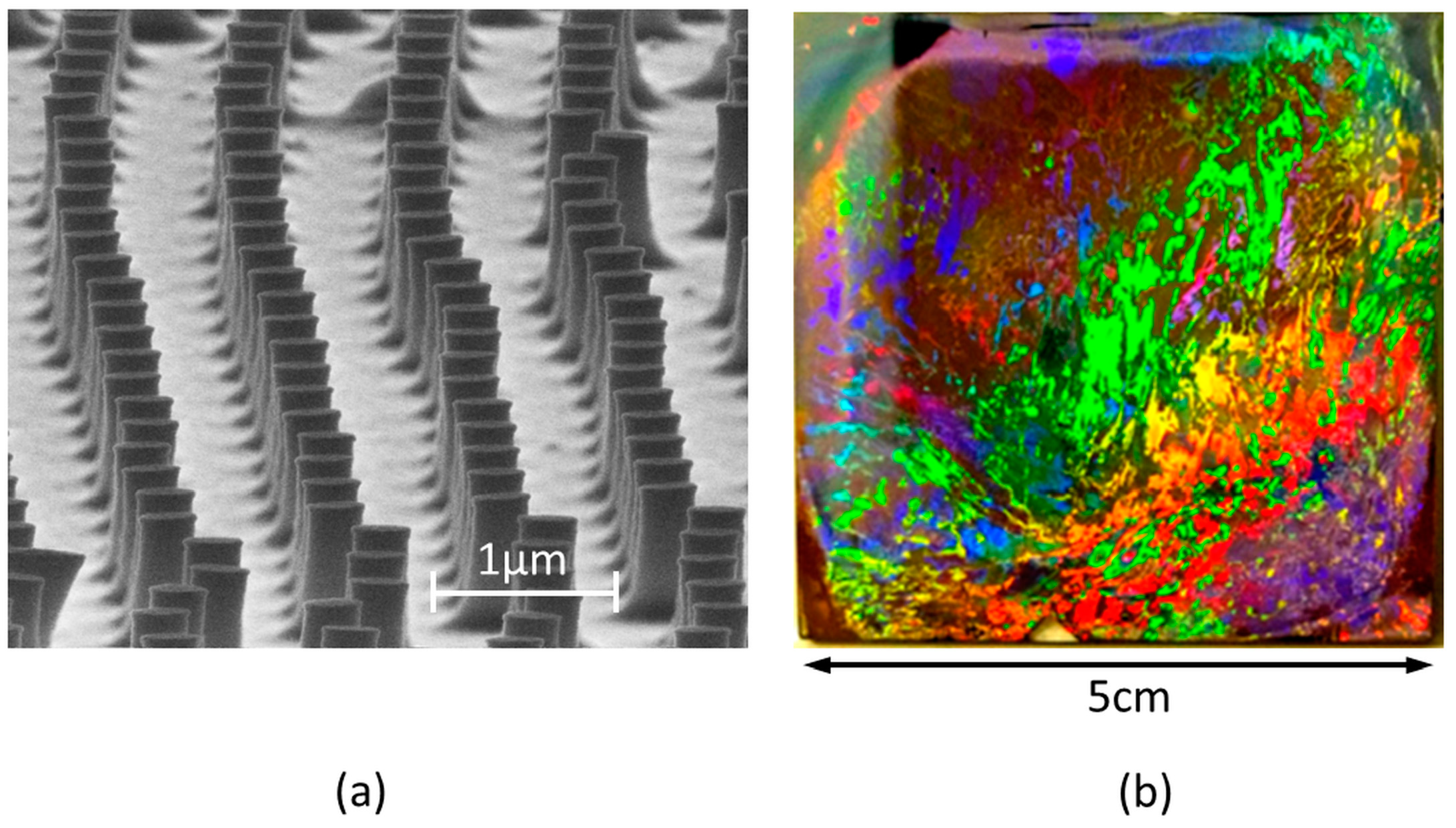

Periodic TiO2 Nanostructures with Improved Aspect and Line/Space Ratio Realized by Colloidal Photolithography Technique

Abstract

:1. Introduction

2. Materials and Methods

2.1. Rigorous Optical Simulation of Nanojets Created by Microsphere Arrays

2.2. Direct Photolithography of the Sol-Gel TiO2

3. Results and Discussion

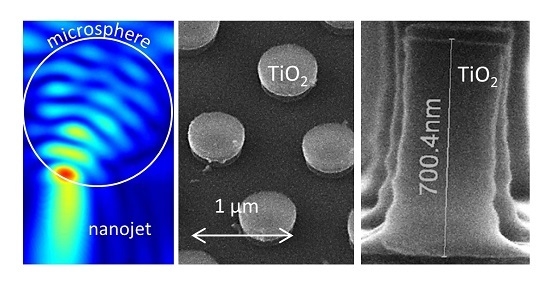

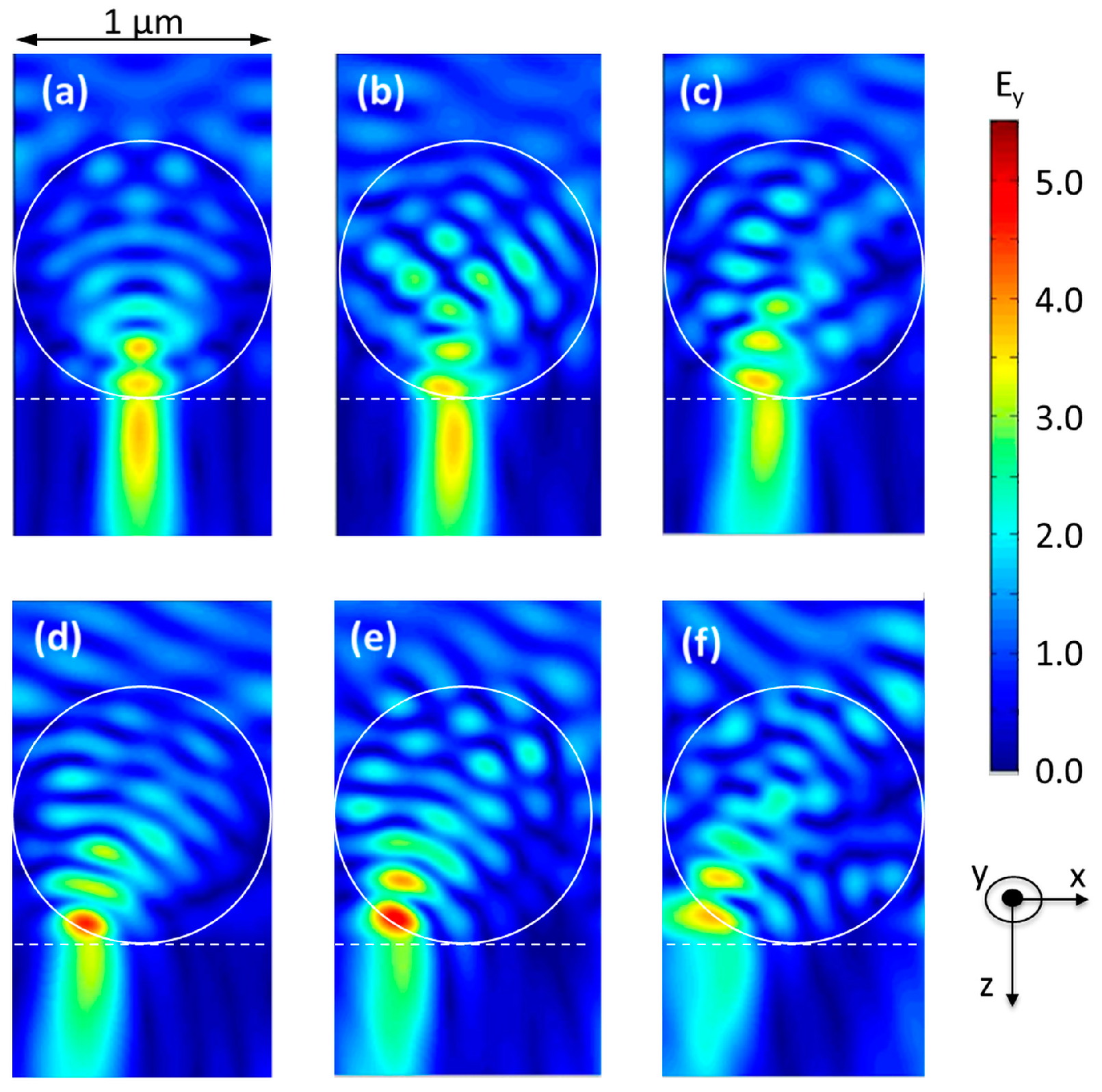

3.1. Simulation and Optimization of the Microsphere-Created Nanojets

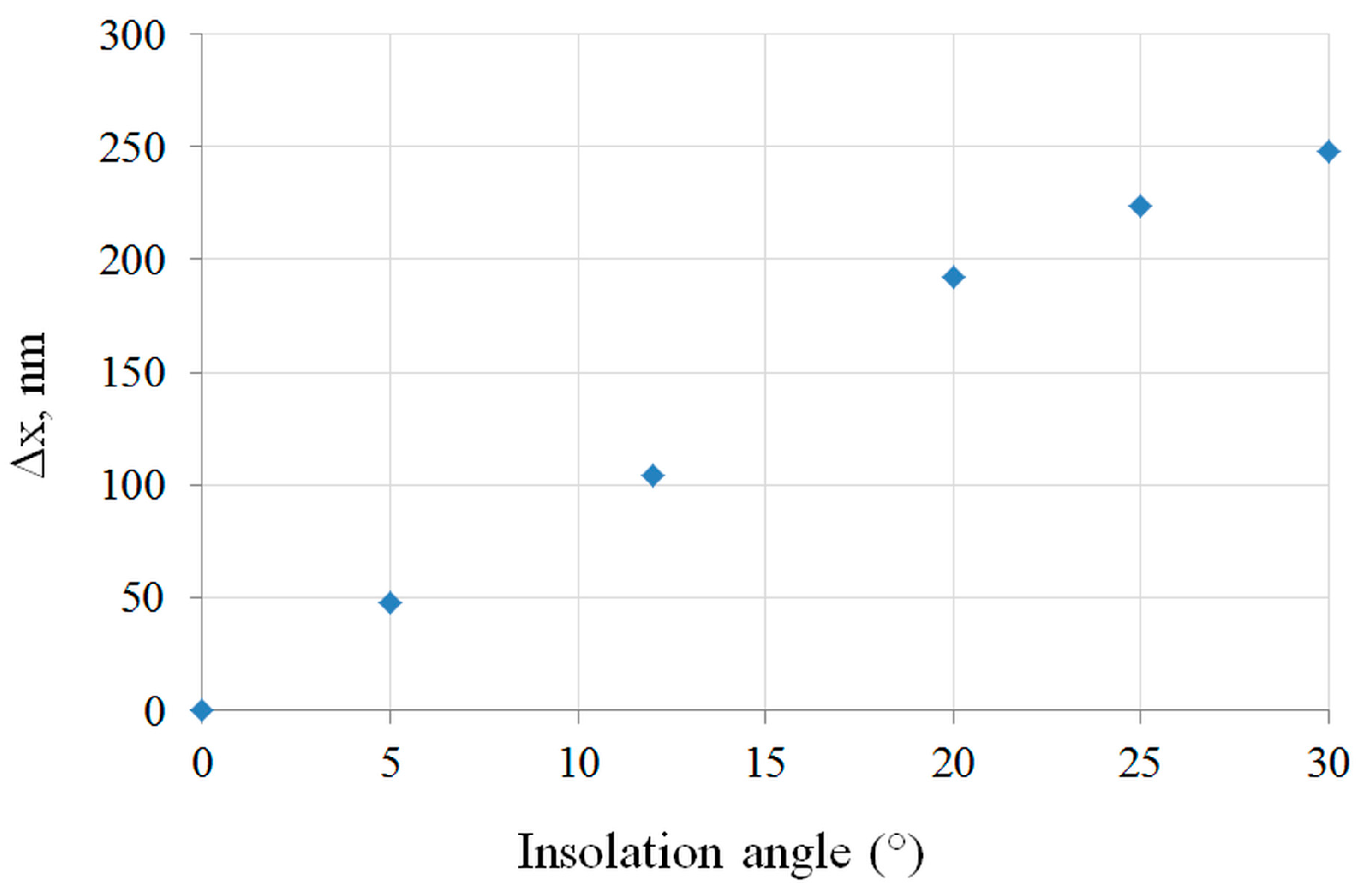

3.2. First Optimization: Increasing the Nanopillars Width and Creating Variable Shapes

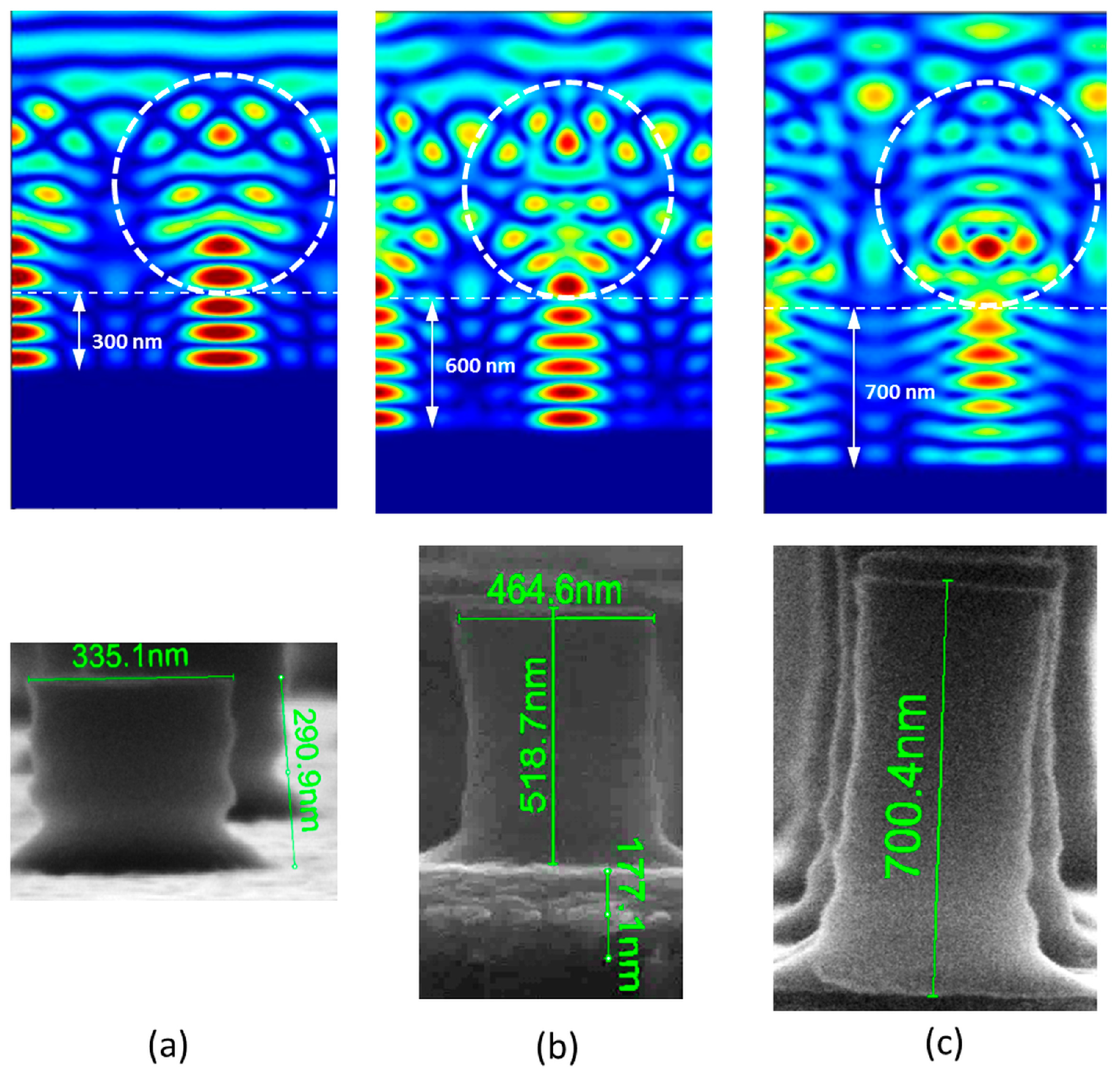

3.3. Second Optimization: Increasing the Nanopillar’s Height

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wu, W.; Dey, D.; Memis, O.G.; Katsnelson, A.; Mohseni, H. A Novel Self-aligned and Maskless Process for Formation of Highly Uniform Arrays of Nanoholes and Nanopillars. Nanoscale Res. Lett. 2008, 3, 123–127. [Google Scholar] [CrossRef]

- Hsu, C.-M.; Connor, S.T.; Tang, M.X.; Cui, Y. Wafer-scale silicon nanopillars and nanocones by Langmuir-Blodgett assembly and etching. Appl. Phys. Lett. 2008, 93, 133109. [Google Scholar] [CrossRef]

- Fallet, M.; Permpoon, S.; Deschanvres, J.L.; Langlet, M. Influence of physico-structural properties on the photocatalytic activity of sol-gel derived TiO2 thin films. J. Mater. Sci. 2006, 41, 2915–2927. [Google Scholar] [CrossRef]

- Briche, S.; Tebby, Z.; Riassetto, D.; Messaoud, M.; Gamet, E.; Pernot, E.; Roussel, H.; Dellea, O.; Jourlin, Y.; Langlet, M. New insights in photo-patterned sol-gel-derived TiO2 films. J. Mater. Sci. 2011, 46, 1474–1486. [Google Scholar] [CrossRef]

- Lazar, M.; Varghese, S.; Nair, S. Photocatalytic Water Treatment by Titanium Dioxide: Recent Updates. Catalysts 2012, 2, 572–601. [Google Scholar] [CrossRef]

- Pelaez, M.; Nolan, N.T.; Pillai, S.C.; Seery, M.K.; Falaras, P.; Kontos, A.G.; Dunlop, P.S.M.; Hamilton, J.W.J.; Byrne, J.A.; O’Shea, K.; et al. A review on the visible light active titanium dioxide photocatalysts for environmental applications. Appl. Catal. B Environ. 2012, 125, 331–349. [Google Scholar] [CrossRef]

- Mor, G.K.; Shankar, K.; Paulose, M.; Varghese, O.K.; Grimes, C.A. Use of Highly-Ordered TiO2 Nanotube Arrays in Dye-Sensitized Solar Cells. Nano Lett. 2006, 6, 215–218. [Google Scholar] [CrossRef] [PubMed]

- Zukalová, M.; Zukal, A.; Kavan, L.; Nazeeruddin, M.K.; Liska, P.; Grätzel, M. Organized Mesoporous TiO2 Films Exhibiting Greatly Enhanced Performance in Dye-Sensitized Solar Cells. Nano Lett. 2005, 5, 1789–1792. [Google Scholar] [CrossRef] [PubMed]

- Spinelli, P.; Macco, B.; Verschuuren, M.A.; Kessels, W.M.M.; Polman, A. Al2O3/TiO2 nano-pattern antireflection coating with ultralow surface recombination. Appl. Phys. Lett. 2013, 102, 233902. [Google Scholar] [CrossRef]

- Shavdina, O.; Berthod, L.; Kämpfe, T.; Reynaud, S.; Veillas, C.; Verrier, I.; Langlet, M.; Vocanson, F.; Fugier, P.; Jourlin, Y.; et al. Large Area Fabrication of Periodic TiO2 Nanopillars Using Microsphere Photolithography on a Photopatternable Sol-Gel Film. Langmuir 2015, 31, 7877–7884. [Google Scholar] [CrossRef] [PubMed]

- Kusaka, K.; Kurosawa, H.; Ohno, S.; Sakaki, Y.; Nakayama, K.; Moritake, Y.; Ishihara, T. Waveguide-mode interference lithography technique for high contrast subwavelength structures in the visible region. Opt. Express 2014, 22, 18748–18756. [Google Scholar] [CrossRef] [PubMed]

- Bonakdar, A.; Rezaei, M.; Brown, R.L.; Fathipour, V.; Dexheimer, E.; Jang, S.J.; Mohseni, H. Deep-UV microsphere projection lithography. Opt. Lett. 2015, 40, 2537. [Google Scholar] [CrossRef] [PubMed]

- Moharam, M.G.; Gaylord, T.K.; Pommet, D.A.; Grann, E.B. Stable implementation of the rigorous coupled-wave analysis for surface-relief gratings: Enhanced transmittance matrix approach. J. Opt. Soc. Am. A 1995, 12, 1077–1086. [Google Scholar] [CrossRef]

- MC Grating Software. Available online: https://mcgrating.com/ (accessed on 11 October 2017).

- Bardosova, M.; Pemble, M.E.; Povey, I.M.; Tredgold, R.H. The Langmuir-Blodgett Approach to Making Colloidal Photonic Crystals from Silica Spheres. Adv. Mater. 2010, 22, 3104–3124. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berthod, L.; Shavdina, O.; Verrier, I.; Kämpfe, T.; Dellea, O.; Vocanson, F.; Bichotte, M.; Jamon, D.; Jourlin, Y. Periodic TiO2 Nanostructures with Improved Aspect and Line/Space Ratio Realized by Colloidal Photolithography Technique. Nanomaterials 2017, 7, 316. https://doi.org/10.3390/nano7100316

Berthod L, Shavdina O, Verrier I, Kämpfe T, Dellea O, Vocanson F, Bichotte M, Jamon D, Jourlin Y. Periodic TiO2 Nanostructures with Improved Aspect and Line/Space Ratio Realized by Colloidal Photolithography Technique. Nanomaterials. 2017; 7(10):316. https://doi.org/10.3390/nano7100316

Chicago/Turabian StyleBerthod, Loïc, Olga Shavdina, Isabelle Verrier, Thomas Kämpfe, Olivier Dellea, Francis Vocanson, Maxime Bichotte, Damien Jamon, and Yves Jourlin. 2017. "Periodic TiO2 Nanostructures with Improved Aspect and Line/Space Ratio Realized by Colloidal Photolithography Technique" Nanomaterials 7, no. 10: 316. https://doi.org/10.3390/nano7100316