1. Introduction

Benefiting from its fascinating mechanical, electrical, optical, and thermal properties, graphene with a two-dimensional honeycomb-like framework emerges as a promising alternative to initiate a new material revolution [

1]. Since the first discovery of graphene by mechanical exfoliation [

2,

3], various methods have been developed, such as chemical vapor deposition (CVD), exfoliation of SiC, and chemical reduction of graphene oxide (GO), aiming at various potential industrial and academic applications in energy storage and conversion, gas sensors, adsorbents, and field-effect transistors (FETs) [

4,

5,

6]. For example, Wang et al. investigated graphene chemical vapor deposition growth on various transition metal surfaces, and found different dissociation rates of methane and diffusion growth of graphene on substrate [

7]. Pei et al. reviewed the state-of-the-art status of GO reduction on both techniques and mechanisms, and discussed the effects of different reduction processes on the properties of reduced GO [

8]. However, these methods are restrictive with the consideration of precursor specification, high processing temperature, heavy energy consumption, and the use of hazardous chemicals [

9]. Non-sustainable and explosive petroleum gases like CH

4 and C

2H

2 are usually designated as carbon precursors, which renders a higher cost of production and safety management. Hence, substantial efforts have been made to develop green and cost-efficient technologies to produce graphene.

Recently, there has been a significant increase in graphene synthesis using non-thermal plasma technologies [

10]. Owing to the generation of energetic electrons and versatile active species (radicals, ions, photons, excited molecules, and atoms), non-thermal plasma affords a low temperature, high chemical reactivity, and flexible parameter tuning environment for the growth of versatile carbon materials [

6,

11]. As such, numerous studies have been performed to investigate the utilization of non-thermal plasma towards tailoring graphene properties for various applications. Among the various non-thermal plasma sources (e.g., gliding arc plasma, glow plasma, microwave plasma, etc.), inductively coupled plasma (ICP) is proposed to realize a controllable vertical graphene (VG) synthesis in the present work. In this stable and non-thermal equilibrium plasma environment, the growth of well-oriented vertical graphene sheets with reactive edge structure and abundant open internal channels is anticipated [

10,

12]. Compared with the conventional horizontal random stacking graphene sheets associated with van der Waals interactions, self-supported VG sheets are favored in practical applications because of their unique mechanical, chemical, and electrochemical properties. For example, the non-agglomerated morphology of VG gives a high specific surface area and abundant open channels between the sheets. Additionally, long, exposed, ultra-thin graphene edges on VG sheets exhibit chemical activity, making VG attractive for emerging energy and environmental application [

6].

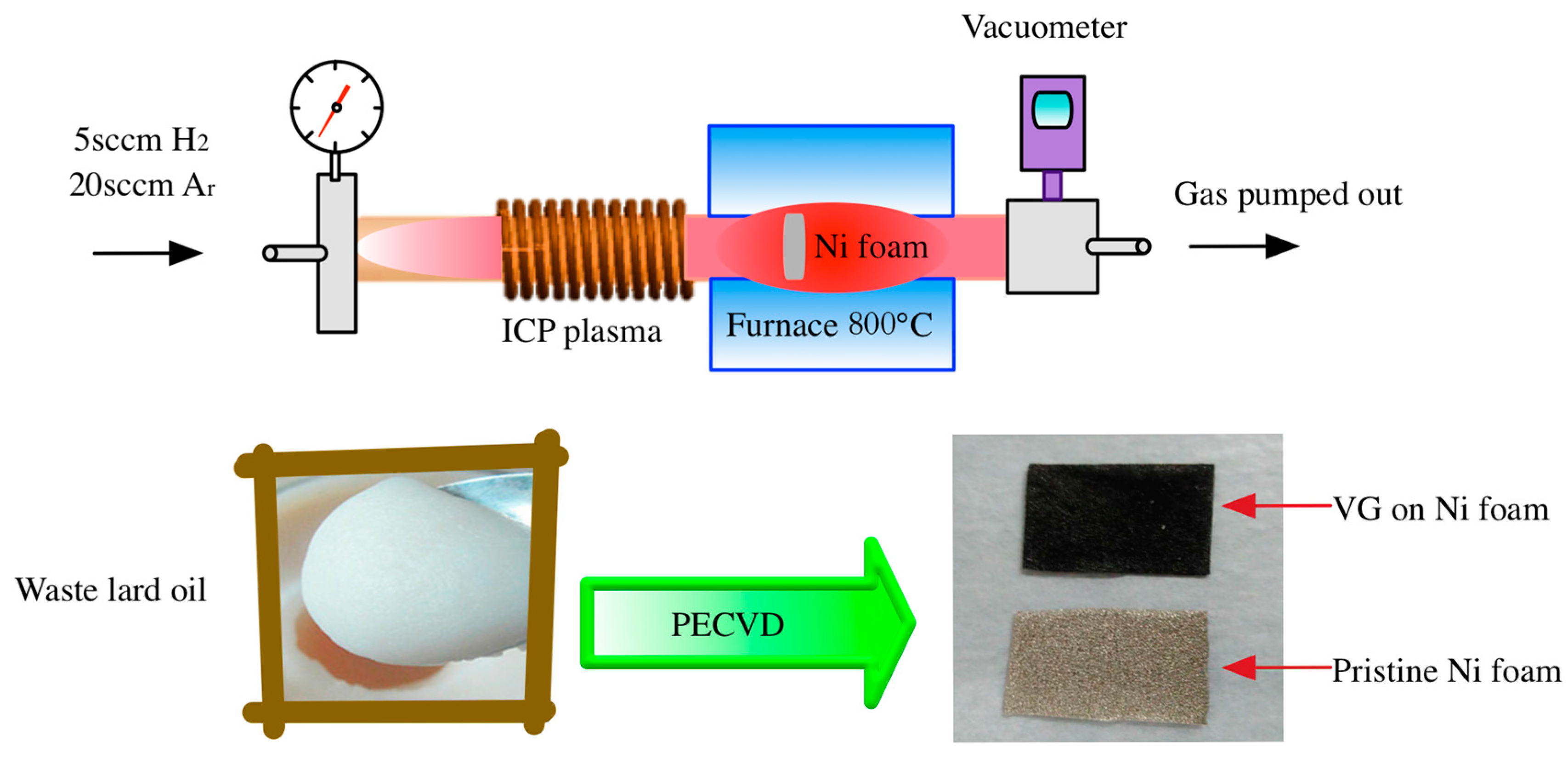

Herein, waste lard oil originated from daily cooking and oil manufacturers is introduced as a cheap and green carbon donor to synthesize VG, aiming at the revalorization of waste into high-value-added materials. Lard oil is one of most significant oils consumed in China. According to the statistics in 2002, the consumption proportion of lard oil occupied nearly 29% amongst various edible oils in daily life [

13]. Hence, waste lard oil with its nature of abundance, nontoxicity, and sustainability exhibits tremendous potential as a carbon source for VG growth. In fact, natural waste has already emerged as a carbon precursor and has been investigated by researchers worldwide. Wang et al. used microwave plasma to convert waste rice husk into graphene and carbon nanotubes hybrids, and this can even be spread to other waste biomass [

14]. Seo et al. used natural honey as a green carbon source to obtain VG sheets using inductively coupled plasma (ICP), and attempted application in gas- and bio-sensing [

4]. Wu et al. converted waste rapeseed oil into hydrogen and carbon materials using gliding arc plasma, and analyzed the discharge characteristics in plasma [

15,

16].

In this paper, we firstly propose the use of waste lard oil as carbon donor for a one-step synthesis of VG sheets using inductively coupled plasma (ICP)-enhanced chemical vapor deposition (PECVD). The morphology, graphitized degree, and wettability of the obtained carbon was investigated. Furthermore, the effects of temperature, gas proportion, and ICP power on the properties of waste lard oil-based graphene were studied. Finally, a probable growth mechanism of VG is suggested.

3. Results and Discussion

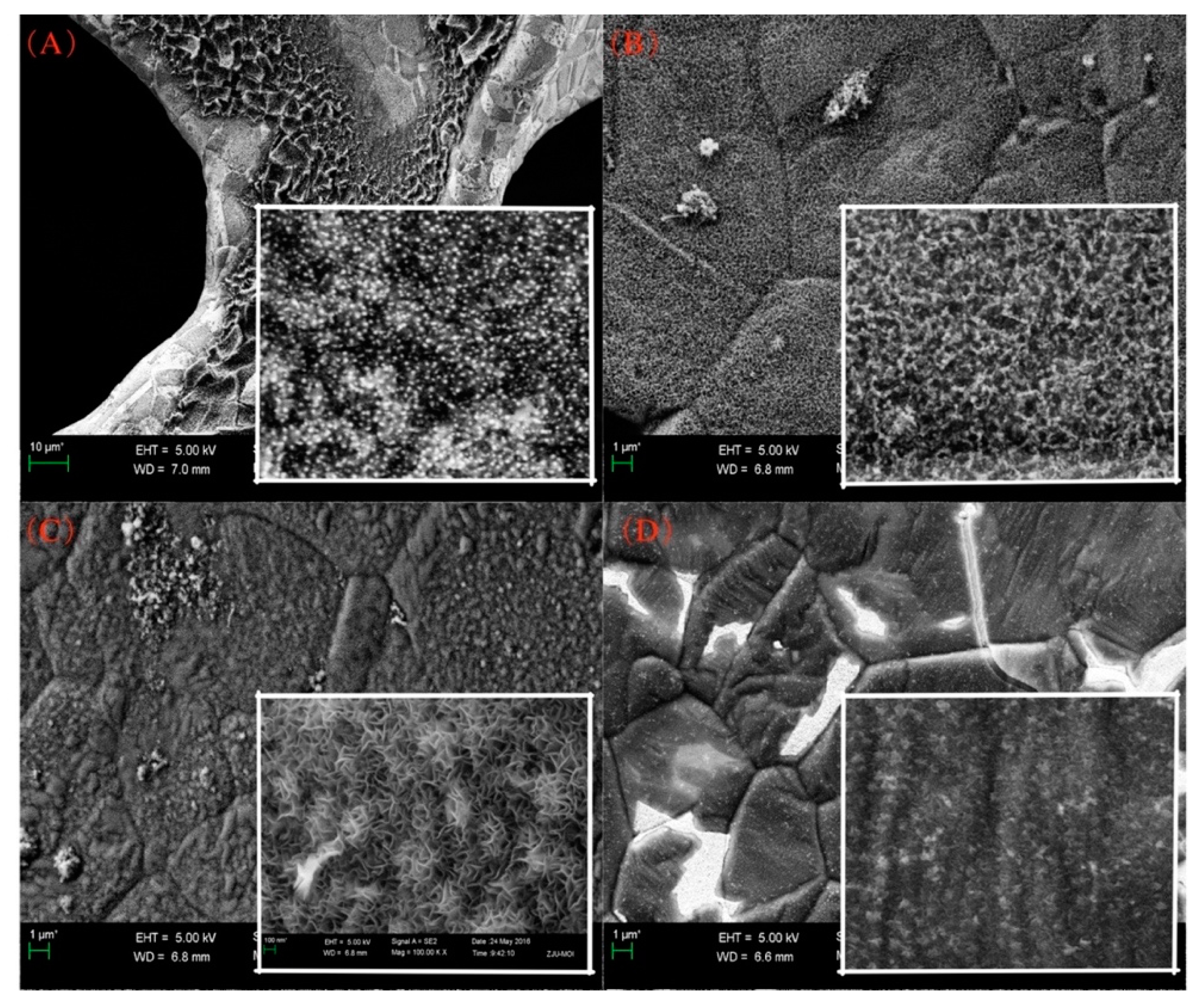

In the SEM images of

Figure 2A, moss-like carbon aggregate was obtained by ICP plasma, which was arranged in an inhomogeneous size distribution. Additionally, small spherical carbon nanoballs were also observed below these coagulations of carbon clusters. Without external heating, a complex and irregular morphology of solid carbon was obtained only using 500 W ICP. Through characterization by Raman spectroscopy, defects and crystallization degree of these obtained carbon could be further revealed. D peak (corresponding to the defects or amorphous carbon) at ~1350 cm

−1, G peak (corresponding to the presence of graphitized carbon and double degenerate deformation vibrations of sp

2 chain) at ~1580 cm

−1, and 2D peak (corresponding to overtone of D peak) at ~2700 cm

−1 were observed in the spectrum [

17,

18]. The intensity ratio of D-to-G peak (

) was used to quantify the structural purity or defect’s quantity in graphitic material, while the 2D-to-G peak (

) indicated the layers of graphene. In

Figure 2C,

and

were approximately 1 and 0.92, respectively, while the intense background signal corresponded to the effect of fatty acids. It was conjectured that although ICP plasma could partly break down long aliphatic chains of oil into light molecules such as aromatic hydrocarbons, alkanes, olefins etc., it was still too low to support the self-assembly of carbon atoms [

16].

In

Figure 2B, well-oriented VG was formed after 15 min treatment via PECVD. Dense VG sheets with sharp edges were discernible, while the thickness and lateral size were of about 10 nm and 200 nm, respectively. Such graphene edges grew upward on the nickel foam and interweaved mutually, resulting into a porous structure and micro channels between sheets. The distribution of pore size formed by VG sheets’ edges indicates a mean diameter of 12 nm. The observed bright films covering the VG sheets was carbonic material, which was attributed to the joint effect of ICP plasma and graphene edges [

19]. Accordingly, sharp and intense D peak with a high

ratio of 1.29 is illustrated in

Figure 2D, in agreement with the rich dense edges observed in SEM. The

of 0.45 implied few-layer sheets formed in VG [

4]. In addition, D + G peak (~2940 cm

−1, corresponding to a combination of scattering peak) and 2D’ (~3200 cm

−1) was also observed in the second-order Raman spectrum [

18].

The contact angles of water droplets on carbon obtained by ICP plasma and PECVD are comparatively analyzed in

Figure 2E,F. The contact angle of water droplet on VG sheets was 141.5

, exhibiting a better hydrophobic property than the counterpart obtained by separate ICP treatment (contact angle = 107.2

). Such super hydrophobic property of waste lard oil-based VG could be attributed to several aspects. Firstly, a high ratio of hybridized sp

2 bonding and

electrons coupling effect promoted the rejection of polar molecules like water droplets. Then, water-repellent effect was also enhanced by amounts of cavities formed by interweaved VG sheets. With the consideration of the relatively high composition ratio of N in lard oil, the heterogeneous atoms doped on the edges of VGs might also cause the hydrophobic surface performance [

20]. Hence, apart from the existing reactive electro-chemical environment induced by ICP plasma, high-quality carbon (VG sheets) was also deeply dependent on external heating.

In fact, heating temperature was a significant parameter to tune the morphology of VG sheets. When temperature was at 600

, only chopped carbon sheets were formed, and were covered by homogeneous granular particles. When the temperature was increased to 700

, spherical carbon particles with relatively regular nanostructure were observed, which were mutually cross-linked and resulted in a dense three-dimensional network distribution. However, still no VG sheet morphology was formed. When the temperature was set at 800

, maze-like VG sheets were generated with the lateral edge size of about 200 nm. Similar morphology of VG sheets was also obtained with pure CH

4 as carbon precursor by ICP-PECVD [

21]. Further increase of heating temperature incurred a shrinkage of lateral size and promoted the formation of larger lateral size carbon sheets. As shown in

Figure 3D, poor-quality graphene sheets with extremely dense and tiny edges were formed and arranged in random orientations when the heating temperature was 900

. Hence, the influence of temperature was prominent, which might be attributed to the surface reaction kinetics of graphene growth. Wang et al. [

22] concluded that VG could not be obtained when the substrate temperature was less than 600

. With the increase of temperature, more species for nucleation as well as nucleation sites could be generated, whereas overheated temperature led to a high degree of corrugation and density of nucleation sites, and restricted the lateral growth of VG sheets. Herein, the optimal heating temperature was 800

for the growth of high-quality VG sheets, with consideration of its potential application in supercapacitors, field emission, and catalysis.

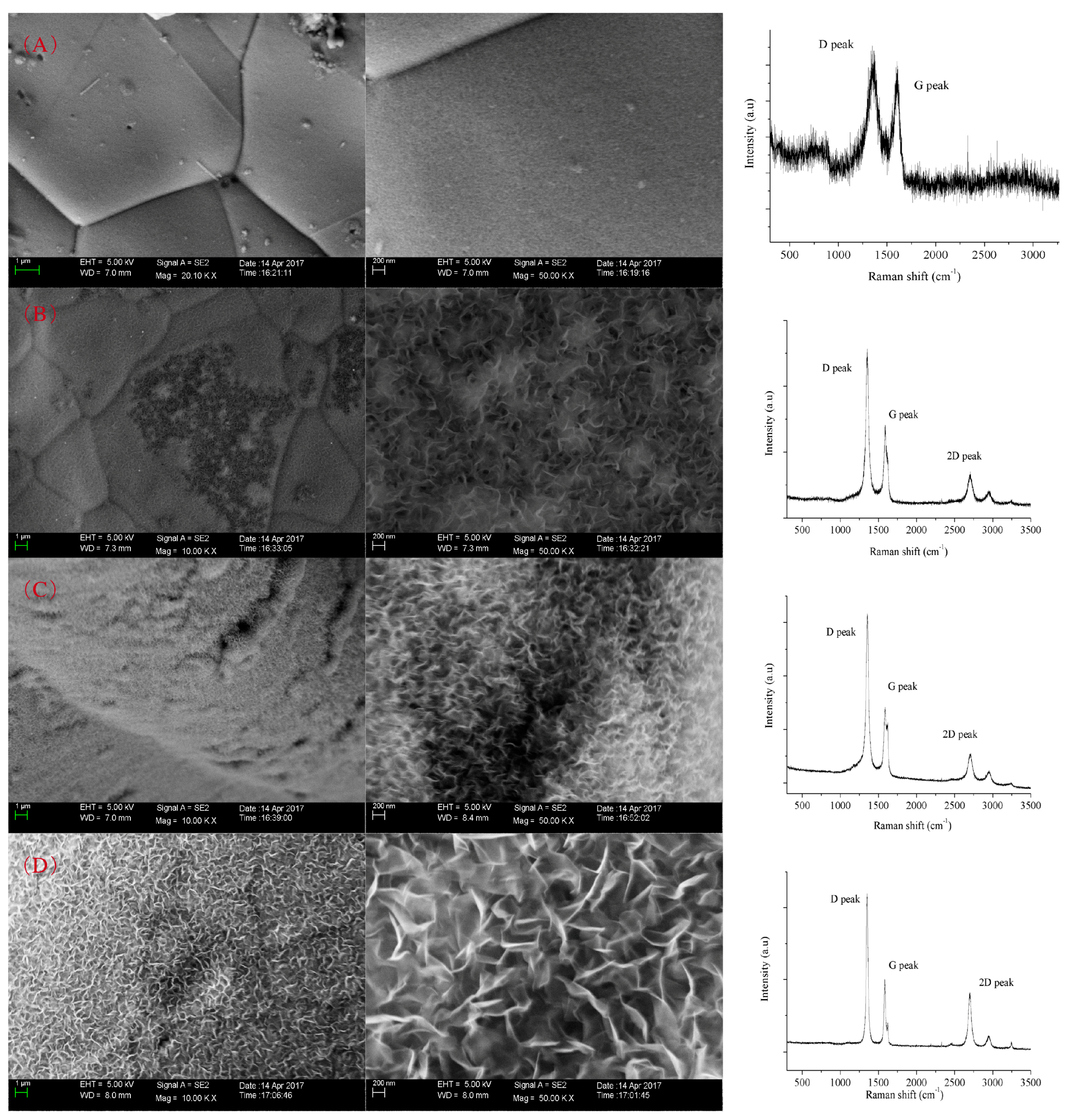

The concentration of H

2 in the carrier gas also had a crucial influence on the morphology and graphitized degree of prepared VG sheets. Without H

2 introduced, a layer of carbon sponge was formed covering the nickel substrate instead of the generation of vertically oriented carbon sheets. Accordingly, low peak intensity and overlapping of D and G peaks was observed, with an

ratio of about 1.11 in

Figure 4A. With the increase of H

2 concentration in carrier gas, a distinguished structure of VG sheets was achieved, which was mutually interweaved in

Figure 4B,C. The lateral sizes of these edges ranged from about 100 nm to 400 nm. In the first-order Raman spectrum, the ratios of

and

were 1.86–2.23 and 0.38–0.47, which implied the formation of few-layer graphene sheets with abundant edge structure. With an H

2/Ar ratio of 3/2, the lateral size of the formed VG increased greatly and led to a high flakiness ratio, facilitating its potential application in catalysis, heat transfer, and conductivity. In

Figure 4D, independent and symmetrical line profiles of D and G peaks were observed with the

ratio as high as 2.1, which indicated a high ratio of sp

2 structure and a high graphitized degree. The intensity of the 2D peak was enhanced with the

ratio of 0.82, which implied the decrease of graphene layers. Additionally, the D’ peak at ~1620 cm

−1 was observed at the shoulder of the G peak, which was also regarded as the characteristic of VG sheets [

20]. In fact, a similar VG sheet Raman spectrum was also observed with cheese as carbon source using ICP, where the ratios of

and

were 1.4 and 0.95, respectively [

22]. Additionally, the plasma source in PECVD would also cause great influence of

in Raman spectrum: 0.7–2.66 for DC glow PECVD, 1.35–2.43 for microwave PECVD [

23,

24,

25].

.

In general, H

2 was indispensable for VG synthesis, while H

2 in the reaction atmosphere was mainly from two sources: the initial carrier gas and gas products attributed to oil decomposition. In terms of waste lard oil conversion by PECVD, H

2, CH

4, and C

2H

4 were the major gas products, while CO, CO

2, C

2H

6, and C

2H

2 were also detected in the exhaust gas. The generation of H

2 in the reaction probably originated from the proton extraction from aliphatic hydrocarbon, graphene formation, or directly splitting into atoms via electron impaction [

26,

27]. On the other hand, the initially injected H

2 not only contributed to total H

2 collected at the exit, but played a significant role during reactions. This is because higher H

2 concentration promoted the lateral growth of VG and inhibited its width increase simultaneously.

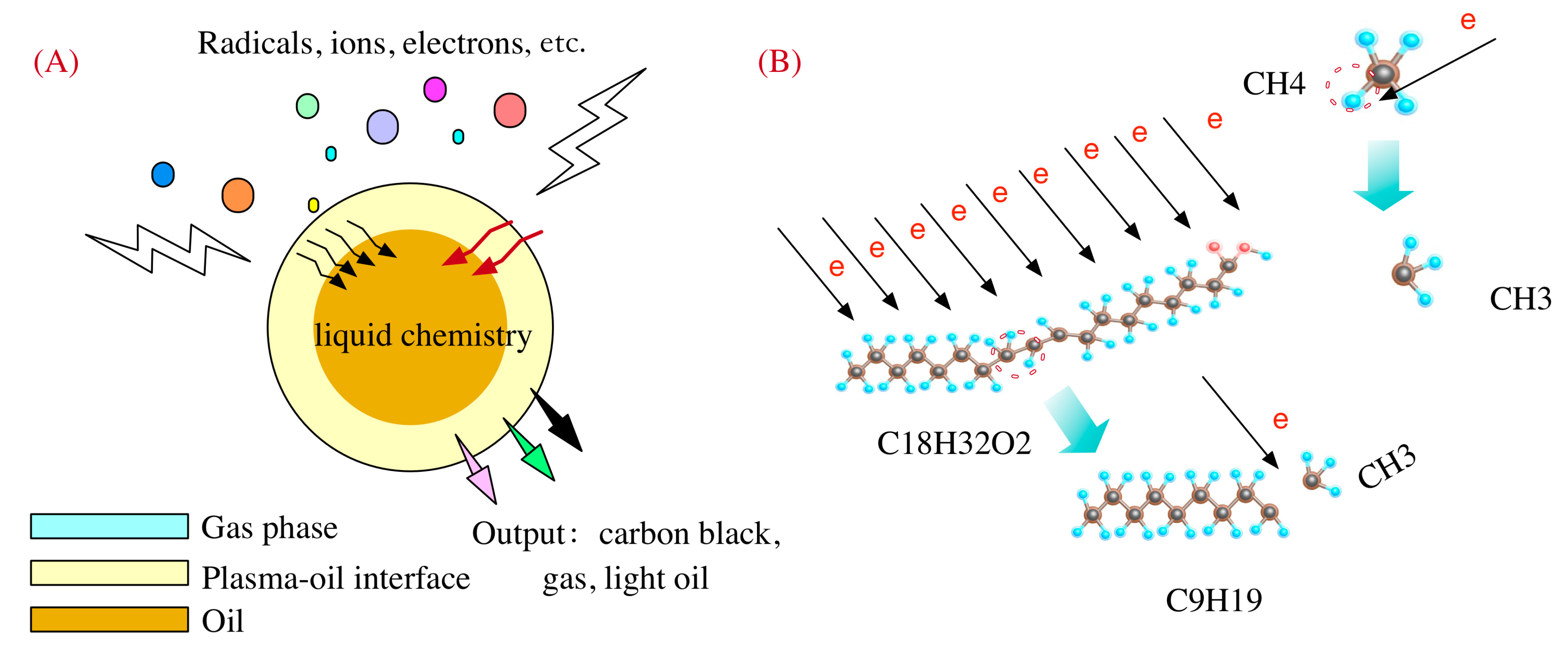

By characterizing the VG sheets and gaseous products by PECVD, it was concluded that the conversion of waste lard oil into vertical graphene sheets and gas was a complex electro-chemical process, as shown in

Figure 5. Firstly, electrons were initiated and propagated by the time-varying electromagnetic filed in ICP, which subsequently collided with

Ar and

H2 molecules to form active species such

H radicals,

Ar excited molecules. These active species were responsible for energy conversion as well as radical reactions [

28].

In addition, high temperature promoted the pyrolysis of aliphatic chains and provided a proper environment for VG growth. Compared with traditional CVD method, the temperature required for VG synthesis was greatly reduced with the help of ICP.

On the other hand, different from conventional carbon precursors such as C

2H

2 or CH

4, waste lard oil constituted by long chain fatty acids or esters was prone to be initially decomposed into various light volatiles, which resulted in a rapid increase of reaction pressure from 600 mTorr to 2 Torr [

14]. Accompanied with the increase of the heating temperature to a designated temperature, carbon-containing species sourced from waste lard oil were gradually converted into amorphous carbon or nucleation sites on the catalytic nickel surface, providing a base for graphene growth. With the onset of 500 W ICP plasma, large amounts of active species such as energetic electrons, excited argon molecules, and H atoms were produced and involved in related reactions. For example, H radicals played a significant role in etching amorphous carbon and bringing away heteroatoms on VG sheets, while the collisions between other active species and light volatiles contributed to the continuous generation of graphene-building species such as C

2 carbon radicals. In addition, under the joint effect of high temperature and reactive ICP plasma, light gaseous hydrocarbons were also detected due to the decarboxylation, decarbonylation, and C–C bond cleavage in the reaction. Additionally, the operating conditions could not only tailor the morphology of formed VG, but also influenced the distribution of gas products. For example, the proportion of CH

4 decreased with the increase of H

2/Ar ratio in carrier gas, whereas the proportion of C

2 hydrocarbons such as C

2H

4, C

2H

2, and C

2H

6 increased in contrast.