Effect of Load Transfer Section to Toughness for Steel Fiber-Reinforced Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fibers

2.2. Mix Design

2.3. Equipment and Test Procedure

3. Experimental Results

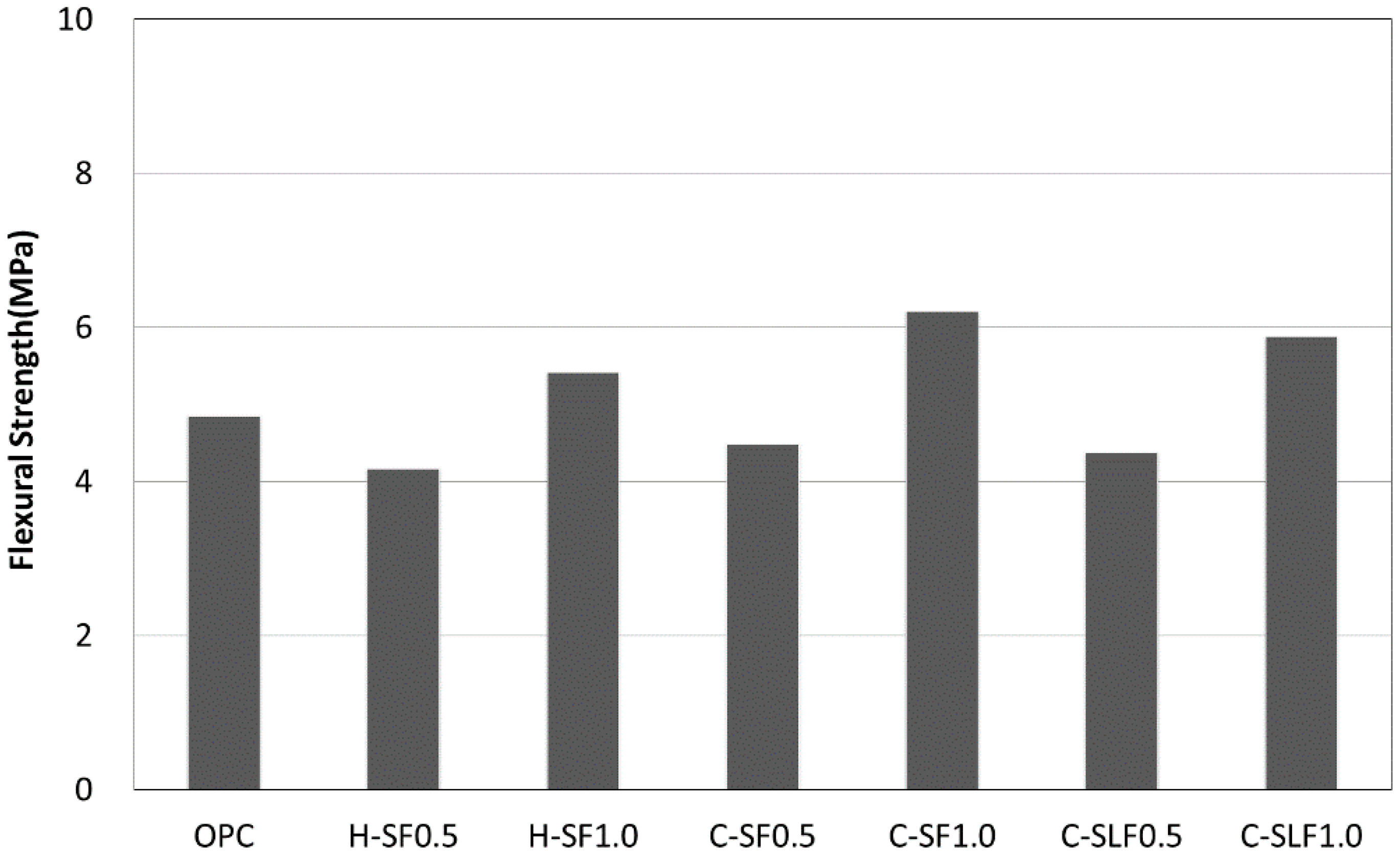

3.1. Flexural Strength

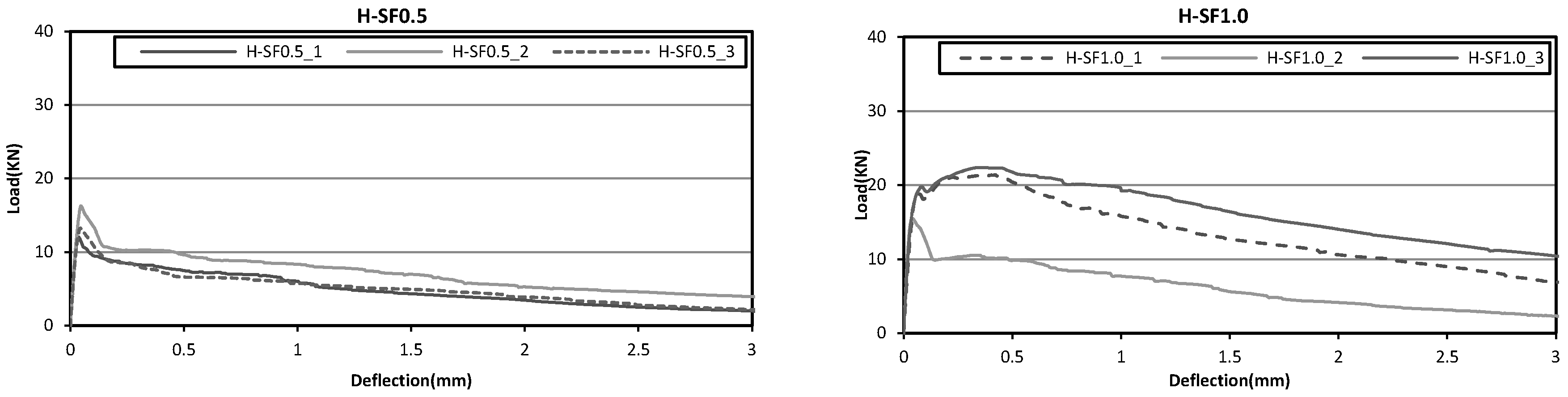

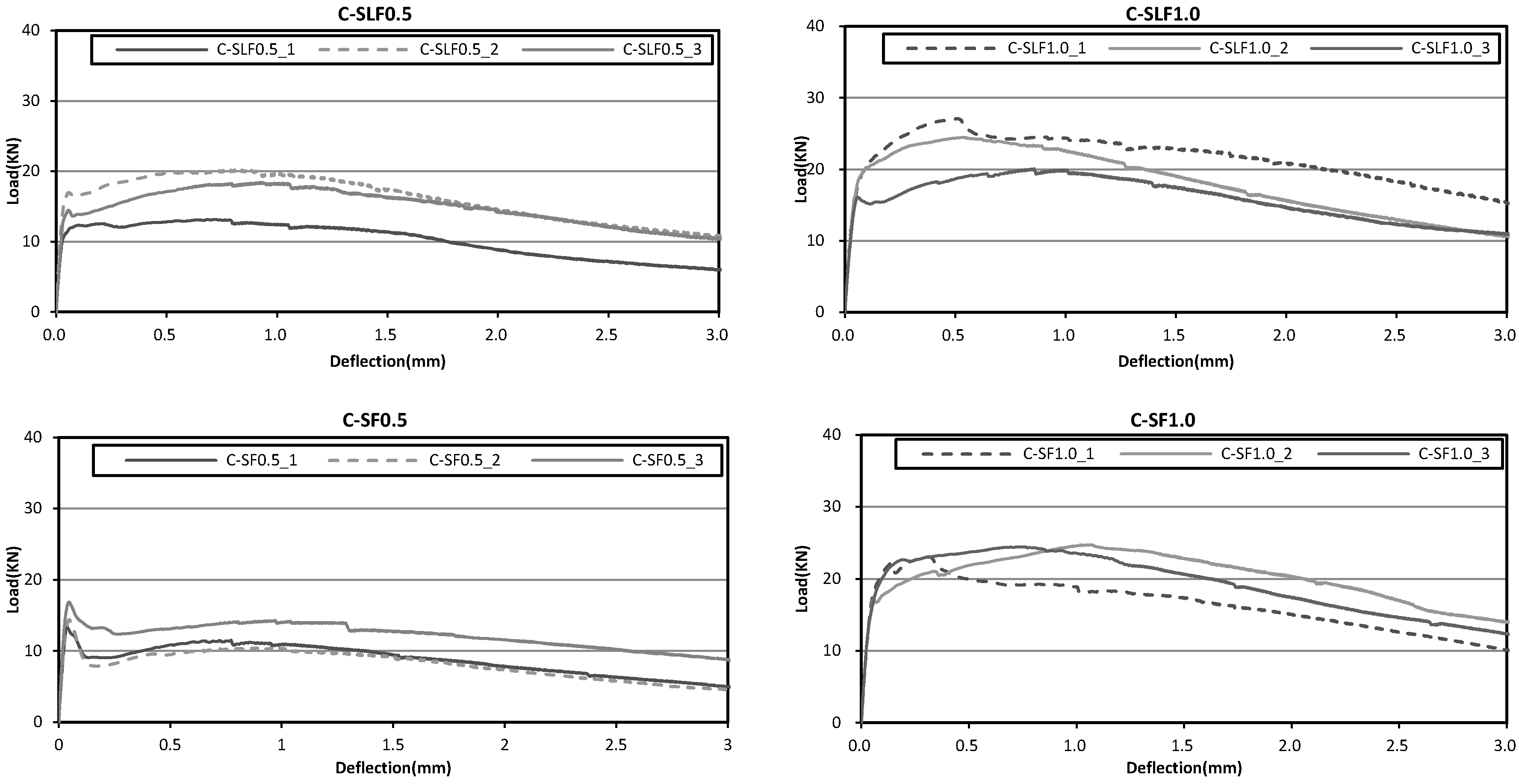

3.2. Flexural Behavior Characteristics

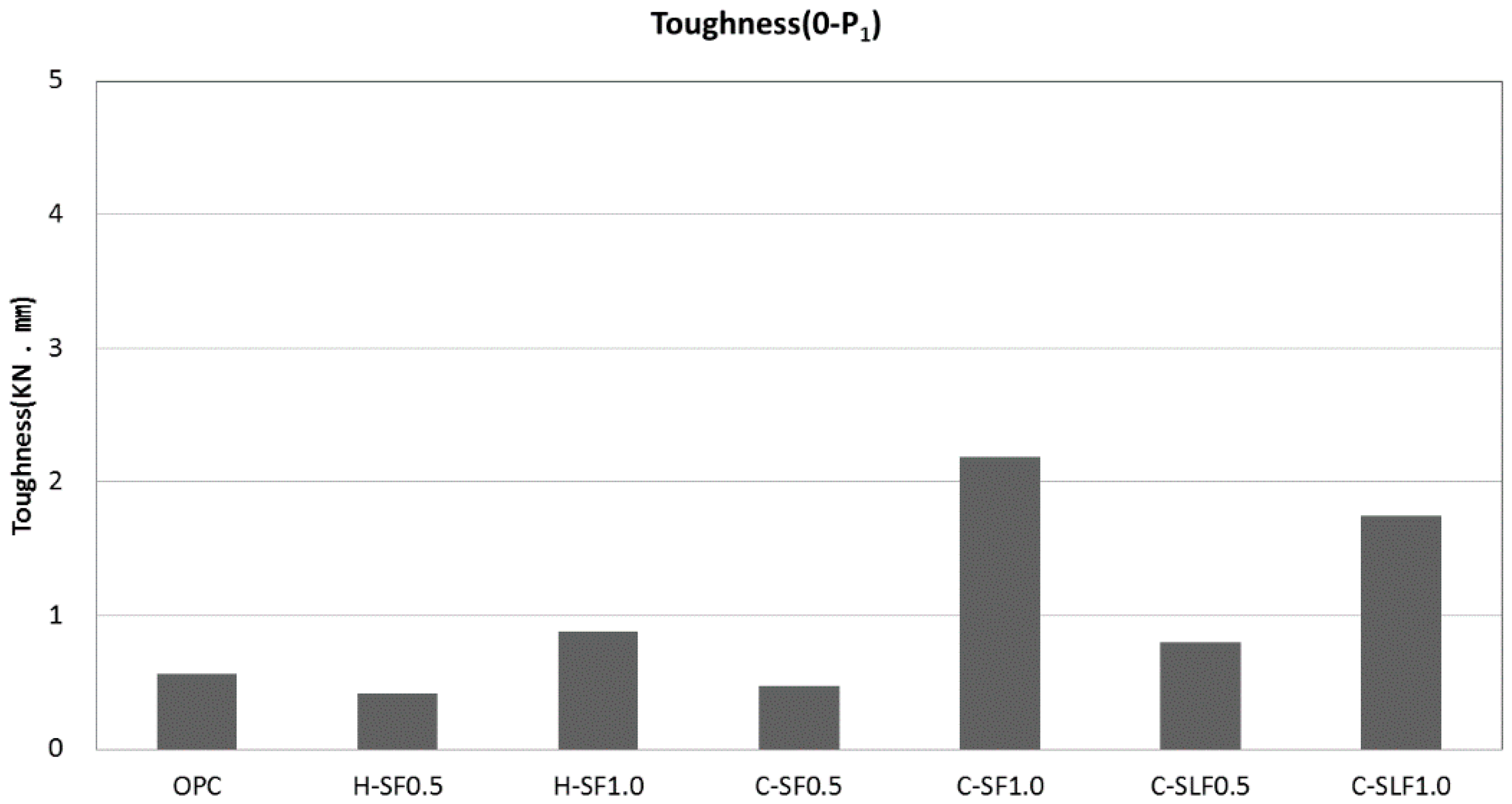

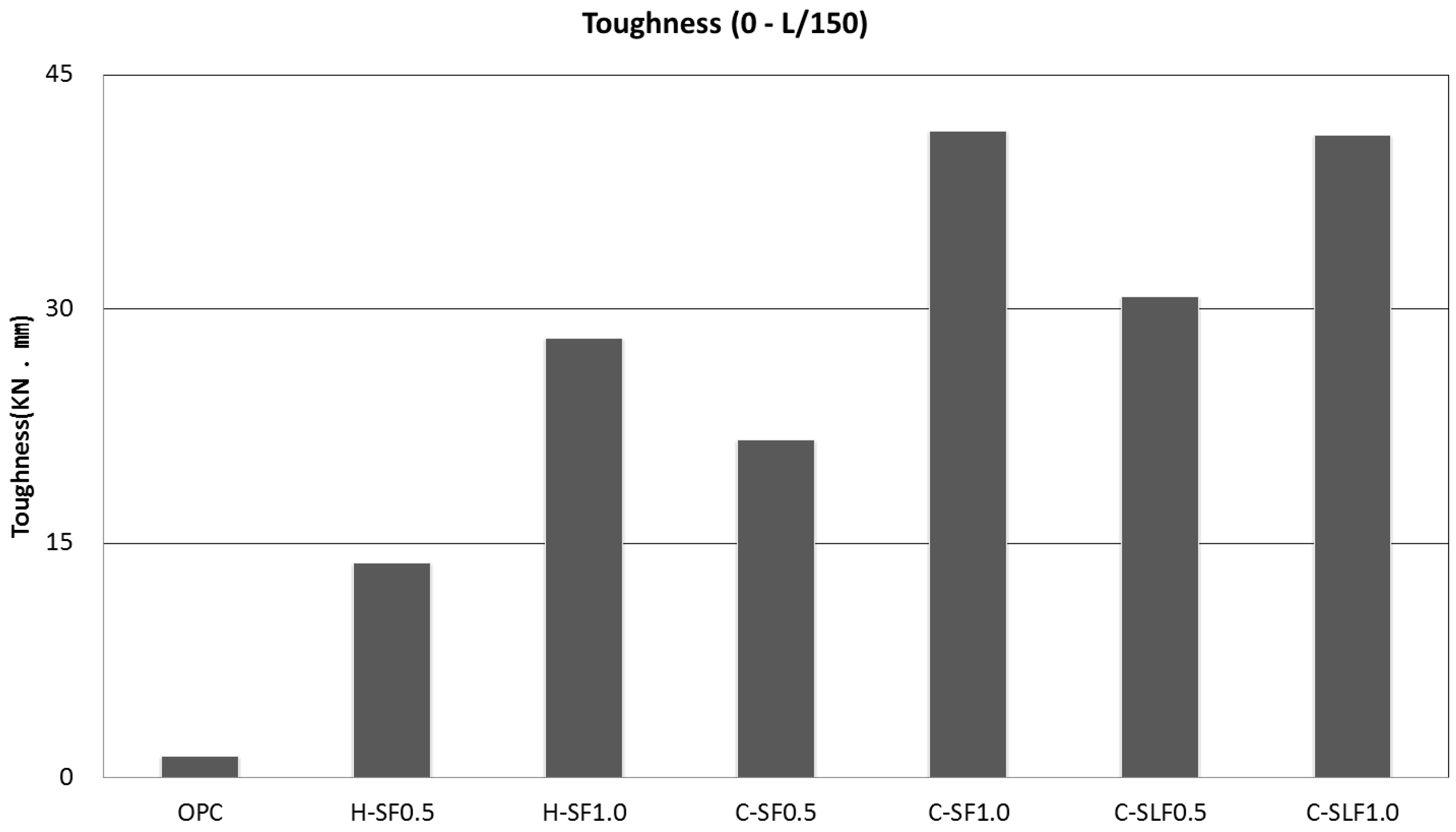

3.3. Flexural Toughness Assessment Results

4. Analysis and Discussion

4.1. Analysis of the Flexural Behavior Characteristics

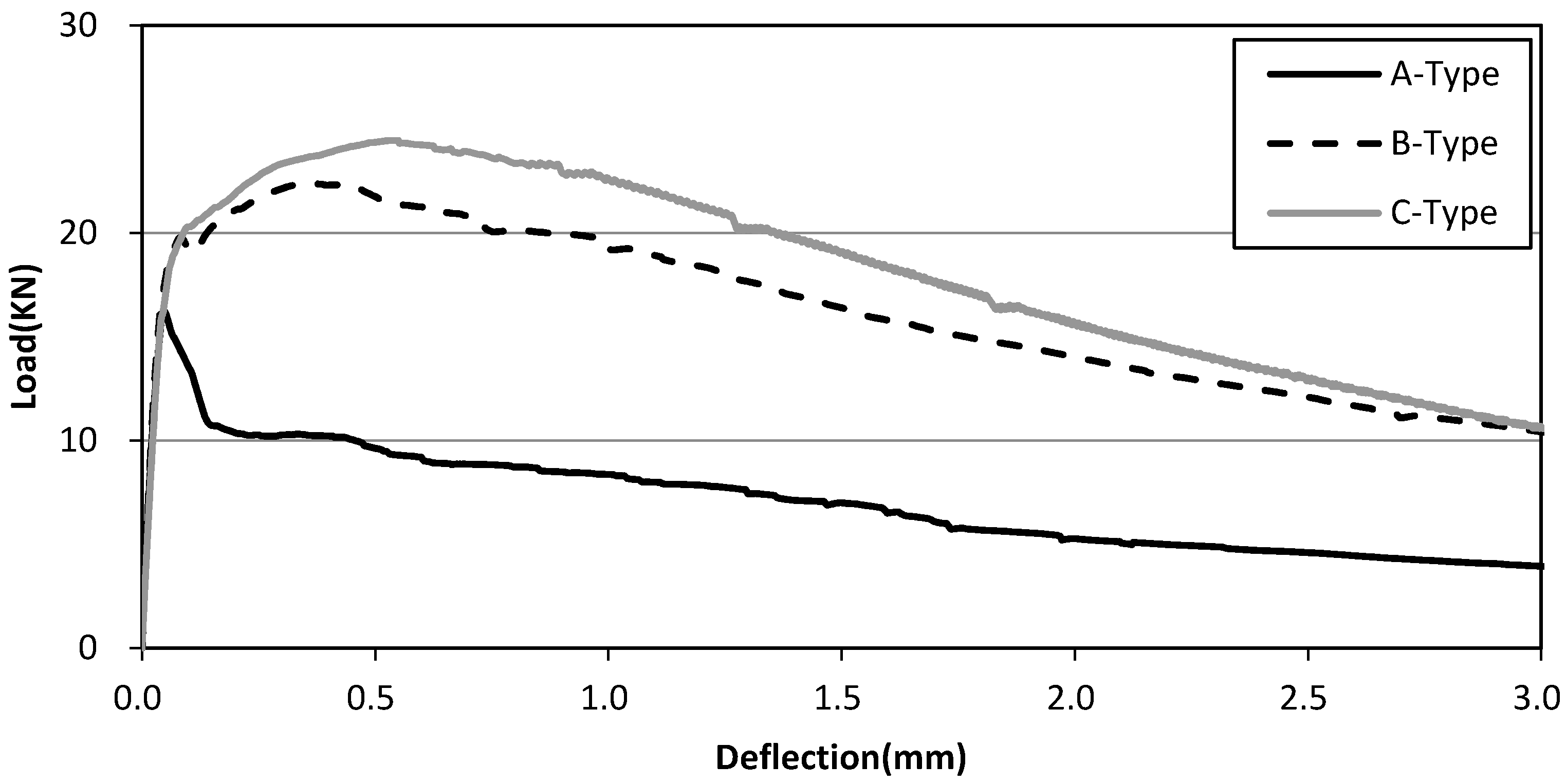

4.2. Load Transfer Types by Fiber Content and Material Properties

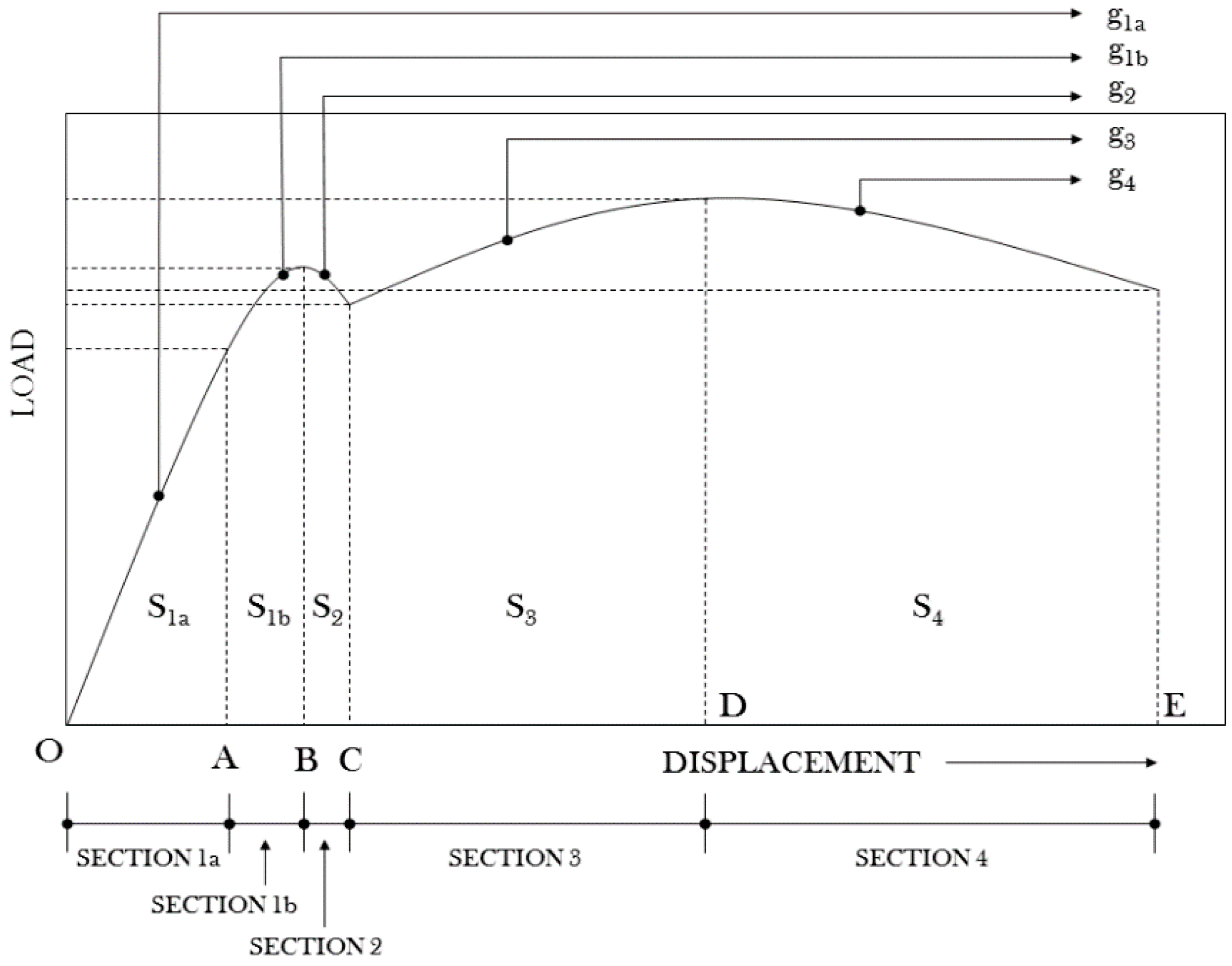

4.3. Load Displacement Curve Analysis by Material

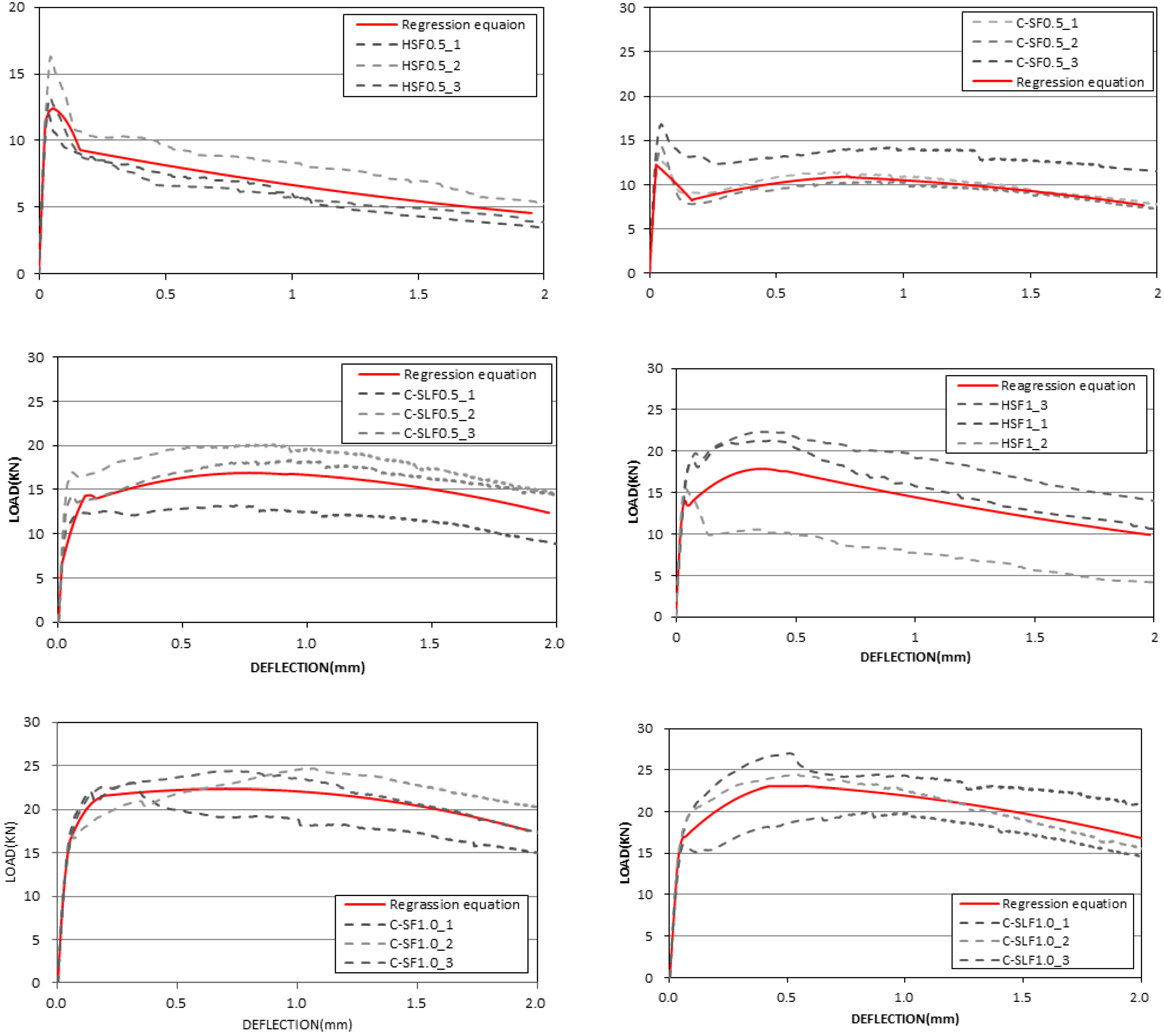

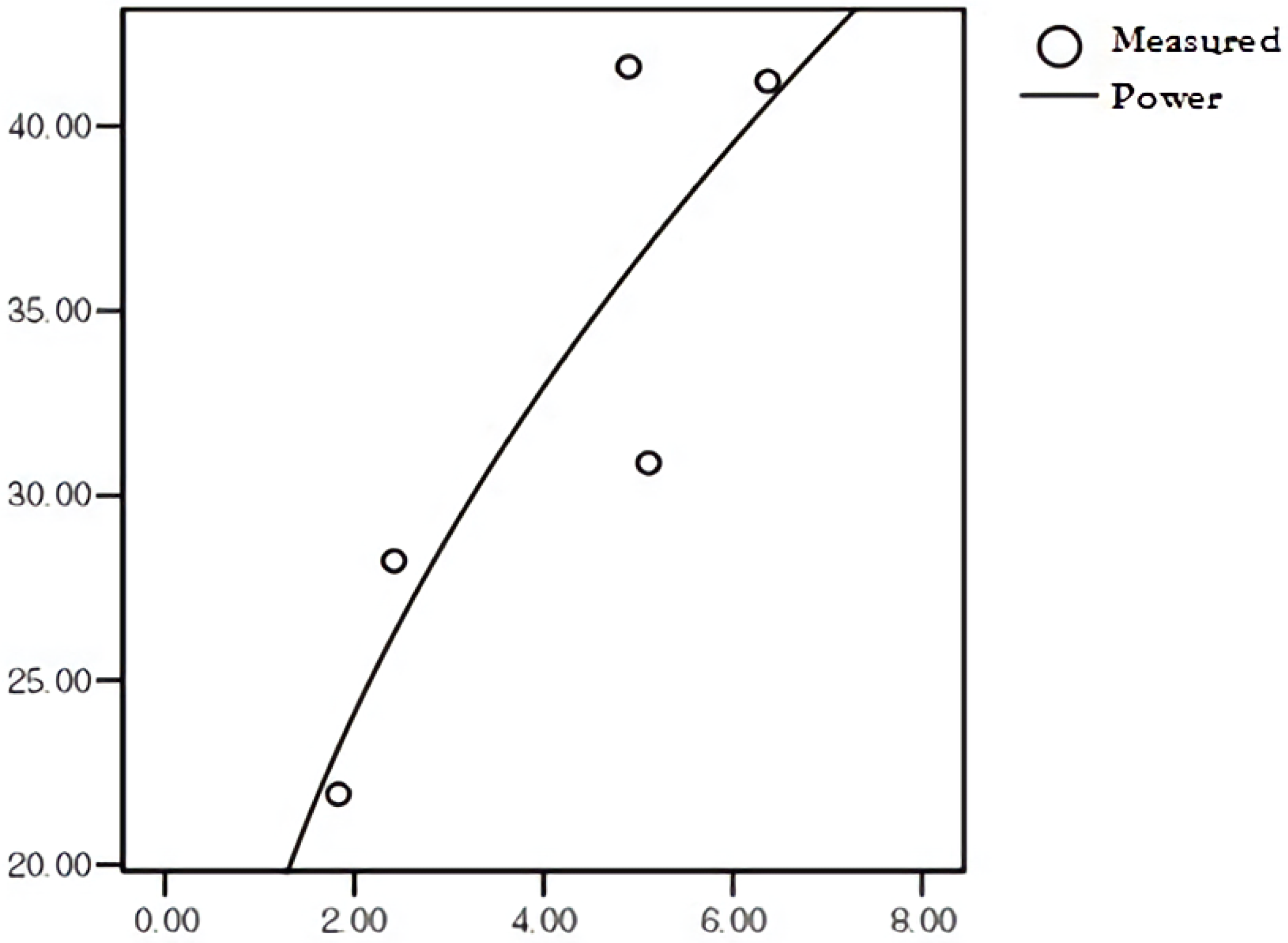

4.4. Regression Curve Analysis

4.4.1. Slope Analysis by Section

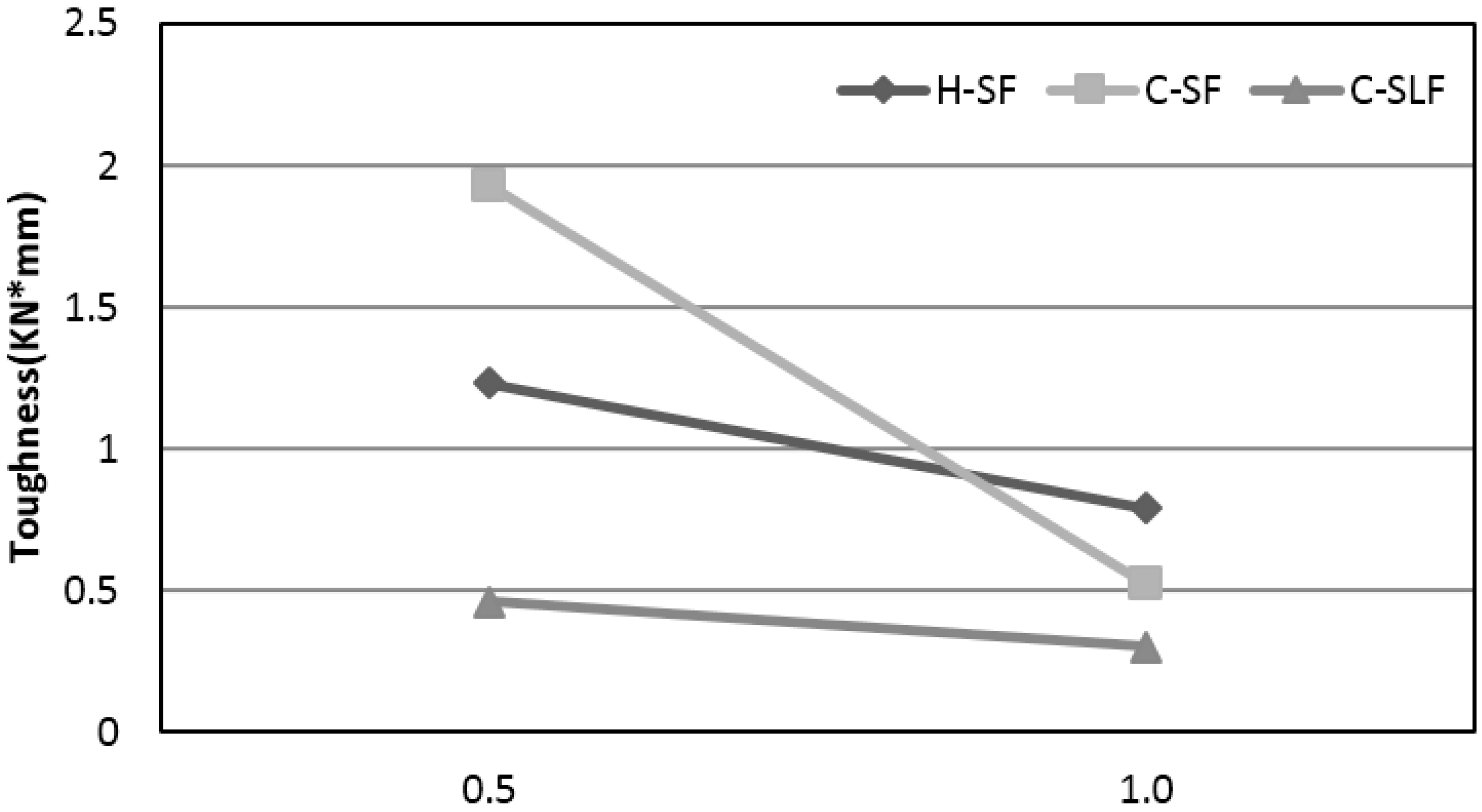

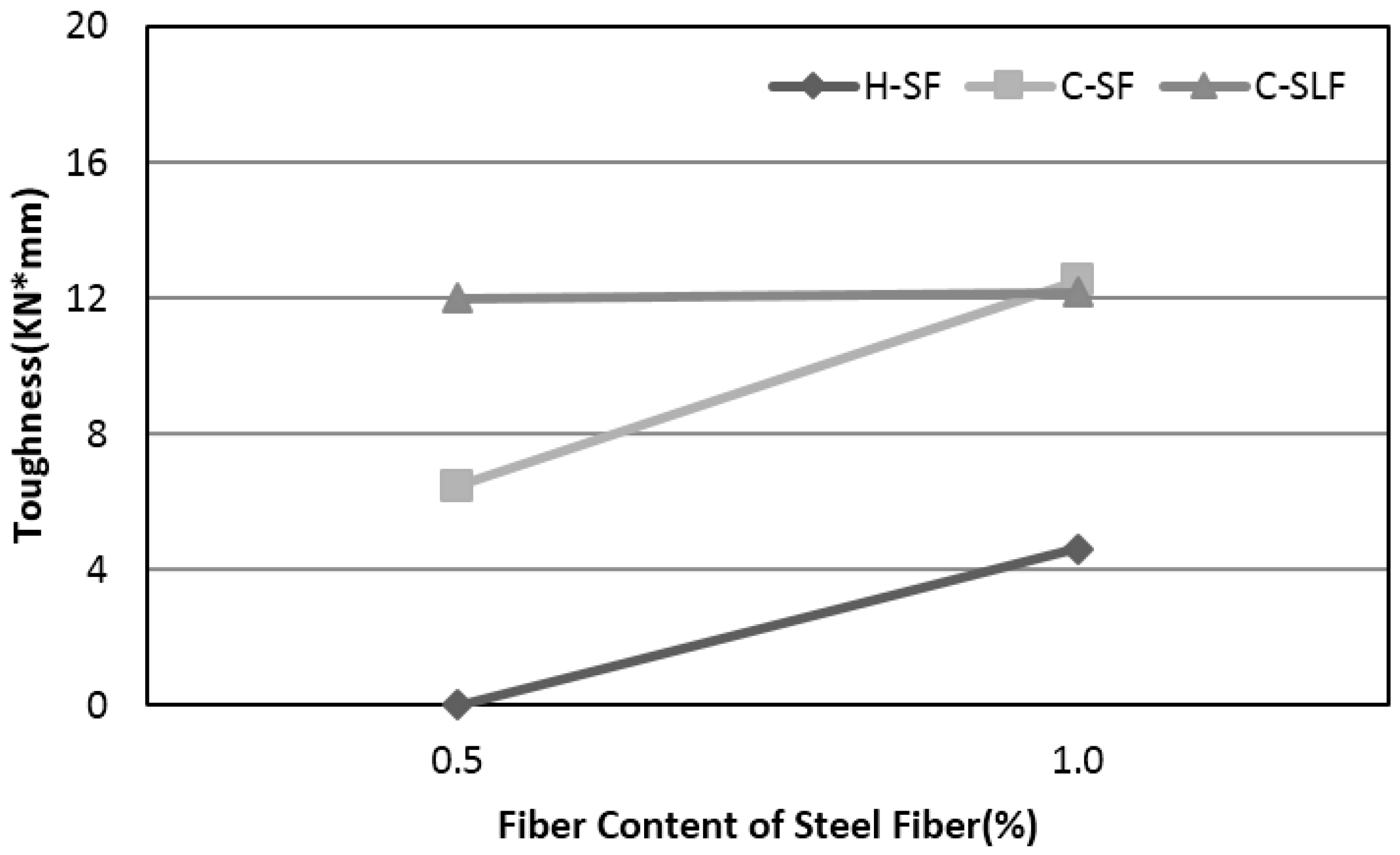

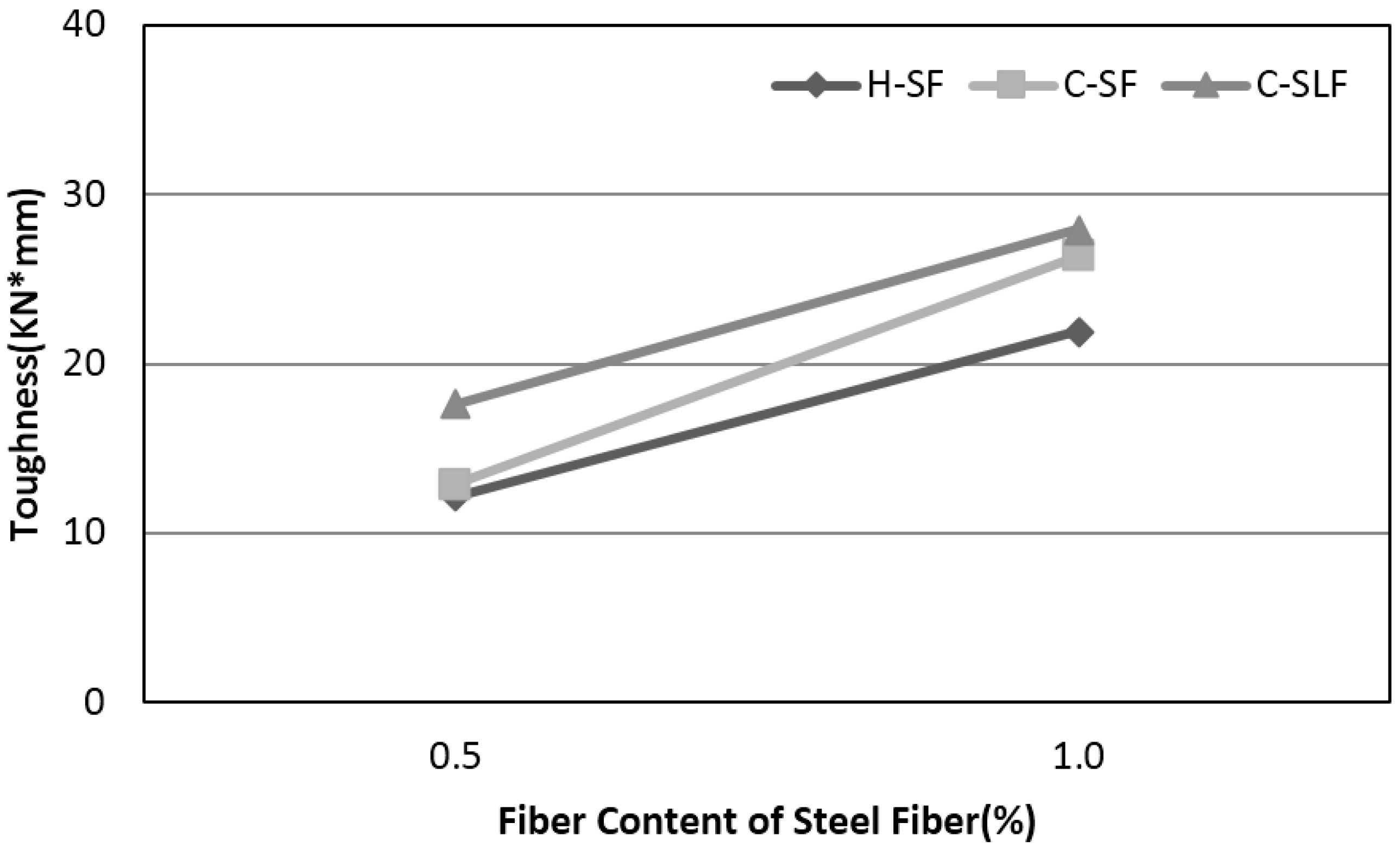

4.4.2. Analysis of the Amount of Energy Absorption by Section

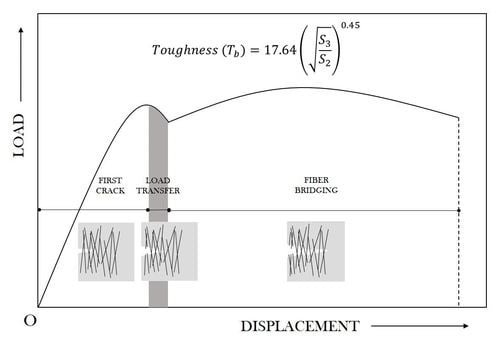

4.5. Analysis of the Correlation between the Load Transfer Sections and the Toughness

- L.T.F.: Load transfer factor (LTF)

- S2: Area of the third section (kN·mm)

- S3: Area of the third section (kN·mm)

- Tb: Toughness (KN·mm)

- S2: Area of the second section

- S3: Area of the third section

5. Conclusions

- (1)

- The study verified the increase in the remaining load and toughness based on the increase in the amount of steel fiber mixed with the concrete, and the degree of increase variation differed by fiber type, fiber content, and shape.

- (2)

- C-SF was shown to offer superior remaining load and toughness at all the fiber contents, and compared to C-SF, C-SLF offered even more superior remaining load and toughness.

- (3)

- From the analysis of the load displacement curve of the steel fiber-reinforced concrete by section, it was verified that the slope of the second section became smooth as with the increase of the fiber content, and that the slope of the third section increased as the section’s load increased.

- (4)

- The load displacement curve of the steel fiber-reinforced concrete showed a correlation between the fiber content, specifically the area of the second section (the load transfer section) and that of the third section. With the increase of the fiber content, the second section area decreased while the third section ratio increased. Based on these results, the study proposed the LTF of steel fiber.

- (5)

- To determine the correlation between the energy transfer capacity of steel fiber and the overall toughness of the load transfer section, the study derived the regression model (Tb) using the LTF.

Acknowledgment

Author Contributions

Conflicts of Interest

Abbreviations

| H-SF | Hooked Steel Fiber |

| C-SF | Crimped Steel Fiber |

| C-SLF | Crimped Stainless Steel Fiber |

| OPC | Ordinary Portland Cement |

| LVDT | Linear Variable Differential Transducers |

| LTF | Load Transfer Factor |

References

- Construction Technology Laboratory. Workability and Dynamic Properties of Steel Fiber Reinforced Concrete; Seoul National University of Science and Technology: Seoul, Korea, 2016; pp. 4–42. [Google Scholar]

- Nataraja, M.C.; Dhang, N.; Gupta, A.P. Toughness Characterization of Steel Fiber-Reinforced Concrete by JSCE Approach. Cem. Concr. Res. 2000, 30, 593–597. [Google Scholar] [CrossRef]

- Han, Y.J. Evaluation of Flexural Behavior Effect in the Load Transfer Zone for Steel Fiber Reinforced Concrete; Seoul National University of Science and Technology: Seoul, Korea, 2017; pp. 1–76. [Google Scholar]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete; Donghwa Technologies: Seoul, Korea, 2003; pp. 649–668. [Google Scholar]

- Leung, C.K.Y.; Li, V.C. New Strength-based Model for the Debonding of Discontinuous Fibres in an Elastic Matrix. J. Mater. Sci. 1991, 26, 5996–6010. [Google Scholar] [CrossRef]

- Gopalaratnam, V.S.; Gettu, R. On the Characterization of Flexural Toughness in Fiber Reinforced Concretes. Cem. Concr. Compos. 1995, 17, 239–254. [Google Scholar] [CrossRef]

- Japan Society of Civil Engineers. JSCE Standards for Test. Method of Test for Flexural Strength and Flexural Toughness of Steel Fiber Reinforced Concrete (Standard SF4); Japan Society of Civil Engineers: Tokyo, Japan, 1984; pp. 58–61. [Google Scholar]

- Japan Concrete Institute. JCI Standards for Test. Methods of Fiber Reinforced Concrete, Method of Test for Flexural Strength and Flexural Toughness of Fiber Reinforced Concrete (Standard SF4); Japan Concrete Institute: Tokyo, Japan, 1983; pp. 45–51. [Google Scholar]

- European Federation of National Associations Representing for Concrete (EFNARC). European Specification for Sprayed Concrete; Specification for Sprayed Concrete; European Federation of National Associations Representing for Concrete (EFNARC): Surrey, UK, 1996; pp. 11–16. [Google Scholar]

- Korean Standards Associations. Korean Standards (F 2566). In Test Method for Flexural Toughness of Steel Fiber Reinforced Concrete; Korean Standards Associations: Gwacheon, Korea, 2014; pp. 1–9. [Google Scholar]

- American Society for Testing and Materials (ASTM). American Standards (C 1609). In Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading); American Society for Testing and Materials: West Conshohocken, PA, USA, 2012; pp. 1–9. [Google Scholar]

- American Concrete Institute. ACI Guidelines (544). In Measurement of Properties of Fiber Reinforced Concrete; American Concrete Institute: Farmington Hills, MI, USA, 1996; pp. 7–23. [Google Scholar]

- Sivakumar, A.; Sounthararajan, V.M. Toughness characterization of steel fibre reinforced concrete—A review on various international standards. J. Civ. Eng. Constr. Tech. 2013, 4, 65–69. [Google Scholar]

- Banthia, N.; Trottier, J.F. Test Methods for Flexural Toughness Characterization of Fiber Reinforced Concrete: Some Concerns and a Proposition. ACI Mater. J. 1995, 92, 48–57. [Google Scholar]

- Swamy, R.N.; Mangat, P.S. A Theory for the Flexural Strength of Steel Fiber Reinforced Concrete. Cem. Concr. Res. 1974, 4, 313–325. [Google Scholar] [CrossRef]

- Jung, B.S. Flexural Toughness of Steel Fiber Reinforced Very Early Strength Latex Modified Concrete; Kangwon National University: Chuncheon, Korea, 2010; pp. 27–31. [Google Scholar]

- Beaudoin, J. Handbook of Fiber-Reinforced Concrete; Noyes Publications: Norwich, NY, USA, 1990; pp. 85–89. [Google Scholar]

- ACI Committee. State-of-the Art Report in Fibre Reinforced Concrete; ACI (American Concrete Institute): Farmington Hills, MI, USA, 1982. [Google Scholar]

- Kanda, T.; Li, V.C. Interface property and apparent strength of high-strength hydrophilic fiber in cement matrix. J. Mater. Civ. Eng. 1998, 10, 5–13. [Google Scholar] [CrossRef]

- Ni, Y. Natural Fibre Reinforced Cement Composites. Ph.D. Thesis, Victoria University of Technology, Melbourne, Australia, 1995; pp. 22–25. [Google Scholar]

- Kim, J.M. Microstructure Changes of Continuous Cooling and Isothermal Transformation Heat-Treated STS 430 Ferritic Stainless Steel after High Temperature Gas Nitriding; Dong-a University: Busan, Korea, 2012; pp. 28–45. [Google Scholar]

- Han, Y.J.; Oh, G.H.; Choi, S.Y.; Oh, S.K.; Kim, B. Fiber Bridge. Analysis of Steel Fiber Reinforced Concrete According to Different Fiber Manufacture & Fiber Addition. In Proceedings of the Annual Conference of the Architectural Institute of Korea, Seoul, Korea, 23–26 October 2016; Volume 36, pp. 917–918. [Google Scholar]

- Han, Y.J.; Ma, S.J.; Oh, G.H.; Oh, S.K.; Kim, B. Comparison of Load Transferring Property for Steel Fiber Production and Type. In Proceedings of the 2016 Spring Conference of the Korea Concrete Institute, Gyeongsan, Korea, 17 April 2016; Volume 28, pp. 383–384. [Google Scholar]

| Name of Standard | Dimensions of the Specimen | Rate of Loading (mm/min) | Type of Loading Arrangement | Maximum Deflection Measured | Toughness Measurement |

|---|---|---|---|---|---|

| JSCE SF-4, JCI SF-4 | 100 × 100 × 300 | L/1500 to L/1300 | 4-point bending test | L/150 | Energy absorbed up to a deflection of L/150 mm |

| EFNARC | 75 × 125 × 450 | 0.25 ± 0.05 | 4-point bending test | 25 | Residual strength factors up to deflection of 1 and 3 mm |

| KS F 2566 | 100 × 100 × 400 150 × 150 × 500 | 0.1–0.2 | 4-point bending test | L/150 | Energy absorbed up to a deflection of L/150 mm |

| ASTM C 1609 | 100 × 100 × 400 150 × 150 × 500 | 0.05–0.10 0.05–0.12 | 4-point bending test/3-point bending test | L/150 | Energy absorbed up to a deflection of L/150 mm |

| French Standard P18-409 | 140 × 140 × 560 | 0.05–0.10 | 4-point bending test | 2.8 | Ratio of load at deflection (0.7 mm, 1.4 mm, 2.8 mm) to load P |

| ACI 544 | 100 × 100 × 350 | 0.05–0.10 | 4-point bending test/3-point bending test | 1.9 | Ratio of energy absorbed up to deflection of 1.9 mm |

| Category | Hook Type | Crimped | Crimped |

|---|---|---|---|

| Code | H-SF (hooked-end steel fiber) | C-SF (crimped steel fiber) | C-SLF (crimped stainless steel fiber) |

| Section | Circular | Circular | Circular |

| Tensile strength (N/mm2) | 1300 | 2896 | 1941 |

| Length (mm) | 35 | 35 | 35 |

| Diameter (mm) | 0.5 | 0.5 | 0.5 |

| Aspect ratio (L/D) | 70 | 70 | 70 |

| Aspect |  |  |  |

| Image |  |  |  |

| Category | Density of Saturated Surface Dry Condition (g/cm3) | Dry Density (g/cm3) | Absorption Ratio (%) | Max. Dimensions (mm) |

|---|---|---|---|---|

| Coarse aggregate | 5711.1 | 5677.7 | 0.59 | 19 |

| Fine aggregate | 500.7 | 485.3 | 3.03 | - |

| Type | Water Cement Ratio (%) | Fine Aggregate Modulus (%) | Unit Weight (kg/m3) | Superplasticizer (C × %) | Air Entraining (C × %) | Fiber Content (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| W | C | S | G | ||||||

| OPC | 45 | 51 | 200 | 440 | 778 | 748 | 1.0 | 0.02 | - |

| H-SF_0.5 | 45 | 51 | 200 | 440 | 766 | 748 | 1.0 | 0.02 | 0.5 |

| H-SF_1.0 | 45 | 51 | 200 | 440 | 753 | 748 | 1.0 | 0.02 | 1.0 |

| C-SF_0.5 | 45 | 51 | 200 | 440 | 766 | 748 | 1.0 | 0.02 | 0.5 |

| C-SF_1.0 | 45 | 51 | 200 | 440 | 753 | 748 | 1.0 | 0.02 | 1.0 |

| C-SLF_0.5 | 45 | 51 | 200 | 440 | 766 | 748 | 1.0 | 0.02 | 0.5 |

| C-SLF_1.0 | 45 | 51 | 200 | 440 | 753 | 748 | 1.0 | 0.02 | 1.0 |

| Category | Range (d: displacement, mm) | Energy Absorption Mechanism | Energy-Absorptive Material | ||

|---|---|---|---|---|---|

| Section | Toughness by Section | Slope by Section | |||

| 1 | S1a | g1a | 0 < d ≤ initial crack point | Linear elastic behavior | Concrete |

| S1b | g1b | Initial crack point < d ≤ first peak load | Progress of fine cracks inside the matrix | Concrete | |

| 2 | S2 | g2 | First peak load < d ≤ lowest load point | Concrete-fiber load transfer section | Concrete, fiber |

| 3 | S3 | g3 | Lowest load point < d ≤ second peak load | Fiber bridging and pullout action | Fiber |

| 4 | S4 | g4 | Second peak load < d ≤ 2.0 | Fiber bridging and pullout action | Fiber |

| Specimen | Displacement | Section 1a | Section 1b | Second Section | Third Section | Fourth Section | |

|---|---|---|---|---|---|---|---|

| H-SF 0.5 | Displacement | 0 ≤ χ ≤ 0.03 | 0.03 ≤ χ ≤ 0.05 | 0.05 ≤ χ ≤ 0.16 | - | 0.16 ≤ χ ≤ 2.00 | |

| Co-efficient | a | 0 | −682.7 | −207.5 | - | 0.5 | |

| b | 455.5 | 94.4 | 15.8 | - | −3.7 | ||

| c | 0 | 9.5 | 12.2 | - | 9.9 | ||

| Correlation coefficient | 99.1 | 99.8 | 99.2 | - | 98.2 | ||

| H-SF 1.0 | Displacement | 0 ≤ χ ≤ 0.02 | 0.02 ≤ χ ≤ 0.04 | 0.04 ≤ χ ≤ 0.07 | 0.07 ≤ χ ≤ 0.46 | 0.46 ≤ χ ≤ 2.00 | |

| Co-efficient | a | 0 | −11,120 | −3295.7 | −46.4 | 0.8 | |

| b | 541.0 | 846 | 338.7 | 33.4 | −7 | ||

| c | 0 | −2.1 | 4.8 | 11.8 | 20.6 | ||

| Correlation coefficient | 99.0 | 99.6 | 98.1 | 97.7 | 99.5 | ||

| C-SF 0.5 | Displacement | 0 ≤ χ ≤ 0.02 | 0.02 ≤ χ ≤ 0.03 | 0.03 ≤ χ ≤ 0.10 | 0.10 ≤ χ ≤ 0.31 | 0.31 ≤ χ ≤ 2.00 | |

| Co-efficient | a | 0 | −10,540 | −80.2 | 30 | −2.1 | |

| b | 486.8 | 643.8 | −12.3 | 15.6 | 3.3 | ||

| c | 0 | 0 | 9.2 | 4.8 | 10.2 | ||

| Correlation coefficient | 99.1 | 99.8 | 96.1 | 97.6 | 94.2 | ||

| C-SF 1.0 | Displacement | 0 ≤ χ ≤ 0.01 | 0.01 ≤ χ ≤ 0.05 | - | 0.05 ≤ χ ≤ 0.18 | 0.18 ≤ χ ≤ 2.00 | |

| Co-efficient | a | 0 | −3924.5 | 0 | −232 | −3 | |

| b | 492.3 | 516.7 | 0 | 91.8 | 4.2 | ||

| c | 0 | 0.3 | 0 | 12.4 | 20.9 | ||

| Correlation coefficient | 99.2 | 99.0 | 98.9 | 97.7 | 97.9 | ||

| C-SLF 0.5 | Displacement | 0 ≤ χ ≤ 0.01 | 0.01 ≤ χ ≤ 0.12 | 0.12 ≤ χ ≤ 0.15 | 0.15 ≤ χ ≤ 0.90 | 0.90 ≤ χ ≤ 2.00 | |

| Co-efficient | a | 0 | −361.6 | −561.1 | −7.7 | −2.5 | |

| b | 486.6 | 126.6 | 139.7 | 11.8 | 3 | ||

| c | 0 | 4.9 | 5.7 | 12.4 | 16.2 | ||

| Correlation coefficient | 99.1 | 99.3 | 96.1 | 93.0 | 98.6 | ||

| C-SLF 1.0 | Displacement | 0 ≤ χ ≤ 0.04 | 0.04 ≤ χ ≤ 0.06 | - | 0.06 ≤ χ ≤ 0.58 | 0.58 ≤ χ ≤ 2.00 | |

| Co-efficient | a | 0 | −4628.5 | 0 | −29.1 | −1.7 | |

| b | 422.3 | 549.1 | 0 | 31.3 | 0 | ||

| c | 0 | 0.6 | 0 | 15 | 23.6 | ||

| Correlation coefficient | 99.0 | 98.8 | 99.6 | 99.1 | 97.1 | ||

| Section | Second Section | Third Section | Fourth Section | ||||

|---|---|---|---|---|---|---|---|

| Mix Name | 0.5% | 1.0% | 0.5% | 1.0% | 0.5% | 1.0% | |

| H-SF | 0.04 | 0.02 | 0 | 2.51 | 4.74 | 7.66 | |

| C-SF | 1.6 | 0 | 3.96 | 4.63 | 2.05 | 3.99 | |

| C-SLF | 0.3 | 0 | 2.77 | 6.02 | 3.83 | 6.23 | |

| Specimen | Load Transfer Factor (LTF) | Overall Toughness (Toughness) |

|---|---|---|

| H-SF 0.5% | 0 | 13.86 |

| H-SF 1.0% | 5.84 | 28.23 |

| SF 0.5% | 3.34 | 21.91 |

| C-SF 1.0% | 24.06 | 41.61 |

| C-SLF 0.5% | 26.09 | 30.88 |

| C-SLF 1.0% | 40.57 | 41.22 |

| Degree of Freedom (df) | F-Statistic | Significance Probability (Sigf) | Coefficient of Determinant (R2) | Regression Model |

|---|---|---|---|---|

| 3 | 11.84 | 0.041 | 0.798 | y = 17.64x0.45 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Y.-J.; Oh, S.-K.; Kim, B. Effect of Load Transfer Section to Toughness for Steel Fiber-Reinforced Concrete. Appl. Sci. 2017, 7, 549. https://doi.org/10.3390/app7060549

Han Y-J, Oh S-K, Kim B. Effect of Load Transfer Section to Toughness for Steel Fiber-Reinforced Concrete. Applied Sciences. 2017; 7(6):549. https://doi.org/10.3390/app7060549

Chicago/Turabian StyleHan, Yoon-Jung, Sang-Keun Oh, and Byoungil Kim. 2017. "Effect of Load Transfer Section to Toughness for Steel Fiber-Reinforced Concrete" Applied Sciences 7, no. 6: 549. https://doi.org/10.3390/app7060549