Fractal Prediction of Grouting Volume for Treating Karst Caverns along a Shield Tunneling Alignment

Abstract

:1. Introduction

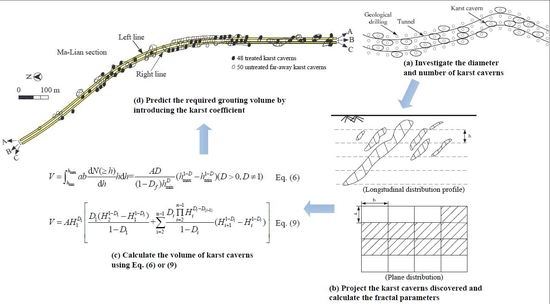

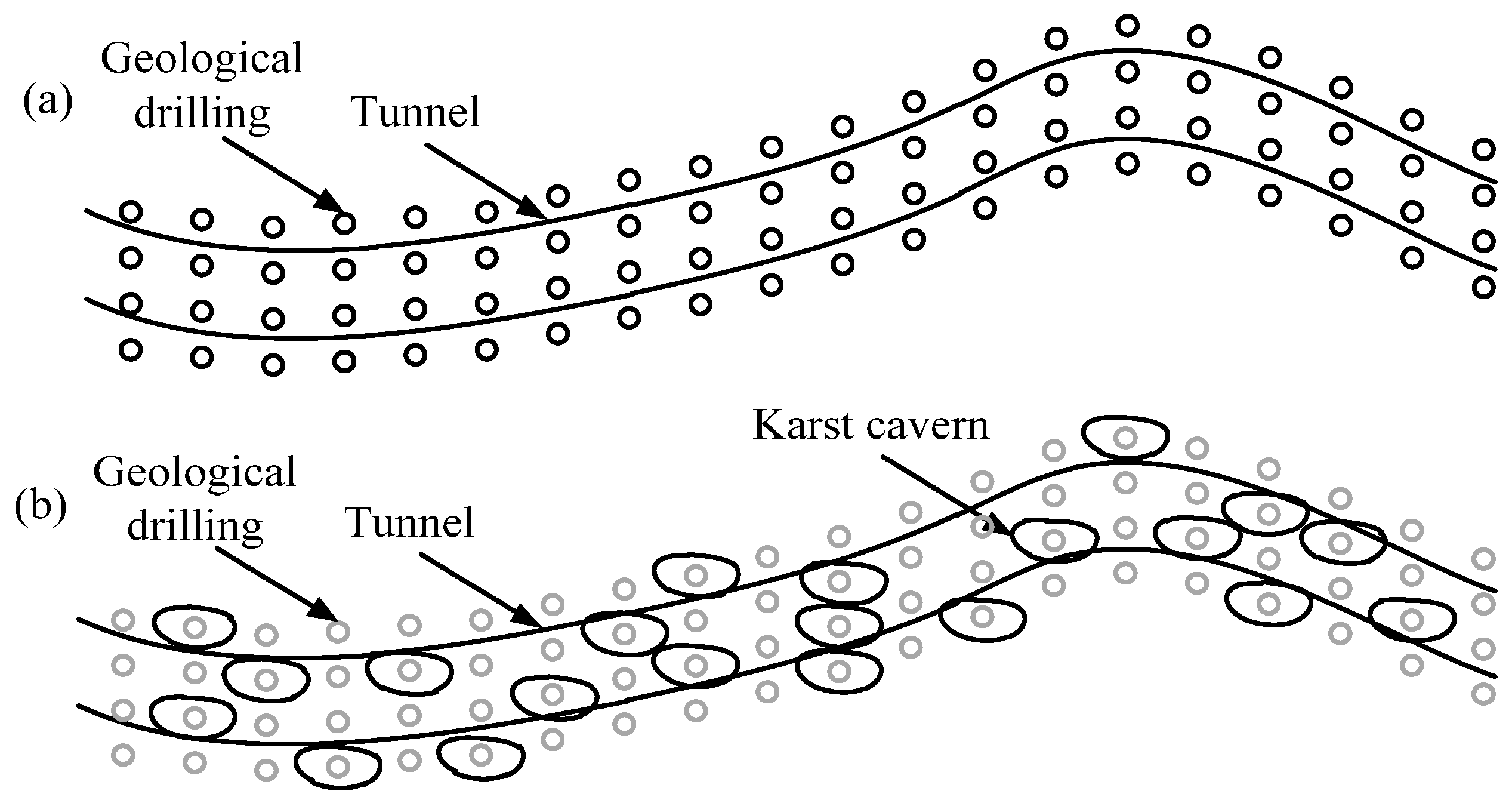

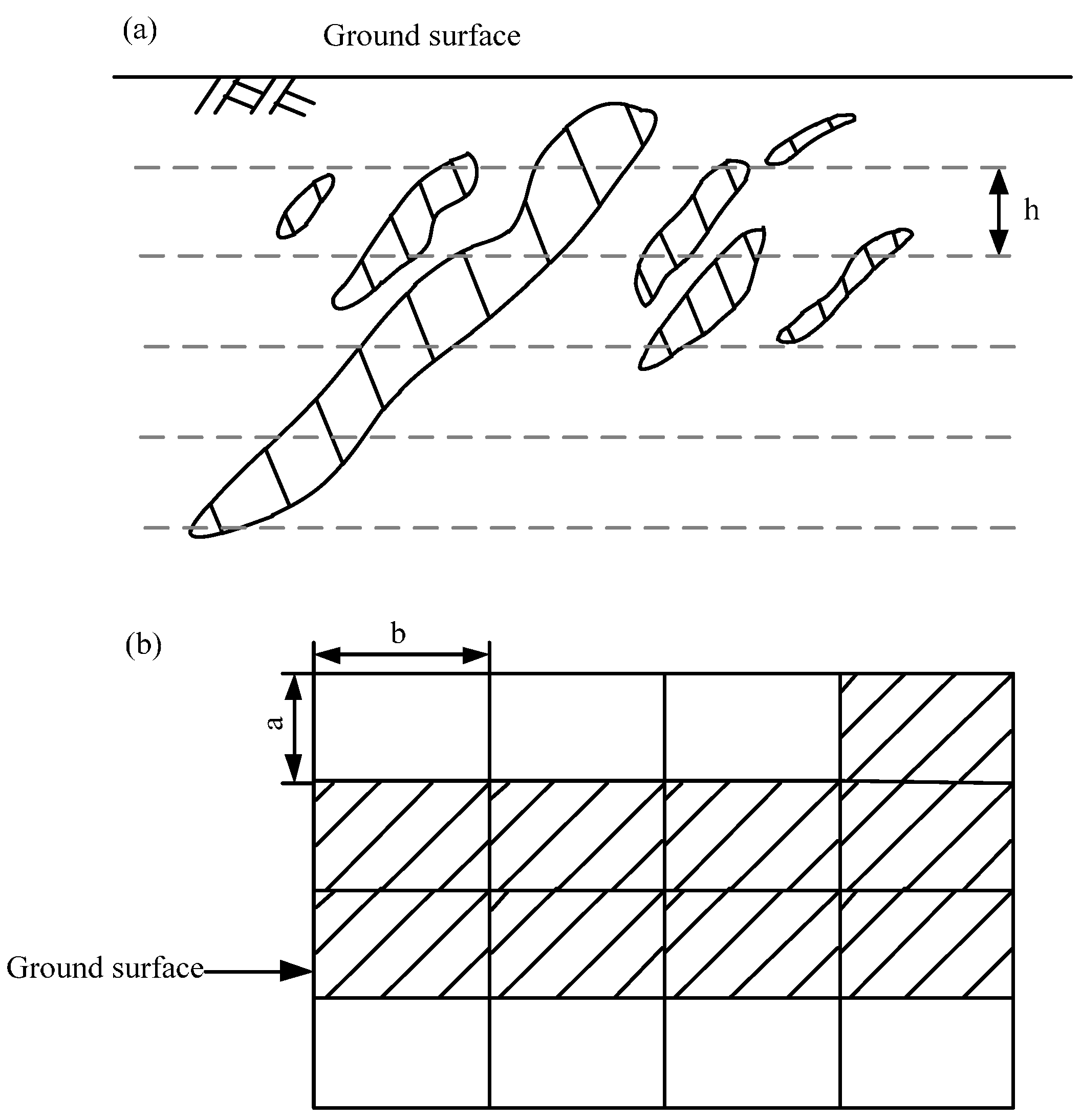

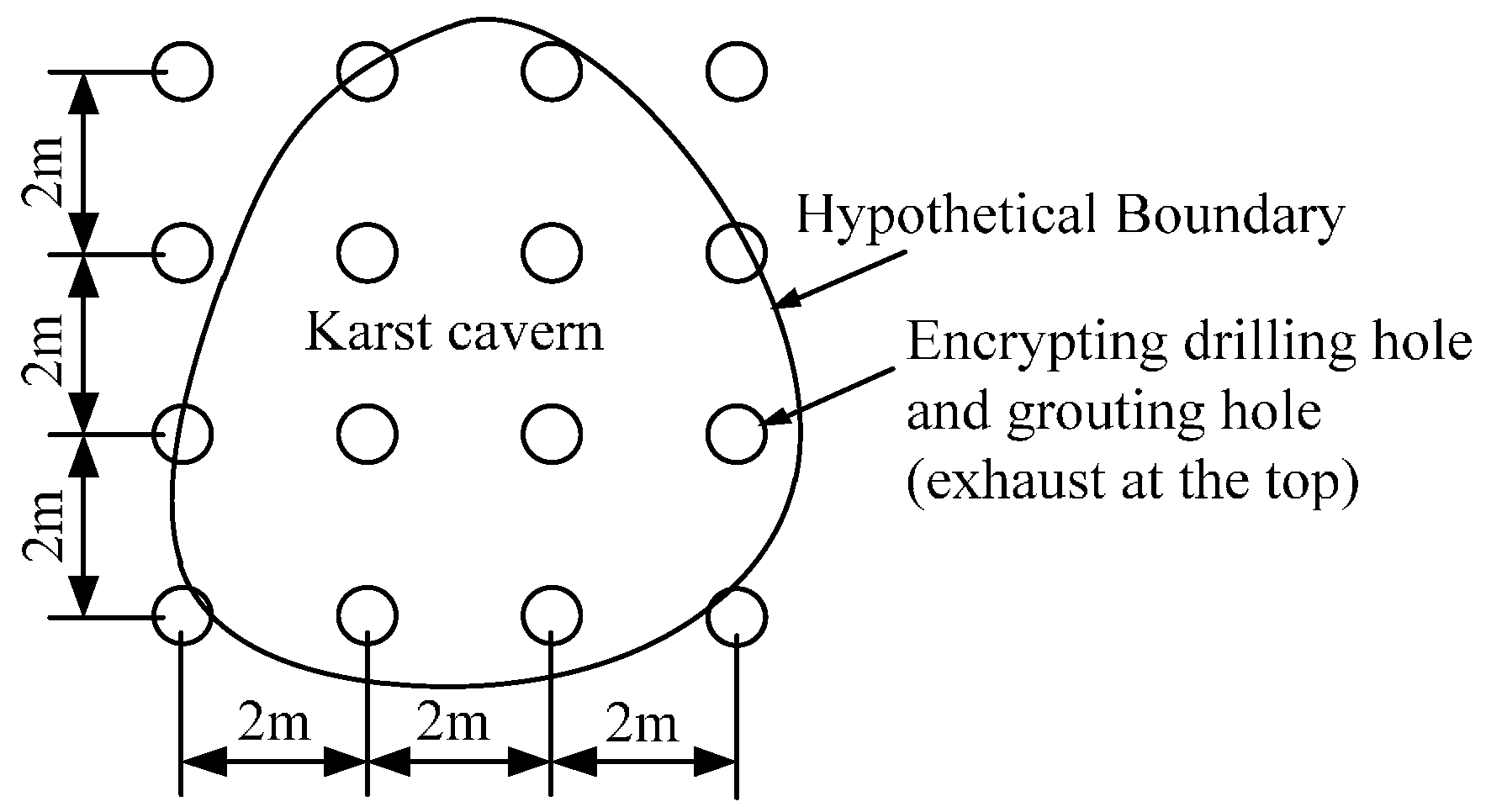

2. Methodology

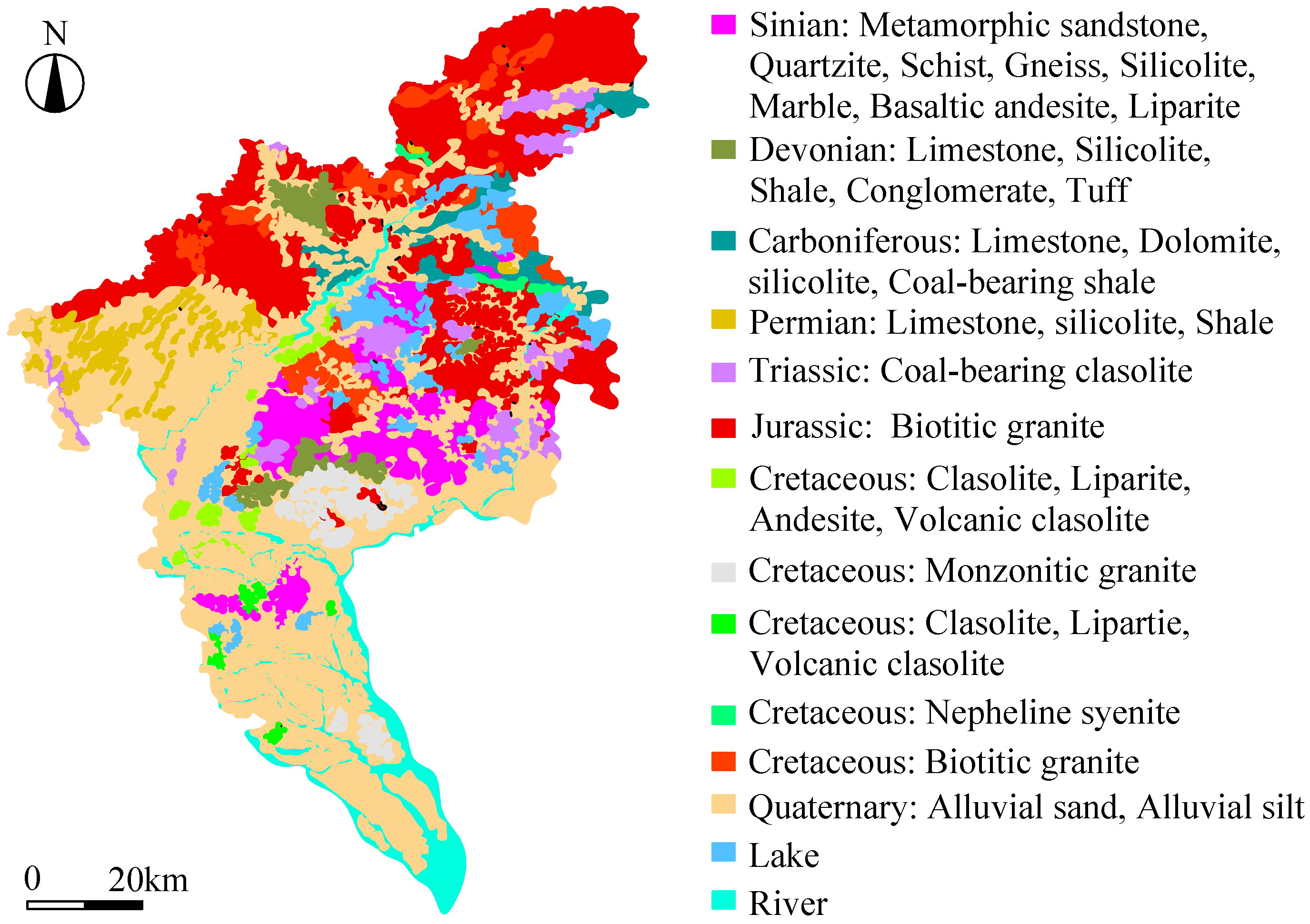

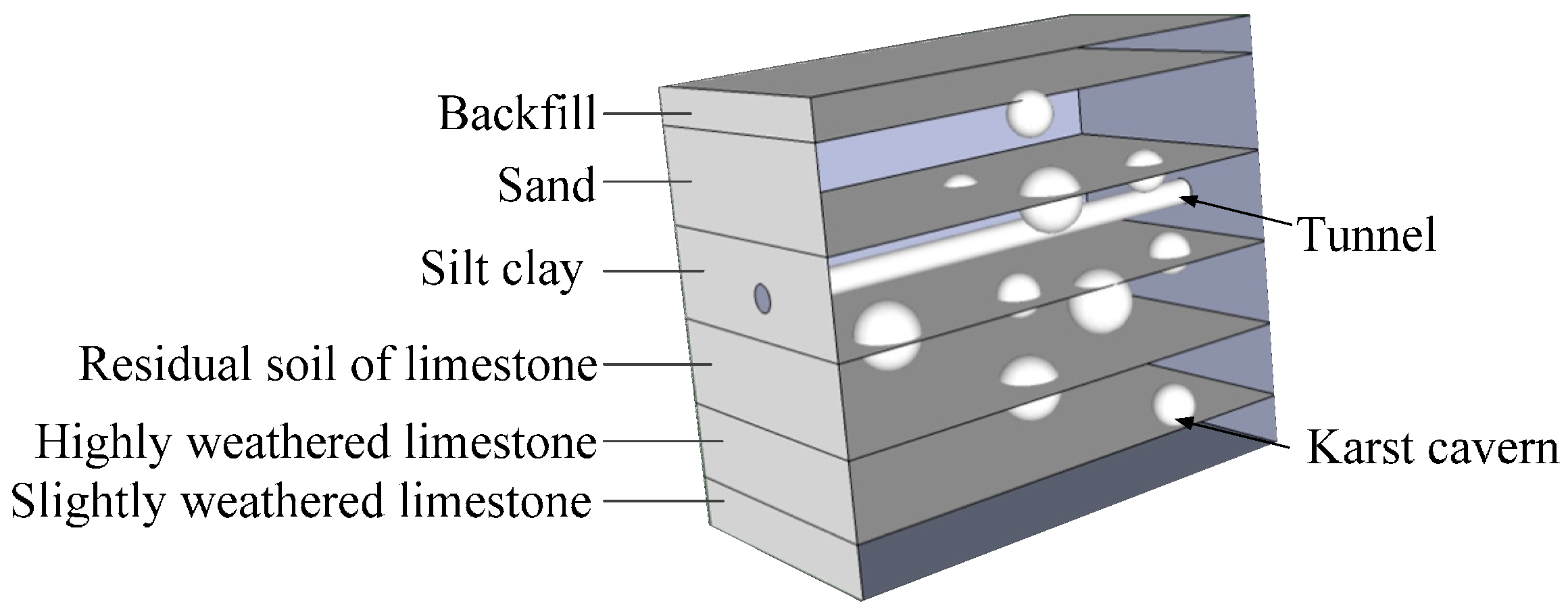

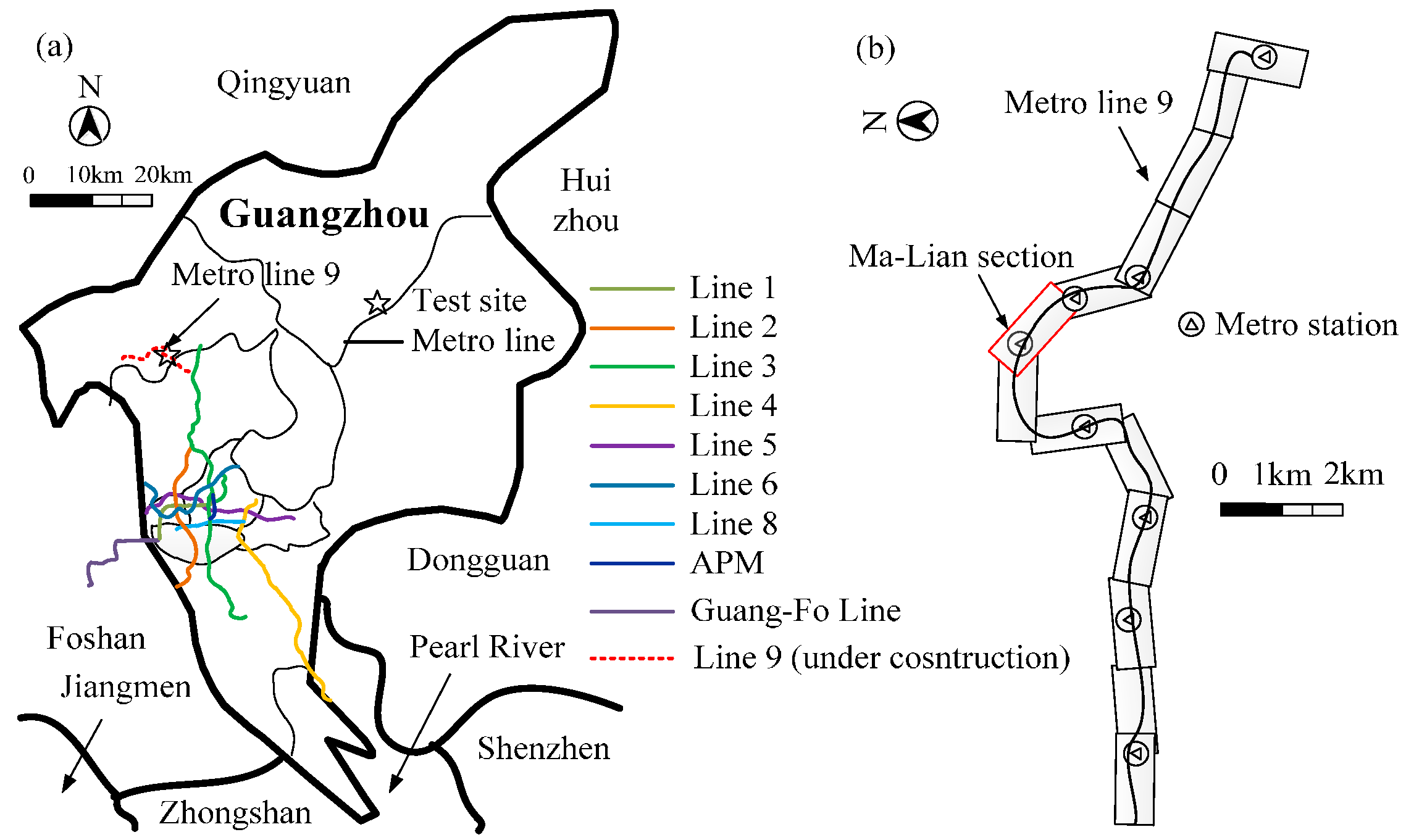

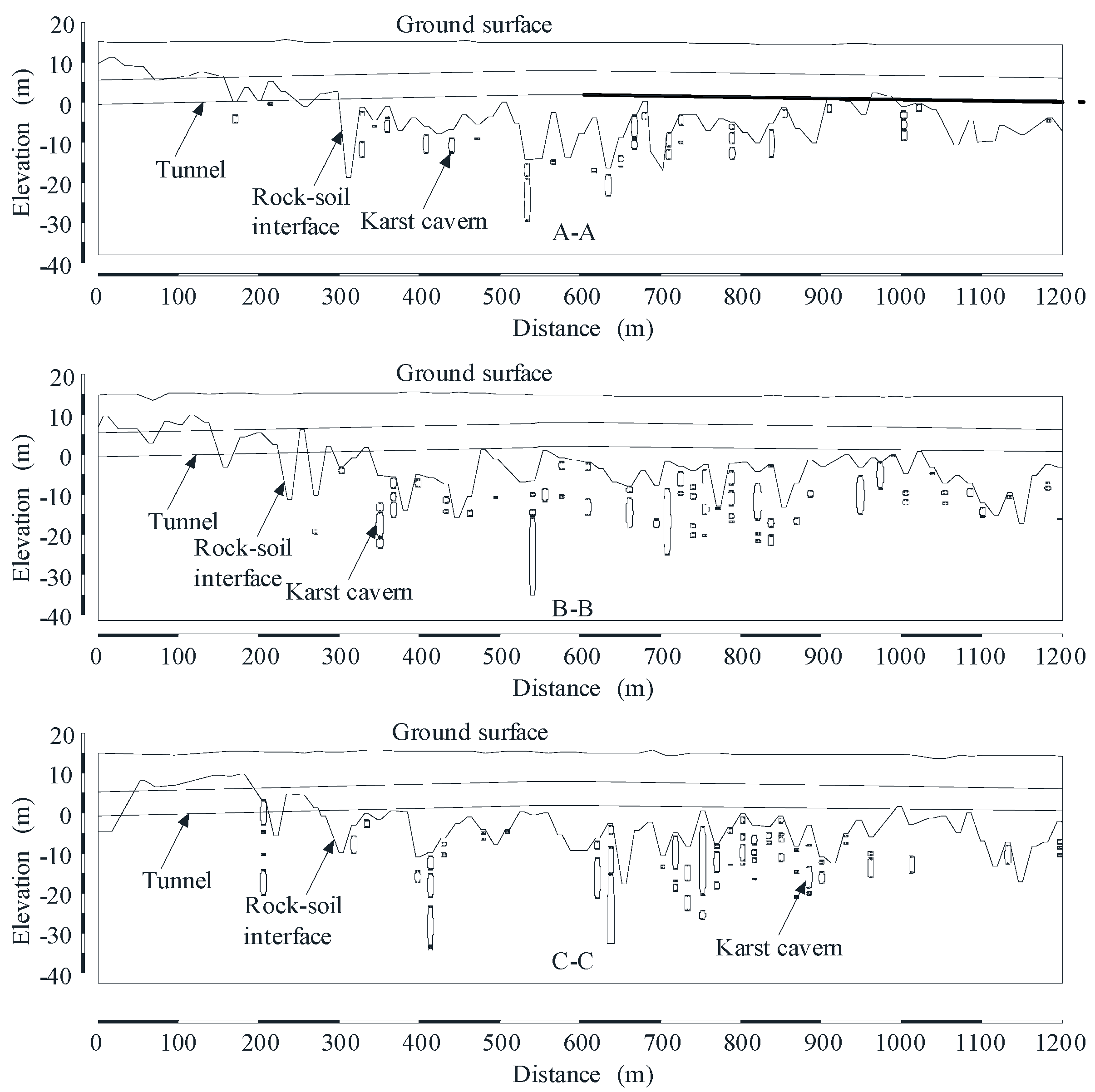

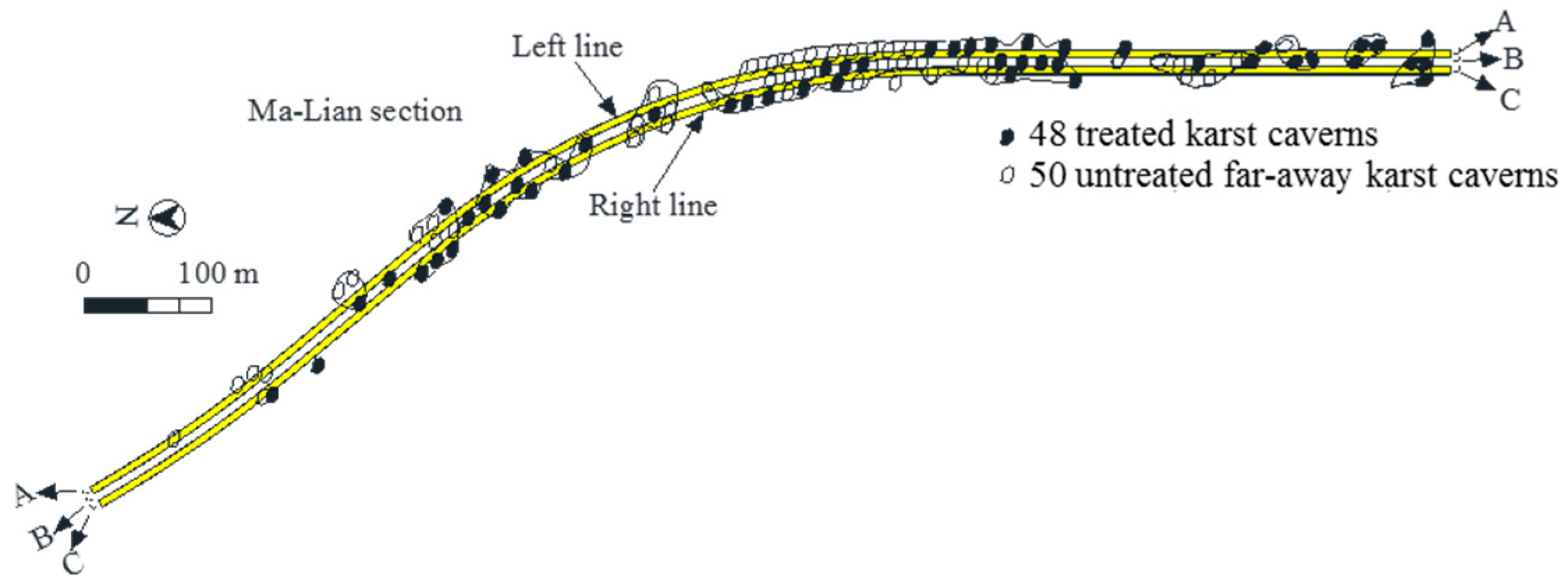

3. Hydrogeology and Engineering Geology of Guangzhou

4. Verification

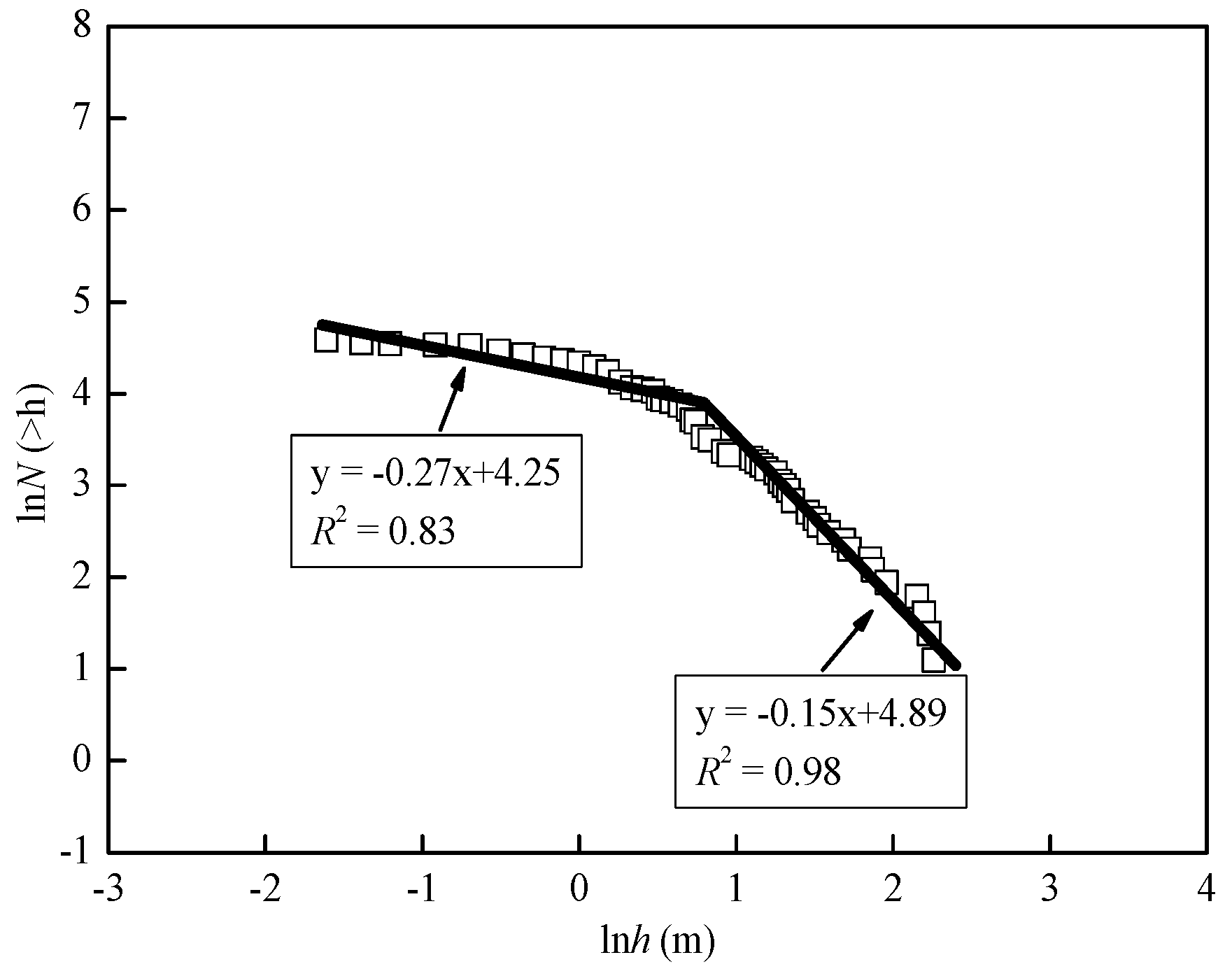

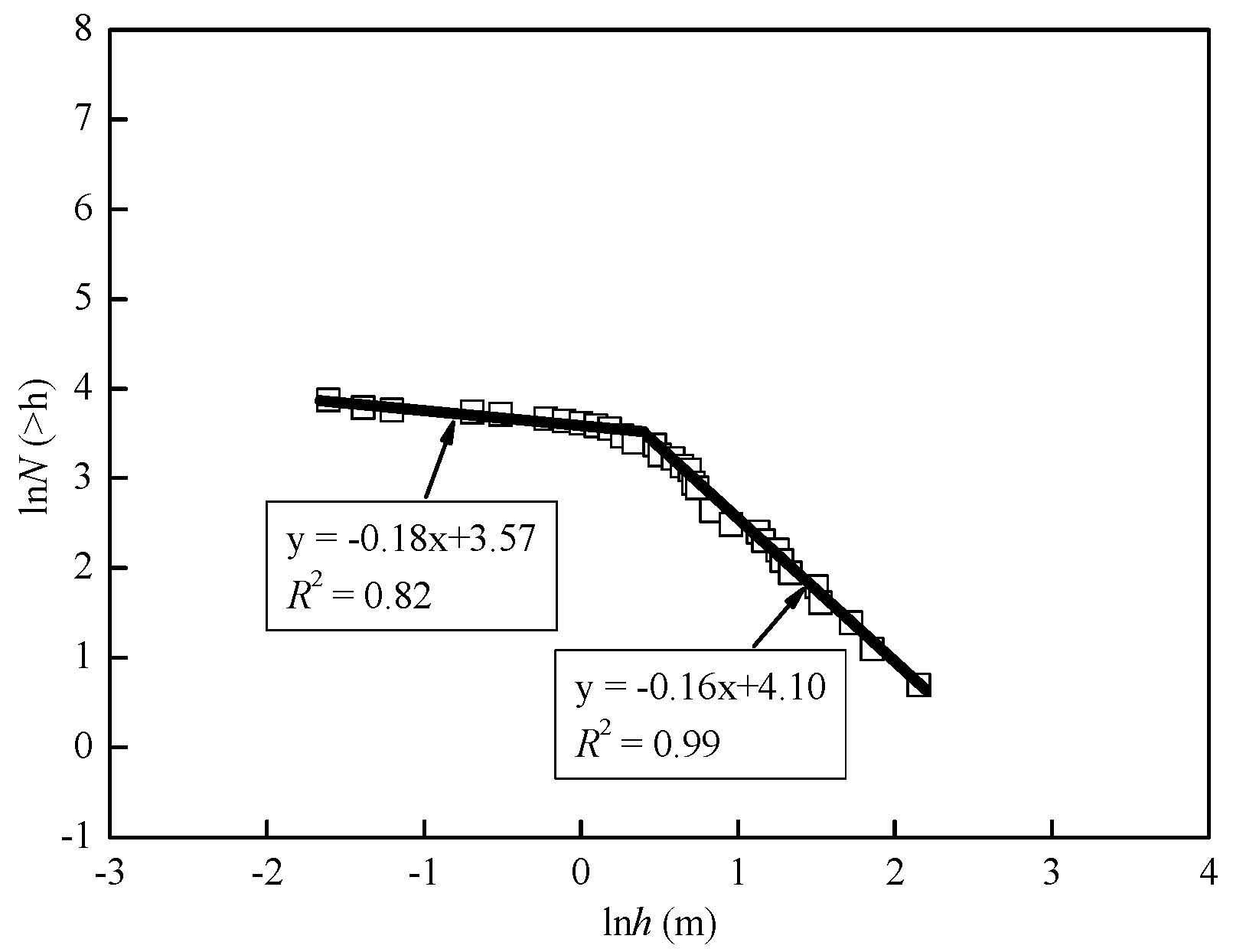

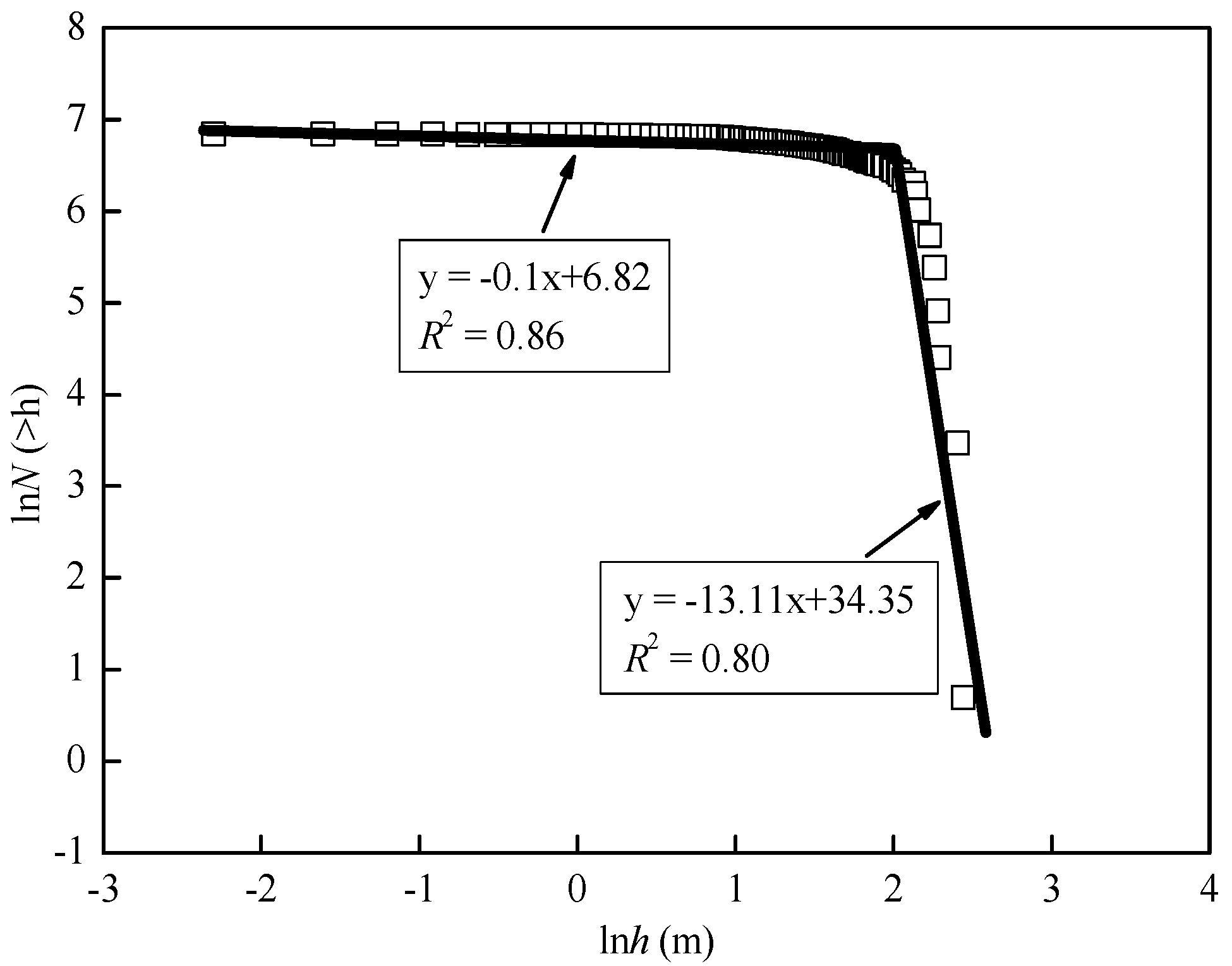

4.1. Fractal Characteristics of Karst Caverns

4.2. Method Verification

4.2.1. Ninety-Eight Geological Drilling Holes

4.2.2. Forty-Eight Geological Drilling Holes

4.2.3. Nine Hundred and Thirty-Seven Grouting Holes

5. Conclusions

- (1)

- Since a karst cavern could be filled with groundwater, sand, or clay, this water along with other sources of groundwater may worsen the geological conditions during shield tunneling. Additionally, severe geo-hazards, such as water ingress, surface settlement, and sinkholes could easily be triggered while tunneling in the buried karst of Guangzhou.

- (2)

- Based on the fractal theory, the proposed method can be used to reasonably estimate the required volume of grouts during treatment. The procedure is: (i) to investigate the distribution of karst caverns along the tunnel alignment; (ii) to calculate the fractal parameters of the karst caverns; (iii) to calculate the total volume of karst caverns; and (iv) to predict the required volume of grouts by introducing the proposed karst grouting coefficient.

- (3)

- The two fractal characteristics—self-similarity and scaling invariance—identified in the literature are also in line with those observed in the karst geology in the Ma-Lian section of Guangzhou metro line no. 9, implying that the fractal theory can be effectively applied to investigate the distribution of karst caverns.

- (4)

- Three datasets including: (i) 98 geological drilling holes; (ii) 48 geological drilling holes; and (iii) 937 grouting holes were established via the presented case history. In the buried karst of Guangzhou, the karst grouting coefficient of 0.26 is recommended for predicting the required volume of grouts for treating karst caverns along tunnel alignment.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Liu, J.H.; Hou, X.Y. Shield Tunnelling Construction; China Railway Publishing House: Beijing, China, 1991. [Google Scholar]

- Mair, R.J. Tunnelling and geotechnics: New horizons. Géotechnique 2008, 58, 695–736. [Google Scholar] [CrossRef]

- Shen, S.L.; Wu, H.N.; Cui, Y.J.; Yin, Z.Y. Long-term settlement behavior of the metro tunnel in Shanghai. Tunn. Undergr. Space Technol. 2014, 40, 309–323. [Google Scholar] [CrossRef]

- Shen, S.L.; Cui, Q.L.; Ho, E.C.; Xu, Y.S. Ground response to multiple parallel microtunneling operations in cemented silty clay and sand. J. Geotech. Geoenviron. Eng. 2016, 142, 04016001. [Google Scholar] [CrossRef]

- Xu, Y.S.; Shen, S.L.; Wu, H.N.; Zhang, N. Risk and impacts on the environment of free-phase biogas in Quaternary deposits along the coastal region of Shanghai. Ocean Eng. 2017, 137, 129–137. [Google Scholar] [CrossRef]

- Wu, H.N.; Huang, R.Q.; Sun, W.J.; Shen, S.L.; Xu, Y.S.; Liu, Y.B.; Du, S.J. Leaking behaviour of shield tunnels under the Huangpu River of Shanghai with induced hazards. Nat. Hazards 2014, 70, 1115–1132. [Google Scholar] [CrossRef]

- Shin, H.S.; Kim, C.Y.; Kim, K.Y.; Bae, G.J.; Hong, S.W. A new strategy for monitoring of adjacent structures to tunnel construction in urban area. Tunn. Undergr. Space Technol. 2006, 21, 461–462. [Google Scholar] [CrossRef]

- Zhao, J.; Gong, Q.M.; Eisensten, Z. Tunnelling through a frequently changing and mixed ground: A case history in Singapore. Tunn. Undergr. Space Technol. 2007, 22, 388–400. [Google Scholar] [CrossRef]

- Standing, J.; Selemetas, D. Greenfield ground response to EPBM tunnelling in London Clay. Geotechnique 2013, 63, 989–1007. [Google Scholar] [CrossRef]

- Tóth, Á.; Gong, Q.; Zhao, J. Case studies of TBM tunneling performance in rock-soil interface mixed ground. Tunn. Undergr. Space Technol. 2013, 38, 140–150. [Google Scholar] [CrossRef]

- Fargnoli, V.; Boldini, D.; Amorosi, A. TBM tunnelling-induced settlements in coarse-grained soils: The case of the new Milan underground line 5. Tunn. Undergr. Space Technol. 2013, 38, 336–347. [Google Scholar] [CrossRef]

- Jiang, M.J.; Konrad, J.M.; Leroueil, S. An efficient technique for generating homogeneous specimens for DEM studies. Comput. Geotech. 2003, 30, 579–597. [Google Scholar] [CrossRef]

- Jiang, M.J.; Leroueil, S.; Konrad, J.M. Insight into strength functions of unsaturated granulates by DEM analysis. Comput. Geotech. 2004, 31, 473–489. [Google Scholar] [CrossRef]

- Jiang, M.J.; Yu, H.S.; Harris, D.A. Novel discrete model for granular material incorporating rolling resistance. Comput. Geotech. 2005, 32, 340–357. [Google Scholar] [CrossRef]

- Jiang, M.J.; Yan, H.B.; Zhu, H.H.; Utili, S. Modeling shear behavior and strain localization in cemented sands by two-dimensional distinct element method analyses. Comput. Geotech. 2011, 38, 14–29. [Google Scholar] [CrossRef]

- Yin, Z.Y.; Karstunen, M.; Chang, C.S.; Koskinen, M.; Lojander, M. Modeling time-dependent behavior of soft sensitive clay. J. Geotech. Geoenviron. Eng. 2011, 137, 1103–1113. [Google Scholar] [CrossRef]

- Yin, Z.Y.; Zhao, J.; Hicher, P.Y. A micromechanics-based model for sand-silt mixtures. Int. J. Solids Struct. 2014, 51, 1350–1363. [Google Scholar] [CrossRef]

- Yin, Z.Y.; Yin, J.H.; Huang, H.W. Rate-dependent and long-term yield stress and strength of soft Wenzhou marine clay: Experiments and modeling. Mar. Georesour. Geotech. 2015, 33, 79–91. [Google Scholar] [CrossRef]

- Yin, Z.Y.; Hicher, P.Y.; Dano, C.; Jin, Y.F. Modeling the mechanical behavior of very coarse granular materials. J. Eng. Mech. 2016, 143. [Google Scholar] [CrossRef]

- Tan, Y.; Li, X.; Kang, Z.; Liu, J.; Zhu, Y. Zoned excavation of an oversized pit close to an existing metro line in stiff clay: Case study. J. Perform. Constr. Facil. 2015, 29, 04014158. [Google Scholar] [CrossRef]

- Yuan, D.X. Karst in China; Shanghai People’s Publishing House: Shanghai, China, 1976. (In Chinese) [Google Scholar]

- Tan, Y.; Lu, Y. Why excavation of a small air shaft caused excessively large displacements: Forensic investigation. J. Perform. Constr. Facil. 2017, 31. [Google Scholar] [CrossRef]

- Shen, S.; Wang, Z.F.; Sun, W.J.; Wang, L.B.; Horpibulsuk, S. A field trial of horizontal jet grouting using the composite-pipe method in the soft deposit of Shanghai. Tunn. Undergr. Space Technol. 2013, 35, 142–151. [Google Scholar] [CrossRef]

- Shen, S.; Wang, Z.F.; Yang, J.; Ho, E.C. Generalized approach for prediction of jet grout column diameter. J. Geotech. Geoenviron. Eng. 2013, 139, 2060–2069. [Google Scholar] [CrossRef]

- Shen, S.; Wang, Z.F.; Horpibulsuk, S.; Kim, Y.H. Jet-Grouting with a newly developed technology: The Twin-Jet Method. Eng. Geol. 2013, 152, 87–95. [Google Scholar] [CrossRef]

- Shen, S.; Xu, Y.S. Numerical evaluation of land subsidence induced by groundwater pumping in Shanghai. Can. Geotech. J. 2011, 48, 1378–1392. [Google Scholar] [CrossRef]

- Wang, Z.F.; Shen, S.; Ho, E.C.; Kim, Y.H. Investigation of field installation effects of horizontal Twin-Jet grouting in Shanghai soft soil deposits. Can. Geotech. J. 2013, 50, 288–297. [Google Scholar] [CrossRef]

- Cui, Q.L.; Wu, H.N.; Shen, S.; Xu, Y.S.; Ye, G.L. Chinese karst geology and measures to prevent geohazards during shield tunnelling in karst region with caves. Nat. Hazards 2015, 77, 129–152. [Google Scholar] [CrossRef]

- Du, Y.J.; Wei, M.L.; Jin, F.; Liu, Z.B. Stress-strain relation and strength characteristics of cement treated zinc-contaminated clay. Eng. Geol. 2013, 167, 20–26. [Google Scholar] [CrossRef]

- Du, Y.J.; Jiang, N.J.; Liu, S.Y.; Jin, F.; Singh, D.N.; Pulppara, A. Engineering properties and microstructural characteristics of cement solidified zinc-contaminated kaolin clay. Can. Geotech. J. 2014, 51, 289–302. [Google Scholar] [CrossRef]

- Du, Y.J.; Horpibulsuk, S.; Wei, M.L.; Martin, L. Modeling compression behavior of cement treated zinc contaminated clayey soils. Soils Found. 2014, 54, 1018–1026. [Google Scholar] [CrossRef]

- Shen, S.L.; Ma, L.; Xu, Y.S.; Yin, Z.Y. Interpretation of increased deformation rate in aquifer IV due to groundwater pumping in Shanghai. Can. Geotech. J. 2013, 50, 1129–1142. [Google Scholar] [CrossRef]

- Xu, Y.S.; Shen, S.; Du, Y.J.; Chai, J.C.; Horpibulsuk, S. Modelling the cutoff behavior of underground structure in multi-aquifer-aquitard groundwater system. Nat. Hazards 2013, 66, 731–748. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. The Fractal Geometry of Nature; W.H. Freeman and Company: San Francisco, CA, USA, 1983; p. 468. [Google Scholar]

- Wang, Q.F.; Deng, J.; Liu, H.; Yang, L.Q.; Wan, L.; Zhang, R.Z. Fractal models for ore reserve estimation. Ore Geol. Rev. 2010, 37, 2–14. [Google Scholar] [CrossRef]

- Li, W.X. The fractal bending of karst cave. Carsologica Sin. 1995, 14, 241–245. (In Chinese) [Google Scholar]

- Hu, Z.X.; Shen, J.F. Study on fractal characteristics of karst morphology system and its mechanism. J. Earth Sci. 1994, 19, 103–108. (In Chinese) [Google Scholar]

- Li, W.X. The change in space density (apparent represent element volume) of karst conduit media and fractal research. Carsologica Sin. 1995, 14, 161–168. (In Chinese) [Google Scholar]

- Pardo-Igúzquiza, E.; Durán, J.J.; Robledo-Ardila, P.A.; Paredes, C. Fractal modeling and estimation of karst conduit porosity. Hydrogeol. Environ. Investig. Karst Syst. 2015, 1, 271–276. [Google Scholar]

- Xu, Y.F.; Cao, L. Fractal representation for effective stress of unsaturated soils. Int. J. Geomech. 2014, 15, 04014098. [Google Scholar] [CrossRef]

- Wan, L.; Deng, J.; Wang, Q.F.; Gao, B.F. Fractal model of the reserve-size distribution of ore deposits and the mathematical analysis of its fractal dimension. Geol. Miner. Resour. South China 2005, 3, 35–37. (In Chinese) [Google Scholar]

- Turcotte, D.L. Fractals in petrology. Lithos 2002, 65, 261–271. [Google Scholar] [CrossRef]

- Wang, Q.F.; Deng, J.; Wan, L.; Yang, L.Q.; Gong, Q.J. Discussion on the kinetic controlling parameter of the stability of orebody distribution in altered rocks in the Dayingezhuang gold deposit, Shandong. Acta Petrol. Sin. 2007, 23, 590–593, (In Chinese with English Abstract). [Google Scholar]

- Deng, J.; Fang, Y.; Yang, L.Q.; Yang, J.C.; Sun, Z.S.; Wang, J.P.; Ding, S.J.; Wang, Q.F. Numerical modelling of ore-forming dynamics of fractal dispersive fluid systems. Acta Geol. Sin. 2001, 75, 220–232. [Google Scholar]

- Deng, J.; Wang, Q.F.; Huang, D.; Wan, L.; Yang, L.Q.; Gao, B.F. Transport network and flow mechanism of shallow ore-bearing magma in Tongling ore cluster area. Sci. China Ser. D 2006, 49, 397–407. [Google Scholar] [CrossRef]

- Feder, J. Fractal; Plenum Press: New York, NY, USA, 1988. [Google Scholar]

- Turcotte, D.L. Fractals and Chaos in Geology and Geophysics; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Agterberg, F.P.; Cheng, Q.M.; Brown, A. Multifractal modelling of fractures in the Lac Bonnet Batholiths, Manitoba. Comput. Geosci. 1996, 22, 497–507. [Google Scholar] [CrossRef]

- Cheng, Q.M. Spatial and scaling modelling for geochemical anomaly separation. J. Geochem. Explor. 1999, 65, 175–194. [Google Scholar] [CrossRef]

- Guangzhou Metro Design & Research Institute Co., Ltd. (GMDRI). General Technical Requirement of Karst Treatment in Guangzhou Metro Line 9 (Trial); Guangzhou Metro Design & Research Institute Co., Ltd. (GMDRI): Guangzhou, China, 2010. (In Chinese) [Google Scholar]

- Lyu, H.M.; Wang, G.F.; Shen, J.; Lu, L.H.; Wang, G.Q. Analysis and GIS mapping of flooding hazards on 10 May, 2016, Guangzhou, China. Water 2016, 8, 447. [Google Scholar] [CrossRef]

- Ma, L.; Xu, Y.S.; Shen, S.; Sun, W.J. Evaluation of the hydraulic conductivity of aquifer with piles. Hydrogeol. J. 2014, 22, 371–382. [Google Scholar] [CrossRef]

- Shen, S.L.; Wu, Y.X.; Xu, Y.S.; Hino, T.; Wu, H.N. Evaluation of hydraulic parameter based on groundwater pumping test of multi-aquifer system of Tianjin. Comput. Geotech. 2015, 68, 196–207. [Google Scholar] [CrossRef]

- Wu, H.N.; Shen, S.; Ma, L.; Yin, Z.Y.; Horpibulsuk, S. Evaluation of the strength increase of marine clay under staged embankment loading: A case study. Mar. Georesour. Geotechnol. 2015, 33, 532–541. [Google Scholar] [CrossRef]

- Wu, Y.X.; Shen, S.; Wu, H.N.; Xu, Y.S.; Yin, Z.Y.; Sun, W.J. Environmental protection using dewatering technology in a deep confined aquifer beneath a shallow aquifer. Eng. Geol. 2015, 196, 59–70. [Google Scholar] [CrossRef]

- Wu, Y.X.; Shen, S.; Xu, Y.S.; Yin, Z.Y. Characteristics of groundwater seepage with cutoff wall in gravel aquifer. I: Field observations. Can. Geotech. J. 2015, 52, 1526–1538. [Google Scholar]

- Wu, Y.X.; Shen, S.; Yin, Z.Y.; Xu, Y.S. Characteristics of groundwater seepage with cutoff wall in gravel aquifer. II: Numerical analysis. Can. Geotech. J. 2015, 52, 1539–1549. [Google Scholar]

- Xu, Y.S.; Ma, L.; Shen, S.; Sun, W.J. Evaluation of land subsidence by considering underground structures penetrated into aquifers in Shanghai. Hydrogeol. J. 2012, 20, 1623–1634. [Google Scholar] [CrossRef]

- Xu, Y.S.; Ma, L.; Du, Y.J.; Shen, S. Analysis on urbanization induced land subsidence in Shanghai. Nat. Hazards 2012, 63, 1255–1267. [Google Scholar] [CrossRef]

- Xu, Y.S.; Shen, S.; Ma, L.; Sun, W.J.; Yin, Z.Y. Evaluation of the blocking effect of retaining walls on groundwater seepage in aquifers with different insertion depths. Eng. Geol. 2014, 183, 254–264. [Google Scholar] [CrossRef]

- Xu, Y.S.; Shen, S.; Ren, D.J.; Wu, H.N. Factor analysis of land subsidence in Shanghai: A view based on Strategic Environmental Assessment. Sustainability 2016, 8, 573. [Google Scholar] [CrossRef]

- Wu, Y.X.; Shen, S.; Yuan, D.J. Characteristics of dewatering induced drawdown curve under barrier effect of retaining wall in aquifer. J. Hydrol. 2016, 539, 554–566. [Google Scholar] [CrossRef]

- Wu, H.N.; Shen, S.; Liao, S.M.; Yin, Z.Y. Longitudinal structural modelling of shield tunnels considering shearing dislocation between segmental rings. Tunn. Undergr. Space Technol. 2015, 50, 317–323. [Google Scholar] [CrossRef]

- Shen, S.L.; Wang, J.P.; Wu, H.N.; Xu, Y.S.; Ye, G.L.; Yin, Z.Y. Evaluation of hydraulic conductivity for both marine and deltaic deposit based on piezocone test. Ocean Eng. 2015, 110, 174–182. [Google Scholar] [CrossRef]

- Shen, S.L.; Wang, Z.F.; Cheng, W.C. Estimation of lateral displacement induced by jet grouting in clayey soils. Geotechnique 2017, 67, 621–630. [Google Scholar] [CrossRef]

- Zhang, N.; Shen, S.; Wu, H.N.; Chai, J.; Yin, Z. Evaluation of effect of basal geotextile reinforcement under embankment loading on soft marine deposits. Geotext. Geomembr. 2015, 43, 506–514. [Google Scholar] [CrossRef]

- Ren, D.J.; Shen, S.L.; Cheng, W.C.; Zhang, N.; Wang, Z.F. Geological formation and geo-hazards during subway construction in Guangzhou. Environ. Earth Sci. 2016, 75, 934. [Google Scholar] [CrossRef]

- Liu, X.X.; Xu, Y.S.; Cheng, W.C.; Shen, S.L.; Horpibulsuk, S. Investigation of hydraulic parameters of a weathered mylonite fault from field pumping tests: A case study. Bull. Eng. Geol. Environ. 2016. [Google Scholar] [CrossRef]

- Ni, J.C.; Cheng, W.C. Steering efficiency of microtunneling in various deposits. Tunn. Undergr. Space Technol. 2012, 28, 321–330. [Google Scholar] [CrossRef]

- Ni, J.C.; Cheng, W.C. Characterising the failure pattern of a station box of Taipei Rapid Transit System (TRTS) and its rehabilitation. Tunn. Undergr. Space Technol. 2012, 32, 260–272. [Google Scholar] [CrossRef]

- Ni, J.C.; Ge, L.; Cheng, W.C. Variation of slurry pipe jacking force in coarse and fine soils. In Proceedings of the 4th GeoChina International Conference Sustainable Civil Infrastructures: Innovative Technologies for Severe Weathers and Climate Changes, Shandong, China, 25–27 July 2016; pp. 182–188. [Google Scholar]

- Cheng, W.C.; Ni, J.C.; Shen, S.L.; Huang, H.W. Investigation into factors affecting jacking force: A case study. ICE Proc. Geotech. Eng. 2017. [Google Scholar] [CrossRef]

- Ruiz, R.L.; Zapata, E.P.; Parra, R.; Harter, T.; Mahlknecht, J. Investigation of the geochemical evolution of groundwater under agricultural land: A case study in northeastern Mexico. J. Hydrol. 2015, 521, 410–423. [Google Scholar] [CrossRef]

- Lu, Y.R. China Karst; Higher Education Press: Beijing, China, 2010. (In Chinese) [Google Scholar]

- Li, C.S. The Applied Study on the Fractal Forecasting Method of Karst Geology. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2006. [Google Scholar]

- Ni, J.C.; Cheng, W.C. Trial grouting under rigid pavement: A case history in Magong Airport, Penghu. J. Test. Eval. 2012, 40, 107–118. [Google Scholar]

- Ni, J.C.; Cheng, W.C. Field response of high speed rail box tunnel during horizontal grouting. J. Test. Eval. 2015, 43, 398–413. [Google Scholar] [CrossRef]

- Ni, J.C.; Cheng, W.C. Shield machine disassembly in grouted soils outside the ventilation shaft: A case history in Taipei Rapid Transit System (TRTS). Tunn. Undergr. Space Technol. 2011, 26, 435–443. [Google Scholar] [CrossRef]

| Case | Covering Area (m2) | Fractal Parameters | V (m3) | RC (m3) | VR | ||||

|---|---|---|---|---|---|---|---|---|---|

| h1 | D1 | h2 | D2 | hmax | |||||

| A | 20,384 | 0.2 | 0.27 | 1.6 | 0.15 | 9.6 | 20,446.9 | 2292.1 | 0.11 |

| B | 9984 | 0.12 | 0.18 | 1.5 | 0.16 | 8.6 | 8742.2 | 0.26 | |

| C | 3748 | 0.1 | 0.1 | 7.9 | 13.11 | 11.5 | 2083.7 | 1.1 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, W.-C.; Cui, Q.-L.; Shen, J.S.-L.; Arulrajah, A.; Yuan, D.-J. Fractal Prediction of Grouting Volume for Treating Karst Caverns along a Shield Tunneling Alignment. Appl. Sci. 2017, 7, 652. https://doi.org/10.3390/app7070652

Cheng W-C, Cui Q-L, Shen JS-L, Arulrajah A, Yuan D-J. Fractal Prediction of Grouting Volume for Treating Karst Caverns along a Shield Tunneling Alignment. Applied Sciences. 2017; 7(7):652. https://doi.org/10.3390/app7070652

Chicago/Turabian StyleCheng, Wen-Chieh, Qing-Long Cui, Jack Shui-Long Shen, Arul Arulrajah, and Da-Jun Yuan. 2017. "Fractal Prediction of Grouting Volume for Treating Karst Caverns along a Shield Tunneling Alignment" Applied Sciences 7, no. 7: 652. https://doi.org/10.3390/app7070652