Exergy Analysis of Serpentine Thermosyphon Solar Water Heater

Abstract

:1. Introduction

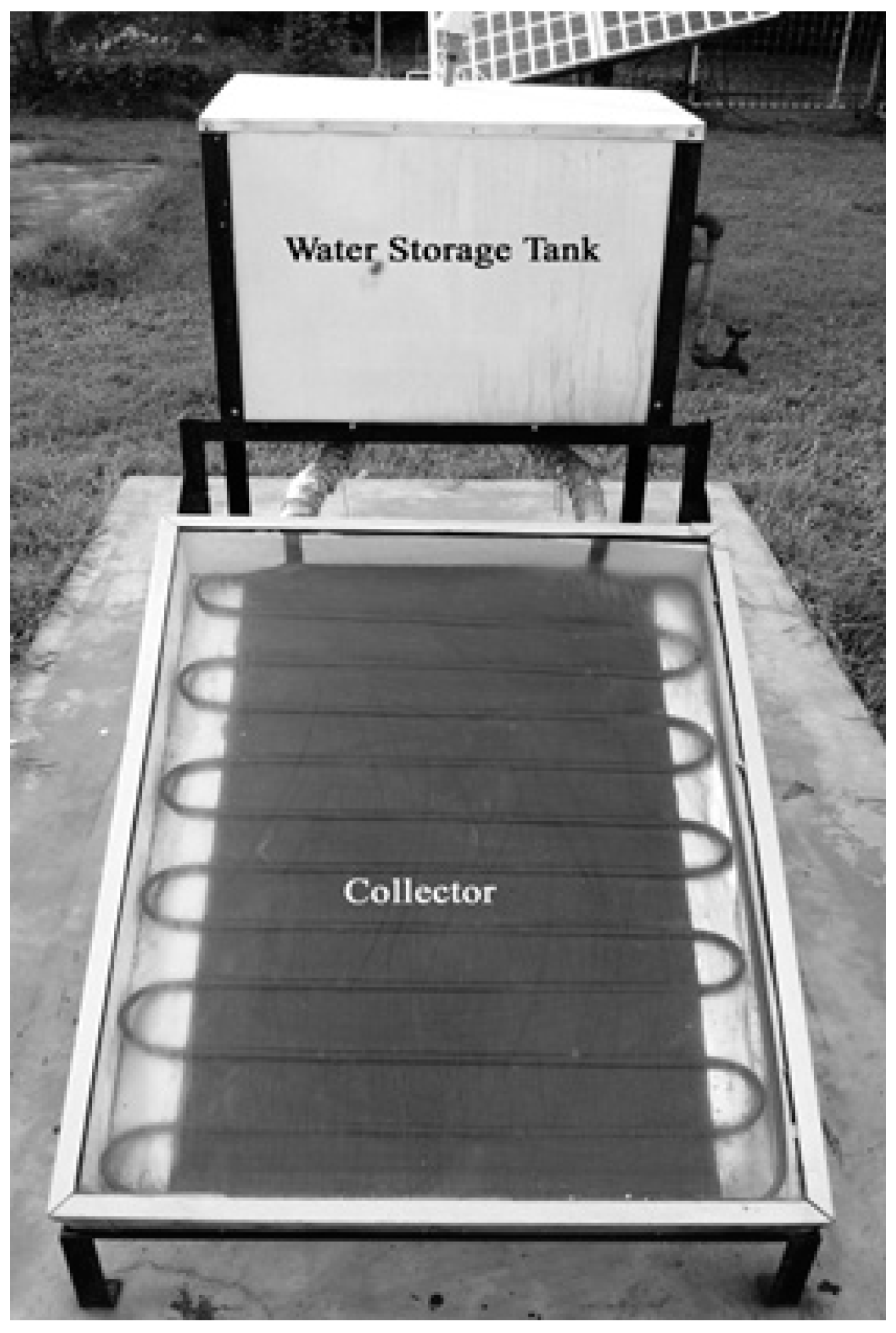

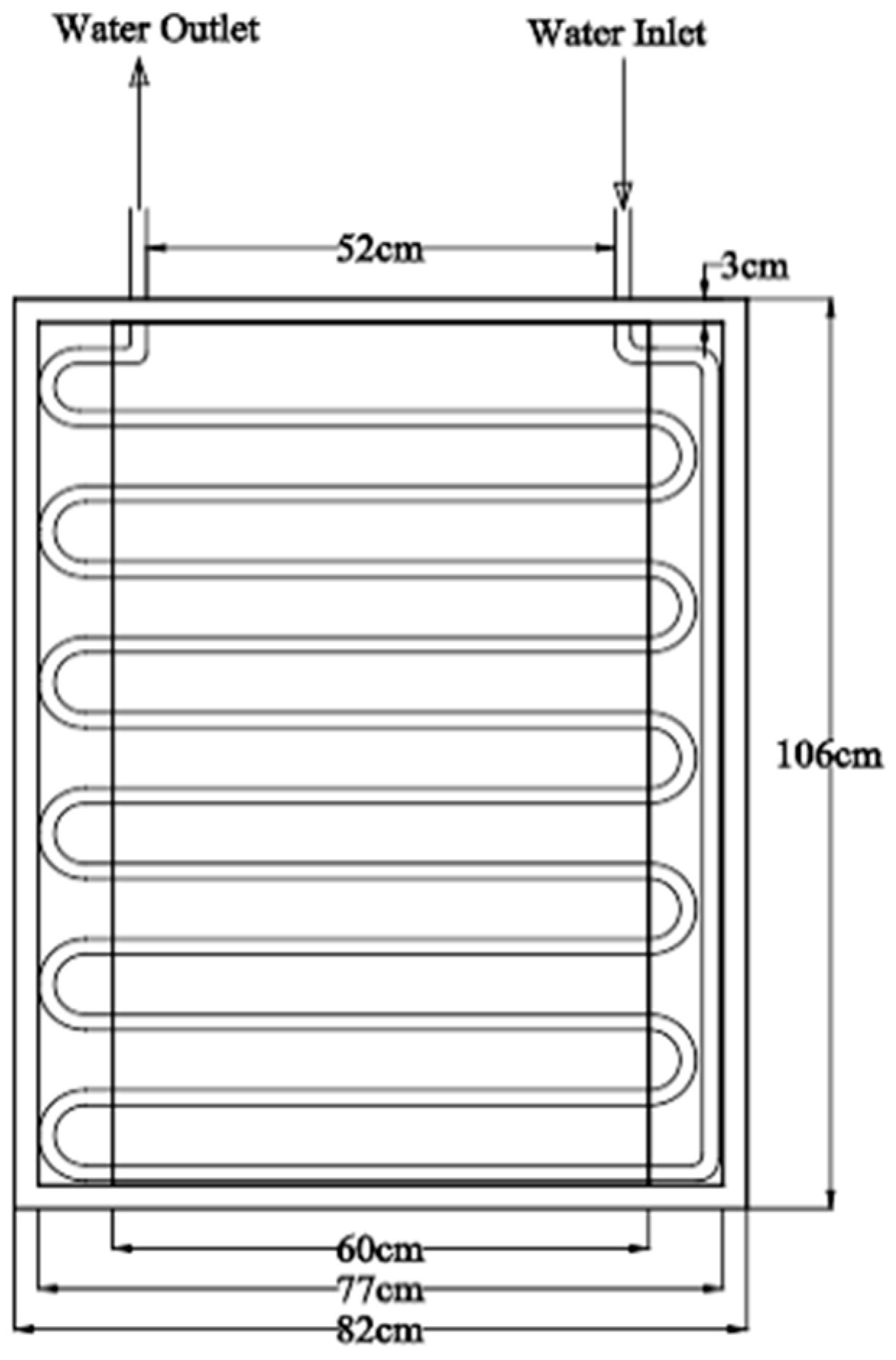

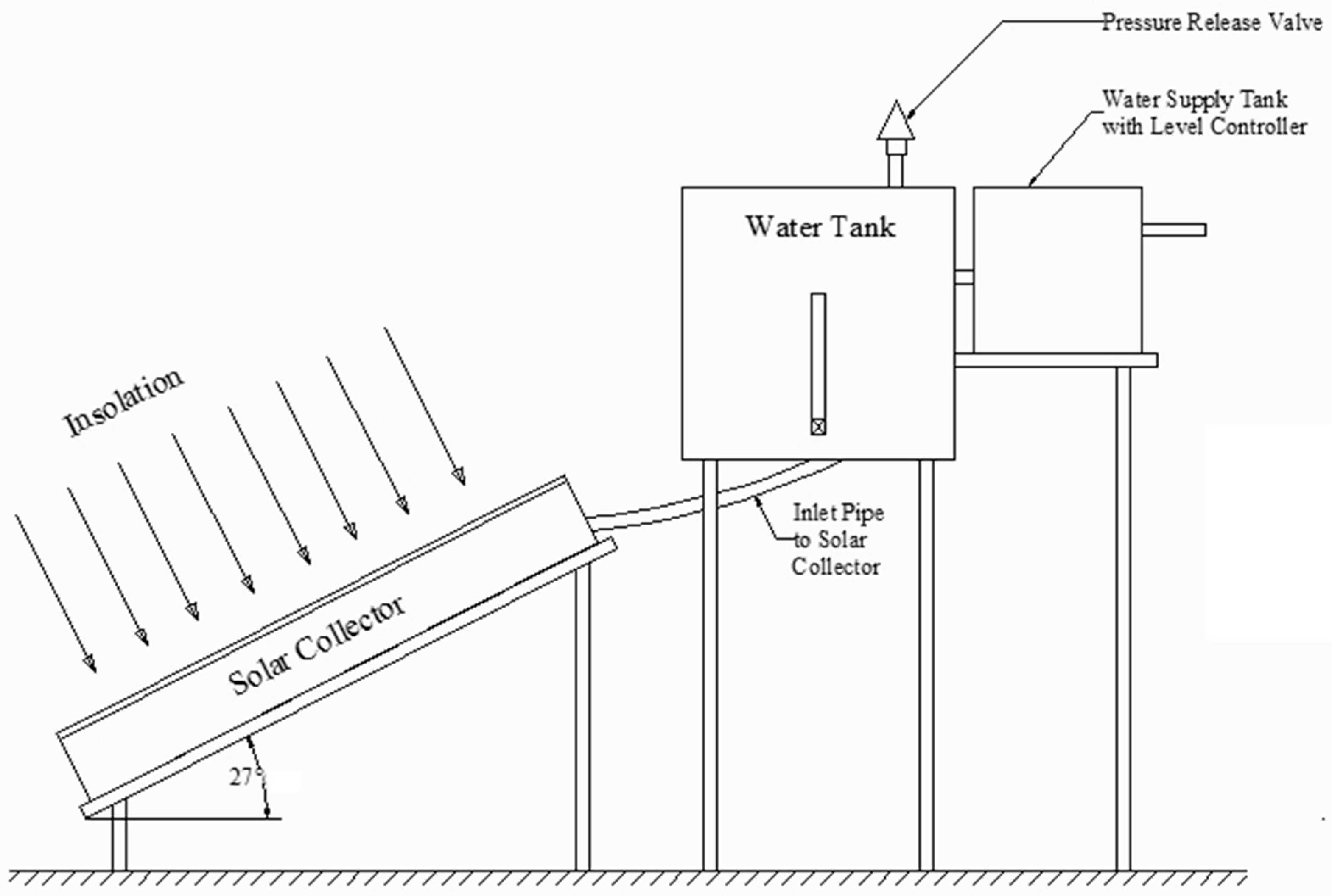

2. The Serpentine Type Thermosyphon Solar Water Heater

- Absorber Plate: It is a flat absorber plate coated with black paint that has high absorptance.

- Pipes: The black painted metallic pipe is placed above the absorber plate and attached to it by welding process.

- Glazing: A glass plate having high transmittance allows solar energy to pass toward absorber and reduces heat loss from the absorber plate.

- Working fluid: Water is used as the working fluid which receives heat from the absorber plate while passing through the serpentine pipe by thermosyphon action.

- Insulation: Glass wool insulation is placed behind the absorber plate to reduce the heat loss from the back side.

- Housing: It is the exterior box that contains the collector and other components.

- Water Tank: An insulated tank containing water is used to maintain the water flow to and from the collector. Density variation of water inside the tank causes the thermosyphon action.

3. Modeling of the System and Optimization

3.1. Energy Model

3.2. Exergy Model

3.2.1. Exergy Losses

3.2.2. Exergy Destruction

3.3. Optimization of the System

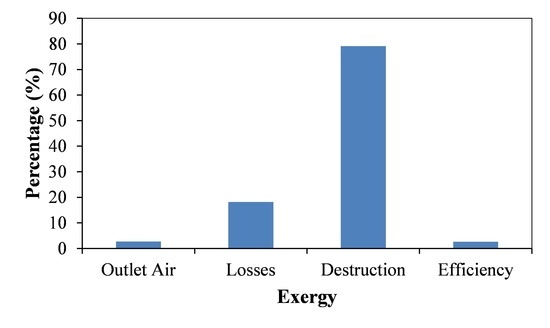

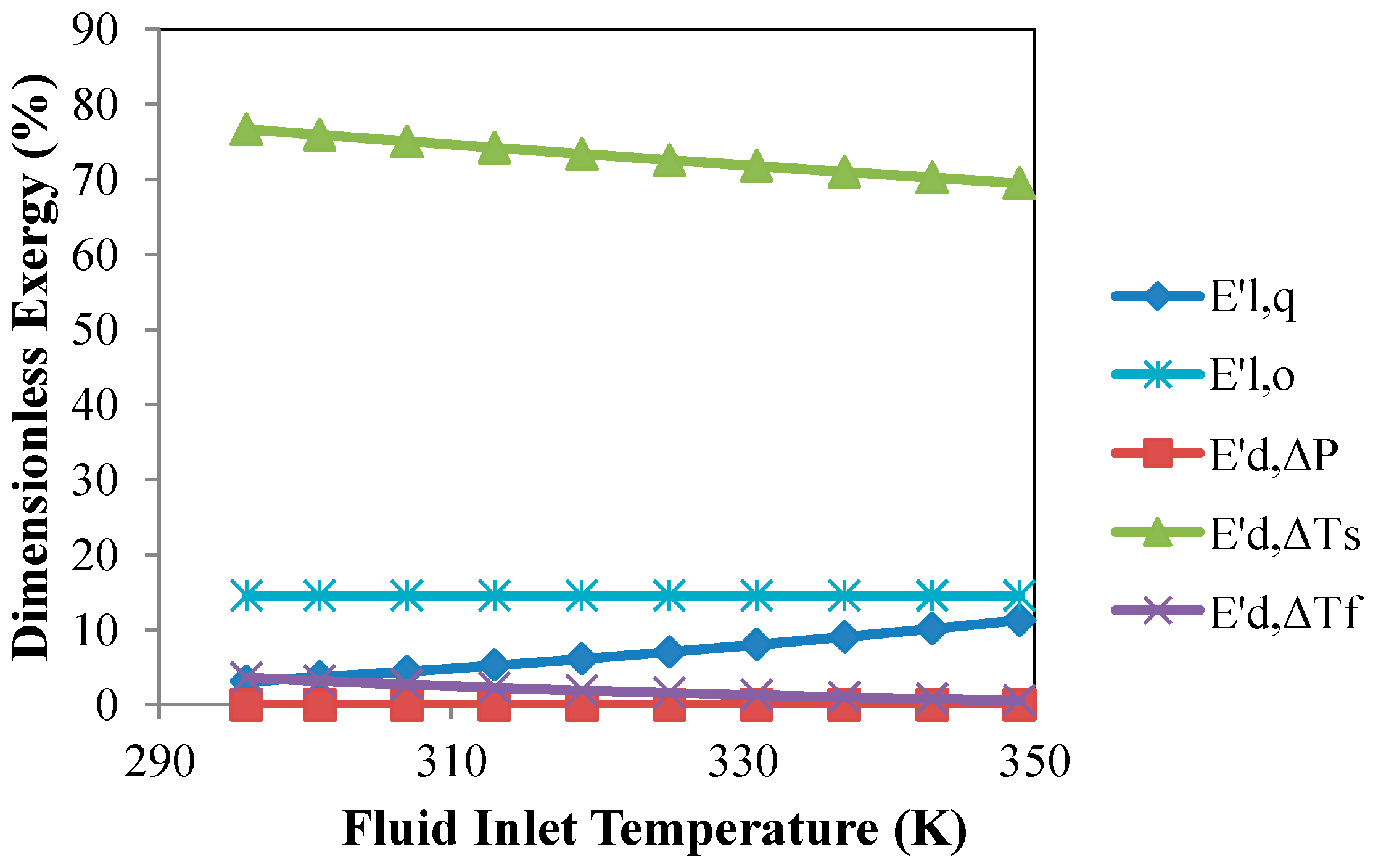

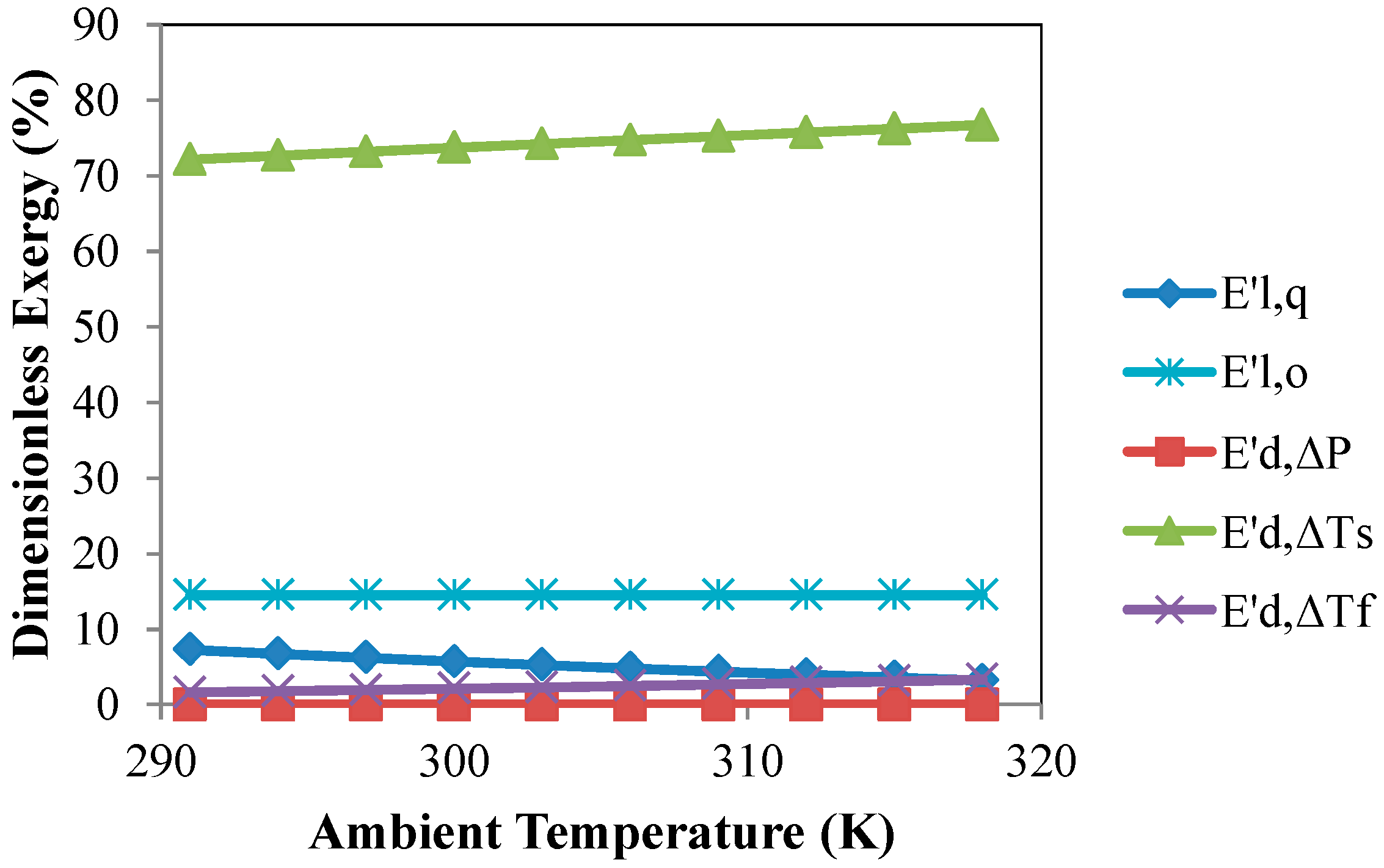

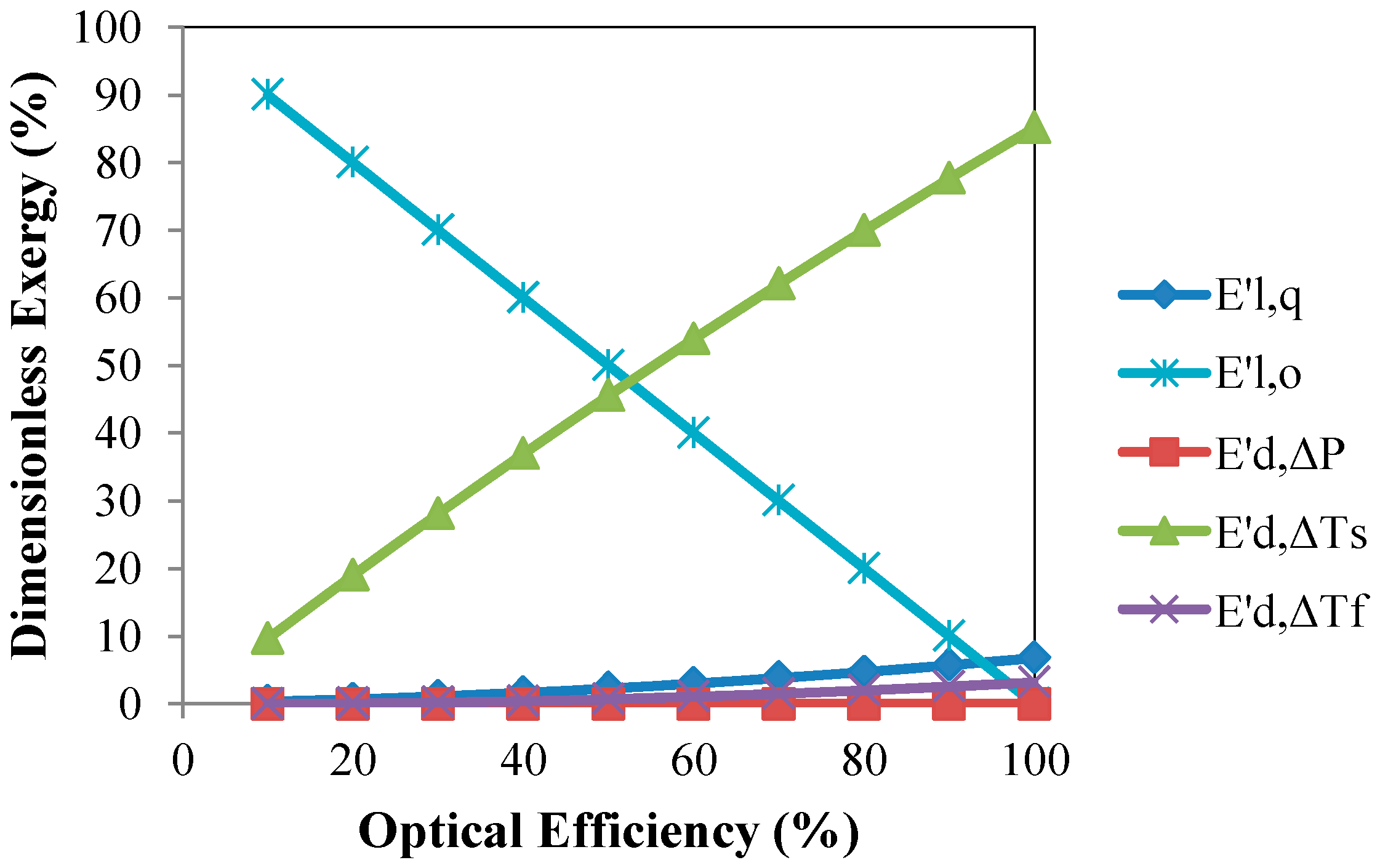

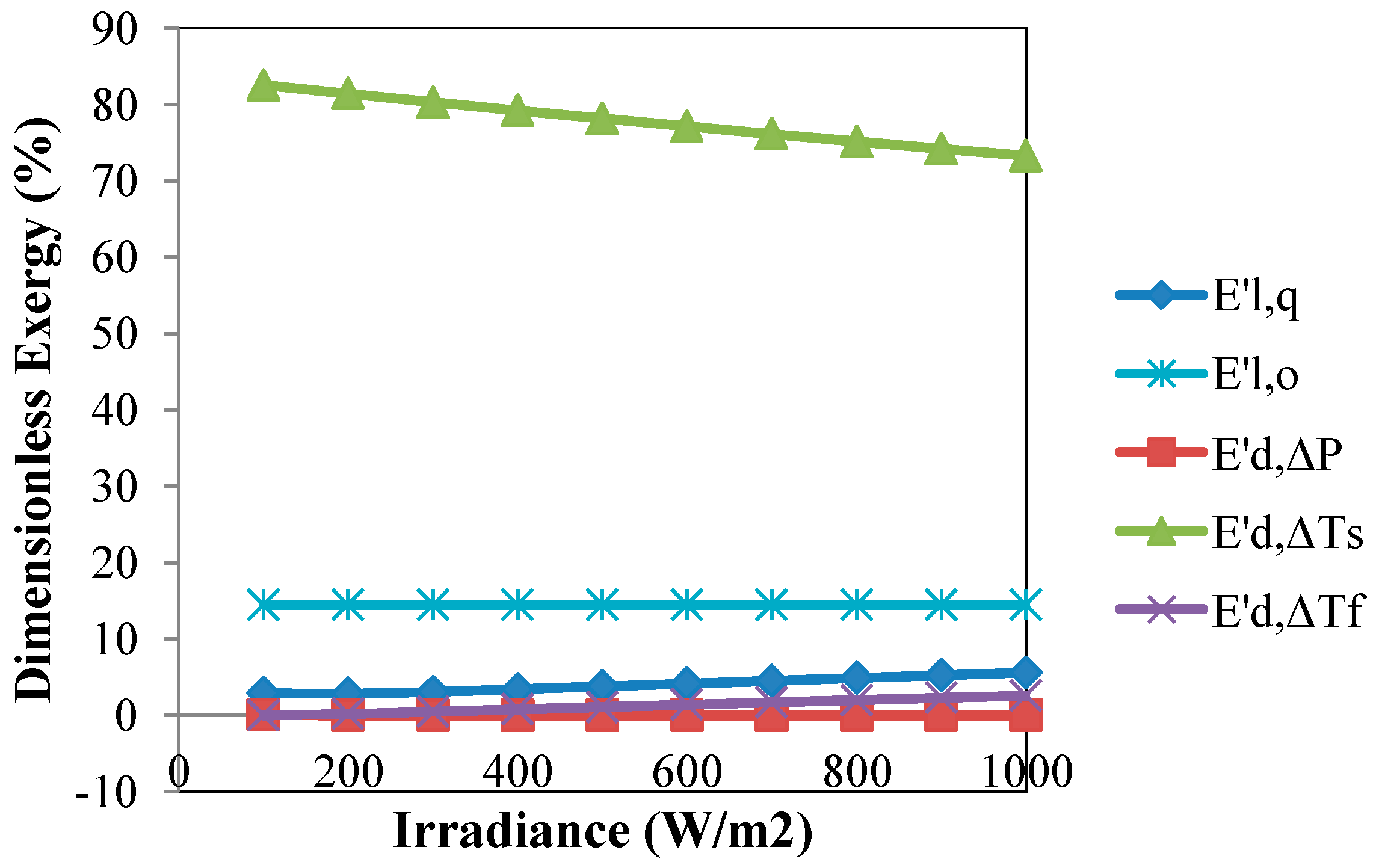

4. Results and Discussion

5. Conclusions

- This analysis is helpful in determining dimensions and operating conditions for the optimum performance of this type of system.

- Maximum exergy efficiency can be obtained over a certain inlet fluid temperature range, but the thermal efficiency decreased with increasing inlet temperature.

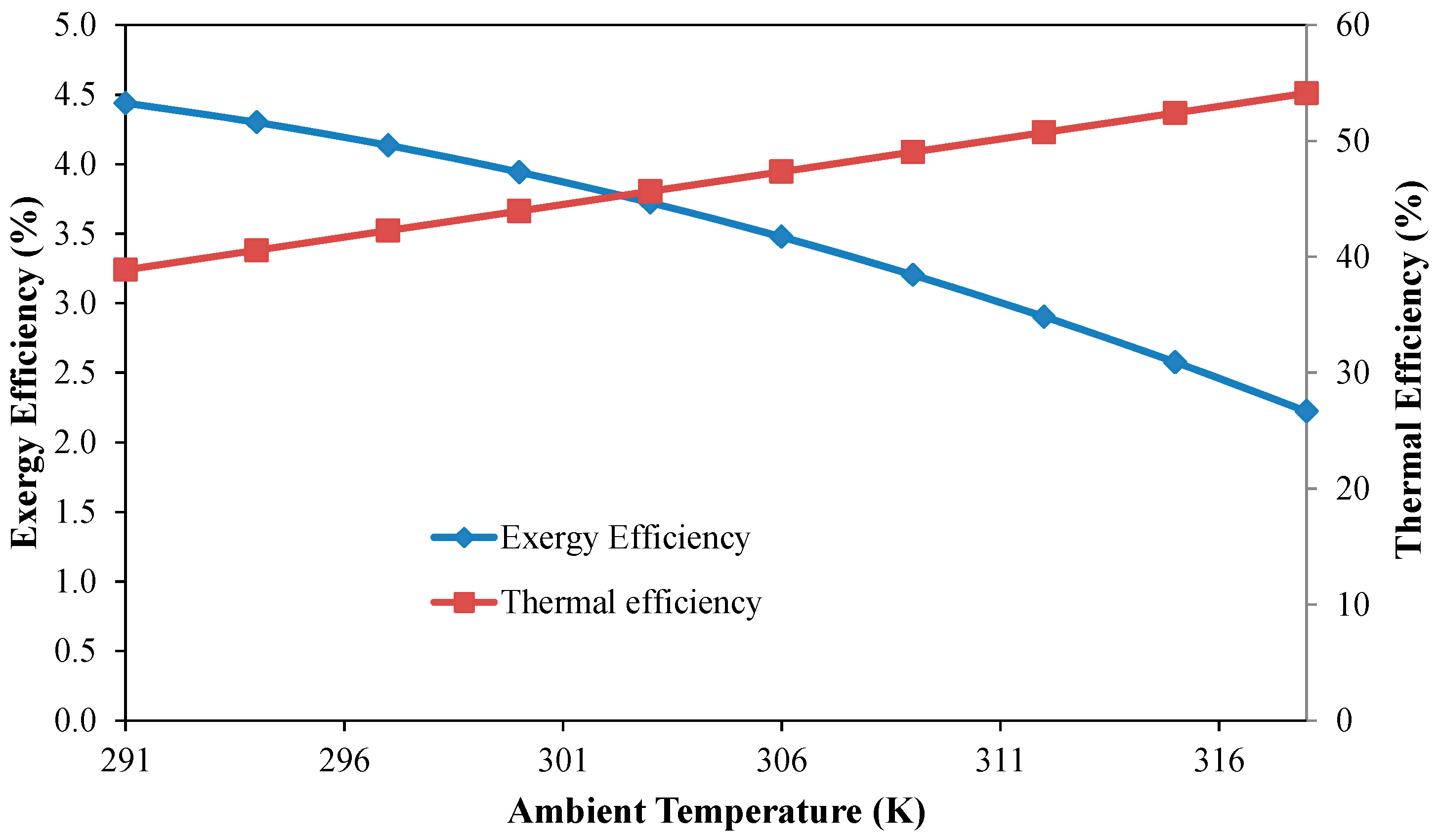

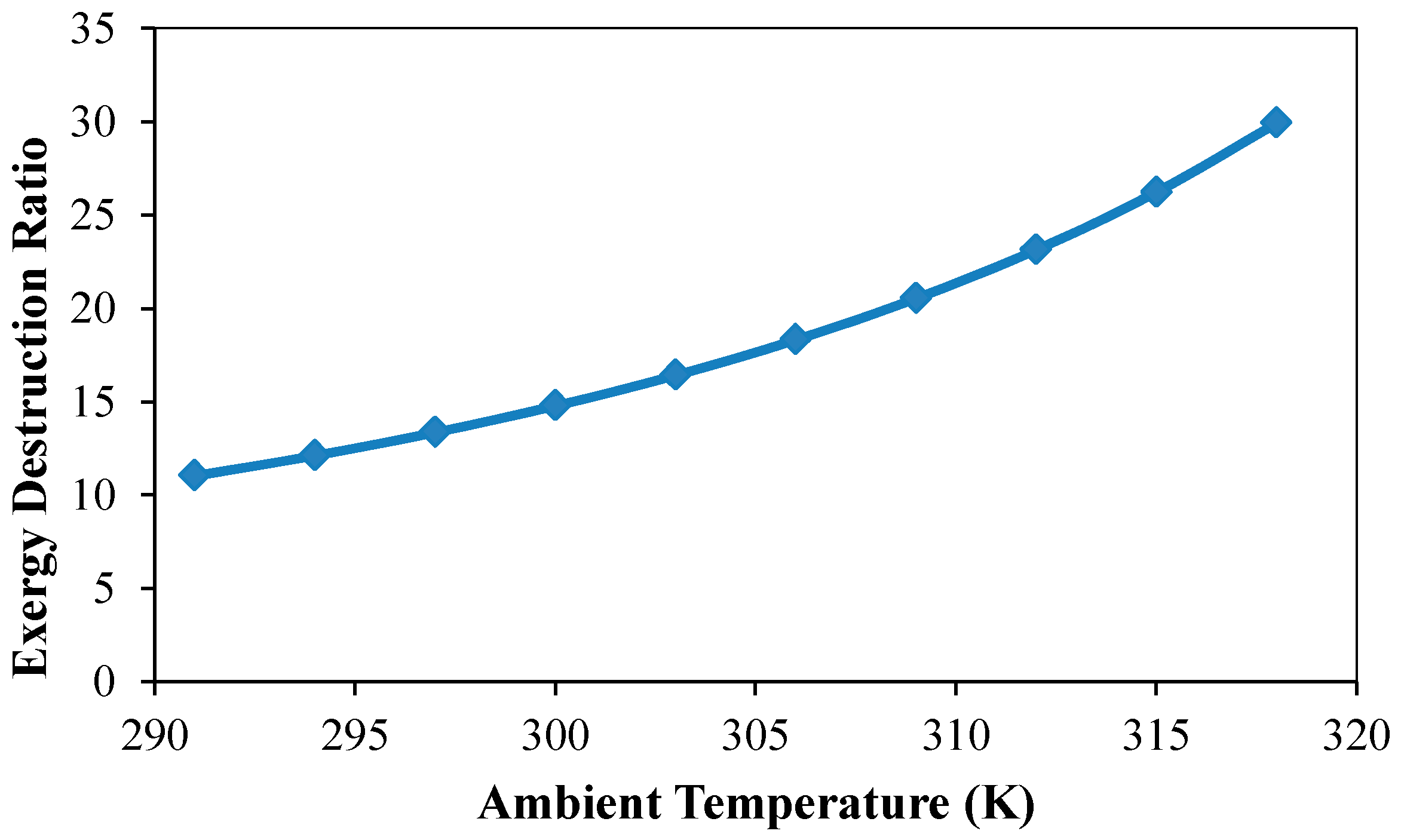

- Ambient temperature has positive effect on the thermal efficiency, whereas it has negative effect on the exergy efficiency.

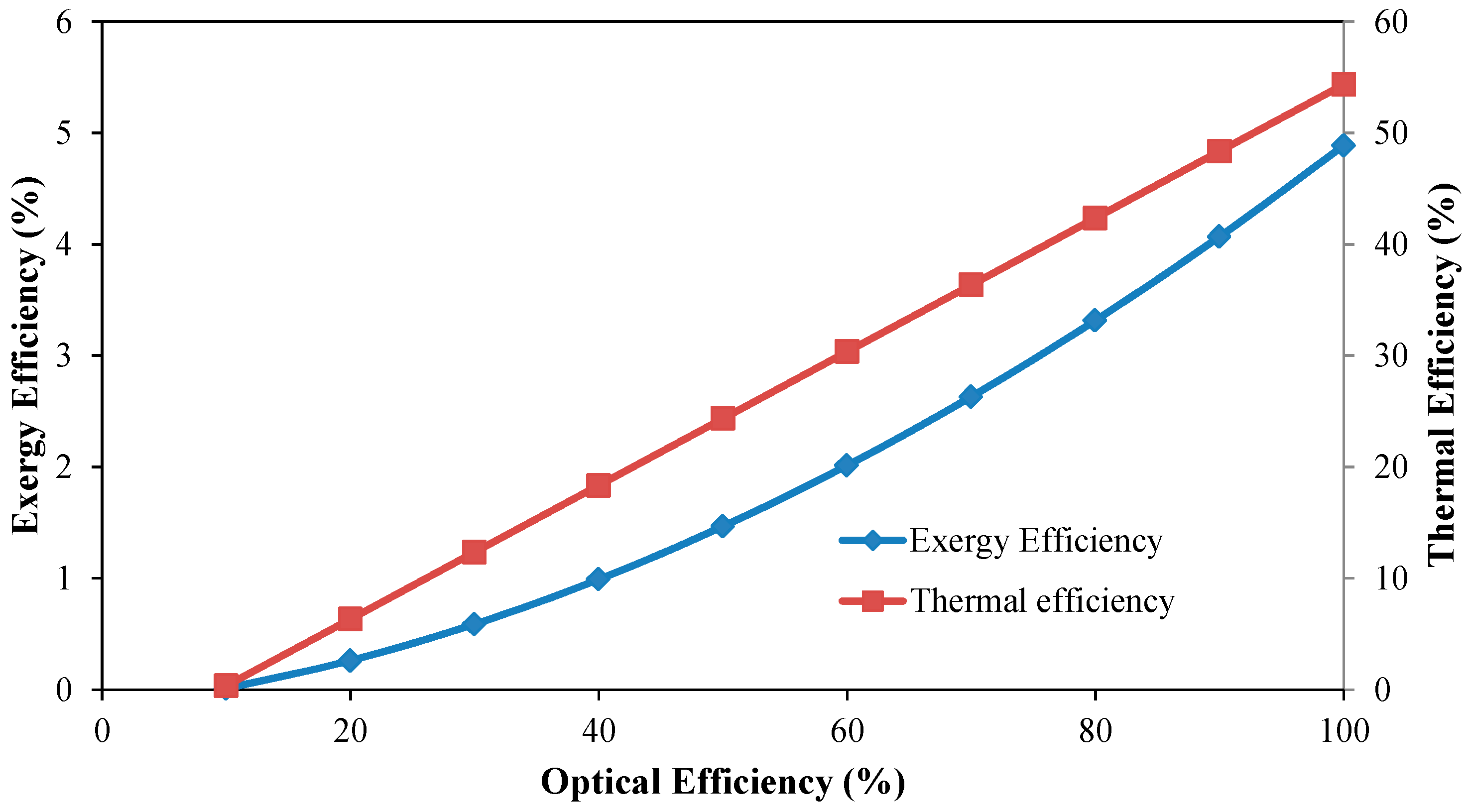

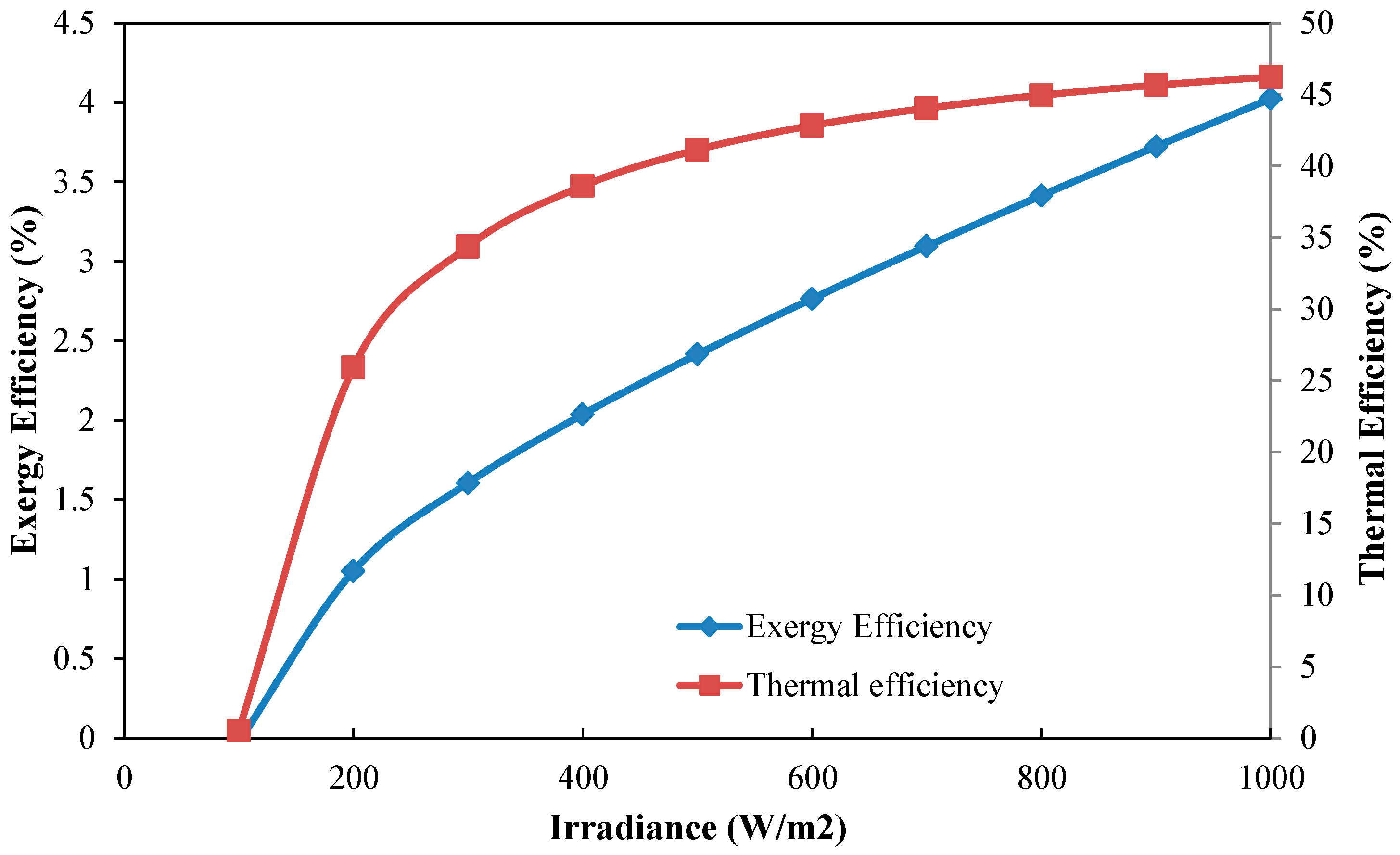

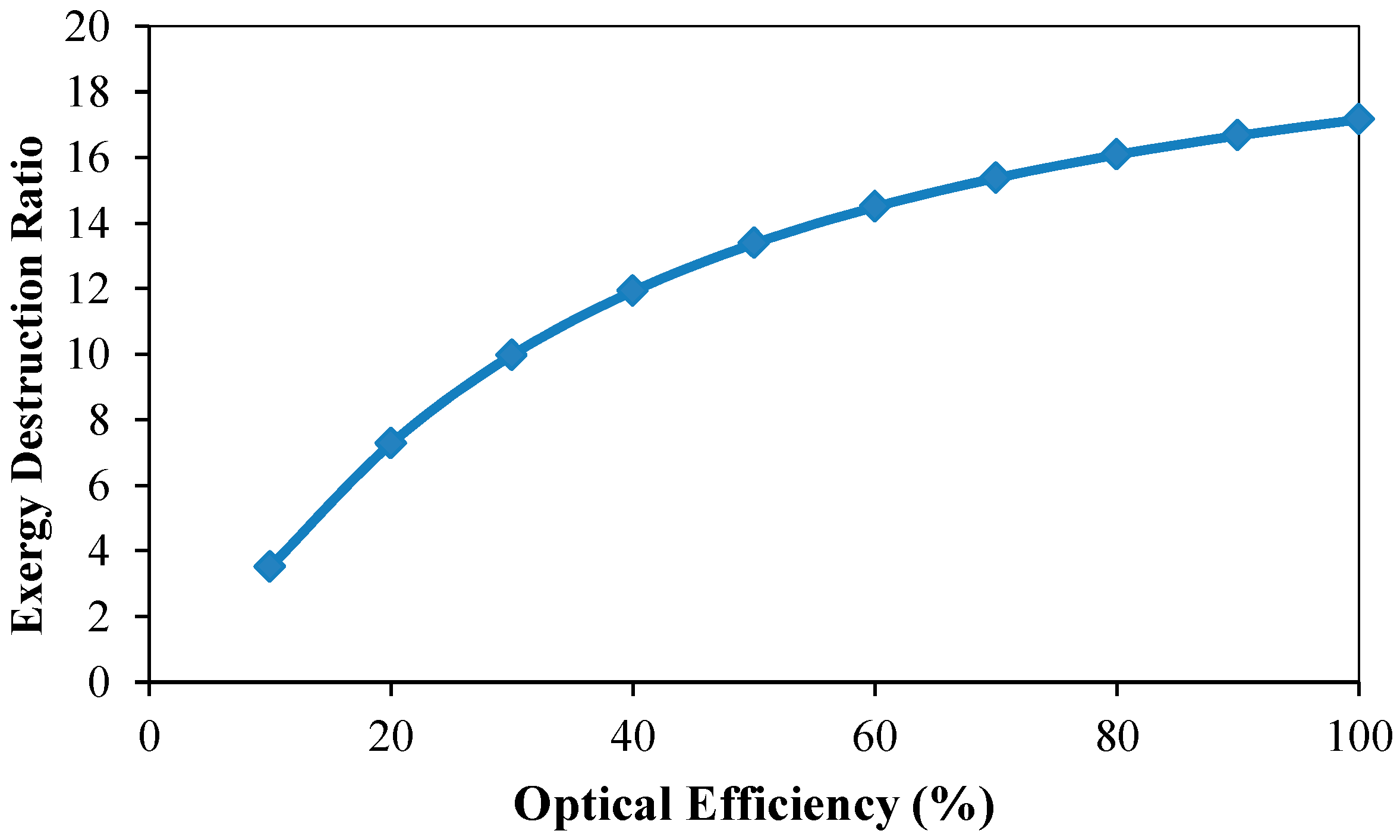

- Both optical efficiency and irradiance have great positive impact on the performance of the water heater. Thermal efficiency and exergy efficiency increase with these two parameters.

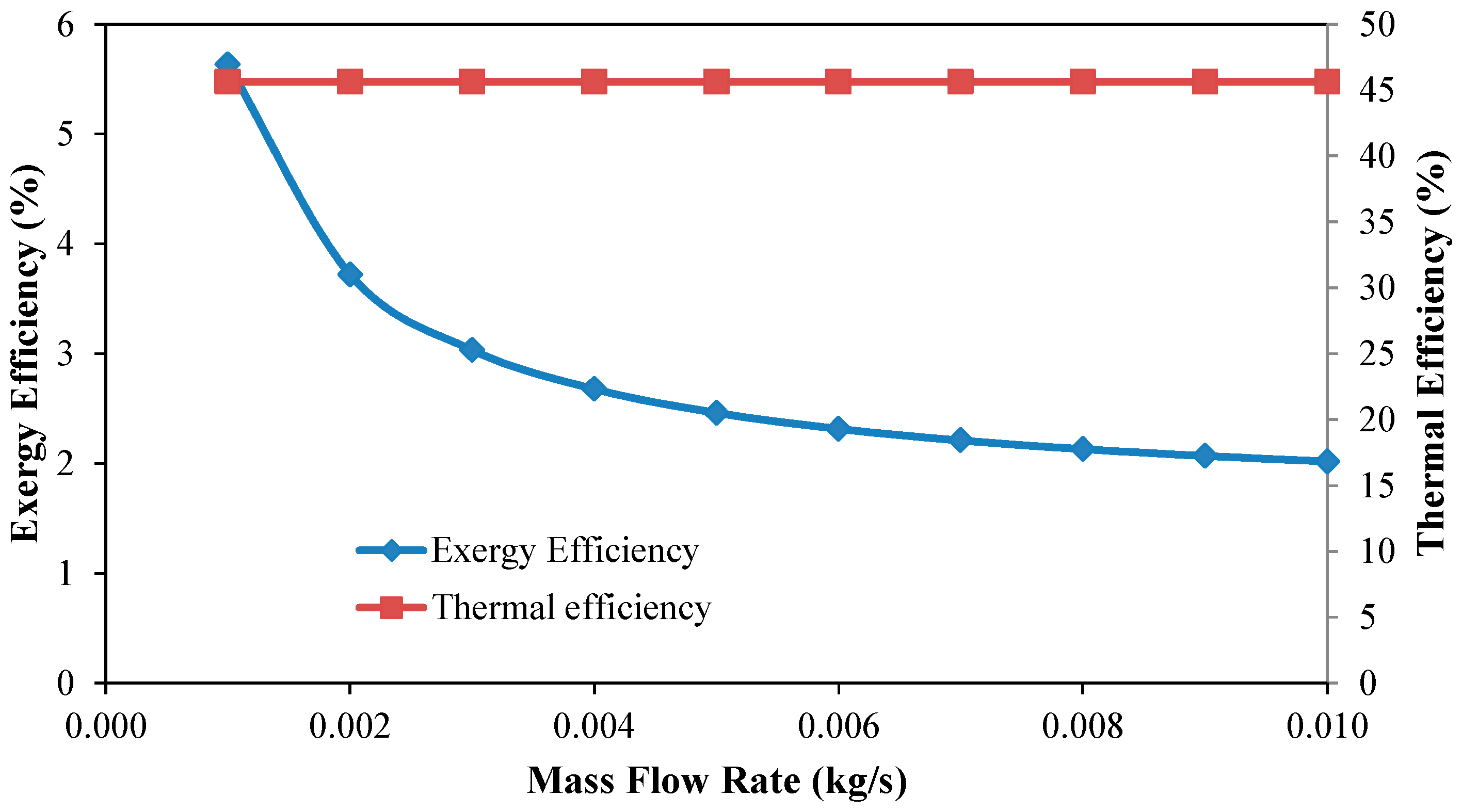

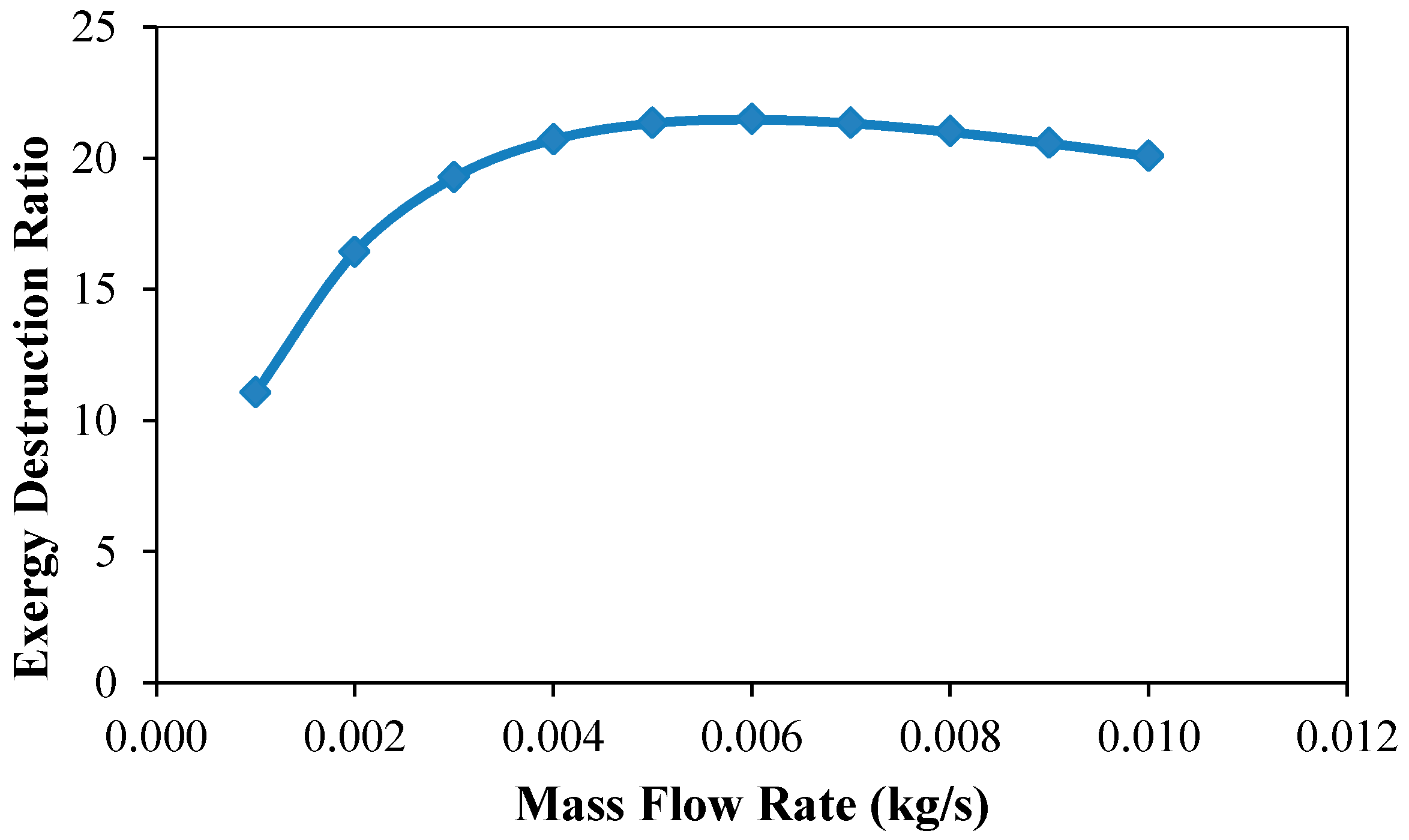

- Thermal efficiency does not depend much on the mass flow rate of this type of passive system, while the exergy efficiency reduces at higher mass flow rate.

- Exergy efficiency of around 3.7% can be expected from this type of passive solar water heating system.

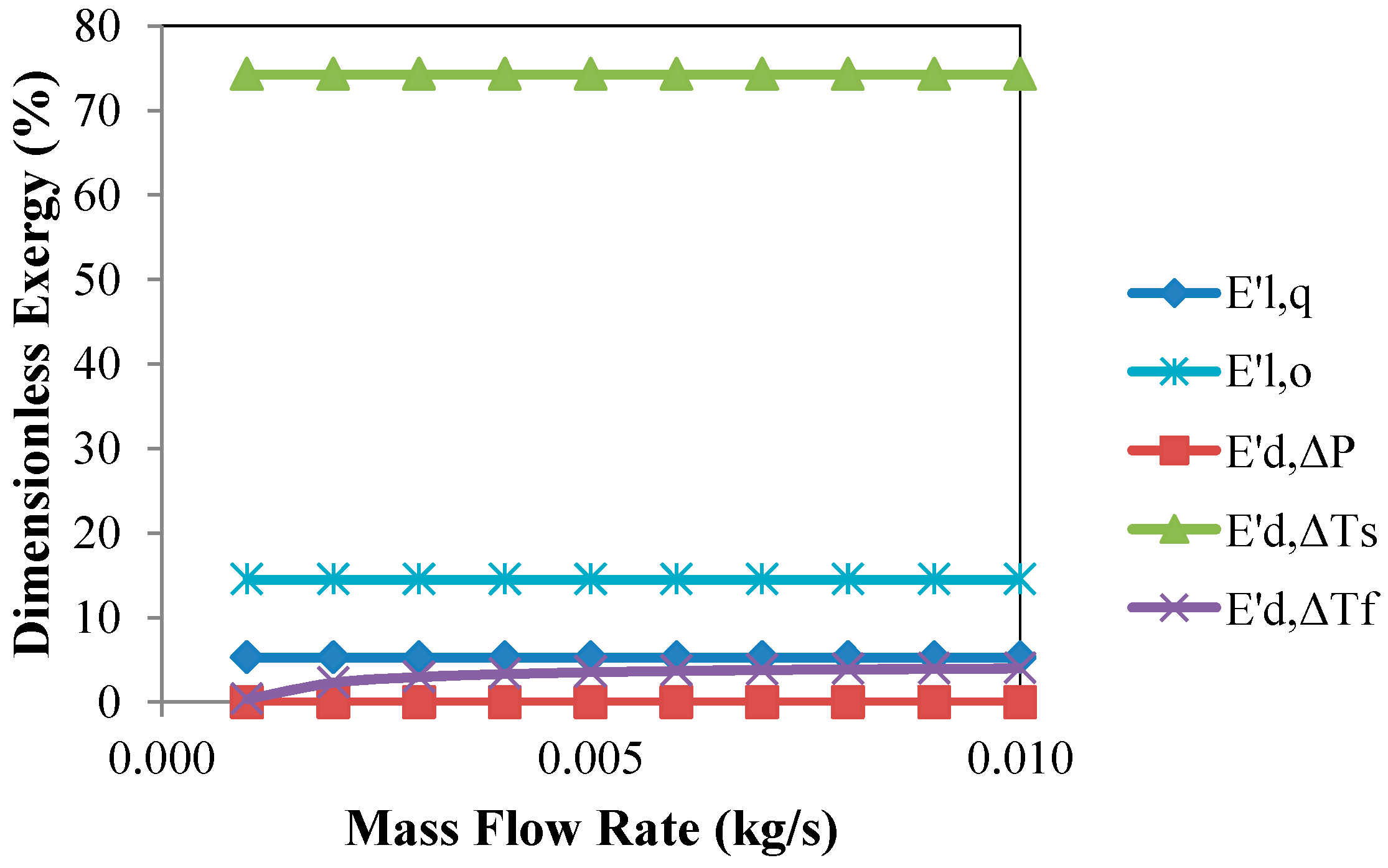

- Most (almost 75%) exergy destruction occurs due to high temperature difference between the sun and the absorber plate.

- Heat loss to the surrounding causes around 5% of exergy loss.

- EDR decreases with increasing fluid inlet temperature and irradiance.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| area of absorber plate [m2] | |

| heat transfer rate [W] | |

| mass flow rate [kg/s] | |

| specific heat of fluid [J/kg K] | |

| absorbed solar radiation flux per unit time [W/m2] | |

| overall heat loss coefficient [W/m2 k] | |

| pressure difference between collector inlet and surrounding (tank) [Pa] | |

| temperature difference between absorber plate and the sun [K] | |

| Exergy rate [W] | |

| solar collector heat removal factor, dimensionless | |

| absorber plate efficiency factor, dimensionless | |

| irradiance [W/m2] | |

| outlet temperature [K] | |

| inlet temperature [K] | |

| ambient temperature [K] | |

| absorber plate average temperature [K] | |

| black body temperature of the sun [~5800 K] | |

| apparent temperature of the sun [~4350 K] | |

| h | enthalpy (J/kg) |

| c | velocity of flow (m/s) |

| g | acceleration due to gravity (9.81 m/s2) |

| z | height (m) |

| Greek symbols | |

| thermal efficiency | |

| optical efficiency | |

| transmittance-absorbtance product | |

| density of fluid [kg/m3] | |

| Petela efficiency | |

| exergetic efficiency | |

| Subscripts | |

| f | fluid |

| in | inlet |

| out | outlet |

| d | destruction |

| l | loss/leakage |

| o | optical |

| ab | absorbed |

| u | utilized |

| cv | control volume |

References

- Mahadi, M.S.-U.-R.; Hasan, M.F.; Ahammed, A.; Kibria, M.T.; Huque, S. Construction, fabrication and performance analysis of an indigenously built serpentine type thermosyphon solar water heater. In Proceedings of the 2014 3rd International Conference on the Developments in Renewable Energy Technology (ICDRET), Dhaka, Bangladesh, 29–31 May 2014; pp. 2–7. [Google Scholar]

- Liu, R.H.T.G.; Cengel, Y.A. Exergy Analysis of a Solar Heating System. J. Sol. Energy Eng. 1995, 117, 249–251. [Google Scholar] [CrossRef]

- Jafarkazemi, F.; Ahmadifard, E. Energetic and exergetic evaluation of flat plate solar collectors. Renew. Energy 2013, 56, 55–63. [Google Scholar] [CrossRef]

- Marletta, L. Air conditioning systems from a 2nd law perspective. Entropy 2013, 15, 859–877. [Google Scholar] [CrossRef]

- Yazdi, M.; Aliehyaei, M.; Rosen, M.A. Exergy, economic and environmental analyses of gas turbine inlet air cooling with a heat pump using a novel system configuration. Sustainability 2015, 7, 14259–14286. [Google Scholar] [CrossRef]

- Gertzos, K.P.; Caouris, Y.G.; Panidis, T. Optimal design and placement of serpentine heat exchangers for indirect heat withdrawal, inside flat plate integrated collector storage solar water heaters (ICSSWH). Renew. Energy 2010, 35, 1741–1750. [Google Scholar] [CrossRef]

- Xiaowu, W.; Ben, H. Exergy analysis of domestic-scale solar water heaters. Renew. Sustain. Energy Rev. 2005, 9, 638–645. [Google Scholar] [CrossRef]

- Ben, H. Analysis and Synthesis of Energy Utilization; Chinese Petrochemical Engineering Press: Beijing, China, 1995. [Google Scholar]

- Hossain, M.S.; Saidur, R.; Fayaz, H.; Rahim, N.A.; Islam, M.R.; Ahamed, J.U.; Rahman, M.M. Review on solar water heater collector and thermal energy performance of circulating pipe. Renew. Sustain. Energy Rev. 2011, 15, 3801–3812. [Google Scholar] [CrossRef]

- Gupta, M.K.; Kaushik, S.C. Exergetic performance evaluation and parametric studies of solar air heater. Energy 2008, 33, 1691–1702. [Google Scholar] [CrossRef]

- Ge, Z.; Wang, H.; Wang, H.; Zhang, S.; Guan, X. Exergy analysis of flat plate solar collectors. Entropy 2014, 16, 2549–2567. [Google Scholar] [CrossRef]

- Luminosu, I.; Fara, L. Determination of the optimal operation mode of a flat solar collector by exergetic analysis and numerical simulation. Energy 2005, 30, 731–747. [Google Scholar] [CrossRef]

- Torres-Reyes, E.; Gortari, J.C.; Ibarra-Salazar, B.; Picon-Nuñez, M. A design method of flat-plate solar collectors based on minimum entropy generation. Exergy Int. J. 2001, 1, 46–52. [Google Scholar] [CrossRef]

- Farahat, H.A.S.; Sarhaddi, F. Exergetic optimization of flat plate solar collectors. Renew. Energy J. 2009, 8, 1169–1174. [Google Scholar] [CrossRef]

- Kalogirou, S.A.; Karellas, S.; Braimakis, K.; Stanciu, C.; Badescu, V. Exergy analysis of solar thermal collectors and processes. Prog. Energy Combust. Sci. 2016, 56, 106–137. [Google Scholar] [CrossRef]

- Pandey, K.M.; Chaurasiya, R. A review on analysis and development of solar flat plate collector. Renew. Sustain. Energy Rev. 2017, 67, 641–650. [Google Scholar] [CrossRef]

- Kalogirou, S.A.; Karellas, S.; Badescu, V.; Braimakis, K. Exergy analysis on solar thermal systems: A better understanding of their sustainability. Renew. Energy 2016, 85, 1328–1333. [Google Scholar] [CrossRef]

- Saidur, R.; Boroumandjazi, G.; Mekhlif, S.; Jameel, M. Exergy analysis of solar energy applications. Renew. Sustain. Energy Rev. 2012, 16, 350–356. [Google Scholar] [CrossRef]

- Park, S.R.; Pandey, A.K.; Tyagi, V.V.; Tyagi, S.K. Energy and exergy analysis of typical renewable energy systems. Renew. Sustain. Energy Rev. 2014, 30, 105–123. [Google Scholar] [CrossRef]

- Colangelo, G.; Favale, E.; Miglietta, P.; De Risi, A. Innovation in flat solar thermal collectors: A review of the last ten years experimental results. Renew. Sustain. Energy Rev. 2016, 57, 1141–1159. [Google Scholar] [CrossRef]

- MKareem, W.; Habib, K.; Ruslan, M.H.; Saha, B.B. Thermal performance study of a multi-pass solar air heating collector system for drying of Roselle (Hibiscus sabdariffa). Renew. Energy 2017, 113, 281–292. [Google Scholar] [CrossRef]

- Kareem, M.W.; Habib, K.; Sopian, K.; Ruslan, M.H. Multi-pass solar air heating collector system for drying of screw-pine leaf (Pandanustectorius). Renew. Energy 2017, 112, 413–424. [Google Scholar] [CrossRef]

- Suzuki, A. General theory of exergy-balance analysis and application to solar collector. Energy 1988, 13, 153–160. [Google Scholar] [CrossRef]

- Matlab Optimization Toolbox, (n.d.). Avalaible online: https://www.mathworks.com/products/optimization.html (accessed on 25 January 2018).

- Cengel, Y.A.; Boles, M.A. Thermodynamics an Engineering Approach, 5th ed.; McGraw-Hill: Boston, MA, USA, 2005. [Google Scholar]

- Padilla, R.V.; Fontalvo, A.; Demirkaya, G.; Martinez, A.; Quiroga, A.G. Exergy analysis of parabolic trough solar receiver. Appl. Therm. Eng. 2014, 67, 579–586. [Google Scholar] [CrossRef]

- Arora, A.; Kaushik, S.C. Theoretical analysis of a vapour compression refrigeration system with R502, R404A and R507A. Int. J. Refrig. 2008, 31, 998–1005. [Google Scholar] [CrossRef]

- Sukhatme, S.P. Solar Energy; McGraw-Hil: New York, NY, USA, 1993. [Google Scholar]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 2nd ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1980. [Google Scholar]

- Nag, P.K. Engineering Thermodynamics, 5th ed.; Tata McGraw-Hill Education: New York, NY, USA.

- Petela, R. Exergy of undiluted thermal radiation. Sol. Energy 2003, 74, 469–488. [Google Scholar] [CrossRef]

- Petela, R. Exergy of Heat Radiation. J. Heat Transf. 1964, 86, 187–192. [Google Scholar] [CrossRef]

| Parameter | Value | |

|---|---|---|

| Absorber plate material | : | Copper |

| Dimensions of the absorber plate: | : | 1 m × 0.6 m |

| Plate thickness | : | 0.2 mm |

| Serpentine pipe material | : | Copper |

| Serpentine pipe inner diameter | : | 10 mm |

| Serpentine pipe thickness | : | 1.5 mm |

| Glazing material | : | Tempered glass |

| Glazing dimensions | : | 1.05 m × 0.81 m |

| Glazing thickness | : | 5 mm |

| Insulation | : | Glass wool and cork sheet |

| Collector tilt angle | : | 27° |

| Thermal conductivity of absorber | : | 401 W/(m K) |

| Thermal conductivity of insulation | : | 0.04 W/(m K) |

| transmittance-absorptance product | : | 0.855 |

| Apparent sun temperature | : | 4350 K |

| Ambient temperature | : | 303 K |

| Irradiance | : | 900 W/m2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasan, M.F.; Mahadi, M.S.U.R.; Miyazaki, T.; Koyama, S.; Thu, K. Exergy Analysis of Serpentine Thermosyphon Solar Water Heater. Appl. Sci. 2018, 8, 391. https://doi.org/10.3390/app8030391

Hasan MF, Mahadi MSUR, Miyazaki T, Koyama S, Thu K. Exergy Analysis of Serpentine Thermosyphon Solar Water Heater. Applied Sciences. 2018; 8(3):391. https://doi.org/10.3390/app8030391

Chicago/Turabian StyleHasan, Muhammad Faisal, Md. Sayeed Ur Rahim Mahadi, Takahiko Miyazaki, Shigeru Koyama, and Kyaw Thu. 2018. "Exergy Analysis of Serpentine Thermosyphon Solar Water Heater" Applied Sciences 8, no. 3: 391. https://doi.org/10.3390/app8030391