Using a Molecular Dynamics Simulation to Investigate Asphalt Nano-Cracking under External Loading Conditions

Abstract

:1. Background and Introduction

2. Molecular Dynamics Simulations

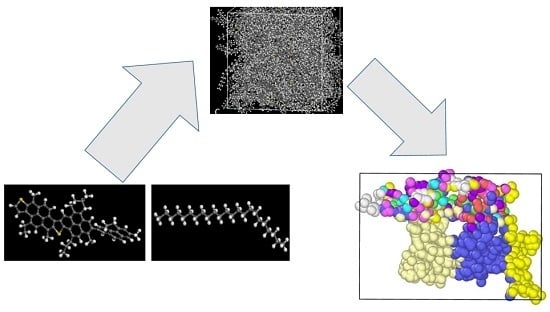

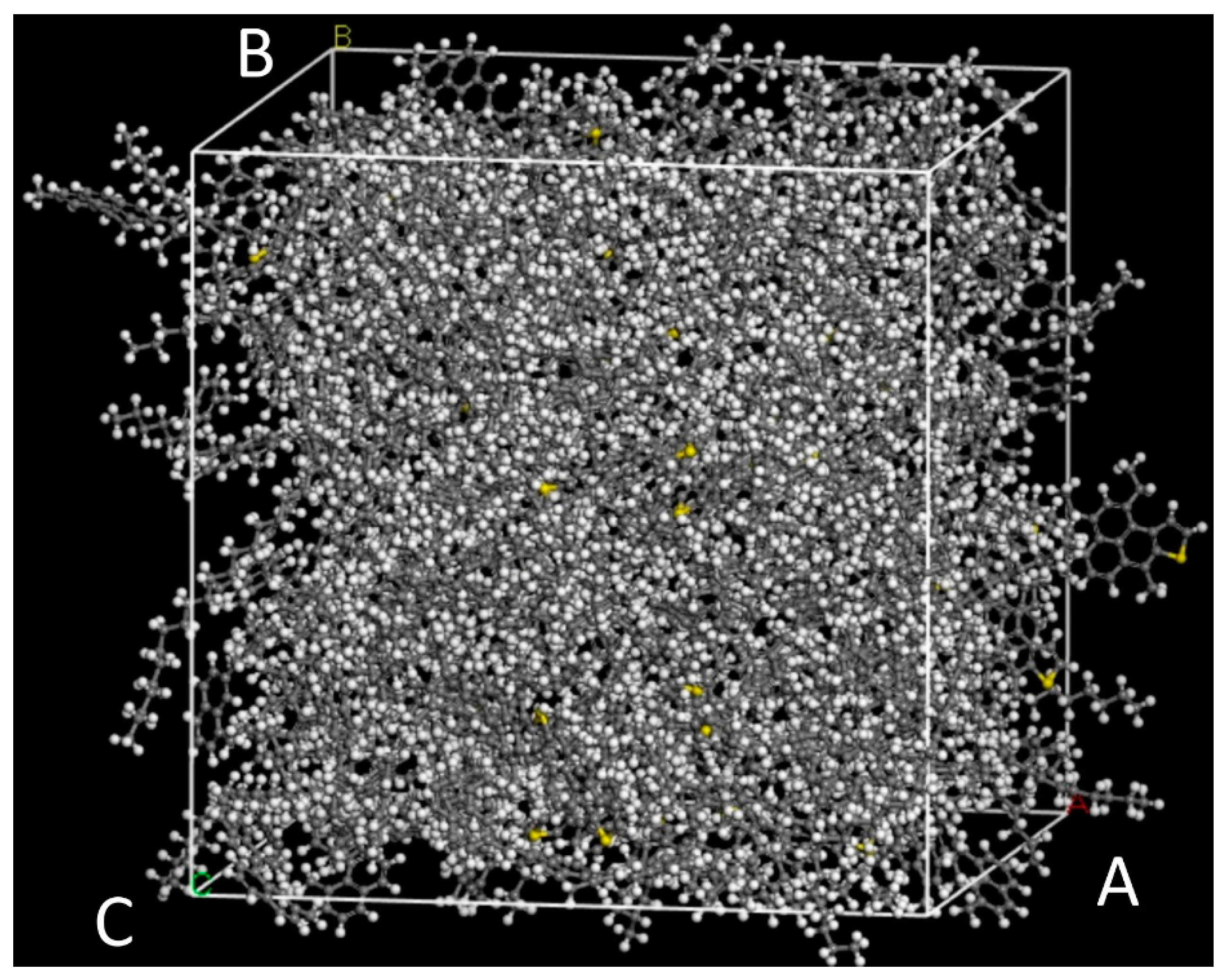

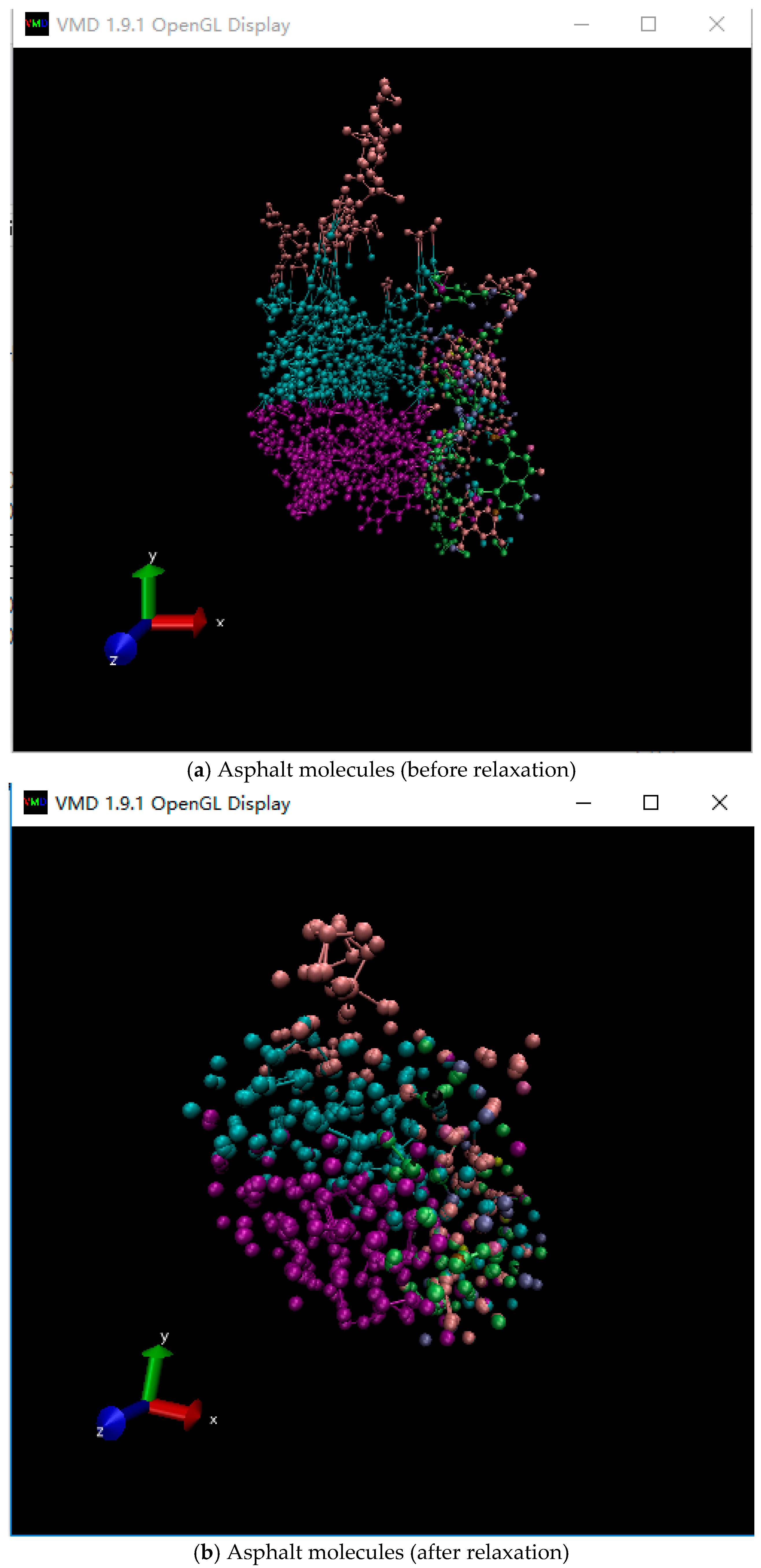

2.1. Asphalt Molecular Structure Construction

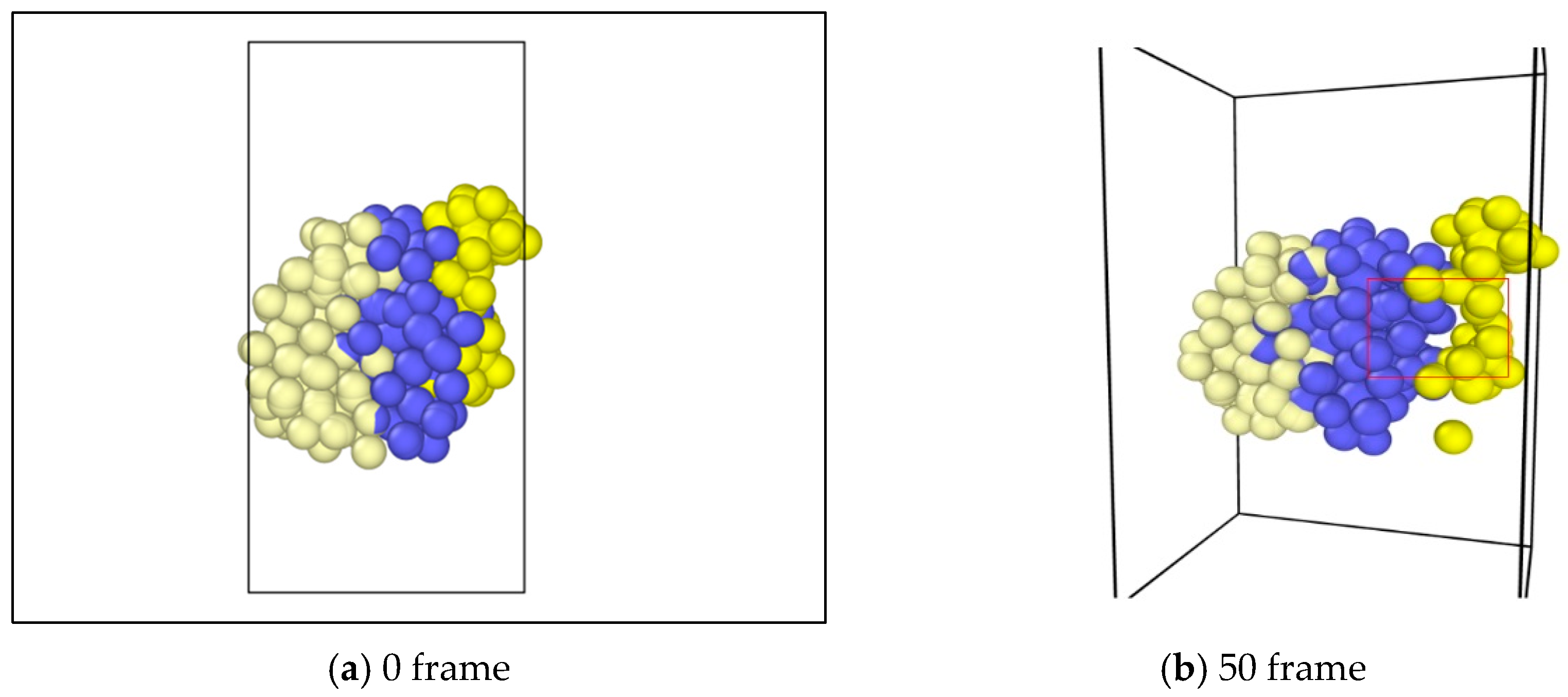

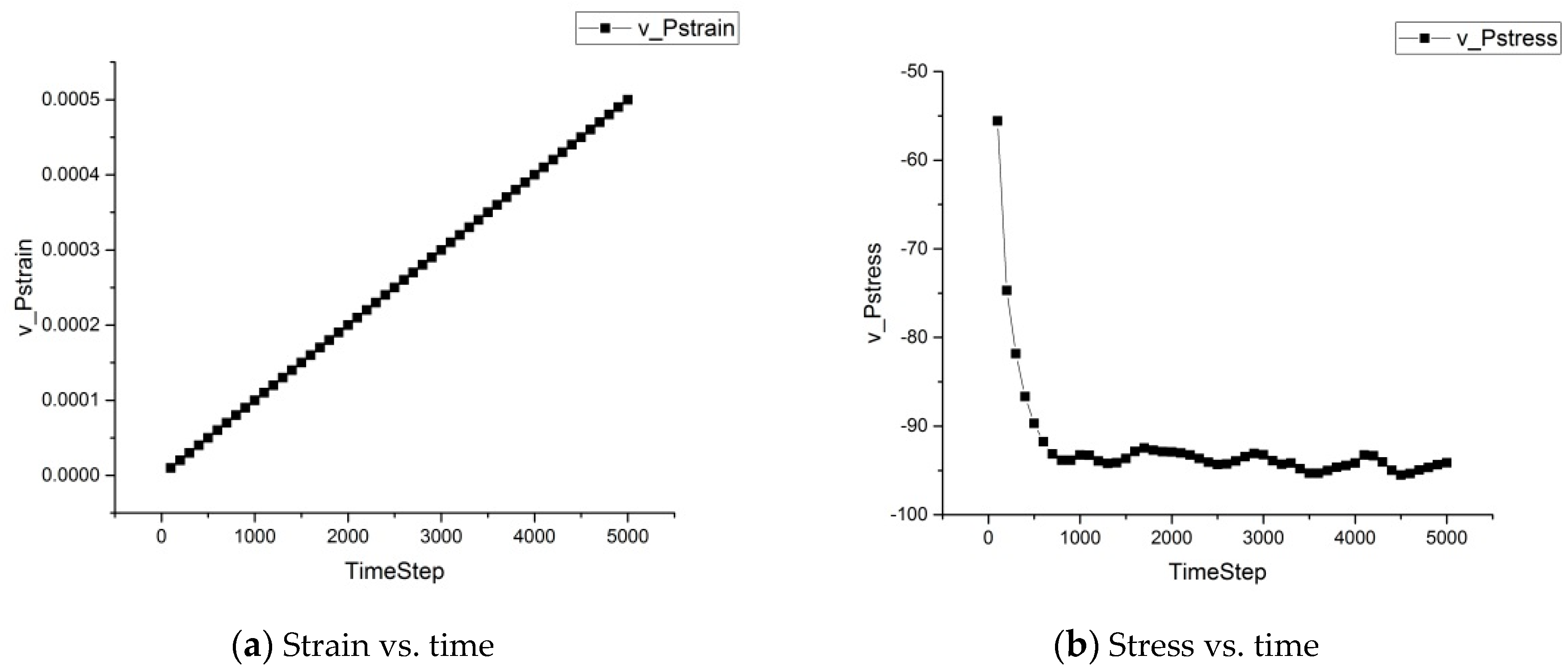

2.2. Simulation Results

3. Conclusions

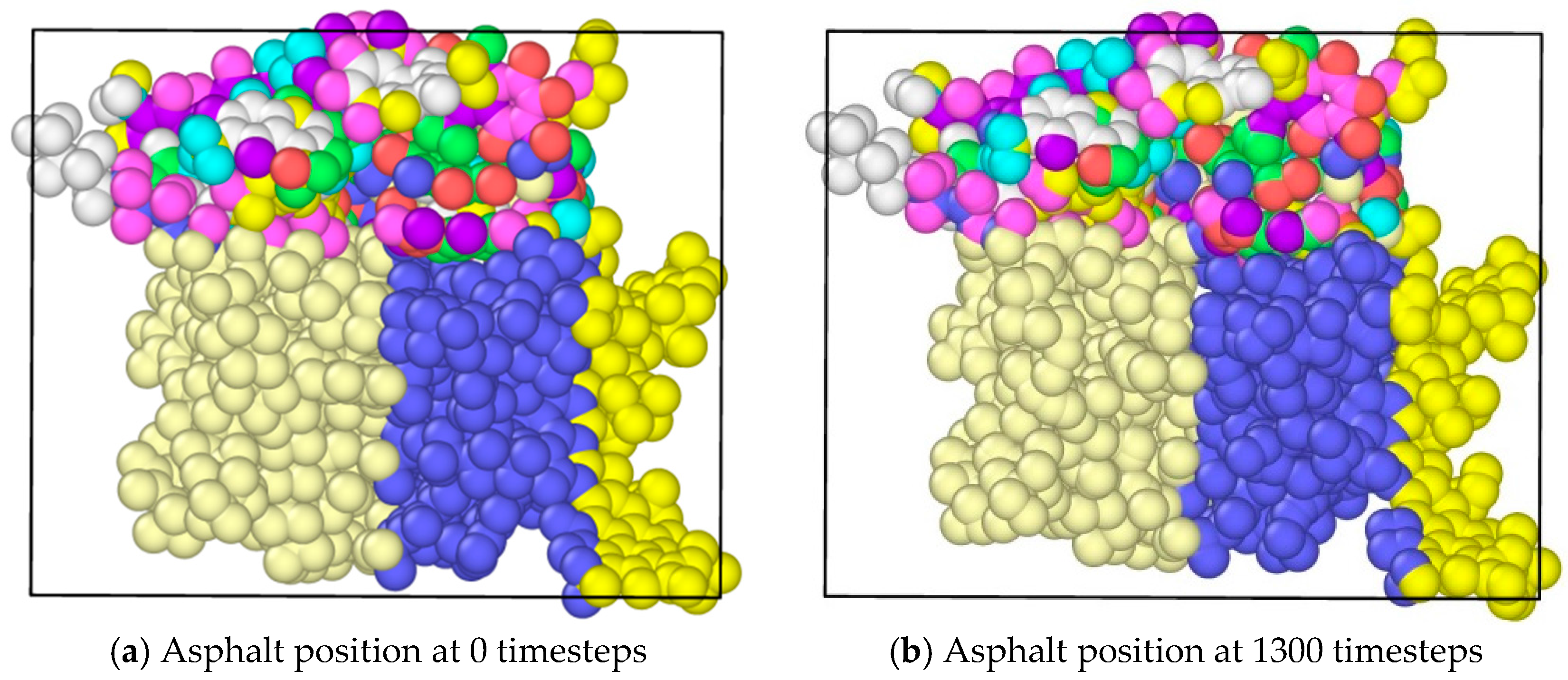

- It was discovered that by applying the tension force, the original “perfect” structure generally stretched and a “hole”, i.e., natural defect, occurred in the microstructure, which can be seen as the initiation of the microcrack. It was expected that with an increase of tension loading, the inside small hole would propagate and finally result in the failure of the asphalt microstructure.

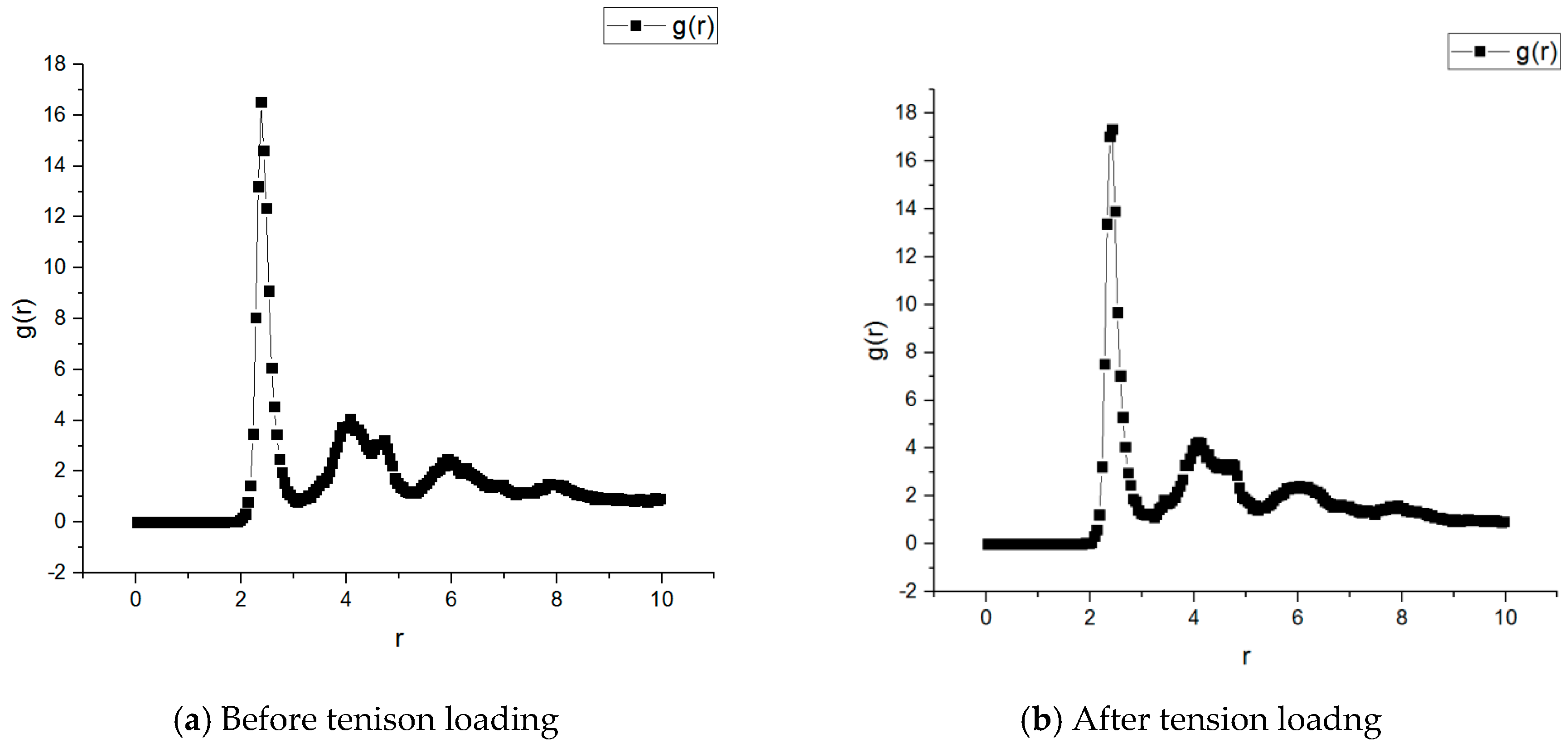

- It was observed that there existed a difference in RDF before and after tension loading. For the asphalt microstructure before the tension loading, when the distance was 2.375 Å, a maximum value of 16.5250 occurred; for the asphalt microstructure after the tension loading, when the distance was 2.375 Å, maximum value of 17.039 occurred. The trends of the curves for the two curves were completely consistent, indicating that many of the atoms in the asphalt microstructure did not change their locations, while a small portions changed.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Guo, M.; Tan, Y.; Wang, L.; Hou, Y. Diffusion of asphaltene, resin, aromatic and saturate components of asphalt on mineral aggregates surface: Molecular dynamics simulation. Road Mater. Pavement 2017, 18, 149–158. [Google Scholar] [CrossRef]

- Hou, Y.; Wang, L.; Wang, D.; Liu, P.; Guo, M.; Yu, J. Characterization of Bitumen Micro-Mechanical Behavior Using AFM, Phase Dynamics Theory and MD Simulation. Materials 2017, 10, 208. [Google Scholar] [CrossRef]

- Mikhailenko, P.; Khadim, H.; Baaj, H. Observation of Asphalt Binder Microstructure with ESEM. In Proceedings of the Transportation Association of Canada Conference, Toronto, ON, Canada, 25–28 September 2016. [Google Scholar]

- Sun, D.Q.; Zhang, L.W.; Zhang, X.L. Quantification of SBS content in SBS polymer modified asphalt by FTIR. Adv. Mater. Res. 2011, 287, 953–960. [Google Scholar] [CrossRef]

- Perez-Martinez, M.; Marsac, P.; Gabet, T.; Chailleux, E. Prediction of the Mechanical Properties of Aged Asphalt Mixes from FTIR Measurements. In Proceedings of the 8th RILEM International Symposium on Testing and Characterization of Sustainable and Innovative Bituminous Materials, Ancona, Italy, 7–9 October 2015; Springer: Haarlem, The Netherlands, 2015. [Google Scholar]

- Feng, Z.G.; Bian, H.J.; Li, X.J.; Yu, J.Y. FTIR analysis of UV aging on bitumen and its fractions. Mater. Struct. 2016, 49, 1381–1389. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, K.; Yin, J.; Zheng, M. Analysis on thermo-stability of modified asphalt using GPC (gel permeation chromatography). Railway Eng. 2013, 8, U414. [Google Scholar]

- Chen, X.L.; Sun, Y.S.; Han, Y.X.; Tian, Z.F. Microstructure and DSC of organic bentonite modified bitumen. J. Northeast. Univer. 2012, 33, 743–747. [Google Scholar]

- Chen, X.L.; Jiang, Y.Z.; Sun, Y.S.; Han, Y.X. Influence of DCCF on the properties of asphalt by DSC. Adv. Mater. Res. 2012, 454, 35–40. [Google Scholar] [CrossRef]

- Nazzal, M.D.; Abu-Qtaish, K.; Powers, D. Using atomic force microscopy to evaluate the nanostructure and nanomechanics of warm mix asphalt. J. Mater. Civ. Eng. 2015, 27, 1–9. [Google Scholar] [CrossRef]

- Jahangir, R.; Little, D.; Bhasin, A. Evolution of asphalt binder microstructure due to tensile loading determined using AFM and image analysis techniques. Int. J. Pavement Eng. 2015, 16, 337–349. [Google Scholar] [CrossRef]

- Tan, Y.; Guo, M. Micro- and nano-characteration of interaction between asphalt and filler. J. Test. Eval. 2014, 42, 1–9. [Google Scholar] [CrossRef]

- Khattak, M.J.; Khattab, A.; Zhang, P.; Rizvi, H.R.; Pesacreta, T. Microstructure and fracture morphology of carbon nano-fiber modified asphalt and hot mix asphalt mixtures. Mater. Struct. 2013, 46, 2045–2057. [Google Scholar] [CrossRef]

- Zareshahabadi, A.; Shokuhfar, A.; Ebrahiminejad, S. Microstructure and properties of nanoclay reinforced asphalt binders. Defect Diffus. Forum 2010, 579–583. [Google Scholar] [CrossRef]

- Sun, L.; Wang, H.; Wang, S.; Xiao, D. Nano-Modified Asphalt and Road Performance; Science Press: Beijing, China, 2012. [Google Scholar]

- Rapaport, D.C.; Blumberg, R.L.; Mckay, S.R.; Christian, W. The Art of Molecular Dynamics Simulation; Cambridge University Press: Cambridge, UK, 2004. [Google Scholar]

- Hou, Y.; Sun, W.; Huang, Y.; Ayatollahi, M.; Wang, L.; Zhang, J. Diffuse Interface Model to Investigate the Asphalt Concrete Cracking Subjected to Shear Loading at a Low Temperature. J. Cold Reg. Eng. 2017, 31, 04016009. [Google Scholar] [CrossRef]

- Hou, Y.; Guo, M.; Ge, Z.; Wang, L.; Sun, W. Mixed-Mode I-II Cracking Characterization of Mortar using Phase-Field Method. J. Eng. Mech. 2017, 143, 04017033. [Google Scholar] [CrossRef]

- Pan, J.; Tarefder, R.A. Investigation of asphalt aging behaviour due to oxidation using molecular dynamics simulation. Mol. Simul. 2016, 42, 1–12. [Google Scholar] [CrossRef]

- Tarefder, R.A.; Arisa, I.R. Molecular Dynamic Simulation of Oxidative Aging in Asphaltene. In Proceedings of the Pavements and Materials: Characterization and Modeling Symposium at Emi Conference, Los Angeles, CA, USA, 8–11 August 2010. [Google Scholar]

- Zhou, X.; Wu, S.; Liu, G.; Pan, P. Molecular simulations and experimental evaluation on the curing of epoxy bitumen. Mater. Struct. 2016, 49, 1–7. [Google Scholar] [CrossRef]

- Xu, M.; Yi, J.; Feng, D.; Huang, Y.; Wang, D. Analysis of adhesive characteristics of asphalt based on atomic force microscopy and molecular dynamics simulation. ACS Appl. Mater. Interfaces 2016, 8, 12393–12403. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Wang, L. Nanoscale Modeling of the Mechanical Properties of Asphalt and Aggregate. In Proceedings of the Pavements and Materials: Characterization and Modeling Symposium at Emi Conference, Los Angeles, CA, USA, 8–11 August 2010. [Google Scholar]

- Lu, Y.; Wang, L. Nanoscale modelling of mechanical properties of asphalt–aggregate interface under tensile loading. Int. J. Pavement Eng. 2010, 11, 393–401. [Google Scholar] [CrossRef]

- Zhang, L.; Greenfield, M.L. Analyzing properties of model asphalts using molecular simulation. Energy Fuels 2007, 21, 1712–1716. [Google Scholar] [CrossRef]

- Ding, Y.; Tang, B.; Zhang, Y.; Wei, J.; Cao, X. Molecular Dynamics Simulation to Investigate the Influence of SBS on Molecular Agglomeration Behavior of Asphalt. J. Mater. Civ. Eng. 2015, 27. [Google Scholar] [CrossRef]

- Hou, Y.; Wang, L.; Yue, P.; Pauli, T.; Sun, W. Modeling Mode I: Cracking Failure in Asphalt Binder by Using Nonconserved Phase-Field Model. J. Mater. Civ. Eng. 2014, 26, 684–691. [Google Scholar] [CrossRef]

- Menapace, I.; Masad, E.; Bhasin, A. Effect of treatment temperature on the microstructure of asphalt binders: Insights on the development of dispersed domains. J. Microsc. 2016, 262, 12–27. [Google Scholar] [CrossRef] [PubMed]

| Molecular Components | Asphaltene | 1,7-Dimethylnapthalene | n-Doccosane |

|---|---|---|---|

| Number | 18 | 306 | 49 |

| Approximate Mass ratio | 20 | 60 | 20 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Y.; Wang, L.; Wang, D.; Qu, X.; Wu, J. Using a Molecular Dynamics Simulation to Investigate Asphalt Nano-Cracking under External Loading Conditions. Appl. Sci. 2017, 7, 770. https://doi.org/10.3390/app7080770

Hou Y, Wang L, Wang D, Qu X, Wu J. Using a Molecular Dynamics Simulation to Investigate Asphalt Nano-Cracking under External Loading Conditions. Applied Sciences. 2017; 7(8):770. https://doi.org/10.3390/app7080770

Chicago/Turabian StyleHou, Yue, Linbing Wang, Dawei Wang, Xin Qu, and Jiangfeng Wu. 2017. "Using a Molecular Dynamics Simulation to Investigate Asphalt Nano-Cracking under External Loading Conditions" Applied Sciences 7, no. 8: 770. https://doi.org/10.3390/app7080770