The Study of Non-Detection Zones in Conventional Long-Distance Ultrasonic Guided Wave Inspection on Square Steel Bars

Abstract

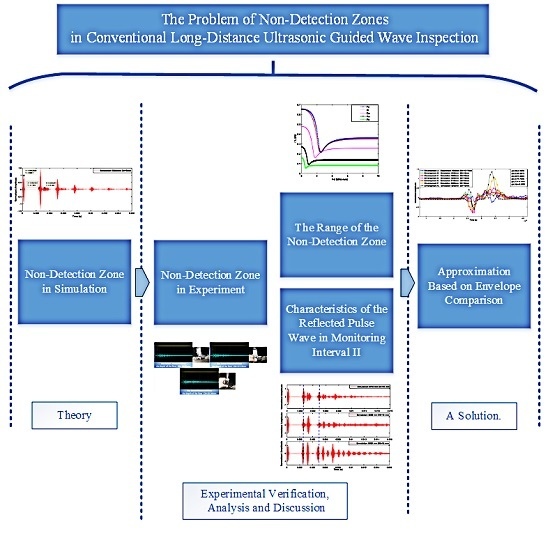

:1. Introduction

2. Theory of the Non-Detection Zone

- A single low-frequency incident pulse is used in the experiments and simulation and the waveforms of the other frequencies are not induced by the excited incident pulse at the corresponding frequencies.

- The mode of the incident pulse wave is a single S0 mode and the frequency of the incident pulse is lower than the S1 and A1 cut-off frequencies so that the mode is simplified and easy to analyze [13].

- In a symmetrical plate-like structure, the reflected pulse is also a single mode S0; in an asymmetrical plate-like structure (such as man-made flaws), the reflected pulses in the A0 mode and S0 mode are excited [14].

- When the frequency-thickness product () is maintained, the group velocity of the S0 and A0 modes remains unchanged under ideal conditions [15].

2.1. The Equivalent Model of Low-Frequency Ultrasonic Guided Wave in a Square Steel Bar

2.1.1. The Mode Selection of Ultrasonic Guided Wave

2.1.2. Theory on the Equivalent Model in Low-Frequency

2.2. Non-Detection Zone in Simulation

- Young’s modulus:

- Density:

- Poisson’s ratio:

3. Experimental Section

4. Analysis and Discussion

4.1. The Range of the Non-Detection Zone

4.2. Characteristics of the Reflected Pulse Wave in Monitoring Interval II

4.3. Approximation Based on Envelope Comparison

- Situation 1: in the actual experimental envelope during monitoring Interval II, the reflected pulse with only one envelope amplitude that is larger than the amplitude of the terminal reflected pulse wave is categorized into a zone ranging from L = 5800 mm to L = 5900 mm;

- Situation 2: the reflected pulses with two similar highest envelope amplitudes are categorized into a zone ranging from L = 5600 mm to L = 5700 mm;

- Situation 3: the remaining flaw detection pulses with different amplitudes are categorized into a zone from L = 5400 mm to L = 5500 mm.

- Step 1: The experimental data with the flaw obtained in the non-detection zone are processed using the envelope calculation and we subtract the envelope of the experimental data without the flaw to reduce the effect of the signal trailing. Then the result of the envelope is extracted in the effective comparison interval (from 7.649 × 10−4 s to 4.653 × 10−3 s).

- Step 2: Based on the obtained experimental envelope (Envelopment 2–Envelopment 1), the simulation range (L [L1, L2]) is selected according to the rough classification described in Section 4.3 to reduce the computation cost.

- Step 3: According to the comparison requirements, the variable value of L is selected in the appropriate range (L1 mm ≤ L1 + kΔx ≤ L2 mm, Δx = 100 mm, k N), the depth of the flaw (y) in the experiment is selected as the value of D0 in the simulation (0 mm ≤ D0 = y < 30 mm), and the simulation results have been processed using the envelope calculations respectively. For every simulation envelope, the envelope of the simulation without the flaw (D0 = 0 mm) is subtracted. Then the results of these envelopes are extracted in the comparison interval as a series of comparisons.

- Step 4: The correlation coefficients between the experimental envelope data from Step 1 and every simulation envelope data from Step 3 are determined and the result returns the maximum correlation coefficient ; subsequently, the estimated position of the flaw (L) is determined according to the reverse correspondence.

4.4. Experimental Validation

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rose, J.L. Ultrasonic Guided Waves in Solid Media, 1st ed.; Cambridge University Press: New York, NY, USA, 2014; ISBN 978-110-70489-59. [Google Scholar]

- Rose, J.L. Ultrasonic Waves in Solid Media, 1st ed.; Cambridge University Press: New York, NY, USA, 1999; ISBN 0521640431. [Google Scholar]

- Ai, C.Y.; Li, J.; Liu, Y.; Ni, T. Ultrasonic Test Theory and Technology for Multilayered Bonding Structure, 1st ed.; National Defence Industry Press: Beijing, China, 2014; ISBN 978-711-80958-07. [Google Scholar]

- Verma, B.; Mishra, T.K.; Balasubramaniam, K.; Rajagopal, P. Interaction of low-frequency axisymmetric ultrasonic guided waves with bends in pipes of arbitrary bend angle and general bend radius. Ultrasonics 2014, 54, 801–808. [Google Scholar] [CrossRef] [PubMed]

- Ryue, J.; Thompson, D.J.; White, P.R.; Thompson, D.R. Decay rates of propagating waves in railway tracks at high frequencies. J. Sound Vib. 2009, 320, 955–976. [Google Scholar] [CrossRef]

- Gravenkamp, H.; Prager, J.; Saputra, A.A.; Song, C. The simulation of lamb waves in a cracked plate using the scaled boundary finite element method. J. Acoust. Soc. Am. 2012, 132, 1358–1367. [Google Scholar] [CrossRef] [PubMed]

- Bartoli, I.; Scalea, F.L.D.; Fateh, M.; Viola, E. Modeling guided wave propagation with application to the long-range defect detection in railroad tracks. NDT E Int. 2005, 38, 325–334. [Google Scholar] [CrossRef]

- Campos-Castellanos, C.; Gharaibeh, Y.; Mudge, P.; Kappatos, V. In the application of long range ultrasonic testing (LRUT) for examination of hard to access areas on railway tracks. Railw. Cond. Monit. Non-Destr. Test. 2012, 1–7. [Google Scholar] [CrossRef]

- Rose, J.L.; Avioli, M.J.; Mudge, P.; Sanderson, R. Guided wave inspection potential of defects in rail. NDT E Int. 2004, 37, 153–161. [Google Scholar] [CrossRef]

- Wu, J.; Wang, Y.; Zhang, W.; Nie, Z.; Lin, R.; Ma, H. Defect detection of pipes using Lyapunov dimension of Duffing oscillator based on ultrasonic guided waves. Mech. Syst. Signal Proc. 2016, 82, 130–147. [Google Scholar] [CrossRef]

- Yao, W.; Sheng, F.; Wei, X.; Zhang, L.; Yang, Y. Propagation characteristics of ultrasonic guided waves in continuously welded rail. Mod. Phys. Lett. B 2017, 1740075. [Google Scholar] [CrossRef]

- Su, Z.; Ye, L.; Lu, Y. Guided lamb waves for identification of damage in composite structures: A review. J. Sound Vib. 2006, 295, 753–780. [Google Scholar] [CrossRef]

- Fateri, S.; Lowe, P.S.; Engineer, B.; Boulgouris, N.V. Investigation of ultrasonic guided waves interacting with piezoelectric transducers. IEEE Sens. J. 2015, 15, 4319–4328. [Google Scholar] [CrossRef]

- Mirahmadi, S.J.; Honarvar, F. Application of signal processing techniques to ultrasonic testing of plates by lamb wave mode. NDT E Int. 2011, 44, 131–137. [Google Scholar] [CrossRef]

- Pai, P.F.; Deng, H.; Sundaresan, M.J. Time-frequency characterization of lamb waves for material evaluation and damage inspection of plates. Mech. Syst. Signal Proc. 2015, 62–63, 183–206. [Google Scholar] [CrossRef]

- Deng, Q.T.; Yang, Z.C. Scattering of S0 lamb mode in plate with multiple damages. Appl. Math. Model. 2011, 35, 550–562. [Google Scholar] [CrossRef]

- Wan, X.; Tse, P.W.; Chen, J.; Xu, G.; Zhang, Q. Second harmonic reflection and transmission from primary s0 mode lamb wave interacting with a localized microscale damage in a plate: A numerical perspective. Ultrasonics 2017, 82, 57–71. [Google Scholar] [CrossRef] [PubMed]

- Glushkov, E.; Glushkova, N.; Eremin, A.; Giurgiutiu, V. Low-cost simulation of guided wave propagation in notched plate-like structures. J. Sound Vib. 2015, 352, 80–91. [Google Scholar] [CrossRef]

- Rucka, M. Experimental and numerical study on damage detection in an l-joint using guided wave propagation. J. Sound Vib. 2010, 329, 1760–1779. [Google Scholar] [CrossRef]

- Le, C.E.; Castaings, M.; Hosten, B. The interaction of the s0 lamb mode with vertical cracks in an aluminium plate. Ultrasonics 2002, 40, 187–192. [Google Scholar] [CrossRef]

- Yang, Y.; Wei, X.; Zhang, L.; Yao, W. The effect of electrical impedance matching on the electromechanical characteristics of sandwiched piezoelectric ultrasonic transducers. Sensors 2017, 17, 2832. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Yang, Y.; Yao, W.; Zhang, L. Pspice modeling of a sandwich piezoelectric ceramic ultrasonic transducer in longitudinal vibration. Sensors 2017, 17, 2253. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Li, F.; Cao, P.; Liu, Y.; Zhang, J.; Fu, S.; Zhang, J.; Hu, N. Generation mechanism of nonlinear ultrasonic lamb waves in thin plates with randomly distributed micro-cracks. Ultrasonics 2017, 79, 60–67. [Google Scholar] [CrossRef] [PubMed]

- Loveday, P.W. Simulation of piezoelectric excitation of guided waves using waveguide finite elements. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 2038. [Google Scholar] [CrossRef] [PubMed]

- Ryue, J.; Thompson, D.J.; White, P.R.; Thompson, D.R. Investigations of propagating wave types in railway tracks at high frequencies. J. Sound Vib. 2008, 315, 157–175. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, D.; Zhou, Z. Time reversal method for guided waves with multimode and multipath on corrosion defect detection in wire. Appl. Sci. 2017, 7, 424. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Xu, J.; Ma, S.W.; Ta, D.A. The high-frequency scattering of the s0 lamb mode by a circular blind hole in a plate. Phys. Procedia 2015, 70, 455–458. [Google Scholar] [CrossRef]

- Santacruz, J.; Tardón, L.; Barbancho, I.; Barbancho, A. Spectral envelope transformation in singing voice for advanced pitch shifting. Appl. Sci. 2016, 6, 368. [Google Scholar] [CrossRef]

- Semay, C. The hellmann–feynman theorem, the comparison theorem, and the envelope theory. Results Phys. 2015, 5, 322–323. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Yang, Y.; Wei, X.; Yao, W. The Study of Non-Detection Zones in Conventional Long-Distance Ultrasonic Guided Wave Inspection on Square Steel Bars. Appl. Sci. 2018, 8, 129. https://doi.org/10.3390/app8010129

Zhang L, Yang Y, Wei X, Yao W. The Study of Non-Detection Zones in Conventional Long-Distance Ultrasonic Guided Wave Inspection on Square Steel Bars. Applied Sciences. 2018; 8(1):129. https://doi.org/10.3390/app8010129

Chicago/Turabian StyleZhang, Lei, Yuan Yang, Xiaoyuan Wei, and Wenqing Yao. 2018. "The Study of Non-Detection Zones in Conventional Long-Distance Ultrasonic Guided Wave Inspection on Square Steel Bars" Applied Sciences 8, no. 1: 129. https://doi.org/10.3390/app8010129