Accelerated Sine-on-Random Vibration Test Method of Ground Vehicle Components over Conventional Single Mode Excitation

Abstract

:1. Introduction

2. Damage Counting with Acceleration Data Only

2.1. Pseudo-Damage Counting

2.2. Physical Damage Counting with Energy Isocline Function

3. Damage Comparison with a Uniaxial Vibration Test

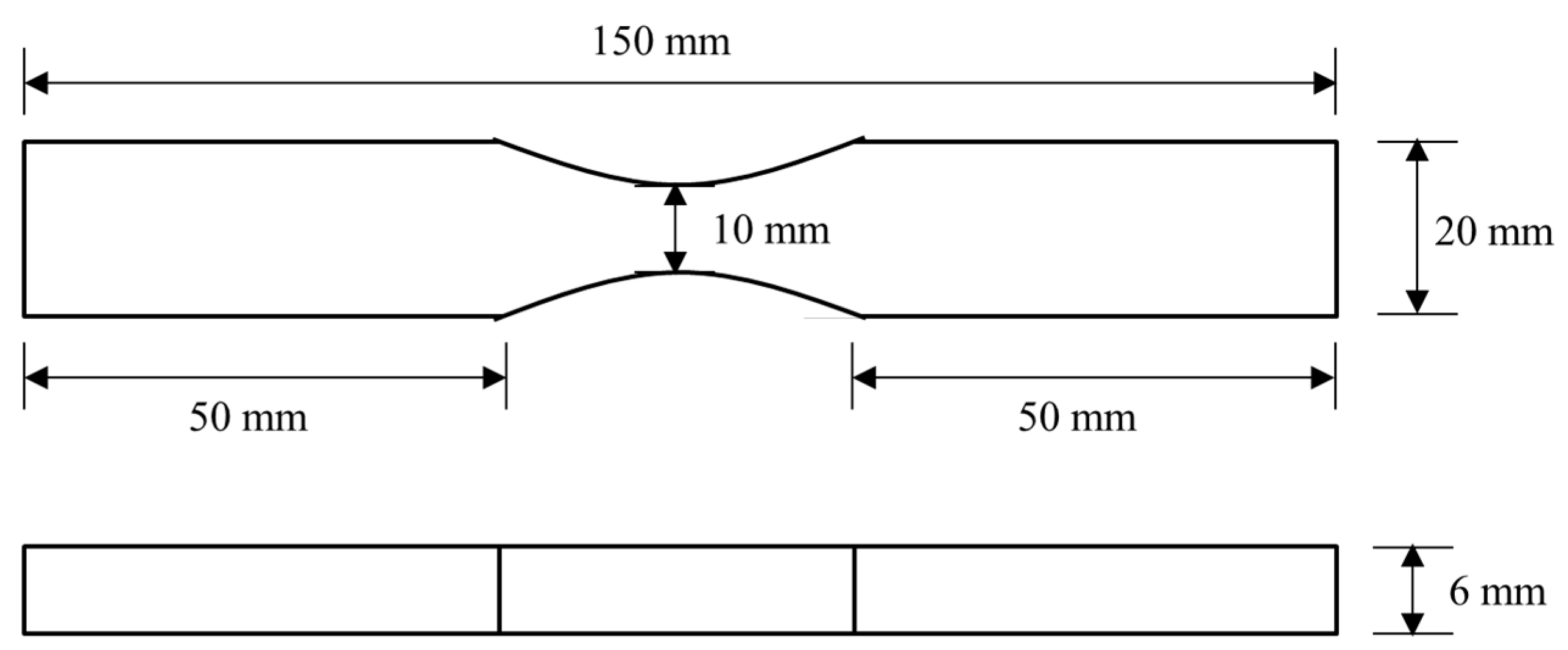

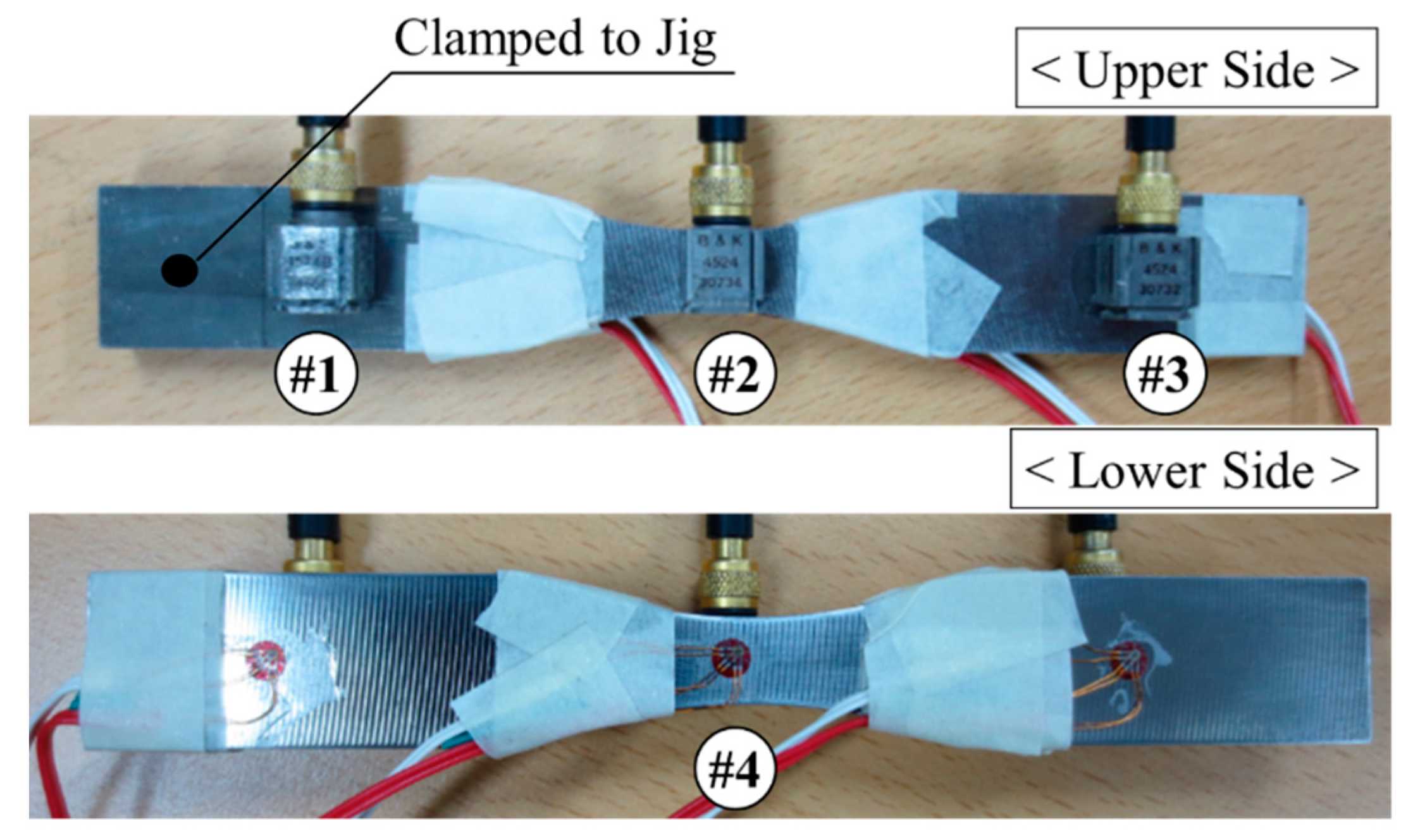

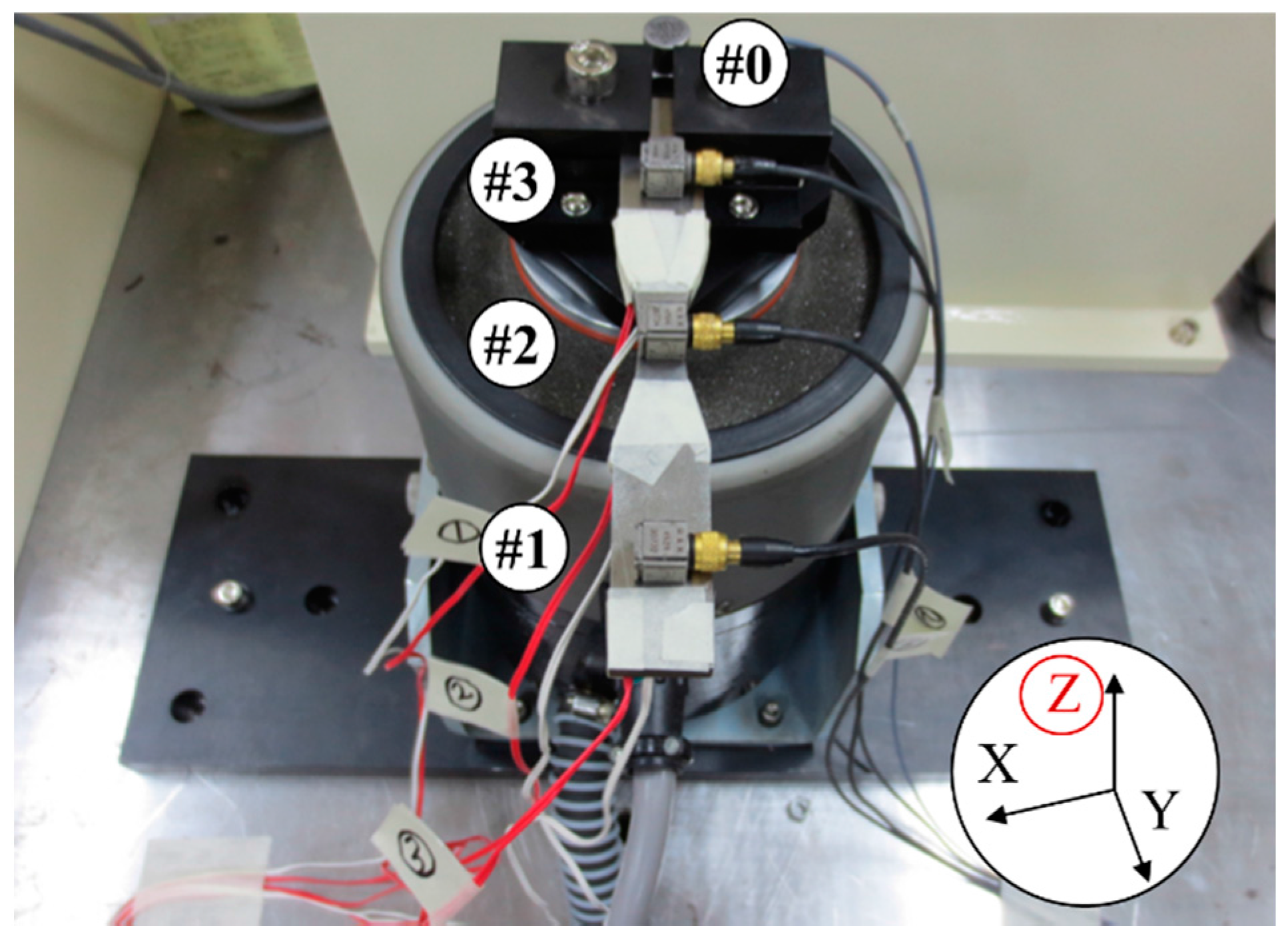

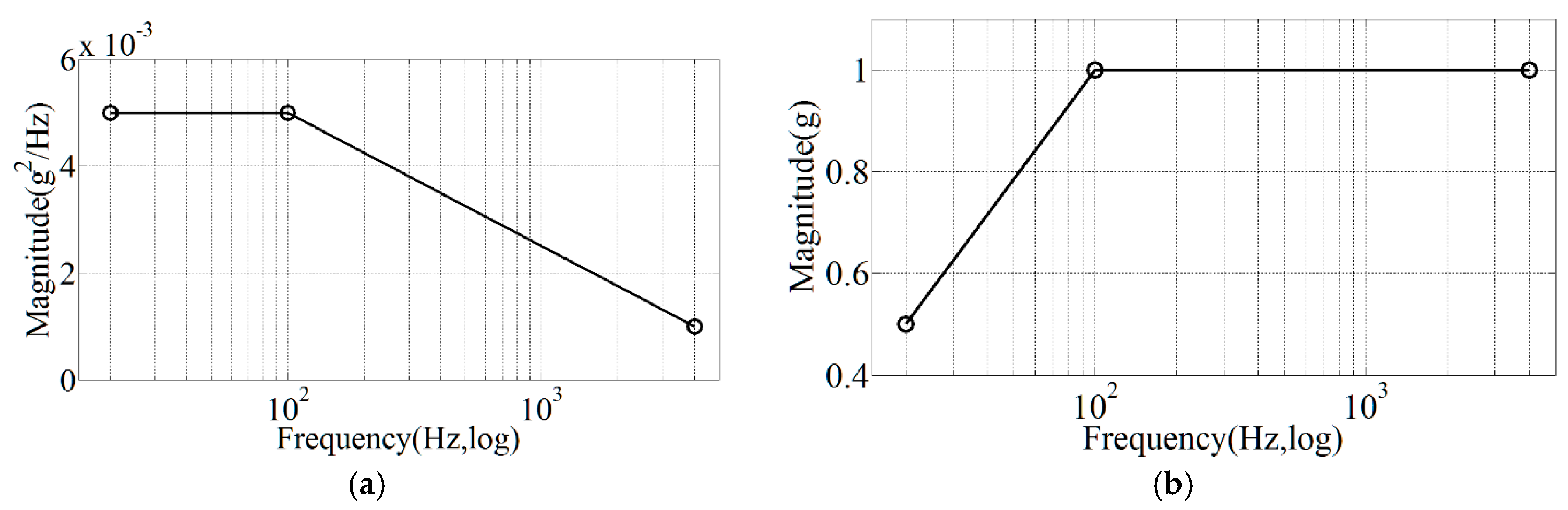

3.1. Uniaxial Vibration Test with a Notched Simple Specimen

3.2. Fatigue Damage of a Notched Simple Specimen

3.3. Discussion

4. Vibration Test Guideline for Ground Vehicle Components

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- Kim, C.J.; Kang, Y.J.; Lee, B.H. Generation of driving profile on a multi-axial vibration table for vibration fatigue damage. Mech. Syst. Signal Process. 2012, 26, 244–253. [Google Scholar] [CrossRef]

- Morill, J.; Achatz, T.; Khosrovaneh, A. An application for fatigue damage analysis using power spectral density from road durability events. SAE Tech. Pap. 1998, 55–62. [Google Scholar] [CrossRef]

- Lin, J.S.; Yim, K.S. Application of random vibration test methods for automotive subsystems using power spectral density (PSD). SAE Tech. Pap. 2000. [Google Scholar] [CrossRef]

- Su, H. Vibration test specification for automotive products based on measured vehicle load data. SAE Tech. Pap. 2006. [Google Scholar] [CrossRef]

- Seba, B.; Nedeljkovic, N.; Paschedag, J.; Lohmann, B. H∞ feedback control and Fx-LMS feedforward control for car engine vibration attenuation. Appl. Acoust. 2005, 66, 277–296. [Google Scholar] [CrossRef]

- Lanchester, F.W. Engine balancing. Proc. Inst. Automob. Eng. 1914, 8, 195–278. [Google Scholar] [CrossRef]

- Kim, C.J.; Kang, Y.J.; Lee, B.H.; Ahn, H.J. Determination of optimal position for both support bearing and unbalance mass of balance shaft. Mech. Mach. Theory 2012, 50, 150–158. [Google Scholar] [CrossRef]

- Bishop, N.W.M.; Sherratt, F. Fatigue life prediction from power spectral density data. Part 1: Traditional approaches. Environ. Eng. 1989, 2, 11–14. [Google Scholar]

- Bishop, N.W.M.; Sherratt, F. Fatigue life prediction from power spectral density data. Part 2: Recent developments. Environ. Eng. 1989, 2, 11–19. [Google Scholar]

- Wirsching, P.H.; Shehata, A.M. Fatigue under wide band random stresses using the rain-flow method. J. Eng. Mater. Technol. 1977, 99, 205–211. [Google Scholar] [CrossRef]

- Liou, H.Y.; Wu, W.F.; Shin, C.S. A modified model for the estimation of fatigue life derived from random vibration theory. Probab. Eng. Mech. 1999, 14, 281–288. [Google Scholar] [CrossRef]

- Kim, C.J.; Kang, Y.J.; Lee, B.H. Experimental spectral damage prediction of a linear elastic system using acceleration response. Mech. Syst. Signal Process. 2011, 25, 2538–2548. [Google Scholar] [CrossRef]

- Kim, C.J.; Lee, B.H.; Kang, Y.J.; Ahn, H.J. Accuracy enhancement of fatigue damage counting using design sensitivity analysis. J. Sound Vib. 2014, 333, 2971–2982. [Google Scholar] [CrossRef]

- Kim, C.J.; Lee, B.H.; Kang, Y.J. Accelerated slam testing of vehicle door plate module using vibration exciter. J. Test. Eval. 2013, 41, 659–666. [Google Scholar] [CrossRef]

- Shin, S.Y.; Kim, C.J. Analysis of spectral fatigue damage of linear elastic systems with different high cyclic loading cases using energy isocline. Trans. Korean Soc. Noise Vib. Eng. 2014, 24, 845–850. [Google Scholar] [CrossRef]

- Koss, L.L.; Karczub, D. Euler beam bending wave solution predictions of dynamic strain using frequency response functions. J. Sound Vib. 1995, 184, 229–244. [Google Scholar] [CrossRef]

- Karczub, D.G.; Norton, M.P. Finite differencing methods for the measurement of dynamic bending strain. J. Sound Vib. 1999, 226, 675–700. [Google Scholar] [CrossRef]

- Lee, G.M. Prediction of strain responses from the measurements of displacement responses. Mech. Syst. Signal Process. 2007, 21, 1143–1152. [Google Scholar] [CrossRef]

- Technical Committee ISO/TC 22. ISO 16750-3(E), Road Vehicles—Environmental Conditions and Testing for Electrical and Electronic Equipment—Part 3: Mechanical Loads; ISO copyright office: Geneva, Switzerland, 2007. [Google Scholar]

- Kim, C.J. Damage count method using acceleration response for vibration test over multi-spectral loading pattern. Trans. Korean Soc. Noise Vib. Eng. 2015, 25, 739–746. [Google Scholar] [CrossRef]

- MIL-STD-810G Committee. Environmental engineering considerations and laboratory tests. In MIL-STD-810G, Department of Defense Test Method Standard; Department of Defense: Washington, DC, USA, 2008. [Google Scholar]

- Stephens, R.I.; Fatemi, A.; Stephens, R.R.; Fuchs, H.O. Metal Fatigue in Engineering; Willey Interscience: Singapore, 2001. [Google Scholar]

- Suresh, S. Fatigue of Materials; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Davenport, W.B., Jr.; Root, W.L. An Introduction to the Theory of Random Signals and Noise; Wiley Interscience: New York, NY, USA, 1987. [Google Scholar]

- Newland, D.E. An Introduction to Random Vibrations, Spectral and Wavelet Analysis; Longman Scientific and Technical: Essex, UK, 1994. [Google Scholar]

- Bendat, J.S.; Piersol, A.G. Random Data Analysis and Measurement Procedures; Wiley Interscience: New York, NY, USA, 2000. [Google Scholar]

- Harrison, M. Vehicle Refinement, Controlling Noise and Vibration in Road Vehicles; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- Hurd, A. Combining accelerated laboratory durability with squeak and rattle evaluation. SAE Tech. Pap. 1991. [Google Scholar] [CrossRef]

- Wan, D.; Kim, H. Evaluation of MAST transfer function in the vehicle exhaust system full system durability test. SAE Tech. Pap. 2002. [Google Scholar] [CrossRef]

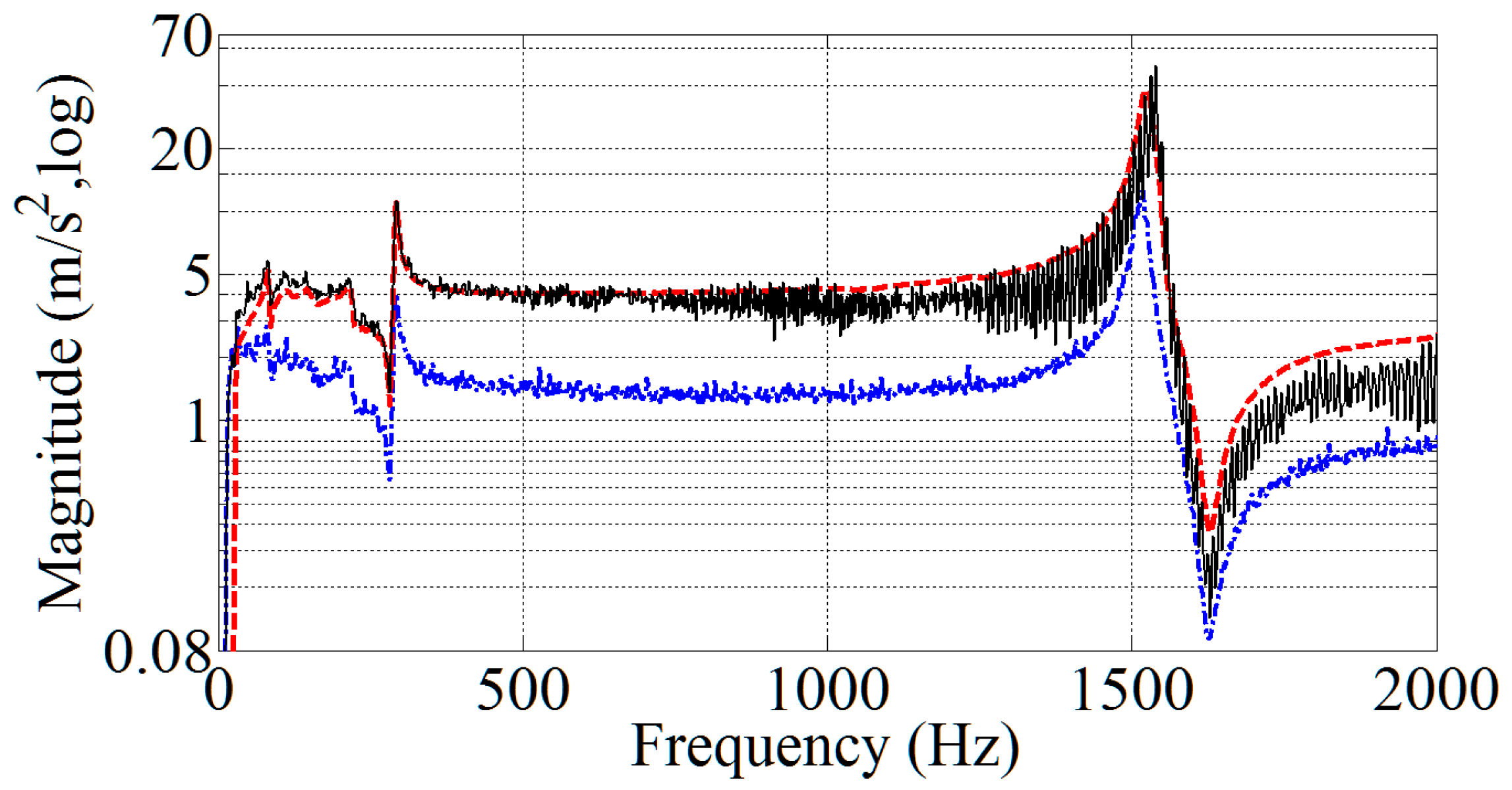

: sine-on-random excitation;

: sine-on-random excitation;  : harmonic excitation; and

: harmonic excitation; and  : random excitation.

: random excitation.

: sine-on-random excitation;

: sine-on-random excitation;  : harmonic excitation; and

: harmonic excitation; and  : random excitation.

: random excitation.

| # | Frequency (Hz) | Damping (%) | Shape Type |

| 1 | 1162.7 | 0.55 | Bending |

| Mode | # | Pseudo Damage | # | Physical Damage |

|---|---|---|---|---|

| Random | 1 | 1.10 × 10−4 | 1 | 1.70 × 10−10 |

| 2 | 1.55 × 10−4 | 2 | 9.95 × 10−10 | |

| 3 | 1.08 × 10−4 | 3 | 3.23 × 10−10 | |

| Avg. | 1.24 × 10−4 | Avg. | 4.96 × 10−10 | |

| Harmonic | 1 | 2.92 × 10−1 | 1 | 5.97 × 10−5 |

| 2 | 3.00 × 10−1 | 2 | 6.01 × 10−5 | |

| 3 | 2.93 × 10−1 | 3 | 6.28 × 10−5 | |

| Avg. | 2.95 × 10−1 | Avg. | 6.09 × 10−5 | |

| Sine-on-Random | 1 | 7.48 × 10−1 | 1 | 1.02 × 10−4 |

| 2 | 7.47 × 10−1 | 2 | 7.03 × 10−5 | |

| 3 | 5.52 × 10−1 | 3 | 5.76 × 10−5 | |

| Avg. | 6.82 × 10−1 | Avg. | 7.67 × 10−5 |

| Mode | Pseudo Damage | Physical Damage |

|---|---|---|

| Random | 0.02 (%) | Less than 0.01 (%) |

| Harmonic | 43.3 (%) | 79.3 (%) |

| Mode | Duration | Physical Damage |

|---|---|---|

| Random | short | very small |

| Harmonic | short | Small |

| Sine → Harmonic or Harmonic → Sine | long | Small |

| Sine-on-random | short | Large |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, C.-J. Accelerated Sine-on-Random Vibration Test Method of Ground Vehicle Components over Conventional Single Mode Excitation. Appl. Sci. 2017, 7, 805. https://doi.org/10.3390/app7080805

Kim C-J. Accelerated Sine-on-Random Vibration Test Method of Ground Vehicle Components over Conventional Single Mode Excitation. Applied Sciences. 2017; 7(8):805. https://doi.org/10.3390/app7080805

Chicago/Turabian StyleKim, Chan-Jung. 2017. "Accelerated Sine-on-Random Vibration Test Method of Ground Vehicle Components over Conventional Single Mode Excitation" Applied Sciences 7, no. 8: 805. https://doi.org/10.3390/app7080805