Sampietrini Stone Pavements: Distress Analysis Using Pavement Condition Index Method

Abstract

:1. Introduction

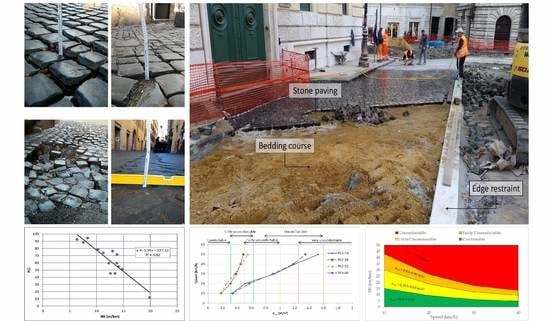

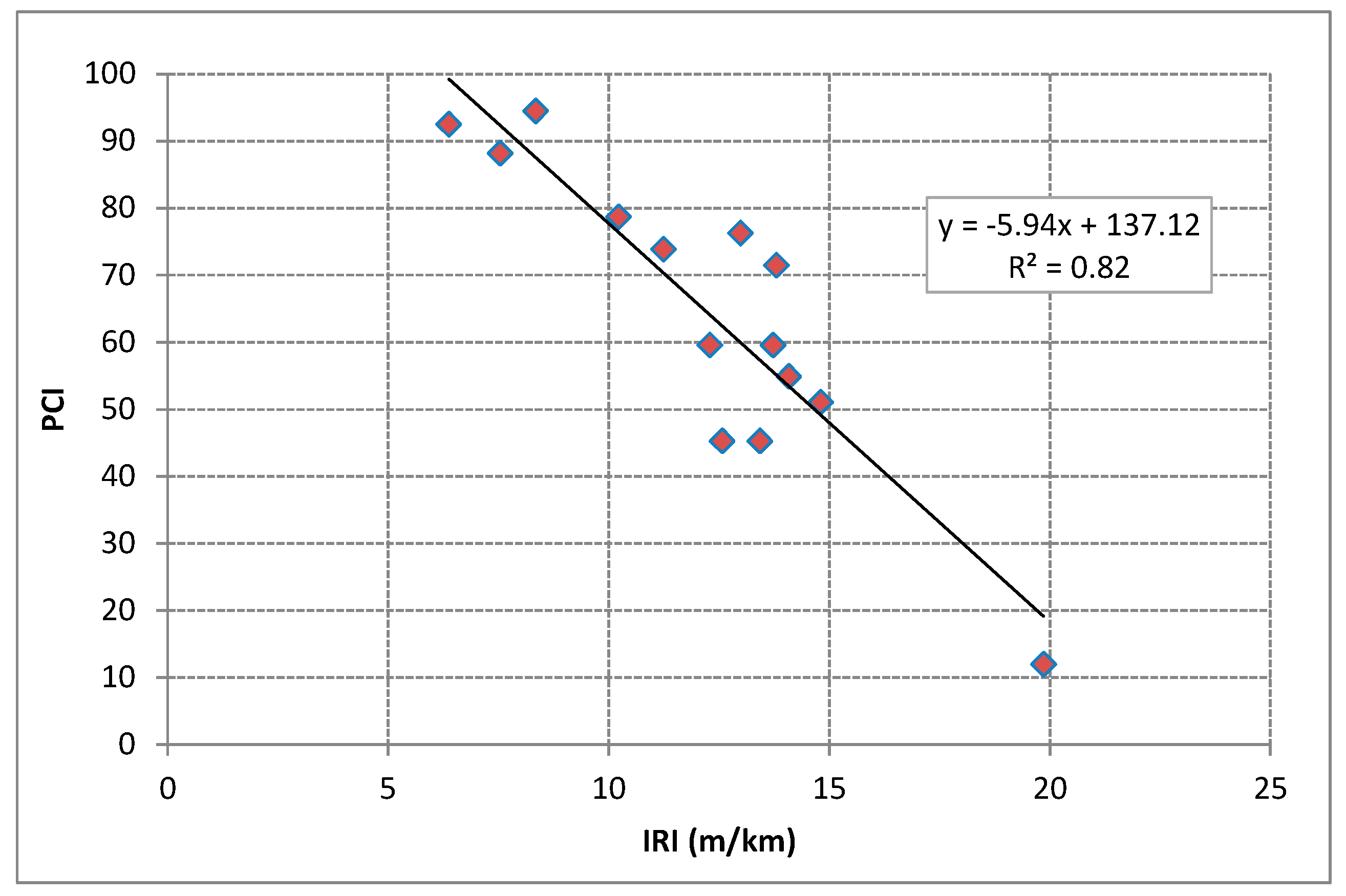

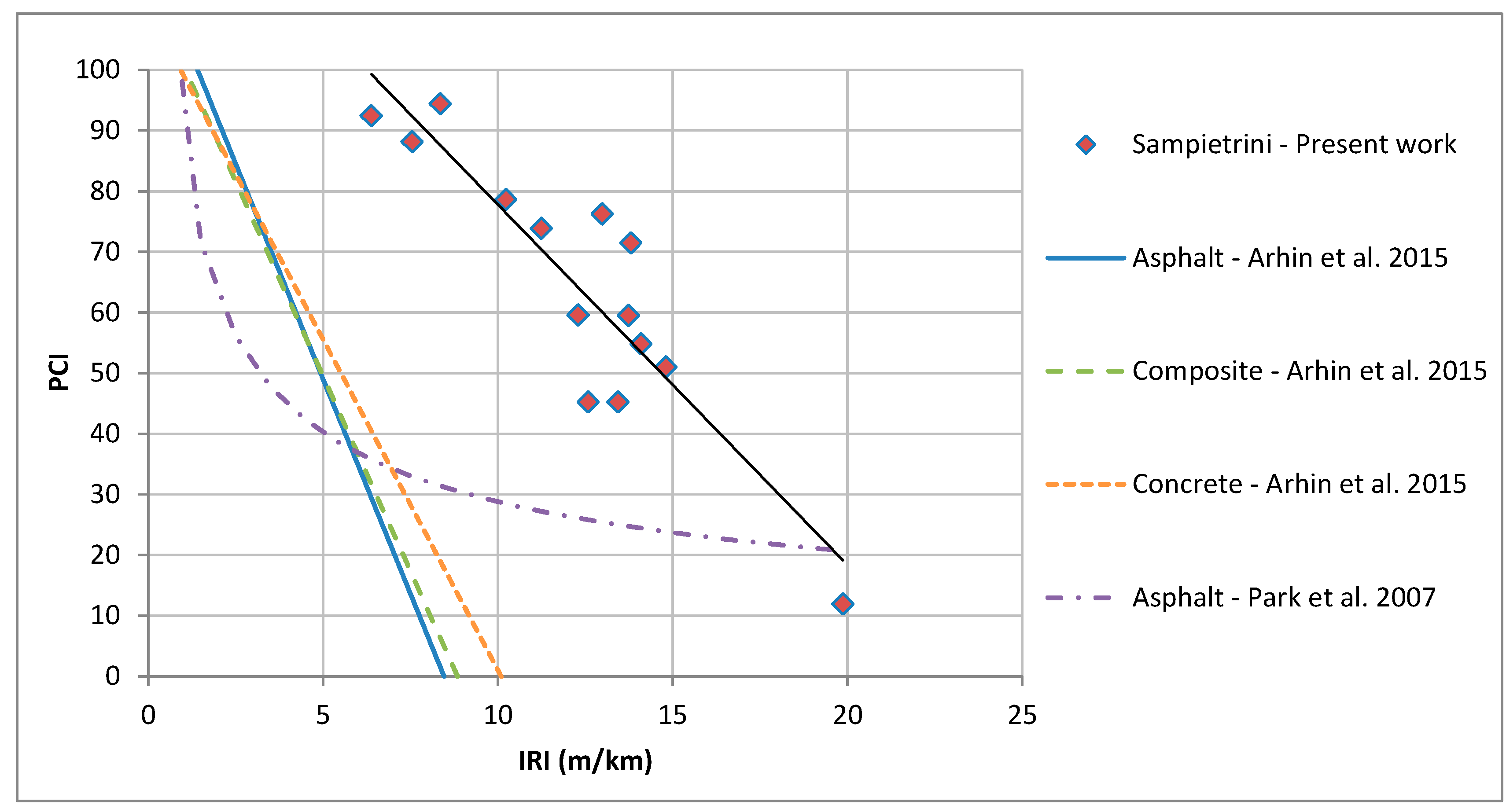

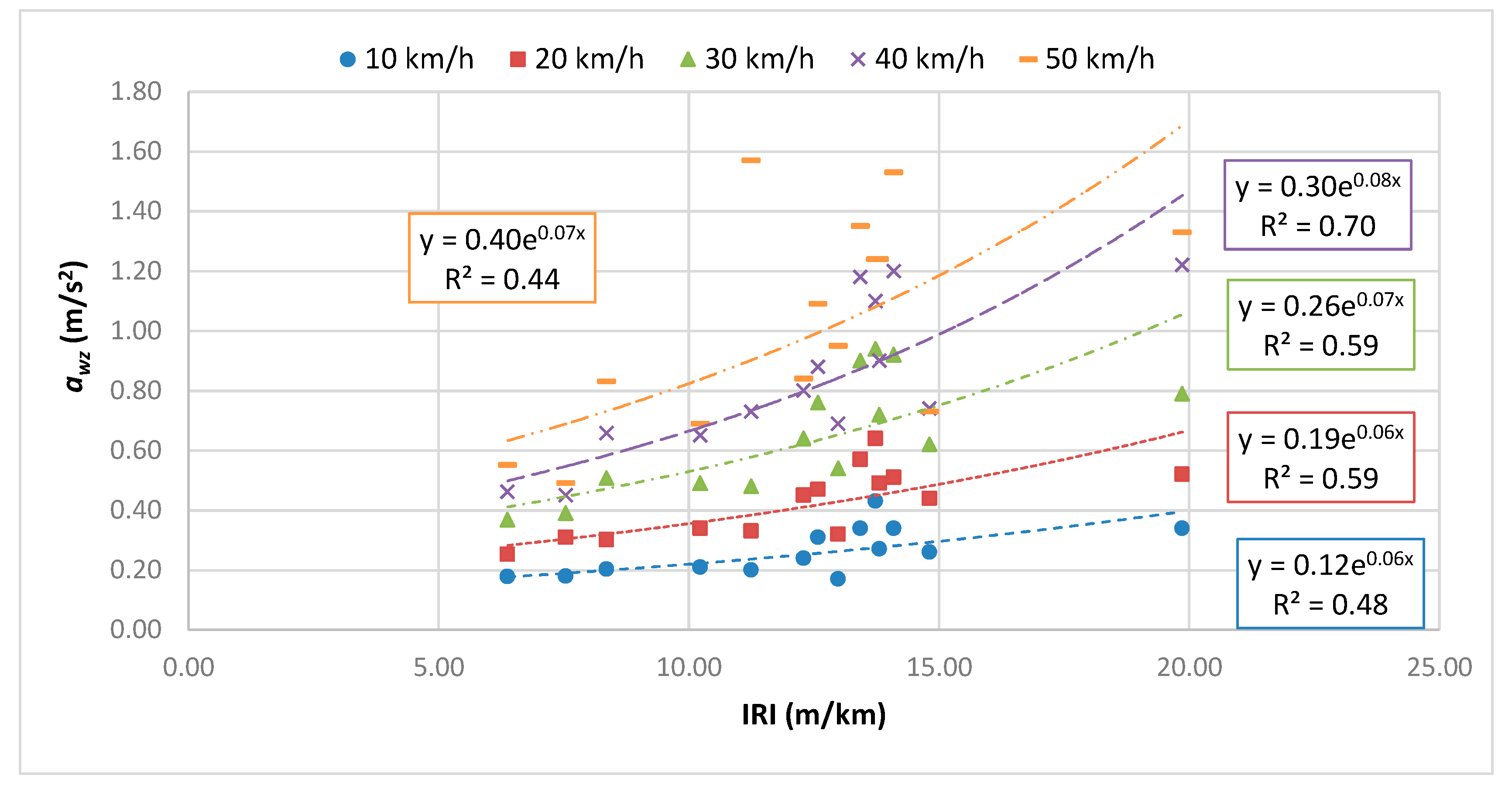

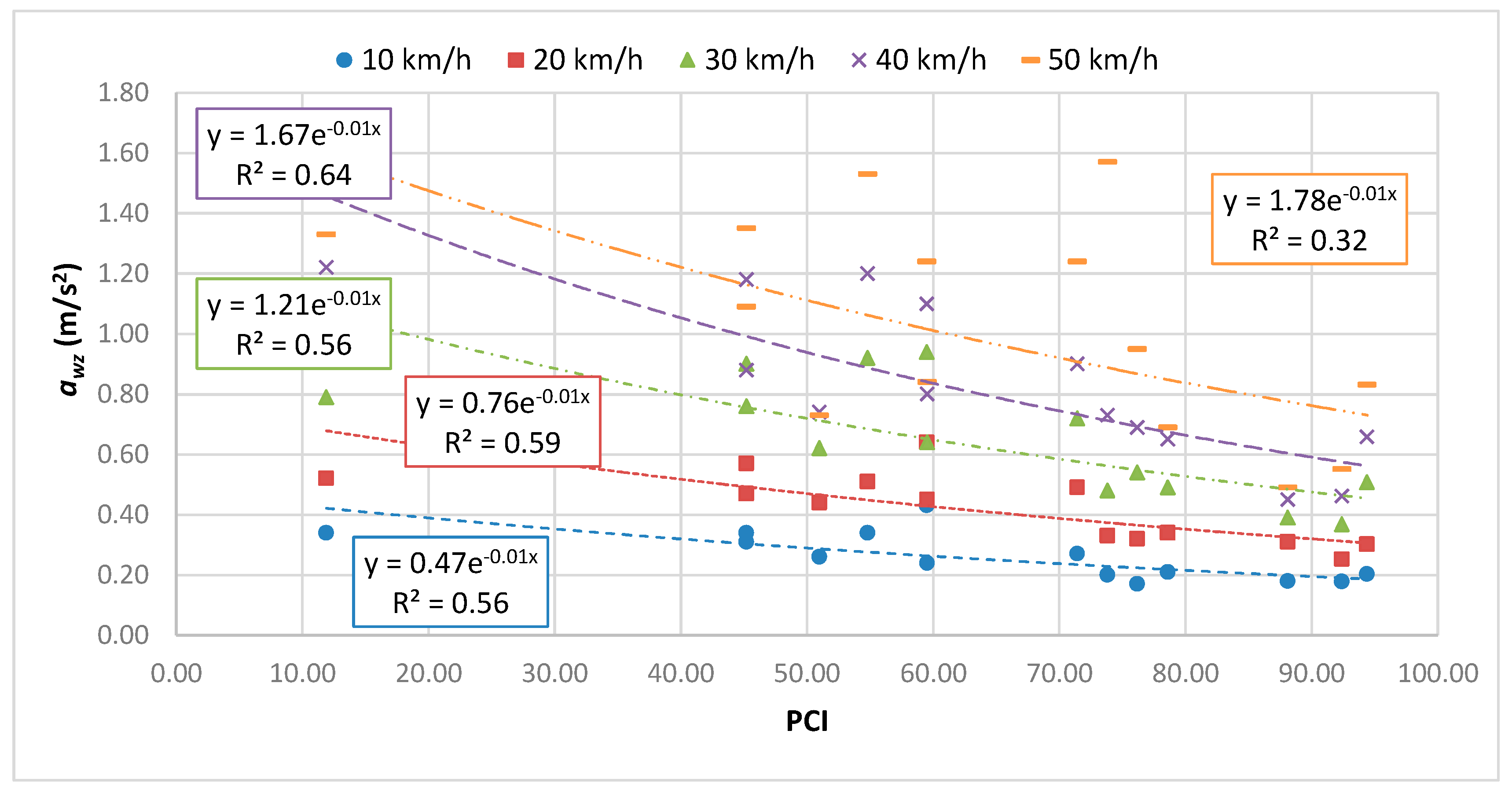

2. Methodology and Data

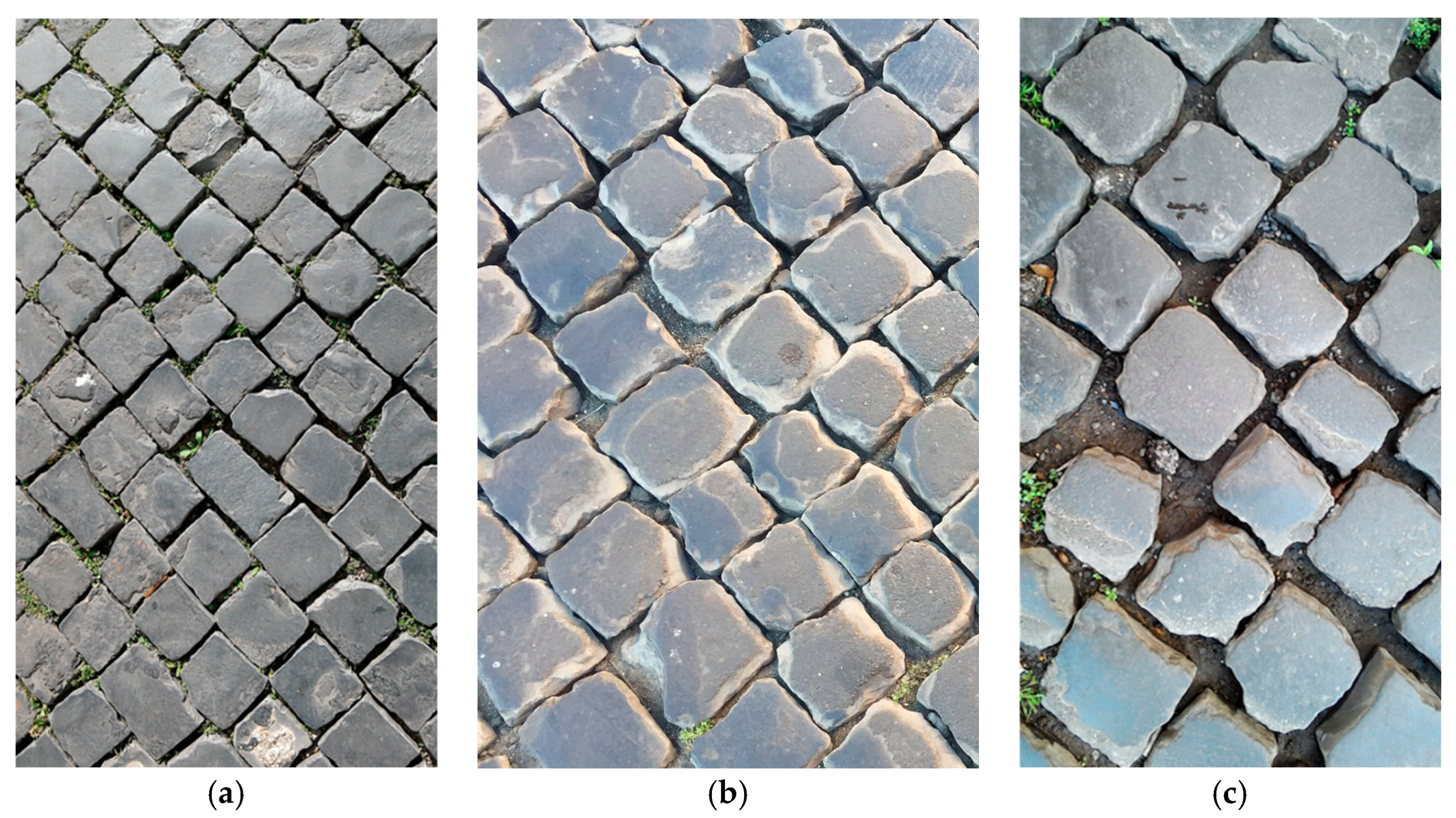

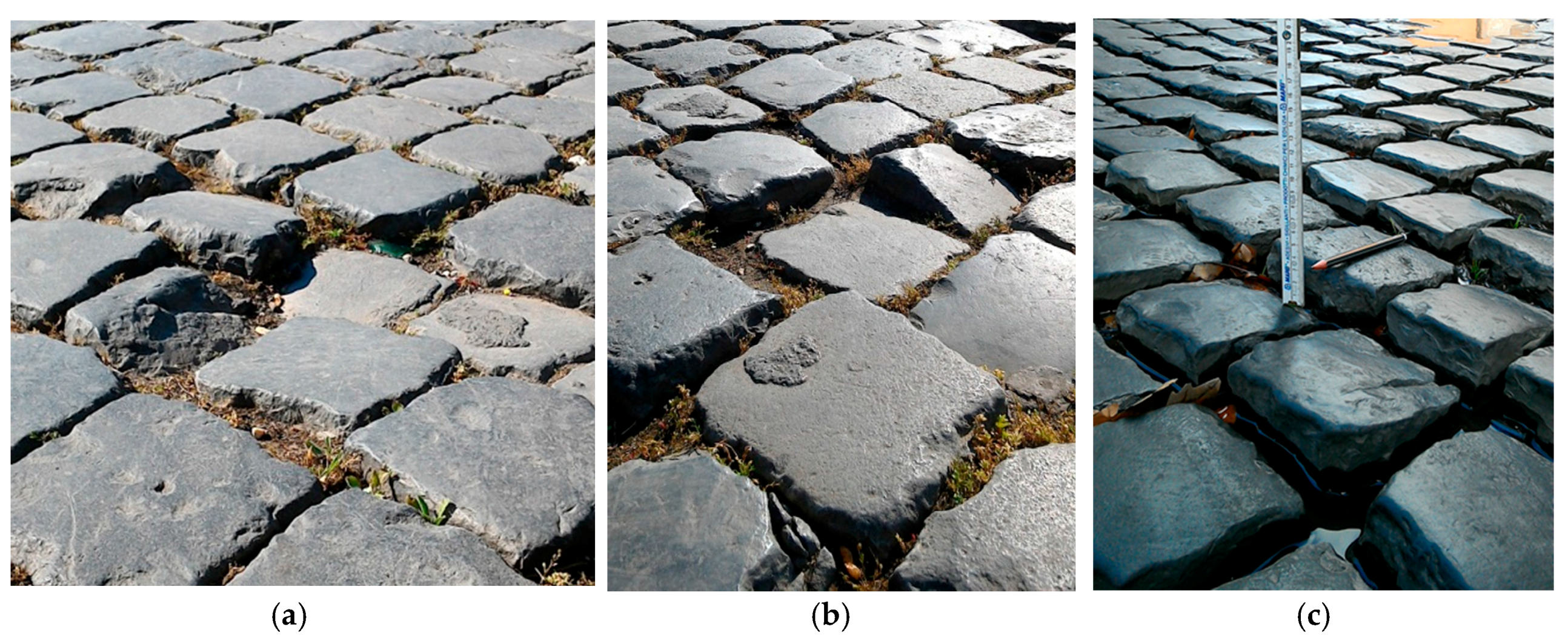

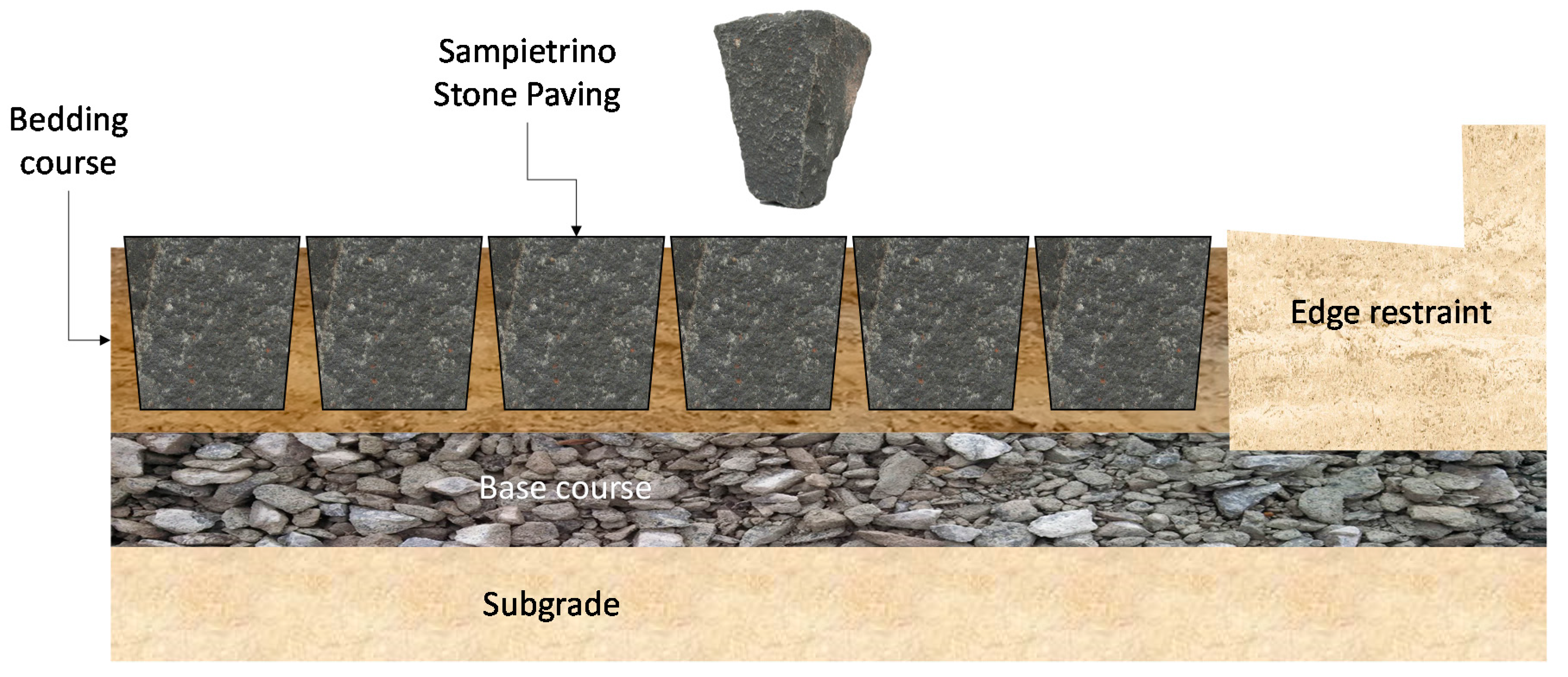

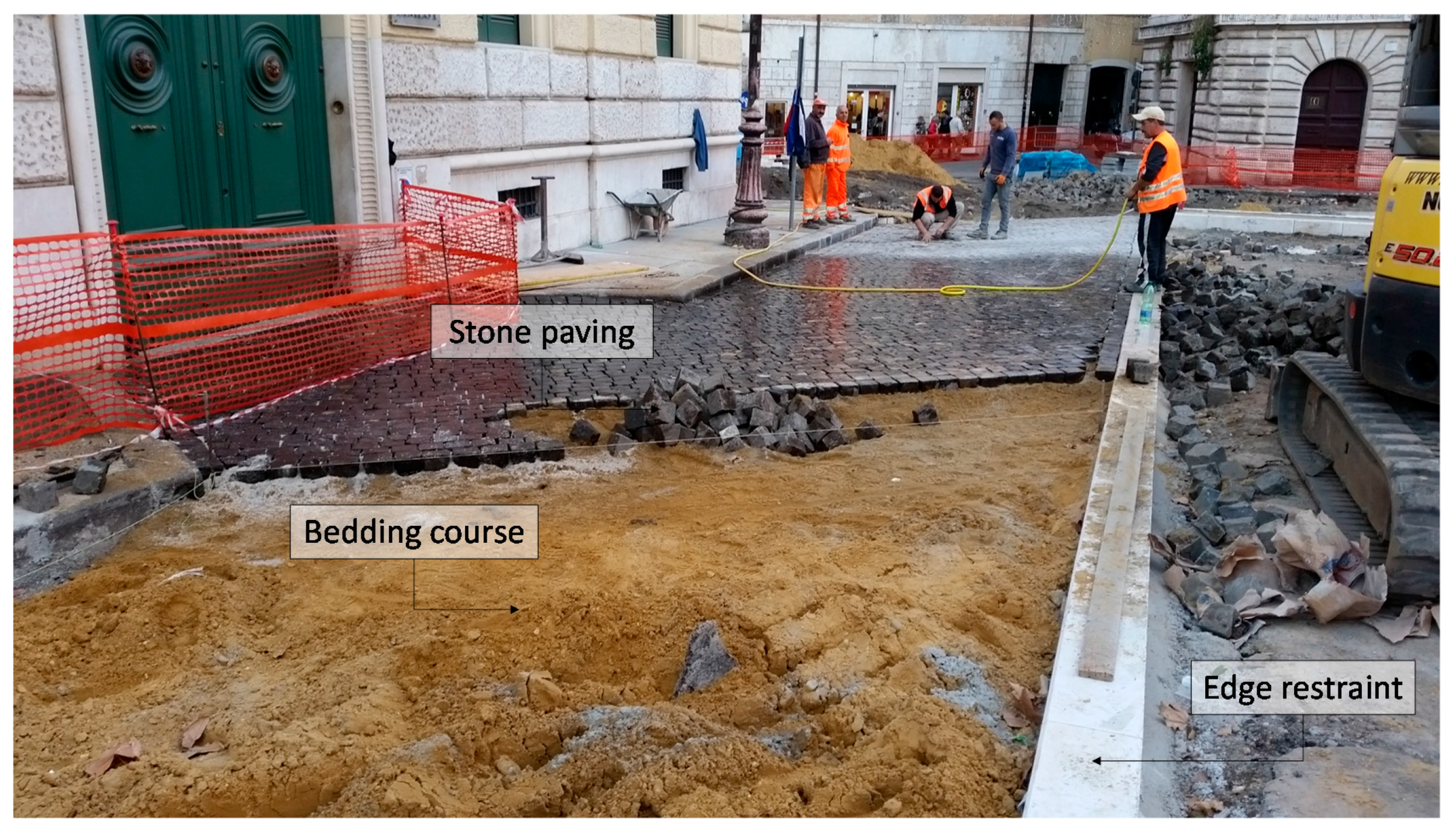

2.1. Sampietrini Pavements

2.2. Performed Analyses

2.2.1. Pavement Condition Index (PCI)

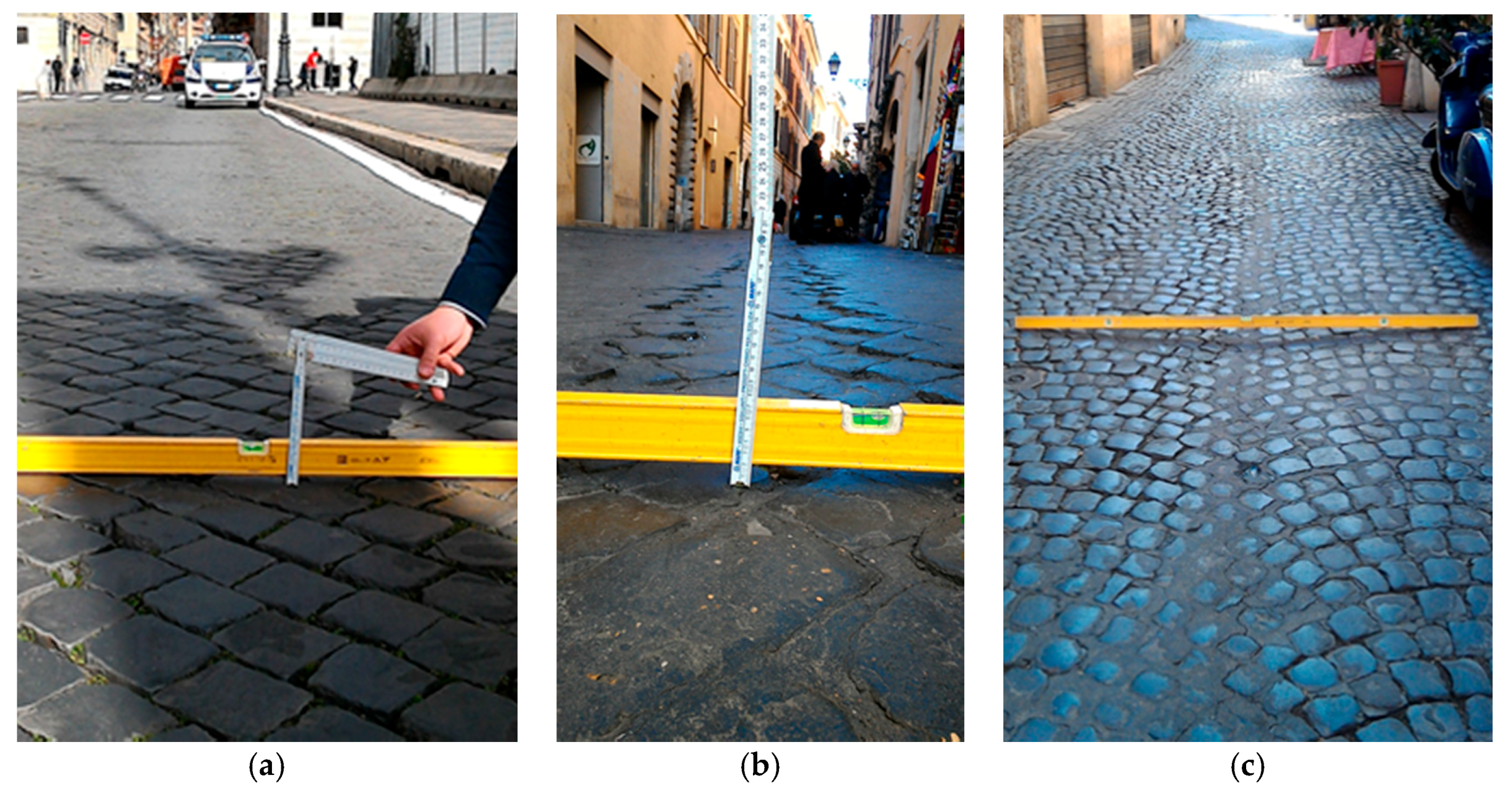

2.2.2. International Roughness Index (IRI)

2.2.3. Frequency-Weighted Vertical Acceleration (awz)

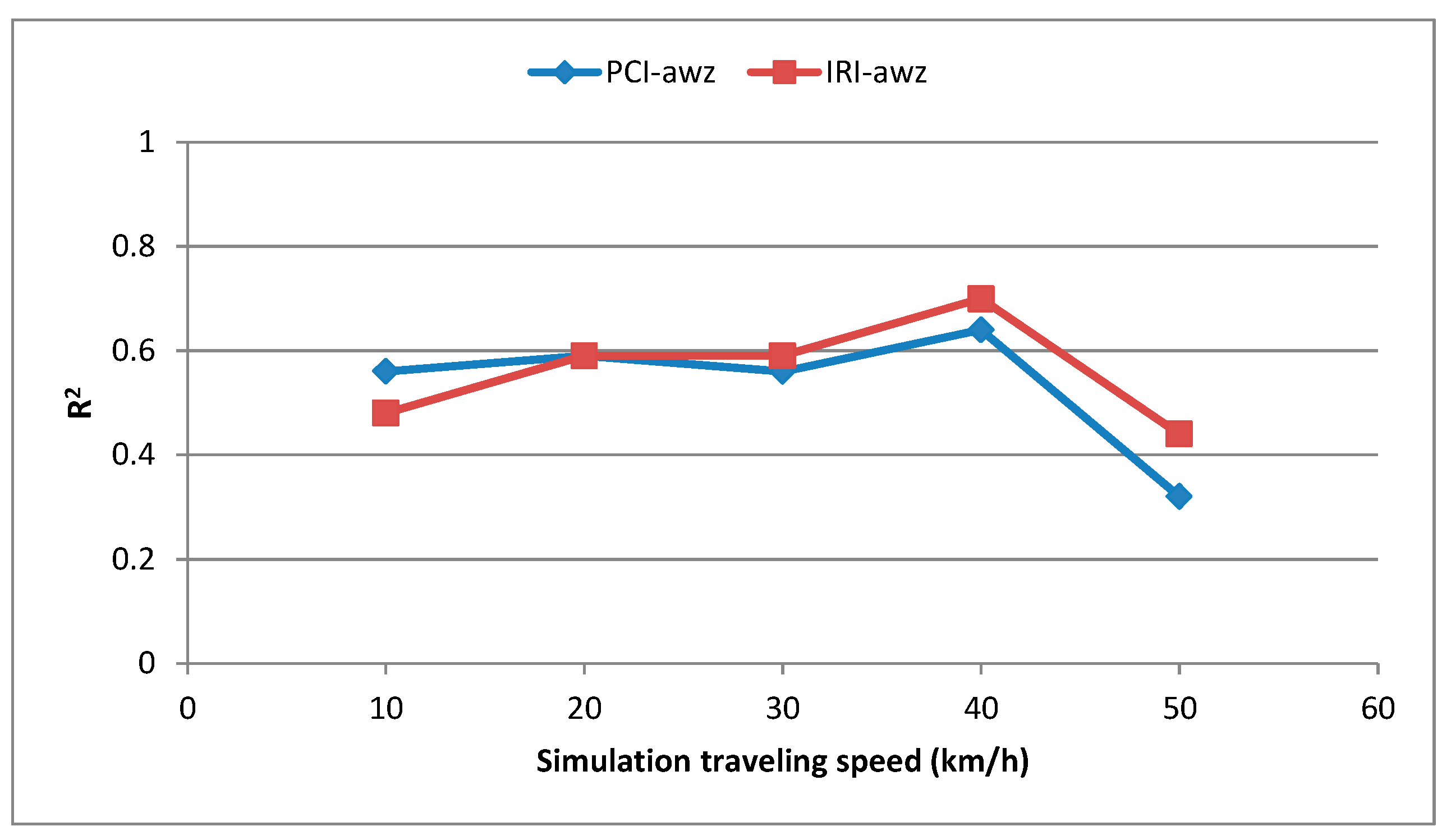

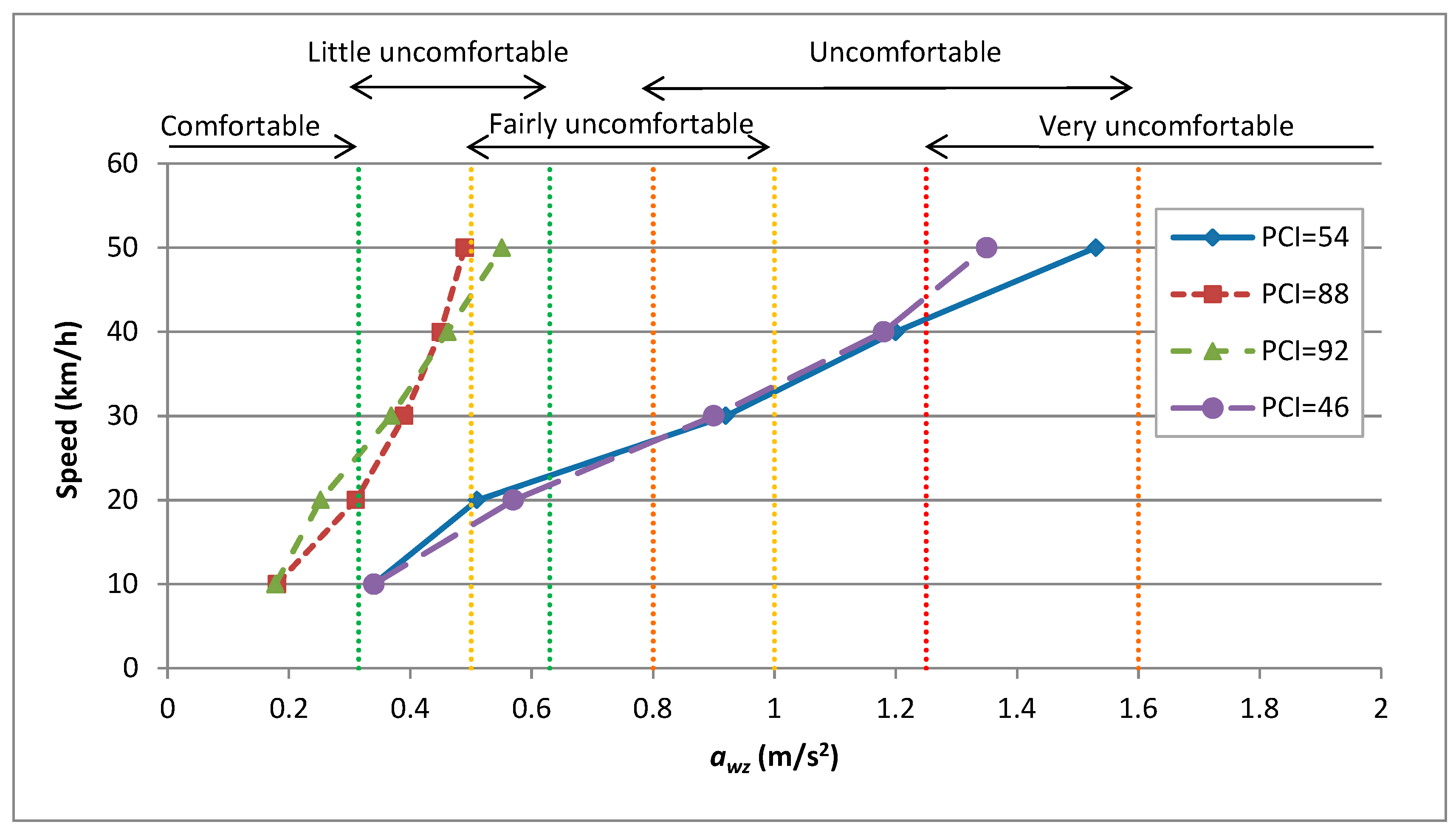

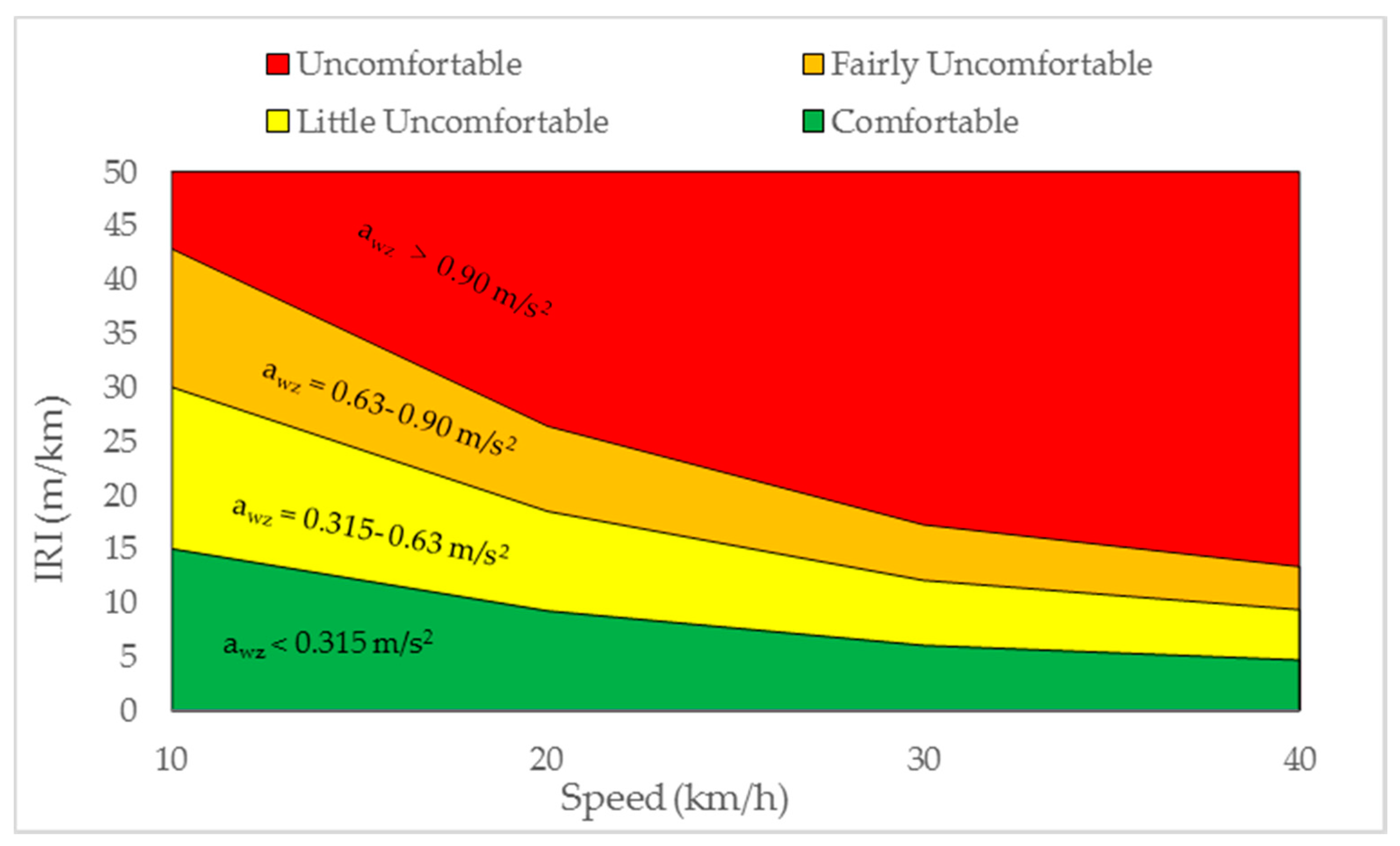

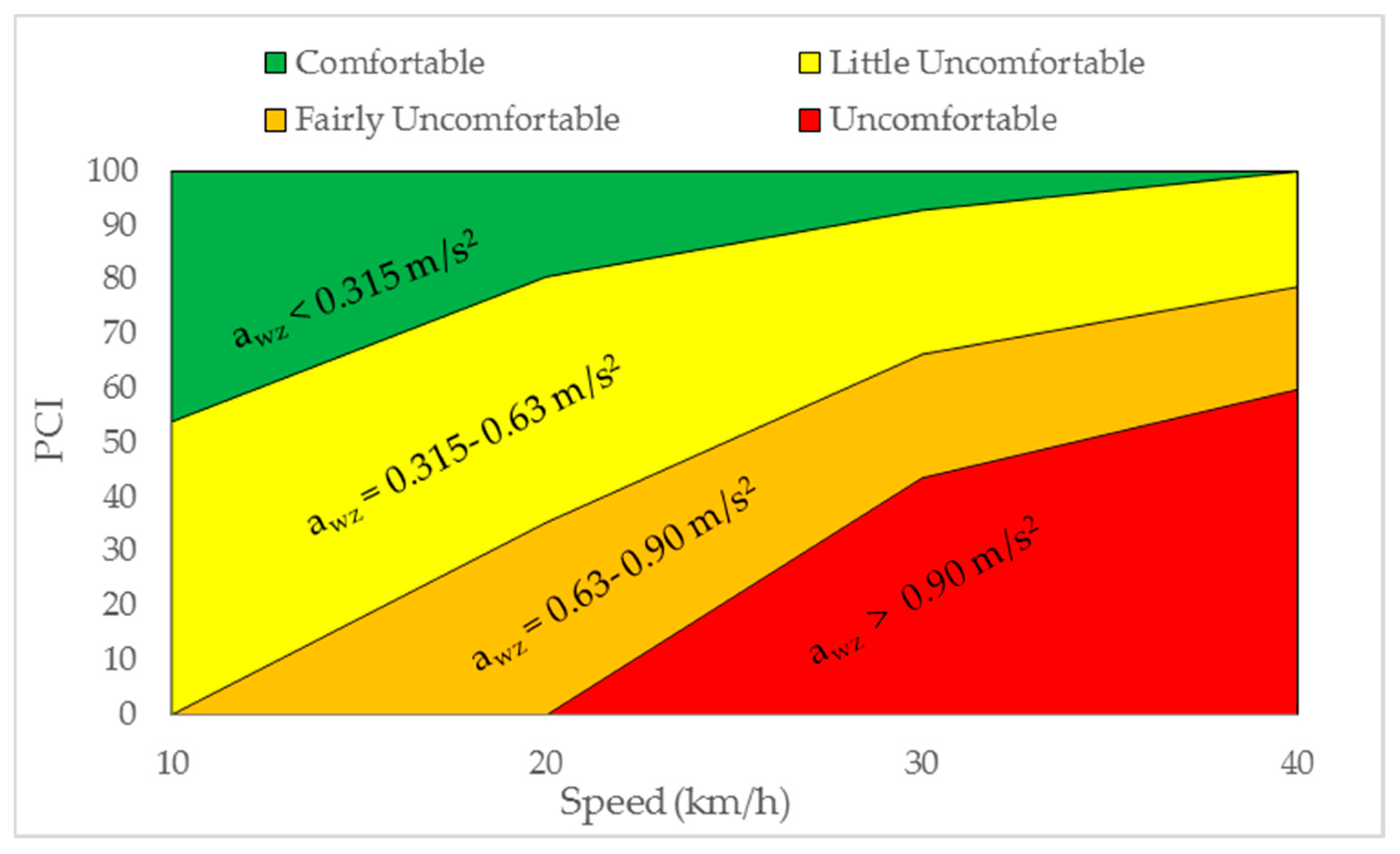

3. Results and Discussions

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| awz | Frequency-weighted vertical acceleration |

| ASTM | American Society of Texting and Materials |

| CDV | Corrected Deduct Value |

| DV | Deduct Value |

| IRI | International Roughness Index |

| ISO | International Organization for Standardization |

| PCI | Pavement Condition Index |

| PMS | Pavement Management System |

| PSD | Power Spectral Density |

| RMS | Root Mean Square |

Appendix A. Distress Identification Catalogue for Sampietrini Pavements

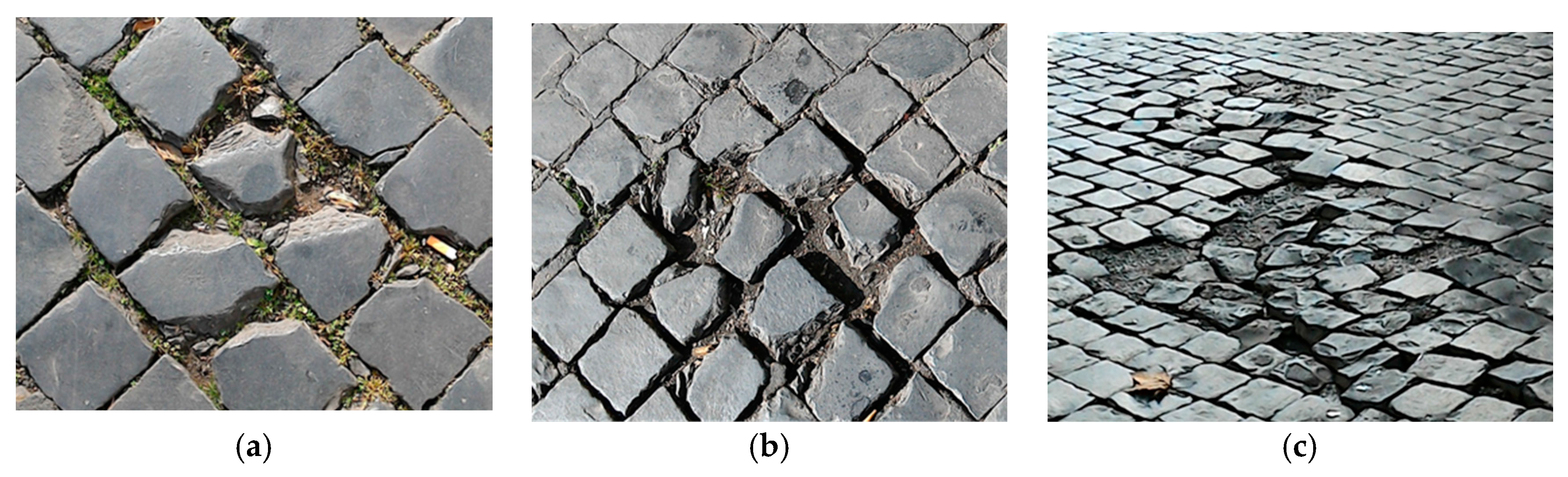

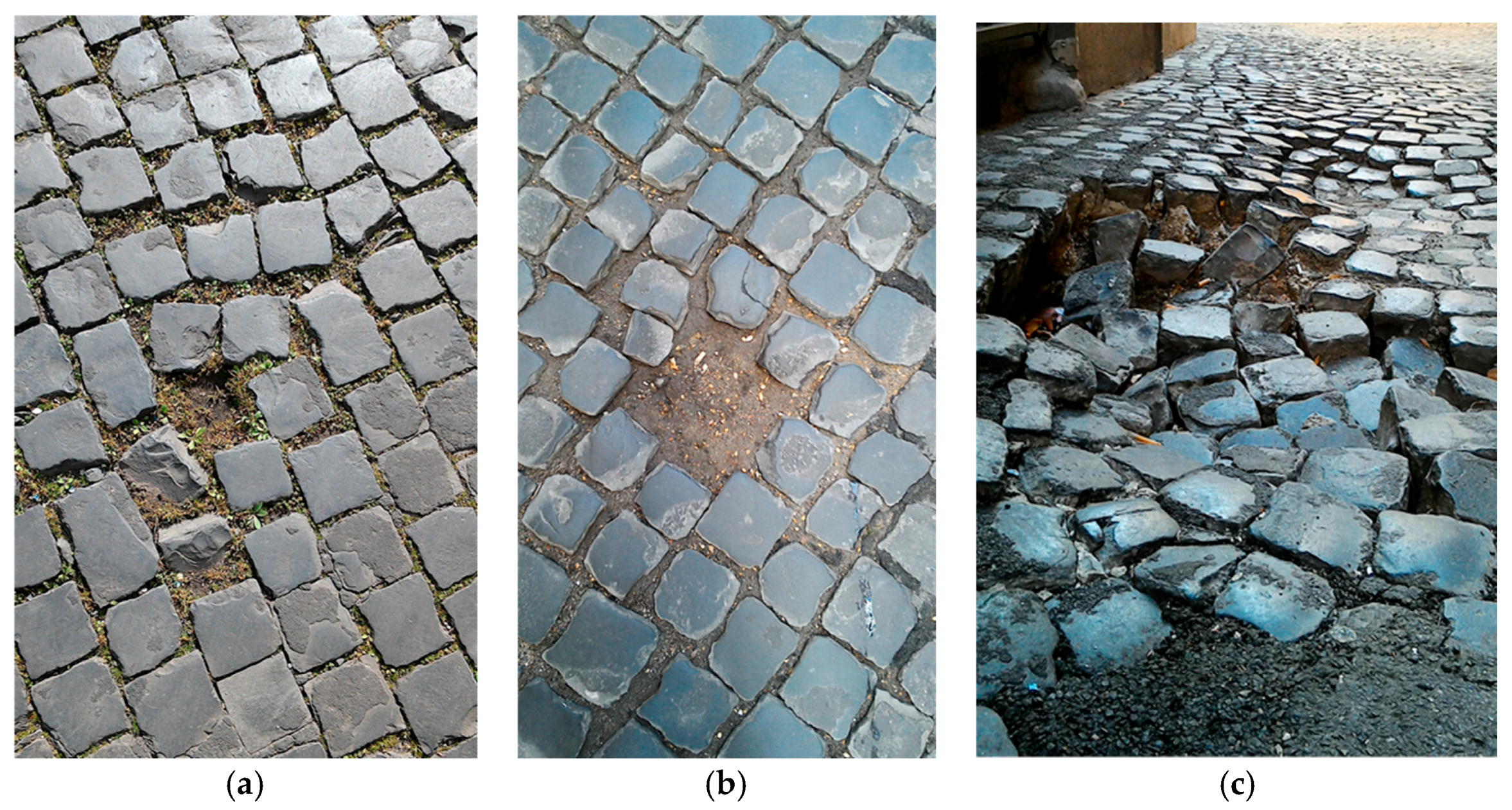

Appendix A.1. Damaged Sampietrini

| Severity Level | Item |

|---|---|

| Low | Individual cracks, separations or alterations |

| Medium | Advanced cracking, separations or alterations |

| High | Blocks are in multiple pieces or are disintegrated |

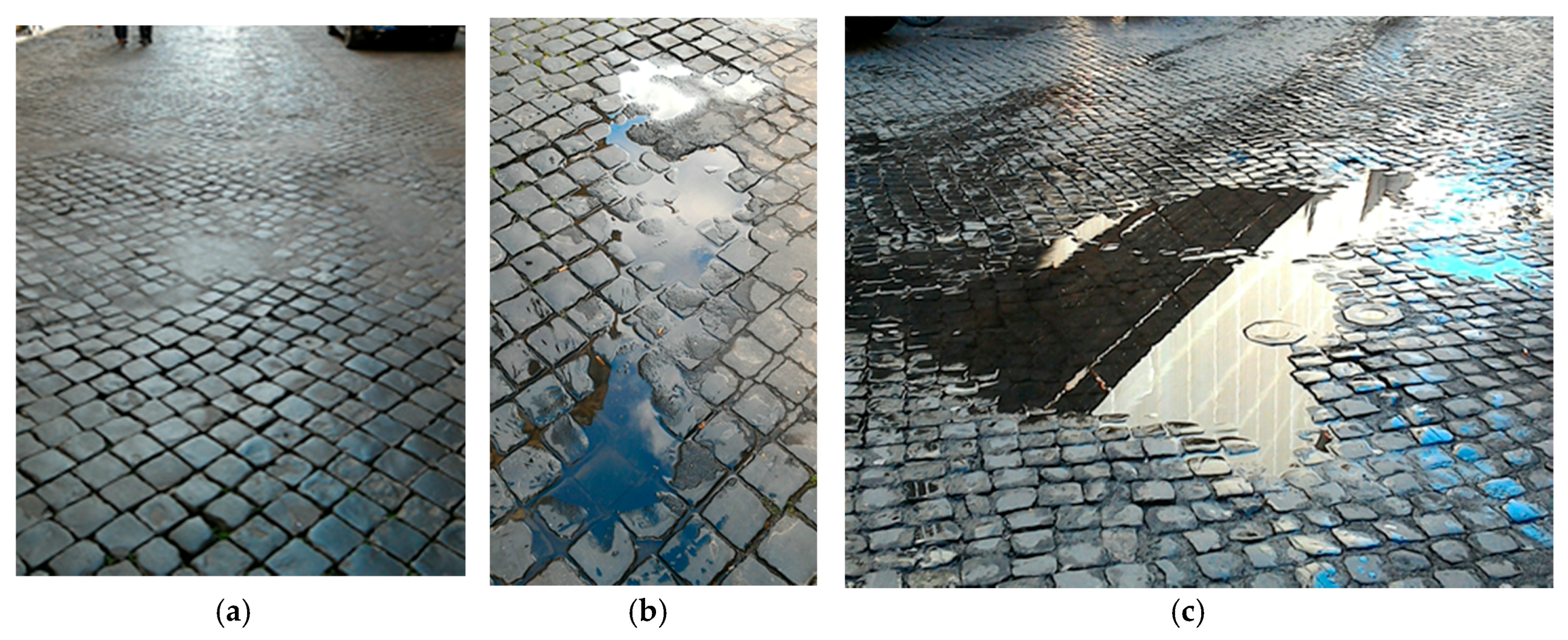

Appendix A.2. Depressions

| Severity Level | Maximum Depth of Depression |

|---|---|

| Low | 15–30 mm |

| Medium | 30–50 mm |

| High | >50 mm |

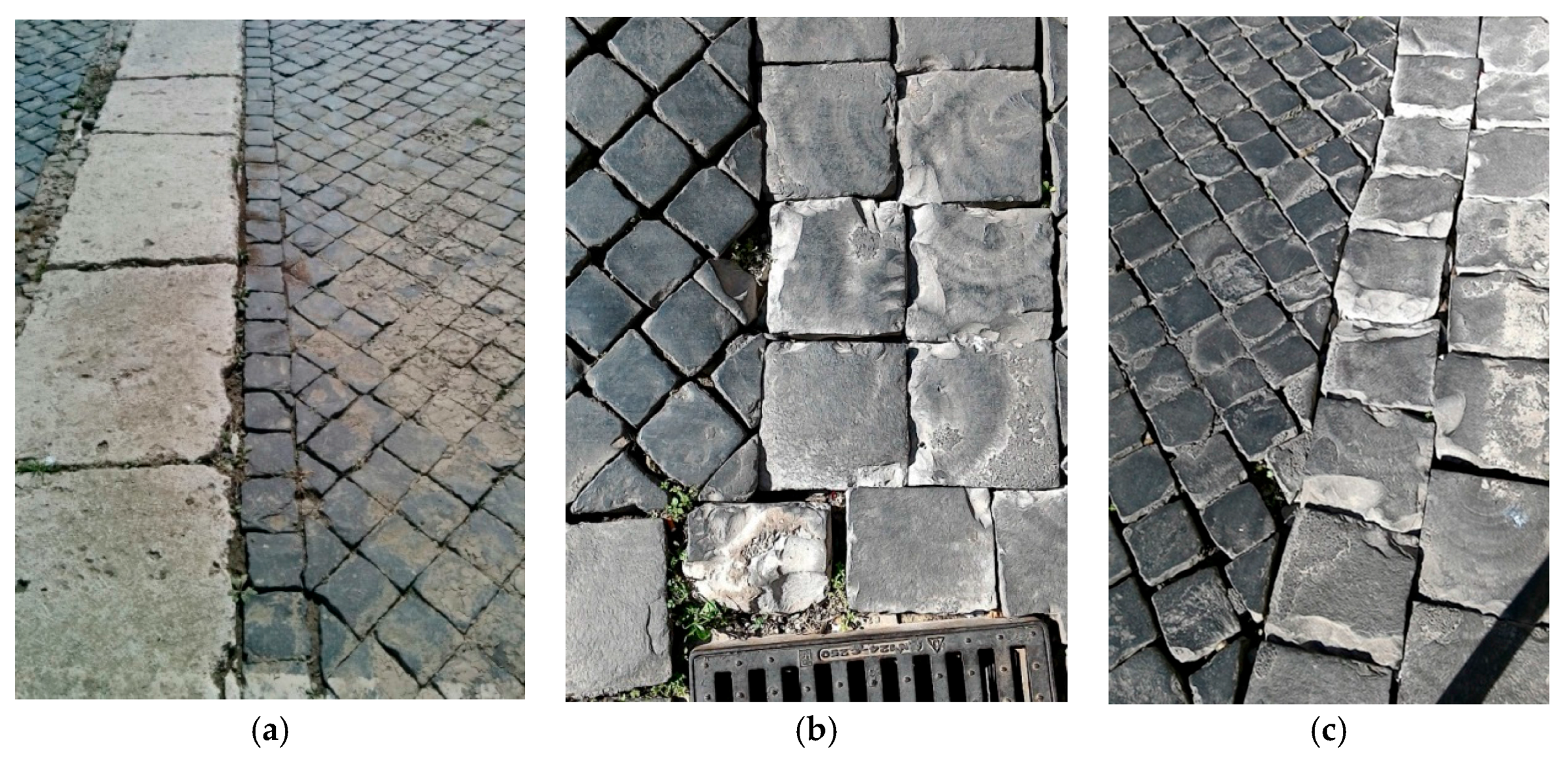

Appendix A.3. Edge Restraint

| Severity Level | Description |

|---|---|

| Low | Evidence of increased joint width; (11–15 mm) to no evidence of paver/curb rotation |

| Medium | Increased joint width (16–30 mm), with evidence of paver/curb rotation |

| High | Increased joint width (>30 mm), with noticeable of paver/curb rotation and local settlement |

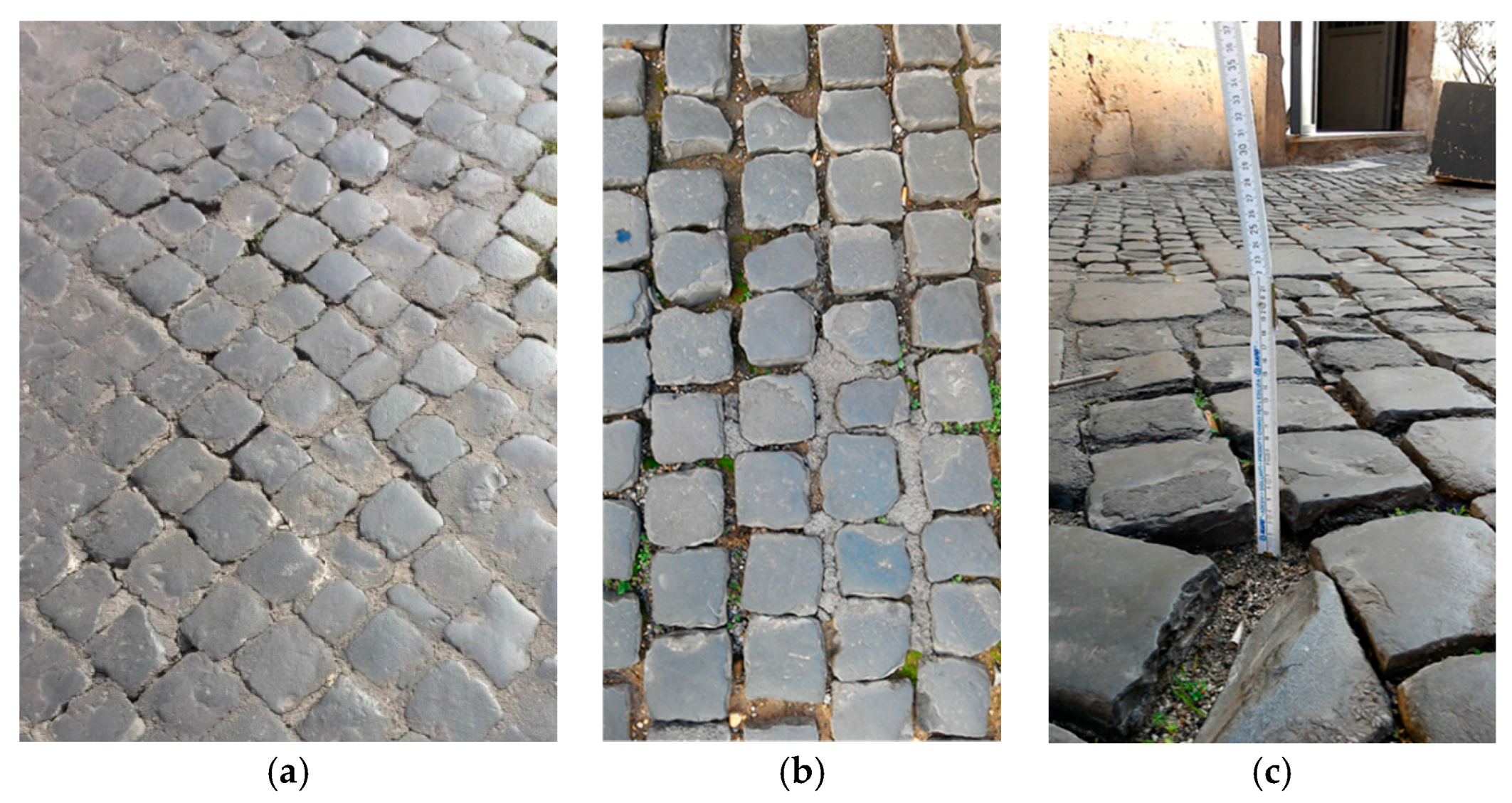

Appendix A.4. Excessive Joint Width

| Severity Level | Average Joint Width |

|---|---|

| Low | 11–15 mm |

| Medium | 16–45 mm |

| High | >45 mm |

Appendix A.5. Faulting

| Severity Level | Elevation Difference |

|---|---|

| Low | 6–10 mm |

| Medium | 11–20 mm |

| High | >20 mm |

Appendix A.6. Heave

| Severity Level | Maximum Height of Heave |

|---|---|

| Low | 15–30 mm |

| Medium | 31–50 mm |

| High | >50 mm |

Appendix A.7. Joint Sand Loss/Pumping

| Severity Level | Depth of Sand Loss |

|---|---|

| Low | 10–25 mm |

| Medium | 26–45 mm |

| High | >45 mm |

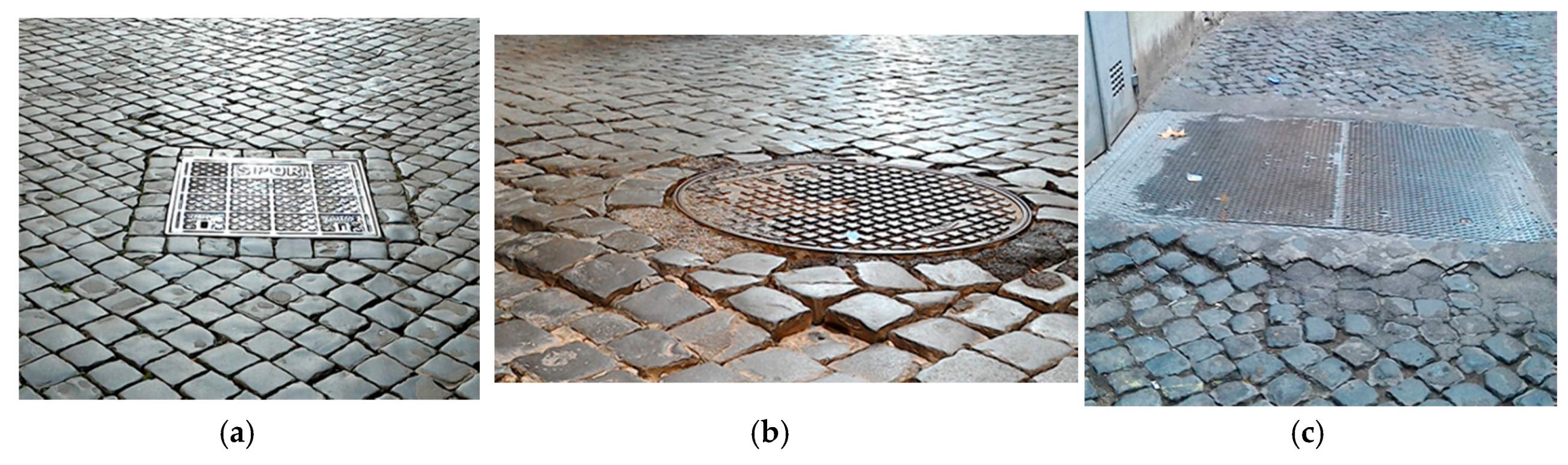

Appendix A.8. Missing Sampietrini

| Severity Level | Description |

|---|---|

| Low | Random individual missing Sampietrini |

| Medium | Missing 2 or more Sampietrini in one area and ride quality unaffected |

| High | Missing 2 or more Sampietrini in one area and ride quality affected |

Appendix A.9. Patching

| Severity Level | Description |

|---|---|

| Low | Patch is in good condition and ride quality is unaffected |

| Medium | Patch is in good to fair condition and ride quality is starting to deteriorate |

| High | Patch is in poor condition and ride quality is affected |

Appendix A.10. Rutting

| Severity Level | Maximum Depth of Rut |

|---|---|

| Low | 5–15 mm |

| Medium | 15–30 mm |

| High | >30 mm |

Appendix B. Distress Identification for All the Inspected Sections

| Section ID | Distress ID | Severity | Quantity | Density | Deduct Value | PCI |

|---|---|---|---|---|---|---|

| Section 01 | 101 | L | 7.3 | 3.0% | 1.4 | 94 |

| 105 | L | 22.1 | 9.2% | 1.4 | ||

| 105 | M | 5.7 | 2.4% | 2.8 | ||

| 106 | M | 1.3 | 0.5% | 0.0 | ||

| 110 | L | 2.5 | 1.1% | 0.0 | ||

| Section 02 | 101 | L | 5.8 | 2.4% | 1.4 | 74 |

| 102 | L | 2.9 | 1.2% | 4.3 | ||

| 102 | M | 5.4 | 2.2% | 14.5 | ||

| 105 | L | 7.6 | 3.2% | 0.4 | ||

| 106 | L | 5.0 | 2.1% | 4.2 | ||

| 108 | L | 6.0 | 2.5% | 0.4 | ||

| 108 | M | 6.0 | 2.5% | 1.4 | ||

| Section 03 | 101 | L | 8.4 | 3.5% | 1.4 | 12 |

| 101 | M | 1.8 | 0.8% | 1.4 | ||

| 102 | L | 2.0 | 0.8% | 4.3 | ||

| 102 | H | 7.0 | 2.9% | 33.3 | ||

| 104 | L | 10.8 | 4.5% | 6.9 | ||

| 104 | M | 14.8 | 6.2% | 27.8 | ||

| 105 | L | 4.1 | 1.7% | 0.1 | ||

| 105 | M | 2.2 | 0.9% | 1.4 | ||

| 106 | L | 4.0 | 1.7% | 4.2 | ||

| 106 | M | 10.9 | 4.5% | 26.4 | ||

| 106 | H | 10.2 | 4.3% | 44.4 | ||

| 109 | H | 0.5 | 0.2% | 36.6 | ||

| 110 | L | 3.2 | 1.3% | 0.3 | ||

| 110 | M | 6.3 | 2.6% | 0.6 | ||

| 110 | H | 1.0 | 0.4% | 0.4 | ||

| Section 04 | 102 | L | 3.1 | 1.3% | 4.3 | 76 |

| 102 | M | 4.7 | 2.0% | 14.5 | ||

| 103 | L | 1.9 | 0.8% | 2.7 | ||

| 103 | M | 2.8 | 1.2% | 9.5 | ||

| 108 | L | 26.9 | 11.2% | 1.4 | ||

| 110 | L | 1.2 | 0.5% | 0.1 |

| Section ID | Distress ID | Severity | Quantity | Density | Deduct Value | PCI |

|---|---|---|---|---|---|---|

| Section 05 | 101 | L | 1.9 | 0.8% | 0.4 | 51 |

| 102 | L | 1.5 | 0.6% | 4.3 | ||

| 102 | M | 4.5 | 1.9% | 13.0 | ||

| 104 | L | 1.8 | 0.8% | 1.4 | ||

| 104 | M | 3.0 | 1.3% | 8.3 | ||

| 108 | L | 6.2 | 2.6% | 0.3 | ||

| 108 | M | 13.3 | 5.5% | 2.8 | ||

| 108 | H | 3.2 | 1.4% | 1.4 | ||

| 111 | L | 8.0 | 3.3% | 16.9 | ||

| 111 | H | 4.8 | 2.0% | 34.0 | ||

| Section 06 | 102 | L | 1.9 | 0.8% | 4.3 | 88 |

| 102 | M | 1.7 | 0.7% | 10.1 | ||

| 105 | M | 0.2 | 0.1% | 0.0 | ||

| Section 07 | 102 | L | 6.7 | 2.8% | 7.2 | 92 |

| 105 | M | 0.8 | 0.3% | 0.3 | ||

| 108 | L | 0.8 | 0.4% | 0.1 | ||

| Section 08 | 102 | M | 7.0 | 2.9% | 8.0 | 60 |

| 102 | H | 5.0 | 2.1% | 30.4 | ||

| 104 | L | 4.8 | 2.0% | 4.2 | ||

| 108 | M | 4.0 | 1.7% | 1.4 | ||

| 108 | H | 2.0 | 0.9% | 1.4 | ||

| 110 | L | 4.0 | 1.7% | 0.3 | ||

| Section 09 | 102 | L | 1.0 | 0.4% | 2.9 | 60 |

| 102 | M | 3.9 | 1.6% | 13.0 | ||

| 102 | H | 4.5 | 1.9% | 29.0 | ||

| 105 | M | 0.6 | 0.3% | 0.4 | ||

| 106 | M | 1.6 | 0.7% | 11.1 | ||

| 108 | L | 1.0 | 0.4% | 0.1 | ||

| 108 | M | 3.0 | 1.3% | 1.1 | ||

| 111 | L | 2.4 | 1.0% | 7.0 | ||

| Section 10 | 102 | L | 13.5 | 5.6% | 11.6 | 55 |

| 102 | M | 11.0 | 4.6% | 20.3 | ||

| 104 | M | 6.0 | 2.5% | 15.3 | ||

| 105 | M | 4.0 | 1.7% | 1.4 | ||

| 109 | L | 2.0 | 0.8% | 18.3 | ||

| 110 | L | 8.4 | 3.5% | 0.4 | ||

| 111 | L | 3.3 | 1.4% | 9.9 |

| Section ID | Distress ID | Severity | Quantity | Density | Deduct Value | PCI |

|---|---|---|---|---|---|---|

| Section 11 | 102 | L | 6.5 | 2.7% | 7.2 | 45 |

| 102 | H | 6.0 | 2.5% | 31.9 | ||

| 104 | M | 5.0 | 2.1% | 12.5 | ||

| 104 | H | 4.5 | 1.9% | 22.2 | ||

| 105 | L | 1.5 | 0.6% | 0.1 | ||

| 105 | M | 10.5 | 4.4% | 2.8 | ||

| 110 | L | 10.7 | 4.5% | 0.4 | ||

| 110 | M | 0.3 | 0.1% | 0.0 | ||

| 111 | L | 6.6 | 2.8% | 15.5 | ||

| Section 12 | 102 | L | 1.0 | 0.4% | 2.9 | 45 |

| 104 | L | 7.5 | 3.1% | 5.6 | ||

| 104 | M | 1.0 | 0.4% | 2.8 | ||

| 105 | L | 0.5 | 0.2% | 0.1 | ||

| 106 | L | 2.0 | 0.8% | 2.8 | ||

| 110 | L | 8.0 | 3.3% | 0.4 | ||

| 110 | H | 3.1 | 1.3% | 1.4 | ||

| 111 | L | 10.0 | 4.2% | 46.5 | ||

| Section 13 | 102 | L | 9.0 | 3.8% | 8.7 | 71 |

| 104 | M | 3.9 | 1.6% | 9.7 | ||

| 106 | L | 2.4 | 1.0% | 2.8 | ||

| 106 | M | 9.0 | 3.8% | 23.6 | ||

| Section 14 | 101 | L | 0.8 | 0.3% | 0.4 | 79 |

| 102 | L | 14.4 | 6.0% | 11.6 | ||

| 102 | M | 1.5 | 0.6% | 10.1 | ||

| 104 | L | 9.1 | 3.8% | 5.6 | ||

| 105 | L | 6.8 | 2.8% | 0.3 | ||

| 105 | M | 4.1 | 1.7% | 1.4 | ||

| 106 | L | 9.0 | 3.8% | 5.6 | ||

| 109 | L | 0.4 | 0.2% | 1.4 | ||

| 110 | L | 0.2 | 0.1% | 0.0 |

References

- Han, D.; Kobayashi, K. Criteria for the development and improvement of PMS models. KSCE J. Civ. Eng. 2013, 17, 1302–1316. [Google Scholar] [CrossRef]

- Shahin, M.Y. Pavement Management for Airports, Roads, and Parking Lots; Springer: New York, NY, USA, 2005; p. 572. [Google Scholar]

- Bonin, G.; Folino, N.; Loprencipe, G.; Oliverio Rossi, G.; Polizzotti, S.; Teltayev, B. Development of a Road Asset Management System in Kazakhstan. In Proceedings of the TIS 2017 International Congress on Transport Infrastructure and Systems, Rome, Italy, 10–12 April 2017; pp. 10–12. [Google Scholar]

- Loprencipe, G.; Cantisani, G.; Di Mascio, P. Global assessment method of road distresses. Proceedings of 4th International Symposium on Life-Cycle Civil Engineering, Tokyo, Japan, 16 November 2014; CRC Press/Balkema: Leiden, The Netherlands, 2015; pp. 1113–1120. Available online: https://www.crcpress.com/Life-Cycle-of-Structural-Systems-Design-Assessment-Maintenance-and-Management/Furuta-Frangopol-Akiyama/p/book/9781138001206 (accessed on 2 January 2017).

- Loprencipe, G.; Pantuso, A.; Di Mascio, P. Sustainable Pavement Management System in Urban Areas Considering the Vehicle Operating Costs. Sustainability, 2017, 9, 453. [Google Scholar] [CrossRef]

- Cottrell, W.D.; Bryan, S.; Chilukuri, B.R.; Kalyani, V.; Stevanovic, A.; Wu, J. Transportation Infrastructure Maintenance Management: Case Study of a Small Urban City. J. Infrastruct. Syst. 2009, 15, 120–132. [Google Scholar] [CrossRef]

- Corazza, M.V.; Di Mascio, P.; Moretti, L. Managing sidewalk pavement maintenance: A case study to increase pedestrian safety. JTTE 2016, 3, 203–214. [Google Scholar] [CrossRef]

- Loprencipe, G.; Pantuso, A. A Specified Procedure for Distress Identification and Assessment for Urban Road Surfaces based on PCI. Coatings 2017, 7, 65. [Google Scholar] [CrossRef]

- Sayers, M.W. On the calculation of international roughness index from longitudinal road profile. Transp. Res. Rec. 1995, 1501, 1–12. [Google Scholar]

- American Society of Texting and Materials D6433-16. Standard Practice for Roads and Parking Lots Pavement Condition Index Surveys; ASTM International: West Conshohocken, PA, USA, 2016; Available online: www.astm.org (accessed on 20 January 2017).

- Sayers, M.W.; Karamihas, S.M. The Little Book of Profiling; The Regent of the University of Michigan: Ann Arbor, MI, USA, 1998. [Google Scholar]

- Arhin, S.A.; Williams, L.N.; Ribbiso, A.; Anderson, M.F. Predicting pavement condition index using international roughness index in a dense urban area. J. Civ. Eng. Res. 2015, 5, 10–17. [Google Scholar]

- Lin, J.D.; Yau, J.T.; Hsiao, L.H. Correlation analysis between international roughness index (IRI) and pavement distress by neural network. In Proceedings of the 82nd Annual Meeting of the Transportation Research Board, Washington, DC, USA, 12–16 January 2003. [Google Scholar]

- Rens, K.L.; Staley, B. Rating City and County of Denver Urban Pavement Constructability Using a Profiler. Pract. Period. Struct. Des. Construct. 2009, 15, 44–49. [Google Scholar] [CrossRef]

- Beuving, E.; Michaut, J.P. Pavement Surface Materials Used in Urban Areas. In Proceedings of the PIARC Committee C 4.3 Seminar, Urban Pavements, Cracow, Poland, 21–22 September 2005. [Google Scholar]

- National Highway Sector Schemes. National Highways Sector Scheme 30 for Modular Paving; Interlay: Glenfield, UK, 2013; Available online: http://www.pavingexpert.com/pdf/NHSS%20UNIT%201%20BLOCKS%20FLAGS%20AND%20SETTS%20-%20RIGID%20MODULAR.pdf (accessed on 25 January 2017).

- Geller, R. Concrete Block Paving Condition Survey and Rating Procedures. In Proceedings of the 5th international Conference on CBP, Tel Aviv, Israel, 23–27 June 1996; pp. 405–412. [Google Scholar]

- Applied Research Associates, Inc. Interlocking Concrete Block Pavement Distress Guide; Interlocking Concrete Pavement Institute (ICPI), 2007. Available online: https://www.icpi.org/sites/default/files/ctools/Distress_Manual_Final_2008.pdf (accessed on 9 February 2017).

- Hein, D.; Burak, R. Development of A Pavement Condition Rating Procedure for Interlocking Concrete Pavements. In Proceedings of the Cost-Effective Assessment/Rehabilitation of the Condition of Materials for the Transportation Association of Canada Fall 2007 Meeting, Saskatoon, SK, Canada, 14–17 October 2007. [Google Scholar]

- Cibin, L. Selciato Romano: Il Sampietrino; Gangemi: Rome, Italy, 2003. [Google Scholar]

- Cantisani, G.; Loprencipe, G. Road roughness and whole-body vibration: Evaluation tools and comfort limits. J. Transp. Eng. 2010, 136, 818–826. [Google Scholar] [CrossRef]

- Ahlin, K.; Granlund, N.O.J. Relating road roughness and vehicle speeds to human whole-body vibration and exposure limits. Int. J. Pavement Eng. 2002, 3, 207–216. [Google Scholar] [CrossRef]

- Loprencipe, G.; Zoccali, P. Use of generated artificial road profiles in road roughness evaluation. JMT 2017, 25, 24–33. [Google Scholar] [CrossRef]

- City of Rome. Tariffa 2012 Parte B Opere Stradali e Infrastrutture a Rete. 2012. Available online: https://www.comune.roma.it/PCR/resources/cms/documents/3_TARIFFA2012BSTRADE.pdf (accessed on 10 March 2017).

- Cantisani, G.; Fascinelli, G.; Loprencipe, G. Urban Road Noise: The Contribution of Pavement Discontinuities. In Proceedings of the 2012 International Conference on Sustainable Design and Construction, Fort Worth, TX, USA, 7–9 November 2012; American Society of Civil Engineers: Reston, VA, USA; pp. 327–334. Available online: http://dx.doi.org/10.1061/9780784412688 (accessed on 28 February 2017).

- American Society of Texting and Materials E1926-08. Standard Practice for Computing International Roughness Index of Roads from Longitudinal Profile Measurements; ASTM International: West Conshohocken, PA, USA, 2008; Available online: www.astm.org (accessed on 20 September 2016).

- International Organization for Standardization. ISO2631-1: Mechanical Vibration and Shock-Evaluation of Human Exposure to Whole-Body Vibration—Part 1: General Requirements ISO/TC108/SC4; ISO: Geneva, Switzerland, 1997. [Google Scholar]

- Loprencipe, G.; Cantisani, G. Unified analysis of road pavement profiles for evaluation of surface characteristics. Mod. Appl. Sci. 2013, 7, 1–14. [Google Scholar] [CrossRef]

- Park, K.; Thomas, N.E.; Wayne Lee, K. Applicability of the international roughness index as a predictor of asphalt pavement condition. J. Transport. Eng. 2007, 133, 706–709. [Google Scholar] [CrossRef]

- Kirbaş, U.; Karaşahin, M. Investigation of ride comfort limits on urban asphalt concrete pavements. Int. J. Pavement Eng. 2016, 1–7. [Google Scholar] [CrossRef]

| Material Property | Value |

|---|---|

| Young’s modulus (GPa) | 37–60 |

| Poisson ratio (-) | 0.15–0.38 |

| Compressive resistance (MPa) | 241–320 |

| Flexural resistance (MPa) | 32–75 |

| Tensile resistance (MPa) | 18–20 |

| PCI | Verbal Rating |

|---|---|

| 86–100 | Good |

| 71–85 | Satisfactory |

| 56–70 | Fair |

| 41–55 | Poor |

| 26–40 | Very Poor |

| 11–25 | Serious |

| 0–10 | Failed |

| Distress ID. | Description |

|---|---|

| 101 | Damaged Sampietrini |

| 102 | Depressions |

| 103 | Edge restraint |

| 104 | Excessive joint width |

| 105 | Faulting |

| 106 | Heave |

| 108 | Joint sand loss/pumping |

| 109 | Missing Sampietrini |

| 110 | Patching |

| 111 | Rutting |

| awz Values (m/s2) | Comfort Level |

|---|---|

| <0.315 | Not uncomfortable |

| 0.315–0.63 | A little uncomfortable |

| 0.5–1 | Fairly uncomfortable |

| 0.8–1.6 | Uncomfortable |

| 1.25–2.5 | Very uncomfortable |

| >2 | Extremely uncomfortable |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zoccali, P.; Loprencipe, G.; Galoni, A. Sampietrini Stone Pavements: Distress Analysis Using Pavement Condition Index Method. Appl. Sci. 2017, 7, 669. https://doi.org/10.3390/app7070669

Zoccali P, Loprencipe G, Galoni A. Sampietrini Stone Pavements: Distress Analysis Using Pavement Condition Index Method. Applied Sciences. 2017; 7(7):669. https://doi.org/10.3390/app7070669

Chicago/Turabian StyleZoccali, Pablo, Giuseppe Loprencipe, and Andrea Galoni. 2017. "Sampietrini Stone Pavements: Distress Analysis Using Pavement Condition Index Method" Applied Sciences 7, no. 7: 669. https://doi.org/10.3390/app7070669