Methodology of Classifying the Causes of Occupational Accidents Involving Construction Scaffolding Using Pareto-Lorenz Analysis

Abstract

:1. Introduction

2. Literature Review

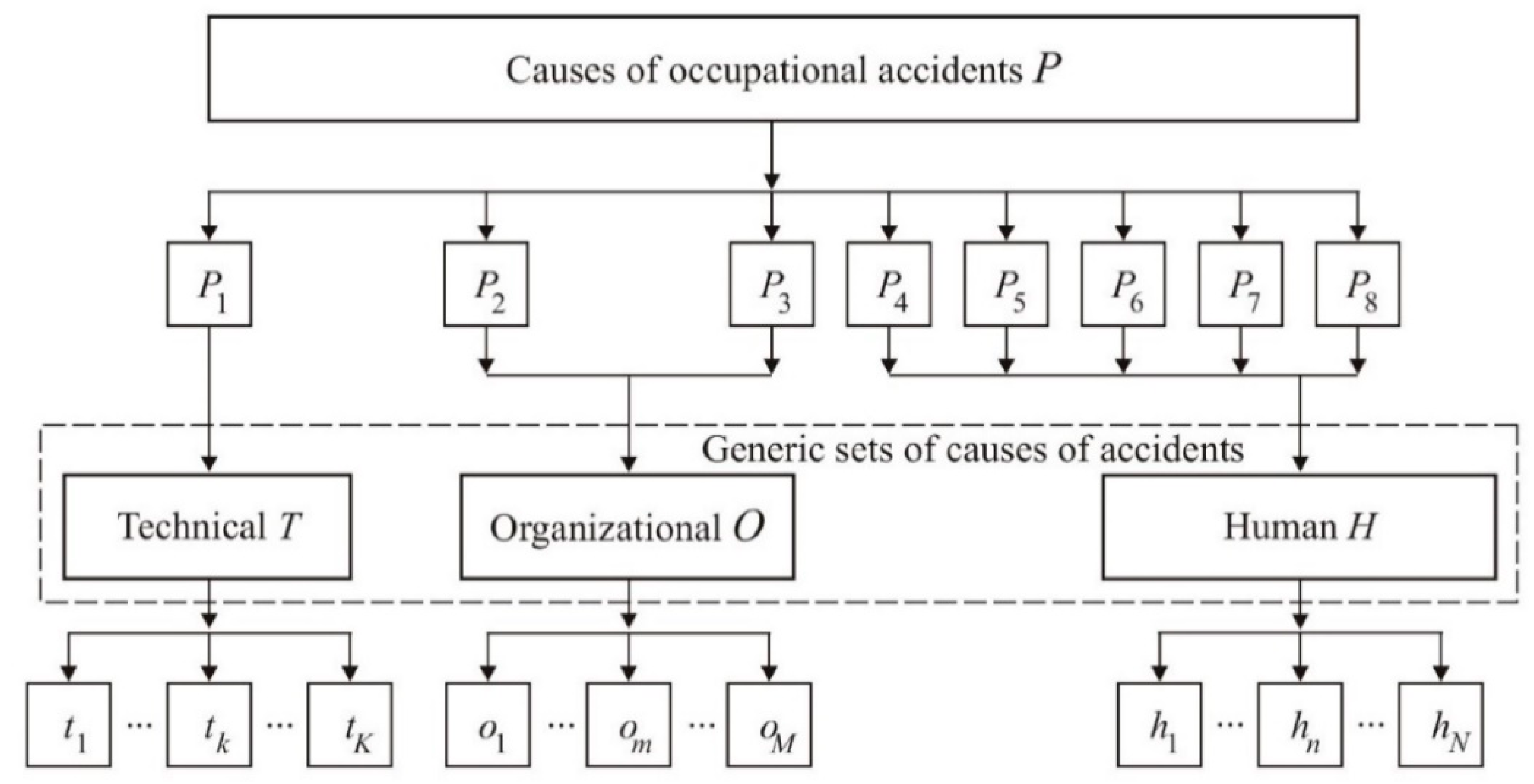

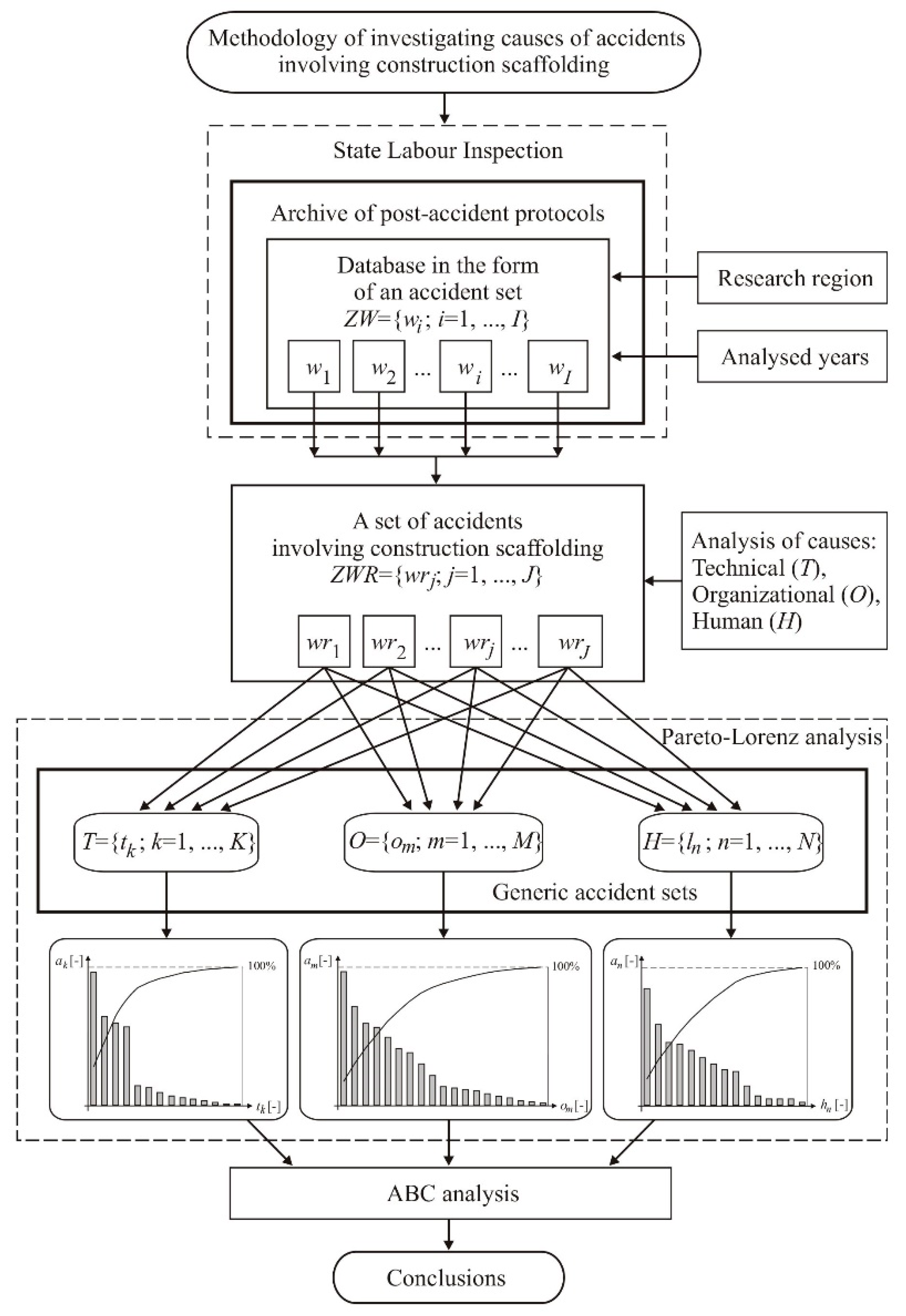

- Developing a methodology for the classification of causes of accidents at work involving construction scaffolding, which is based on the division of causes into three generic groups: technical (T), organizational (O), and human (H).

- Developing a methodology for assessing the importance of particular causes in particular generic groups, called the ABC classification, according to which the causes of accidents are divided into three validity classes: important causes (A), relevant causes (B), irrelevant causes (C).

3. Proposed Research Methodology

- Defining specific detailed causes and their cardinalities in the analyzed generic group. This information can be presented as a sequence of ordered pairs of numbers , where (x = 1, …, X) (represents the identified detailed cause and ax indicates the number of occurrences of the examined cause in the analysed subset T, O, or H.

- Organizing sequences of pairs of numbers that describe the analysed causes in a descending order. The position of a pair in the ordered sequence is determined by the number of the occurrences of attribute px in the subset T, O or H according to the rule

- Determining the percentage share of occurrences of cause px in the total of all examined causes according to the following formula

- Determining the percentage of the cumulated sum of subsequent causes according to the following formula

- Defining the affiliation of specific causes to one of the valid classes in order to classify causes according to the degree of their influence on the occurrence of an accident, ABC analysis, which is known in economics and is simple-to-use, was applied [23]. According to the ABC method, it is necessary to divide causes from the set into three subgroups. It was assumed that:

- ✓

- the set of important causes, designated as A, forms causes that account for 80% of all the causes that are attributable to a particular cause group,

- ✓

- the set of less relevant causes, designated as B, forms causes that account for 15% of all the causes that are attributable to a particular cause group,

- ✓

- the set of irrelevant causes, designated as C, forms causes that account for 5% of all the causes identified in the set.

4. Application of the Proposed Methodology

4.1. Information About the Used Database

4.2. Research Results

4.3. Analysis of the Obtained Results

5. Summary

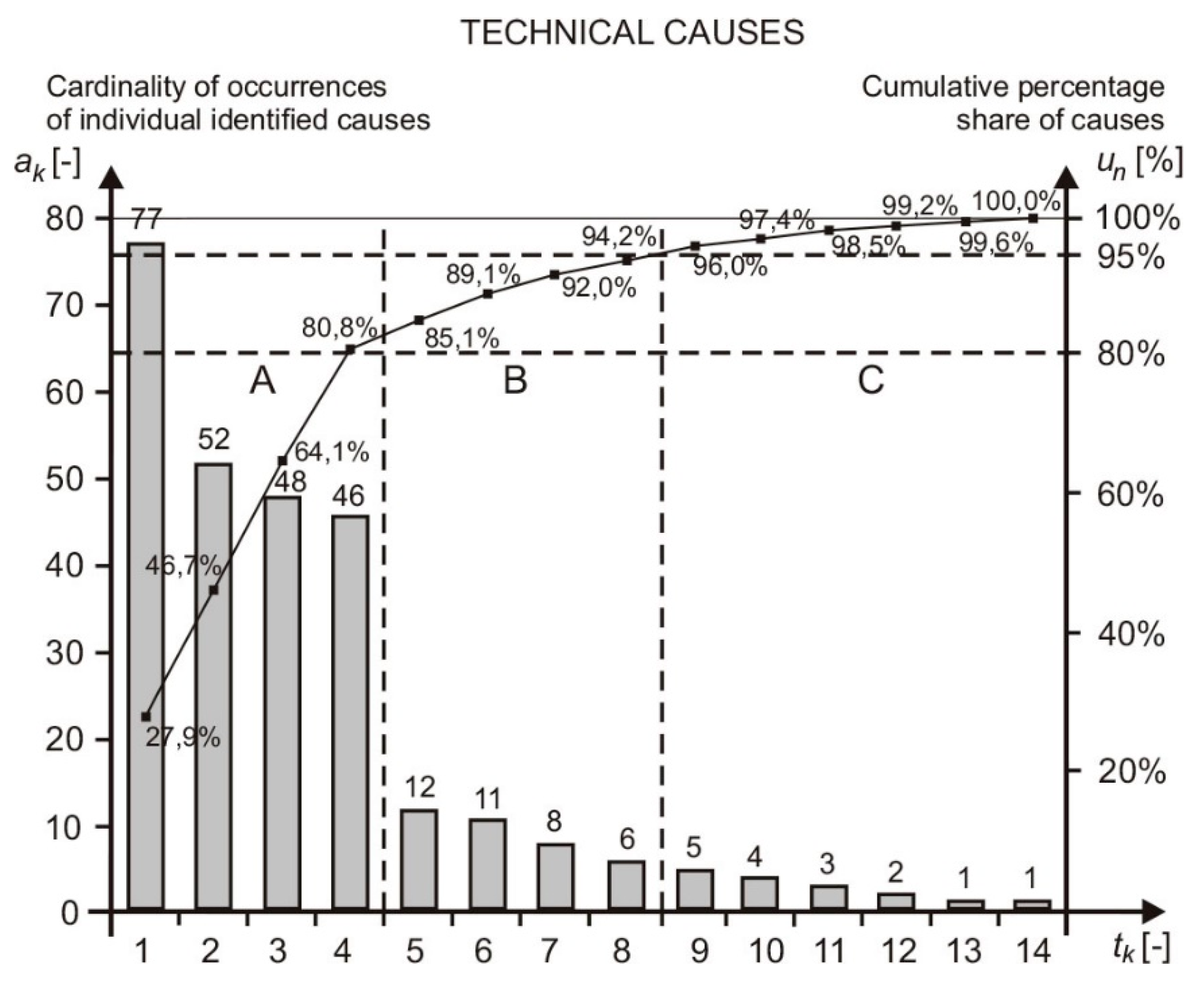

- In the group of technical causes: a lack of or improper devices protecting workplaces on scaffolding, improper collective protection measures, improper stability of scaffolding or its components, and also improper spatial structure of scaffolding.

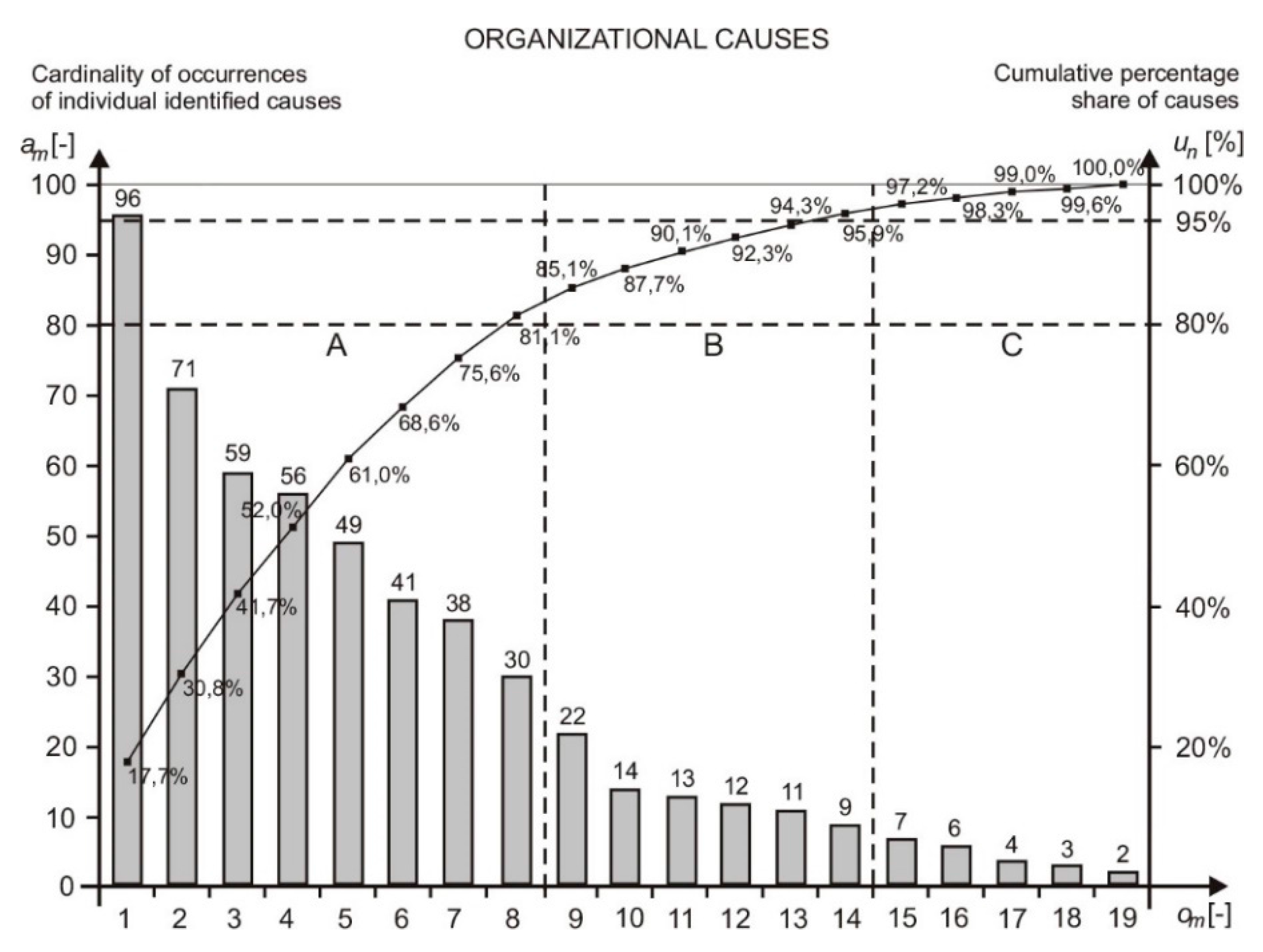

- In the group of organizational causes, first and foremost: a lack of direct supervision by a construction manager or executive manager during the performance of work, approval of scaffolding for operation without the required inspections and supervisions, tolerance by the supervisors of derogations from the rules and regulations of occupational health and safety, a lack of or inadequate training of employees in occupational health and safety, giving permission to an employee to work with medical contraindications or without medical examination, and also a lack of instructions for safe work on scaffolding or failure to familiarize with such instructions by employees.

- In the group of human causes, first of all: failure to use personal protective equipment by an employee; disregard of a danger; inappropriate psychophysical state of an employee due to the consumption of alcohol, drugs or psychotropic substances; being surprised with an unexpected event; going to, driving through, or being in unauthorized places; arrogant and risky behavior of an employee causing disregard of a hazard, and also improper behavior of an employee due to ignorance of rules and regulations of occupational health and safety.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Central Statistical Office. Occupational Accidents in 2015; Department of Statistical Publishing: Warsaw, Poland, 2016.

- Bureau of Labor Statistics (BLS). Available online: https://www.bls.gov (accessed on 11 October 2017).

- Hoła, B.; Szóstak, M. Analysis of the State of the Accident Rate in the Construction Industry in European Union Countries. Arch. Civ. Eng. 2015, 61, 19–34. [Google Scholar] [CrossRef]

- Hoła, B.; Sawicki, M. Tacit knowledge contained in construction enterprise documents. Procedia Eng. 2014, 85, 231–239. [Google Scholar] [CrossRef]

- Hoła, B. Identification and evaluation of processes in a construction enterprise. Arch. Civ. Mech. Eng. 2015, 15, 419–426. [Google Scholar] [CrossRef]

- Haslam, R.; Hide, S.; Gibb, A.; Gyi, D.; Pavitt, T.; Atkinson, S.; Duff, A. Contributing factors in construction accidents. Appl. Ergon. 2005, 36, 401–415. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hoła, B.; Szóstak, M. Analysis of the development of accident situations in the construction industry. Procedia Eng. 2014, 91, 429–434. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, C.; Wang, T. Fatal occupational falls in the Taiwan construction industry. J. Chin. Inst. Ind. Eng. 2011, 2, 586–596. [Google Scholar] [CrossRef]

- López Arquillos, A.; Rubio Romero, J.; Gibb, A. Analysis of construction accidents in Spain, 2003–2008. J. Saf. Res. 2012, 43, 381–388. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liy, C.; Ibrahim, S.; Affandi, R.; Rosli, N.; Nawi, M. Causes of fall hazards in construction site management. Int. Rev. Manag. Mark. 2016, 6, 257–263. [Google Scholar]

- Whitaker, S.; Graves, R.; James, M.; McCann, P. Safety with access scaffolds: Development of a prototype decision aid based on accident analysis. J. Saf. Res. 2003, 34, 249–261. [Google Scholar] [CrossRef]

- Suraji, A.; Duff, A.; Peckitt, S. Development of casual model of construction accident causation. J. Constr. Eng. Manag. 2001, 12, 337–344. [Google Scholar] [CrossRef]

- Chi, S.; Han, S. Analyses of systems theory for construction accident prevention with specific reference to OSHA accident reports. Int. J. Proj. Manag. 2013, 31, 1027–1041. [Google Scholar] [CrossRef] [Green Version]

- Halperin, K.; McCann, M. An evaluation of scaffold safety at construction sites. J. Saf. Res. 2004, 35, 141–150. [Google Scholar] [CrossRef] [PubMed]

- Evanoff, B.; Dale, A.; Zeringue, A.; Fuchs, M.; Gaal, J.; Lipscomb, H.; Kaskutas, V. Results of a fall prevention educational intervention for residential construction. Saf. Sci. 2016, 89, 301–307. [Google Scholar] [CrossRef]

- Wong, L.; Wang, Y.; Law, T.; Lo, C. Association of Root Causes in Fatal Fall-from-Height Construction Accidents in Hong Kong. J. Constr. Eng. Manag. 2016, 142, 04016018. [Google Scholar] [CrossRef]

- Gibb, A.; Hide, S.; Haslam, R.; Hastings, S.; Suraji, A.; Duff, A.R.; Abdelhamid, T.S.; Everett, J.G. Identifying Root Causes of Construction Projects. J. Constr. Eng. Manag. 2001, 127, 348–349. [Google Scholar] [CrossRef]

- Gibb, A.G.F.; Haslam, R.; Gyi, D.E.; Hide, S.; Duff, R. What causes accidents? Proc. ICE Civ. Eng. 2006, 159, 46–50. [Google Scholar] [CrossRef] [Green Version]

- Błazik-Borowa, E.; Szer, J. The analysis of the stage of scaffolding “life” with regard to the decrease in the hazard at building works. Arch. Civ. Mech. Eng. 2015, 15, 516–524. [Google Scholar] [CrossRef]

- Błazik-Borowa, E.; Gontarz, J. The influence of the dimension and the configuration of the geometric imperfections on the static strength of a typical façade scaffolding. Arch. Civ. Mech. Eng. 2016, 16, 269–281. [Google Scholar] [CrossRef]

- Hoła, A.; Hoła, B.; Szóstak, M. Analysis of the causes and consequences of falls from scaffolding using the Polish construction industry as an example. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251. [Google Scholar] [CrossRef]

- Dhoka, D.; Choudary, Y. ABC Classification for Inventory Optimization. J. Bus. Manag. (IOSR-JBM) 2013, 15, 38–41. [Google Scholar] [CrossRef]

- Chu, C.; Liang, G.; Liao, C. Controlling inventory by combining ABC analysis and fuzzy classifications. Comput. Ind. Eng. 2008, 55, 841–851. [Google Scholar] [CrossRef]

| Type of Cause | Cardinality of Occurrence | Share | Cumulative Share (%) | Validity Class of Cause | |

|---|---|---|---|---|---|

| Technical causes (T); T = {tk: k = 1, …, K} | |||||

| Lack of or inadequate protective devices | 77 | 27.9% | 27.9% | A | |

| Lack of or inadequate measures of collective protection | 52 | 18.8% | 46.7% | A | |

| Improper spatial structure of scaffolding | 48 | 17.4% | 64.1% | A | |

| Improper stability of scaffolding | 46 | 16.7% | 80.8% | A | |

| Design defects of scaffolding that are a source of a hazard | 12 | 4.3% | 85.1% | B | |

| Use of substitute materials | 11 | 4.0% | 89.1% | B | |

| Lack of or incorrect signaling of hazards | 8 | 2.9% | 92.0% | B | |

| Inadequate strength of scaffolding | 6 | 2.2% | 94.2% | B | |

| Hidden material defects | 5 | 1.8% | 96.0% | B | |

| Failure to meet required technical parameters | 4 | 1.4% | 97.4% | C | |

| Inadequate maintenance of scaffolding | 3 | 1.1% | 98.5% | C | |

| Excessive use of scaffolding | 2 | 0.7% | 99.2% | C | |

| Improper repairs and renovations of scaffolding | 1 | 0.4% | 99.6% | C | |

| Failure to meet required technical parameters | 1 | 0.4% | 100% | C | |

| Organizational causes (O); | |||||

| Lack of supervision | 96 | 17.7% | 17.7% | A | |

| Admission of scaffolding to operation without the required inspection and supervisions | 71 | 13.1% | 30.8% | A | |

| Acceptance of deviations from the rules and regulations of occupational health and safety | 59 | 10.9% | 41.7% | A | |

| Lack of or inadequate training in the area of occupational health and safety | 56 | 10.3% | 52.0% | A | |

| Admission of an employee to work without medical examination or with medical contraindications | 49 | 9.0% | 61.0% | A | |

| Lack of instructions of safe execution of work on scaffolding | 41 | 7.6% | 68.6% | A | |

| Inadequate passages and paths | 38 | 7.0% | 75.6% | A | |

| Inadequate professional training of an employee | 30 | 5.5% | 81.1% | A | |

| Lack of personal protective equipment | 22 | 4.0% | 85.1% | A | |

| Acceptance of the use of improper technology by supervisors | 14 | 2.6% | 87.7% | B | |

| Improper placement and storage of work items | 13 | 2.4% | 90.1% | B | |

| Incorrect coordination of collective work | 12 | 2.2% | 92.3% | B | |

| Incorrect job sharing or task scheduling | 11 | 2.0% | 94.3% | B | |

| Incorrect location of equipment at a workstation | 9 | 1.6% | 95.9% | B | |

| Improper selection of personal protective equipment | 7 | 1.3% | 97.2% | C | |

| Removal of unnecessary items, substances, or energy, e.g., waste | 6 | 1.1% | 98.3% | C | |

| Incorrect commands of superiors | 4 | 1% | 99.0% | C | |

| Performing work when short-staffed | 3 | 0.6% | 99.6% | C | |

| Performing work on command that is not included in the scope of an employee’s duties | 2 | 0.4% | 100.0% | C | |

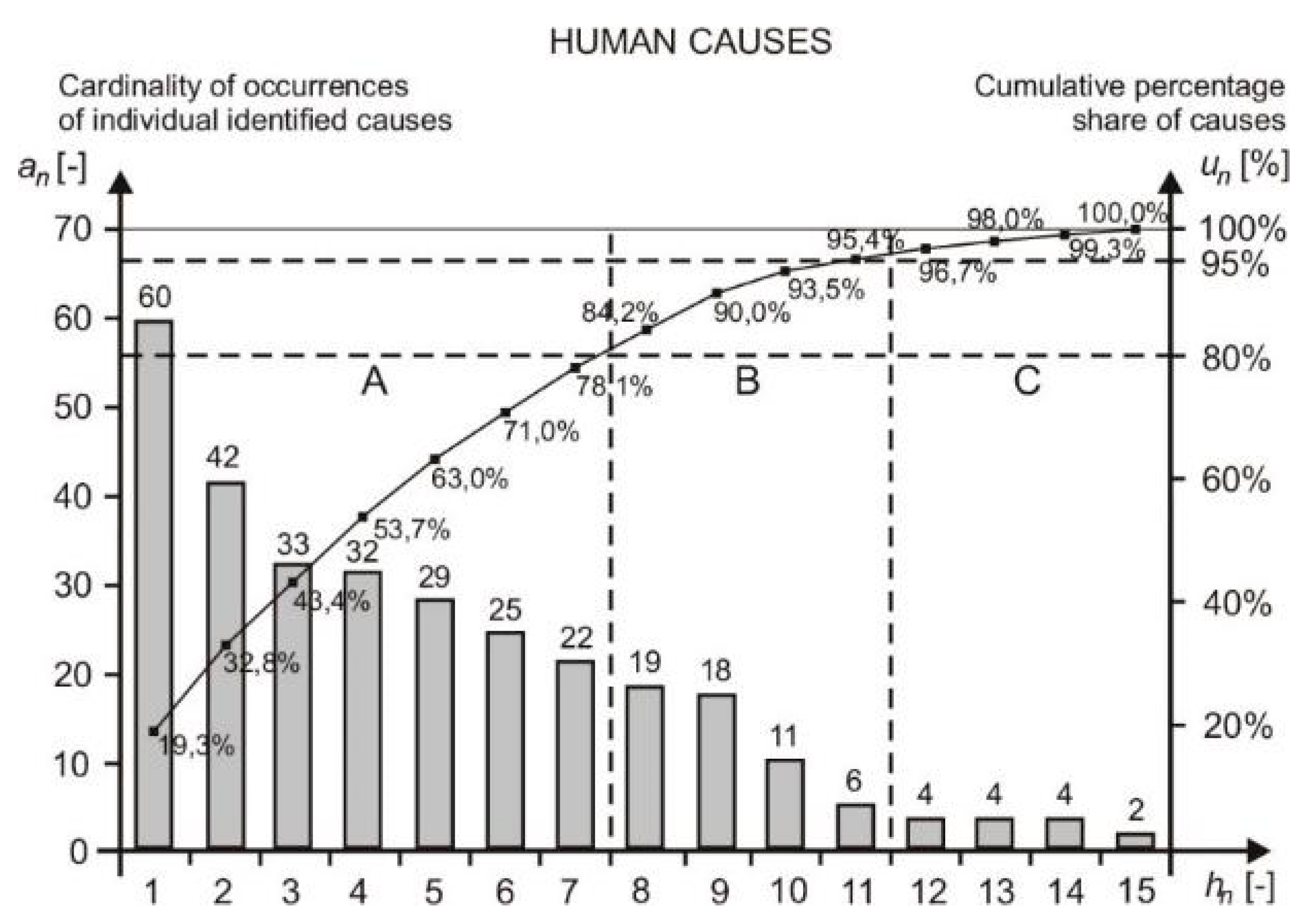

| Human causes (H); | |||||

| Failure to use personal protective equipment by an employee | 60 | 19.3% | 19.3% | A | |

| Disregard of a danger | 42 | 13.5% | 32.8% | A | |

| Lack of or improper use of a material factor by an employee | 33 | 10.6% | 43.4% | A | |

| Consumption of alcohol, drugs or psychotropic substances | 32 | 10,3% | 53.7% | A | |

| Being surprised by an unexpected event | 29 | 9.3% | 63.0% | A | |

| Going to, driving through, or staying in places that are forbidden | 25 | 8.0% | 71.0% | A | |

| Insufficient concentration | 22 | 7.1% | 78.1% | A | |

| Ignorance of hazards, regulations, and rules of occupational health and safety | 19 | 6.1% | 84.2% | A | |

| Performing work that is not included in the scope of an employee’s duties | 18 | 5.8% | 90.0% | B | |

| Entering an endangered area without making sure that there is no danger | 11 | 3.5% | 93.5% | B | |

| Failure to use collective protection measures | 6 | 1.9% | 95.% | B | |

| Sudden illness, physical deterioration, fatigue | 4 | 1.3% | 97% | C | |

| Disregard of superiors’ commands | 4 | 1.3% | 98% | C | |

| Improper pace of work | 4 | 1.3% | 99% | C | |

| Lack of experience | 2 | 0.6% | 100% | C | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoła, A.; Sawicki, M.; Szóstak, M. Methodology of Classifying the Causes of Occupational Accidents Involving Construction Scaffolding Using Pareto-Lorenz Analysis. Appl. Sci. 2018, 8, 48. https://doi.org/10.3390/app8010048

Hoła A, Sawicki M, Szóstak M. Methodology of Classifying the Causes of Occupational Accidents Involving Construction Scaffolding Using Pareto-Lorenz Analysis. Applied Sciences. 2018; 8(1):48. https://doi.org/10.3390/app8010048

Chicago/Turabian StyleHoła, Anna, Marek Sawicki, and Mariusz Szóstak. 2018. "Methodology of Classifying the Causes of Occupational Accidents Involving Construction Scaffolding Using Pareto-Lorenz Analysis" Applied Sciences 8, no. 1: 48. https://doi.org/10.3390/app8010048