1. Introduction

Although it is now feasible to use Reynolds-averaged Navier–Stokes (RANS) solvers to calculate the flow around a propeller operating in the vicinity of its supporting structure, such calculations are still complex and long. A simpler alternative is to replace the propeller in the RANS calculation by a time-averaged force field which accelerates the fluid in the same manner. The force field can be determined by an independent propeller analysis program typically using the boundary element method (BEM). To determine the mutual interaction between the propeller and its support, the flow calculation proceeds in an iterative manner with successive calculations of the flow using the RANS solver and the BEM propeller program. The RANS solver determines the inflow for the BEM program; the BEM program determines the force field to be used in the RANS solver.

The complete calculation is simpler than a full RANS calculation because the details of the propeller need not be reflected in the RANS grid, nor is there a need to have a separate rotating domain within the RANS grid. In addition, since the force field is averaged in time, the RANS calculation is usually steady resulting in much decreased computation times. Even if the RANS simulation is unsteady, when the time scales associated with the propeller are much shorter than those of the RANS flow (as may be the case, for example, with a manoeuvering ship), significant computational savings may be obtained by using time-averaged forced fields to model the propeller.

However, it should be noted that time-averaging is not necessary. For example, Greve et al. [

1] have modelled the propeller of a ship in a seaway using a time-varying force field. Nevertheless, the time-saving advantages of the coupling scheme are not nearly so significant when the RANS solution is unsteady. In the remainder of this paper it will be assumed that the force fields are averaged in time.

The RANS-BEM coupling scheme can be implemented whenever the interaction between the propeller and its immediate surroundings is important. The problem that has motivated this research is that of a propeller operating on a ship and its interaction with the hull and its appendages. The inflow into the BEM propeller program, including the interaction effects with the hull, is called the effective wake.

The use of a force field to model the propeller has a long history. Actuator disk theory dates back to Rankine [

2] and Froude [

3]. In 1964, Hough and Ordway [

4] determined an analytic solution for an actuator disk with constant radial load. Their expressions were generalized further by Conway [

5,

6]. The purpose of an actuator disk is to provide a rudimentary model of the action of the propeller so its effect on the flow around the ship can be determined. Typically, the mutual interaction of the disk and the ship is ignored although a linear theory of the interaction of an actuator disk and an axisymmetric body was developed by Sparenberg [

7].

The converse problem of determining the effect of the ship on the propeller, i.e., calculating the effective wake, was addressed by Huang and Groves [

8] with their V-shaped Segments (VSM) method. It applied to axisymmetric hulls but was later generalized to arbitrary hulls by Bujnicki [

9]. The Force Field Method (FFM) was developed at Maritime Institute of the Netherlands (MARIN) for the Cooperative Research Ships organization [

10]. Neither VSM nor FFM account for the effect of the propeller on the flow around the ship.

The mutual interaction of hull and propeller was modelled by Choi and Kinnas [

11] using an Euler solver initialized one propeller diameter upstream of the propeller disk and a vortex lattice propeller code. Coupling of a RANS code for the flow past the ship and a vortex lattice code for the flow past the propeller has been reported by Stern et al. [

12]. Three methods were tried for adding the effect of the propeller in the RANS solution: a force field method, a method in which extra boundary conditions were prescribed at the surfaces of an internal volume containing the propeller, and a method in which the propeller-induced flow field was prescribed. They found that the force-field approach gave the best results.

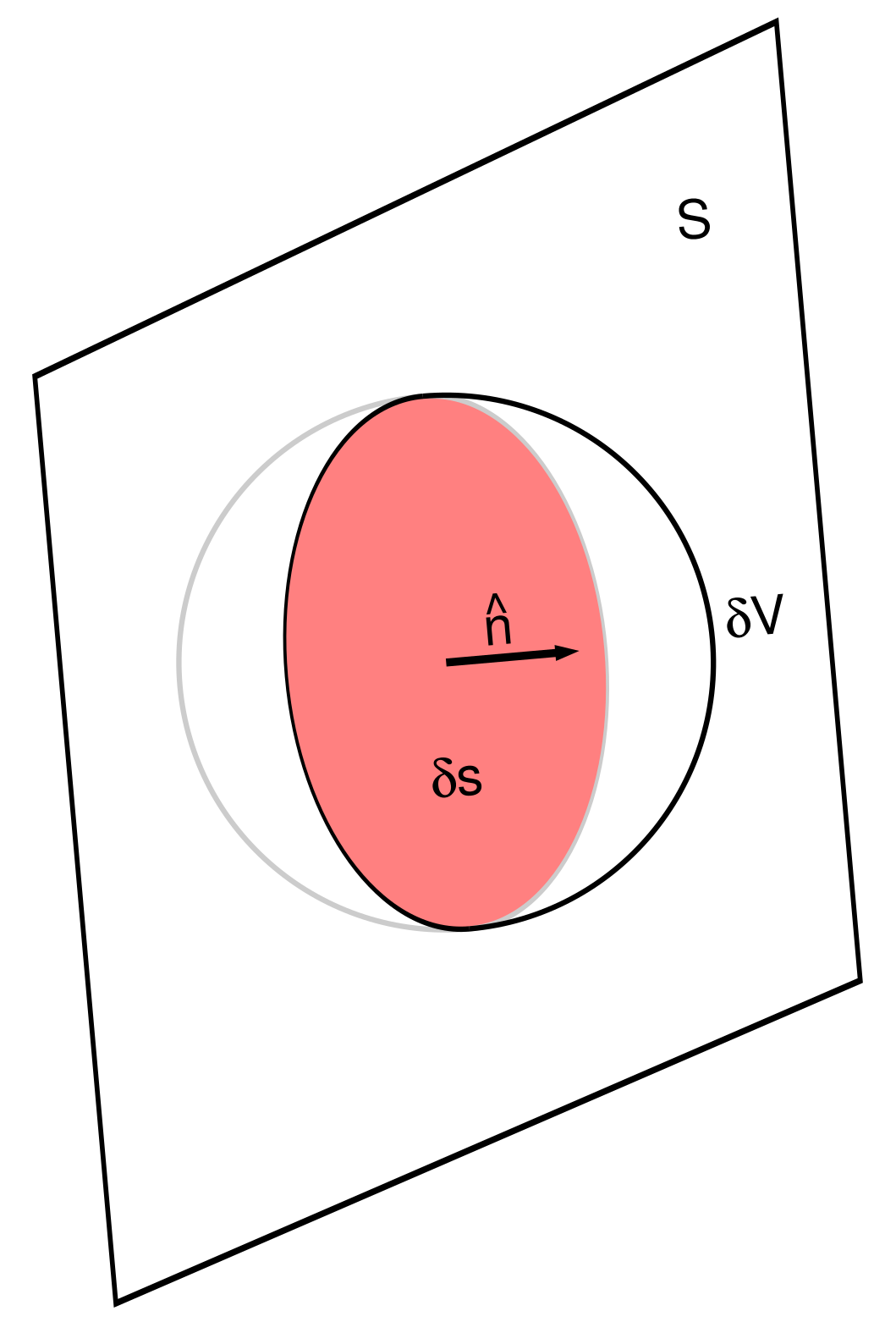

In the RANS-BEM coupling scheme, since both programs calculate the propeller induction, it must be subtracted from the flow field calculated by the RANS program before it is used as the inflow to the BEM program. To avoid errors in the BEM inflow, it is important that the inductions calculated by RANS and BEM match well. Hally and Laurens [

13] showed that a good match cannot be achieved unless the blockage of the flow by the propeller is taken into account; because the propeller blades displace some of the fluid volume, they tend to retard the flow upstream, an effect that is not captured by the force field since it displaces no fluid. They accounted for this effect by calculating the flow inside the propeller blades in the BEM calculation to produce a force field that included the retarding effect. However, the flow inside the blades has high velocities making the method sensitive to the panelling of the propeller blades.

Starke and Bosschers [

14] accounted for the blockage effects in a different way. Using the Morino formulation [

15] of the BEM, they argued that the blockage is caused by the source terms distributed on the panels while the propeller induction is caused by the dipole terms. Therefore, when calculating the propeller induction, they simply set the sources to zero and include the effect of the dipoles alone. The match between RANS and BEM inductions is then good, but the upstream flow is not correct since any interaction with the hull caused by the retardation of the flow will not be present.

Hally [

16,

17] described a third method for accounting for the propeller blockage by adding a source term to the continuity equation in the RANS solver; an additional term must also be added to the momentum equations to account for the change in momentum induced by the injection of mass. This method has subsequently been used by Su et al. [

18]. It is comparatively insensitive to the blade panelling and includes the retarding effects in the propeller–hull interaction.

The current paper expands on the description by Hally [

16,

17] of the modelling of the propeller by force and mass rate density fields. The expressions for the sources in the momentum and continuity equations are derived more completely and an error in the momentum source induced by the injection of mass is corrected. The method for allocating the force and mass rate densities to RANS cells is described in detail and the sensitivities to various parameters are investigated. An example of the use of the method in a self-propulsion calculation can be found in Ref. [

17].

5. Comparison of RANS and BEM Flow Fields in Open Water

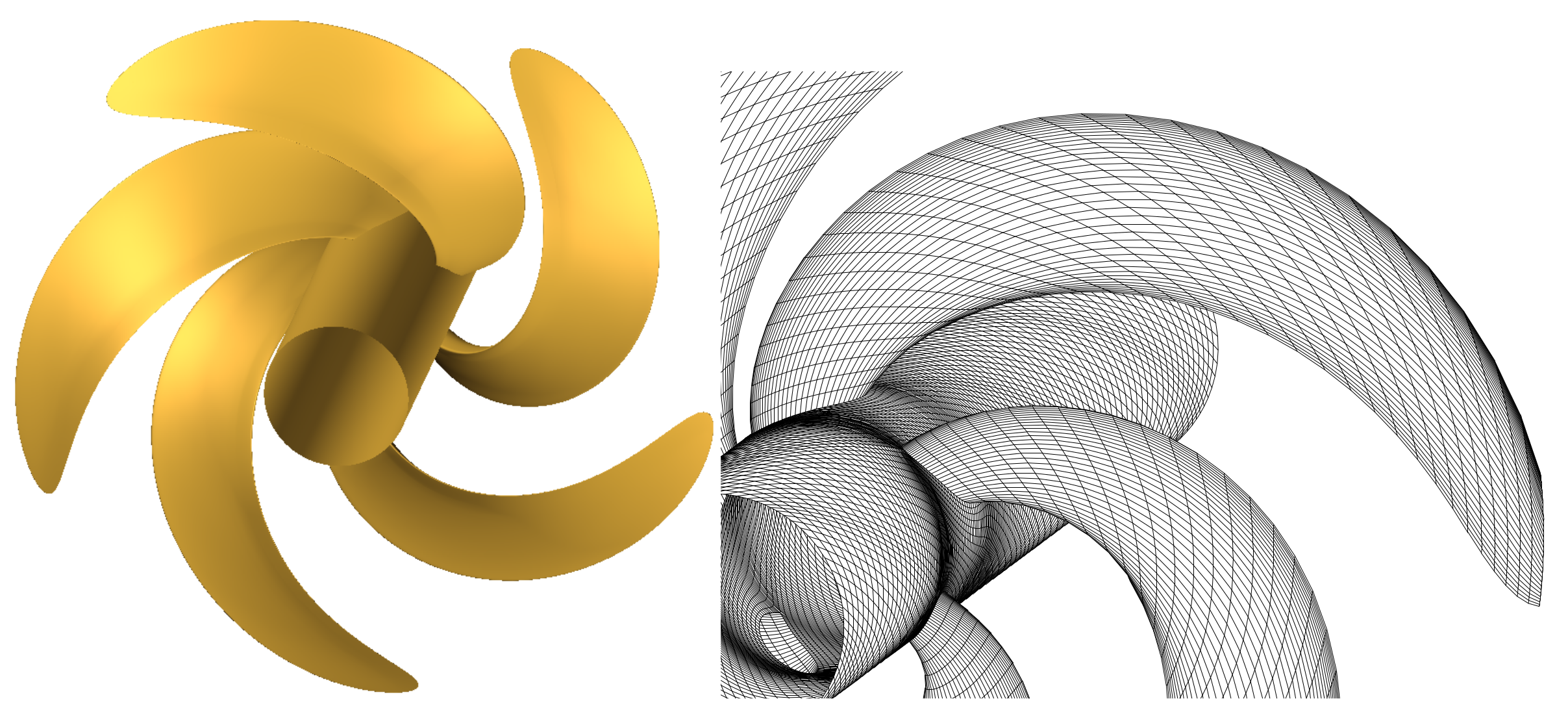

If the propeller operates in open water, the time-averaged flow calculated using the BEM code and the flow calculated using the RANS code with force and mass rate fields should be the same. Therefore, open water flow provides a test of the ability of the force and mass rate fields to mimic the action of the propeller. Here, the flow past propeller DTMB P4384 is presented as an example. This propeller is part of the NSRDC skewed propeller series described by Boswell [

22]. It is the most skewed of the series having

of unbalanced skew: see

Figure 2. There is no generator rake for this propeller, but the skew induced rake is

, making the angle of skew induced rake

(measured from the generator line at the hub through the tip).

The points at which the RANS and BEM flow fields are evaluated and compared will normally depend on the details of the RANS-BEM coupling procedure. Often, the comparison is made at one or more planes upstream of the propeller but Hally [

17], Kinnas et al. [

19] and Su et al. [

18] have advocated making the comparison at points within the swept volume of the blades. Here, the RANS and BEM flow fields will be compared throughout the flow field: upstream, in the swept volume of the blades, and in the slipstream downstream.

The BEM panelling, also shown in

Figure 2, used 40 panels between the leading edge and trailing edge on each side of the blades, and 30 between the root and tip: 2400 panels in total per blade. The panel heights were uniform, but their widths decreased near the leading edge and trailing edge to resolve the blade geometry better in those locations. The hub was a cylinder extending one propeller radius upstream and two propeller radii downstream. There were 150 panels along the length of the hub and 15 panels between each pair of blades.

PROCAL has several different methods for determining the locations of the wake panels in the slipstream of the propeller. For this comparison, the wake contraction was determined from an empirical equation derived from a fit to experimental data reported by Min [

23]; an iterative method was used determine the pitch of the panels. Details of these models are given by Bosschers [

24]. The effect of the wake panels on the solution will be discussed further in

Section 5.2.

The BEM solution provides values of the source and dipole strengths on each panel at each time step. The velocity at any point in the flow field can then be obtained by summing the influence of each panel at the point. Analytic expressions for the influence of a panel at an arbitrary point are given by Morino et al. [

15].

To determine the time-averaged BEM velocities at points between the blades, the method described by Hally [

17] was used: induced velocities at each time step are calculated at a sequence of

points joining the centroids of panels on neighbouring blades, then interpolated and averaged in time. The portion of time that the evaluation point is inside one of the blades is included in the average but contributes nothing to it as the induced velocity is zero inside the blades. A similar method is used to determine the velocities in the wake. For these calculations,

was set to 51.

The RANS grid covered an annular region between the cylindrical hub at and an outer cylinder at . It extended upstream and downstream and consisted of a single axisymmetric structured block having 152 nodes axially, 89 nodes radially and 90 nodes around the circumference: 1,217,520 points and 1,195,920 hexahedral cells in all. Over the swept volume of the blades, the size of the cells in the axial and radial directions was and in the circumferential direction increased from at the hub to at the tip. The node separation increased upstream, downstream and radially beyond the blade tips.

When allocating the forces and mass rates to the RANS cells, a maximum split level of 9 was used.

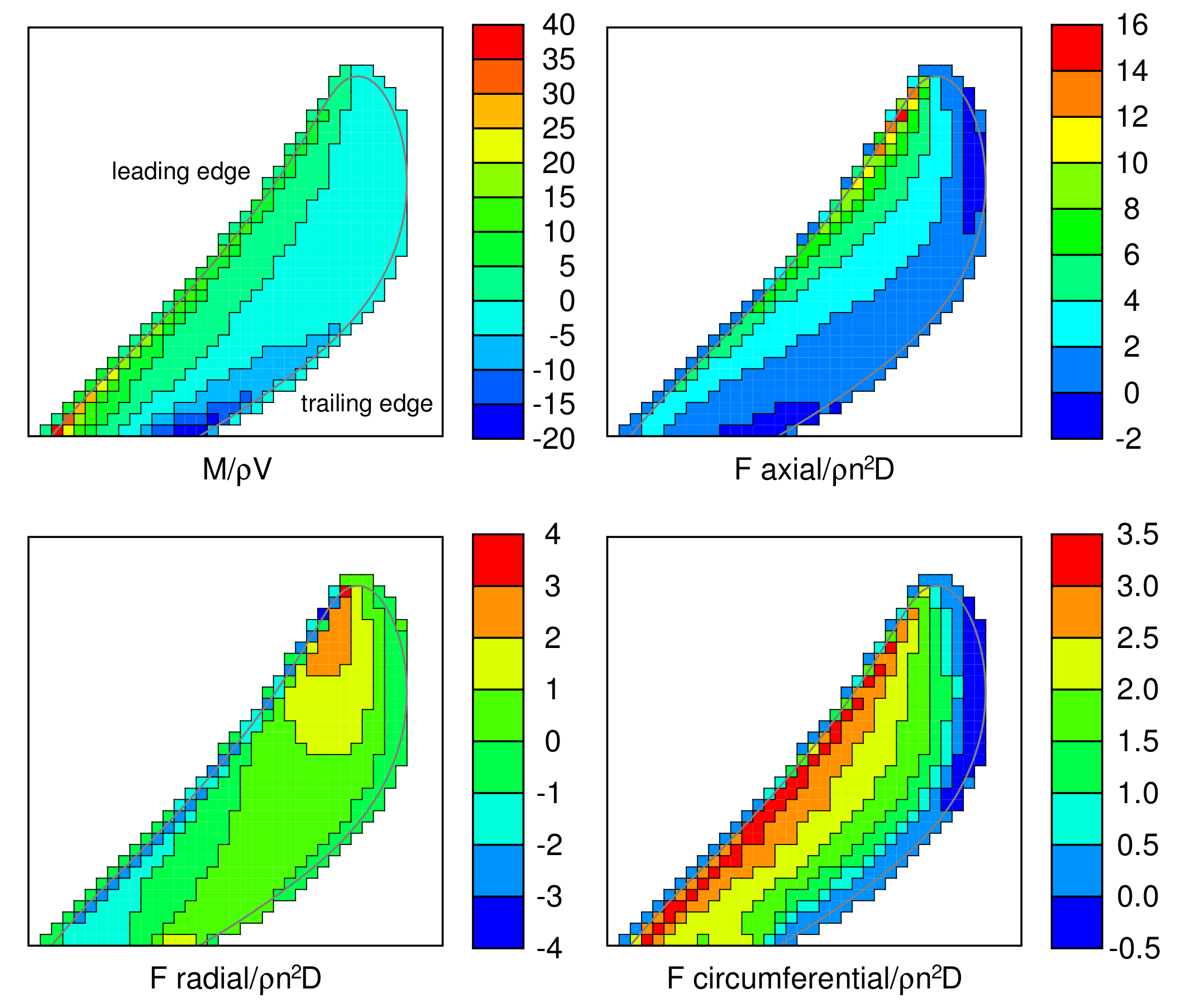

Figure 3 shows the distribution of

and

, where

V is the speed of inflow,

n is the rotation rate in revolutions per unit time and

D is the propeller diameter. The non-dimensionalized mass rate is independent of the advance coefficient; the non-dimensional force is shown for

. The distributions are shown in a single

plane (the distributions are axisymmetric) with the flow coming from left to right. The mass rate is positive at the leading edge as

is directed into the blades increasing the mass there, negative near the trailing edge where

is directed out of the blades. The axial force is positive when directed downstream. The circumferential force is positive in the direction of rotation of the blades.

Figure 3 also provides an indication of the size of the RANS cells. Because the match between the RANS cells and BEM panels is imperfect, the fields can extend up to one cell width outside the swept volume of the blades. There are 43,290 cells in which the mass rate and force density are non-zero.

On the inflow plane, the velocity was set to match the inflow in the BEM computation; the normal pressure gradient was set to zero. The outflow plane was divided into two annuli at . On both annuli, the normal gradient of the velocity was set to zero. The pressure was set to zero on the outer annulus, but its normal gradient was set to zero on the inner annulus. Both the hub and the outer cylinder were treated as free slip walls.

At , the thrust obtained from integration of the RANS force field was 0.2% higher than that obtained from summing the pressure-induced force over the BEM panels; at it was 0.1% higher. The torques obtained in a similar way were 0.3% higher for and 0.2% higher at . In the velocity field comparisons shown below, no correction was made for this small mismatch.

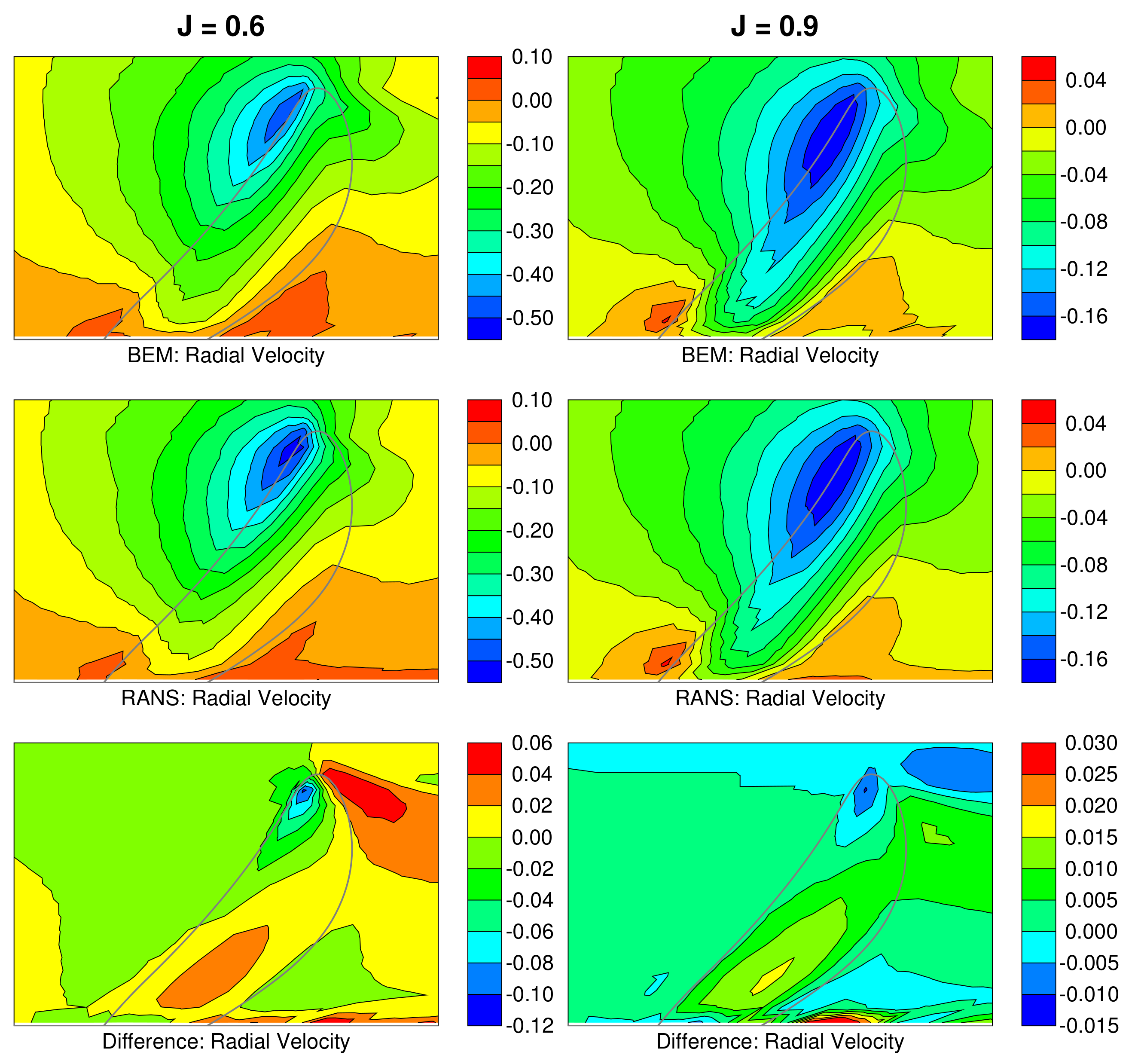

Figure 4,

Figure 5 and

Figure 6 show the components of the velocity field, normalized relative to the inflow speed

V, generated by PROCAL and OpenFOAM at advance coefficients

and

. The latter is very close to the design advance coefficient of

. The difference between the RANS and BEM velocities is also shown (the BEM velocity field is subtracted from the RANS velocity field). The flow is displayed in a single

plane with the outline of the swept volume of the blades shown as a grey line. In these figures, the velocity components are consistent with the components of force in

Figure 3: i.e., the axial velocity is positive if it is directed downstream and the circumferential velocity is positive in the direction of rotation of the blades.

At both advance coefficients, the largest differences between the RANS and BEM flow fields occur in the wake at the radial extremes of the wake panels: i.e., close to the hub and close to the location of the tip vortex. Discrepancies in these locations are not important for the RANS-BEM coupling procedure as the RANS and BEM flow fields will only be compared either upstream or within the swept volume of the blades. There is also a relatively large mismatch in the circumferential velocity where the blade meets the hub.

For , the differences are less than everywhere upstream of the propeller and less than over almost the entire swept volume of the blades. For the lower advance coefficient, the differences are less than everywhere upstream of the propeller and less than over almost the entire swept volume of the blades. The degradation in accuracy at higher loading has been found to be consistent for a wide variety of propellers.

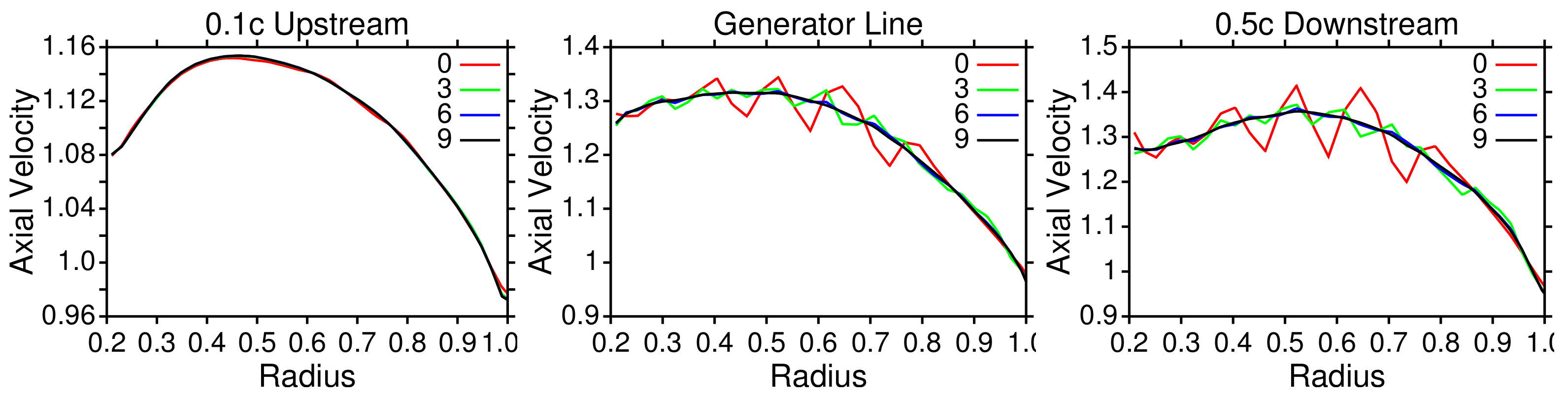

5.1. Sensitivity to the Maximum Split Level

The flow field predicted by the RANS solver will depend to some extent on the maximum split level used when allocating the cells. The higher the maximum split level, the more accurately the force and mass rate are distributed among the RANS cells. A choice which is too small will cause the flow field between the blades to fluctuate in an unphysical manner. However, the most appropriate choice of maximum split level will also depend on the mean size of the cells in the RANS grid close to the propeller. The more refined the grid, the smaller the maximum split level can be.

The sensitivity to the split level was tested by generating force and mass rate fields with maximum split levels of 0, 3, 6 and 9.

Figure 7 shows the axial velocity predicted by OpenFOAM at three locations: about one tenth of the chord length upstream of the leading edge, along the generator line, and about one half of the chord length downstream of the trailing edge.

Upstream of the propeller, the flow field is insensitive to the maximum split level; in the swept volume of the blades and downstream, the flow field is quite sensitive. If the RANS and BEM wakes are to be compared upstream, then a maximum split level of 3 should suffice. For comparisons between the blades, the maximum split level should be at least 6.

5.2. Sensitivity to Wake Panels

The sensitivity to the location of the wake panels was tested by choosing among several of the different wake model options provided by PROCAL. There are two empirical models for the wake contraction: the Hoshino model [

25] and a fit to experimental data reported by Min [

23]. Details of these models are given by Bosschers [

24]. In addition, there is an iterative method that adjusts the contraction of the tip vortex so it is parallel to the flow. The iterative model is not very robust and could not be made to converge, so it was not considered in this study. The calculations shown in

Figure 3,

Figure 4,

Figure 5 and

Figure 6 used the Min method.

For this propeller, the Min method was much better than the Hoshino method. At , the mismatch in RANS and BEM velocities at the outer edge of the slipstream was reduced by about 50%. At , the reduction was about 70%. There were similar reductions upstream of the blades. In the swept volume of the blades, the difference between the two methods was significantly smaller than the difference between the RANS and BEM velocities: about at and at .

The Min method is a fit to experimental data for four propellers, all of which are closely related to DTMB P4384; they are the other three propellers from the NSRDC skewed propeller series, P4381, P4382 and P4383, as well as a fourth propeller equivalent to P4383 but with extra rake. Therefore, it is perhaps not surprising that the Min method performs well for P4384. Whether it does so consistently for other propellers is not yet clear.

The pitch of the wake panels can be set using three different empirical formulae depending on the pitch at each section, the advance coefficient and the skew angle at the tip (details given by Bosschers [

24]). There is also an iterative method that adjusts the pitch of the panels to be parallel to the flow.

At , the choice of method for the pitch of the wake panels resulted in very small differences to the flow: typically less than and significantly smaller than the differences between the RANS and BEM flow fields. Near the design advance coefficient the choice of pitch model is not very important.

At , the iterative wake model performed significantly better than the empirical models in the slipstream, reducing the RANS-BEM discrepancy in axial velocity by about 80%, though the differences in the tangential velocity components were not significant. Upstream of the blades there was also a significant reduction in the discrepancy of both the axial and radial velocity components. In the swept volume of the blades, the RANS-BEM difference in axial velocity was consistently about lower than for the empirical methods. This difference is a significant portion of the total RANS-BEM mismatch but meant that the empirical methods performed better near the leading edge while the iterative method performed better near the trailing edge. Overall, the iterative method gave the best results.

5.3. Sensitivity to RANS Cell Size

The sensitivity to the cell size in the RANS grid was checked by making a second grid with mean cell size of radially and axially and with 180 cells around the circumference. For , the difference in velocity was less than over almost the entire flow field. For , the change in all velocity components was less than almost everywhere.

For both advance coefficients, the highest differences occurred in the slipstream near the hub and at its outer edge. At the outer edge of the slipstream where the velocity gradient is very high, the differences were caused by increased diffusion on the coarser grid; the differences in this region were considerably larger (about ) at than at (about ). Near the hub, the radial and circumferential velocities showed small oscillations when the coarser grid was used causing differences of about ; these were much improved by the finer grid.

For both advance coefficients, there was also a small region where the leading edge of the blade meets the hub for which the differences were about .

5.4. Sensitivity to Other Parameters

The following sensitivity tests were also performed.

The sensitivity to , the number of points used to average the flow field between the blades, was checked by repeating the calculations with 11, 21 and 51 points.

To check that the dimensions of the RANS flow domain were sufficiently large, the RANS flow field for the case was recalculated on a grid whose outer dimensions were increased from to .

Two additional PROCAL blade panellings were used:

- -

20 panels root to tip and 30 panels from leading to trailing edge;

- -

40 panels root to tip and 60 panels from leading to trailing edge.

In all cases, the changes in the RANS-BEM mismatch were found to be insignificant.