The Assessment of Possibility of Using Sanitary Ceramic Waste as Concrete Aggregate—Determination of the Basic Material Characteristics

Abstract

:1. Introduction

2. Materials and Methods

Characteristics of Concrete Mix

3. Results

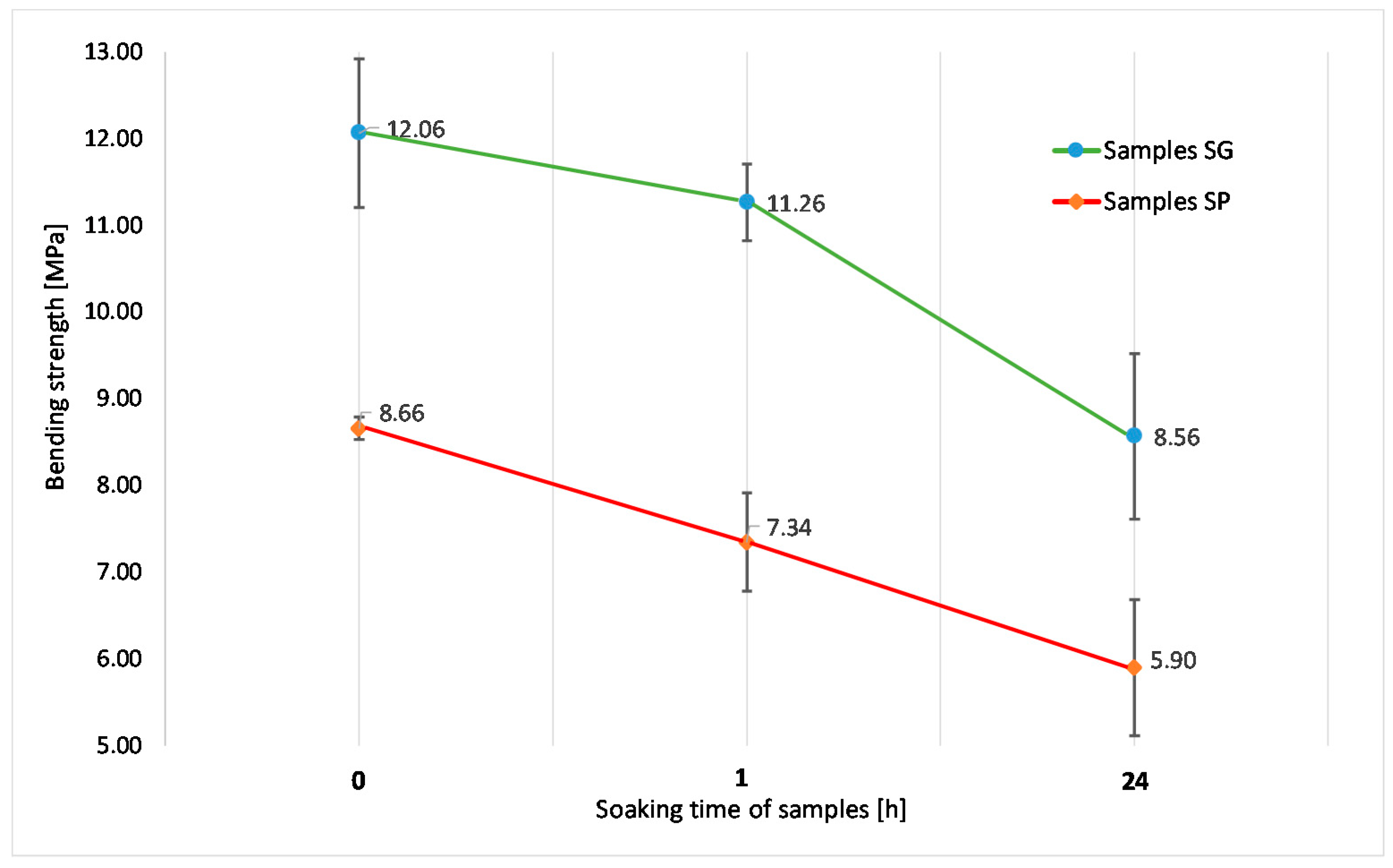

3.1. Compressive and Bending Strength

- frame with pressure up to 3000 kN for testing the compressive strength of concrete elements with maximum dimensions of 200 × 200 × 200 mm

- frame with pressure up to 250 kN for testing the strength of mortars for bending (samples 40 × 40 × 160 mm),

- frame with pressure up to 250 kN for testing the compressive strength of mortars, as well as elements with maximum dimensions of 100 × 100 × 100 mm (e.g., standard samples of cellular concrete).

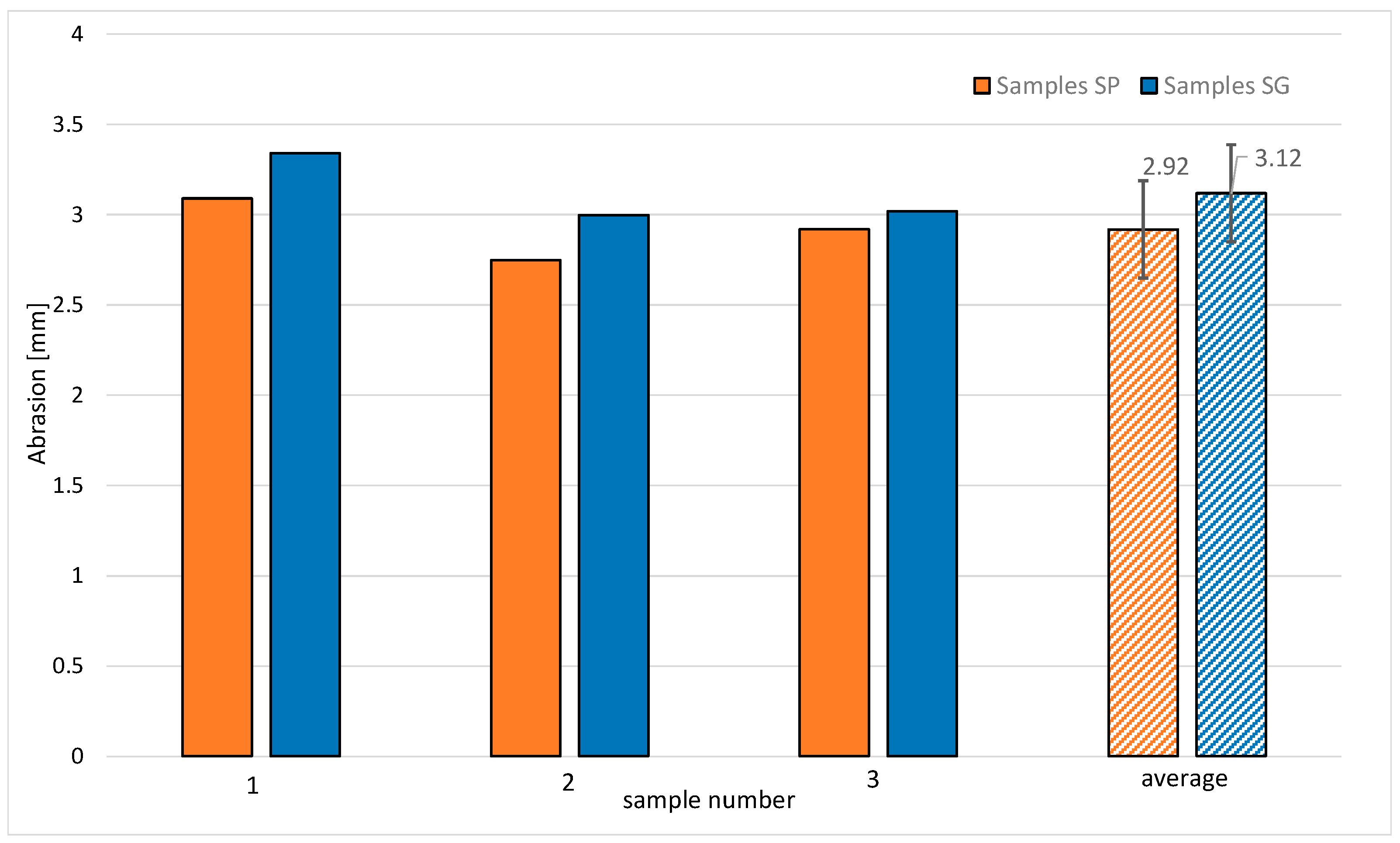

3.2. Resistance to Abrasion

3.3. Frost Resistance of Concrete

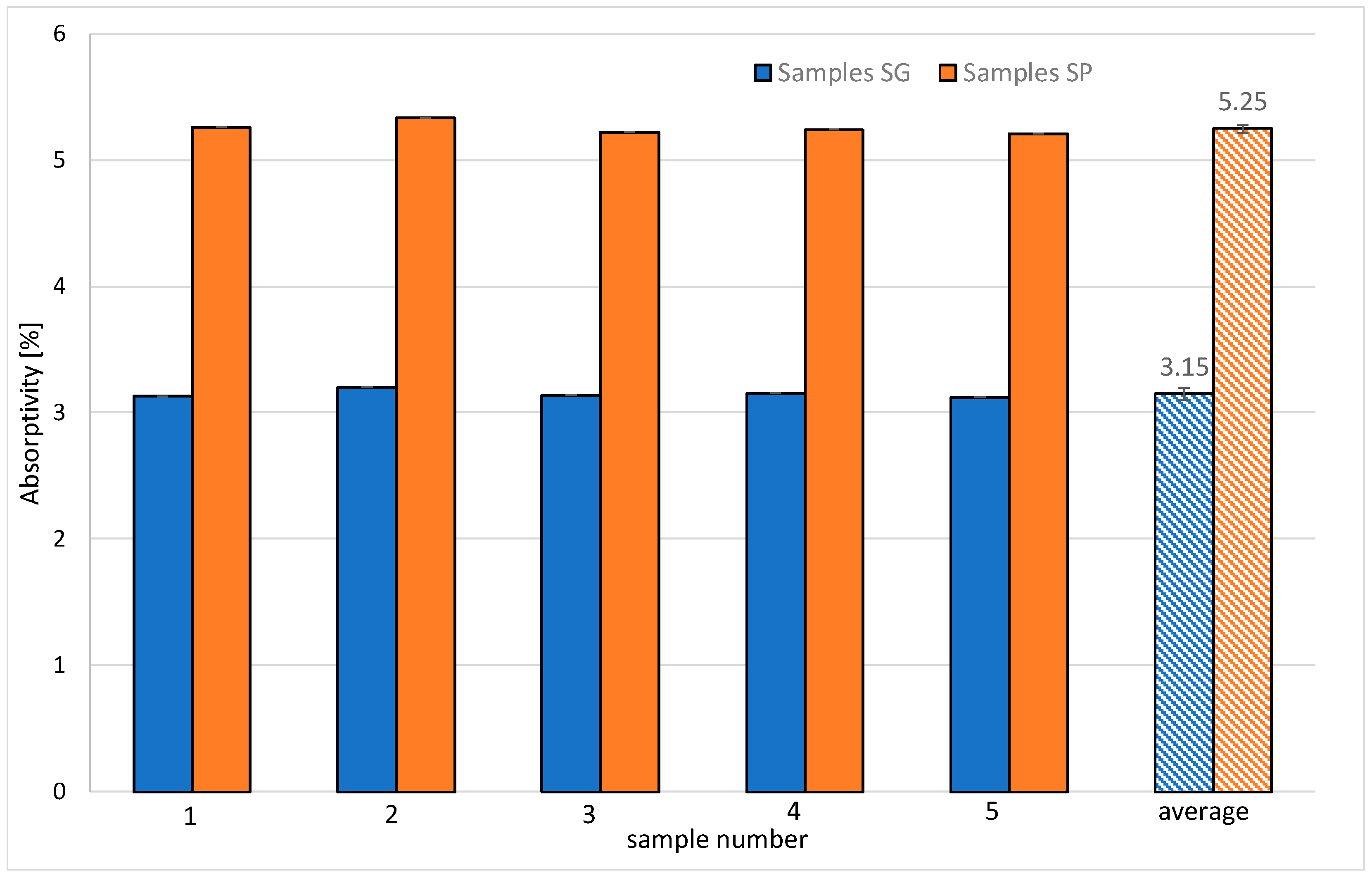

3.4. Water Absorption of Concrete

3.5. Depth of Penetration of Water under Pressure

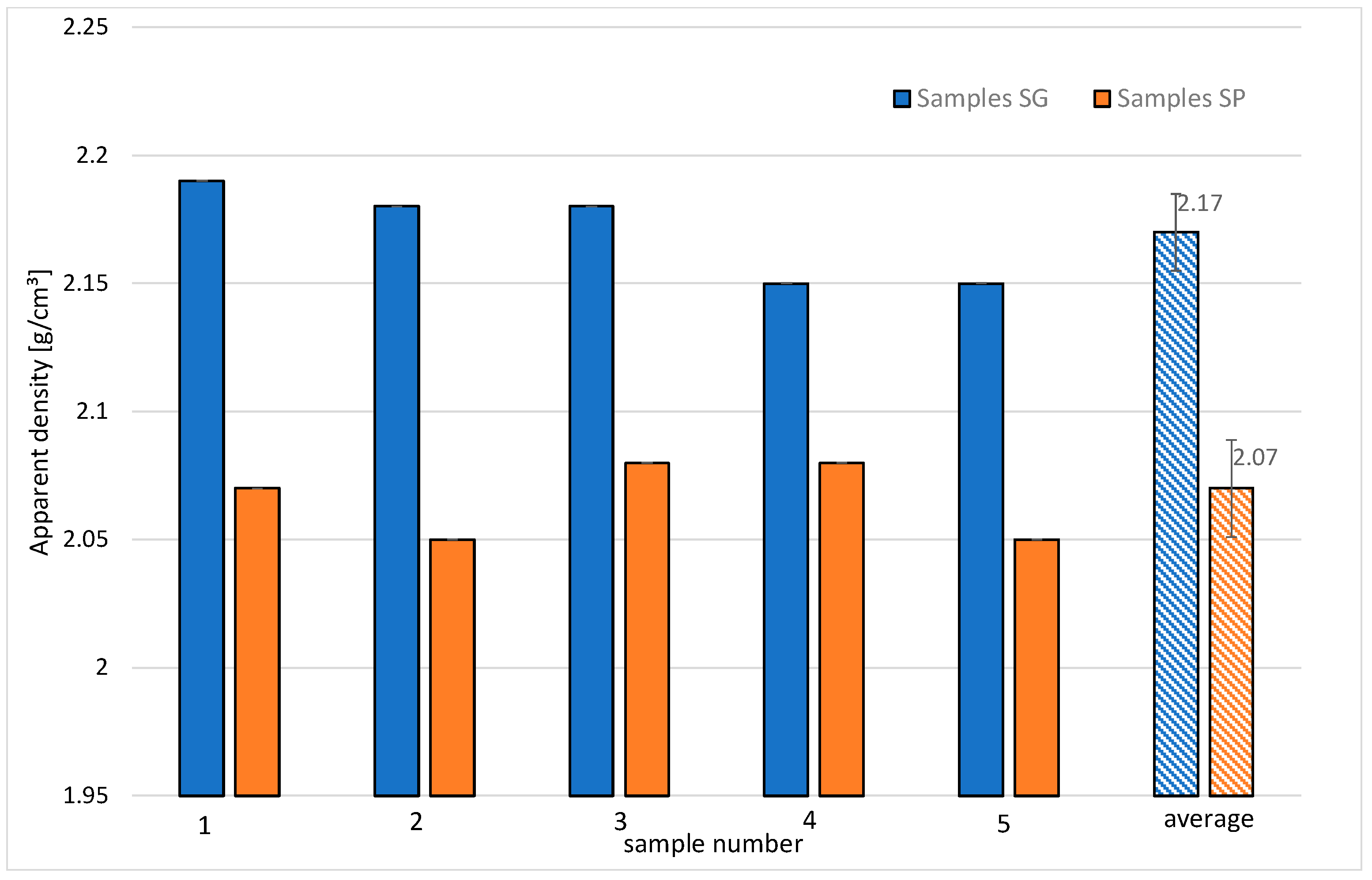

3.6. Determination of Bulk Density

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- European-Commission. European-Commission COM (2011) 21 a Resource-efficient Europe—Flagship Initiative under the 2020 Strategy; Communication from the Commission to the European Parliament; EC-European Commission: Brussels, Belgium, 2011. [Google Scholar]

- European-Commission. European-Commission COM (2011) 571 Roadmap to a Resource Efficient Europe; Communication from the Commission to the European Parliament; EC-European Commission: Brussels, Belgium, 2011. [Google Scholar]

- Gomes, M.; de Brito, J. Structural concrete with incorporation of coarse recycled concrete and ceramic aggregates: Durability performance. Mater. Struct. 2009, 42, 663–675. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. Influence of double hooked-end steel fibers and slag on mechanical and durability properties of high performance recycled aggregate concrete. Compos. Struct. 2017, 181, 273–284. [Google Scholar] [CrossRef]

- Liu, Q.; Xiao, J.; Sun, Z. Experimental study on the failure mechanism of recycled concrete. Cem. Concr. Res. 2011, 41, 1050–1057. [Google Scholar] [CrossRef]

- Vieira, T.; Alves, A.; de Brito, J.; Correia, J.R.; Silva, R.V. Durability-related performance of concrete containing fine recycled aggregates from crushed bricks and sanitary ware. Mater. Des. 2016, 90, 767–776. [Google Scholar] [CrossRef]

- Singh, A.; Srivastava, V. Ceramic waste in concrete—A Review. In Proceedings of the IEEE International Conference Recent Advances on Engineering, Technology and Computational Sciences (RAETCS), Allahabad, India, 6–8 February 2018. [Google Scholar]

- Alves, A.V.; Vieira, T.F.; de Brito, J.; Correia, J.R. Mechanical properties of structural concrete with fine recycled ceramic aggregates. Constr. Build. Mater. 2014, 64, 103–113. [Google Scholar] [CrossRef]

- Gayarre, F.L.; González, J.S.; Viñuela, R.B.; Pérez, C.L.-C.; Serrano López, M.A. Use of recycled mixed aggregates in floor blocks manufacturing. J. Clean. Prod. 2017, 167, 713–722. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Improvement of mechanical properties of recycled aggregate concrete basing on a new combination method between recycled aggregate and natural aggregate. Constr. Build. Mater. 2017, 148, 376–385. [Google Scholar] [CrossRef]

- Señas, L.; Priano, C.; Marfil, S. Influence of recycled aggregates on properties of self-consolidating concretes. Constr. Build. Mater. 2016, 113, 498–505. [Google Scholar] [CrossRef]

- Omary, S.; Ghorbel, E.; Wardeh, G. Relationships between recycled concrete aggregates characteristics and recycled aggregates concretes properties. Constr. Build. Mater. 2016, 108, 163–174. [Google Scholar] [CrossRef]

- Xuan, D.; Zhan, B.; Poon, C.S. Assessment of mechanical properties of concrete incorporating carbonated recycled concrete aggregates. Cem. Concr. Compos. 2016, 65, 67–74. [Google Scholar] [CrossRef]

- Li, T.; Xiao, J.; Zhu, C.; Zhong, Z. Experimental study on mechanical behaviors of concrete with large-size recycled coarse aggregate. Constr. Build. Mater. 2016, 120, 321–328. [Google Scholar] [CrossRef]

- Tarek, U.M.; Hare, K.D.; Aziz, H.M.; Nafiur, R.; Awal, M.A. Flexural performance of RC beams made with recycled brick aggregate. Constr. Build. Mater. 2017, 134, 67–74. [Google Scholar] [CrossRef]

- Letelier, V.; Tarela, E.; Moriconi, G. Mechanical Properties of Concretes with Recycled Aggregates and Waste Brick Powder as Cement Replacement. Procedia Eng. 2017, 171, 627–632. [Google Scholar] [CrossRef]

- Baradaran-Nasiri, A.; Nematzadeh, M. The effect of elevated temperatures on the mechanical properties of concrete with fine recycled refractory brick aggregate and aluminate cement. Constr. Build. Mater. 2017, 147, 865–875. [Google Scholar] [CrossRef]

- De Brito, J.; Pereira, A.S.; Correia, J.R. Mechanical behaviour of non-structural concrete made with recycled ceramic aggregates. Cem. Concr. Compos. 2005, 27, 429–433. [Google Scholar] [CrossRef]

- Correia, J.R.; de Brito, J.; Pereira, A.S. Effects on concrete durability of using recycled ceramic aggregates. Mater. Struct. 2006, 39, 169–177. [Google Scholar] [CrossRef]

- Elçi, H. Utilisation of crushed floor and wall tile wastes as aggregate in concrete production. J. Clean. Prod. 2016, 112, 742–752. [Google Scholar] [CrossRef]

- Anderson, D.J.; Smith, S.T.; Au, F.T.K. Mechanical properties of concrete utilising waste ceramic as coarse aggregate. Constr. Build. Mater. 2016, 117, 20–28. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Ndambuki, J.M.; Akinmusuru, J.O.; Omole, D.O. Characterization of ceramic waste aggregate concrete. HBRC J. 2016. [Google Scholar] [CrossRef]

- Guerra, I.; Vivar, I.; Lamas, B.; Juan, A.; Moran, J. Eco-efficient concretes: The effects of using recycled ceramic material from sanitary installations on the mechanical properties of concrete. Waste Manag. 2009, 29, 643–646. [Google Scholar] [CrossRef] [PubMed]

- Medina, C.; Sanchez de Rojas, M.I.; Frias, M. Reuse of sanitary ceramic wastes as coarse aggregate in eco-efficient concretes. Cem. Concr. Compos. 2012, 34, 48–54. [Google Scholar] [CrossRef]

- Senthamarai, R.; Manoharan, P.D. Concrete with ceramic waste aggregate. Cem. Concr. Compos. 2005, 27, 910–913. [Google Scholar] [CrossRef]

- Sekar, T.; Ganesan, N.; Nampoothiri, N. Studies on strength characteristics on utilization of waste materials as coarse aggregate in concrete. Int. J. Eng. Sci. Technol. 2011, 3, 5436–5440. [Google Scholar]

- Zeng, Z.; Wan, C. Experimental research on basic mechanical properties of recycled ceramic concrete. In Proceedings of the Shanghai International Conference on Technology of Architecture and Structure, Shanghai, China, 1–3 September 2009. [Google Scholar]

- Cabral, A.E.B.; Schalch, V.; Molin, D.C.C.D.; Ribeiro, J.L.D. Mechanical properties modeling of recycled aggregate concrete. Constr. Build. Mater. 2010, 24, 421–430. [Google Scholar] [CrossRef]

- Jimenez, J.; Ayuso, J.; Lopez, M.; Fernandez, J.; de Brito, J. Use of recycled aggregates from ceramic waste in masonry mortar manufacturing. Constr. Build. Mater. 2013, 40, 679–690. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Compressive strength and durability properties of ceramic wastes based concrete. Mater. Struct. 2011, 44, 155–167. [Google Scholar] [CrossRef] [Green Version]

- Torkittikul, P.; Chaipanich, A. Utilization of ceramic waste as fine aggregate within Portland cement and clay ash concretes. Cem. Concr. Compos. 2010, 32, 440–449. [Google Scholar] [CrossRef]

- Ay, N.; Unal, M. The use of ceramic tile in cement production. Cem. Concr. Res. 2000, 30, 497–499. [Google Scholar] [CrossRef]

- Puertas, F.; Garcia-Diaz, I.; Barba, A.; Gazulla, M.; Palacios, M.; Gomez, M.; Martinez-Ramirez, S. Ceramic wastes as alternative raw materials for Portland cement clinker production. Cem. Concr. Compos. 2008, 30, 798–805. [Google Scholar] [CrossRef]

- García-González, J.; Rodríguez-Robles, D.; Juan-Valdés, A.; Morán-del Pozo, J.M.; Guerra-Romero, M.I. Ceramic ware waste as coarse aggregate for structural concrete production. Environ. Technol. 2015, 36, 3050–3059. [Google Scholar] [CrossRef] [PubMed]

- Medina, C.; Frías, M.; Sánchez de Rojas, M.I. Microstructure and properties of recycled concretes using sanitary ware industry waste as coarse aggregate. Constr. Build. Mater. 2012, 31, 112–118. [Google Scholar] [CrossRef]

- Medina, C.; Frías, M.; Sánchez de Rojas, M.I. Leaching in concretes containing recycled ceramic aggregate from the sanitary ware industry. J. Clean. Prod. 2014, 66, 85–91. [Google Scholar] [CrossRef] [Green Version]

- Farinha, C.; de Brito, J.; Veiga, R. Incorporation of fine sanitary ware aggregates in coating mortars. Constr. Build. Mater. 2015, 83, 194–206. [Google Scholar] [CrossRef]

- Lucas, J.; de Brito, J.; Veiga, R.; Farinha, C. The effect of using sanitary ware as aggregates on rendering mortars’ performance. Mater. Des. 2016, 91, 155–164. [Google Scholar] [CrossRef]

- Medina, C.; Sánchez de Rojas, M.I.; Thomas, C.; Polanco, J.A.; Frías, M. Durability of recycled concrete made with recycled ceramic sanitary ware aggregate. Inter-indicator relationship. Constr. Build. Mater. 2016, 105, 480–486. [Google Scholar] [CrossRef]

- Ogrodnik, P.; Szulej, J. The impact of aeration of concrete based on ceramic aggregate, exposed to high temperatures, on its strength parameters. Constr. Build. Mater. 2017, 157, 909–916. [Google Scholar] [CrossRef]

- Halicka, A.; Ogrodnik, P.; Zegardło, B. Using ceramic sanitary ware waste as concrete aggregate. Constr. Build. Mater. 2013, 48, 295–305. [Google Scholar] [CrossRef]

- Ogrodnik, P.; Zegardło, B.; Radzikowska, M. Wykorzystanie poprodukcyjnych odpadów ceramiki sanitarnej jako napełniacza do kompozytów cementowych o wysokiej odporności chemicznej. Przem. Chem. 2016, 96, 1100–1104. [Google Scholar] [CrossRef]

- PN-EN 933-1:2012 Badania geometrycznych właściwości kruszyw—Część 1: Oznaczanie składu ziarnowego-Metoda przesiewania. [Tests for Geometrical Properties of Aggregates. Determination of Particle Size Distribution. Sieving Method.]. Available online: http://sklep.pkn.pl/pn-en-933-1-2012e.html (accessed on 19 July 2018). (In Polish).

- PN-B-06714-40:1978 Kruszywa mineralne. Badania. Oznaczanie wytrzymałości na miażdżenie. [Mineral Aggregates. Research. Determination of Crush Strength.]. Available online: http://sklep.pkn.pl/pn-b-06714-40-1978p.html (accessed on 19 July 2018). (In Polish).

- PN-EN 12390-3:2011 Badania betonu. Część 3. Wytrzymałość na ściskanie próbek do badania. [Concrete testing. Part 3. Compressive Strength of Test Specimens.]. Available online: http://sklep.pkn.pl/pn-en-12390-3-2011p.html (accessed on 19 July 2018).

- PN-EN 12390-5:2011 Badania betonu. Część 5. Wytrzymałość na zginanie próbek do badań. [Concrete Testing. Part 5. Bending Strength of Test Specimens.]. Available online: http://sklep.pkn.pl/pn-en-12390-5-2011p.html (accessed on 19 July 2018).

- PN-EN 12390-4:2001. Badania betonu Część 4. Wytrzymałość na ściskanie. Wymagania dla maszyn wytrzymałościowych. [Tesing concrete Part 4. Compressive strength. Requirements for endurance machines.]. Available online: http://sklep.pkn.pl/pn-en-12390-4-2001p.html (accessed on 19 July 2018).

- Neville, A.M. Właściwości Betonu, 5th ed.; Stowarzyszenie Producentów Cementu: Warszawa, Polska, 2012; p. 900. ISBN 978-83-61331-16-2. [Google Scholar]

- PN-EN 1339:2005 Betonowe płyty brukowe. Wymagania i metody badań. [Concrete Paving Flags. Requirements and Test Methods.]. Available online: http://sklep.pkn.pl/pn-en-1339-2005p.html (accessed on 19 July 2018).

- PN-88B-06250: Beton zwykły [PN-88/B-06250 Ordinary Concrete.]. Available online: http://sklep.pkn.pl/pn-b-06250-1988p.html (accessed on 19 July 2018).

- PN-B-06265:2004 Krajowe uzupełnienia PN-EN 206-1:2003 Beton—Część 1: Wymagania, właściwości, produkcja i zgodność. [National Supplements PN-EN 206-1: 2003 Concrete—Part 1: Requirements, Properties, Production and Compliance.]. Available online: http://sklep.pkn.pl/pn-b-06265-2004p.html (accessed on 19 July 2018).

- Glinicki, M. Widmo nasiąkliwości. Bub. Technol. Arch. 2007, 3, 50–53. [Google Scholar]

- Gołda, A.; Kaszuba, S. Nasiąkliwość betonu—Wymagania a metody badawcze. Cem. Wapno Beton 2009, 6, 308–313. [Google Scholar]

- PN-EN 12390-8:2011: Badania betonu. Część 8: Głębokość penetracji wody pod ciśnieniem. [Concrete Testing. Part 8: Depth of Penetration of Water under Pressure.]. Available online: http://sklep.pkn.pl/pn-en-12390-8-2011p.html (accessed on 19 July 2018).

| Sample Determination | SG | SP |

|---|---|---|

| Aluminous cement “Górkal 70” (kg) | 488 | - |

| Portland cement 32.5R (kg) | - | 488 |

| Aggregate 0 ÷ 4 mm (kg) | 997.14 | 997.14 |

| Aggregate 4 ÷ 8 mm (kg) | 398.86 | 398.86 |

| Water (L) | 199 | 199 |

| No. | Mass before Freezing (g) | Mass after Freezing (g) | Average Mass Loss (%) | Stress (MPa) | Stress–Samples from Water (MPa) | Average Drop in Strength (%) |

|---|---|---|---|---|---|---|

| Aluminous cement | ||||||

| 1 | 7645.0 | 7645.0 | 0.4 | 47.56 | 51.60 | 29.2 |

| 2 | 7573.5 | 7503.0 | 44.25 | 59.08 | ||

| 3 | 7519.0 | 7453.5 | 19.77 | 56.71 | ||

| 4 | 7674.0 | 7673.0 | 42.31 | 46.83 | ||

| 5 | 7613.5 | 7603.0 | 36.26 | 54.33 | ||

| Portland cement | ||||||

| 1 | 7220.5 | 7214.0 | 0.1 | 65.44 | 62.89 | 2.2 |

| 2 | 7227.5 | 7225.5 | 51.92 | 61.32 | ||

| 3 | 7386.5 | 7364.0 | 64.45 | 62.98 | ||

| 4 | 7378.0 | 7380.5 | 68.77 | 60.97 | ||

| 5 | 7269.0 | 7265.5 | 49.15 | 58.40 | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogrodnik, P.; Szulej, J. The Assessment of Possibility of Using Sanitary Ceramic Waste as Concrete Aggregate—Determination of the Basic Material Characteristics. Appl. Sci. 2018, 8, 1205. https://doi.org/10.3390/app8071205

Ogrodnik P, Szulej J. The Assessment of Possibility of Using Sanitary Ceramic Waste as Concrete Aggregate—Determination of the Basic Material Characteristics. Applied Sciences. 2018; 8(7):1205. https://doi.org/10.3390/app8071205

Chicago/Turabian StyleOgrodnik, Paweł, and Jacek Szulej. 2018. "The Assessment of Possibility of Using Sanitary Ceramic Waste as Concrete Aggregate—Determination of the Basic Material Characteristics" Applied Sciences 8, no. 7: 1205. https://doi.org/10.3390/app8071205