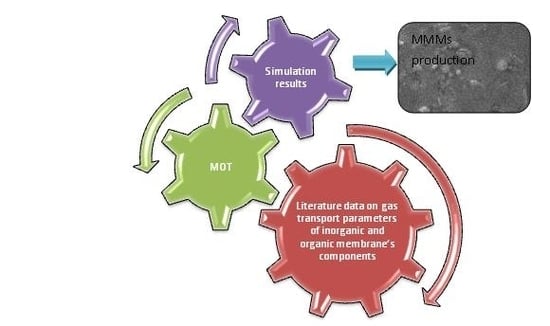

Modeling of Gas Permeation through Mixed-Matrix Membranes Using Novel Computer Application MOT

Abstract

:1. Introduction

2. Materials and Methods

2.1. Maxwell Model

- D1—a diffusion coefficient of gas penetrant no. 1 (cm2/s), and

- S1—a sorption coefficient of gas penetrant no. 1 (cm3STP/ cm3cmHg).

- Pr—relative permeability of gas components,

- P—effective permeability of gas components in MMM (Barrer), ,

- Pm—permeability of gas components in a polymer matrix (continuous phase) (Barrer),

- Φ—volume fraction of filler particles,

- λdm—Pd/Pm permeability ratio, and

- Pd—permeability of components in the dispersed phase.

2.2. Materials

2.3. Synthesis of HBPI and Zeolite 4A-HBPI Mixed-Matrix Membranes

2.4. Characterization of Mixed-Matrix Membranes

3. Results and Discussion

- main window for model selection (Figure 2). Individual models are selected from the combo box.

- the additional tools, such as the diffusion and sorption coefficient calculator, as well as the ability to add the user’s experimental data, are located in the More options menu (Figure 4).

- —number of data points,

- —estimated value, and

- —experimental value.

- Pi—the permeability of the more permeable gas,

- α—the selectivity coefficient (Pi/Pj), and

- n—the slope of the log–log limit.

- Φs—the volume fraction of filler core particle in the combined volume of core and interfacial shell (in a single core–shell particle),

- PI—the permeability of the gas penetrant in the interfacial shell, and

- Peff—the effective permeability of a gas penetrant in a single core–shell particle.

- Φ—the volume fraction of total dispersed phase (core–shell particles) in the whole membrane, and

- Pm—the permeability of gas components in a polymer matrix (Barrer).

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhao, L.; Primabudi, E.; Stolten, D. Investigation of a Hybrid System for Post-Combustion Capture. Energy Procedia 2014, 63, 1756–1772. [Google Scholar] [CrossRef]

- Olajire, A.A. CO2 capture and separation technologies for end-of-pipe applications. Energy 2010, 35, 2610–2628. [Google Scholar] [CrossRef]

- Minko, E.; Sysel, P.; Hauf, M.; Brus, J.; Kobera, L. Synthesis and properties of hyperbranched polyimides combined with silica. Macromol. Symp. 2010, 295, 88–93. [Google Scholar] [CrossRef]

- Fang, J.; Hidetoshi, K.; Okamoto, K. Hyperbranched Polyimides for Gas Separation Applications. 1. Synthesis and Characterization. Macromolecules 2000, 33, 4639–4646. [Google Scholar] [CrossRef]

- Vu, D.Q.; Koros, W.J.; Miller, S.J. Mixed-matrix membranes using carbon molecular sieves: I. Preparation and experimental results. J. Membr. Sci. 2003, 211, 311–334. [Google Scholar] [CrossRef]

- Krystl, V.; Hradil, J.; Bernauer, B.; Kocirık, M. Heterogeneous membranes based on zeolites for separation of small molecules. React. Funct. Polym. 2001, 48, 129–139. [Google Scholar] [CrossRef]

- Ionita, M.; Vasile, E.; Crica, L.E.; Voicu, S.I.; Pandele, A.M.; Dinescu, S.; Predoiu, L.; Galateanu, B.; Hermenean, A.; Costache, M. Synthesis, characterization and in vitro studies of polysulfone/graphene oxide composite membranes. Compos. Part B-Eng. 2015, 72, 108–115. [Google Scholar] [CrossRef]

- Ahmad, A.L.; Jawad, Z.A.; Low, S.C.; Zein, S.H.S. A cellulose acetate/multi-walled carbon nanotubes mixed-matrix membrane for CO2/N2 separation. J. Membr. Sci. 2014, 451, 55–66. [Google Scholar] [CrossRef]

- Vinh-Thang, H.; Kaliaguine, S. Predictive Models for Mixed-Matrix Membrane Performance: A Review. Chem. Rev. 2013, 113, 4980–5028. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Pan, Q.; Li, M.; Fu, S. Preparation and mechanical properties of novel polyimide/T-silica hybrid films. Compos. Sci. Technol. 2007, 67, 54–60. [Google Scholar] [CrossRef]

- Huang, J.; Li, X.; Luo, L.; Wang, H.; Wang, X.; Li, K.; Zhang, C.; Liu, X. Releasing silica-confined macromolecular crystallization to enhance mechanical properties of polyimide/silica hybrid fibers. Compos. Sci. Technol. 2014, 101, 24–31. [Google Scholar] [CrossRef]

- Suzuki, T.; Yamada, Y. Physical and gas transport properties of novel hyperbranched polyimide/silica hybrid membranes. Polym. Bull. 2005, 53, 139. [Google Scholar] [CrossRef]

- Chung, T.S.; Jiang, L.Y.; Li, Y.; Kulprathipanja, S. Mixed-matrix membranes comprising organic polymers with dispersed inorganic fillers for gas separation. Prog. Polym. Sci. 2007, 32, 483. [Google Scholar] [CrossRef]

- Xin, Q.; Gao, Y.; Wu, X.; Li, C.; Liu, T.; Shi, Y.; Li, Y.; Jiang, Z.; Wu, H.; Cao, X. Incorporating one-dimensional aminated titania nanotubes into sulfonated poly (ether ether ketone) membrane to construct CO2-facilitated transport pathways for enhanced CO2 separation. J. Membr. Sci. 2015, 488, 13–29. [Google Scholar] [CrossRef]

- Wu, B.; Li, X.; An, D.; Zhao, S.; Wang, Y. Electro-casting aligned MWCNTs/polystyrene composite membranes for enhanced gas separation performance. J. Membr. Sci. 2014, 462, 62–68. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Z.; Li, N.; Liao, J.; Zhao, S.; Wang, J.; Wang, S. Relationship between polymer–filler interfaces in separation layers and gas transport properties of mixed matrix composite membranes. J. Membr. Sci. 2015, 495, 252–268. [Google Scholar] [CrossRef]

- Cong, H.; Zhang, J.; Radosz, M.; Shen, Y. Carbon nanotube composite membranes of brominated poly(2,6-diphenyl-1,4-phenylene oxide) for gas separation. J. Membr. Sci. 2007, 294, 178–185. [Google Scholar] [CrossRef]

- Oueiny, C.; Berlioz, S.; Perrin, F.-X. Carbon nanotube–polyaniline composites. Prog. Polym. Sci. 2014, 39, 707–748. [Google Scholar] [CrossRef]

- Petropoulos, J.H. A comparative study of approaches applied to the permeability of binary composite polymeric materials. J. Polym. Sci. Pol. Phys. 1985, 23, 1309–1324. [Google Scholar] [CrossRef]

- Rybak, A.; Kaszuwara, W. Magnetic properties of the magnetic hybrid membranes based on various polymer matrices and inorganic fillers. J. Alloys Compd. 2015, 648, 205–214. [Google Scholar] [CrossRef]

- Rybak, A.; Grzywna, Z.J.; Sysel, P. Mixed-matrix membranes composed of various polymer matrices and magnetic powder for air separation. Sep. Purif. Technol. 2013, 118, 424–431. [Google Scholar] [CrossRef]

- Rybak, A.; Rybak, Au.; Kaszuwara, W.; Awietjan, S.; Molak, R.; Sysel, P.; Grzywna, Z.J. The magnetic inorganic–organic hybrid membranes based on polyimide matrices for gas separation. Compos. B Eng. 2017, 110, 161–170. [Google Scholar] [CrossRef]

- Rybak, A.; Rybak, Au.; Kaszuwara, W.; Awietjan, S.; Jaroszewicz, J. The rheological and mechanical properties of magnetic hybrid membranes for gas mixtures separation. Mater. Lett. 2016, 183, 170–174. [Google Scholar] [CrossRef]

- Rybak, A.; Rybak, A.; Kaszuwara, W.; Awietjan, S.; Sysel, P.; Grzywna, Z.J. The studies on novel magnetic polyimide inorganic–organic hybrid membranes for air separation. Mater. Lett. 2017, 208, 14–18. [Google Scholar] [CrossRef]

- Rybak, A.; Dudek, G.; Krasowska, M.; Strzelewicz, A.; Grzywna, Z.J.; Sysel, P. Magnetic mixed-matrix membranes in the air separation. Chem. Pap. 2014, 68, 1332–1340. [Google Scholar] [CrossRef]

- Rybak, A.; Dudek, G.; Krasowska, M.; Strzelewicz, A.; Grzywna, Z.J. Magnetic mixed-matrix membranes consisting of PPO matrix and magnetic filler in gas separation. Sep. Sci. Technol. 2014, 49, 1729–1735. [Google Scholar] [CrossRef]

- Rybak, A.; Rybak, Au.; Kaszuwara, W.; Boncel, S. Poly (2,6-dimethyl-1,4-phenylene oxide) hybrid membranes filled with magnetically aligned iron-encapsulated carbon nanotubes (Fe@MWCNTs) for enhanced air separation. Diam. Relat. Mater. 2018, 83, 21–29. [Google Scholar] [CrossRef]

- Pal, R. Permeation models for mixed-matrix membranes. J. Colloid Interface Sci. 2008, 317, 191–198. [Google Scholar] [CrossRef] [PubMed]

- Vu, D.Q.; Koros, W.J.; Miller, S.J. Mixed-matrix membranes using carbon molecular sieves II. Modeling permeation behavior. J. Membr. Sci. 2003, 211, 335–348. [Google Scholar] [CrossRef]

- Shimekit, B.; Mukhtar, H.; Murugesan, T. Prediction of the relative permeability of gases in mixed-matrix membranes. J. Membr. Sci. 2011, 373, 152–159. [Google Scholar] [CrossRef]

- Bouma, H.B.; Checchetti, A.; Chidichimo, G.; Drioli, E. Permeation through a heterogeneous membrane: the effect of the dispersed phase. J. Membr. Sci. 1997, 128, 141–149. [Google Scholar] [CrossRef]

- Maxwell, J.C. A Treatise on Electricity and Magnetism, 3rd ed.; Dover: New York, NY, USA, 1954. [Google Scholar]

- Zhang, C.; Dai, Y.; Johnson, J.R.; Karvan, O.; Koros, W.J. High performance ZIF-8/6FDA-DAM mixed-matrix membrane for propylene/propane separations. J. Membr. Sci. 2012, 389, 34–42. [Google Scholar] [CrossRef]

- Petropoulos, J.H.; Papadokostaki, K.G.; Doghieri, F.; Minelli, M. A fundamental study of the extent of meaningful application of Maxwell’s and Wiener’s equations to the permeability of binary composite materials. Part III: Extension of the binary cubes model to 3-phase media. Chem. Eng. Sci. 2015, 131, 360–366. [Google Scholar] [CrossRef]

- Di Maio, F.P.; Santaniello, A.; Di Renzo, A.; Golemme, G. Description of gas transport in perfluoropolymer/SAPO-34 mixed-matrix membranes using four-resistance model. Sep. Purif. Technol. 2017, 185, 160–174. [Google Scholar] [CrossRef]

- Pakizeh, M.; Ofoghi, S.; Shooshtari, S.H.R. Modeling of gas permeation through mixed-matrix membranes using a comprehensive computational method. Korean J. Chem. Eng. 2016, 33, 3194–3202. [Google Scholar] [CrossRef]

- Hasebe, S.; Aoyama, S.; Tanaka, M.; Kawakami, H. CO2 separation of polymer membranes containing silica nanoparticles with gas permeable nano-space. J. Membr. Sci. 2017, 536, 148–155. [Google Scholar] [CrossRef]

- Xiang, L.; Pan, Y.; Jiang, J.; Chen, Y.; Chen, J.; Zhang, L.; Wang, C. Thin poly (ether-block-amide)/attapulgite composite membranes with improved CO2 permeance and selectivity for CO2/N2 and CO2/CH4. Chem. Eng. Sci. 2017, 160, 236–244. [Google Scholar] [CrossRef]

- Mahajan, R.; Koros, W.J. Mixed-matrix membrane Materials with Glassy Polymers. Part 2. Polym. Eng. Sci. 2002, 42, 1432–1441. [Google Scholar] [CrossRef]

- Mahajan, R.; Burns, R.; Schaeffer, M.; Koros, W.J. Challenges in Forming Successful Mixed-matrix membranes with Rigid Polymeric Materials. J. Appl. Polym. Sci. 2002, 86, 881–890. [Google Scholar] [CrossRef]

- Mahajan, R.; Koros, W.J. Factors Controlling Successful Formation of Mixed-Matrix Gas Separation Materials. Ind. Eng. Chem. Res. 2000, 39, 2692–2696. [Google Scholar] [CrossRef]

- Najafi, M.; Sadeghi, M.; Bolverdi, A.; Chenar, M.P.; Pakizeh, M. Gas permeation properties of cellulose acetate/silica nanocomposite membrane. Adv. Polym. Technol. 2017, 1–10. [Google Scholar] [CrossRef]

- Ghemaisi, K.M.; Peydayesh, M.; Mohammadi, T.; Bakhtiari, O. Prediction of CO2/CH4 permeability through Sigma-1–Matrimid®5218 MMMs using the Maxwell model. J. Membr. Sci. 2014, 466, 265–273. [Google Scholar] [CrossRef]

- Vinh-Thang, H.; Kaliaguine, S. A comprehensive computational strategy for fitting experimental permeation data of mixed-matrix membranes. J. Membr. Sci. 2014, 452, 271–276. [Google Scholar] [CrossRef]

- Hashemifard, S.A.; Ismail, A.F.; Matsuura, T. Prediction of gas permeability in mixed-matrix membranes using theoretical models. J. Membr. Sci. 2010, 347, 53–61. [Google Scholar] [CrossRef]

- Hussain, M.; König, A. Mixed-Matrix Membrane for Gas Separation: Polydimethylsiloxane Filled with Zeolite. Chem. Eng. Technol. 2012, 35, 561–569. [Google Scholar] [CrossRef]

- Shen, Y.; Lua, A.C. Theoretical and experimental studies on the gas transport properties of mixed-matrix membranes based on polyvinylidene fluoride. AIChE J. 2013, 59, 4715–4726. [Google Scholar] [CrossRef]

- Witkowska, D. Basics of Econometrics and Forecasting, 2nd ed.; Economic Publishing House: Krakow, Poland, 2006; ISBN 83-7484-029-3. [Google Scholar]

- Gruszczyński, M.; Podgórska, M. Econometrics, 7th ed.; SGH Publishing House: Warsaw, Poland, 2007; ISBN 83-8668-952-8. [Google Scholar]

- Robeson, L.M.; Freeman, B.D.; Paul, D.R.; Rowe, B.W. An empirical correlation of gas permeability and permselectivity in polymers and its theoretical basis. J. Membr. Sci. 2009, 341, 178–185. [Google Scholar] [CrossRef]

- Fernández-Barquín, A.; Casado-Coterillo, C.; Palomino, M.; Valencia, S.; Irabien, A. LTA/Poly (1-trimethylsilyl-1-propyne) Mixed-Matrix Membranes for High-Temperature CO2/N2 Separation. Chem. Eng. Technol. 2015, 38, 658–666. [Google Scholar] [CrossRef]

- Casado-Coterillo, C.; Fernández-Barquín, A.; Zornoza, B.; Tellez, C.; Coronas, J.; Irabien, A. Synthesis and characterisation of MOF/ionic liquid/chitosan mixed-matrix membranes for CO2/N2 separation. RSC Adv. 2015, 5, 102350–102361. [Google Scholar] [CrossRef]

| Membrane | Φ | Experimental Data | Theoretical Data | AARE (%) | RMSE (%) | ||

|---|---|---|---|---|---|---|---|

| αO2/N2 | PO2 (Barrer) | αO2/N2 | PO2 (Barrer) | ||||

| M1 | 0.20 | 9.50 | 0.47 | 9.40 | 0.55 | 30 | 15 |

| M2 | 0.30 | 10.70 | 0.40 | 10.87 | 0.57 | ||

| M3 | 0.40 | 12.45 | 0.37 | 12.63 | 0.60 | ||

| Membrane | Φ | Experimental Data | Theoretical Data | AARE (%) | RMSE (%) | ||

|---|---|---|---|---|---|---|---|

| αO2/N2 | PO2 (Barrer) | αO2/N2 | PO2 (Barrer) | ||||

| M1 | 0.15 | 9.70 | 0.38 | 9.73 | 0.43 | 29 | 10 |

| M2 | 0.35 | 12.85 | 0.28 | 13.09 | 0.49 | ||

| Membrane | Φ | Experimental data | Theoretical data | AARE (%) | RMSE (%) | ||

|---|---|---|---|---|---|---|---|

| αO2/N2 | PO2 (Barrer) | αO2/N2 | PO2 (Barrer) | ||||

| M1 | 0.15 | 7.50 | 0.45 | 7.40 | 0.54 | 36 | 29 |

| M2 | 0.25 | 8.40 | 0.40 | 8.65 | 0.56 | ||

| M3 | 0.40 | 10.10 | 0.32 | 11.03 | 0.60 | ||

| Membrane | Φ | Experimental Data | Theoretical Data | AARE (%) | RMSE (%) | ||

|---|---|---|---|---|---|---|---|

| αO2/N2 | PO2 (Barrer) | αO2/N2 | PO2 (Barrer) | ||||

| M1 | 0.15 | 7.35 | 0.56 | 7.11 | 0.66 | 31 | 18 |

| M2 | 0.20 | 7.87 | 0.53 | 7.62 | 0.67 | ||

| M3 | 0.25 | 8.38 | 0.51 | 8.18 | 0.67 | ||

| M4 | 0.30 | 8.89 | 0.48 | 8.80 | 0.67 | ||

| M5 | 0.35 | 9.41 | 0.45 | 9.48 | 0.68 | ||

| M6 | 0.40 | 9.92 | 0.42 | 10.23 | 0.69 | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rybak, A.; Rybak, A.; Sysel, P. Modeling of Gas Permeation through Mixed-Matrix Membranes Using Novel Computer Application MOT. Appl. Sci. 2018, 8, 1166. https://doi.org/10.3390/app8071166

Rybak A, Rybak A, Sysel P. Modeling of Gas Permeation through Mixed-Matrix Membranes Using Novel Computer Application MOT. Applied Sciences. 2018; 8(7):1166. https://doi.org/10.3390/app8071166

Chicago/Turabian StyleRybak, Aurelia, Aleksandra Rybak, and Petr Sysel. 2018. "Modeling of Gas Permeation through Mixed-Matrix Membranes Using Novel Computer Application MOT" Applied Sciences 8, no. 7: 1166. https://doi.org/10.3390/app8071166