Swirling Gas Jet-Assisted Laser Trepanning for a Galvanometer-Scanned CO2 Laser

Abstract

:1. Introduction

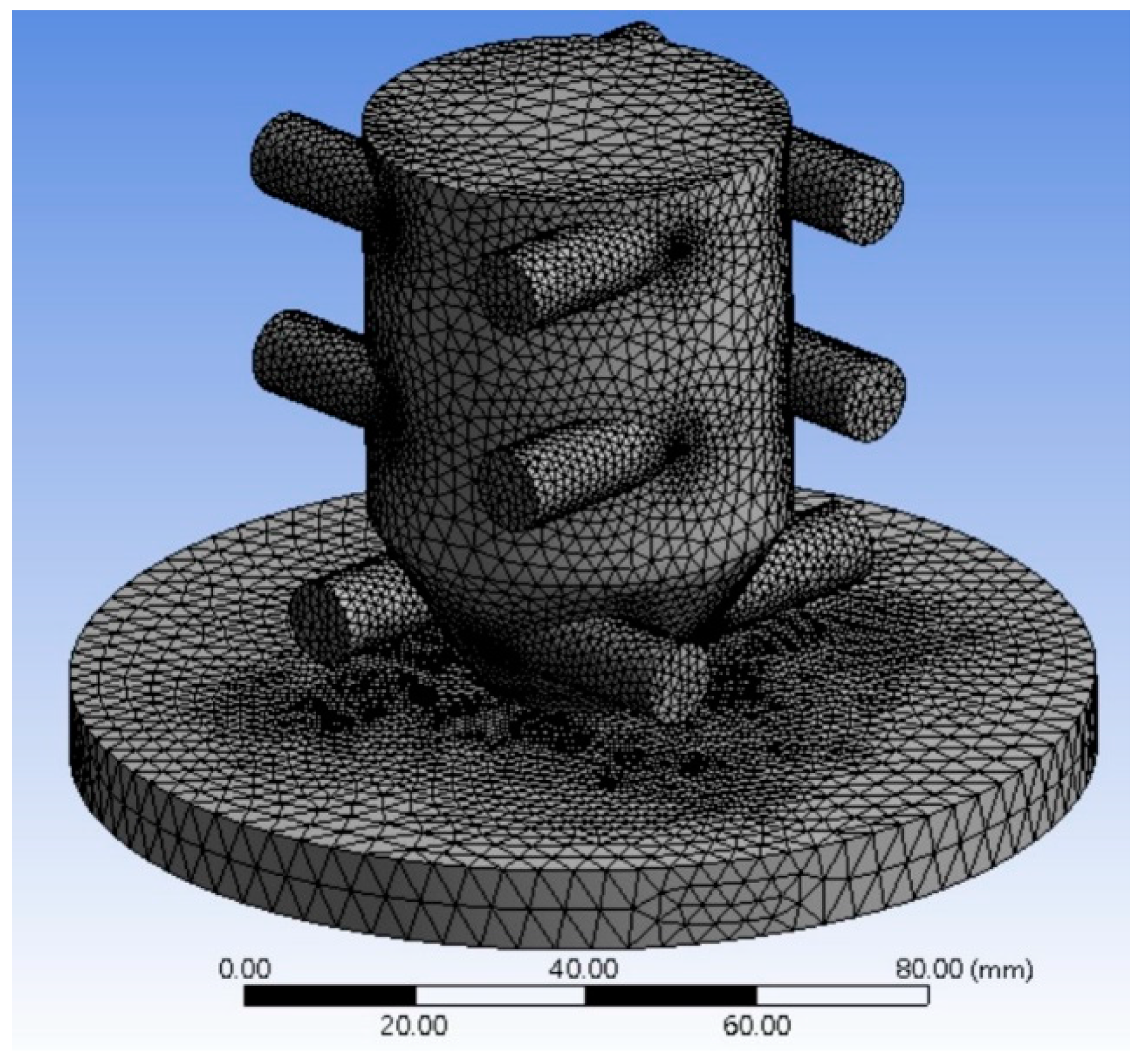

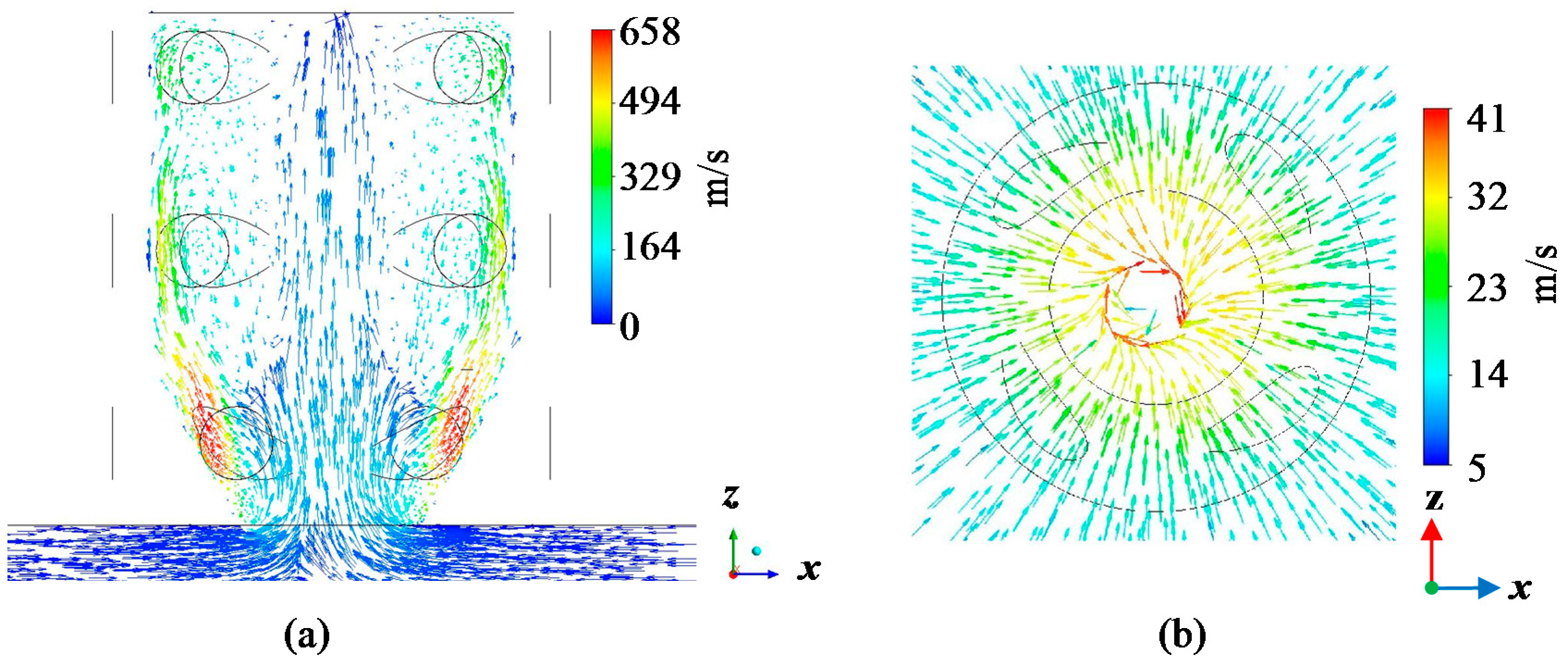

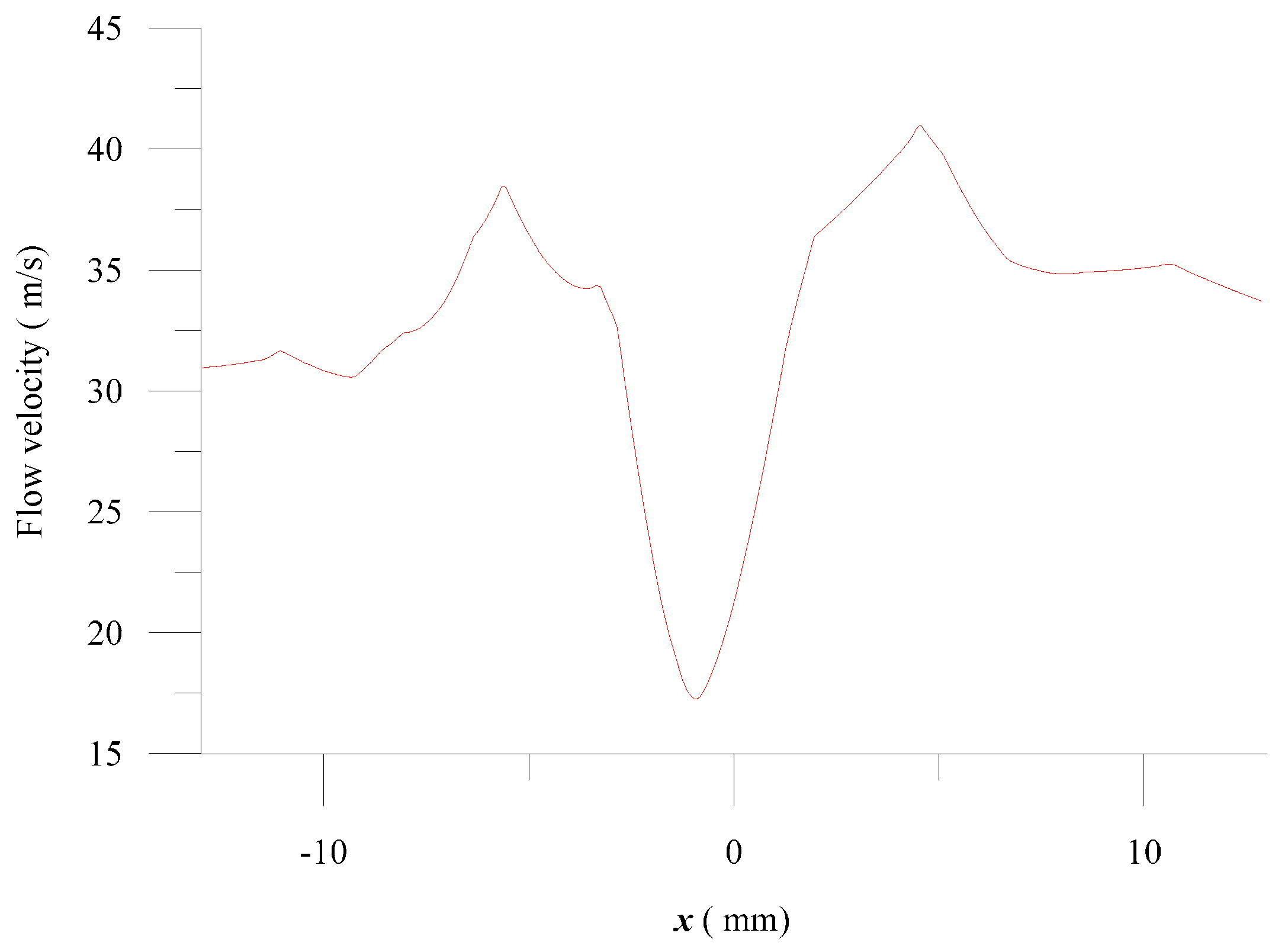

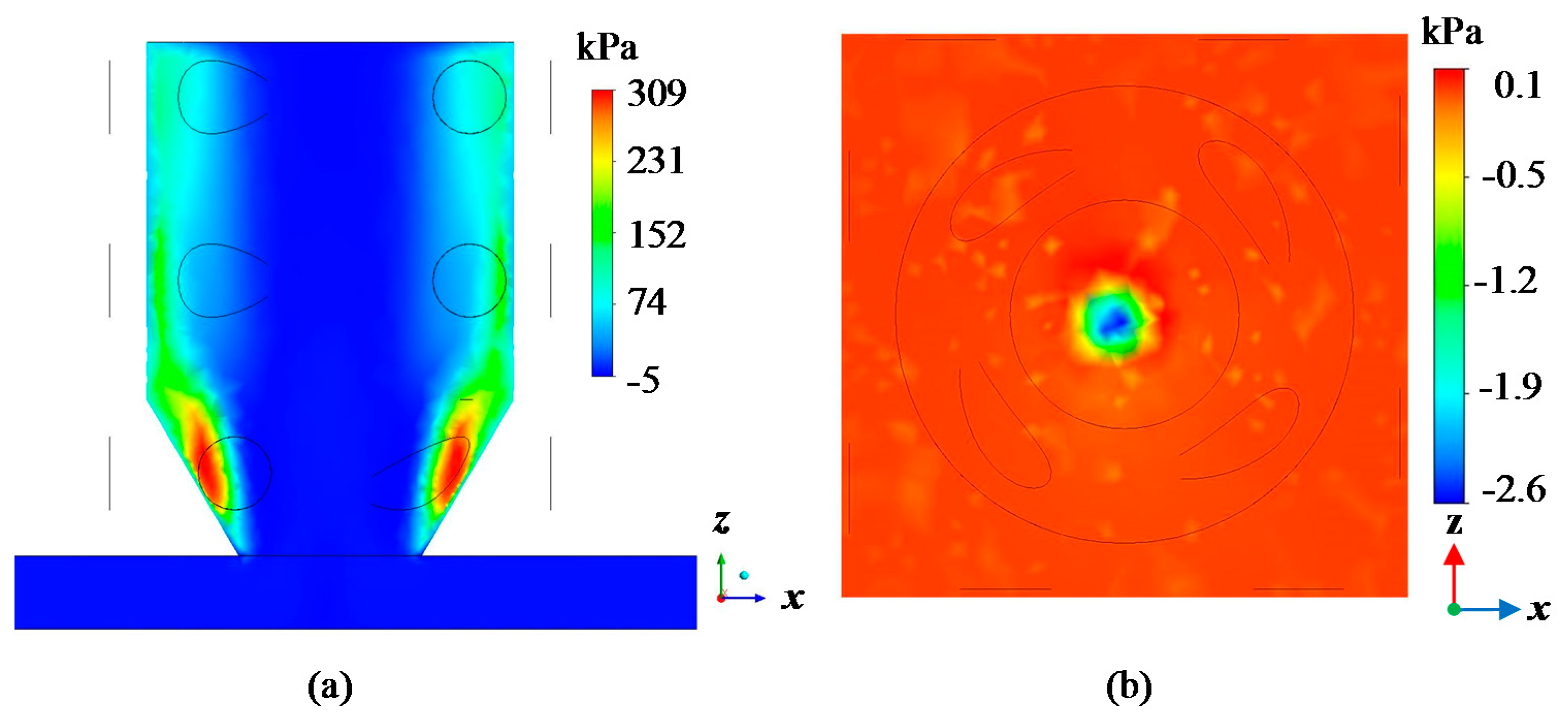

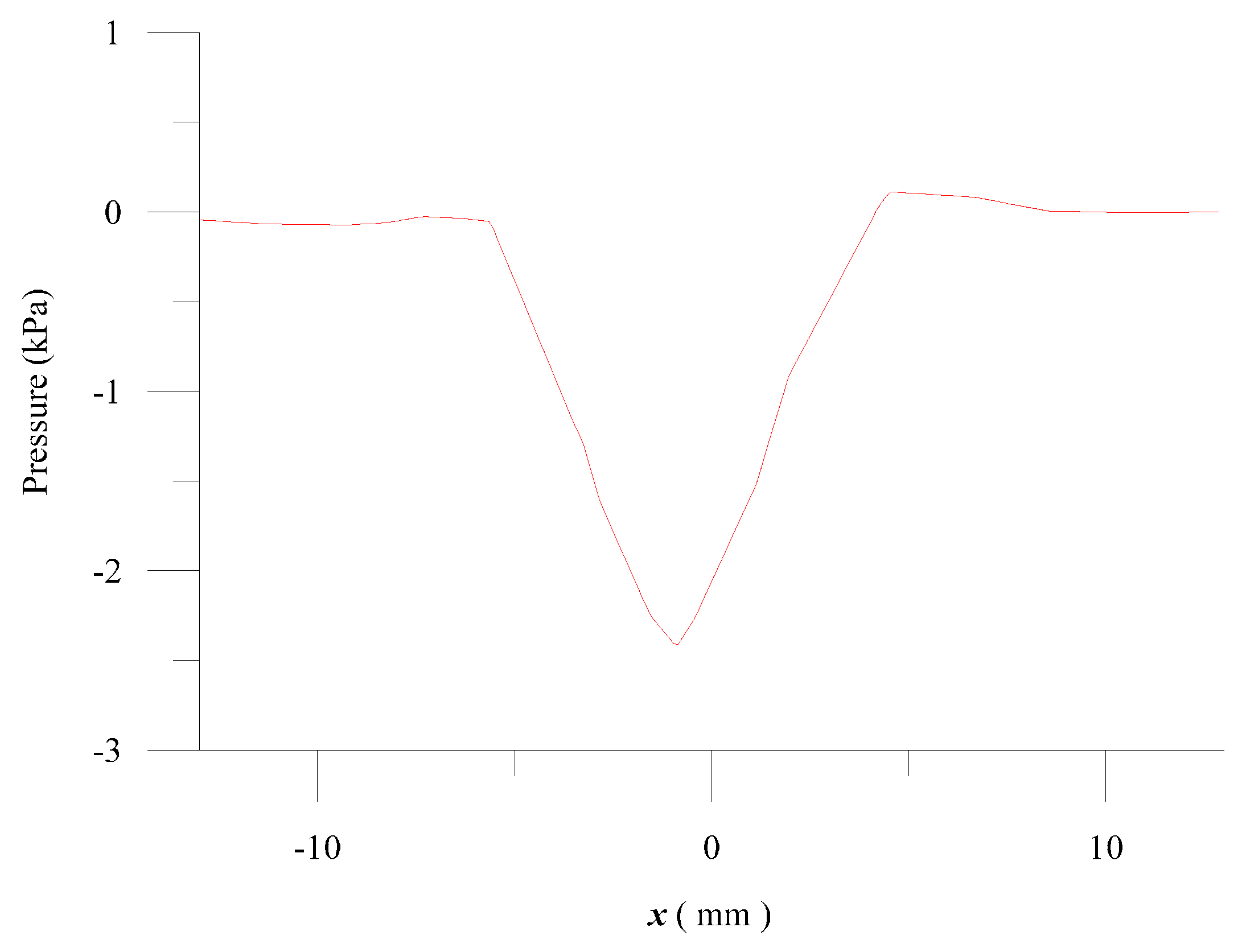

2. Model of the Computation Domain by the Assisted Gas Jets

3. Numerical Results

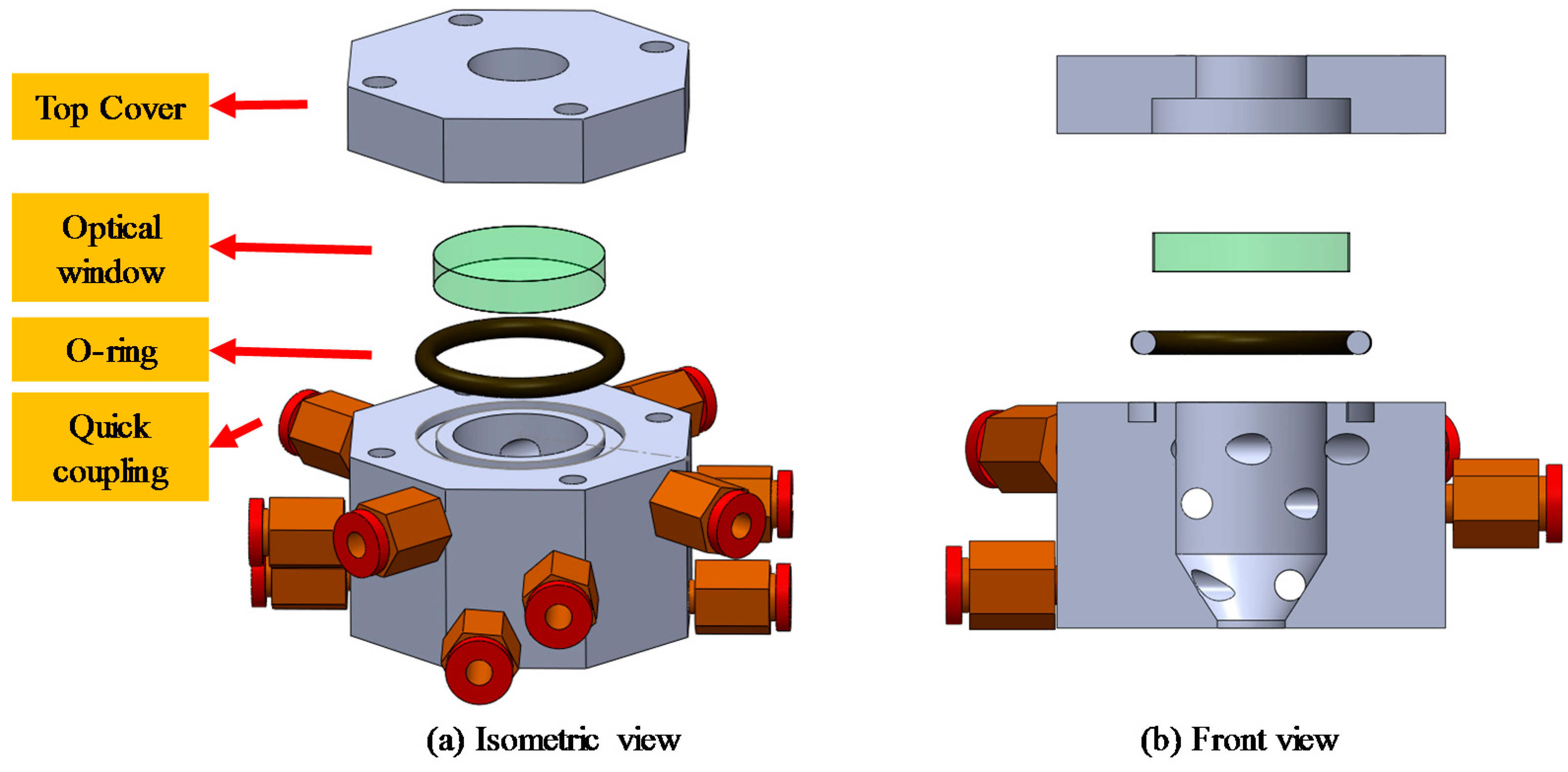

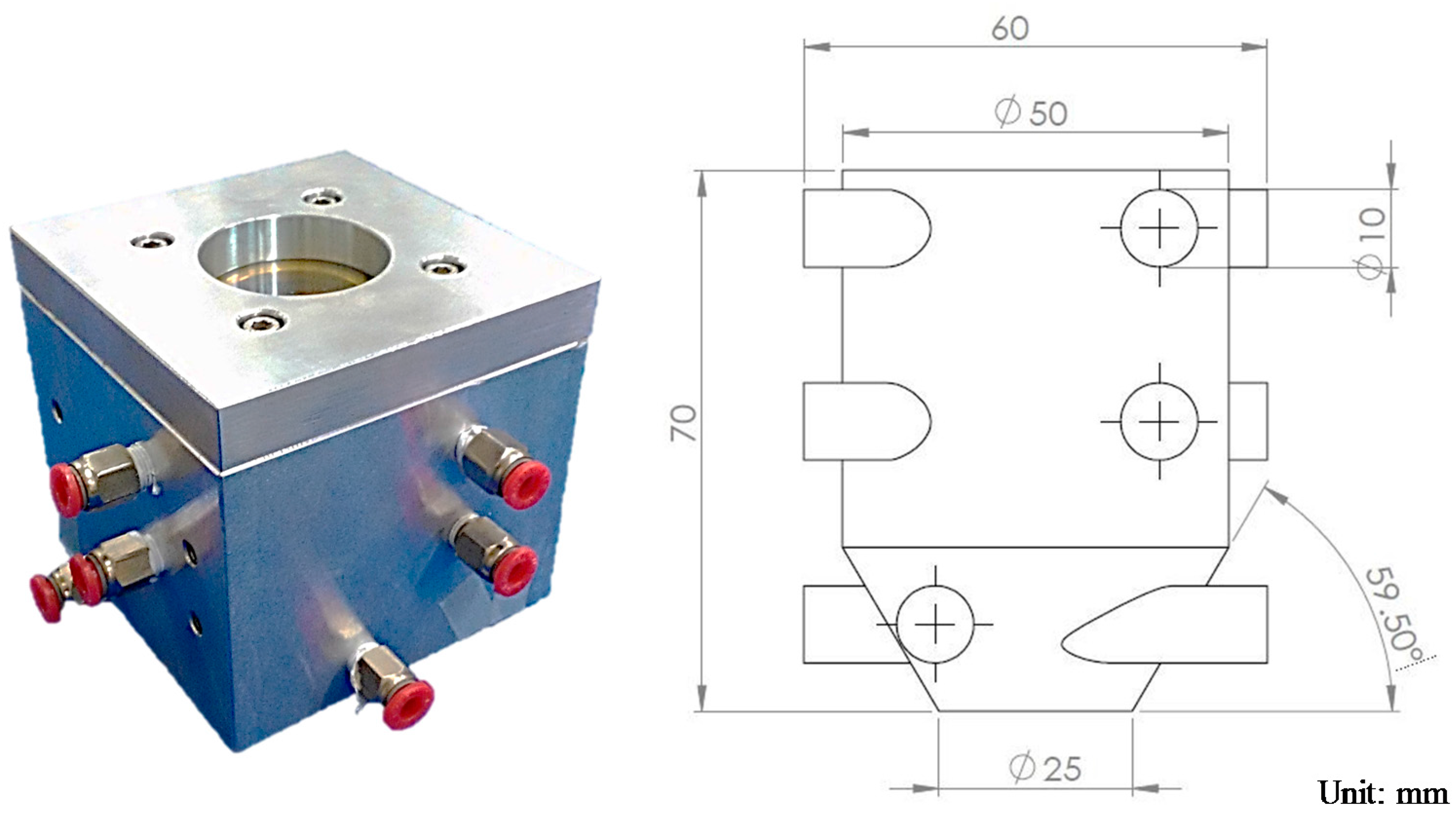

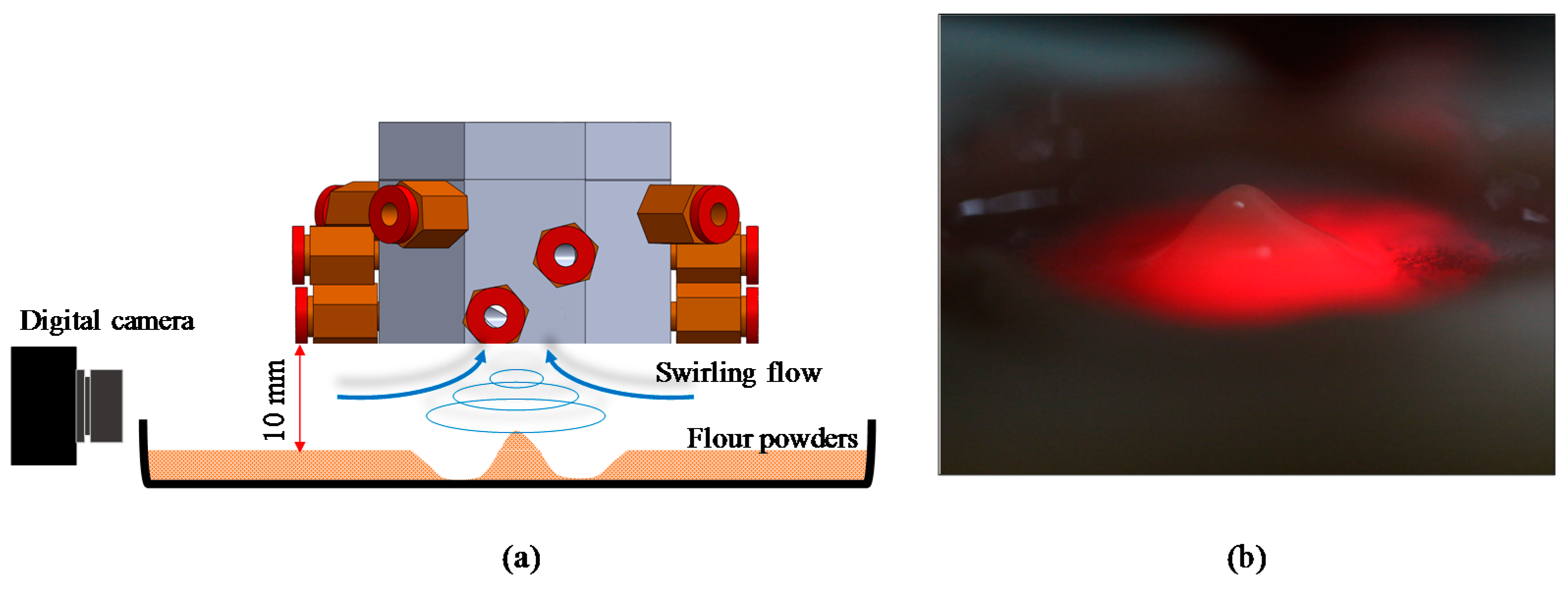

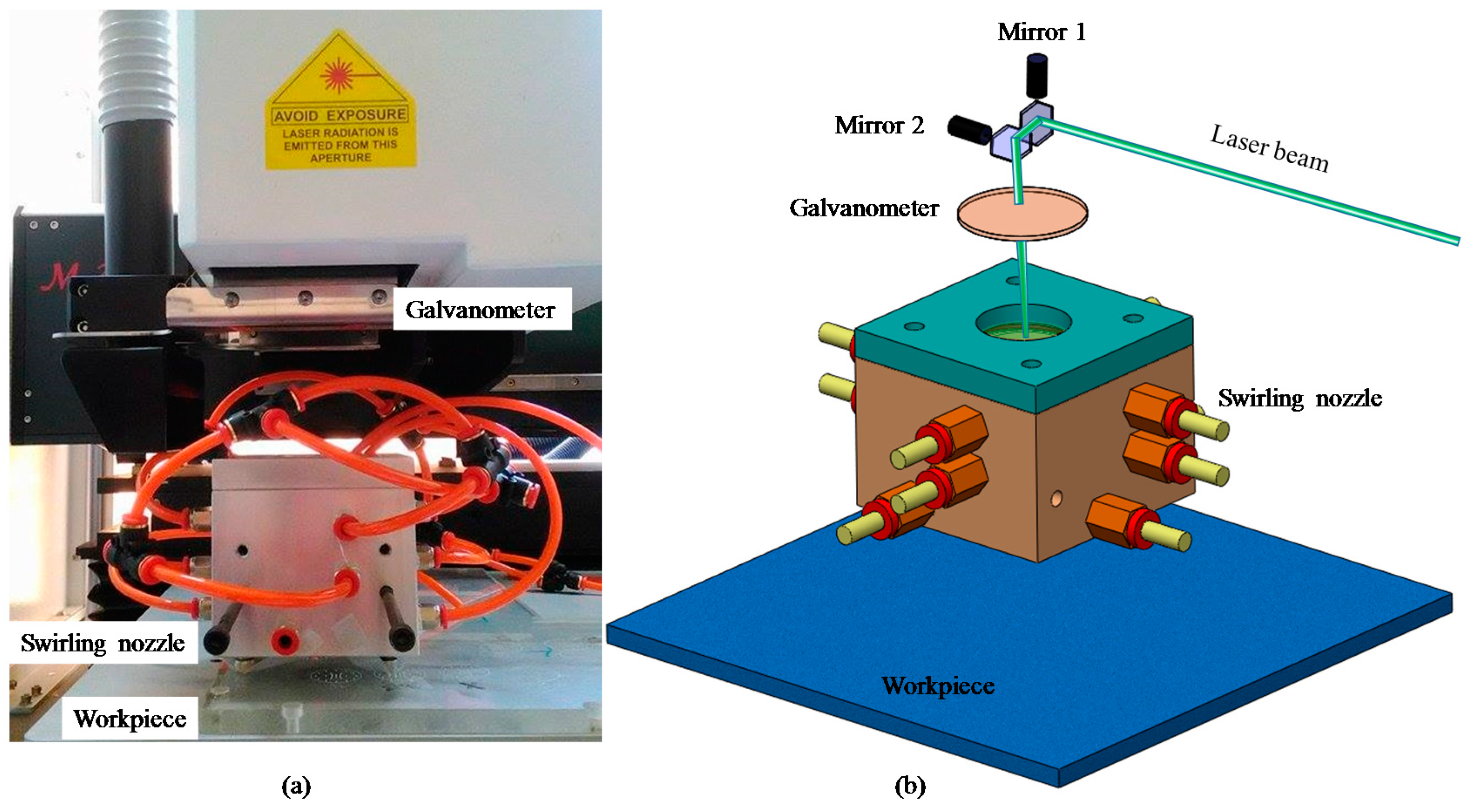

4. Experiment

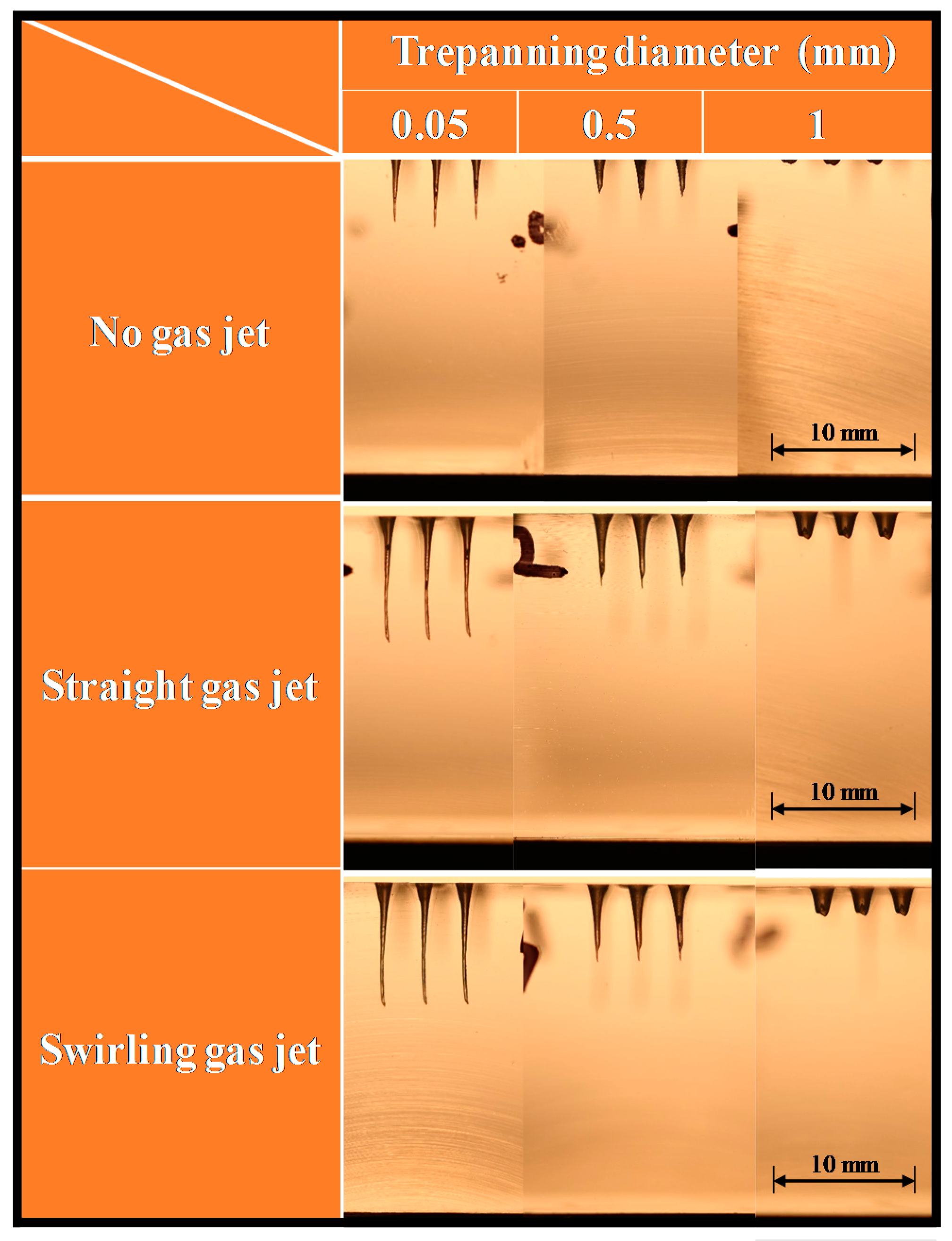

4.1. Gas Flow Visualization

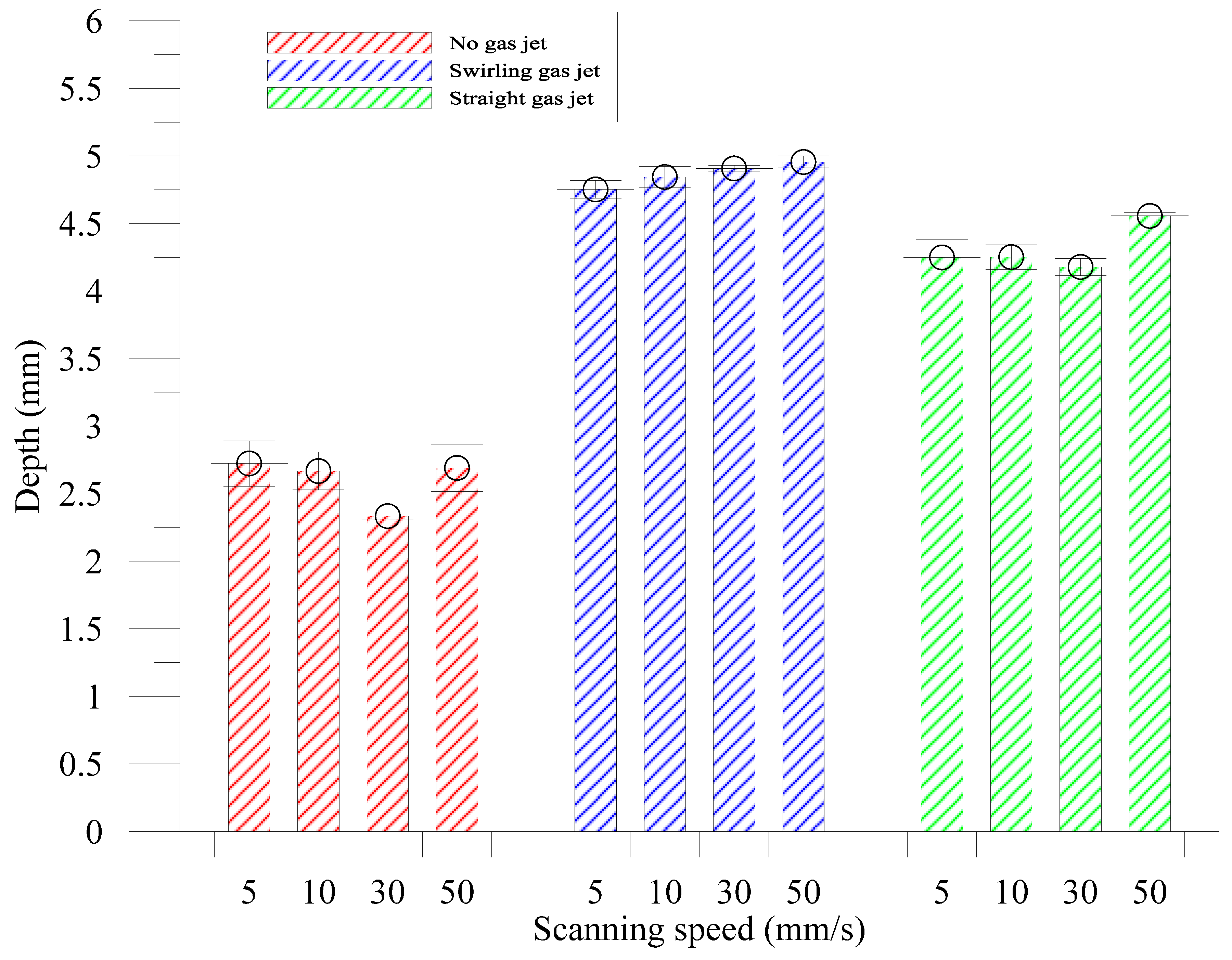

4.2. Laser Trepanning Depth Comparison

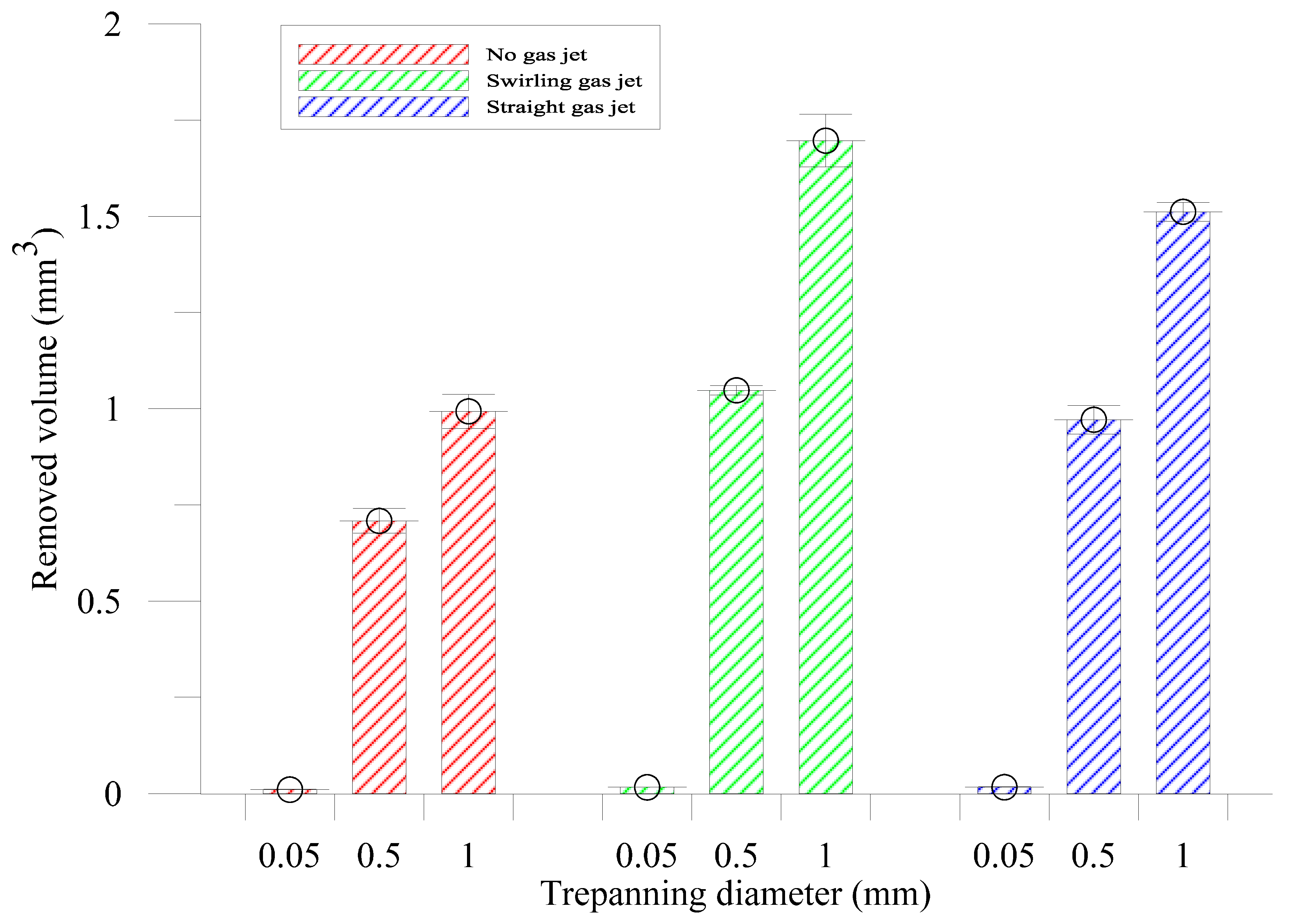

4.3. Laser Trepanning Volume Comparison

5. Conclusions

Supplementary Files

Supplementary File 1Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sezer, H.; Li, L.; Leigh, S. Twin gas jet-assisted laser drilling through thermal barrier-coated nickel alloy substrates. Int. J. Mach. Tools Manuf. 2009, 49, 1126–1135. [Google Scholar] [CrossRef]

- Ho, C.-C.; Liang, Y.-S. Research and development of high-speed laser scanning galvanometer system. Smart Sci. 2013, 1, 82–85. [Google Scholar] [CrossRef]

- Karnakis, D.; Rutterford, G.; Knowles, M. High power DPSS laser micro-machining of stainless steel and silicon for device singulation. Pulse 2007, 1000, 3. [Google Scholar]

- Mishra, S.; Yadava, V. Laser beam micromachining (LBMM)—A review. Opt. Lasers Eng. 2015, 73, 89–122. [Google Scholar] [CrossRef]

- Meng, F.; Wang, H. CAD/CAM software framework design for the laser micromachining device driven by two stages. In Proceedings of the 2010 11th International Conference on Electronic Packaging Technology & High Density Packaging (ICEPT-HDP), Xi’an, China, 16–19 August 2010; pp. 902–905. [Google Scholar]

- Chak, S.K. Electrochemical discharge machining-discharge generation: A review. J. Mater. Sci. Mech. Eng. 2015, 2, 49–53. [Google Scholar]

- Kacar, E.; Mutlu, M.; Akman, E.; Demir, A.; Candan, L.; Canel, T.; Gunay, V.; Sınmazcelik, T. Characterization of the drilling alumina ceramic using Nd: YAG pulsed laser. J. Mater. Process. Technol. 2009, 209, 2008–2014. [Google Scholar] [CrossRef]

- Biffi, C.; Previtali, B. Spatter reduction in nanosecond fibre laser drilling using an innovative nozzle. Int. J. Adv. Manuf. Technol. 2013, 66, 1231–1245. [Google Scholar] [CrossRef]

- Ho, C.-C.; Chen, Y.-M.; Hsu, J.-C.; Chang, Y.-J.; Kuo, C.-L. Characteristics of the effect of swirling gas jet assisted laser percussion drilling based on machine vision. J. Laser Appl. 2015, 27, 042001. [Google Scholar] [CrossRef]

- Hsu, J.-C.; Liao, C.-Y.; Ho, C.-C.; Chang, Y.-J.; Kuo, C.L. Experiment on intermittent gas jet assisted modulated fiber laser drilling. In Applied Mechanics and Materials; Trans Tech Publication Ltd.: Zurich, Switzerland, 2014; pp. 91–95. [Google Scholar]

- Hsu, J.-C.; Lin, W.-Y.; Chang, Y.-J.; Ho, C.-C.; Kuo, C.-L. Continuous-wave laser drilling assisted by intermittent gas jets. Int. J. Adv. Manuf. Technol. 2015, 79, 449–459. [Google Scholar] [CrossRef]

- Rodden, W.; Kudesia, S.; Hand, D.; Jones, J. Use of “assist” gas in the laser drilling of titanium. J. Laser Appl. 2001, 13, 204–208. [Google Scholar] [CrossRef]

- Low, D.; Li, L.; Corfe, A. Effects of assist gas on the physical characteristics of spatter during laser percussion drilling of NIMONIC 263 alloy. Appl. Surf. Sci. 2000, 154, 689–695. [Google Scholar] [CrossRef]

- Khan, A.; Celotto, S.; Tunna, L.; O’Neill, W.; Sutcliffe, C. Influence of microsupersonic gas jets on nanosecond laser percussion drilling. Opt. Lasers Eng. 2007, 45, 709–718. [Google Scholar] [CrossRef]

- Xiahui, T.; Haihong, Z.; Guofu, Z.; Shiming, L.; Zaiguang, L. Study on aerodynamic nozzle specialized for laser welding. Laser Technol. 2000, 2, 9. [Google Scholar]

- Lei, H.; Yi, Z. Technological study of laser cutting silicon steel controlled by rotating gas flow. Opt. Laser Technol. 2009, 41, 328–333. [Google Scholar] [CrossRef]

- Boutinguiza, M.; Pou, J.; Lusquinos, F.; Quintero, F.; Soto, R.; Perez-Amor, M.; Watkins, K.; Steen, W. CO2 laser cutting of slate. Opt. Lasers Eng. 2002, 37, 15–25. [Google Scholar] [CrossRef]

- Tsai, D.-Y.; Lin, J. Characteristics of the plume particles removed by a swirling flow nozzle in laser ablation. Opt. Laser Technol. 2007, 39, 219–224. [Google Scholar] [CrossRef]

- Dahotre, N.B.; Harimkar, S.P. Laser Fabrication and Machining of Materials; Springer: Berlin/Heidelberg, Germany, 2008; Volume 51. [Google Scholar]

- ANSYS, Inc. ANSYS Fluent Theory Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2013. [Google Scholar]

- Ho, C.-C.; Luo, Y.-H.; Chang, Y.-J.; Hsu, J.-C.; Kuo, C.-L. Mask assisted laser percussion drilling. J. Laser Micro Nanoeng. 2016, 11, 41–45. [Google Scholar] [CrossRef]

- Beck, T.; Bostanjoglo, G.; Kugler, N.; Richter, K.; Weber, H. Laser beam drilling applications in novel materials for the aircraft industry. Proceedings Laser Materials Processing Conference, San Diego, CA, USA, 17–20 November 1997; Laser Institute of America: Orlando, FL, USA, 1997. [Google Scholar]

- Zeng, D.; Latham, W.; Kar, A. Temperature distributions due to annular laser beam heating. J. Laser Appl. 2005, 17, 256–262. [Google Scholar] [CrossRef]

| Analysis Type | Steady-State |

|---|---|

| Turbulence model | k-ε model |

| Air type | air at 25 °C |

| Boundary condition | Reference pressure: 1 atm |

| Gas inlet P1: 300 kPa | |

| Gas outlet P2: 30 kPa | |

| Minimum mesh size | 0.09 (mm) |

| Maximum mesh size | 18.70 (mm) |

| Number of mesh nodes | 43,791 |

| Mesh Elements | 225,630 |

| Laser (Synrad Series 48 Model) | |

|---|---|

| Laser source | CO2 |

| Laser radiation energy | 10 W |

| Laser wavelength | 10.6 μm |

| Focal length | 170 mm |

| Beam quality | M2 < 1.2 |

| Beam diameter | 6.6 mm |

| Beam divergence | 4 mR |

| Rise time | <150 μs |

| Inlet gas pressure P1 | 300 kPa |

| Outlet gas pressure P2 | 30 kPa |

| Galvanometer scanner (Miniscan II, Raylase) | |

| Scan speed | 7000 mm/s |

| Repeatability | 20 μm |

| Field size | 100 × 100 mm2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, C.-C.; Shen, K.-Y.; Chen, C.-S.; Chang, Y.-J.; Hsu, J.-C.; Kuo, C.-L. Swirling Gas Jet-Assisted Laser Trepanning for a Galvanometer-Scanned CO2 Laser. Appl. Sci. 2017, 7, 502. https://doi.org/10.3390/app7050502

Ho C-C, Shen K-Y, Chen C-S, Chang Y-J, Hsu J-C, Kuo C-L. Swirling Gas Jet-Assisted Laser Trepanning for a Galvanometer-Scanned CO2 Laser. Applied Sciences. 2017; 7(5):502. https://doi.org/10.3390/app7050502

Chicago/Turabian StyleHo, Chao-Ching, Ke-Ying Shen, Chang-Sheng Chen, Yuan-Jen Chang, Jin-Chen Hsu, and Chia-Lung Kuo. 2017. "Swirling Gas Jet-Assisted Laser Trepanning for a Galvanometer-Scanned CO2 Laser" Applied Sciences 7, no. 5: 502. https://doi.org/10.3390/app7050502