A New Mixture Refrigerant for Space Heating Air Source Heat Pump: Theoretical Modelling and Performance Analysis

Abstract

:Featured Application

Abstract

1. Introduction

2. Methods

2.1. Mixture Refrigerant Proposal

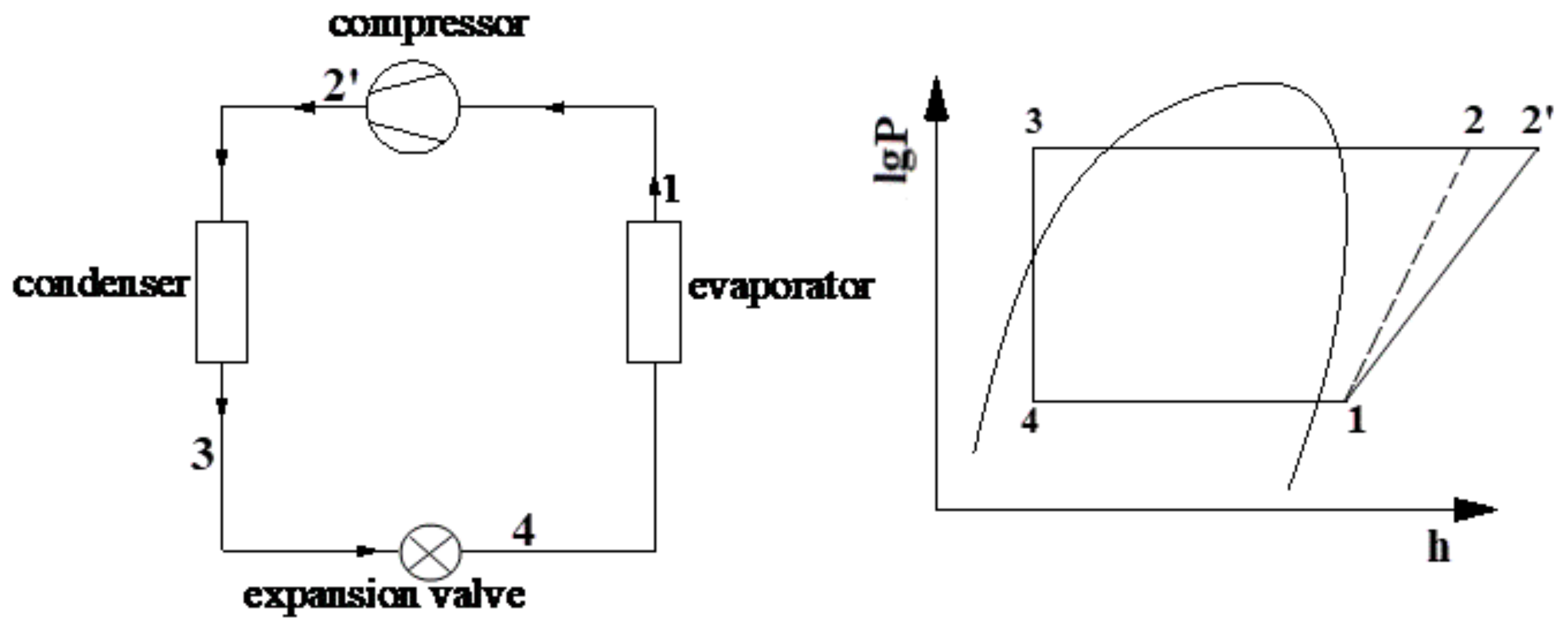

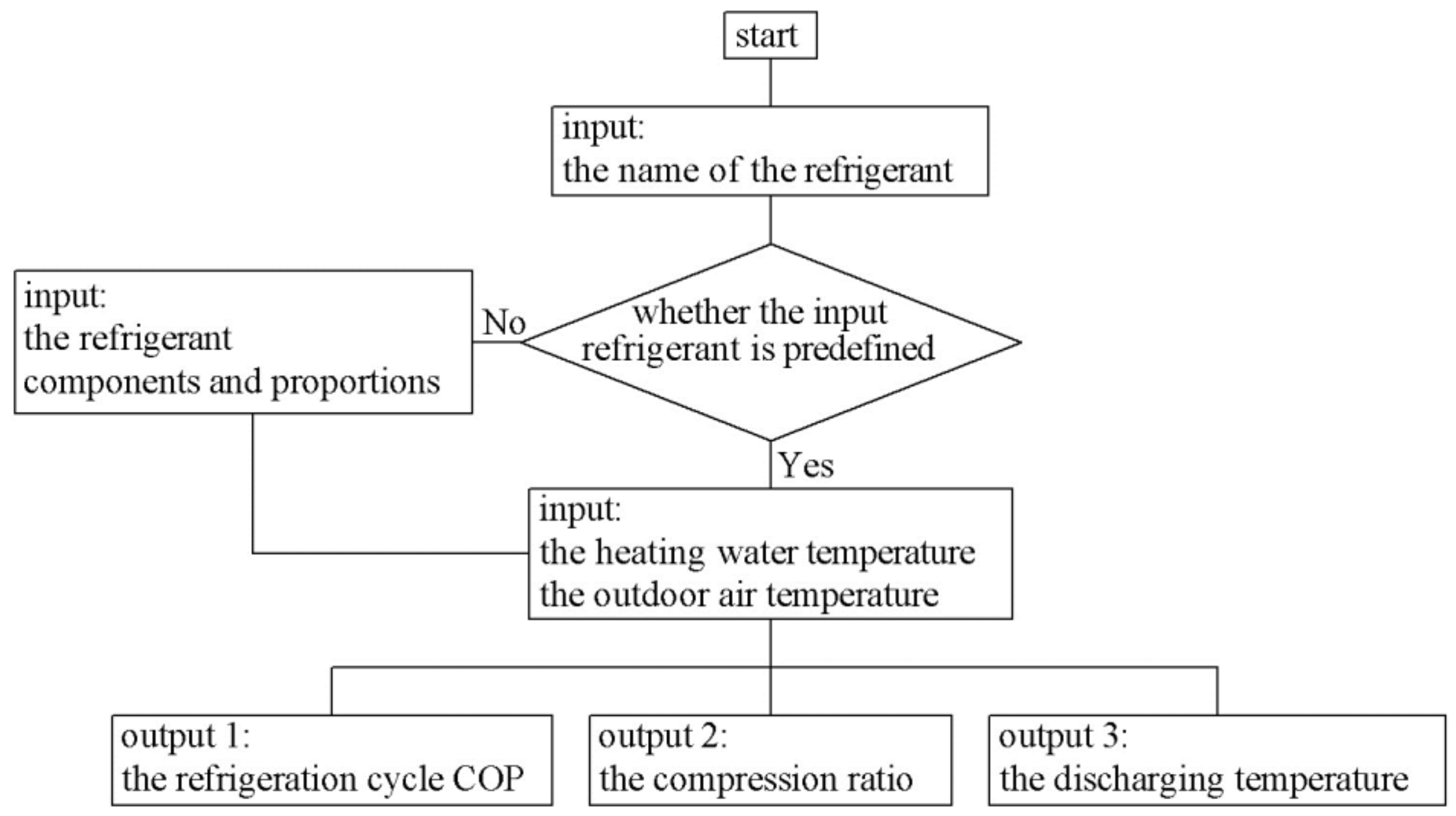

2.2. Theoretical Modelling and Simulation Tools

2.3. Case Design

3. Results

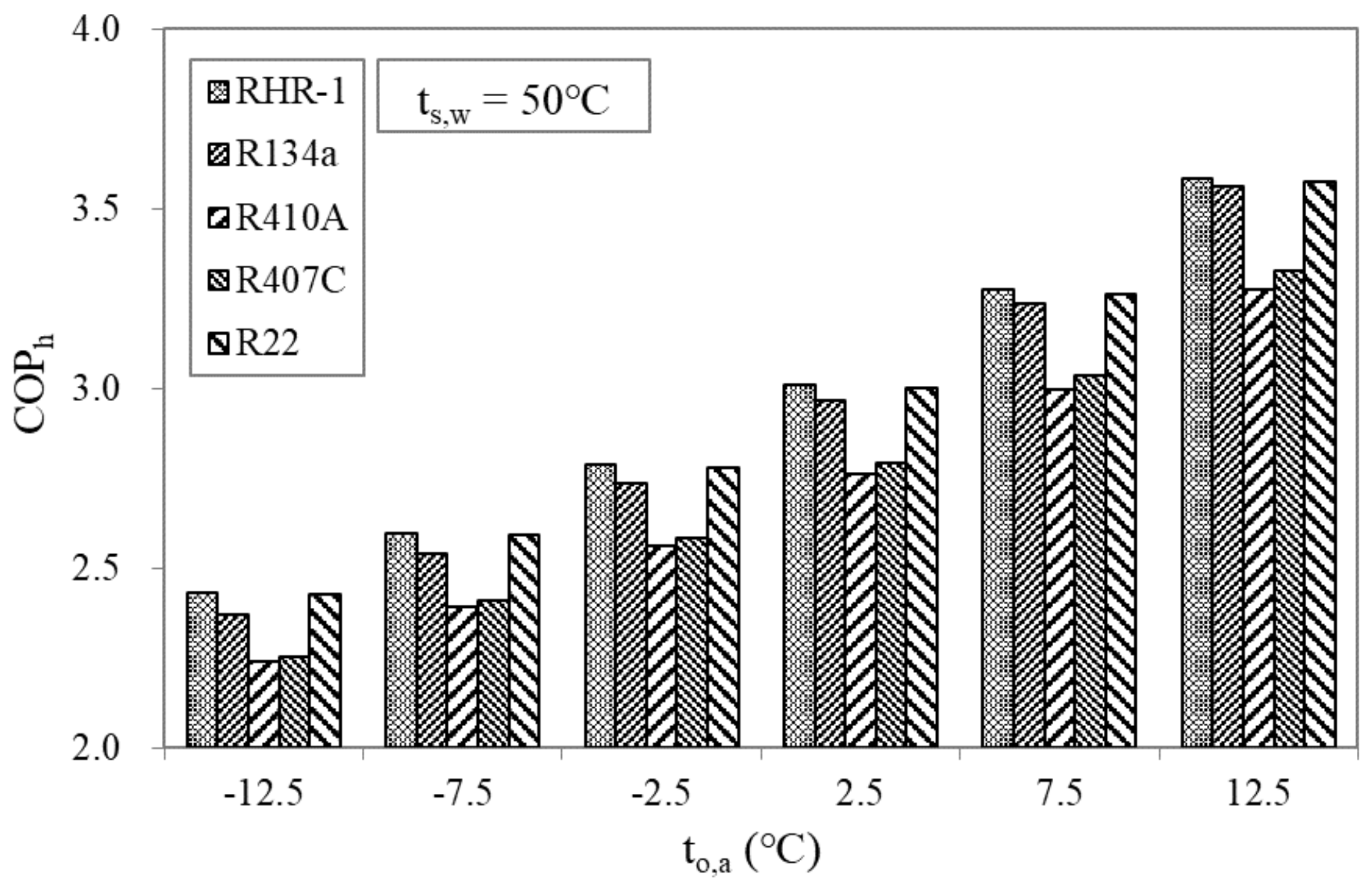

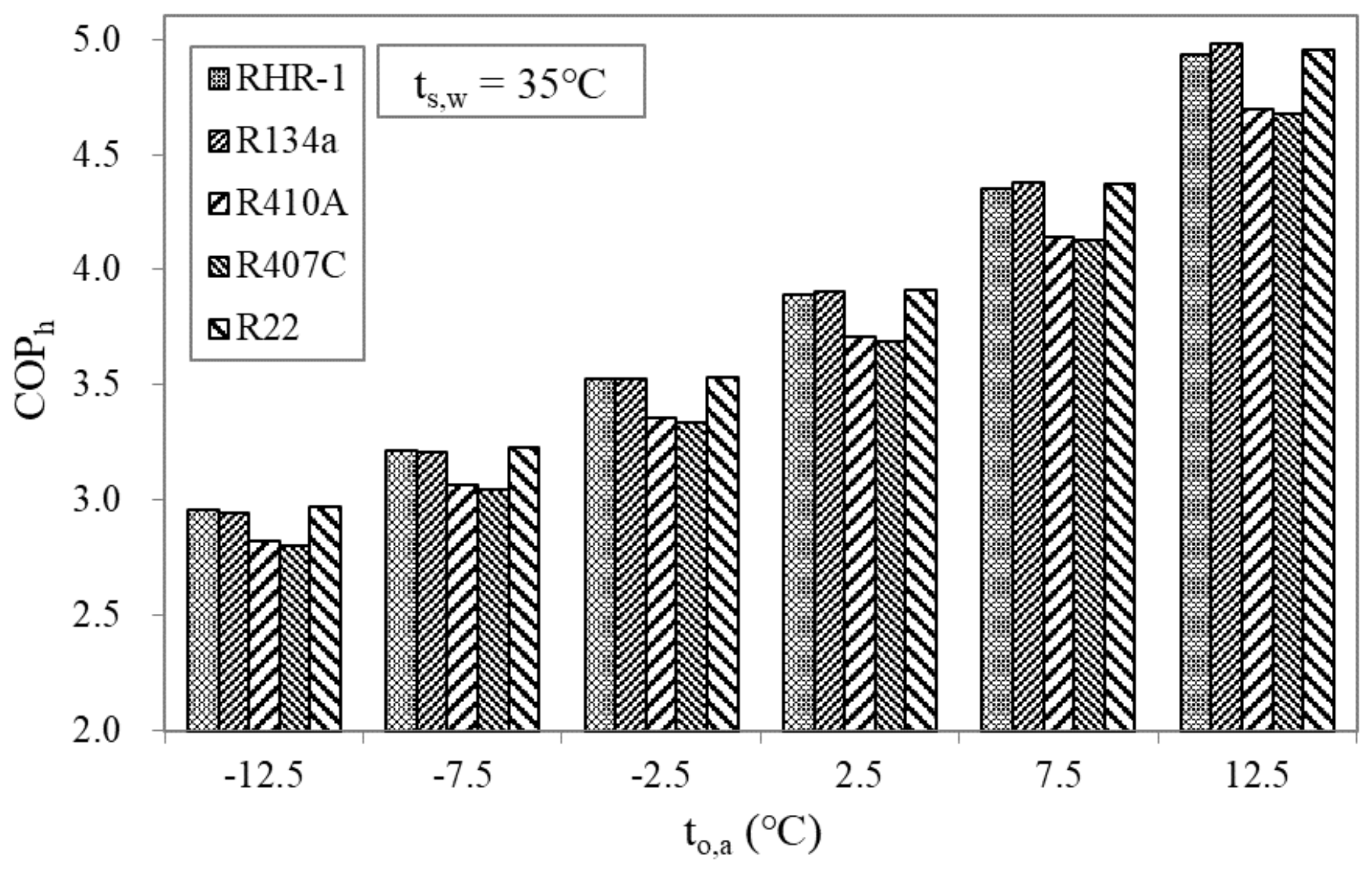

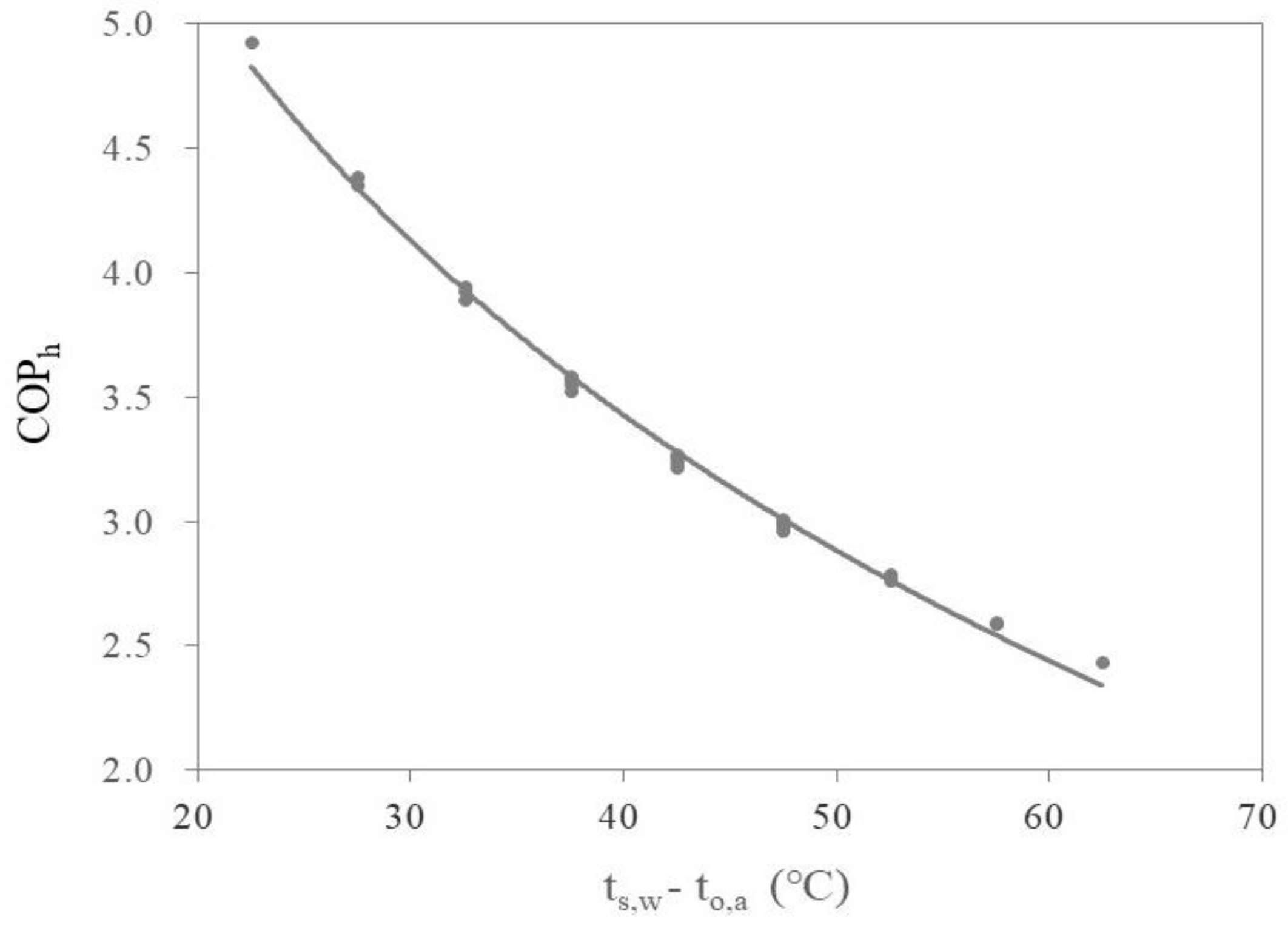

3.1. Heat Pump COPh

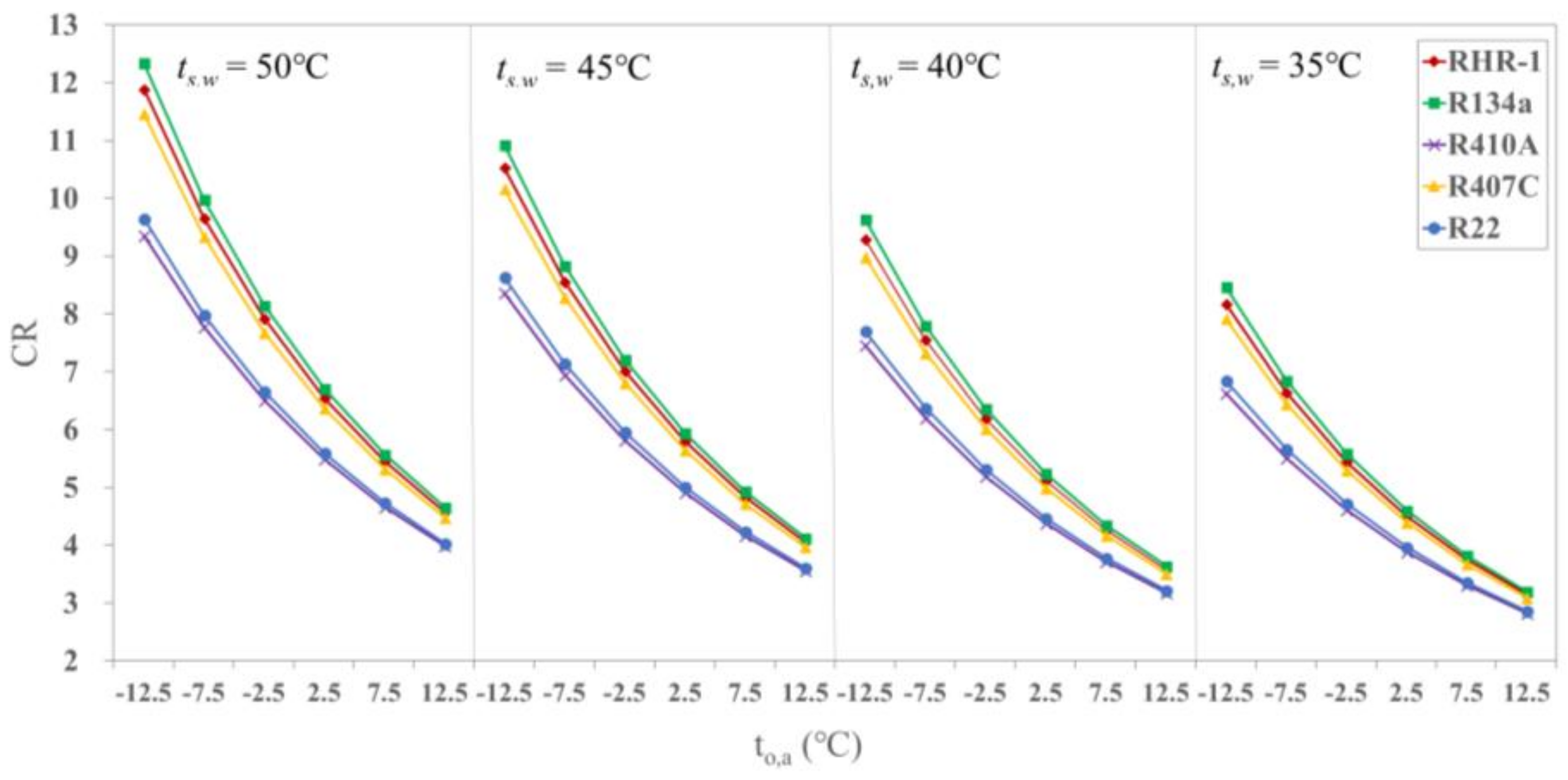

3.2. Compression Ratio

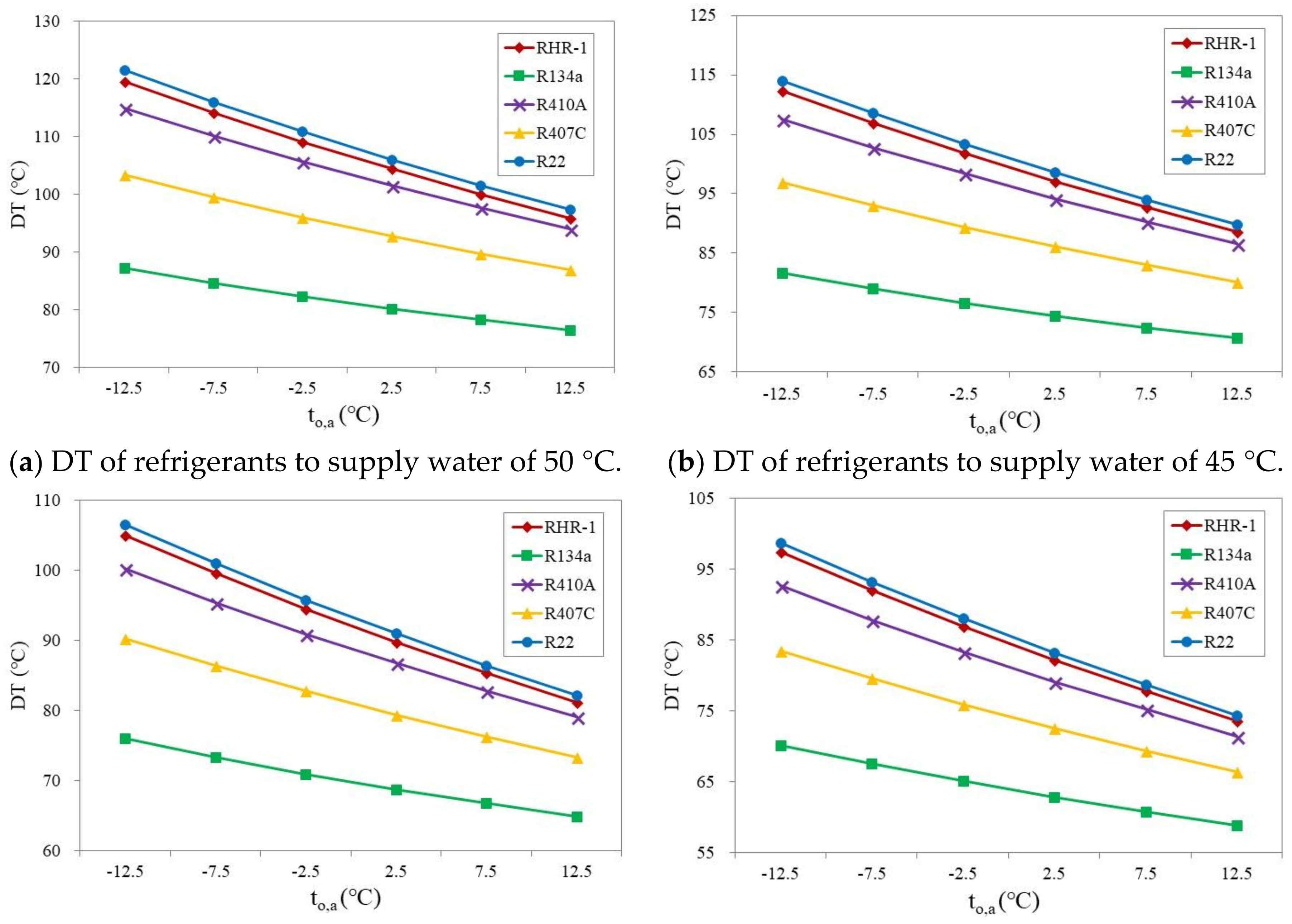

3.3. Refrigerant Discharging Temperature

4. Discussions

5. Conclusions

- RHR-1 has no ozone depletion potential and relatively low global warming potential compared to commonly used refrigerants including R134a, R410A, R407C and R22.

- The COPh of RHR-1 is in the range of 2.43–4.93, which is higher than other candidates in most design cases. The CR and DT of RHR-1 are in the middle levels among the compared refrigerants.

- RHR-1 might be a reasonable refrigerant in ASHP for space heating due to its high COPh, appropriate compression ratio and discharging temperature, no ODP and low GWP.

- According to the regression analysis, the temperature difference between outdoor air and supply water of ASHP using RHR-1 is suggested to be controlled within 47.5 °C to get a reasonable COPh.

- Constant water flow control strategy was suggested to improve the energy efficiency of air source heat pump units under partial heating load cases.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| COP | coefficient of performance |

| CR | compression ratio |

| DT | discharging temperature, °C |

| ODP | ozone depletion potential |

| GWP | global warming potential |

| h | enthalpy, kJ/kg |

| η | efficiency |

| t | temperature, °C |

| α | proportion of refrigerant |

| Subscripts | |

| o | outdoor |

| a | air |

| s | supply |

| w | water |

| is | isentropic |

| li | liquid |

| va | vapor |

| m | friction |

| d | engine transmission |

| e | motor |

References

- Chen, Y.; Shen, G.; Huang, Y.; Zhang, Y.; Han, Y.; Wang, R.; Shen, H.; Su, S.; Lin, N.; Zhu, D.; et al. Household air pollution and personal exposure risk of polycyclic aromatic hydrocarbons among rural residents in Shanxi, China. Indoor Air 2015, 26, 246–258. [Google Scholar] [CrossRef] [PubMed]

- Romieu, I.; Samet, J.M.; Smith, K.R.; Bruce, N. Outdoor air pollution and acute respiratory infections among children in developing countries. J. Occup. Environ. Med. 2002, 44, 640–649. [Google Scholar] [CrossRef] [PubMed]

- Smith, K.R.; Mehta, S. The burden of disease from indoor air pollution in developing countries: Comparison of estimates. Int. J. Hyg. Environ. Health 2003, 206, 279–289. [Google Scholar] [CrossRef] [PubMed]

- Chua, K.J.; Chou, S.K.; Yang, W.M. Advances in heat pump systems: A review. Appl. Energy 2010, 87, 3611–3624. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, L.; Nie, J.; Li, Y. Techno-economic analysis of air source heat pump applied for space heating in northern China. Appl. Energy 2017, 207, 533–542. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, Y.; Ma, L. Assessment for central heating systems with different heat sources: A case study. Energy Build. 2012, 48, 168–174. [Google Scholar] [CrossRef]

- Greening, B.; Azapagic, A. Domestic heat pumps: Life cycle environmental impacts and potential implications for the UK. Energy 2012, 39, 205–217. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, Q.; Li, B.; Fan, X.; Fu, Z. Application of an air source heat pump (ASHP) for heating in Harbin, the coldest provincial capital of China. Energy Build. 2017, 138, 96–103. [Google Scholar] [CrossRef]

- Poppi, S.; Bales, C.; Heinz, A.; Hengel, F.; Chèze, D.; Mojic, L.; Cialani, C. Analysis of system improvements in solar thermal and air source heat pump combisystems. Appl. Energy 2016, 173, 606–623. [Google Scholar] [CrossRef] [Green Version]

- Braun, D.; Rowley, P. Modelling the contribution of domestic heat pumps to delivering UK energy policy objectives. Appl. Sci. 2013, 3, 338–354. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, S.; Jin, X.; Yu, Y. Optimum compressor cylinder volume ratio for two-stage compression air source heat pump systems. Int. J. Refrig. 2016, 67, 77–89. [Google Scholar] [CrossRef]

- Li, Y.; Yu, J. Theoretical analysis on optimal configurations of heat exchanger and compressor in a two-stage compression air source heat pump system. Appl. Therm. Eng. 2015, 96, 682–689. [Google Scholar] [CrossRef]

- Xu, S.; Ma, G. Exergy analysis for quasi two-stage compression heat pump system coupled with ejector. Exp. Therm. Fluid Sci. 2011, 35, 700–705. [Google Scholar] [CrossRef]

- Peng, J.; Li, H.; Zhang, C. Performance comparison of air-source heat pump water heater with different expansion devices. Appl. Therm. Eng. 2016, 99, 1190–1200. [Google Scholar] [CrossRef]

- Zeng, J.; Li, N.; Cheng, J.; Zhang, Y.; Wang, C. Evaluation of the sensible heat storage air source heat pump for residential heating in central-south China. Energy Procedia 2016, 88, 703–708. [Google Scholar] [CrossRef]

- Jiang, Y.; Dong, J.; Qu, M.; Deng, S.; Yao, Y. A novel defrosting control method based on the degree of refrigerant superheat for air source heat pumps. Int. J. Refrig. 2013, 36, 2278–2288. [Google Scholar] [CrossRef]

- Touchie, M.F.; Pressnail, K.D. Testing and simulation of a low-temperature air source heat pump operating in a thermal buffer zone. Energy Build. 2014, 75, 149–159. [Google Scholar] [CrossRef]

- Hu, B.; Li, Y.; Cao, F.; Xing, Z. Extremum seeking control of COP optimization for air-source transcritical CO2 heat pump water heater system. Appl. Energy 2015, 147, 361–372. [Google Scholar] [CrossRef]

- Dai, N.; Xu, X.; Li, S.; Zhang, Z. Simulation of hybrid photovoltaic solar assisted loop heat pipe/heat pump system. Appl. Sci. 2017, 7, 197. [Google Scholar] [CrossRef]

- Seong, K.; Lee, D.; Lee, J. The effects of wet compression by the electronic expansion valve opening on the performance of a heat pump system. Appl. Sci. 2017, 7, 248. [Google Scholar] [CrossRef]

- Chen, W. A comparative study on the performance and environmental characteristics of R410A andR22 residential air conditioners. Appl. Therm. Eng. 2008, 28, 1–7. [Google Scholar] [CrossRef]

- Bolaji, B.O. Performance investigation of ozone-friendly R404A and R507refrigerants as alternatives to R22 in a window air-conditioner. Energy Build. 2011, 43, 3139–3143. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, F.; Ma, Z.; Song, M. Numerical study on the operating performances of a novel frost-freeair-source heat pump unit using three different types of refrigerant. Appl. Therm. Eng. 2017, 112, 248–258. [Google Scholar] [CrossRef]

- Fannou, J.L.C.; Rousseau, C.; Lamarche, L.; Kajl, S. A comparative performance study of adirect expansion geothermal evaporator using R410A and R407C as refrigerant alternatives to R22. Appl. Therm. Eng. 2015, 82, 306–317. [Google Scholar] [CrossRef]

- Cabello, R.; Torrella, E.; Navarro-Esbrí, J. Experimental evaluation of a vapour compression plant performance using R134a, R407C and R22 as working fluids. Appl. Therm. Eng. 2004, 24, 1905–1917. [Google Scholar] [CrossRef]

- Han, X.; Qiu, Y.; Xu, Y.; Zhao, M.; Wang, Q.; Chen, G. Cycle performance studies on a new HFC-161/125/143a mixture as an alternative refrigerant to R404A. Appl. Phys. Eng. 2012, 13, 132–139. [Google Scholar] [CrossRef]

- Ln, S.; Cho, K.; Lim, B.; Lee, C. Partial load performance test of residential heat pump system with low-GWP refrigerants. Appl. Therm. Eng. 2015, 85, 179–187. [Google Scholar] [CrossRef]

- Mota-Babiloni, A.; Navarro-Esbri, J.; Barragán, Á.; Molés, F.; Peris, B. Theoretical comparison of low GWP alternatives for different refrigeration configurations taking R404A as baseline. Int. J. Refrig. 2014, 44, 81–90. [Google Scholar] [CrossRef]

- Devecioglu, A.G. Seasonal performance assessment of refrigerants with low GWP as substitutes for R410A in heat pump air conditioning devices. Appl. Therm. Eng. 2017, 125, 401–411. [Google Scholar] [CrossRef]

- Tian, Q.; Cai, D.; Ren, L.; Tang, W.; Xie, Y.; He, G.; Liu, F. An experimental investigation of refrigerant mixture R32/R290 as drop-in replacement for HFC410A in household air conditioners. Int. J. Refrig. 2015, 57, 216–228. [Google Scholar] [CrossRef]

- Alabdulkarem, A.; Eldeeb, R.; Hwang, Y.; Aute, V.; Radermacher, R. Testing, simulation and soft-optimization of R410 low-GWP alternatives in heat pump system. Int. J. Refrig. 2015, 60, 106–117. [Google Scholar] [CrossRef]

- Hakkaki-Fard, A.; Aidoun, Z.; Ouzzane, M. Research paper: Improving cold climate air-source heat pump performance with refrigerant mixtures. Appl. Therm. Eng. 2015, 78, 695–703. [Google Scholar] [CrossRef]

- Devotta, S.; Padalkar, A.S.; Mali, K.V. Low GWP refrigerants as alternatives to HCFC-22 in room air conditioners. Sci. Technol. Built Environ. 2016, 22, 1128–1135. [Google Scholar] [CrossRef]

- Ma, G.; Zhang, C.; Ding, Y.; Li, B. A study on the use of dual mixed refrigerant in a cascade dual mixed refrigerant cycle. Adv. Mech. Eng. 2017, 9. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, H.; Zhang, Q.; Qiu, J.; Rui, S. The study of thermodynamic properties of zeotropic mixtures of R600a/R23/R14. Adv. Mech. Eng. 2017, 9. [Google Scholar] [CrossRef]

- Dipippo, R. Geothermal Power Plants, 2nd ed.; Butterworth-Heinemann Press: Oxford, UK, 2008; ISBN 978-0-7506-8620-4. [Google Scholar]

- Calm, J.M.; Hourahan, G.C. Physical, safety, and environmental data for current and alternative refrigerants. In Proceedings of the 23rd International Congress of Refrigeration, Prague, Czech, 21–26 August 2011; pp. 4120–4141. [Google Scholar]

- Nie, J.; Fang, L.; Zhang, G.; Sheng, Y.; Kong, X.; Zhang, Y.; Olesen, B.W. Theoretical study on volatile organic compound purification and energy performance of a novel heat pump assisted solid desiccant cooling system. Build. Environ. 2015, 85, 233–242. [Google Scholar] [CrossRef]

| Items | RHR-1 | R134a | R410A | R407C | R22 |

|---|---|---|---|---|---|

| Molecular weight (g mol−1) | 62.54 | 102.03 | 72.58 | 86.20 | 86.47 |

| Critical temperature (°C) | 101.2 | 101.1 | 71.4 | 86 | 96.1 |

| Critical pressure (MPa) | 5.18 | 4.06 | 4.90 | 4.63 | 4.99 |

| Critical density (kg m−3) | 377 | 512 | 489 | 527 | 526 |

| Boiling point at 101.3 kPa (°C) | −51.7 to −24 | −26.1 | −51.4 | −43.6 | −40.8 |

| Toxicity/Flammability | A2 | A1 | A1 | A1 | A1 |

| ODP a | 0 | 0 | 0 | 0 | 0.04 |

| GWP (100 year) b | 279 | 1370 | 2100 | 1700 | 1790 |

| Class No. | Outdoor Air Temperature Range (°C) | Representative Outdoor Air Temperature (°C) | Number of Hours (h) |

|---|---|---|---|

| Class 1 | −15 to −10 | −12.5 | 38 |

| Class 2 | −10 to −5 | −7.5 | 504 |

| Class 3 | −5–0 | −2.5 | 1020 |

| Class 4 | 0–5 | 2.5 | 871 |

| Class 5 | 5–10 | 7.5 | 356 |

| Class 6 | 10–15 | 12.5 | 98 |

| Outdoor Air Temperature (°C) | Supply Water Temperature (°C) | |||

|---|---|---|---|---|

| −12.5 | 35 | 40 | 45 | 50 |

| −7.5 | 35 | 40 | 45 | 50 |

| −2.5 | 35 | 40 | 45 | 50 |

| 2.5 | 35 | 40 | 45 | 50 |

| 7.5 | 35 | 40 | 45 | 50 |

| 12.5 | 35 | 40 | 45 | 50 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, X.; Zhang, Y.; Nie, J. A New Mixture Refrigerant for Space Heating Air Source Heat Pump: Theoretical Modelling and Performance Analysis. Appl. Sci. 2018, 8, 622. https://doi.org/10.3390/app8040622

Kong X, Zhang Y, Nie J. A New Mixture Refrigerant for Space Heating Air Source Heat Pump: Theoretical Modelling and Performance Analysis. Applied Sciences. 2018; 8(4):622. https://doi.org/10.3390/app8040622

Chicago/Turabian StyleKong, Xiangrui, Yufeng Zhang, and Jinzhe Nie. 2018. "A New Mixture Refrigerant for Space Heating Air Source Heat Pump: Theoretical Modelling and Performance Analysis" Applied Sciences 8, no. 4: 622. https://doi.org/10.3390/app8040622