Adhesion Promoters in Bituminous Road Materials: A Review

Abstract

:Featured Application

Abstract

1. Introduction

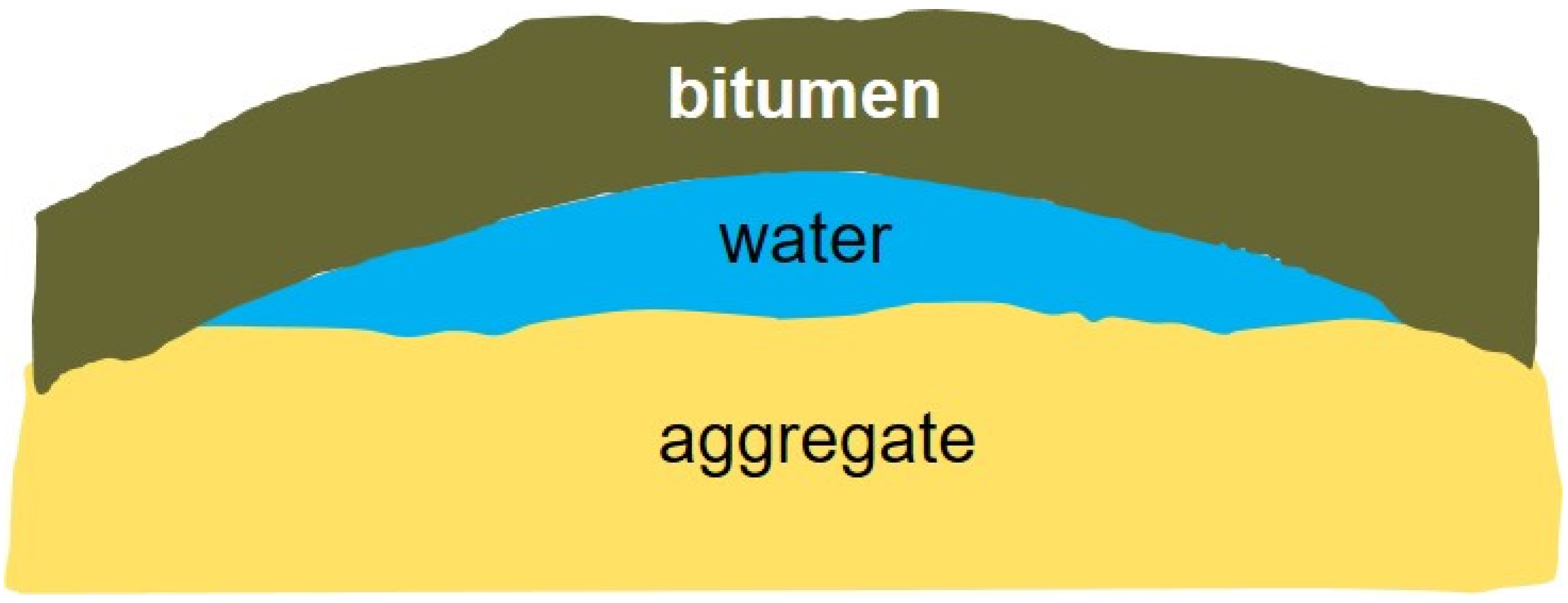

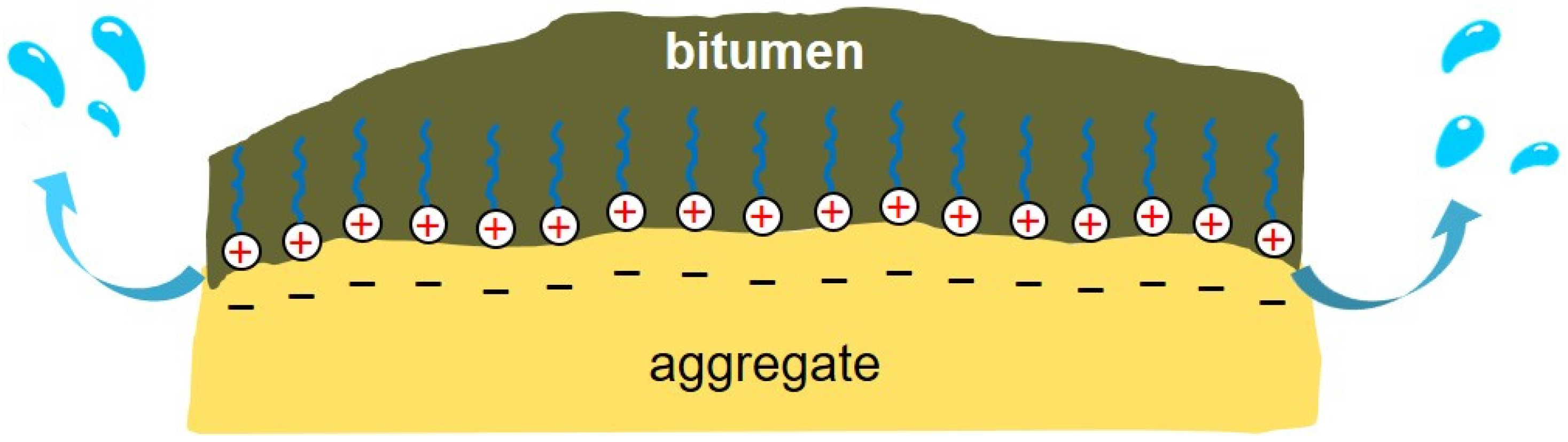

2. The Structure of Bitumen and Its Interaction with Mineral Aggregates

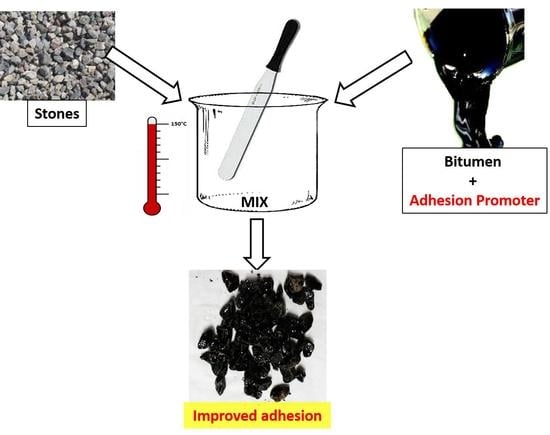

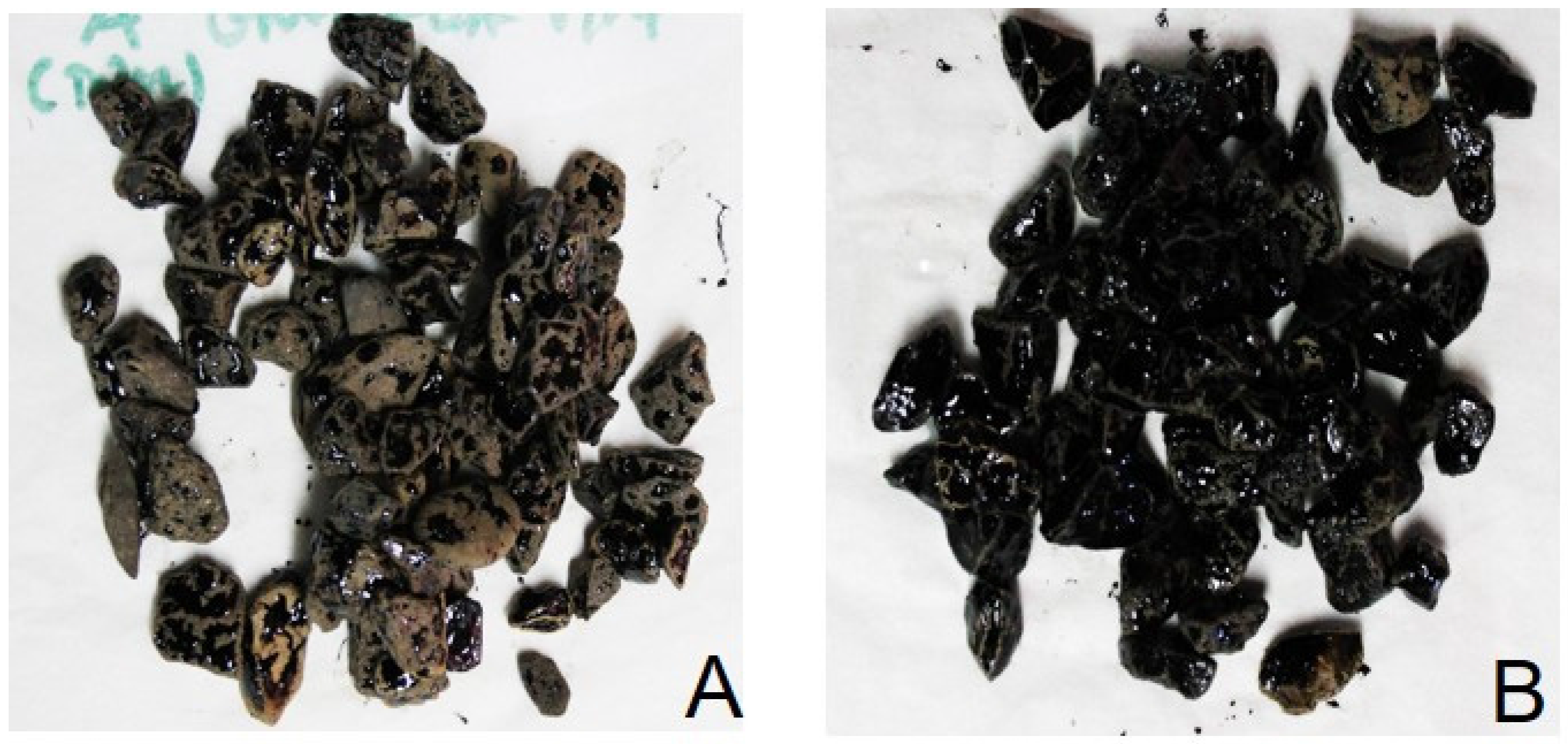

3. Survey of Types of Adhesion Promoters Currently Used in the Asphalt Industry and Their Functions

4. Effects of Adhesion Promoters on the Mechanical Performances of Modified Bitumen

5. Conclusions and Suggested Future Research

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| APs | adhesion promoters |

| ASAs | anti-strip additives |

| AAPs | active adhesion promoters |

| AMAPs | amine-based adhesion promoters |

| FGPs | food grade phospholipids |

| HMA | hot-mix asphalt |

| OSAPs | organosilane-based adhesion promoters |

| PAPs | passive adhesion promoters |

| PPA | polyphosphoric acid |

| SBS | styrene butadiene styrene |

| WMA | warm-mix asphalt |

References

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid. Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef] [PubMed]

- Loeber, L.; Muller, G.; Morel, J.; Sutton, O. Bitumen in colloid science: A chemical, structure and rheological approach. Fuel 1998, 77, 1443–1450. [Google Scholar] [CrossRef]

- Briscoe, O.E. Asphalt Rheology: Relationship to Mixture; ASTM Spec. Publ. 941, American Society for Testing and Materials: Philadelphia, PA, USA, 1987. [Google Scholar]

- European Asphalt Pavement Association. The Use of Warm Mix Asphalt. EAPA Position Paper. Available online: http://www.eapa.org/usr_img/position_paper/the_use_of_warm_mix_asphalt_january_2010.pdf (accessed on 14 March 2017).

- Rubio, C.; Martínez, G.; Baena, L.; Moreno, F. Warm mix asphalt: An overview. J. Clean. Prod. 2012, 24, 76–84. [Google Scholar] [CrossRef]

- Aman, M.Y.; Hamzah, M.O. Effects of Anti-Stripping Additives on Moisture Sensitivity of Warm Porous Asphalt Mixtures. IJCEM 2014, 1, 10–16. [Google Scholar]

- Kakar, M.R.; Hamzah, M.O.; Valentin, J. A review on moisture damages of hot and warm mix asphalt and related investigations. J. Clean. Prod. 2015, 99, 39–58. [Google Scholar] [CrossRef]

- Kim, Y.R.; Pinto, I.; Park, S.W. Experimental evaluation of anti-stripping additives in bituminous mixtures through multiple scale laboratory test results. Constr. Build. Mater. 2012, 29, 386–393. [Google Scholar] [CrossRef]

- Labib, M.E. Asphalt-aggregate interactions and mechanisms for water stripping. Fuel 1992, 37, 1472–1481. [Google Scholar]

- Kennedy, T.W. Prevention of Water Damage in Asphalt in Mixtures in Evaluation and Prevention of Water Damage to Asphalt Pavement Materials Asphalt; Ruth, B.E., Ed.; American Society for Testing and Materials: Philadelphia, PA, USA, 1985; pp. 119–133. [Google Scholar]

- Bagampadde, U.; Isacsson, U.; Kiggundu, B.M. Classical and contemporary aspects of stripping in bituminous mixtures. Road Mater. Pavement Des. 2004, 5, 7–45. [Google Scholar] [CrossRef]

- Huurman, M.; Mo, L.; Woldekidan, M.F.; Khedoe, R.N.; Moraal, J. Overview of the LOT meso mechanical research into porous asphalt raveling. In Advanced Testing and Characterization of Bituminous Materials; CRC Press, Taylor & Francis Group: Boca Raton, Florida, FL, USA, 2009; pp. 507–517. [Google Scholar]

- Kluttz, R.; Jellema, E.; Woldekidan, M.; Huurman, M. Highly Modified Bitumen for Prevention of Winter Damage in OGFCs. Airfield Highway Pavement 2013, 1075–1087. [Google Scholar] [CrossRef]

- Sirota, E.B. Physical Structure of Asphaltenes. Energy Fuels 2005, 19, 1290–1296. [Google Scholar]

- Yen, T.F.; Chilingarian, G.V. Asphalthenes and Asphalts; Elsevier Science: Amsterdam, The Netherlands, 1994. [Google Scholar]

- Rozeveld, S.; Shin, E.; Bhurke, A.; France, L.; Drzal, L.T. Network morphology of straight and polymer modified asphalt cements. Microscopy Res. Techn. 1997, 38, 529–543. [Google Scholar] [CrossRef]

- Boulangé, L.; Sterczynski, F. Study of interfacial interactions between asphalt and various aggregates used in road construction. J. Adhes. Sci. Technol. 2012, 26, 163–173. [Google Scholar]

- Xiao, Q.Y.; Wei, L.Y. A precise evaluation method for adhesion of asphalt aggregate. J. Pavement Res. Technol. 2009, 6, 270–274. [Google Scholar]

- Vassaux, S.; Gaudefroy, V.; Boulangé, L.; Pévère, A. Towards a better understanding of wetting regimes at the interface asphalt/aggregate during warm-mix process of asphalt mixtures. Constr. Build. Mater. 2017, 133, 182–195. [Google Scholar] [CrossRef]

- Airey, G.D.; Collop, A.C.; Zoorob, S.E.; Elliott, R.C. The influence of aggregate, filler and bitumen on asphalt mixture moisture damage. Constr. Build Mater. 2008, 22, 2015–2024. [Google Scholar] [CrossRef]

- Tarefder, R.; Zaman, A. Nanoscale evaluation of moisture damage in polymer modified asphalts. J. Mater. Civ. Eng. 2010, 22, 714–725. [Google Scholar] [CrossRef]

- Grenfell, J.; Ahmad, N.; Liu, Y.; Apeagyei, A.; Large, D.; Aireyet, G. Assessing asphalt mixture moisture susceptibility through intrinsic adhesion, bitumen stripping and mechanical damage. Road Mater. Pavement Des. 2014, 15, 131–152. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Kakar, M.R.; Quadri, S.A.; Valentin, J. Quantification of moisture sensitivity of warm mix asphalt using image analysis technique. J. Clean Prod. 2014, 68, 200–208. [Google Scholar] [CrossRef]

- Hurley, G.C.; Prowell, B.D.; Reinke, G. Evaluation of potential processes for use in Warm Mix Asphalt. J. Assoc. Asphalt Paving Technol. 2006, 75, 41–90. [Google Scholar]

- Karlsson, R.; Isacsson, U. Material-Related Aspects of Asphalt Recycling. State-of-the-Art. J. Mater. Civ. Eng. 2006, 18, 81–92. [Google Scholar] [CrossRef]

- Ameri, M.; Behnood, A. Laboratory studies to investigate the properties of CIR mixes containing steel slag as a substitute for virgin aggregates. Constr. Build. Mater. 2012, 26, 475–480. [Google Scholar] [CrossRef]

- Behnood, A.; Gharehveran, M.M.; Asl, F.G.; Ameri, M. Effects of copper slag and recycled concrete aggregate on the properties of CIR mixes with bitumen emulsion, rice husk ash, Portland cement and fly ash. Constr. Build. Mater. 2015, 96, 172–180. [Google Scholar] [CrossRef]

- Akzo Nobel. Available online: http://sc.akzonobel.com/en/asphalt/Pages/applications-adhesion-promoters.aspx (accessed on 21 September 2016).

- Mathews, D.H. Surface Active Agents in Bituminous Road Materials. J. Appl. Chem. 1962, 12, 56–73. [Google Scholar] [CrossRef]

- Goh, S.W.; Hasan, M.R.M.; You, Z. Performances Evaluation of Cecabase® RT in Warm Mix Asphalt Technology. Proced. Soc. Behav. Sci. 2013, 96, 2782–2790. [Google Scholar] [CrossRef]

- Levin, J.O.; Andersson, K.; Hallgren, C. Exposure to low molecular polyammines during road paving. Ann. Occup. Hyg. 1994, 38, 257–264. [Google Scholar] [PubMed]

- Arega, Z.; Bhasin, A.; Motamed, A.; Turner, F. Influence of warm-mix additives and reduced aging on the rheology of asphalt binders with different natural wax contents. J. Mater. Civ. Eng. 2011, 23, 1453–1459. [Google Scholar] [CrossRef]

- Syroezhko, A.; Baranov, M.; Ivanov, S.; Maidanova, N. Influence of natural additives and those synthesized by the Fischer-Tropsch method on the properties of petroleum bitumen and quality of floated asphalt. Coke Chem. 2011, 54, 26–31. [Google Scholar] [CrossRef]

- Jamshidi, A.; Golchin, B.; Hamzah, M.O.; Turner, P. Selection of type of warm mix asphalt additive based on the rheological properties of asphalt binders. J. Clean. Prod. 2015, 100, 89–106. [Google Scholar] [CrossRef]

- Kakar, M.R.; Hamzah, M.O.; Akhtar, M.N.; Woodward, D. Surface free energy and moisture susceptibility evaluation of asphalt binders modified with surfactant-based chemical additive. J. Clean. Prod. 2016, 112, 2342–2353. [Google Scholar] [CrossRef]

- Oliveira, J.R.; Silva, H.M.; Abreu, L.P.; Fernandes, S.R. Use of a warm mix asphalt additive to reduce the production temperatures and to improve the performance of asphalt rubber mixtures. J. Clean. Prod. 2013, 41, 15–22. [Google Scholar] [CrossRef]

- Woodhams, R.T. Ferric Oxide Adhesion Promoters for Water Resistant Asphalt Pavements. J. Adhesion 1998, 68, 65–91. [Google Scholar] [CrossRef]

- McConnoughay, K.E. Making a Paving Composition Using a Bituminous Binder Containing an Adhesion Promoter. S. African Pat. 1971, 7008, 111–122. [Google Scholar]

- Oliviero Rossi, C.; Caputo, P.; Baldino, N.; Lupi, F.R.; Miriello, D.; Angelico, R. Effects of adhesion promoters on the contact angle of bitumen-aggregate interface. Int. J. Adhe. Adhes. 2016, 70, 297–303. [Google Scholar] [CrossRef]

- Oliviero Rossi, C.; Caputo, P.; Baldino, N.; Szerb, E.I.; Teltayev, B. Quantitative evaluation of organosilane-based adhesion promoter effect on bitumen-aggregate bond by contact angle test. Int. J. Adhe. Adhes. 2017, 72, 117–122. [Google Scholar] [CrossRef]

- ASTM D3625/D3625M-12. Standard Practice for Effect of Water on Bituminous-Coated Aggregate Using Boiling Water; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Bagampadde, U.; Al-Abdul Wahhab, H.I.; Aiban, S.A. Optimization of steel slag aggregates for bituminous mixes in Saudi Arabia. J. Mater. Civ. Eng. 1999, 11, 30–35. [Google Scholar] [CrossRef]

- Kodrat, I.; Sohn, D.; Hesp, S.A.M. Comparison of polyphosphoric acid-modified asphalt binders with straight and polymer-modified materials. Transp. Res. Rec. J. Transp. Res. Board. 2007, 1998, 47–55. [Google Scholar] [CrossRef]

- Baldino, N.; Gabriele, D.; Oliviero Rossi, C.; Seta, L.; Lupi, F.R.; Caputo, P. Low temperature rheology of polyphosphoric acid (PPA) added bitumen. Constr. Build. Mater. 2012, 36, 592–598. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.; Wang, H.; Hao, P. Rheological property investigations for polymer and polyphosphoric acid modified asphalt binders at high temperatures. Constr. Build. Mater. 2014, 64, 316–323. [Google Scholar] [CrossRef]

- Oliviero Rossi, C.; Spadafora, A.; Teltayev, B.; Izmailova, G.; Amerbayev, Y.; Bortolotti, V. Polymer modified bitumen: Rheological properties and structural characterization. Colloids Surf. A: Physicochem. Eng. Aspects. 2015, 480, 390–397. [Google Scholar] [CrossRef]

- Baumgardner, G.L.; Masson, J.F.; Hardee, J.R.; Menapace, A.M.; Williams, A.G. Polyphosphoric acid modified asphalt: proposed mechanisms. J. Assoc. Asphalt Paving Technol. 2005, 74, 283–305. [Google Scholar]

- Baldino, N.; Gabriele, D.; Lupi, F.R.; Oliviero Rossi, C.; Caputo, P.; Falvo, T. Rheological effects on bitumen of polyphosphoric acid (PPA) addition. Constr. Build. Mater. 2013, 40, 397–404. [Google Scholar] [CrossRef]

- Edwards, Y.; Tasdemir, Y.; Isacsson, U. Rheological effects of commercial waxes and polyphosphoric acid in bitumen 160/220-low temperature performance. Fuel 2016, 85, 989–997. [Google Scholar]

- Cui, S.; Blackman, B.R.K.; Kinloch, A.J.; Ambrose, C.T. Durability of asphalt mixtures: Effect of aggregate type and adhesion promoters. Int. J. Adhe. Adhes. 2014, 54, 100–111. [Google Scholar] [CrossRef]

- Liu, D.; Ma, F. Soybean Phospholipids. In Recent Trends for Enhancing the Diversity and Quality of Soybean Products; Krezhova, D., Ed.; InTech: Rijeka, Croatia, 2011; ISBN 978–953–307–533–4. [Google Scholar]

- Angelico, R.; Amin, S.; Monduzzi, M.; Murgia, S.; Olsson, U.; Palazzo, G. Impact of branching on the wormlike micelles viscoelasticity. Soft Matter 2012, 8, 10941–10949. [Google Scholar] [CrossRef]

- Angelico, R.; Gentile, L.; Ranieri, G.A.; Oliviero Rossi, C. Flow Induced Structures observed in a Viscoelastic Reverse Wormlike Micellar System by Magnetic Resonance Imaging and NMR Velocimetry. RSC Adv. 2016, 6, 33339–33347. [Google Scholar] [CrossRef]

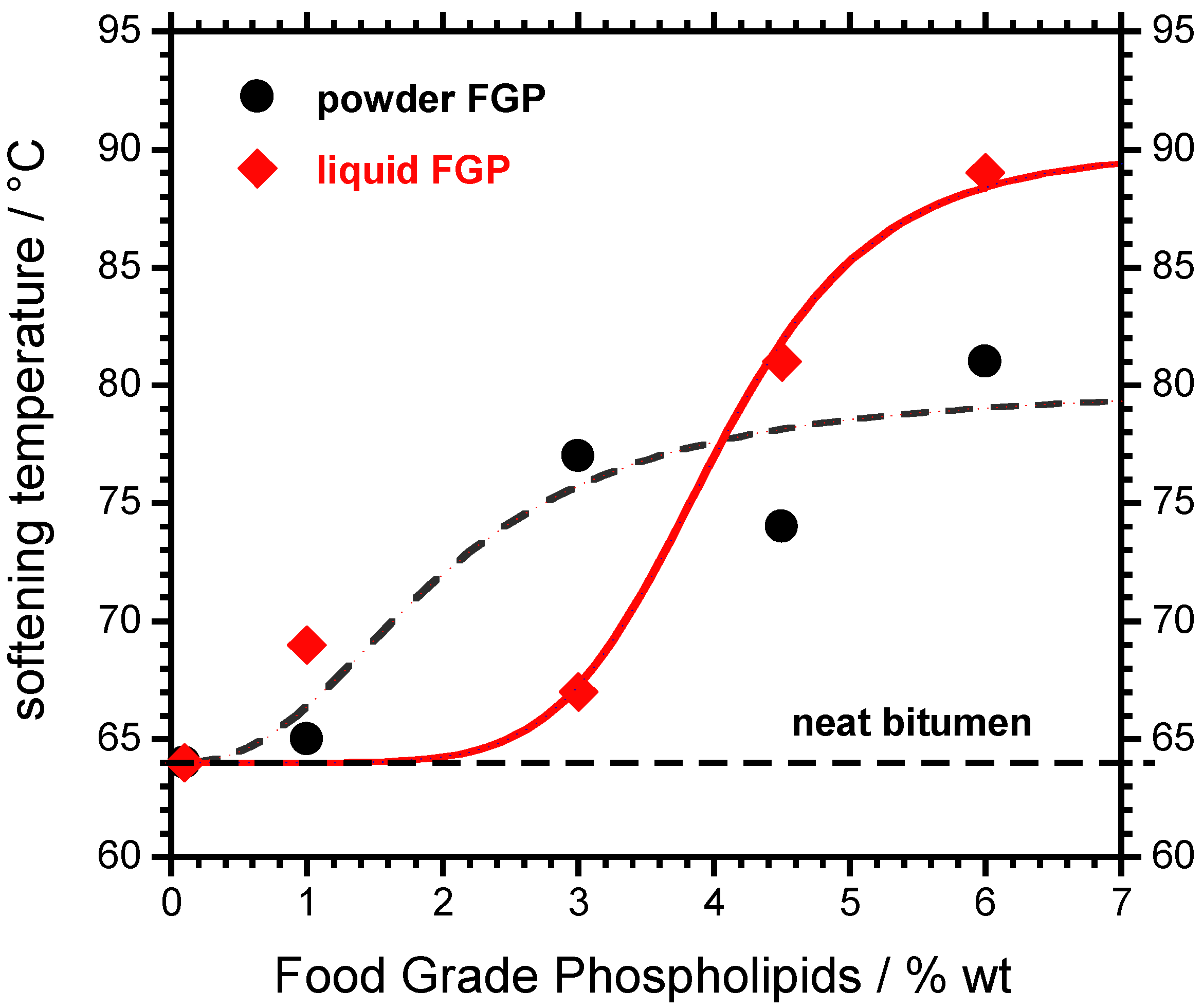

- Oliviero Rossi, C.; Caputo, P.; Loise, V.; Miriello, D.; Taltayev, B.; Angelico, R. Role of a food grade additive in the high temperature performance of modified bitumens. Colloids Surf. A: Physicochem. Eng. Aspects 2017. [Google Scholar] [CrossRef]

- Lesueur, D.; Gérard, J.F. A structure related model to describe asphalt linear viscoelasticity. J. Rheol. 1996, 40, 813–836. [Google Scholar] [CrossRef]

- Lesueur, D.; Gérard, J.F.; Claudy, P.; Létoffé, J.M.; Planche, J.P.; Martin, D. Relationships between the structure and the mechanical properties of paving grade asphalt cements. J. Assoc. Asphalt Paving Techn. 1997, 66, 486–507. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliviero Rossi, C.; Teltayev, B.; Angelico, R. Adhesion Promoters in Bituminous Road Materials: A Review. Appl. Sci. 2017, 7, 524. https://doi.org/10.3390/app7050524

Oliviero Rossi C, Teltayev B, Angelico R. Adhesion Promoters in Bituminous Road Materials: A Review. Applied Sciences. 2017; 7(5):524. https://doi.org/10.3390/app7050524

Chicago/Turabian StyleOliviero Rossi, Cesare, Bagdat Teltayev, and Ruggero Angelico. 2017. "Adhesion Promoters in Bituminous Road Materials: A Review" Applied Sciences 7, no. 5: 524. https://doi.org/10.3390/app7050524