An Event Reporting and Early-Warning Safety System Based on the Internet of Things for Underground Coal Mines: A Case Study

Abstract

:1. Introduction

- (1)

- We propose the use of an Arduino-based, scalable, cost effective, reliable, and distributed network for underground environmental monitoring.

- (2)

- We propose the seamless integration of key technologies of information systems based on IoT and cloud services for underground mine informatics, in which a cloud server communicates with mobile devices.

- (3)

- We originally proposed a single “Mine Warning Index (MWI)” for an easy and quick assessment of mine safety.

- (4)

- We proposed an outlier detection algorithm for event detection and identification in an underground coal mine.

- (5)

- When compared to the conventional receive signal strength (RSS) method, the proposed RSS range-based weighted centroid localization algorithm improved tracking accuracy by 30%.

2. Related Work

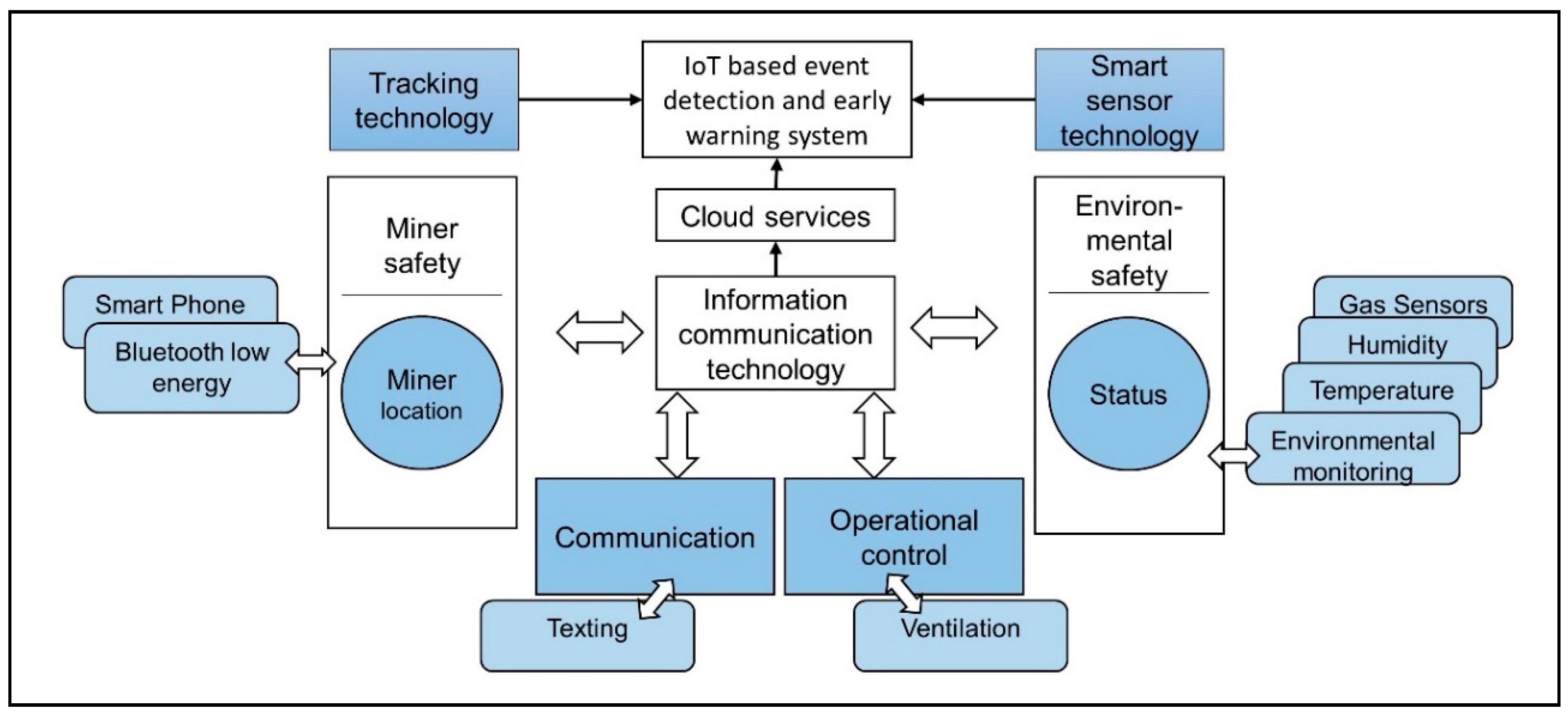

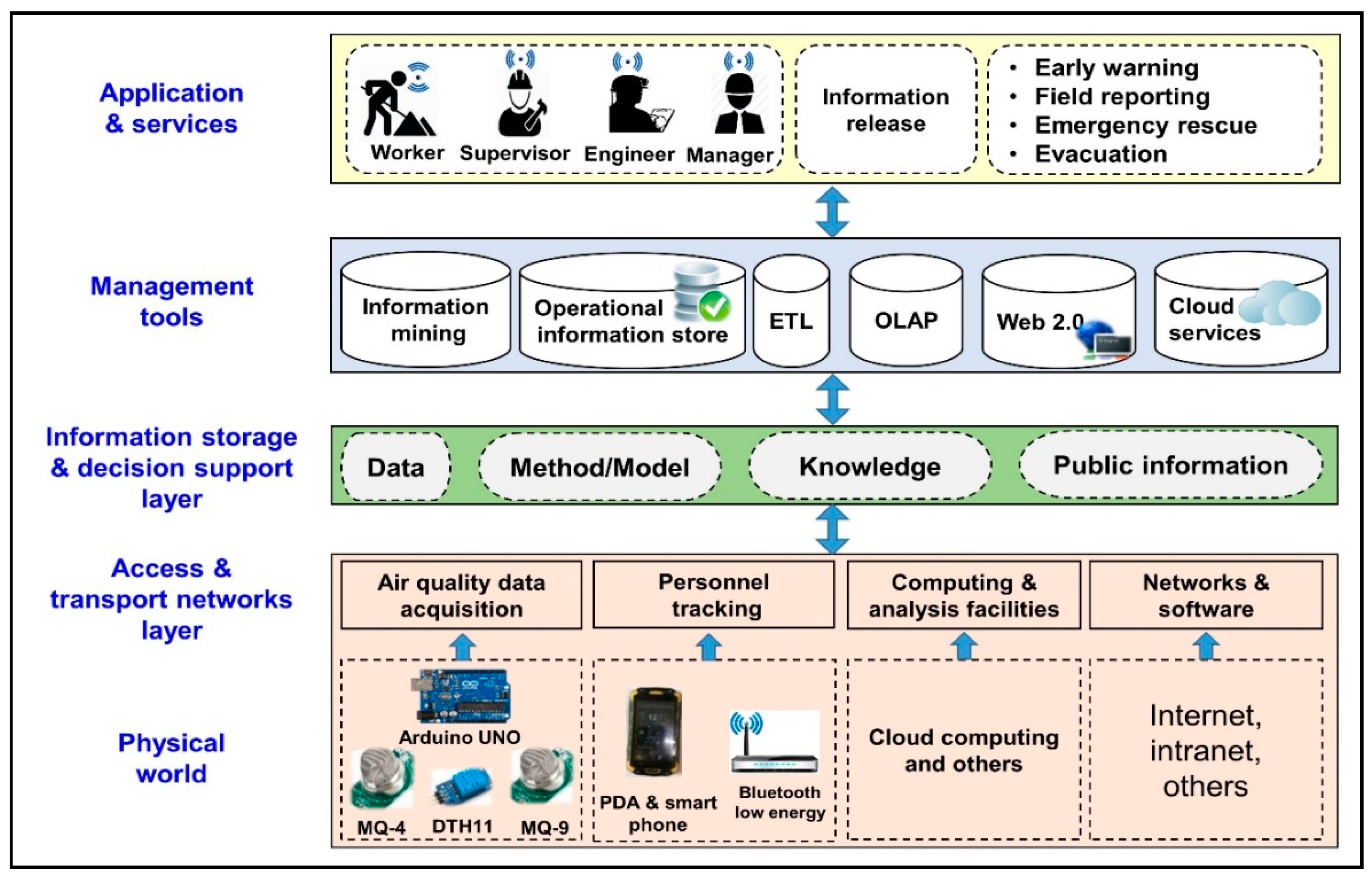

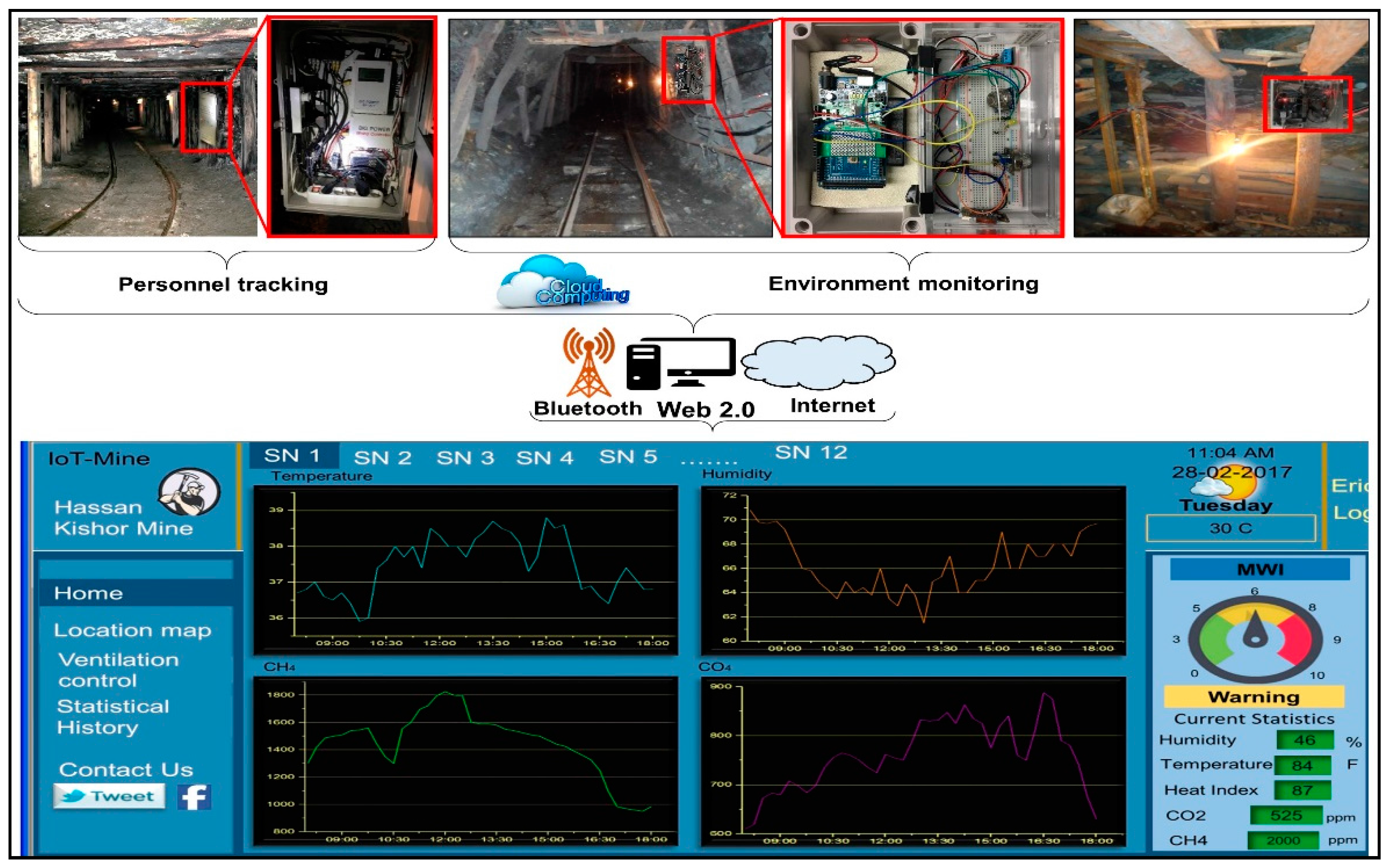

3. System Overview

4. System Design

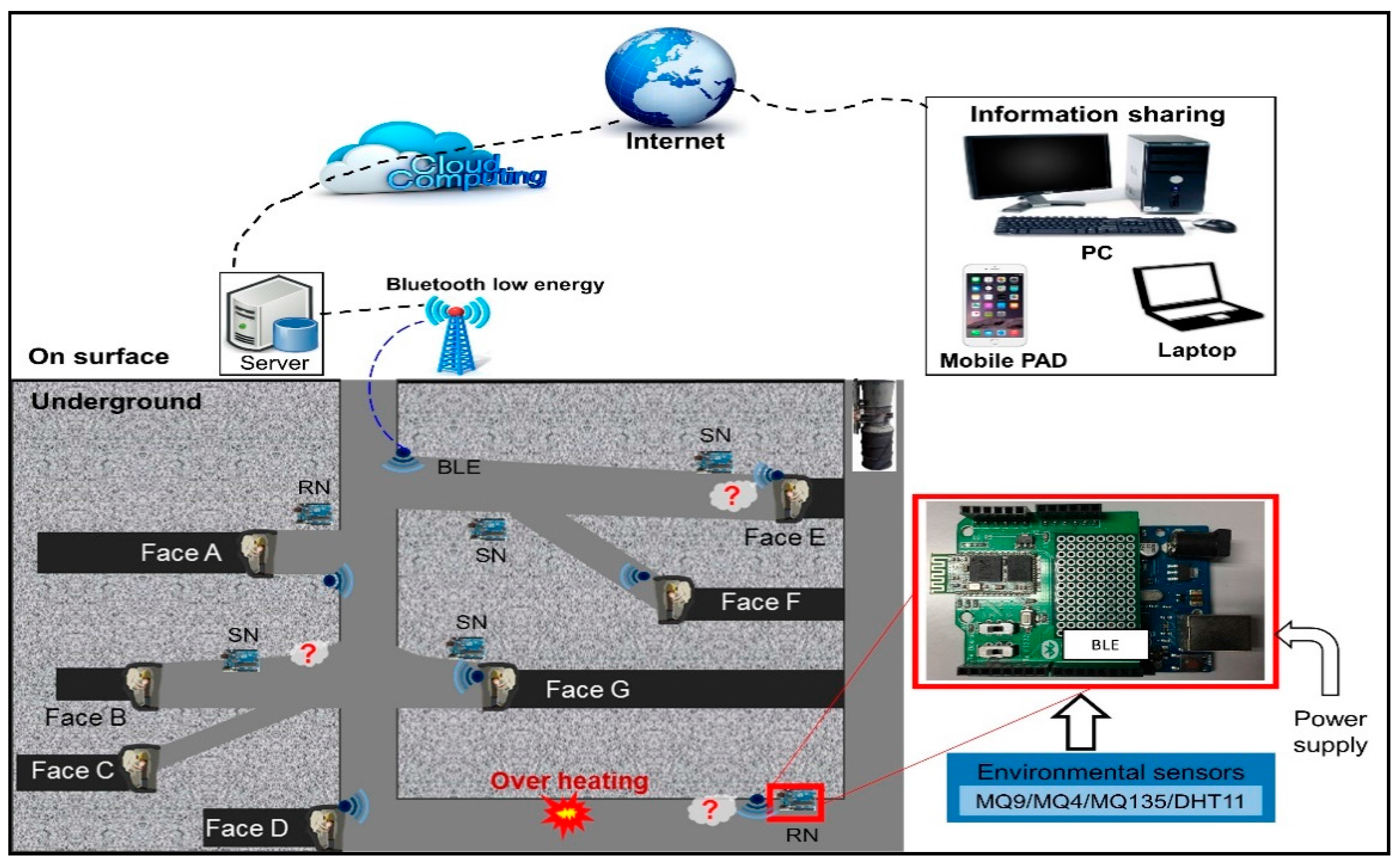

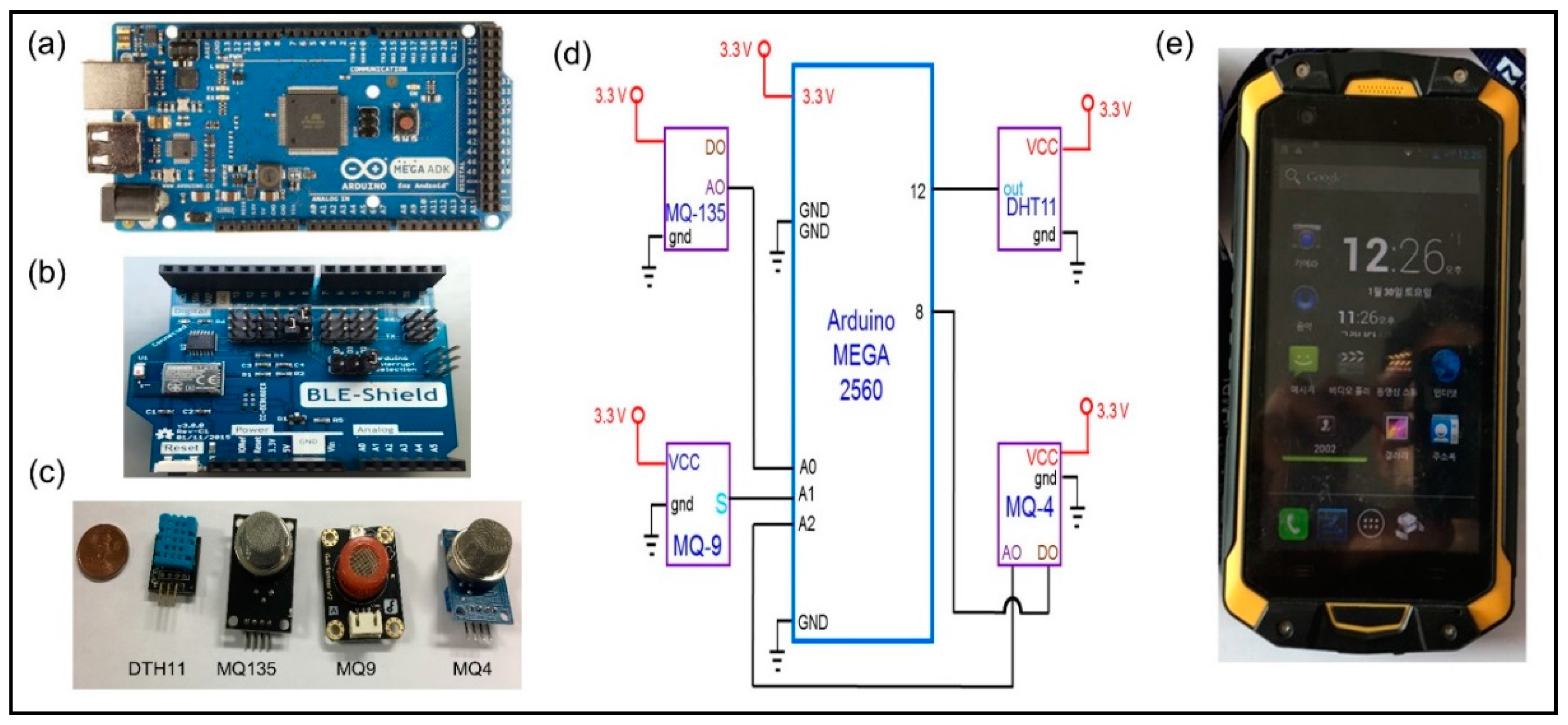

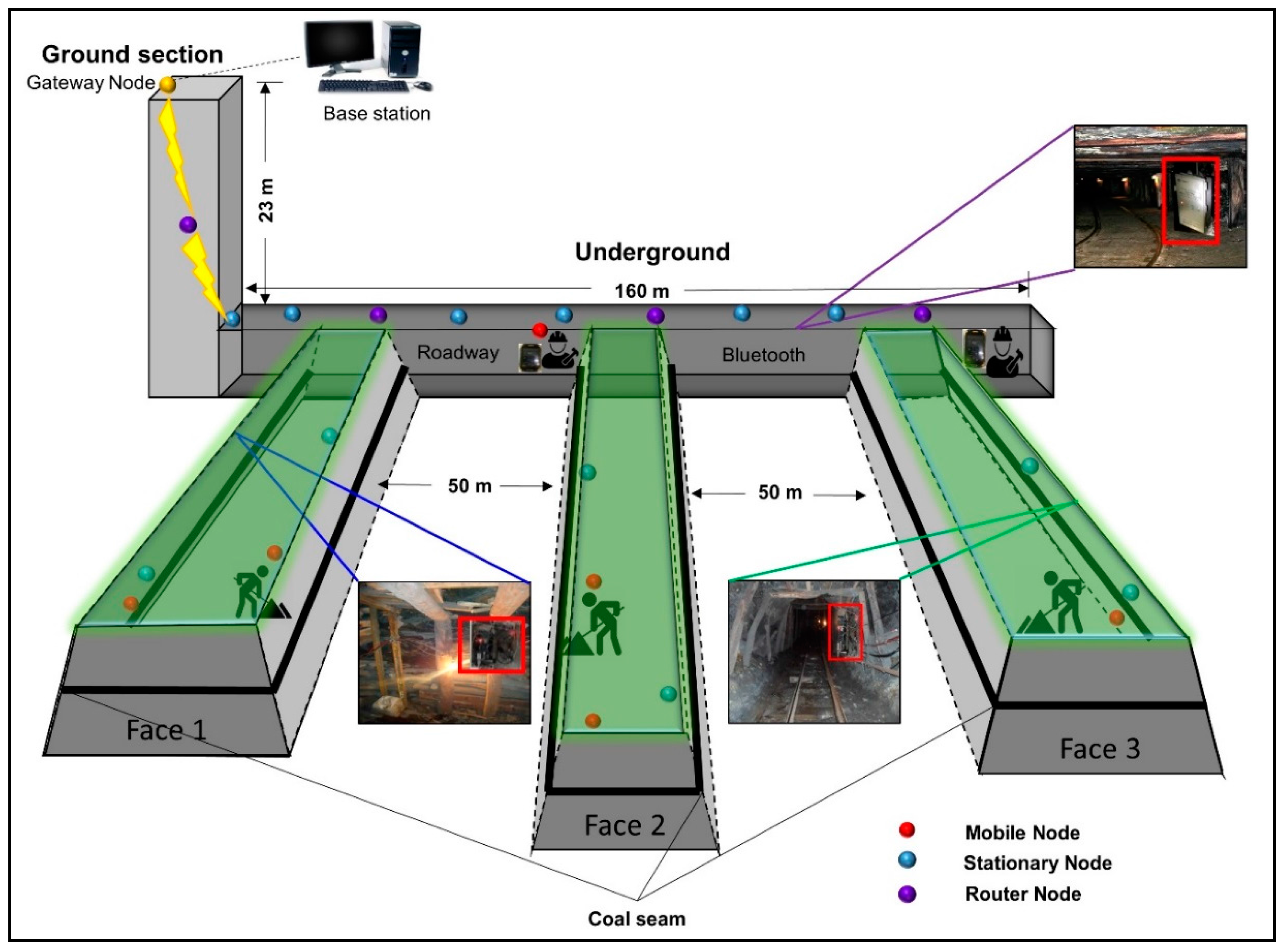

4.1. Physical Layer: Data Collection

4.1.1. Stationary Node Design (Environment Parameter Monitoring)

4.1.2. Mobile Nodes and Other Nodes (Miner Location Tracking)

4.2. Network Layer: Communication Protocol

4.3. Information Storage, Decision Support System and Application Layer

5. Methods and Models

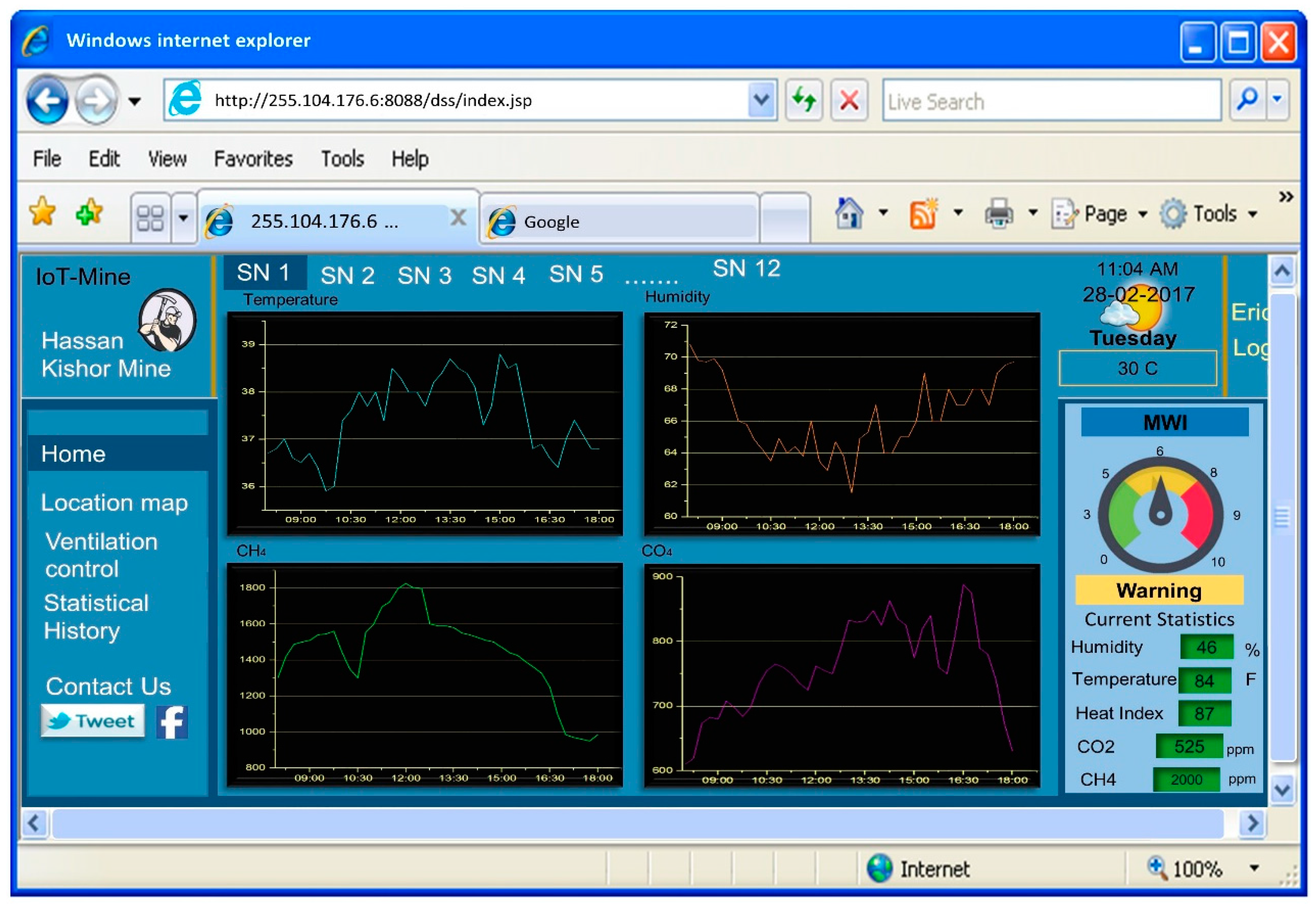

5.1. Mine Warning Index (MWI) and Ambient Intelligence

- 1.

- What is the most well-known range of gas concentration?

- 2.

- What is the safety state in each region of the mine?

- 3.

- What are the variations from the norm and why? Are they detected?

- 4.

- What is the relationship between the different monitoring parameters?

5.2. Outlier Detection Algorithm

5.3. Event Reporting and Global Event Detection

5.4. Miner Tracking Algorithm

6. Implementation: Case Study

- (1)

- BLE shields were installed and programmed using Arduino. Then, the sensor modules for temperature, humidity, CO2, CH4, and CO were fabricated with Arduino. The sensing prototype was pre-programmed with the threshold limits of gases, temperature, and humidity, as summarized in Table 1 in Arduino Integrated Development Environment (IDE 1.0.X Arduino AG).

- (2)

- The SNs and RNs were installed on the side walls of the mine at different locations shown in Figure 5.

- (3)

- Power at 3 V to 5 V was supplied to SNs and RNs using the electrical power of the underground mine.

- (4)

- The entire framework of the system was installed on a PC server (Intel Xeon E5420 2.5 GHz with 8G RAM) running on an operating system of Windows 7 (Microsoft, Redmond, WA, USA).

- (5)

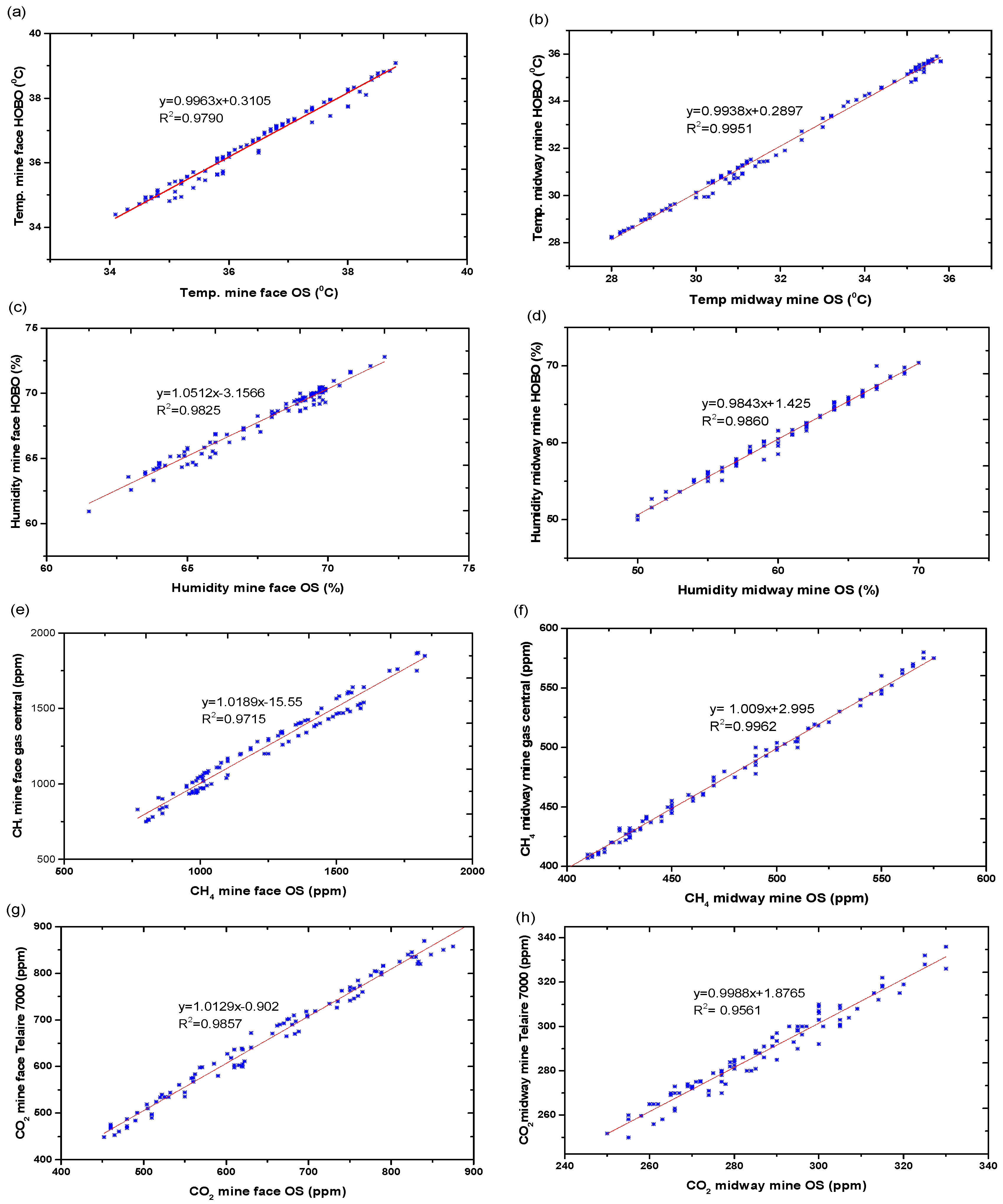

- The early-warning data was transferred to the main server every second. Initially, the monitored data were compared with commercially available well-known devices for a day. These devices included: Onset HOBO U12-012 (Onset, Bourne, MA, USA) [42] for temperature and humidity, Gas central CH4C 100 (Ventilation Control Products, Brodalsvägen 7, Hus Z, Partille, Sweden) for methane (CH4) gas, Telaire 7000 series (Amphenol Thermometrics, Inc., Saint Marys, Pennsylvania, PA, USA) for CO2 and Fluke CO-220 (Fluke Corporation, Everett, WA, USA) for CO.

- (6)

- The RSS-weighted centroid localization algorithm was defined and programmed in the computer for miner tracking.

7. System Performance and Evaluation

7.1. Calibration

7.2. Intelligent Decision Making

7.3. Outlier Detection and Event Identification

7.4. Localization Results

7.5. Information Sharing Web Page

7.6. Performance of Web Page

8. Discussion

9. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, H.; Cheng, Y.; Yuan, L. Gas outburst disasters and the mining technology of key protective seam in coal seam group in the huainan coalfield. Nat. Hazards 2013, 67, 763. [Google Scholar] [CrossRef]

- Joy, G.J. Evaluation of the approach to respirable quartz exposure control in us coal mines. J. Occup. Environ. Hyg. 2012, 9, 65–68. [Google Scholar] [CrossRef] [PubMed]

- Molina, S.; Soto, I.; Carrasco, R. Detection of gases and collapses in underground mines using wsn, Industrial Technology (ICIT). In Proceedings of the 2011 IEEE International Conference on Industrial Technology (ICIT), Auburn, AL, USA, 14–16 March 2011; pp. 219–225. [Google Scholar]

- Trevits, M.; Yuan, L.; Smith, A.; Thimons, E.; Goodman, G. The status of mine fire research in the United States. In Proceedings of the 21st World Mining Congress; Taylor & Francis Group: Krakow, Poland; London, UK, 2008; pp. 303–308. [Google Scholar]

- Annual Report, 2011 of Chief Inspector of Mines, Punjab. Available online: http://cim.pitb.gov.pk/system/files/CIM_AnnualReport_2011.pdf (accessed on 30 April 2017).

- CDC. Center for Disease Control and Prevention Mining Facilities. Available online: http://www.cdc.gov/niosh/mining/statistics/allmining.html (accessed on 6 September 2017).

- Osunmakinde, I.O. Towards safety from toxic gases in underground mines using wireless sensor networks and ambient intelligence. Int. J. Distrib. Sens. Netw. 2013. [Google Scholar] [CrossRef]

- Welbourne, E.; Battle, L.; Cole, G.; Gould, K.; Rector, K.; Raymer, S.; Balazinska, M.; Borriello, G. Building the Internet of Things using rfid: The rfid ecosystem experience. IEEE Int. Comput. 2009, 13. [Google Scholar] [CrossRef]

- Miorandi, D.; Sicari, S.; De Pellegrini, F.; Chlamtac, I. Internet of things: Vision, applications and research challenges. Ad Hoc Netw. 2012, 10, 1497–1516. [Google Scholar] [CrossRef]

- Sun, E.J.; Zhang, X.K.; Li, Z.X. The Internet of Things (iot) and cloud computing (cc) based tailings dam monitoring and pre-alarm system in mines. Saf. Sci. 2012, 50, 811–815. [Google Scholar] [CrossRef]

- Dohare, Y.S.; Maity, T.; Das, P.S.; Paul, P.S. Wireless communication and environment monitoring in underground coal mines—Review. IETE Tech. Rev. 2015, 32, 140–150. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Lu, G. Application of wsn in mine emergency communication system. In Proceedings of the 4th International Conference on Wireless Communications, Networking and Mobile Computing, Dalian, China, 12–14 October 2008; pp. 1–3. [Google Scholar]

- Zhang, Y.; Yang, W.; Han, D.; Kim, Y.-I. An integrated environment monitoring system for underground coal mines—Wireless sensor network subsystem with multi-parameter monitoring. Sensors 2014, 14, 13149–13170. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharjee, S.; Roy, P.; Ghosh, S.; Misra, S.; Obaidat, M.S. Wireless sensor network-based fire detection, alarming, monitoring and prevention system for bord-and-pillar coal mines. J. Syst. Softw. 2012, 85, 571–581. [Google Scholar] [CrossRef]

- Roy, P.; Bhattacharjee, S.; Ghosh, S.; Misra, S.; Obaidat, M.S. Fire monitoring in coal mines using wireless sensor networks. In Proceedings of the 2011 International Symposium on Performance Evaluation of Computer & Telecommunication Systems (SPECTS), The Hague, The Netherlands, 27–30 June 2011; pp. 16–21. [Google Scholar]

- Misra, P.; Kanhere, S.; Ostry, D.; Jha, S. Safety assurance and rescue communication systems in high-stress environments: A mining case study. IEEE Commun. Mag. 2010, 48, 66–73. [Google Scholar] [CrossRef]

- Moridi, M.A.; Kawamura, Y.; Sharifzadeh, M.; Chanda, E.K.; Jang, H. An investigation of underground monitoring and communication system based on radio waves attenuation using zigbee. Tunn. Undergr. Space Technol. 2014, 43, 362–369. [Google Scholar] [CrossRef]

- Jafarian, M.; Jaseemuddin, M. Routing of emergency data in a wireless sensor network for mines. In Proceedings of the IEEE International Conference on Communications, Beijing, China, 19–23 May 2008; pp. 2813–2818. [Google Scholar]

- Song, J.-L.; Gao, H.-W.; Song, Y.-J. Research on transceiver system of wsn based on v-mimo underground coal mines. In Proceedings of the 2010 International Conference on Communications and Mobile Computing (CMC), Shenzhen, China, 12–14 April 2010; pp. 374–378. [Google Scholar]

- Li, M.; Liu, Y.H. Underground coal mine monitoring with wireless sensor networks. ACM Trans. Sens. Netw. 2009, 5, 10. [Google Scholar] [CrossRef]

- Shen, G.; Zetik, R.; Thoma, R.S. Performance comparison of toa and tdoa based location estimation algorithms in los environment. In Proceedings of the 5th Workshop on Positioning, Navigation and Communication, Hannover, Germany, 27 March 2008; pp. 71–78. [Google Scholar]

- Di Stefano, G.; Petricola, A. A distributed aoa based localization algorithm for wireless sensor networks. J. Comput. 2008, 3, 1–8. [Google Scholar] [CrossRef]

- Wang, J.; Gao, Q.; Yu, Y.; Cheng, P.; Wu, L.; Wang, H. Robust device-free wireless localization based on differential rss measurements. IEEE Trans. Ind. Electron. 2013, 60, 5943–5952. [Google Scholar] [CrossRef]

- Akeila, E.; Salcic, Z.; Swain, A.; Croft, A.; Stott, J. Bluetooth-based indoor positioning with fuzzy based dynamic calibration. In Proceedings of the 2010 IEEE Region 10 Conference, Fukuoka, Japan, 21–24 November 2010; pp. 1415–1420. [Google Scholar]

- Qandour, A.; Habibi, D.; Ahmad, I. Applied application of sensor networks in underground mines. In Proceedings of the 9th IEEE International Conference on Networking, Sensing and Control (ICNSC), Beijing, China, 11–14 April 2012; pp. 256–260. [Google Scholar]

- Bychkov, I.V.; Oparin, V.N.; Potapov, V.P. Cloud technologies in mining geoinformation science. J. Min. Sci. 2014, 50, 142–154. [Google Scholar] [CrossRef]

- Niu, X.; Huang, X.; Zhao, Z.; Zhang, Y.; Huang, C.; Cui, L. The design and evaluation of a wireless sensor network for mine safety monitoring. In Proceedings of the Global Telecommunications Conference, Washington, DC, USA, 26–30 November 2007; pp. 1291–1295. [Google Scholar]

- Huang, Y.; Cheng, W.; Tang, C.; Wang, C. Study of multi-agent-based coal mine environmental monitoring system. Ecol. Indic. 2015, 51, 79–86. [Google Scholar] [CrossRef]

- Kiritsis, D. Closed-loop plm for intelligent products in the era of the Internet of Things. Comput. Aided Des. 2011, 43, 479–501. [Google Scholar] [CrossRef]

- Arduino. Arduino Mega 2560. Available online: https://www.arduino.cc/en/Main/arduinoBoardMega2560 (accessed on 28 August 2017).

- Arduino. Available online: https://www.arduino.cc/en/Guide/Introduction (accessed on 28 August 2017).

- Kriz, P.; Maly, F.; Kozel, T. Improving indoor localization using bluetooth low energy beacons. Mob. Inf. Syst. 2016, 2016, 2083094. [Google Scholar] [CrossRef]

- Ibeacon for Developers-Apple Developer. Available online: https://developer.apple.com/ibeacon/ (accessed on 12 July 2017).

- Wang, Y.; Yang, X.; Zhao, Y.; Liu, Y.; Cuthbert, L. Bluetooth positioning using rssi and triangulation methods. In Proceedings of the Consumer Communications and Networking Conference (CCNC), Las Vegas, NV, USA, 11–14 January 2013; pp. 837–842. [Google Scholar]

- National Weather Service. What Is the Heat Index? Available online: http://www.srh.noaa.gov/ama/?n=heatindex (accessed on 6 September 2017).

- Moridi, M.A.; Kawamura, Y.; Sharifzadeh, M.; Chanda, E.K.; Wagner, M.; Jang, H.; Okawa, H. Development of underground mine monitoring and communication system integrated zigbee and gis. Int. J. Min. Sci. Technol. 2015, 25, 811–818. [Google Scholar] [CrossRef]

- Coal Mine Regulations, 1926. Available online: http://www.mnm.punjab.gov.pk/system/files/COAL%20MINES%20REGULATIONS%2C%201926.doc_.pdf (accessed on 28 August 2017).

- Maxwell, N. Data Matters: Conceptual Statistics for a Random World; Key College Pub.: Charlottesville, VA, USA, 2004. [Google Scholar]

- Shahid, N.; Naqvi, I.H.; Qaisar, S.B. Characteristics and classification of outlier detection techniques for wireless sensor networks in harsh environments: A survey. Artif. Intell. Rev. 2015, 43, 193–228. [Google Scholar] [CrossRef]

- Jain, A.K. Data clustering: 50 years beyond k-means. Pattern Recognit. Lett. 2010, 31, 651–666. [Google Scholar] [CrossRef]

- Rousseeuw, P.J. Silhouettes: A graphical aid to the interpretation and validation of cluster analysis. J. Comput. Appl. Math. 1987, 20, 53–65. [Google Scholar] [CrossRef]

- Onset. Available online: http://www.onsetcomp.com/products/data-loggers/u12-012 (accessed on 6 September 2017).

- Menon, K.U.; Maria, D.; Thirugnanam, H. Power optimization strategies for wireless sensor networks in coal mines. In Proceedings of the 9th International Conference on Wireless and Optical Communications Networks (WOCN), Indore, India, 20–22 September 2012; pp. 1–5. [Google Scholar]

- Haifeng, J.; Jiansheng, Q.; Yanjing, S.; Guoyong, Z. Energy optimal routing for long chain-type wireless sensor networks in underground mines. Min. Sci. Technol. 2011, 21, 17–21. [Google Scholar] [CrossRef]

- Kandris, D.; Tsioumas, P.; Tzes, A.; Nikolakopoulos, G.; Vergados, D.D. Power conservation through energy efficient routing in wireless sensor networks. Sensors 2009, 9, 7320–7342. [Google Scholar] [CrossRef] [PubMed]

| Previous Work | Standard Monitoring and Reporting | MWI | Intelligent Event Detection/Identification | Miner Tracking | Priority Transmission for Emergency | Distributed Processing |

|---|---|---|---|---|---|---|

| [7] | ✓ | ✓ | ||||

| [20] | ✓ | Partial | Partial | |||

| [13] | ✓ | Partial | ✓ | |||

| [27] | ✓ | Partial | ✓ | |||

| [28] | ✓ | Partial | Partial | |||

| Proposed system | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Specification | Sensor Model | |||

|---|---|---|---|---|

| MQ-9 | MQ-4 | MQ-135 | DTH11 | |

| Voltage | 5.0 V | 5.0 V | 5.0 V | 3–5 V |

| Detection | CO and CG * | Methane | NH3, smoke, CO2 | Temperature and Humidity |

| Measurement Range | 10–1000 ppm (CO), 100–10,000 ppm (CG) | 200–1000 ppm | 10–300 ppm NH3 | 20–90% RH **, 0–50 °C |

| Accuracy | ±5% | ±5% | ±5% | ±5% RH, ±2 °C Temperature |

| Sensitive Material | SnO2 | SnO2 | SnO2 | -- |

| Configuration | 3-pin | 4-pin | 4-pin | 4-pin |

| Digital/Analog | Analog | Both | Both | Digital |

| MWI | Serving State | Variables | |||||

|---|---|---|---|---|---|---|---|

| HI | Temperature (T1, T2, …, Tn) (°C) | Humidity (H1, H2, …, Hn) (%) | Gases Concentrations (ppm) | ||||

| CH4 | CO | CO2 | |||||

| 0−3.5 | Normal | <90 | Ti ≤ 28 | Hi ≤ 70 | Gia ≤ 2000 | Gib ≤ 15 | Gic ≤ 2000 |

| 3.5−7.9 | Warning | 90 < Hi < 103 | 28 < Ti < 40 | 70 < Hi < 80 | 2000 < Gia < 4000 | 15 < Gib < 25 | 2000 < Gic < 5000 |

| 8−10 | Alarming | 103 < Hi < 124 | Ti ≥ 40 | Hi ≥ 80 | Gia ≥ 4000 | Gib ≥ 25 | Gic ≥ 5000 |

| 1 Byte | 1 Byte | 1Byte | Variable |

|---|---|---|---|

| RFD (0×0a) | Limit | Type | PaRm |

| 1 Byte | 1 Byte | 2 Byte | 1 Byte | Variable | … | 2 Byte | 1 Byte | Variable |

|---|---|---|---|---|---|---|---|---|

| RN (0×0b) | Num | Addr1 | Type 1 | PaRm 1 | … | Addr n | Type n | PaRm n |

| Pt ID | SeqF | Pt Num | Node ID | Next | … | Node ID | Next |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 2 | 2 | … | 2 | 2 |

| Reader No. | Reader Type | Location | Distance from Incline Lower End (m) |

|---|---|---|---|

| 1 | GN | Incline | −23 |

| 2 | RN1 | −10 | |

| 3 | SN1 | 0 | |

| 4 | SN2 | Main roadway of mine (25 below surface) | 17 |

| 5 | RN2 | 34 | |

| 6 | SN3 | 51 | |

| 7 | SN4 | 68 | |

| 8 | RN3 | 85 | |

| 9 | SN5 | 102 | |

| 10 | SN6 | 119 | |

| 11 | RN4 | 140 | |

| 12 | SN7 | Gallery 1 | 46 |

| 13 | SN8 | 60 | |

| 14 | SN9 | Gallery 2 | 96 |

| 15 | SN10 | 110 | |

| 16 | SN11 | Gallery 3 | 151 |

| 17 | SN12 | 160 |

| T0 ……. T1440 | Temp. | Humidity | CH4 | CO2 | CO |

|---|---|---|---|---|---|

| Average | 36.35567 | 67.57835 | 1224.175 | 651.6824 | 2.536082 |

| Standard Error | 0.124595 | 0.24012 | 28.06941 | 12.36075 | 0.1185 |

| Median | 36.3 | 68.5 | 1185 | 656 | 3 |

| Mode | 35.9 | 69.7 | 985 | 460 | 3 |

| Standard Deviation | 1.227 | 2.364917 | 276.4516 | 121.73932 | 1.16709 |

| Skewness | 0.221967 | −0.50707 | 0.317597 | 0.07118 | −0.128 |

| Variance | 1.5058 | 5.6510 | 76176 | 351.6563 | 1.3621 |

| T0 ……. T1440 | Temp. | Humidity | CH4 | CO2 | CO |

|---|---|---|---|---|---|

| Average | 32.06907 | 61.26804 | 465.3711 | 285.7732 | 2.5154 |

| Standard Error | 0.258292 | 0.5165 | 6.68 | 1.9040 | 0.119 |

| Median | 31.2 | 62 | 450 | 284 | 3 |

| Mode | 35.2 | 64 | 450 | 300 | 3 |

| Standard Deviation | 2.54388 | 5.087 | 65.8494 | 18.75 | 1.17736 |

| Skewness | 0.1108 | −0.37651 | −2.3288 | 0.366078 | −0.11685 |

| Variance | 6.4713 | 25.8857 | 4336.152 | 351.6563 | 0.5262 |

| Characteristics | Our System | [25] | [15] |

|---|---|---|---|

| Open-source | ✓ | ✓ | × |

| Cost-effective | ✓ | × | N/A |

| Cloud computing | ✓ | × | × |

| Multi-parameters and multiple aspects of safety | ✓ | partial | Single aspect of safety |

| Easy user interface | ✓ | ✓ | × |

| Real application | ✓ | × | × |

| Energy efficient | N/A | ✓ | N/A |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jo, B.W.; Khan, R.M.A. An Event Reporting and Early-Warning Safety System Based on the Internet of Things for Underground Coal Mines: A Case Study. Appl. Sci. 2017, 7, 925. https://doi.org/10.3390/app7090925

Jo BW, Khan RMA. An Event Reporting and Early-Warning Safety System Based on the Internet of Things for Underground Coal Mines: A Case Study. Applied Sciences. 2017; 7(9):925. https://doi.org/10.3390/app7090925

Chicago/Turabian StyleJo, Byung Wan, and Rana Muhammad Asad Khan. 2017. "An Event Reporting and Early-Warning Safety System Based on the Internet of Things for Underground Coal Mines: A Case Study" Applied Sciences 7, no. 9: 925. https://doi.org/10.3390/app7090925