Monitoring and Precision Spraying for Orchid Plantation with Wireless WebCAMs

Abstract

:1. Introduction

2. Materials and Methods

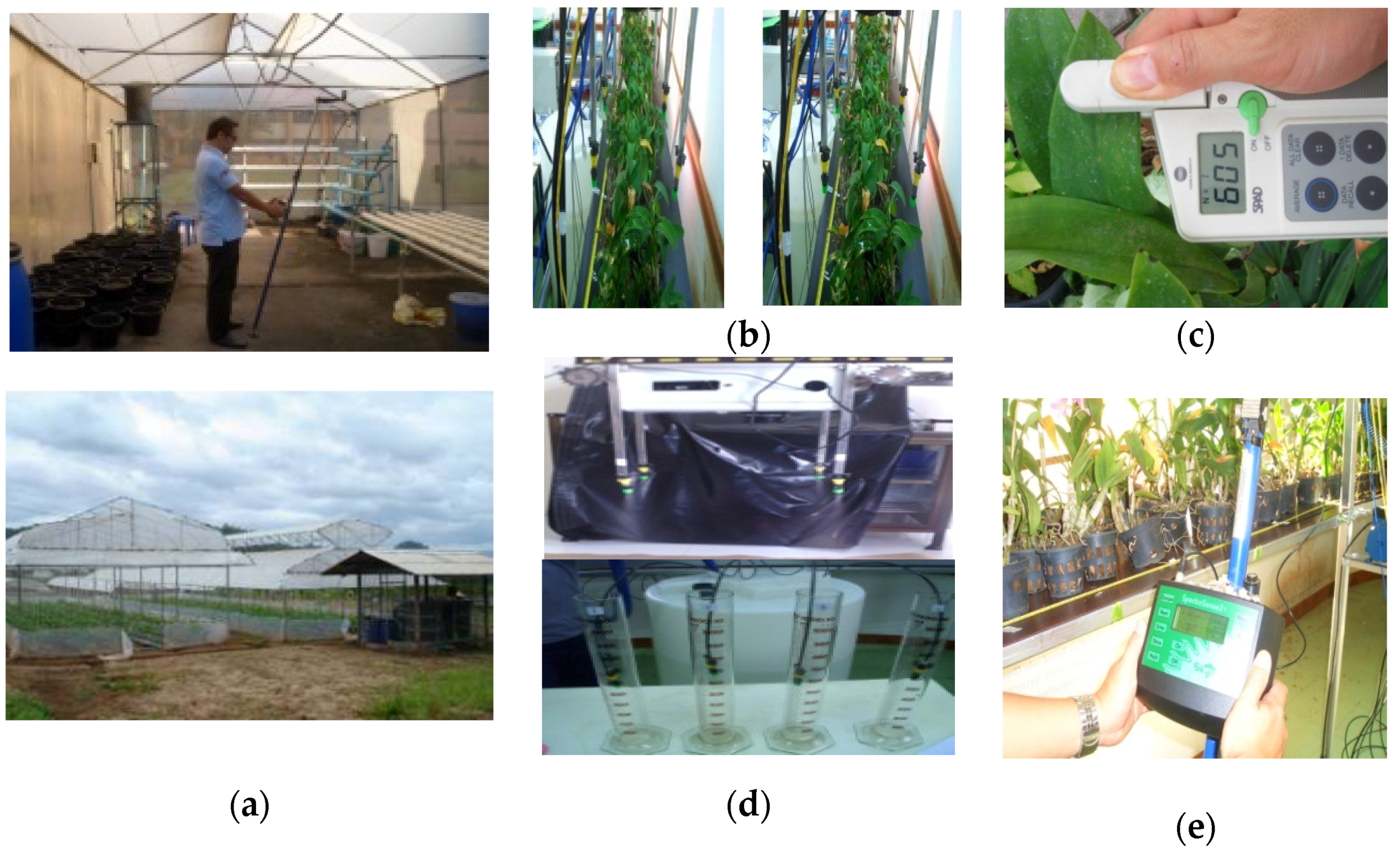

2.1. Experimental Set Up and Field Preparation

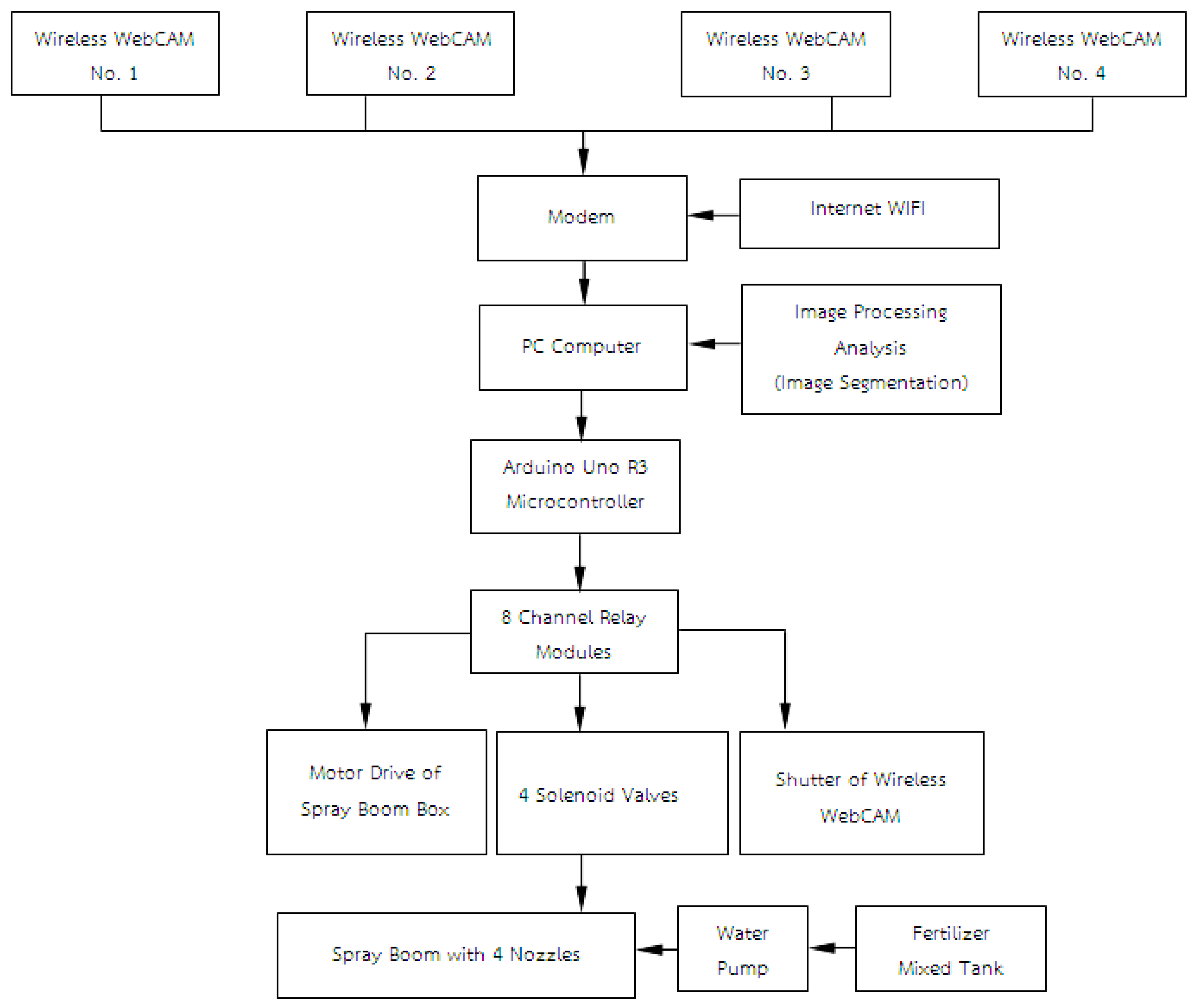

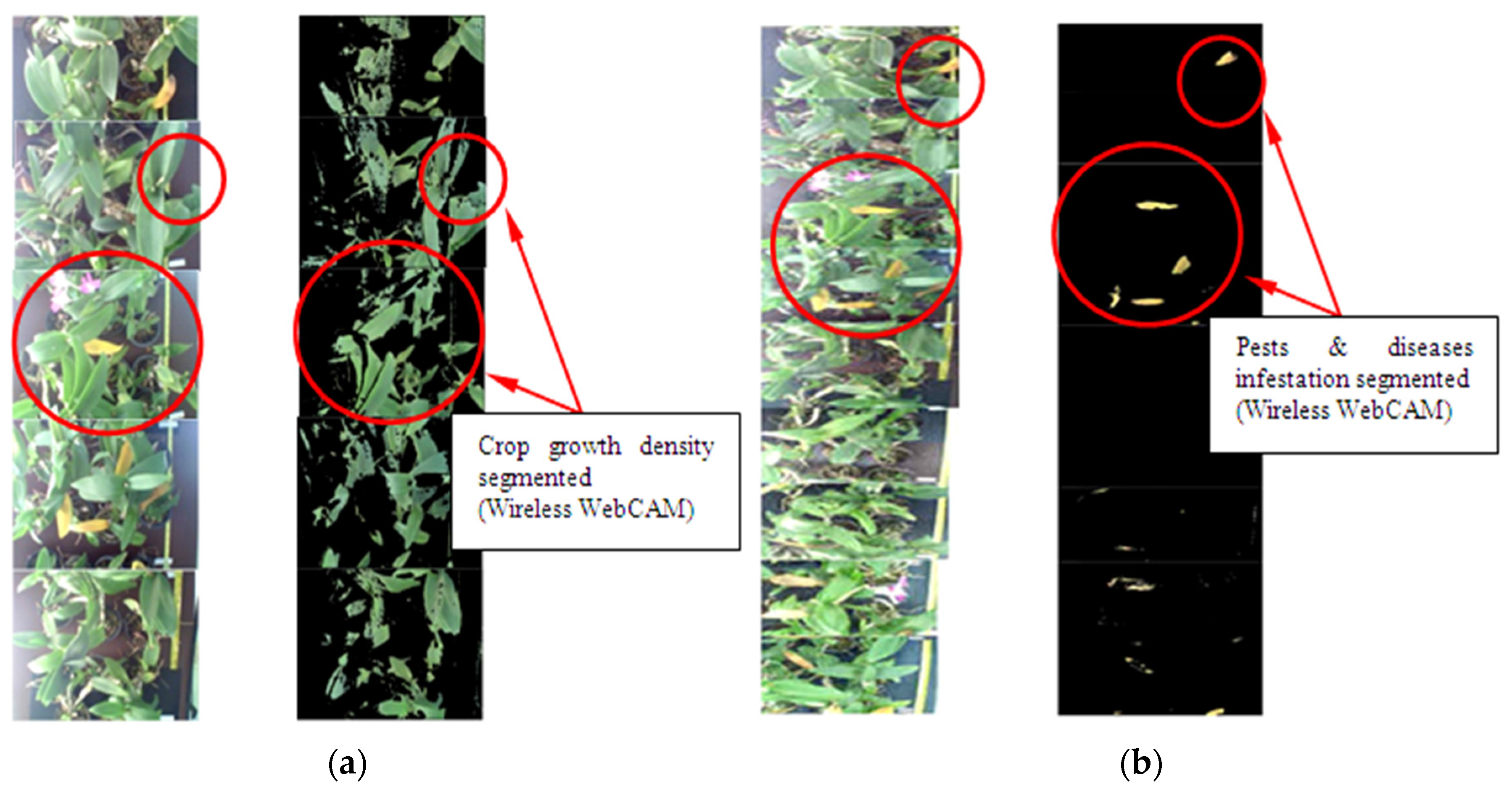

2.2. Crop Growth, Pests and Diseases Infestation Monitoring and Spraying Systems

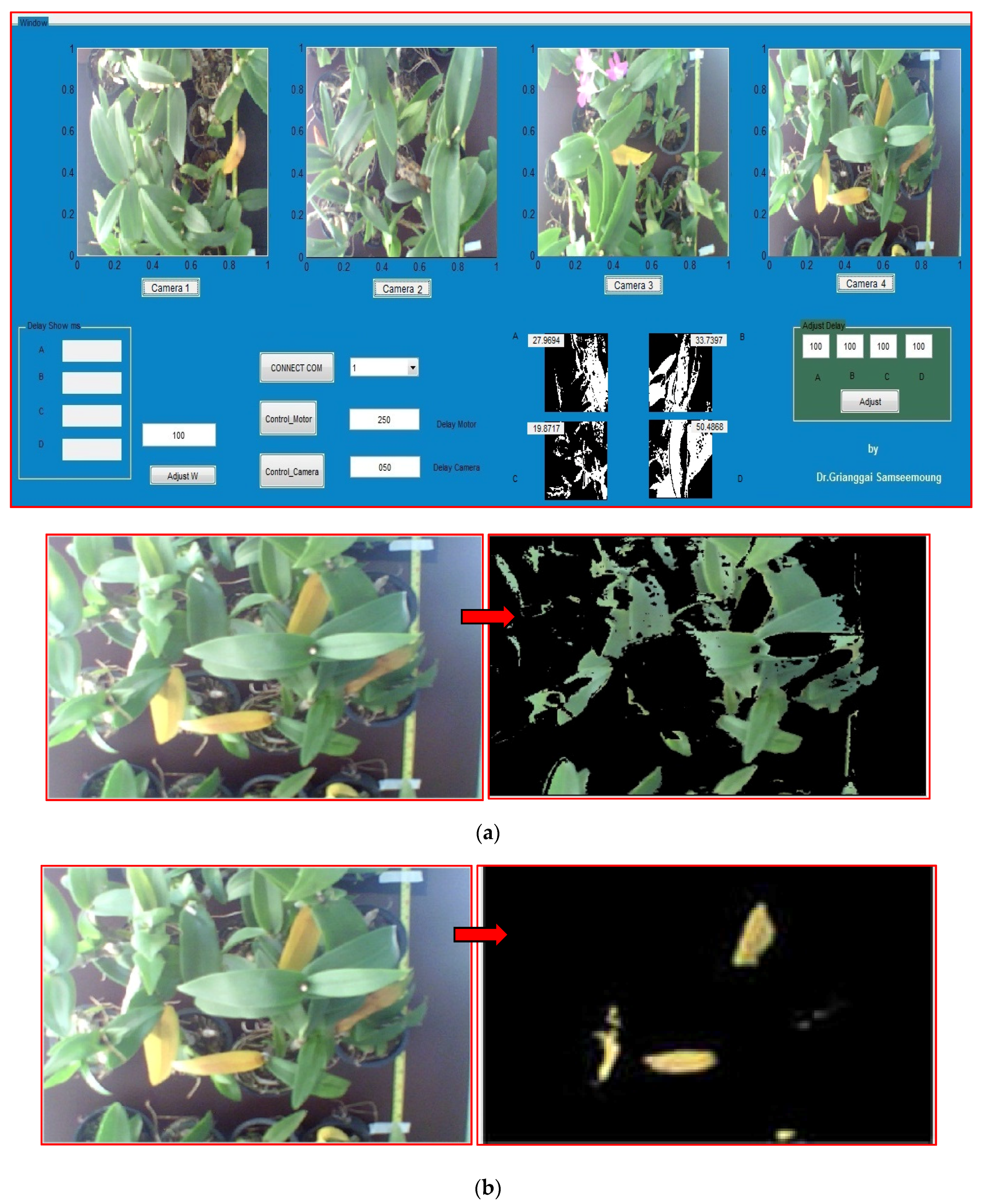

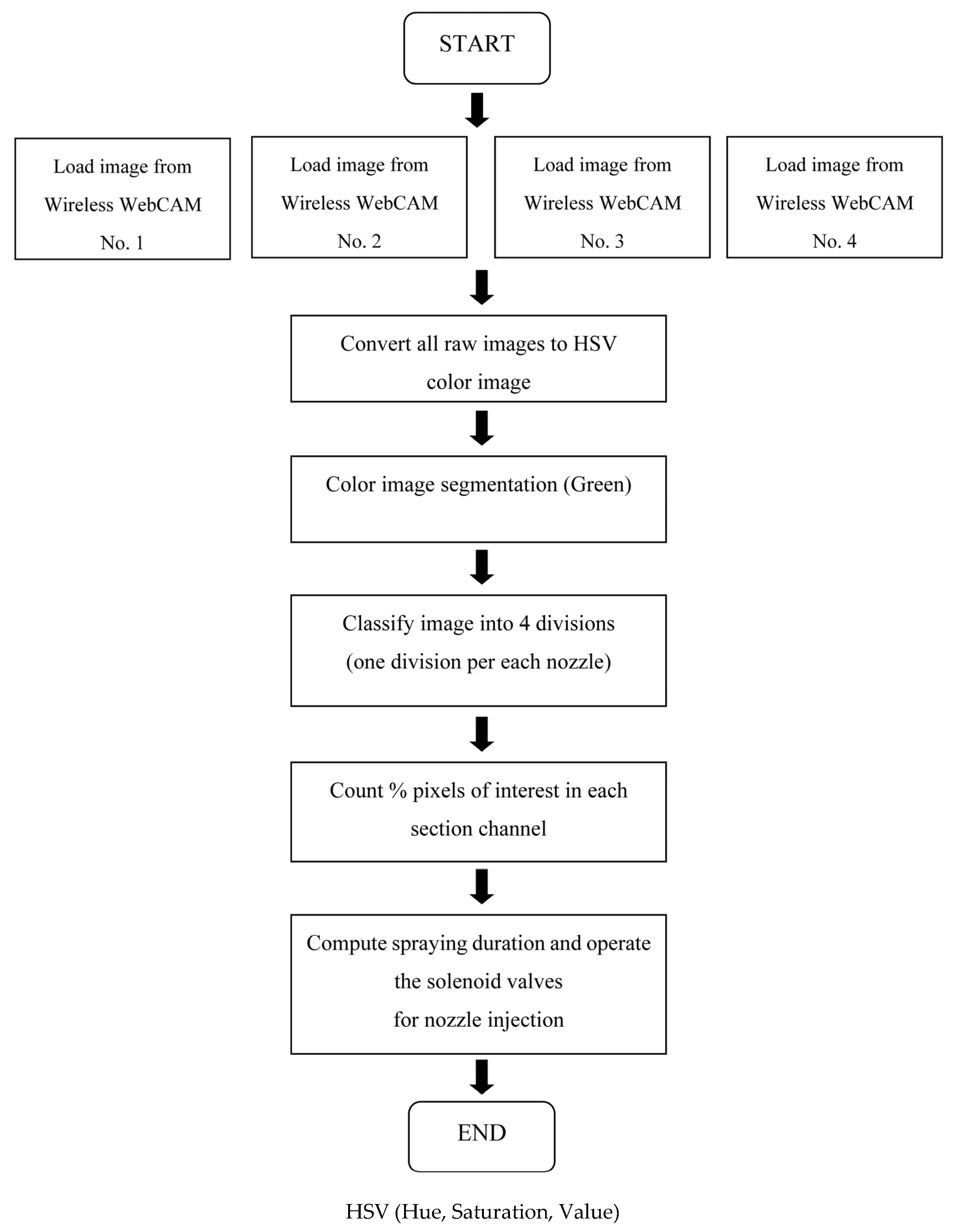

2.3. Low Altitude Image Data Acquisition and Processing

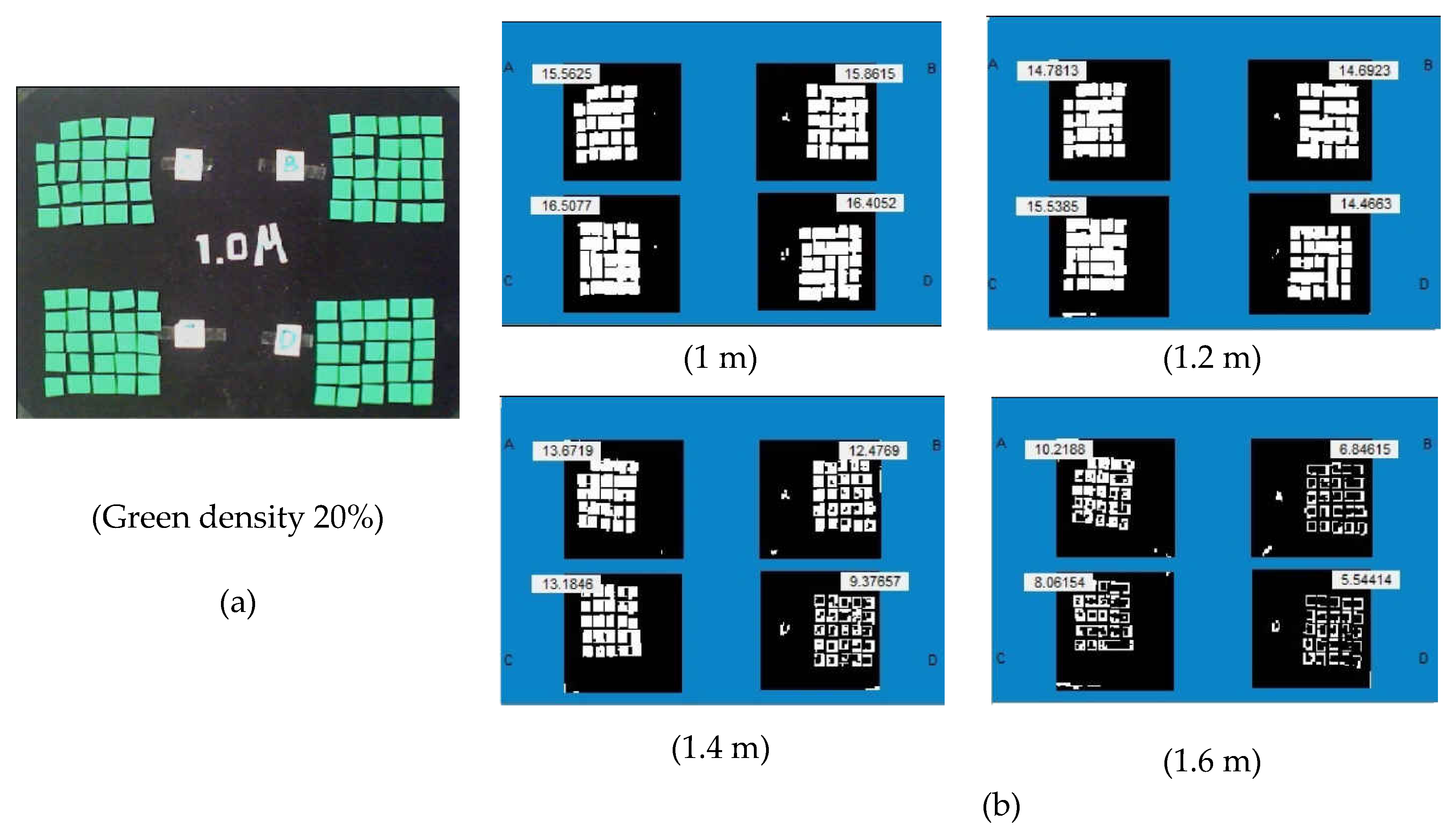

2.4. Image Data Calibration

2.5. Statistical Analysis

2.6. Ground Truthing Measurements

3. Results

3.1. Calibration of Variable Rate Spraying System

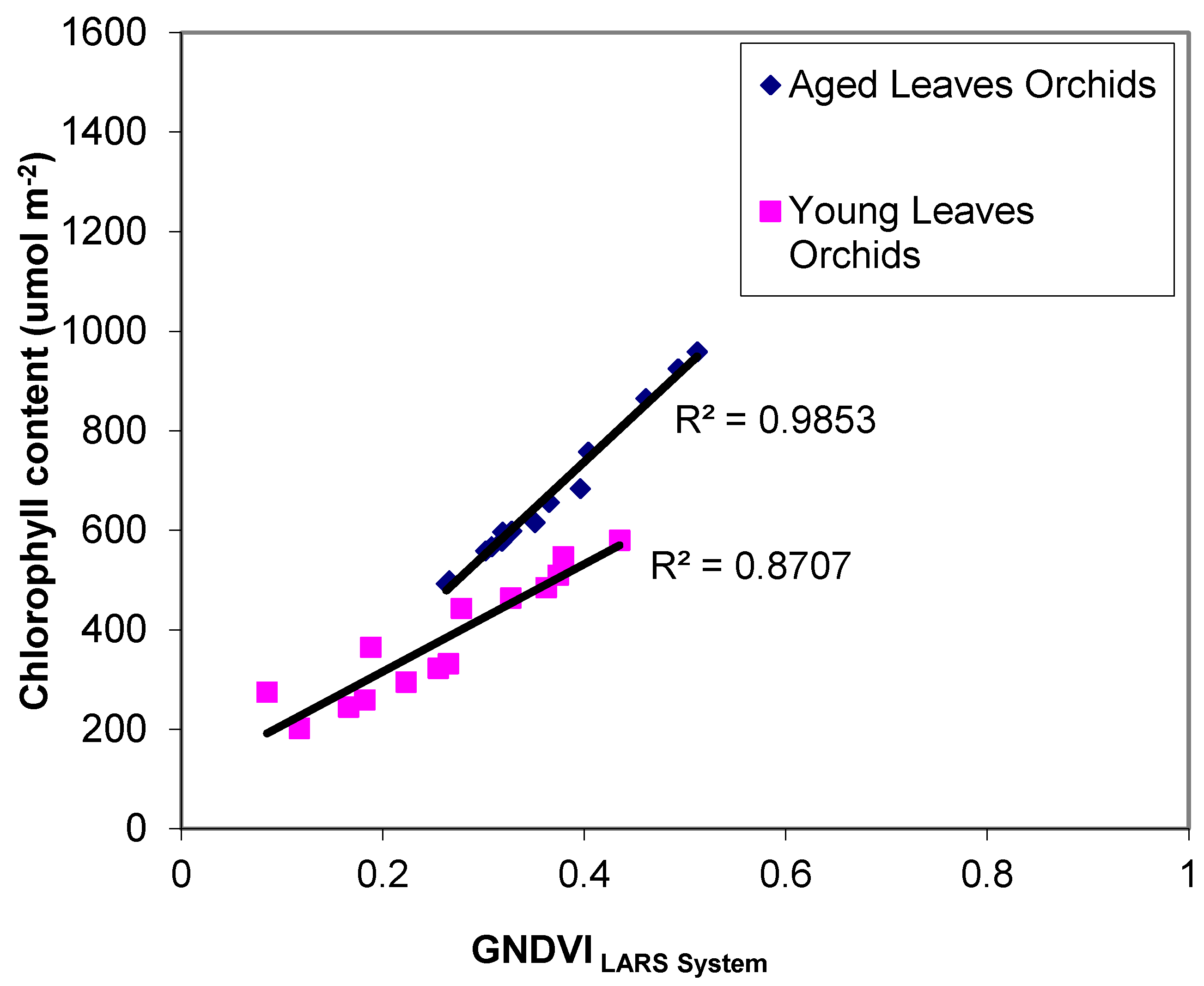

3.2. Estimation of Leaf Chlorophyll Content with Vegetation Index

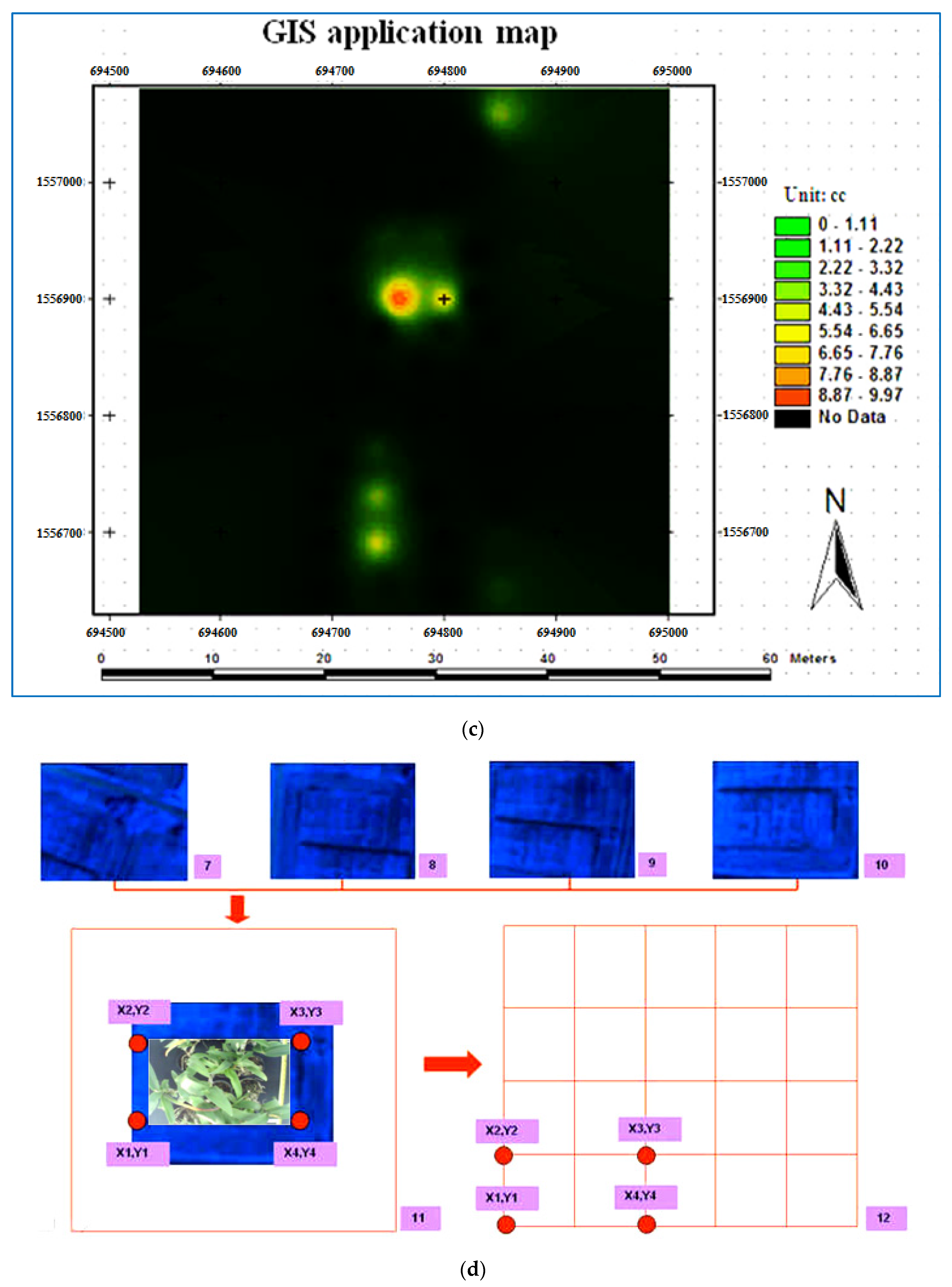

3.3. Crop Growth Status Monitoringand Application Map

4. Discussion

5. Conclusions

Acknowledgements

Author Contributions

Conflicts of Interest

Abbreviations

| Hectare | ha |

| Kilogram | kg |

| Kilowatt | kW |

| Kilowatt-hour | kWh |

| Liter | L |

| Meter | m |

| Revolutions per minute | rpm |

| Square | sq. |

| Volt | V |

| Watt | W |

References

- Samseemoung, G.; Soni, P.; Jayasuriya, H.P.W.; Salokhe, V.M. Oil palm pest infestation monitoring and evaluation by helicopter-mounted, low altitude remote sensing platform. J. Appl. Remote Sens. 2011, 5, 053540. [Google Scholar] [CrossRef]

- Samseemoung, G.; Soni, P.; Jayasuriya, H.P.W.; Salokhe, V.M. Application of low altitude remote sensing (LARS) platform for monitoring crop growth and weed infestation in a soybean plantation. Precis. Agric. 2012, 13, 611–627. [Google Scholar] [CrossRef]

- Putra, B.T.W.; Soni, P. Evaluating NIR-Red and NIR-Red edge external filters with digital cameras for assessing vegetation indices under different illumination. Infrared Phys. Technol. 2017, 81, 148–156. [Google Scholar] [CrossRef]

- Markwell, J.; Osterman, J.; Mitchell, J. Calibration of the Minolta SPAD-502 leaf chlorophyll meter. Photosynth 1995, 46, 467–472. [Google Scholar] [CrossRef] [PubMed]

- Stafford, J.V.; Benloch, J.V. Machine assisted detection of weeds and weed patches. In Proceedings of the First European Conference on Precision Agriculture; BIOS Scientific Publishers Limited: Oxford, UK, 1997; pp. 511–518. [Google Scholar]

- Dasari, M.; Friedman, L.; Jesberger, J.; Stuve, T.A.; Finding, R.L.; Swales, T.P.; Schulz, S.C. A magnetic resonance imaging study of thalamic area in adolescent patients with either schizophrenia or bipolar disorder as compared to healthy controls. Psychiatry Res. Neuronimaging 1999, 91, 155–162. [Google Scholar] [CrossRef]

- Putra, B.T.W.; Soni, P. Enhanced Broadband Greenness in Assessing Chlorophyll a and b, Carotenoid, and Nitrogen in Robusta Coffee Plantations using a Digital Camera. Precis. Agric. 2017. [CrossRef]

- Chaisattapagon, C.; Zhang, N. Effective criteria for weed identification in wheat fields using machine vision. Trans. ASAE 1995, 38, 965–974. [Google Scholar] [CrossRef]

- Franz, H.; Armanini, M.P. Characterization of a multi-component receptor for GDNF. Nature 1996. [Google Scholar] [CrossRef]

| Wireless WebCAMsVimicro USB2.0 UVC PC Camera (SWIFT-TECH ELECTRONICS Co. Ltd., Beijing, China) | Chlorophyll Meter (Minolta SPAD 502 Meter; Konica Minolta Sensing Inc., Osaka, Japan) | Illumination Sensor SKR-1800 (Spectrum Technology Inc., Powys, PA, USA) | Microcontroller Board Arduino Uno R3 (Shenzhen Shanhai Technology Ltd., Shenzhen, China) | ||||

|---|---|---|---|---|---|---|---|

| Feature | Value | Feature | Value | Feature | Value | Feature | Value |

| Image size resolution | 2.0 to 6.0 Mega pixels | Type | Hand held meter | Range | Two channels each between 400–1050 nm | Type | Microcontroller ATmega328 |

| Ground pixel size | 10X real-time digital zoom | Measuring sample | Crop leaves | Construction | Dupont “Delrin” acrylic | Operating Voltage | 5 V |

| Spectral bands | RGB (Red, Green, Blue) | Measuring system | Optical density difference | Filters | Metal interference | Input Voltage (limits) | 6–20 V |

| Lens type | VGA format frame rate up to 30 fps | Measuring area | 2 mm × 3 mm | Detectors | GaP, GaAsP, or silicon | Digital I/O Pins | 14 |

| Mostly used | Hold true for laptop and desktop PC | Data memory | 30 data points | Cable | Screened. 7-4-C military specification 3m standard length | Analog Input Pins | 6 |

| Triggering | Manual/Optional by software | Accuracy | +/− 1.0 SPAD unit reading | Temperature Range | −25 °C to +75 °C (for a fixed PVC cable) | DC Current per I/O Pins | 40 mA |

| Simulated Stage of Crop Growth and Infestation | Altitude Levels (m) | |||

|---|---|---|---|---|

| 1 | 1.2 | 1.4 | 1.6 | |

| 1. Green color | ||||

| 5% | 4.340 a | 3.995 a | 3.756 a | 3.410 a |

| 10% | 8.365 d,e | 7.813 c,d | 6.604 b,c | 4.476 a |

| 15% | 12.400 f | 11.284 f | 9.515 e | 5.721 b |

| 20% | 16.084 g | 14.869 g | 12.178 f | 7.667 c,d |

| 2. Yellow color | ||||

| 5% | 2.837 a | 4.491 b | 4.097 b | 4.260 b |

| 10% | 7.816 d | 7.970 d | 6.724 c | 6.750 c |

| 15% | 10.926 f | 10.760 f | 9.411 e | 8.522 d |

| 20% | 14.048 h | 12.457 g | 11.947 g | 10.884 f |

| 3. Brown color | ||||

| 5% | 4.756 b | 4.786 b | 4.182 b | 2.264 a |

| 10% | 8.241 d,e | 9.244 e,f | 7.402 d | 5.228 b,c |

| 15% | 11.097 g | 11.644 g | 8.888 e,f | 6.186 c |

| 20% | 14.068 h | 14.809 h | 11.901 g | 9.432 f |

| Volume Flow Rate, L/min | Spraying Height, m | Pesticide or Chemical Scatterable Distance, m |

|---|---|---|

| 0.02 at pressure 1 bar | 0.25 | 0.220 a |

| 0.35 | 0.235 a | |

| 0.45 | 0.255 b | |

| 0.55 | 0.280 c | |

| 0.06 at pressure 1 bar | 0.25 | 0.325 a |

| 0.35 | 0.360 b | |

| 0.45 | 0.375 b | |

| 0.55 | 0.467 c | |

| 0.11 at pressure 1 bar | 0.25 | 0.530 a |

| 0.35 | 0.635 b | |

| 0.45 | 0.722 c | |

| 0.55 | 0.817 d |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samseemoung, G.; Soni, P.; Sirikul, C. Monitoring and Precision Spraying for Orchid Plantation with Wireless WebCAMs. Agriculture 2017, 7, 87. https://doi.org/10.3390/agriculture7100087

Samseemoung G, Soni P, Sirikul C. Monitoring and Precision Spraying for Orchid Plantation with Wireless WebCAMs. Agriculture. 2017; 7(10):87. https://doi.org/10.3390/agriculture7100087

Chicago/Turabian StyleSamseemoung, Grianggai, Peeyush Soni, and Chaiyan Sirikul. 2017. "Monitoring and Precision Spraying for Orchid Plantation with Wireless WebCAMs" Agriculture 7, no. 10: 87. https://doi.org/10.3390/agriculture7100087