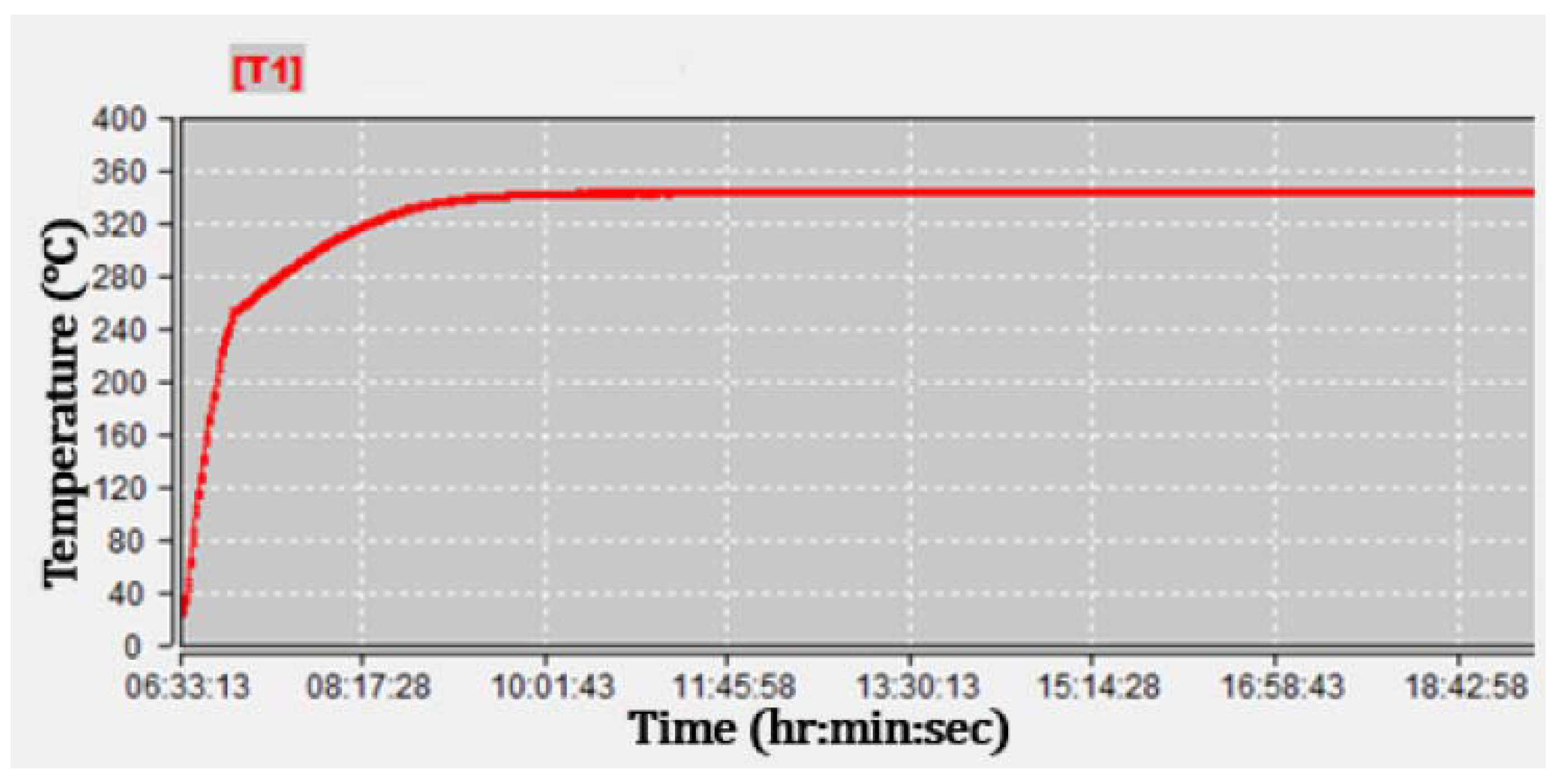

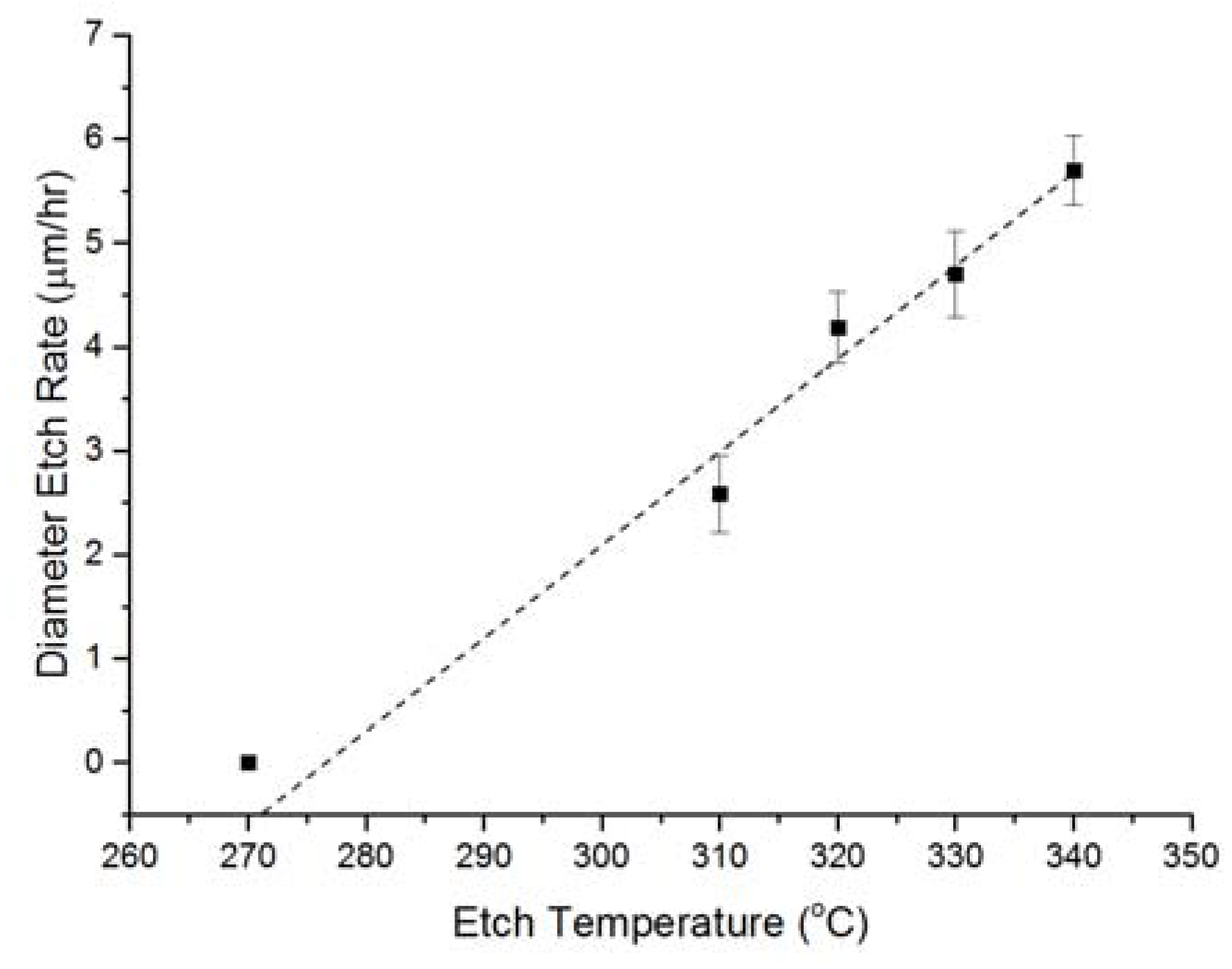

To initiate etching, a thermocouple probe (Omega) was inserted into a small sealed fused quartz tube upon which the sapphire components were previously mounted, and this assembly was immersed in the acid solution at room temperature. The opening of the vessel was enclosed with Teflon tape (with a small outlet for pressure relief), and the voltage was increased to a value optimized to quickly heat the solution without causing rapid boiling of the sulfuric acid component. Etching would typically be allowed to occur for 8–10 h at a time before the sapphire sample was removed for analysis and the etching solution was refreshed, during which the temperature was recorded every 15 s using a Digisense datalogging digital thermocouple reader (Davis Instruments, Vernon Hills, IL, USA).

2.2. Far-Field Modal Analysis

After etching, the diameter of the sapphire fiber was measured using an Olympus BX51 (Waltham, MA, USA) optical microscope and StreamMotion software. After polishing the tip of the fiber using 100 nm diamond lapping film (Ultra Tec, Santa Anna, CA, USA) to remove facets caused by preferential etching of the

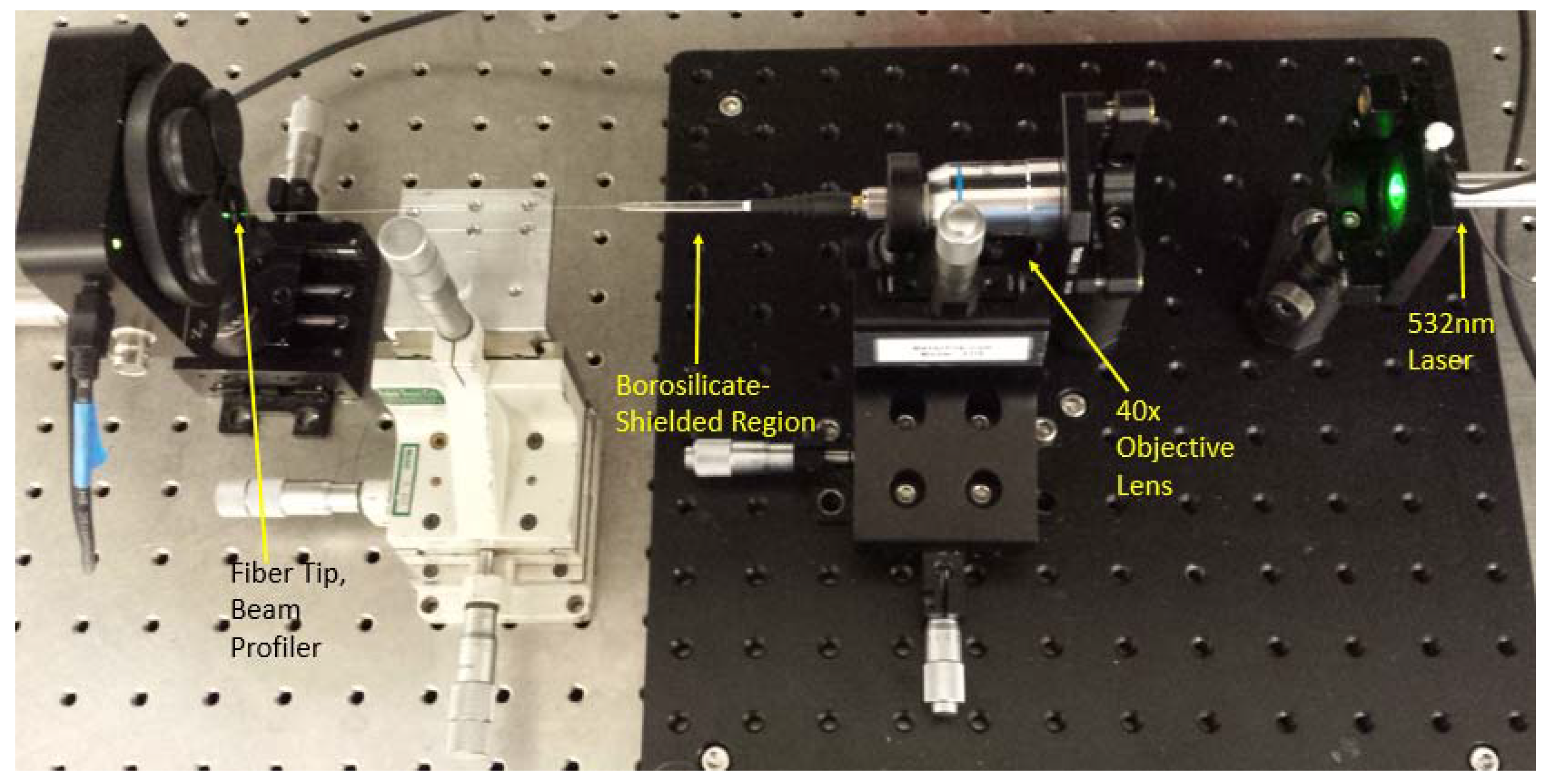

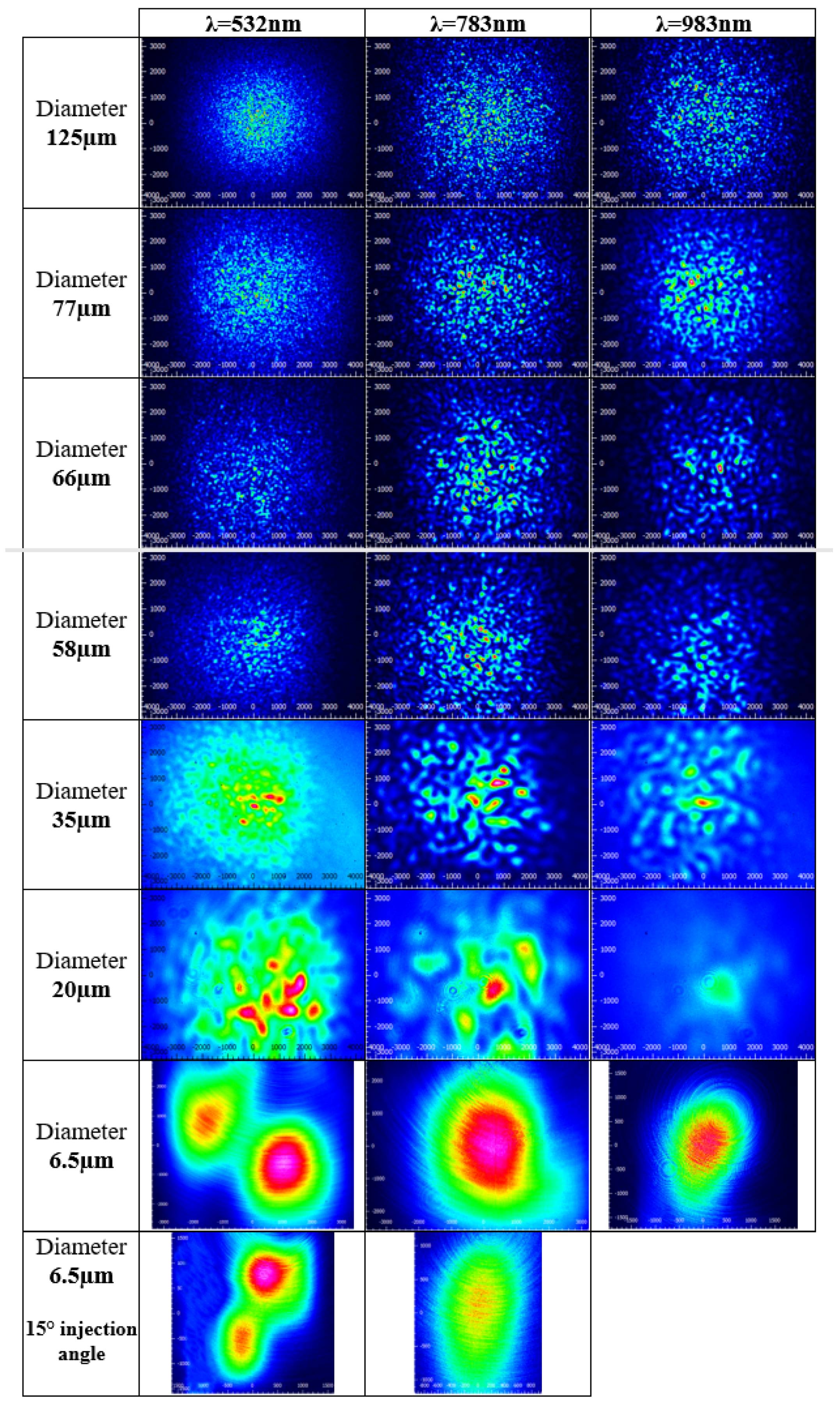

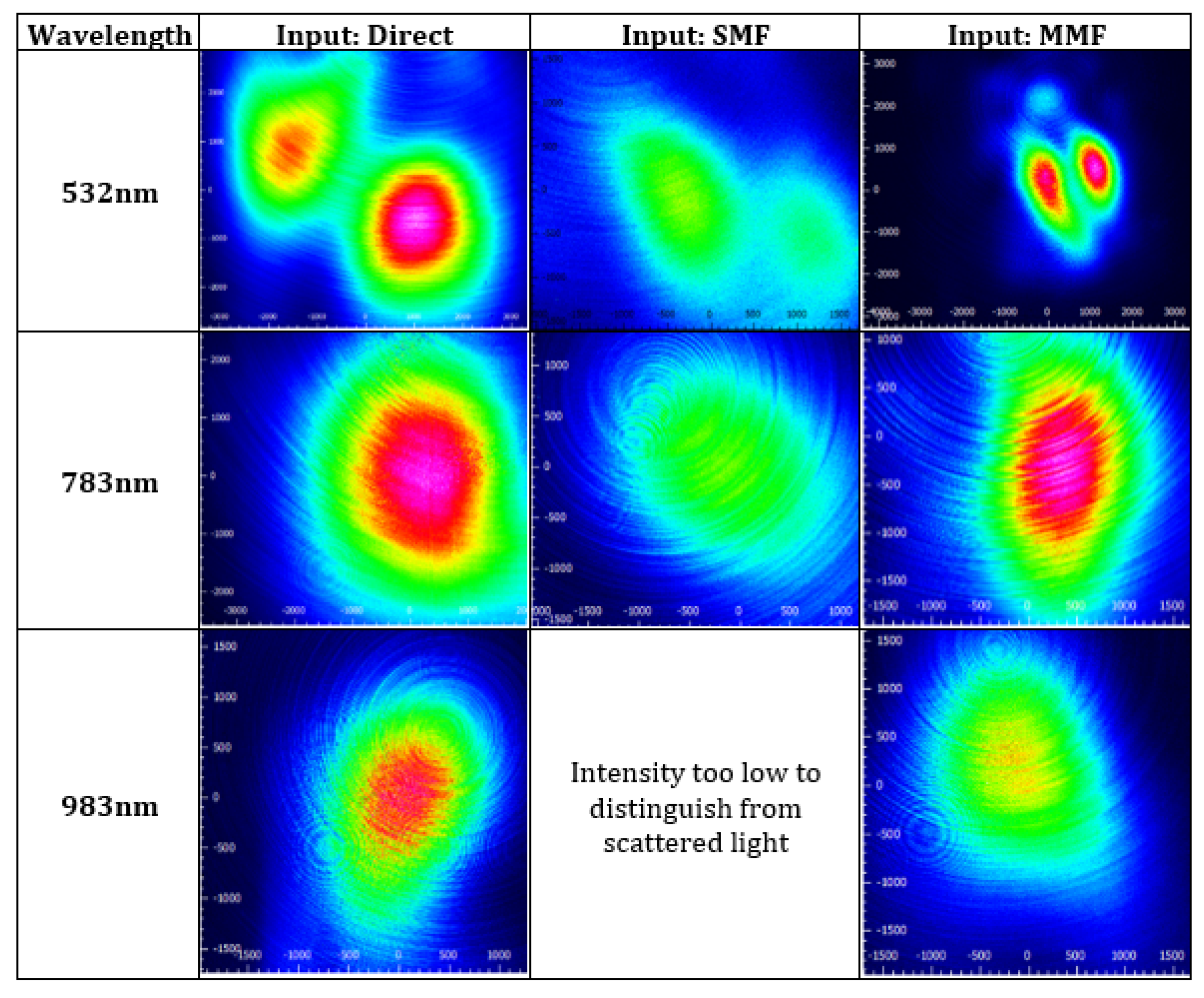

r-plane, the far-field patterns of the reduced-diameter sapphire fiber were captured between etching sessions to collect data at many different diameters. Three 5 mW laser wavelengths were used: 532 nm, 783 nm, and 983 nm (Thorlabs, Newton, NJ, USA) in order to expand the breadth of data collected per measured diameter. The lasers were linearly polarized with a polarization extinction ratio of 4 dB and were mounted at the same angle of rotation for all experiments. These lasers were focused into the fiber using a 40× objective lens, whose numerical aperture (NA) is larger than that of sapphire, ensuring the modal state would be “overfilled” [

13]. A BC-106VIS charge coupled device (CCD) beam profiler (Thorlabs) was used to capture the far-field profiles, which were then catalogued using Thorlabs’ Beam 6.0 software. Most components were mounted on 2-or 3-axis stages to aid alignment. A sample under evaluation using the described setup is visible in

Figure 2.

2.3. Effective Numerical Aperture Measurement

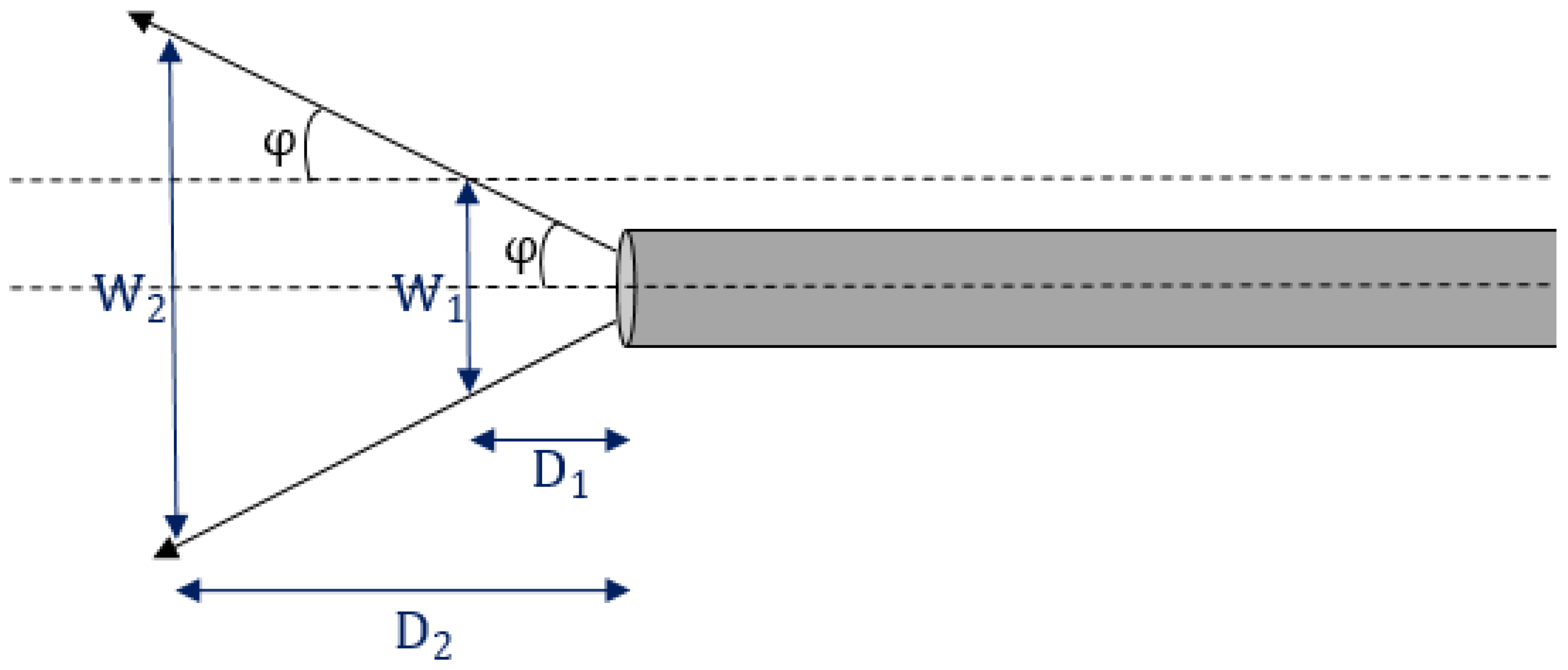

A common numerical aperture measurement method for single-mode fiber was employed to determine the effective

NA of the sapphire fiber at its smallest diameter [

14]. The beam width of the fundamental mode was measured (4σ cutoff intensity) at a nominal distance from the beam profiler (within 2 mm of the detector window) and then measured again when moved 1 mm away from the profiler, illustrated by

Figure 3. The resulting calculation of divergence angle provided an approximate measurement of the effective numerical aperture.

4. Discussion

Theoretical estimations of modal volume for a step-index fiber using standard weakly-guiding approximations [

19] would predict the support of 461–1614 modes at wavelengths of 532–983 nm and an air-clad sapphire fiber diameter of 6.5 µm. Furthermore, to achieve single-mode behavior in air-clad sapphire at this wavelength range, fiber diameters would need to be less than 500 nm or so according to weakly-guiding assumptions. However, it is widely considered that the weakly-guiding approximation, which in large part is based on ray-optics assumptions, does not retain accuracy as conditions reach the single-mode cutoff, where wave considerations are dominant. This is especially true when a large refractive index difference exists between core and cladding (i.e., it is not considered to be “weakly guiding”); while these estimations are still useful and reasonably accurate at larger sapphire fiber diameters and correspondingly large modal volumes, they may not be reliable as core diameter and modal volume is reduced. That said, if parameters of the approximations (such as numerical aperture) that are theoretically derived using ray-optic assumptions are experimentally measured rather than calculated, the accuracy of these simple approximations could be improved in the low modal volume regime.

In fact, it is frequently reported that the effective numerical aperture of sapphire fiber in particular varies greatly from its theoretical

NA due to non-circular cross section (grown fibers are slightly hexagonal due to sapphire’s crystal structure), attenuation factors, large refractive index between itself and its air cladding, and other parameters, some of which seem to become more impactful as fiber diameter decreases and core-cladding interactions become increasingly important. For instance, while the theoretical

NA of air-clad sapphire as calculated by Equation (1) would be around 1.4 at the tested wavelengths, researchers and manufacturers have previously measured effective

NAs of ~0.35 at λ = 2.94 µm for unclad sapphire fiber at a diameter of 300 µm [

6] and ~0.45 at λ = 633 nm and a diameter of 125 µm [

20]. Replacement of the theoretical

NA with a measured effective

NA may therefore improve accuracy of weakly-guiding approximations predicting modal volume for air-clad sapphire of reduced diameter.

To evaluate this consideration in the context of the reported experimental observations, the measured effective numerical aperture of the 6.5 µm-diameter sapphire fiber (

NAeff = 0.090) replaced the theoretical

NA (

NAth = 1.4) in simple weakly-guiding approximations of modal volume for step-index fibers. The effect of this

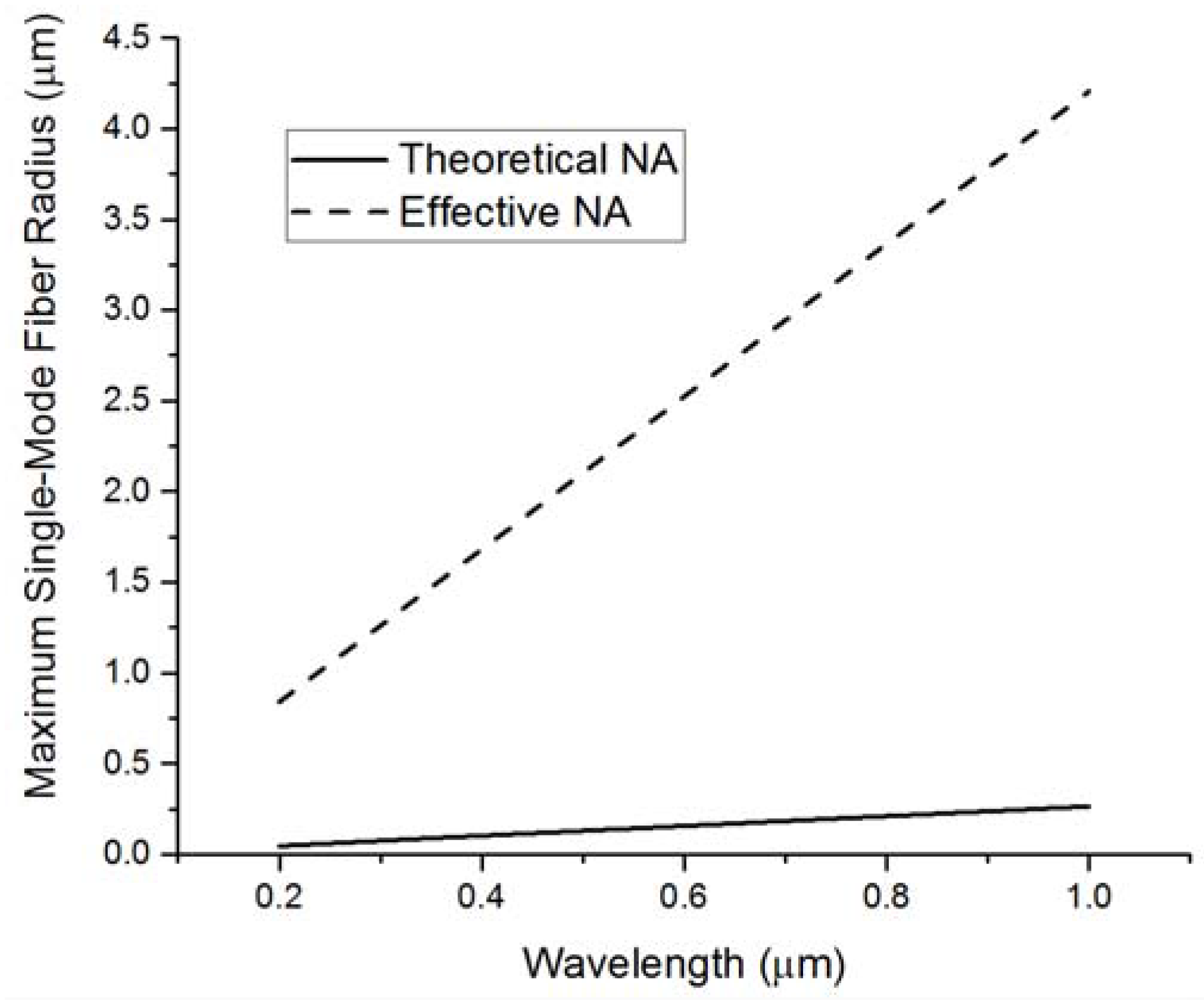

NA value replacement is contrastingly illustrated in

Figure 9, where the calculated maximum radius for air-clad sapphire optical fiber supporting only a single mode is plotted versus input wavelength for both numerical aperture values (theoretical

NA versus measured effective

NA). This plot was generated by solving the

V-parameter equation (Equation (2)) for radius,

a, where

V = 2.405 is the single-mode cutoff.

Using the effective NA measured for the 6.5 µm-diameter sapphire fiber, this calculation predicts that only the fundamental mode would be supported at wavelengths greater than ~760 nm, which is in fact what was observed experimentally; the higher-order LP11 mode profile was observed at a laser wavelength of 532 nm, while the LP01 mode was observed at laser wavelengths of 783 nm and 983 nm. As it appears the effective numerical aperture of sapphire is highly dependent upon fiber diameter in this low modal volume regime, NAeff measurements would need to be taken at any given fiber diameter to improve the accuracy of predictions at other fiber diameters (i.e., it is not likely that this relationship is linear). Extrapolation using the measured NAeff at a diameter of 6.5 µm for the diameter range of 0–9 µm is certainly within a reasonable window of accuracy for purposes of demonstrating this approximation, however. Greater predictive accuracy may be afforded through continued development of wave-based models for low modal volume sapphire optical fiber, but the reported experimentation suggests that legacy ray-based weakly-guiding approximations may be used with considerable accuracy if the effective numerical aperture is measured and utilized in calculations.

5. Conclusions

In this work, very low modal volume was observed in an air-clad single-crystal sapphire optical fiber, with single-mode behavior observed for the first time at laser wavelengths of 783 nm and 983 nm. The stability of far-field mode profile measurements for the 6.5 µm-diameter sapphire fiber was demonstrated through the alteration of input conditions, bolstering confidence in the observed low modal volume. It is possible that some higher order modes are yet supported by sapphire optical fiber of this diameter but are simply too leaky to propagate for substantial lengths; this consideration will be the subject of continued experimentation. For the practical purposes of distributed sensing applications, however, this work has demonstrated that dominant power in a 6.5 µm-diameter sapphire optical fiber is coupled in the lowest order modes in the wavelength range of 532 nm–983 nm.

It was also demonstrated that modal volume calculations using weakly-guiding approximations are inaccurate at these fiber diameters if the theoretical numerical aperture is input, but accuracy is greatly improved if the effective numerical aperture is measured and substituted for the theoretical NA using weakly-guiding approximations. Finally, the discovery that single-mode behavior is exhibited at sapphire fiber diameters on the microscale rather than the nanoscale predicted using original assumptions is of huge benefit to the extreme-environment sensing community; sapphire microfibers are much more easily manufactured, handled, and deployed than nanofibers, and the power capacity of a microfiber will be exponentially greater than a nanofiber. Additionally, detection resolutions may be increased in distributed sensors and sensing schemes requiring low modal volume or single mode behavior (such as Bragg gratings) are now enabled in sapphire.