P(VDF-TrFE) Film on PDMS Substrate for Energy Harvesting Applications

Abstract

:1. Introduction

2. Experimental Details

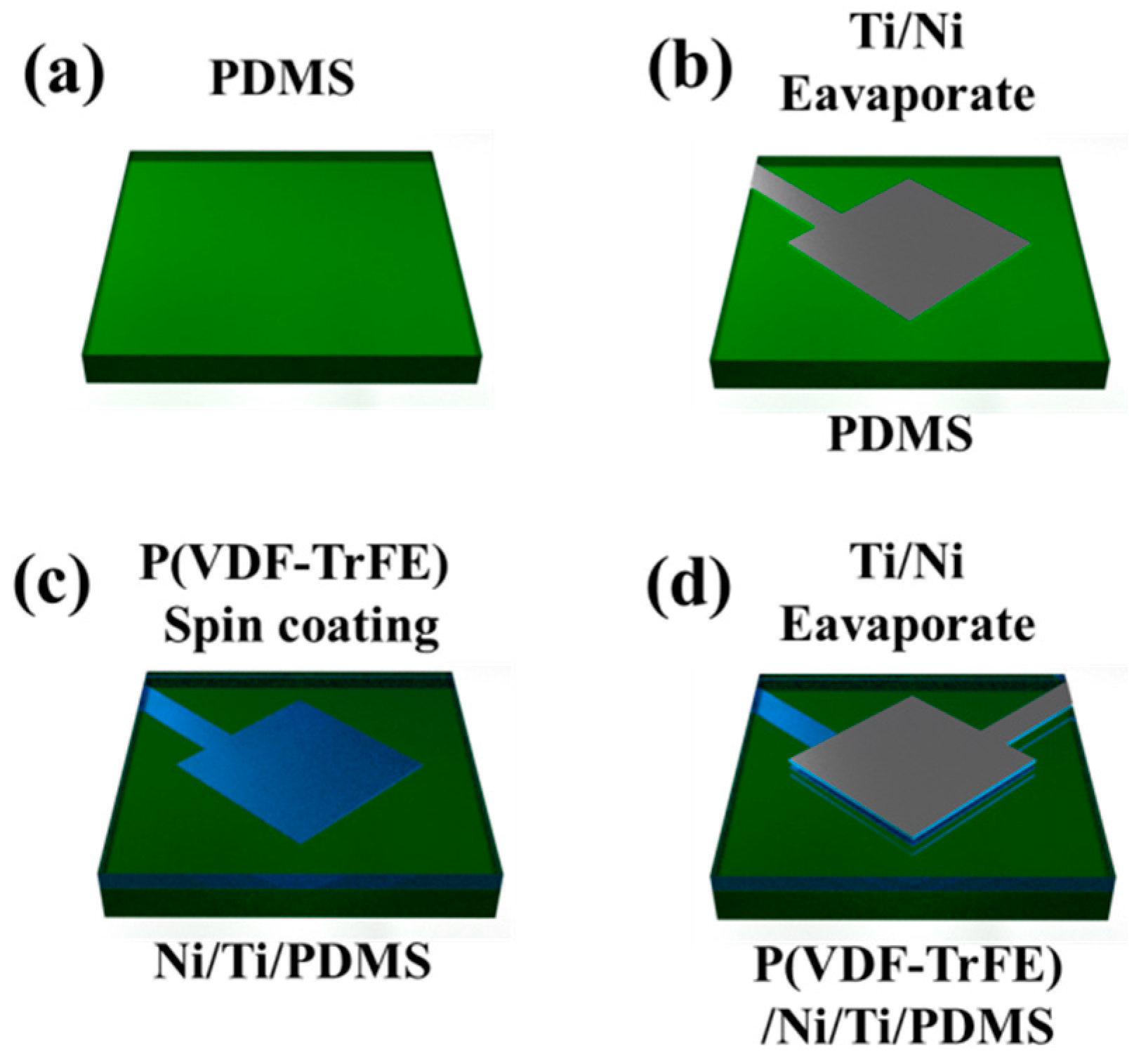

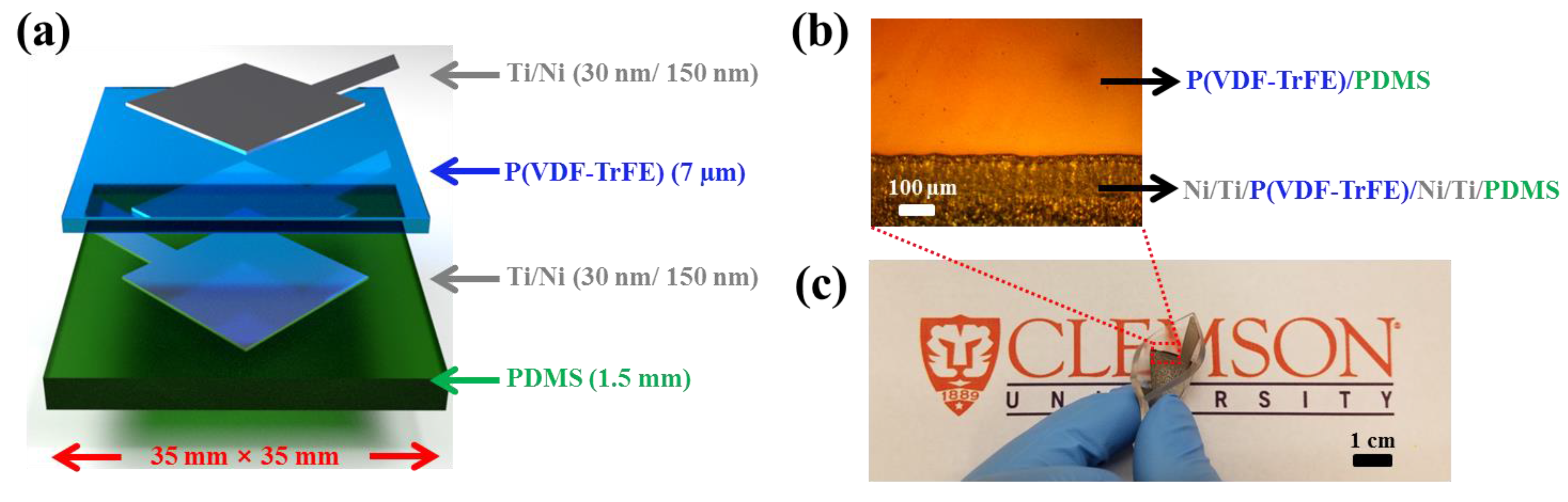

2.1. Fabrication of the Flexible Piezoelectric Energy Harvester

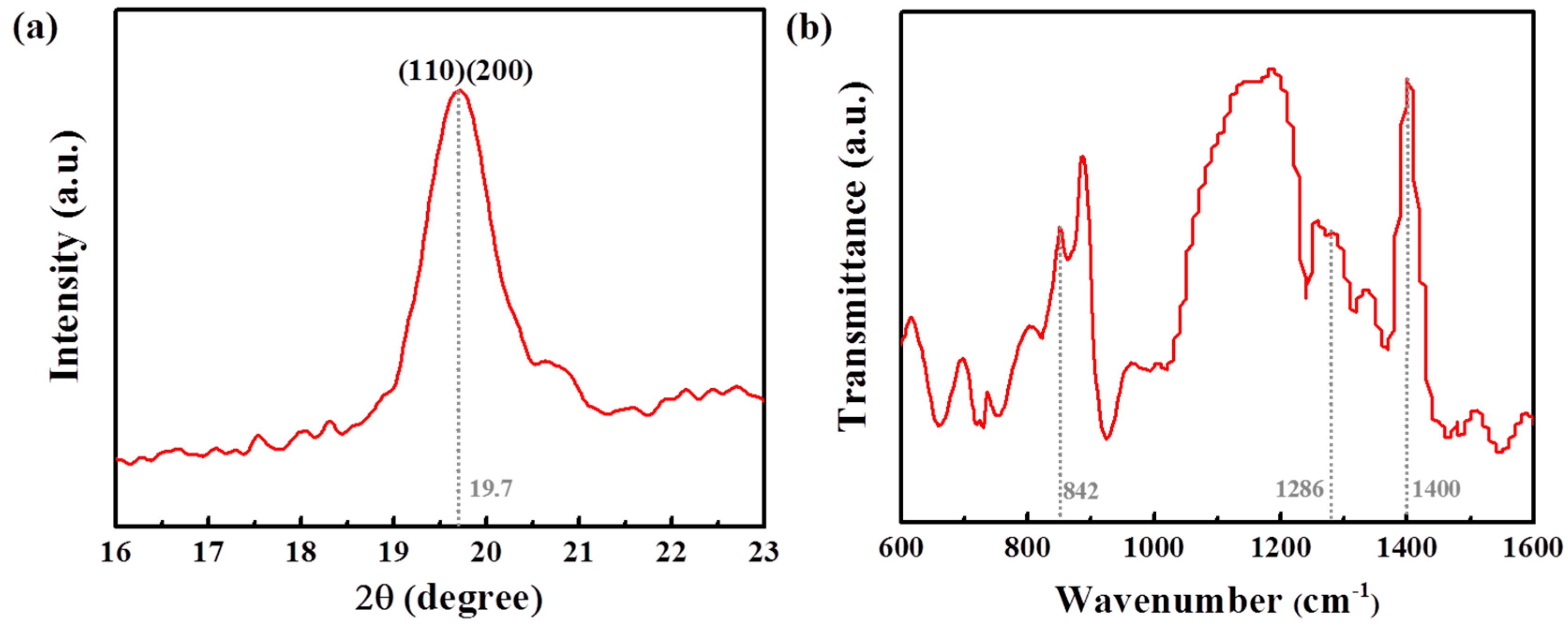

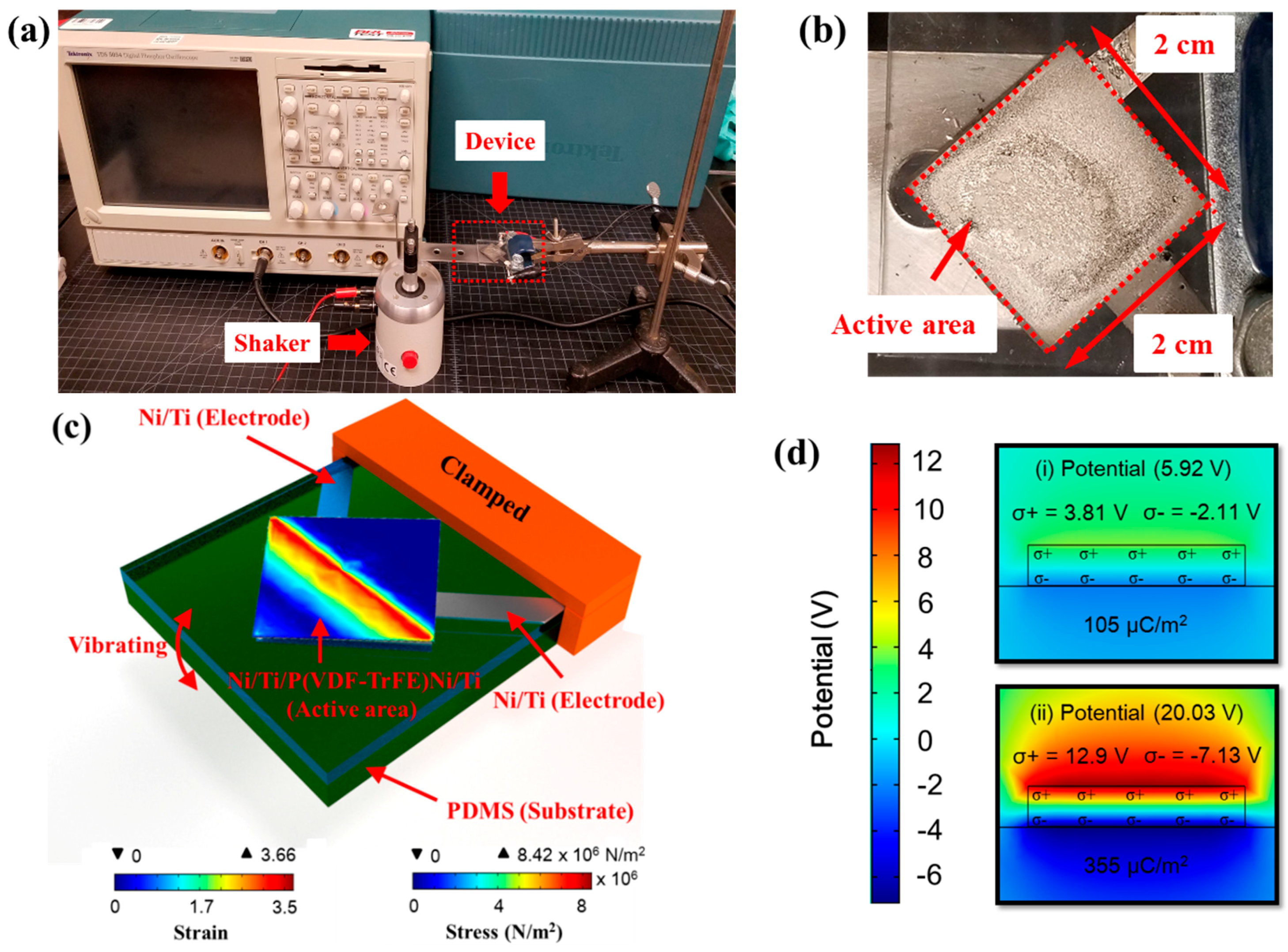

2.2. Measurement and Characterization

2.3. Simulations: Strain, Stress, and Potential

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lee, J.-H.; Yoon, H.-J.; Kim, T.Y.; Gupta, M.K.; Lee, J.H.; Seung, W.; Ryu, H.; Kim, S.-W. Micropatterened P(VDF-TrFE) film-based piezoelectric nanogenerators for highly sensitive self-powered pressure sensors. Adv. Funct. Mater. 2015, 25, 3203–3209. [Google Scholar] [CrossRef]

- Hwang, G.-T.; Park, H.; Lee, J.-H.; Oh, S.; Park, K.-I.; Byun, M.; Park, H.; Ahn, G.; Jeong, C.K.; No, K.; et al. Self-powered cardiac pacemaker enable by flexible single crystalline PMN-PT piezoelectric energy harvester. Adv. Mater. 2014, 26, 4880–4887. [Google Scholar] [CrossRef] [PubMed]

- Gafforelli, G.; Corigliano, A.; Xu, R.; Kim, S.-G. Experimental verification of a bridge-shaped, nonlinear vibration energy harvester. Appl. Phys. Lett. 2014, 105, 203901. [Google Scholar] [CrossRef]

- Soares dos Santos, M.P.; Ferreira, J.A.F.; Simoes, J.A.O.; Pascoal, R.; Torrao, J.; Xue, X.; Furlani, E.P. Magnetic levitation-based electromagnetic energy harvesting: A semi-analytical non-linear model for energy transduction. Sci. Rep. 2016, 6, 18579. [Google Scholar] [CrossRef] [PubMed]

- Tao, K.; Wu, J.; Tang, L.; Hu, L.; Lye, S.W.; Miao, J. Enhanced electrostatic vibrational energy harvesting using integrated opposite-charged electrets. J. Micromech. Microeng. 2017, 27, 044002. [Google Scholar] [CrossRef]

- Alluri, N.R.; Selvarajan, S.; Chandrasekhar, A.; Saravanakumar, B.; Lee, G.M.; Jeong, J.H.; Kim, S.-J. Worm structure piezoelectric energy harvester using ionotropic gelation of barium titanate-clacium alginate composite. Energy 2017, 118, 1146–1155. [Google Scholar] [CrossRef]

- Khan, F.U.; Qadir, M.U. State-of-the-art in vibration-based electrostatic energy harvesting. J. Micromech. Microeng. 2016, 26, 103001. [Google Scholar] [CrossRef]

- Kim, D.Y.; Lee, S.; Lin, Z.-H.; Choi, K.H.; Doo, S.G.; Chang, H.; Leem, J.-Y.; Wang, Z.L.; Kim, S.-O. High temperature processed ZnO nanorods using flexible and transparent mica substrates for dye-sensitized solar cells and piezoelectric nanogenerators. Nano Energy 2014, 9, 101–111. [Google Scholar] [CrossRef]

- Chen, C.Y.; Huang, J.H.; Zhou, Y.; Lin, L.; Huang, P.C.; Liu, C.P.; He, J.H.; Wang, Z.L. Anisotropic outputs of a nanogeneator from oblique-aligned ZnO nanowire arrays. ACS Nano 2011, 5, 6707–6713. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.Y.; Kim, D.; Lee, J.-H.; Kim, T.Y.; Gupta, M.J.; Kim, S.-W. Unidirectional high-power generation via stress-induced dipole alignment from ZnSnO3 nanocubes/polymer hybrid piezoelectric nanogenerator. Adv. Funct. Mater. 2014, 24, 37–43. [Google Scholar] [CrossRef]

- Wu, J.M.; Xu, C.; Zhang, Y.; Wang, Z.L. Lead-free nanogeneator made from single ZnSnO3 microbelt. ACS Nano 2012, 6, 4335–4340. [Google Scholar] [CrossRef] [PubMed]

- Park, K.-I.; Son, J.H.; Hwang, G.-T.; Jeong, C.K.; Ryu, J.; Koo, M.; Choi, I.; Lee, S.H.; Byun, M.; Wang, Z.L.; et al. Highly-efficient, flexible piezoelectric PZT thin film nanogenerator on plastic substrates. Adv. Mater. 2014, 26, 2514–2520. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Xu, S.; Yao, N.; Shi, Y. Nanogenerator for mechanical energy harvesting using PZT nanofibers. Nano Lett. 2010, 10, 2133–2137. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.-H.; Ryu, H.; Kim, T.-Y.; Kwak, S.-S.; Yoon, H.-J.; Kim, T.-H.; Seung, W.; Kim, S.-W. Thermally induced strain-coupled highly stretchable and sensitive pyroelectric nanognerators. Adv. Energy Mater. 2015, 5, 1500704. [Google Scholar] [CrossRef]

- Chen, X.; Tian, H.; Li, X.; Shao, J.; Ding, Y.; An, N.; Zhou, Y. A high performance P(VDF-TrFE) nanogenerator with self-connected and vertically integrated fibers by patterned EHD pulling. Nanoscale 2015, 7, 11536–11544. [Google Scholar] [CrossRef] [PubMed]

- Simoes, R.D.; Rodriguez-Perez, M.A.; Saja, J.A.D.; Constantino, C.J.L. Tailoring the structural properties of PVDF and P(VDF-TrFE) by using natural polymers as additives. Polym. Eng. Sci. 2009, 47, 2150–2157. [Google Scholar] [CrossRef]

- Ducrot, P.-H.; Dufour, I.; Ayela, C. Optimization of PVDF-TrFE processing conditions for the fabrication of organic MEMS resonators. Sci. Rep. 2016, 6, 19426. [Google Scholar] [CrossRef] [PubMed]

- Pi, Z.; Zhang, J.; Wen, C.; Zhang, Z.-B.; Wu, D. Flexible piezoelectric nanogenerator made of poly(vinylidenefluoride-co-trifluorethylene)(PVDF-TrFE) thin film. Nano Energy 2014, 7, 33–41. [Google Scholar] [CrossRef]

- Lee, J.-H.; Lee, K.Y.; Gupta, M.K.; Kim, T.Y.; Lee, D.-Y.; Oh, J.; Ryu, C.; Yoo, W.J.; Kang, C.-Y.; Yoon, S.-J.; et al. Highly stretchable piezoelectric-pyroelectric hybrid nanogenerator. Adv. Mater. 2014, 26, 765–769. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Yang, B.; Liu, J.; Zhu, T.; Yang, C.; He, Q. A flexible triboelectric-piezoelectric hybrid nanogenrator based on P(VDF-TrFE) nanofibers and PDMS/MWCNT for wearable devices. Sci. Rep. 2016, 6, 36409. [Google Scholar] [CrossRef] [PubMed]

- Han, M.; Zhang, X.-S.; Meng, B.; Liu, W.; Tang, W.; Sun, X.; Wang, W.; Zhang, H. r-Shaped hybrid nanogenerator with enhanced piezoelectricity. ACS Nano 2013, 7, 8554–8560. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Duan, Y.; Huang, Y.A. Electrohydrohynamically printed, flexible energy harvester using in situ poled piezoelectric nanofibers. Energy Technol. 2015, 3, 351–358. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, S.; Jin, Y.M.; Ouyang, H.; Zou, Y.; Wang, X.X.; Xie, L.X.; Li, Z. Flexible piezoelectric nanogenerator in wearable self-powered active sensor for respiration and healthcare monitoring. Semicond. Sci. Technol. 2017, 32, 064004. [Google Scholar] [CrossRef]

- Bhavanasi, V.; Kumar, V.; Parida, K.; Wang, J.; Lee, P.S. Enhanced piezoelectric energy harvesting performance of flexible PVDF-TrFE bilayer films with graphene oxide. ACS Appl. Mater. Interfaces 2016, 8, 521–529. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Towfeeq, I.; Bayram, F.; Khan, D.; Koley, G. Highly flexible P(VDF-TrFE) film-based piezoelectric self-powered energy harvester. In Proceedings of the IEEE Sensors, Orlando, FL, USA, 30 October–3 November 2016; pp. 1–3. [Google Scholar]

- Chen, S.; Yao, K.; Tay, F.E.H.; Chew, L.L.S. Comparative investigation of the structure and properties of ferroelectric poly(vinylidene fluoride) and poly(vinylidene fluoride-trifluoroethylene) thin films crystallized on substrates. J. Appl. Polym. Sci. 2010, 116, 3331–3337. [Google Scholar] [CrossRef]

- Paik, H.; Choi, Y.-Y.; Hong, S.; No, K. Effect of Ag nanoparticle concentration on the electrical and ferroelectric properties of Ag/P(VDF-TrFE) composite films. Sci. Rep. 2015, 5, 13209. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.; Zhang, J.; Chen, S.; Wang, X. Crystalline phase formation of poly(vinylidenefluoride) from tetrahydrofuran/N,N-dimethylformamide mixed solutions. J. Macromol. Sci. B 2008, 47, 434–449. [Google Scholar] [CrossRef]

- Ko, Y.H.; Nagaraju, G.; Lee, S.H.; Yu, J.S. PDMS-based triboelectric and transparent nanogenerators with ZnO nanorod arrays. ACS Appl. Mater. Interfaces 2014, 6, 6631–6637. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.-R.; Tian, Z.-Q.; Wang, Z.L. Flexible triboelectric generator! Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Sinha, T.K.; Ghosh, S.K.; Maiti, R.; Jana, S.; Adhikari, B.; Mandal, D.; Ray, S.K. Graphene-silver-induced self-polarized PVDF-based flexible plasmonic nanogenerator toward the realization for new class of self powered optical sensor. ACS Appl. Mater. Interfaces 2016, 8, 14986–14993. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Gupta, M.K.; Lee, K.Y.; Sohn, A.; Kim, T.Y.; Shin, K.-S.; Kim, D.; Kim, S.K.; Lee, K.H.; Shin, H.-J.; et al. Transparent flexible graphene triboelectric nanognerators. Adv. Mater. 2014, 26, 3918–3925. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Lin, M.-F.; Wang, J.; Gaw, S.L.; Parida, K.; Lee, P.S. Wearable all-fabric-based triboelectric generator for water energy harvesting. Adv. Energy Mater. 2017, 1701243, 1–10. [Google Scholar] [CrossRef]

- Moyet, R.P.; Stace, J.; Amin, A.; Finkel, P.; Rossetti, G.A. Non-resonant electromechanical energy harvesting using inter-ferroelectric phase transitions. Appl. Phys. Lett. 2015, 107. [Google Scholar]

- Bonisoli, E.; Repetto, M.; Manca, N.; Gasparini, A. Electromechanical and electronic integrated harvester for shoes application. IEEE/ASME Trans. Mech. 2017, 22, 1921–1932. [Google Scholar] [CrossRef]

- Takhedmit, H.; Saddi, Z.; Karami, A.; Basset, P.; Cirio, L. Electrostatic vibration energy harvester with 2.4-GHz cockcroft-walton rectenna start-up. C. R. Phys. 2017, 18, 98–106. [Google Scholar] [CrossRef]

- Liu, H.; Chen, T.; Sun, L.; Lee, C. An electromagnetic MEMS energy harvester array with multiple vibration modes. Micromachines 2015, 6, 984–992. [Google Scholar] [CrossRef]

- Roy, S.; Podder, P.; Mallick, D. Nonlinear energy harvesting using electromagnetic transduction for wide bandwidth. IEEE Magn. Lett. 2016, 7, 5701004. [Google Scholar] [CrossRef]

- Lee, Y.; Blaauw, D.; Sylvester, D. Ultralow power circuit design for wireless sensor nodes for structural health monitoring. Proc. IEEE 2016, 104, 1529–1546. [Google Scholar] [CrossRef]

- Jeong, S.; Foo, Z.; Lee, Y.; Sim, J.-Y.; Blaauw, D.; Sylvester, D. A fully-integrated 71 nW CMOS temperature sensor for low power wireless sensor nodes. IEEE J. Solid State Circuits 2014, 49, 1682–1693. [Google Scholar] [CrossRef]

- Lim, W.; Lee, I.; Sylvester, D.; Blaauw, D. Batteryless sub-nW cortex-MO+ processor with dynamic leakage-suppression logic. In Proceedings of the 2015 IEEE International Solid-State Circuits Conference, San Francisco, CA, USA, 22–26 February 2015. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, Y.; Nomani, M.W.; Wen, X.; Hsia, T.Y.; Koley, G. A highly sensitive pressure sensor using a Au-patterned polydimethylsiloxane membrane for biosensing applications. J. Micromech. Microeng. 2013, 23, 025022. [Google Scholar] [CrossRef]

- Koley, G.; Liu, J.; Nomani, M.W.; Yim, M.; Wen, X.; Hsia, T.Y. Miniaturized implantable pressure and oxygen sensors based on polydimethylsiloxane thin films. Mater. Sci. Eng. C 2009, 29, 685–690. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Uddin, M.A.; Sudarshan, T.; Koley, G. Tunable reverse-biased graphene/silicon heterojunction schottky diode sensor. Small 2014, 10, 1555–1565. [Google Scholar] [CrossRef] [PubMed]

| Substrate | Piezoelectric Material (µm) | Size (cm2) | Output Performance | Input Frequency (Hz) | Reference | ||

|---|---|---|---|---|---|---|---|

| Voltage (V) | Current (µA) Current Density (µA/cm2) | Power Density (mW/cm3) | |||||

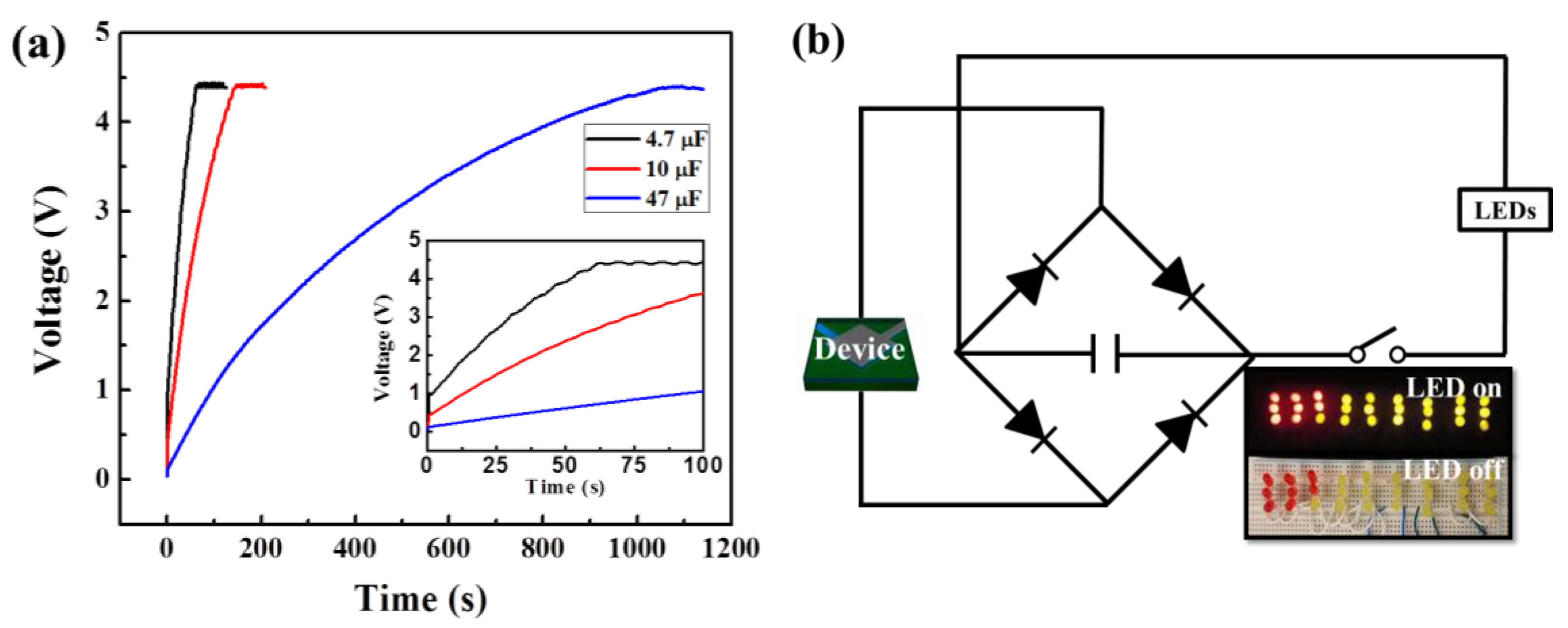

| PDMS | P(VDF-TrFE) (7 µm) | 2 × 2 | 5.8 V | 3.2 µA 0.8 µA/cm2 | 6.62 | 5~30 | This work |

| CNT/PDMS | P(VDF-TrFE) (7 µm) | 4 × 4 | 1.4 V | ~150 nA | 0.018 | N/A | [19] |

| MWCNT/PDMS | P(VDF-TrFE) (85 µm) | 0.8 × 0.8 | 2.5 V | ~2.5 µA | 0.689 | 1~4 | [20] |

| PDMS | PVDF (100 µm) | 4 × 2 | 52.8 V | 20.75 µA/cm2 | 10.95 | 5~10 | [21] |

| PDMS | PVDF (5 µm) | 3 × 3 | 150 mV | 4 nA | 1.33 × 10−4 | 1~2.3 | [22] |

| ITO | P(VDF-TrFE) (50 µm) | 1 × 1 | 4.0 V | 2.6 µA | 2.08 | 1~100 | [15] |

| Silicone | PVDF (200 µm) | 4.2 × 2 | 1.5 V | 400 nA | 3.57 × 10−3 | ~1.4 | [23] |

| N/A (ITO & Gold electrodes) | P(VDF-TrFE) (30 µm) | 1 × 1 | 4 V | 1.88 µA | 2.5 | 1 | [24] |

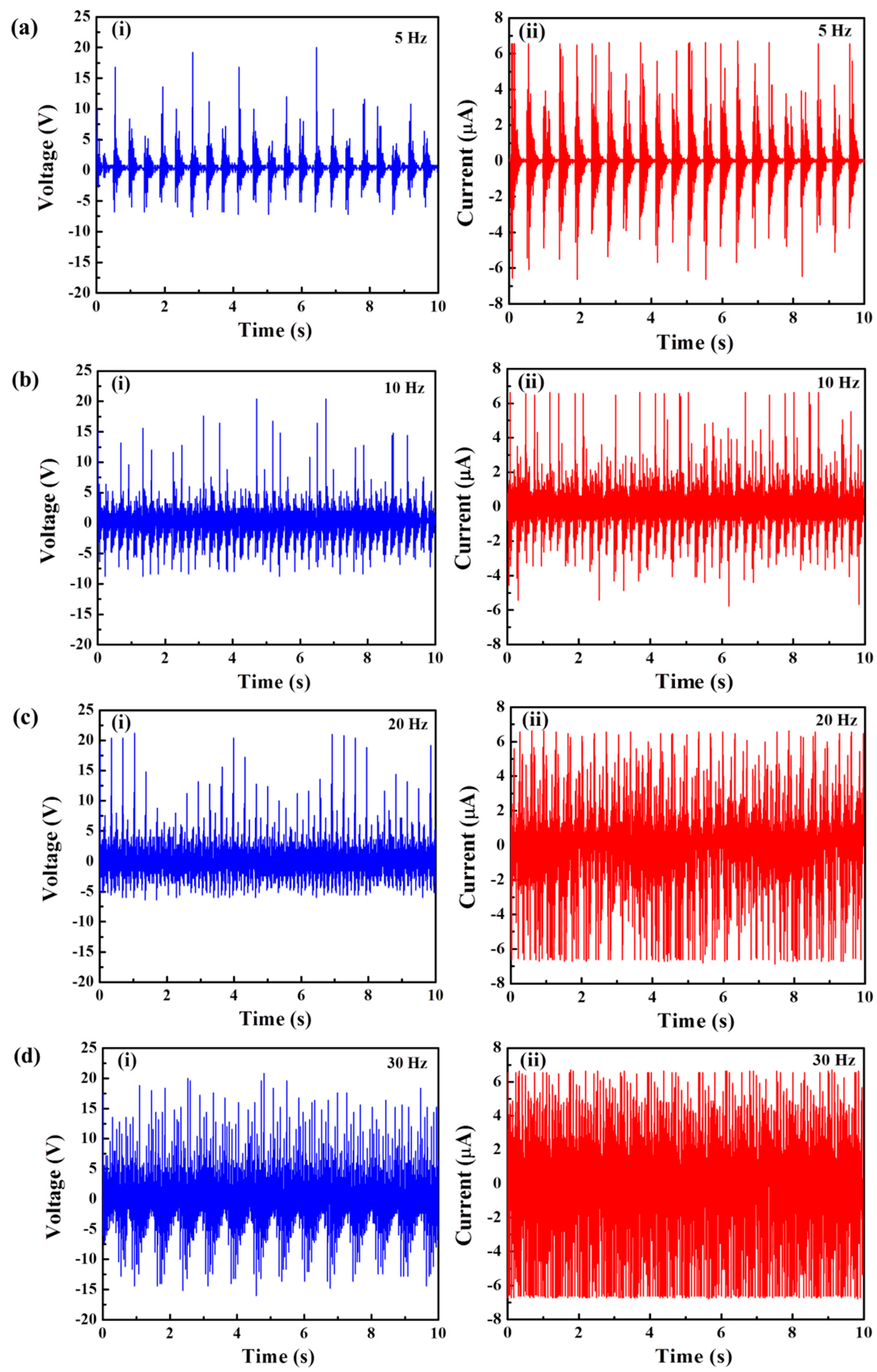

| Frequency (Hz) | Average Voltage (V) | Average Current (µA) | Average Power (µW) |

|---|---|---|---|

| 5 | 2.8 | 1.2 | 3.36 |

| 10 | 3.3 | 1.5 | 4.95 |

| 20 | 3.8 | 2.1 | 7.98 |

| 30 | 5.8 | 3.2 | 18.56 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Towfeeq, I.; Dong, Y.; Gorman, S.; Rao, A.M.; Koley, G. P(VDF-TrFE) Film on PDMS Substrate for Energy Harvesting Applications. Appl. Sci. 2018, 8, 213. https://doi.org/10.3390/app8020213

Kim S, Towfeeq I, Dong Y, Gorman S, Rao AM, Koley G. P(VDF-TrFE) Film on PDMS Substrate for Energy Harvesting Applications. Applied Sciences. 2018; 8(2):213. https://doi.org/10.3390/app8020213

Chicago/Turabian StyleKim, Soaram, Itmenon Towfeeq, Yongchang Dong, Sean Gorman, Apparao M. Rao, and Goutam Koley. 2018. "P(VDF-TrFE) Film on PDMS Substrate for Energy Harvesting Applications" Applied Sciences 8, no. 2: 213. https://doi.org/10.3390/app8020213