Suppression of CH4 Emission by Rice Straw Removal and Application of Bio‐Ethanol Production Residue in a Paddy Field in Akita, Japan

Abstract

:1. Introduction

2. Materials and Methods

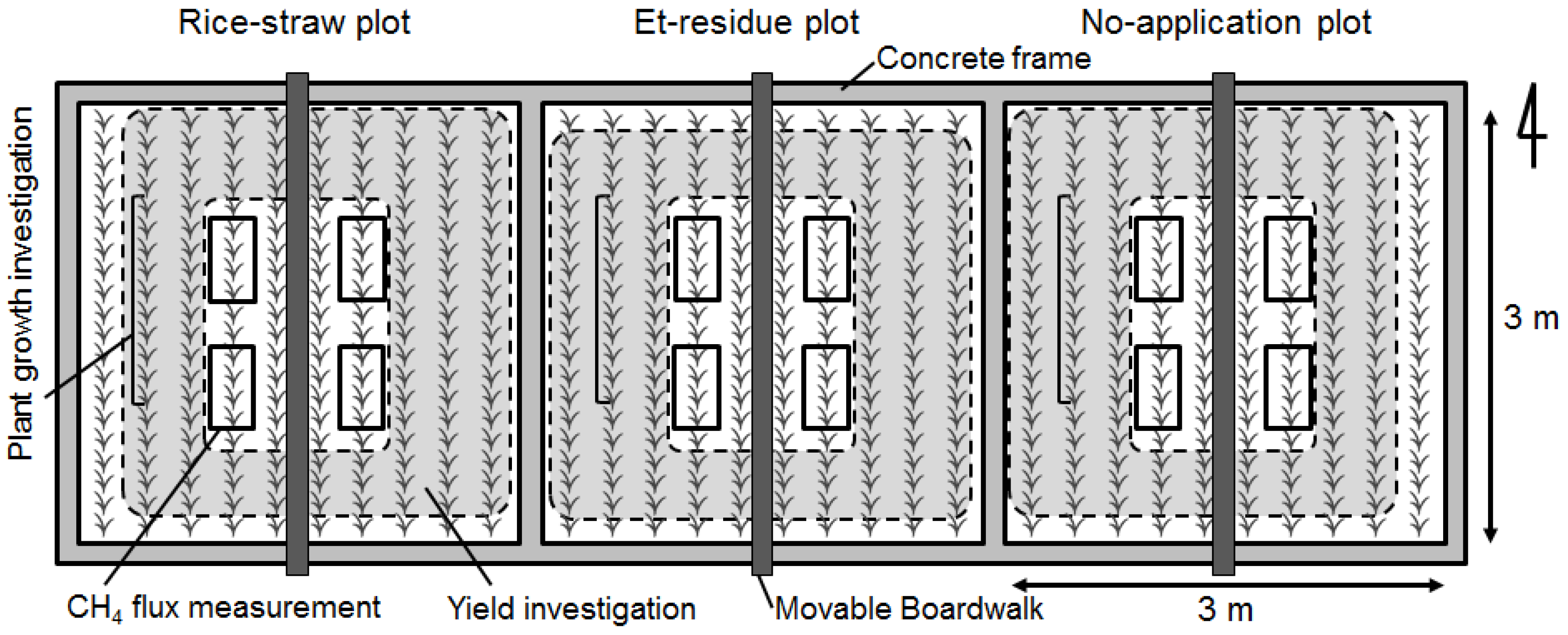

2.1. Experimental Conditions

2.2. Rice Cultivation

2.3. Growth and Yield Investigations of Rice Plants

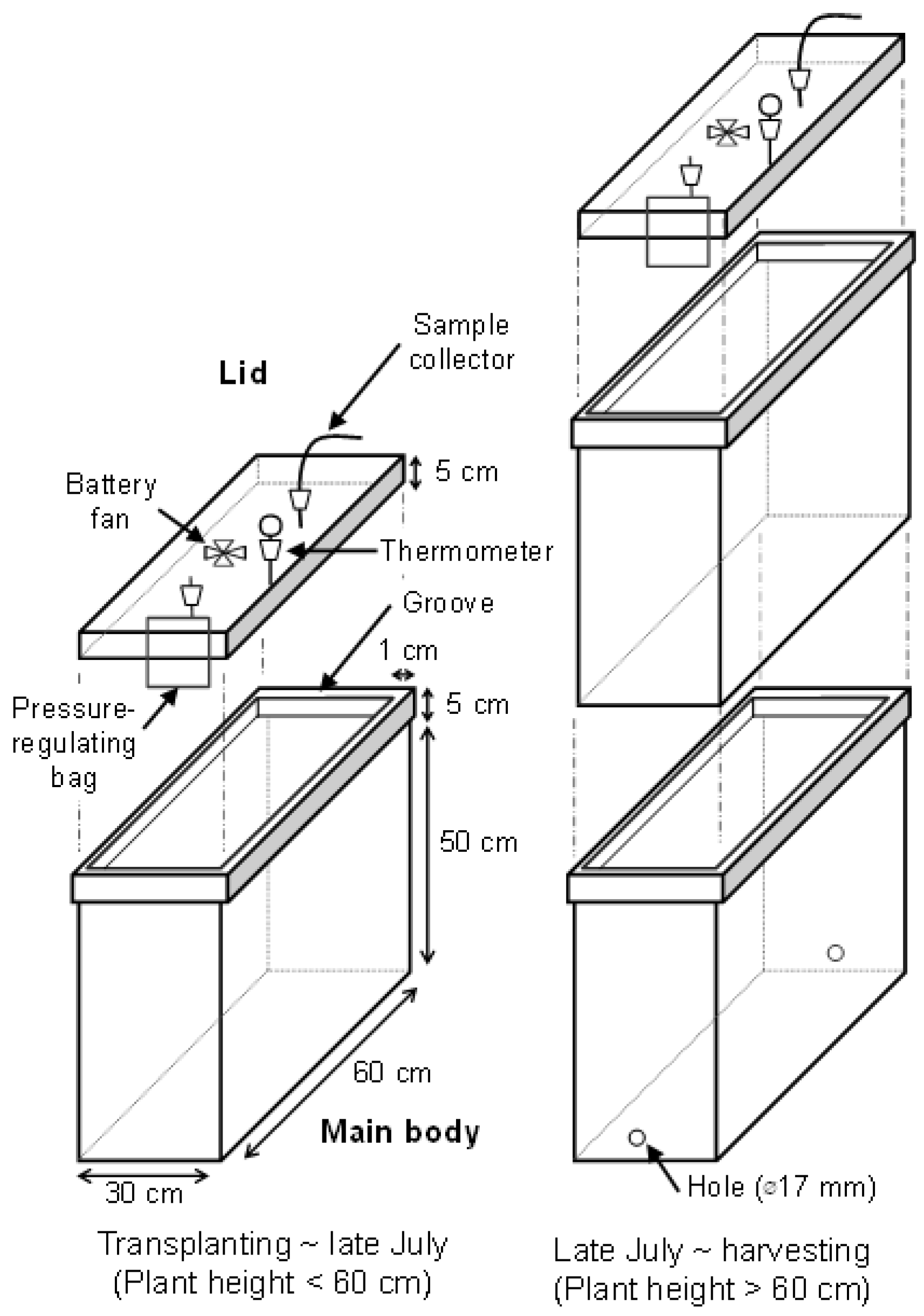

2.4. CH4 Flux Measurement

2.5. Statistical Analyses

3. Results

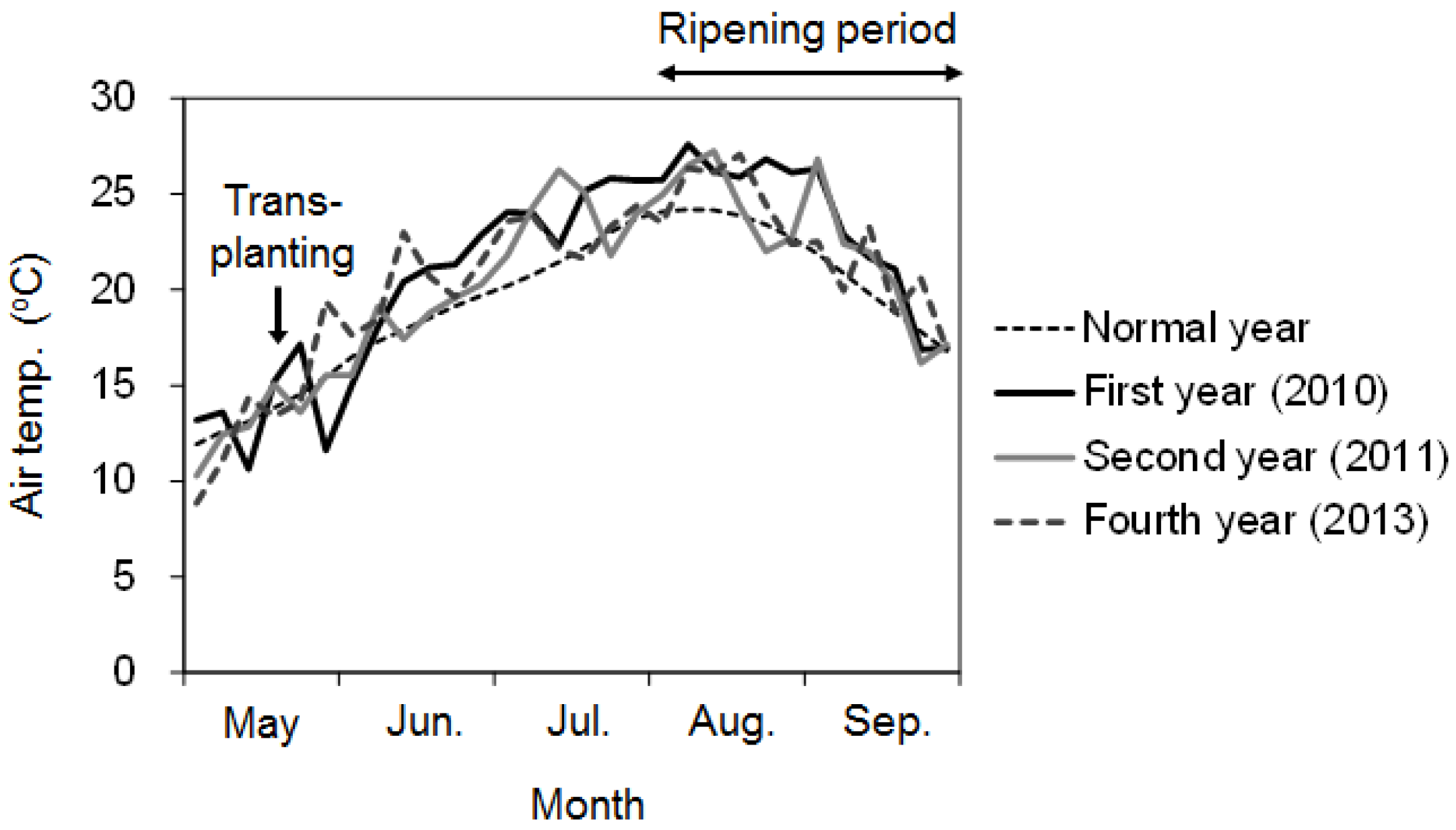

3.1. Air Temperature

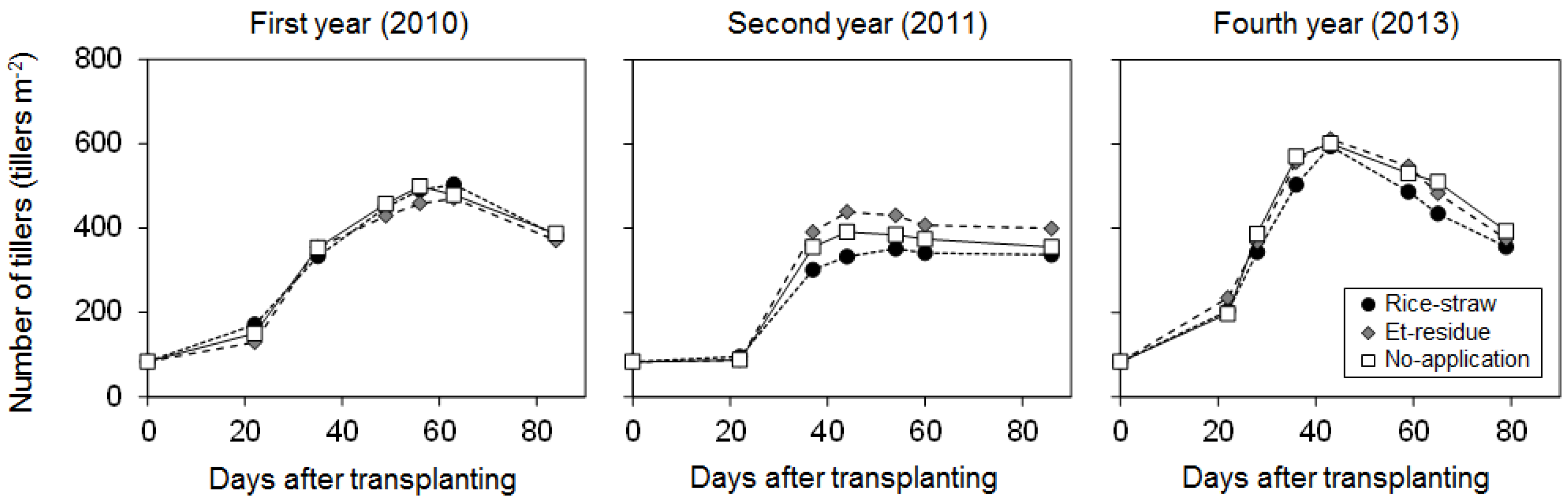

3.2. Number of Tillers and Grain Yield

3.3. Soil Eh and CH4 Flux

4. Discussion

4.1. Effects on Rice Growth

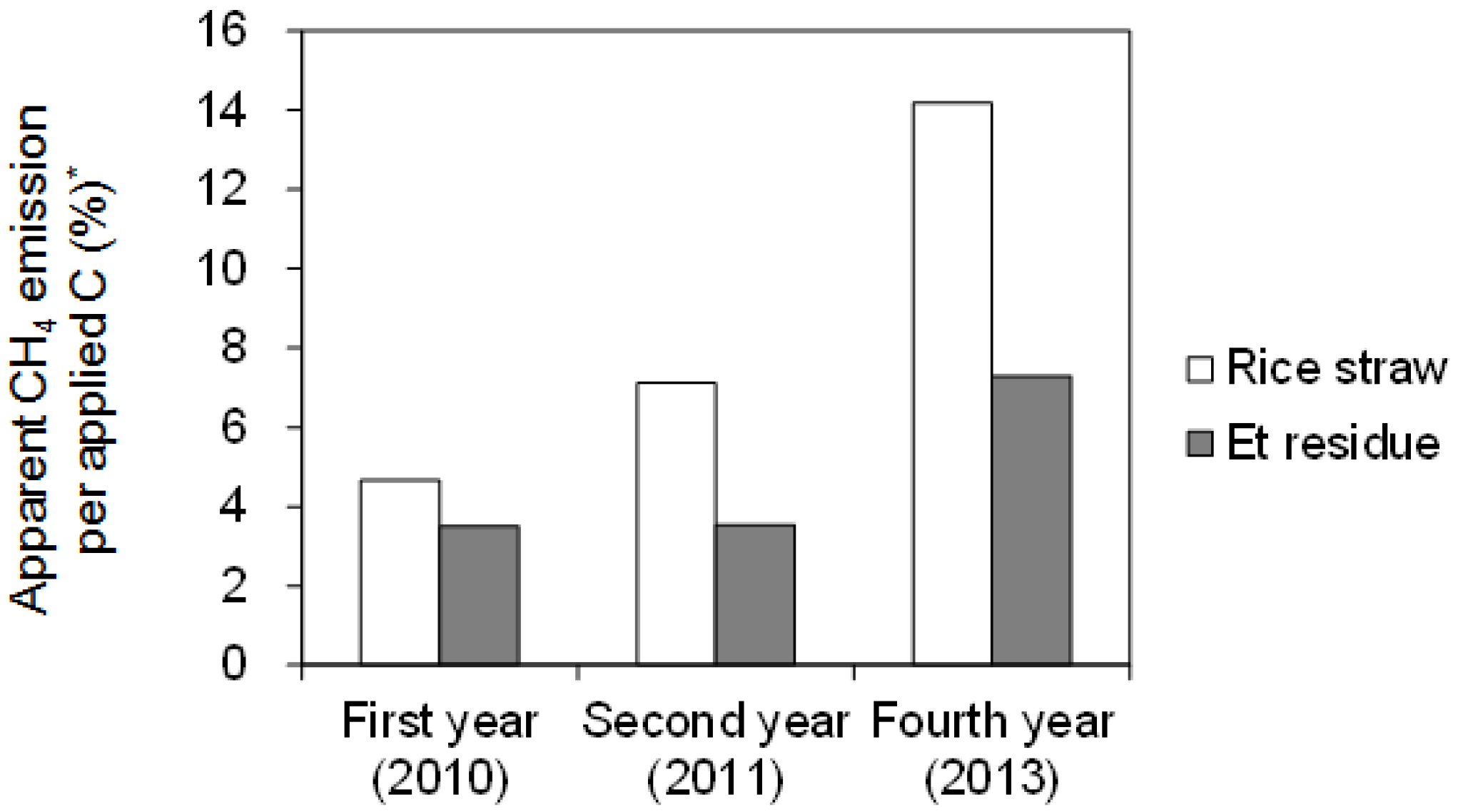

4.2. Effects on CH4 Emission

4.3. Possible Choices of Timing for Et-Residue Application and Incorporation

4.4. Possible Issues Involved with Long-Term Application of Et-Residue

4.5. Issues to Solve for the Practical Use of This Technology

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- OECD (Organization for Economic Cooperation and Development)-IEA (International Energy Agency). Good Practice Guidelines: Bioenergy Project Development and Biomass Supply; OECD-IEA: Paris, France, 2007. [Google Scholar]

- Balat, M.; Balat, H. Recent trends in global production and utilization of bio-ethanol fuel. Appl. Energy 2009, 86, 2273–2282. [Google Scholar] [CrossRef]

- Sarkar, N.; Ghosh, S.K.; Bannerjee, S.; Aikat, K. Bioethanol production from agricultural wastes: An overview. Renew. Energy 2012, 37, 19–27. [Google Scholar] [CrossRef]

- Kubota, M. Reasonable application of rice straw to wet and semiwet paddy fields with heavy clay soil in Niigata. J. Niigata Agric. Exp. Stn. 1992, 39, 1–87. (In Japanese) [Google Scholar]

- Livestock Department, MAFF (Ministry of Agriculture, Forestry and Fisheries of Japan). Current Status of Rice Straw 2005. Available online: http://www.maff.go.jp/j/chikusan/souti/lin/l_siryo/koudo/h170906/pdf/ref_data01.pdf (accessed on 7 March 2017). (In Japanese)

- Ueda, T. Feasibility study on producing domestic biofuels from agricultural biomass in Japan. Tech. Rep. Natl. Inst. Rural Eng. Jpn. 2011, 211, 131–151. [Google Scholar]

- Maeda, K. Quantitative estimation of behavior of nitrogen applied to paddy field. Bull. Natl. Agric. Res. Cent. 1983, 1, 121–192. [Google Scholar]

- Tanno, F.; Kameyama, K.; Sekiya, S. Effect of straw application under low soil temperature on the growth of rice plants and the dynamic behavior of nutrients in the soil. Bull. Fukushima Prefect. Agric. Exp. Stn. 1990, 29, 1–13. (In Japanese) [Google Scholar]

- Watanabe, A.; Katoh, K.; Kimura, M. Effect of rice straw application on CH4 emission from paddy fields. II. Contribution of organic constituents in rice straw. Soil Sci. Plant Nutr. 1993, 39, 707–712. [Google Scholar] [CrossRef]

- Watanabe, A.; Yoshida, M.; Kimura, K. Contribution of rice straw carbon to CH4 emission from rice paddies using 13C-enriched rice straw. J. Geophys. Res. 1998, 103, 8237–8242. [Google Scholar] [CrossRef]

- Goto, E.; Miyamori, Y.; Hasegawa, S.; Inatsu, O. Reduction effects of accelerating rice straw decomposition and water management on methane emission from paddy fields in a cold distinct. Jpn. J. Soil Sci. Plant Nutr. 2004, 75, 191–201. (In Japanese) [Google Scholar]

- Watanabe, A.; Katoh, K.; Kimura, M. Effect of rice straw application on CH4 emission from paddy fields. I. Effect of weathering of rice straw in the field during off-crop season. Soil Sci. Plant Nutr. 1993, 39, 701–706. [Google Scholar] [CrossRef]

- Yagi, K.; Minami, K. Effect of organic matter application on methane emission from some Japanese paddy fields. Soil Sci. Plant Nutr. 1990, 36, 599–610. [Google Scholar] [CrossRef]

- Itoh, C.; Shibuya, T.; Kobayashi, H. Effect of long-term nutrient subtractive condition and organic matter application on paddy soil in Hachirogata polder II. Annual changes of soil chemical properties and rice yield in paddy field from which rice straw was continuously removed after rice harvest. Tohoku Agric. Res. 2009, 62, 43–44. (In Japanese) [Google Scholar]

- Shirato, Y.; Yagasaki, Y.; Nishida, M. Using different versions of the Rothamsted Carbon model to simulate soil carbon in long-term experimental plots subjected to paddy–upland rotation in Japan. Soil Sci. Plant Nutr. 2011, 57, 597–606. [Google Scholar] [CrossRef]

- Chen, Y.; Shiono, T. A study on the effect of applying vinasse from bio-ethanol production to farmland on leaching and physical and chemical properties of soil. Tech. Rep. Natl. Inst. Rural Eng. Jpn. 2011, 211, 153–169. (In Japanese) [Google Scholar]

- Nishimura, T.; Shinohara, T.; Imoto, H.; Miyazaki, T. Production of CH4 and CO2 following application of residue from a bio-ethanol plant to paddy field. In Proceedings of the Annual Meeting of the Japanese Society of Irrigation, Drainage and Rural Engineering, Tsukuba, Japan, 4–6 August 2009; pp. 832–833. (In Japanese)

- FAO (Food and Agriculture Organization of the United Nations)-UNESCO (the United Nations Educational, Scientific and Cultural Organization). Soil Map of the World, Revised Legend; World Soil Resources Report 60; FAO: Rome, Italy, 1990. [Google Scholar]

- Kanke, B. Application of the proximate analysis to soil saccharides. Jpn. J. Soil Sci. Plant Nutr. 1987, 58, 556–560. (In Japanese) [Google Scholar]

- Miura, Y. Rice straw management for mitigation of methane emission from paddy field. Spec. Bull. Fukushima Prefect. Agric. Exp. Stn. 2003, 7, 1–38. (In Japanese) [Google Scholar]

- Waksman, S.A.; Stevens, K.R. Acritical study of the methods of determining the nature and abundance of soil organic matter. Soil Sci. 1930, 30, 67–116. [Google Scholar] [CrossRef]

- Minami, K.; Yagi, K. Method for measuring methane flux from rice paddies. Jpn. J. Soil Sci. Plant Nutr. 1988, 59, 458–463. (In Japanese) [Google Scholar]

- Morita, S. Prospect for developing measures to prevent high temperature damage to rice grain ripening. Jpn. J. Crop Sci. 2008, 77, 1–12. (In Japanese) [Google Scholar] [CrossRef]

- Itoh, M.; Sudo, S.; Mori, S.; Saito, H.; Yoshida, T.; Shiratori, Y.; Suga, S.; Yoshikawa, N.; Suzue, Y.; Mizukami, H.; et al. Mitigation of methane emissions from paddy fields by prolonging midseason drainage. Agric. Ecosyst. Environ. 2011, 141, 359–372. [Google Scholar] [CrossRef]

- Minamikawa, K.; Sakai, N. The practical use of water management based on soil redox potential for decreasing methane emission from a paddy field in Japan. Agric. Ecosyst. Environ. 2006, 116, 181–188. [Google Scholar] [CrossRef]

- Yagi, K.; Tsuruta, H.; Kanda, K.; Minami, K. Effect of water management on methane emission from a Japanese rice paddy field: Automated methane monitoring. Glob. Biogeochem. Cycles 1996, 10, 255–267. [Google Scholar] [CrossRef]

- Kumagai, K.; Konno, Y. Methane Emission from Rice Paddy Fields after Upland Farming. Jpn. J. Soil Sci. Plant Nutr. 1998, 69, 333–339. (In Japanese) [Google Scholar]

- Furukawa, Y.; Shiratori, Y.; Inubushi, K. Depression of methane production potential in paddy soils by subsurface drainage systems. Soil Sci. Plant Nutr. 2008, 54, 950–959. [Google Scholar] [CrossRef]

- Shiratori, Y.; Watanabe, H.; Furukawa, Y.; Tsuruta, H.; Inubushi, K. Effectiveness of a subsurface drainage system in poorly drained paddy fields on reduction of methane emissions. Soil Sci. Plant Nutr. 2007, 53, 387–400. [Google Scholar] [CrossRef]

- Furukawa, Y.; Inubushi, K. Evaluation of slag application to decrease methane emission from paddy soil and fate of iron. Soil Sci. Plant Nutr. 2004, 50, 1029–1036. [Google Scholar] [CrossRef]

- Roy, P.K.; Tokuyasu, T.; Orikasa, N.; Shiina, T. A review of life cycle assessment (LCA) of bioethanol from lignocellulostic biomass. JARQ 2012, 46, 41–57. [Google Scholar] [CrossRef]

| Eelement | Content (%, Dry) † | Application Rate (g·m−2) | ||

|---|---|---|---|---|

| Rice Straw | Et Residue | Rice Straw ‡ | Et Residue § | |

| Total N (nitrogen) | 1.1 | 3.0 | 5.5 | 10.8 |

| Total P (phosphorus) | 0.15 | 0.038 | 0.76 | 0.14 |

| Total K (potassium) | 2.0 | 0.13 | 10.0 | 0.45 |

| Silica (SiO2) | 15.6 | 20.8 | 80 | 75 |

| Total C (carbon) | 37.5 | 36.2 | 191 | 130 |

| Total Ca (calcium) | 0.22 | - | 0.78 | |

| pH | - | 3.9 | - | - |

| (Carbon fraction) ¶ | ||||

| Lipids | 1.0 | 0.9 | 4.9 | 3.1 |

| Sugars | 5.1 | 9.4 | 25.8 | 33.9 |

| Hemi-cellulose | 14.7 | 7.6 | 75.1 | 27.5 |

| Cellulose | 14.8 | 7.5 | 75.7 | 27.1 |

| Residue (mainly lignin) | 2.0 | 10.7 | 10.0 | 38.7 |

| Year | Plot | Number of Panicles | Number of Spikelets per Panicle | Total Number of Spikelets | Filled Spikelets | 1000-Kernel Weight † | Grain Yield † (Brown Rice) |

|---|---|---|---|---|---|---|---|

| (m−2) | (×103 m−2) | (%) | (g) | (g·m−2) | |||

| First year (2010) | Rice-straw plot | 383 | 19.9 | 463 | |||

| Et-residue plot | 370 | ND ‡ | ND ‡ | ND ‡ | 20.7 | 488 | |

| No-application plot | 387 | 20.2 | 542 | ||||

| Second year (2011) | Rice-straw plot | 337 | 94.6 | 29.4 | 79.8 | 568 | |

| Et-residue plot | 399 | 83.2 | 31.7 | 82.3 | ND ‡ | 554 | |

| No-application plot | 356 | 86.8 | 31.2 | 82.5 | 561 | ||

| Fourth year (2013) | Rice-straw plot | 356 | 79.5 | 28.3 | 86.9 | 22.3 | 560 |

| Et-residue plot | 374 | 81.2 | 30.4 | 85.1 | 22.0 | 597 | |

| No-application plot | 393 | 67.9 | 26.7 | 92.2 | 22.1 | 532 | |

| Average § | Rice-straw plot | 358 | 87.0 | 28.9 | 83.4 | 21.1 | 530 |

| Et-residue plot | 381 | 82.2 | 31.1 | 83.7 | 21.4 | 546 | |

| No-application plot | 379 | 77.3 | 28.9 | 87.3 | 21.2 | 545 |

| Year | Plot | CH4 Emission (g·C·m−2) | ||

|---|---|---|---|---|

| Before Mid-Season Drainage | After Mid-Season Drainage | Total (Rice-Growing Period) | ||

| First year (2010) † | Rice-straw plot | 11.4 ± 6.5 | 7.8 ± 1.8 | 19.1 ± 8.3 |

| Et-residue plot | 4.8 ± 0.6 | 10.0 ± 0.7 | 14.8 ± 0.2 | |

| No-application plot | 3.1 ± 1.1 | 7.1 ± 1.8 | 10.2 ± 3.0 | |

| Second year (2011) † | Rice-straw plot | 18.5 ± 4.8 | 3.3 ± 0.6 | 21.8 ± 5.4 |

| Et-residue plot | 5.5 ± 0.8 | 7.3 ± 2.8 | 12.8 ± 3.4 | |

| No-application plot | 4.1 ± 1.0 | 4.1 ± 1.1 | 8.2 ± 1.5 | |

| Fourth year (2013) † | Rice-straw plot | 17.1 ± 4.0 | 18.2 ± 2.2 | 35.3 ± 5.6 |

| Et-residue plot | 1.9 ± 1.3 | 14.4 ± 1.4 | 16.3 ± 2.5 | |

| No-application plot | 1.2 ± 0.7 | 16.2 ± 0.5 | 17.4 ± 0.3 | |

| Average ‡ | Rice-straw plot | 15.7 ± 3.8 b (100) | 9.7 ± 7.6 a (100) | 25.4 ± 8.7 b (100) |

| Et-residue plot | 4.1 ± 1.9 a (26) | 10.6 ± 3.6 a (108) | 14.6 ± 1.8 a,b (58) | |

| No-application plot | 2.8 ± 1.5 a (18) | 9.1 ± 6.3 a (94) | 11.9 ± 4.8 a (47) | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takakai, F.; Ichikawa, J.; Ogawa, M.; Ogaya, S.; Yasuda, K.; Kobayashi, Y.; Sato, T.; Kaneta, Y.; Nagahama, K. Suppression of CH4 Emission by Rice Straw Removal and Application of Bio‐Ethanol Production Residue in a Paddy Field in Akita, Japan. Agriculture 2017, 7, 21. https://doi.org/10.3390/agriculture7030021

Takakai F, Ichikawa J, Ogawa M, Ogaya S, Yasuda K, Kobayashi Y, Sato T, Kaneta Y, Nagahama K. Suppression of CH4 Emission by Rice Straw Removal and Application of Bio‐Ethanol Production Residue in a Paddy Field in Akita, Japan. Agriculture. 2017; 7(3):21. https://doi.org/10.3390/agriculture7030021

Chicago/Turabian StyleTakakai, Fumiaki, Jota Ichikawa, Masato Ogawa, Saki Ogaya, Kentaro Yasuda, Yukiya Kobayashi, Takashi Sato, Yoshihiro Kaneta, and Ken‐ichiro Nagahama. 2017. "Suppression of CH4 Emission by Rice Straw Removal and Application of Bio‐Ethanol Production Residue in a Paddy Field in Akita, Japan" Agriculture 7, no. 3: 21. https://doi.org/10.3390/agriculture7030021