Slot Waveguide Enhanced Bloch Surface Waves

Abstract

:1. Introduction

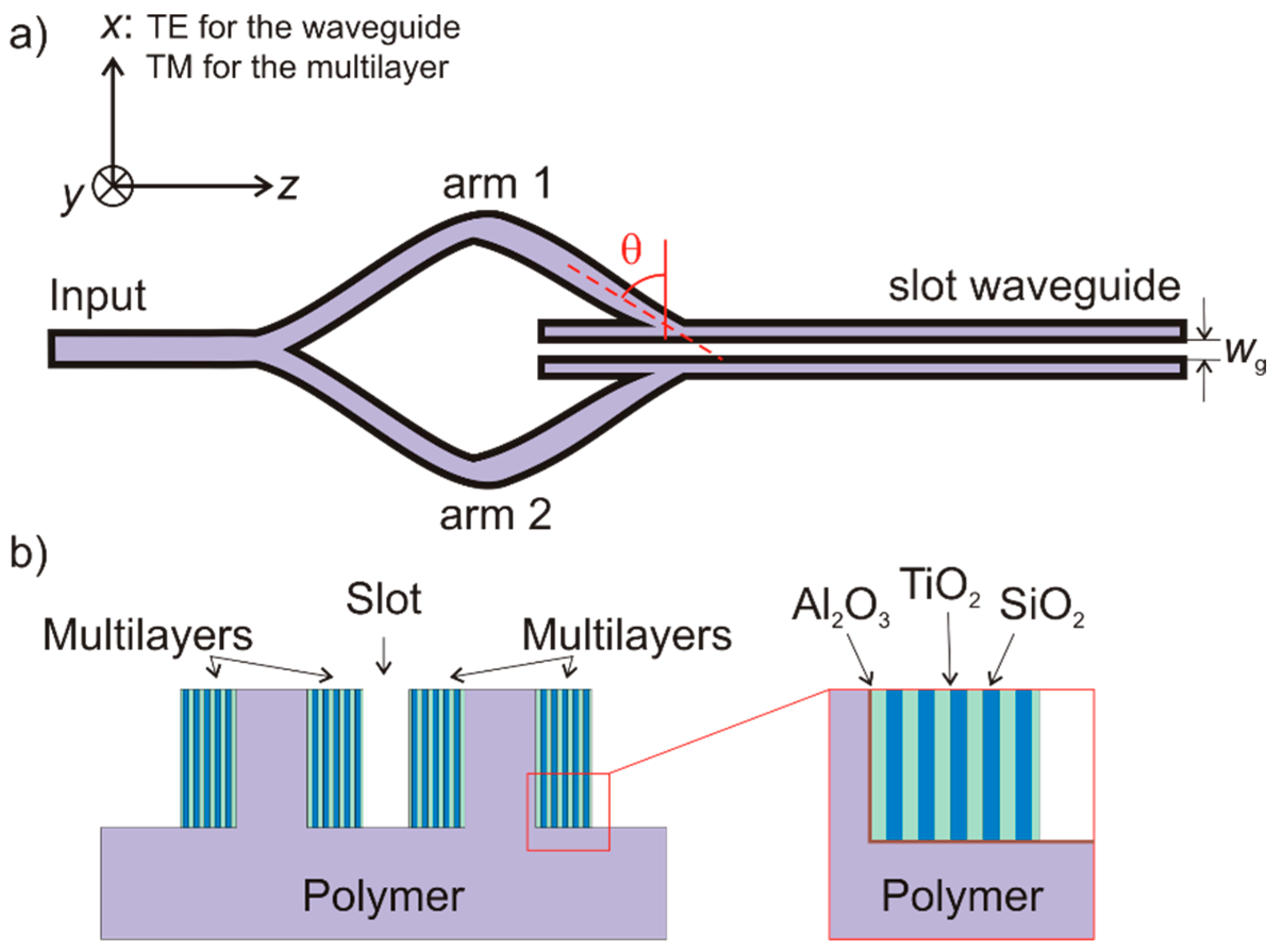

2. Materials and Methods

2.1. Materials

2.2. Simulation Methods

2.3. Towards Fabrication

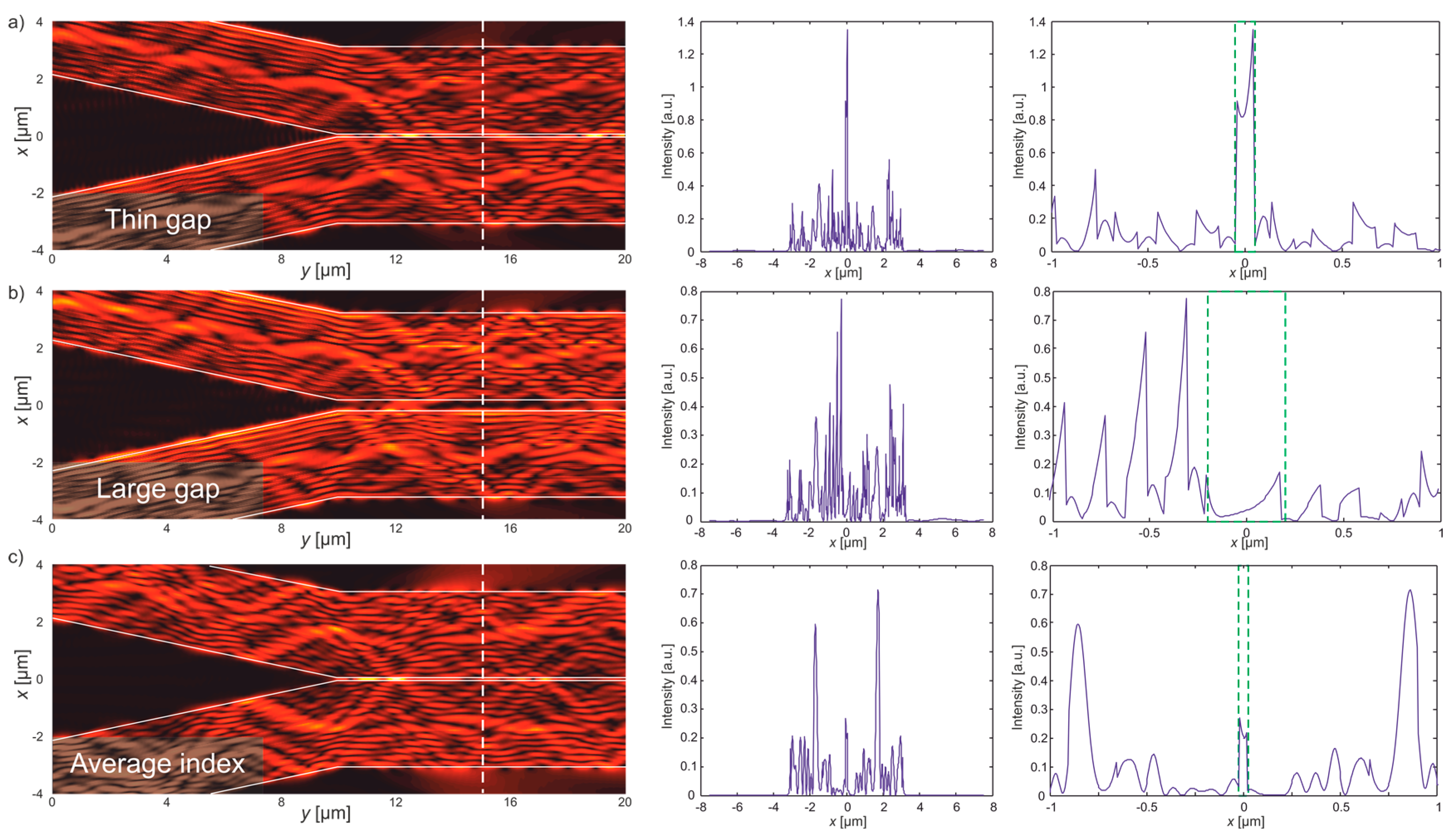

3. Results

3.1. Multilayer

3.2. Waveguide Integration

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Shinn, M.; Robertson, W.M. Surface plasmon-like sensor based on surface electromagnetic waves in a photonic band-gap material. Sens. Actuators B Chem. 2005, 105, 360–364. [Google Scholar] [CrossRef]

- Paeder, V.; Musi, V.; Hvozdara, L.; Herminjard, S.; Herzig, H.P. Detection of protein aggregation with a Bloch surface wave based sensor. Sens. Actuators B Chem. 2011, 157, 260–264. [Google Scholar] [CrossRef]

- Sinibaldi, A.; Danz, N.; Descrovi, E.; Munzert, P.; Schulz, U.; Sonntag, F.; Dominici, L.; Michelotti, F. Direct comparison of the performance of Bloch surface wave and surface plasmon polariton sensors. Sens. Actuators B Chem. 2012, 174, 292–298. [Google Scholar] [CrossRef]

- Yeh, P.; Yariv, A.; Cho, A.Y. Optical surface waves in periodic layered media. Appl. Phys. Lett. 1978, 32, 104–105. [Google Scholar] [CrossRef]

- Dubey, R.; Barakat, E.; Häyrinen, M.; Roussey, M.; Honkanen, S.K.; Kuittinen, M.; Herzig, H.P. Experimental investigation of the propagation properties of Bloch surface waves on dielectric platform. J. Eur. Opt. Soc. Rapid Publ. 2017, 13, 5. [Google Scholar] [CrossRef]

- Descrovi, E.; Sfez, T.; Quaglio, M.; Brunazzo, D.; Dominici, L.; Michelotti, F.; Herzig, H.P.; Martin, O.J.F.; Giorgis, F. Guided bloch surface waves on ultrathin polymeric ridges. Nano Lett. 2010, 10, 2087–2091. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Barakat, E.; Sfez, T.; Hvozdara, L.; Di Francesco, J.; Peter Herzig, H. Manipulating Bloch surface waves in 2D: A platform concept-based flat lens. Light Sci. Appl. 2014, 3, e124. [Google Scholar] [CrossRef]

- Dubey, R.; Vosoughi Lahijani, B.; Häyrinen, M.; Roussey, M.; Kuittinen, M.; Herzig, H.P. Ultra-thin Bloch-surface-wave-based reflector at telecommunication wavelength. Photonics Res. 2017, 5, 494–499. [Google Scholar] [CrossRef]

- Kim, M.-S.; Vosoughi Lahijani, B.; Descharmes, N.; Straubel, J.; Negredo, F.; Rockstuhl, C.; Häyrinen, M.; Kuittinen, M.; Roussey, M.; Herzig, H.P. Subwavelength focusing of Bloch surface waves. ACS Photonics 2017, 4, 1477–1483. [Google Scholar] [CrossRef]

- Kovalevitch, T.; Boyer, P.; Suarez, M.; Kim, M.-S.; Herzig, H.P.; Bernal, M.-P.; Grosjean, T. Polarization controlled directional propagation of Bloch surface wave. Opt. Express 2017, 25, 5710–5715. [Google Scholar] [CrossRef] [PubMed]

- Almeida, V.R.; Xu, Q.; Barrios, C.A.; Lipson, M. Guiding and confining light in void nanostructure. Opt. Lett. 2004, 29, 1209–1211. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Xia, H.; Zhang, D.; Chen, J.; Zhu, L.; Wang, Y.; Yang, E.; Zang, T.; Wen, X.; Zou, G.; et al. Bloch surface waves confined in one dimension with a single polymeric nanofibre. Nat. Commun. 2017, 8, 14330. [Google Scholar] [CrossRef] [PubMed]

- Puurunen, R.L. A short history of atomic layer deposition: Tuomo Suntola’s atomic layer epitaxy. Chem. Vap. Depos. 2014, 20, 332–344. [Google Scholar] [CrossRef]

- Autere, A.; Karvonen, L.; Säynätjoki, A.; Roussey, M.; Färm, E.; Kemell, M.; Tu, X.; Liow, T.Y.; Lo, G.Q.; Ritala, M.; et al. Slot waveguide ring resonators coated by atomic layer deposited organic/inorganic nanolaminate. Opt. Express 2015, 23, 26940–26951. [Google Scholar] [CrossRef] [PubMed]

- Hiltunen, M.; Hiltunen, J.; Stenberg, P.; Aikio, S.; Kurki, L.; Vahimaa, P.; Karioja, P. Polymeric slot waveguide interferometer for sensor applications. Opt. Express 2014, 22, 7229–7237. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi, L.; Tervo, J.; Saarinen, J.; Honkanen, S. Enhanced sensitivity in polymer slot waveguides by atomic layer deposited bylayer coatings. Appl. Opt. 2013, 52, 8089–8094. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi, L.; Hiltunen, M.; Stenberg, P.; Roussey, M.; Saarinen, J.; Honkanen, S. ALD-coated polymer slot waveguide young interferometer. Opt. Express 2016, 24, 10275–10285. [Google Scholar] [CrossRef] [PubMed]

- Paul, S.; Vartiainen, I.; Roussey, M.; Saastamoinen, T.; Tervo, J.; Honkanen, S.; Kuittinen, M. Add-drop filter based on TiO2 coated shifted Bragg grating. Opt. Express 2016, 24, 26901–26910. [Google Scholar] [CrossRef] [PubMed]

- Paul, S.; Saastamoinen, T.; Honkanen, S.; Roussey, M.; Kuittinen, M. Multi-wavelength filtering with waveguide integrated quasi-random Bragg grating. Opt. Lett. 2017, 42, 4635–4638. [Google Scholar] [CrossRef] [PubMed]

- Pélisset, S.; Laukkanen, J.; Kuittinen, M.; Honkanen, S.; Roussey, M. Modal properties of a strip-loaded horizontal slot waveguide. J. Eur. Opt. Soc. Rapid Publ. 2017, 13, 37. [Google Scholar] [CrossRef]

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roussey, M. Slot Waveguide Enhanced Bloch Surface Waves. Appl. Sci. 2018, 8, 39. https://doi.org/10.3390/app8010039

Roussey M. Slot Waveguide Enhanced Bloch Surface Waves. Applied Sciences. 2018; 8(1):39. https://doi.org/10.3390/app8010039

Chicago/Turabian StyleRoussey, Matthieu. 2018. "Slot Waveguide Enhanced Bloch Surface Waves" Applied Sciences 8, no. 1: 39. https://doi.org/10.3390/app8010039