NiCo2O4-Based Supercapacitor Nanomaterials

Abstract

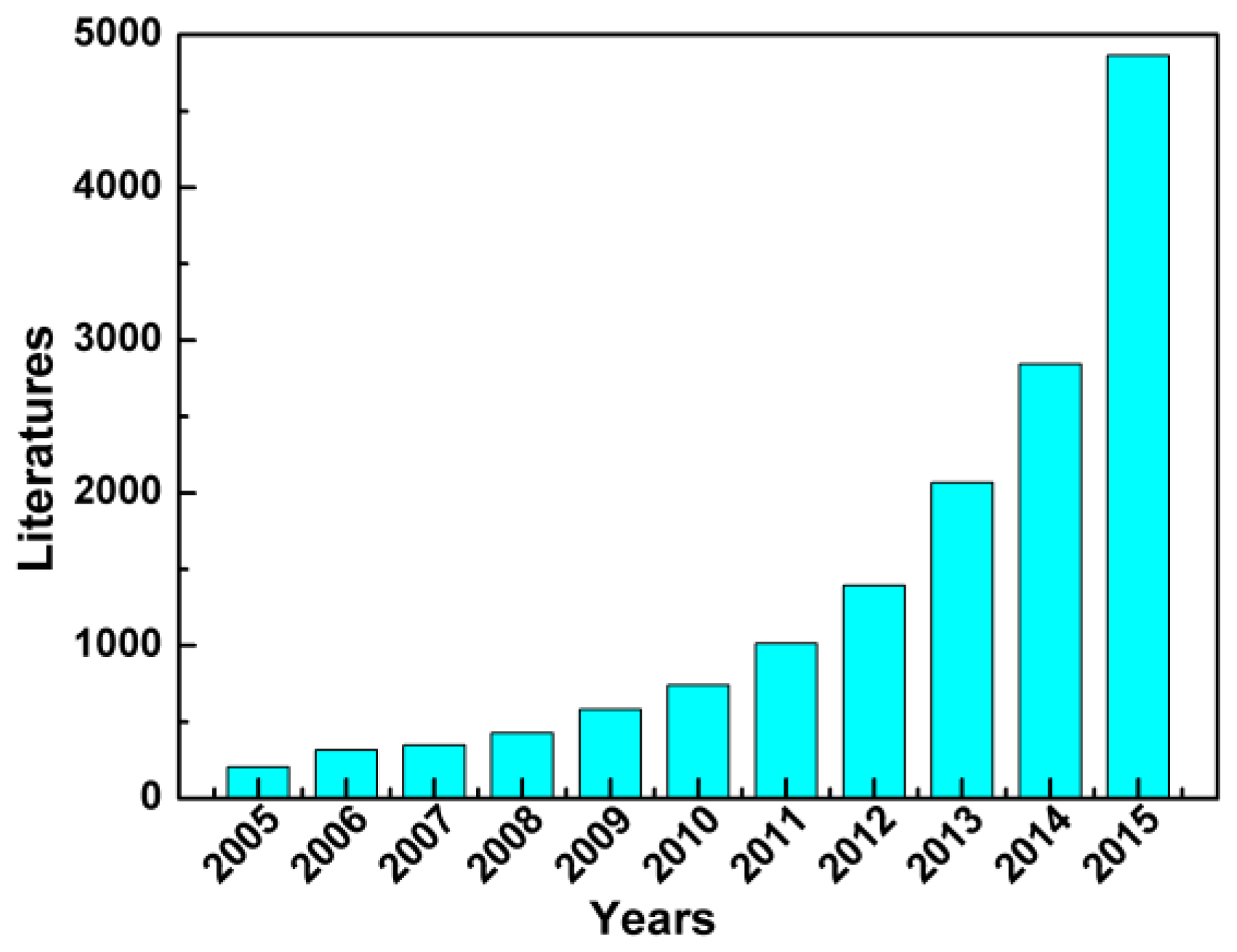

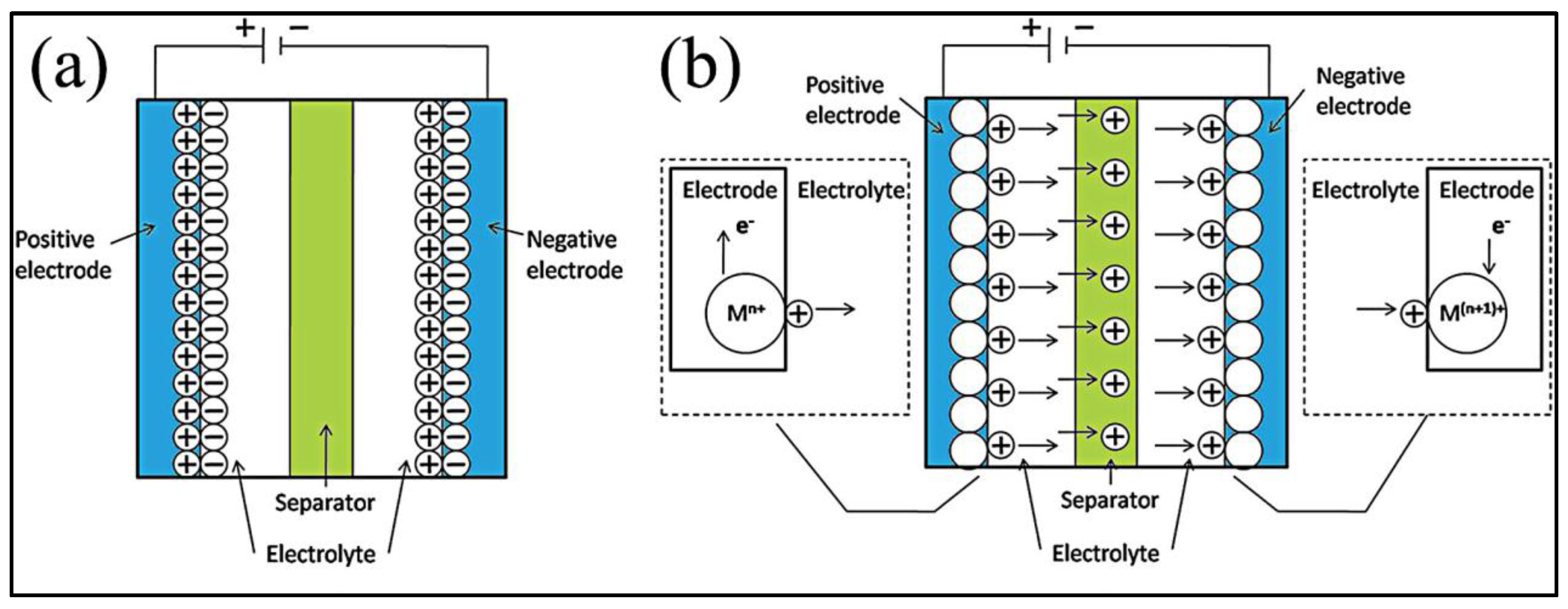

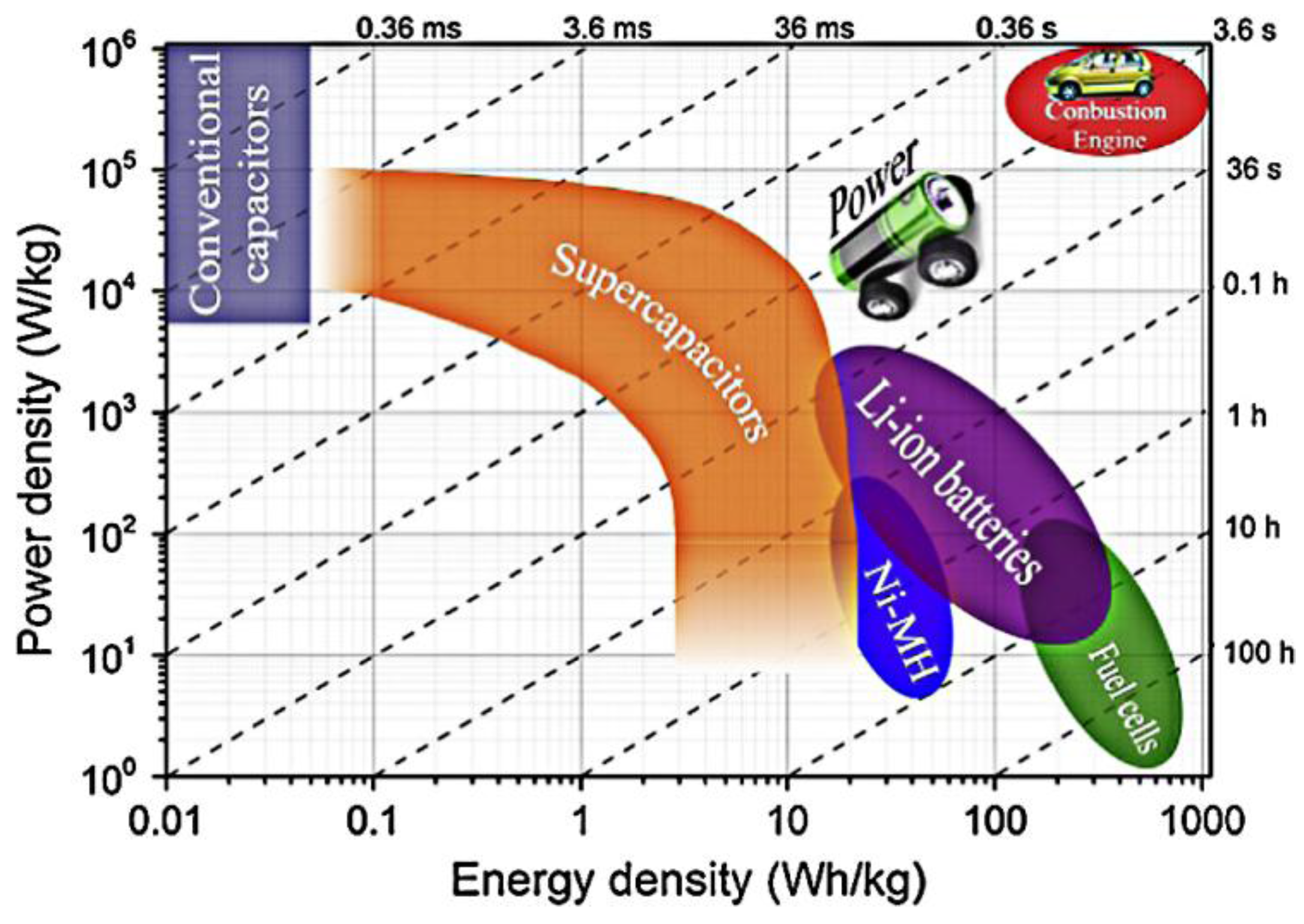

:1. Introduction

2. Synthetic Strategies and Performance for NiCo2O4-Based Nanomaterials

2.1. Approaches to Synthesize NiCo2O4 Nanomaterials

2.1.1. Hydrothermal/Solvothermal Method

2.1.2. Electrochemical Deposition Method

2.1.3. Other Methods

2.2. The Morphologies of NiCo2O4 Nanostructures

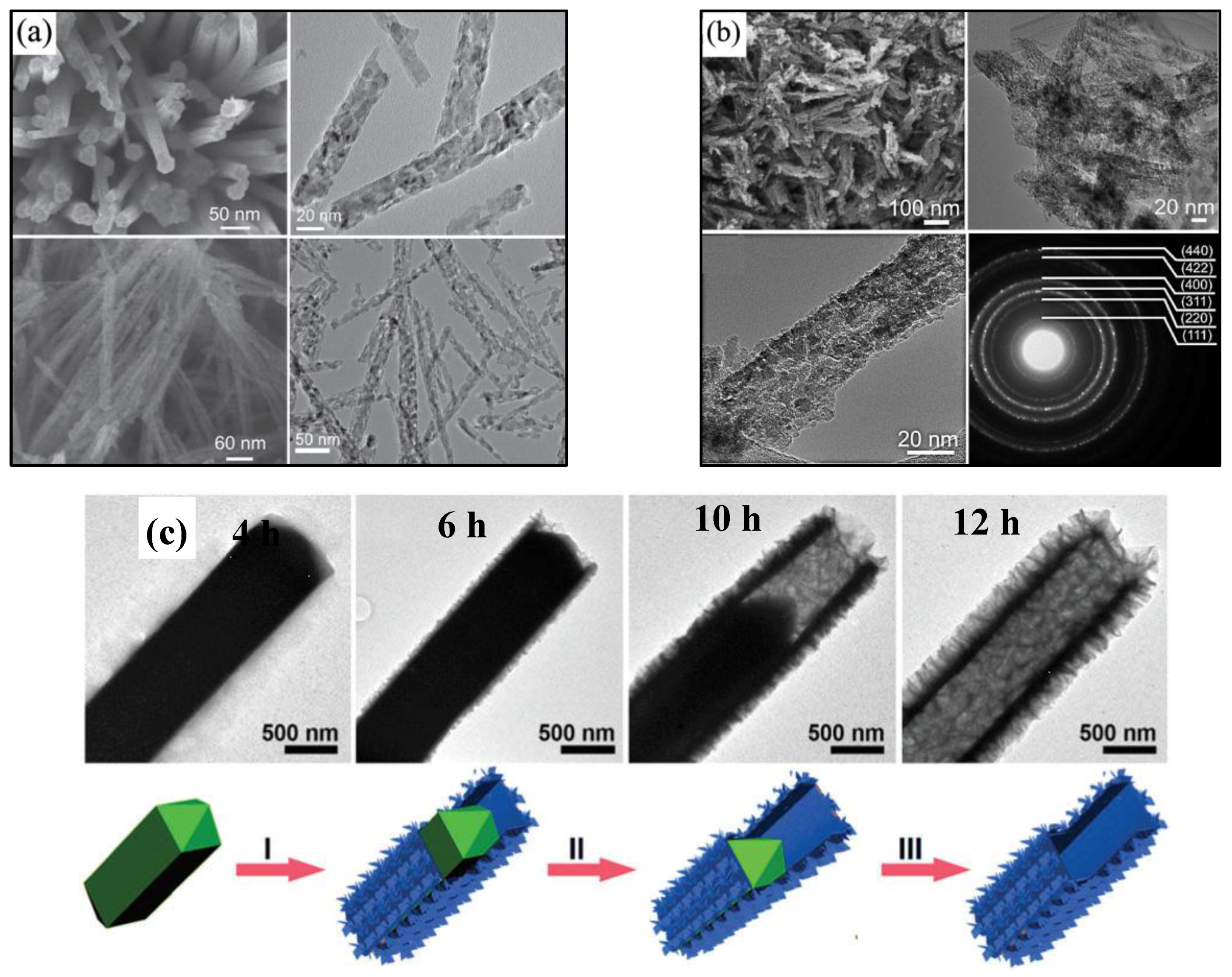

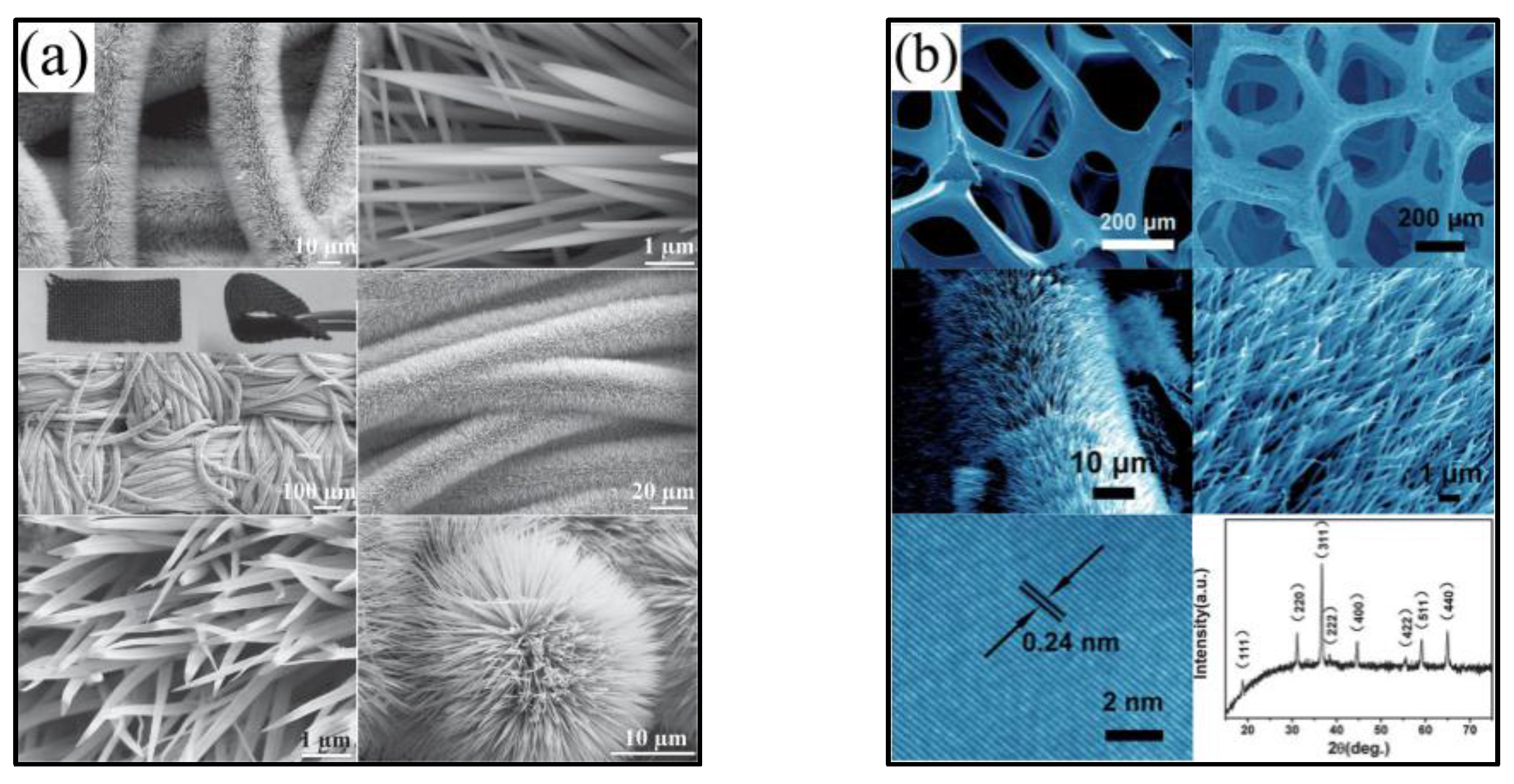

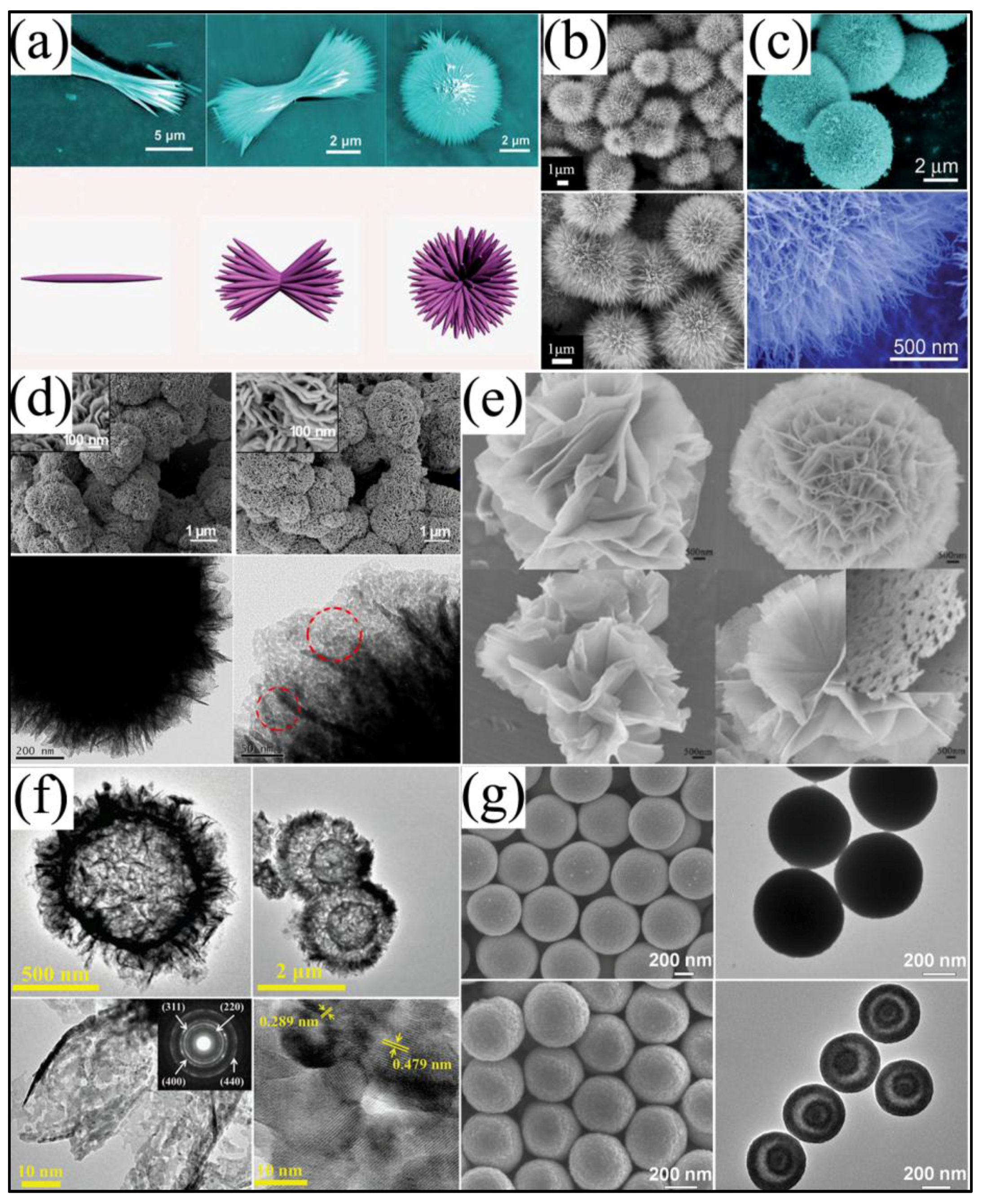

2.2.1. 1D NiCo2O4 Nanostructures

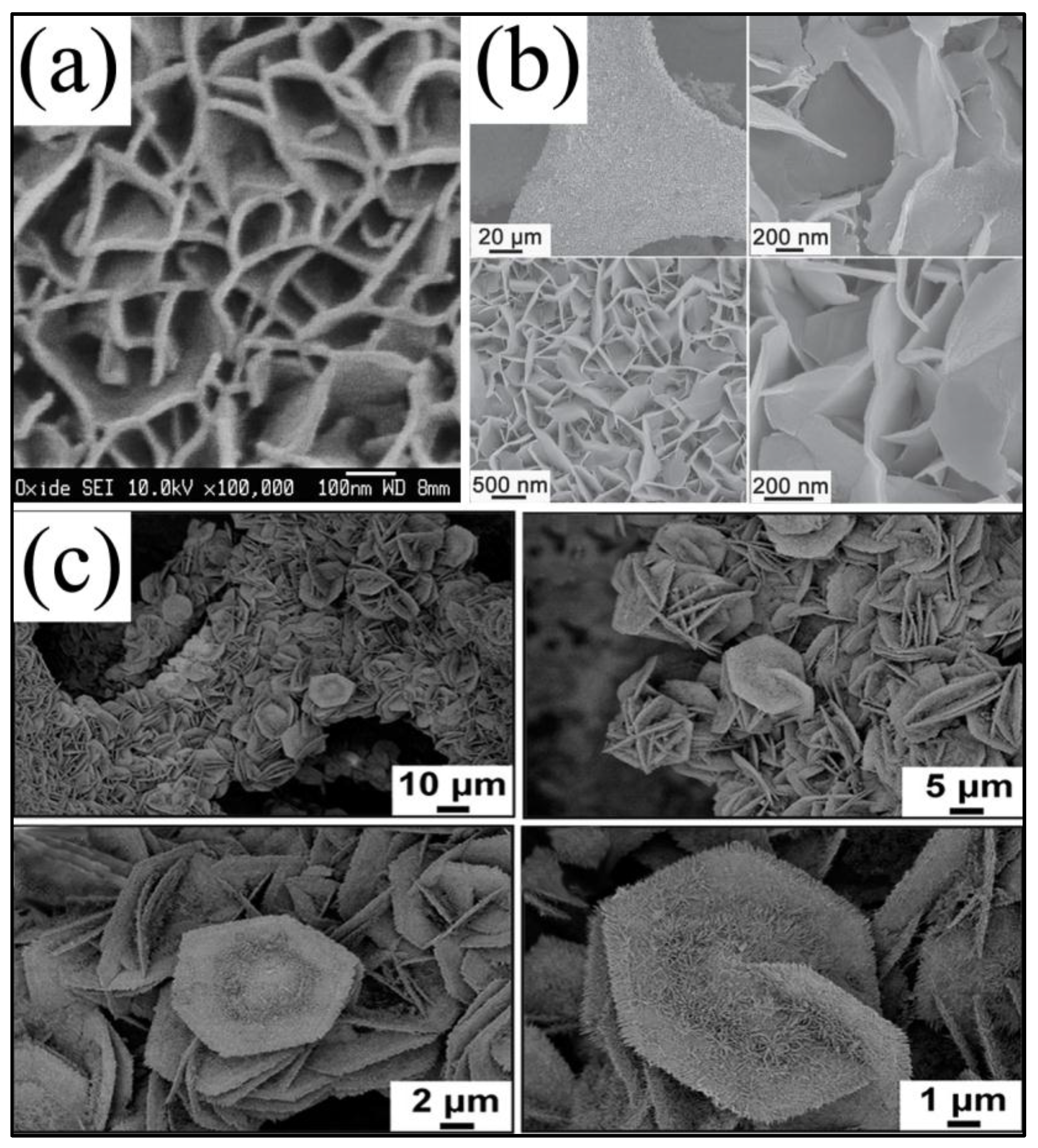

2.2.2. 2D NiCo2O4 Nanostructures

2.2.3. 3D NiCo2O4 Spheres

2.3. NiCo2O4-Based Composites Nanostructures

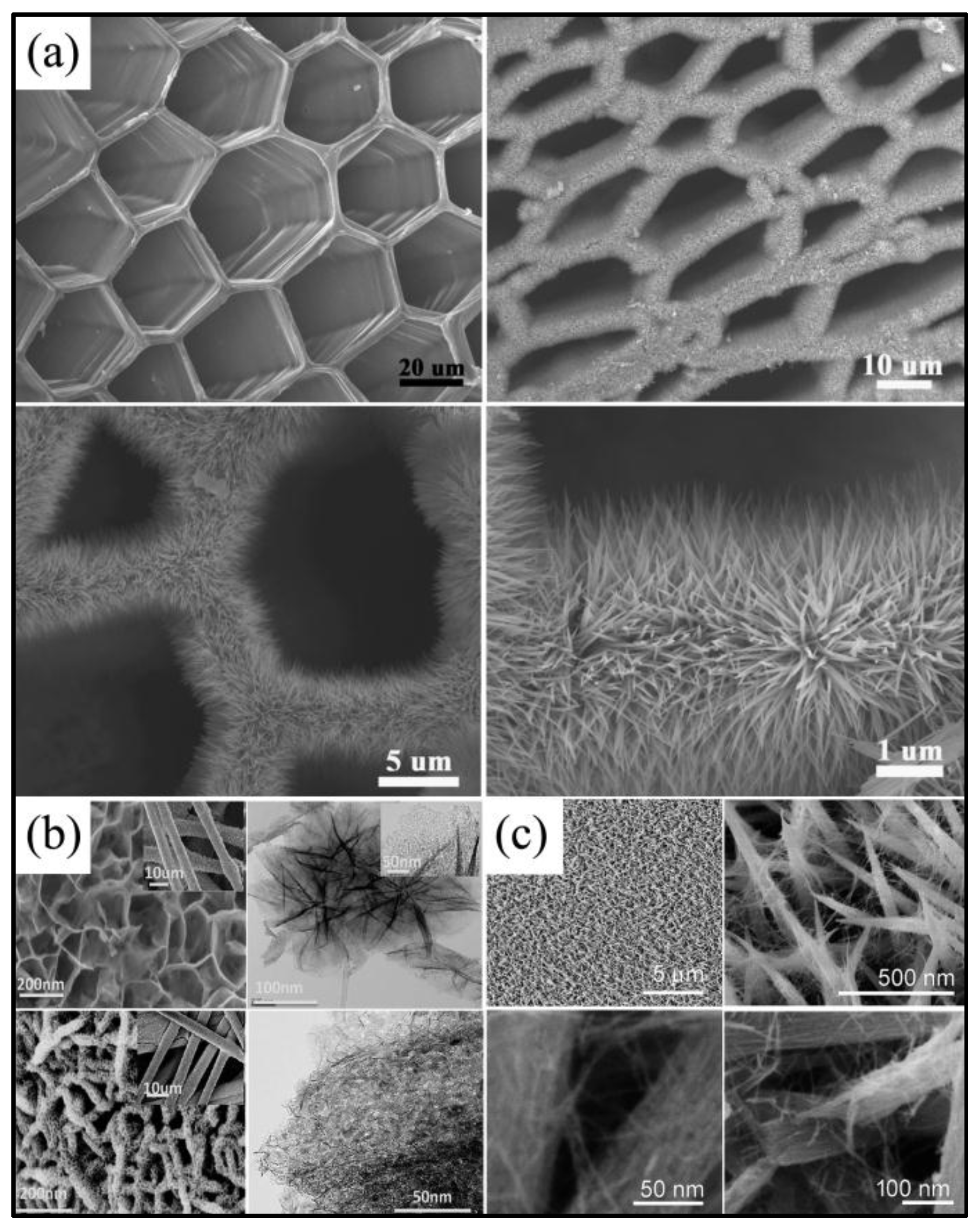

2.3.1. The Combination of NiCo2O4-Based Materials with Carbonaceous Materials

2.3.2. The Combination of NiCo2O4-Based Materials with TMO/Hs

4. Conclusions

Acknowledgments

Conflicts of Interest

Abbreviations

| EDLCs | Electrical double-layer capacitors |

| PCs | Pseudocapacitors |

| TMO/Hs | Transition metal oxides/hydroxides |

| ESR | Equivalent series resistance |

| Ksp | Solubility constant |

| SCE | Saturated calomel electrode |

| SEM | Scanning electron microscope |

| TEM | Transmission electron microscope |

| SAED | Selected area electron diffraction |

References

- Augustyn, V.; Simon, P.; Dunn, B. Pseudocapacitive oxide materials for high-rate electrochemical energy storage. Energy Environ. Sci. 2014, 7, 1597–1614. [Google Scholar] [CrossRef]

- Zhou, E.; Wang, C.; Shao, M.; Deng, X.; Xu, X. MoO2 nanoparticles grown on carbon fibers as anode materials for lithium-ion batteries. Cera. Int. 2017, 43, 760–765. [Google Scholar] [CrossRef]

- Wang, X.; Cao, X.; Bourgeois, L.; Guan, H.; Chen, S.; Zhong, Y.; Tang, D.-M.; Li, H.; Zhai, T.; Li, L.; et al. N-Doped grapheme-SnO2 sandwich paper for high-performance lithium-ion batteries. Adv. Funct. Mater. 2012, 22, 2682–2690. [Google Scholar] [CrossRef]

- Li, W.; Gan, L.; Guo, K.; Ke, L.; Wei, Y.; Li, H.; Shen, G.; Zhai, T. Self-supported Zn3P2 nanowire arrays grafted on carbon fabrics as an advanced integrated anode for flexible lithium ion batteries. Nanoscale 2016, 8, 8666–8672. [Google Scholar] [CrossRef] [PubMed]

- Yao, N.; Huang, J.; Fu, K.; Liu, S.; Dong, E.; Wang, Y.; Xu, X.; Zhu, M.; Cao, B. Efficiency enhancement in dye-sensitized solar cells with down conversion material ZnO: Eu3+, Dy3+. J. Power Sources 2014, 267, 405–410. [Google Scholar] [CrossRef]

- Wang, X.; Tian, W.; Zhai, T.; Zhi, C.; Bando, Y.; Golberg, D. Cobalt (II, III) oxide hollow structures: Fabrication, properties and applications. J. Mater. Chem. 2012, 22, 23310–23326. [Google Scholar] [CrossRef]

- Wen, Y.; Huang, C.; Wang, L.; Hulicova-Jurcakova, D. Heteroatom-doped graphene for electrochemical energy storage. Chin. Sci. Bull. 2014, 59, 2102–2121. [Google Scholar] [CrossRef]

- Helmholtz, H. Ueber einige Gesetze der Vertheilung elektrischer Ströme in körperlichen Leitern, mit Anwendung auf die thierisch-elektrischen Versuche. Ann. Phys. 1853, 165, 353–377. [Google Scholar] [CrossRef]

- Gouy, M. Surla constitution de la charge electrique a la surface d'un electrolyte. J. Phys. Theor. Appl. 1910, 9, 457–468. [Google Scholar] [CrossRef]

- Stern, O. Zur theorie der elektrolytischen doppelschicht. Z. Elektrochem. Angew. Phys. Chem. 1924, 30, 508–516. [Google Scholar]

- Becker, H.I. Low Voltage Electrolytic Capacitor. U.S. Patent 2800616, 23 July 1957. [Google Scholar]

- Beguin, F.; Frackowiak, E. Supercapacitors: Materials, System, and Applications; Lu, M., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 56–89. [Google Scholar]

- Zhou, E.; Wang, C.; Zhao, Q.; Li, Z.; Shao, M.; Deng, X.; Liu, X.; Xu, X. Facile synthesis of MoO2 nanoparticles as high performance supercapacitor electrodes and photocatalysts. Ceram. Int. 2016, 42, 2198–2203. [Google Scholar] [CrossRef]

- Zhang, L.L.; Zhao, X.S. Carbon-based materials as supercapacitor electrodes. Chem. Soc. Rev. 2009, 38, 2520–2531. [Google Scholar] [CrossRef] [PubMed]

- Zhong, C.; Deng, Y.; Hu, W.; Qiao, J.; Zhang, L.; Zhang, J. A review of electrolyte materials and compositions for electrochemical supercapacitors. Chem. Soc. Rev. 2015, 44, 7484–7539. [Google Scholar] [CrossRef] [PubMed]

- Conway, B.E. Electrochemical Supercapacitors: Scientific Fundamentals and Technological Applications; Kluwer Academic Press/Plenum Publishers: New York, NY, USA, 1999; pp. 221–257. [Google Scholar]

- Wang, L.; Sasaki, T. Titanium Oxide Nanosheets: Graphene Analogues with Versatile Functionalities. Chem. Rev. 2014, 114, 9455–9486. [Google Scholar] [CrossRef] [PubMed]

- Ye, D.L.; Ozawa, K.; Wang, B.; Ozawa, K.; Wang, B.; Hulicova-Jurcakova, D.; Zou, J.; Sun, C.; Wang, L. Capacity-controllable Li-rich cathode materials for lithium-ion batteries. Nano Energy 2014, 6, 92–102. [Google Scholar] [CrossRef]

- Snook, G.A.; Kao, P.; Best, A.S. Conducting-polymer-based supercapacitor devices and electrodes. J. Power Sources 2011, 196, 1–12. [Google Scholar] [CrossRef]

- Zhou, E.; Wang, C.; Ding, M.; Shao, M.; Huang, J.; Liu, X.; Li, Z.; Xu, X. Mesoporous MoO2 grown on carbon fiber as flexible supercapacitor electrodes. Sci. Adv. Mater. 2016, 8, 1263–1267. [Google Scholar] [CrossRef]

- Lin, T.; Chen, I.W.; Liu, F.; Yang, C.; Bi, H.; Xu, F.; Huang, F. Nitrogen-doped mesoporous carbon of extraordinary capacitance for electrochemical energy storage. Science 2015, 350, 1508–1513. [Google Scholar] [CrossRef] [PubMed]

- Shi, F.; Li, L.; Wang, X.L.; Gu, C.D.; Tu, J.P. Metal oxide/hydroxide-based materials for supercapacitors. RSC Adv. 2014, 4, 41910–41921. [Google Scholar] [CrossRef]

- Béguin, F.; Presser, V.; Balducci, A.; Frackowiak, E. Carbons and electrolytes for advanced supercapacitors. Adv. Mater. 2014, 26, 2219–2251. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Yang, W.; Wang, C.; Deng, X.; Liu, B.; Xu, X. Morphology-controlled syntheses of α-MnO2 for electrochemical energy storage. Phys. Chem. Chem. Phys. 2016, 18, 15235–15243. [Google Scholar] [CrossRef] [PubMed]

- Sennu, P.; Aravindan, V.; Lee, Y.S. High energy asymmetric supercapacitor with 1D@2D structured NiCo2O4@Co3O4 and jackfruit derived high surface area porous carbon. J. Power Sources 2016, 306, 248–257. [Google Scholar] [CrossRef]

- Wang, J.G.; Kang, F.; Wei, B. Engineering of MnO2-based nanocomposites for high-performance supercapacitors. Prog. Mater. Sci. 2015, 74, 51–124. [Google Scholar] [CrossRef]

- Hu, C.C.; Chang, K.H.; Lin, M.C.; Wu, Y.T. Design and tailoring of the nanotubular arrayed architecture of hydrous RuO2 for next generation supercapacitors. Nano Lett. 2006, 6, 2690–2695. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Han, X.; Hu, Z.; Zhang, X.; Tao, Z.; Chen, J. Nanostructured Mn-based oxides for electrochemical energy storage and conversion. Chem. Soc. Rev. 2015, 44, 699–728. [Google Scholar] [CrossRef] [PubMed]

- Zhou, E; Wang, C.; Deng, X.; Xu, X. Ag nanoparticles anchored NiO/GO composites for enhanced capacitive performance. Cera. Inter. 2016, 42, 12644–12650. [Google Scholar] [CrossRef]

- Hu, C.C.; Chen, W.C. Effects of substrates on the capacitive performance of RuOx·nH2O and activated carbon-RuOx electrodes for supercapacitors. Electrochim. Acta 2004, 49, 3469–3477. [Google Scholar] [CrossRef]

- Yuan, C.; Li, J.; Hou, L.; Lin, J.; Zhang, X.; Xiong, S. Polymer-assisted synthesis of a 3D hierarchical porous network-like spinel NiCo2O4 framework towards high-performance electrochemical capacitors. J. Mater. Chem. A 2013, 1, 11145–11151. [Google Scholar] [CrossRef]

- Cui, B.; Lin, H.; Li, J.B.; Li, X.; Yang, J.; Tao, J. Core-ring structured NiCo2O4 nanoplatelets: Synthesis, characterization, and electrocatalytic applications. Adv. Funct. Mater. 2008, 18, 1440–1447. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, B.; Wang, X.; Ran, S.; Wang, L.; Chen, D.; Shen, G. Morphology evolution of urchin-like NiCo2O4 nanostructures and their applications as psuedocapacitors and photoelectrochemical cells. J. Mater. Chem. 2012, 22, 21647–21653. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, J.; Zhang, L.; Qi, T.; Xia, D.; Wan, H. Facilely synthesized porous NiCo2O4 flowerlike nanostructure for high-rate supercapacitors. J. Power Sources 2014, 248, 28–36. [Google Scholar] [CrossRef]

- Wu, J.; Guo, P.; Mi, R.; Liu, X.; Zhang, H.; Liu, H.; Lau, W.-M.; Liu, L.-M. Ultrathin NiCo2O4 nanosheets grown on three-dimensional interwoven nitrogen-doped carbon nanotubes as binder-free electrodes for high-performance supercapacitors. J. Mater. Chem. A 2015, 3, 15331–15338. [Google Scholar] [CrossRef]

- Wei, T.Y.; Chen, C.H.; Chien, H.C.; Lu, S.Y.; Hu, C.C. A cost-effective supercapacitor material of ultrahigh specific capacitances: Spinel nickel cobaltite aerogels from an epoxide-driven sol-gel process. Adv. Mater. 2010, 22, 347–351. [Google Scholar] [CrossRef] [PubMed]

- Yuan, C.; Li, J.; Hou, L.; Zhang, X.; Shen, L.; Lou, X.W.D. Ultrathin mesoporous NiCo2O4 nanosheets supported on Ni foam as advanced electrodes for supercapacitors. Adv. Funct. Mater. 2012, 22, 4592–4597. [Google Scholar] [CrossRef]

- Li, X.; Jiang, L.; Zhou, C.; Liu, J.; Zeng, H. Integrating large specific surface area and high conductivity in hydrogenated NiCo2O4 double-shell hollow spheres to improve supercapacitors. NPG Asia Mater. 2015, 7, e165. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, F.; Cheng, J.P.; Zhang, X.B. Binary Nickel–Cobalt oxides electrode materials for high-performance supercapacitors: influence of its composition and porous nature. Acs Appl. Mater. Inter. 2015, 7, 17630–17640. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.; Ma, L.; Zhang, Q.; Wang, C.; Xu, X. SnO2-based nanomaterials: Synthesis and application in lithium-ion batteries and supercapacitors. J. Nanomater. 2015, 6, 850147. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, E.; Deng, X.; Shao, M.; Huang, J.; Wei, X.; Xu, X. Three-dimensionally porous NiCo2O4 nanoneedle arrays for high performance supercapacitor. Sci. Adv. Mater. 2016, 8, 1298–1304. [Google Scholar] [CrossRef]

- Shen, L.; Che, Q.; Li, H.; Zhang, X. Mesoporous NiCo2O4 nanowire arrays grown on carbon textiles as binder-free flexible electrodes for energy storage. Adv. Funct. Mater. 2014, 24, 2630–2637. [Google Scholar] [CrossRef]

- Zhang, G.; Lou, X.W.D. Controlled growth of NiCo2O4 nanorods and ultrathin nanosheets on carbon nanofibers for high-performance supercapacitors. Sci. Rep. 2013, 3, 1470. [Google Scholar] [CrossRef] [PubMed]

- Zou, R.; Xu, K.; Wang, T.; He, G.; Liu, Q.; Liu, X.; Zhang, Z.; Hu, J. Chain-like NiCo2O4 nanowires with different exposed reactive planes for high-performance supercapacitors. J. Mater. Chem. A 2013, 1, 8560–8566. [Google Scholar] [CrossRef]

- Gupta, V.; Gupta, S.; Miura, N. Electrochemically synthesized nanocrystalline spinel thin film for high performance supercapacitor. J. Power Sources 2010, 195, 3757–3760. [Google Scholar] [CrossRef]

- Lu, X.F.; Wu, D.J.; Li, R.Z.; Li, Q.; Ye, S.H.; Tong, Y.X.; Li, G.R. Hierarchical NiCo2O4 nanosheets@hollow microrod arrays for high-performance asymmetric supercapacitors. J. Mater. Chem. A 2014, 2, 4706–4713. [Google Scholar] [CrossRef]

- Du, J.; Zhou, G.; Zhang, H.; Cheng, C.; Ma, J.; Wei, W.; Chen, L.; Wang, T. Ultrathin porous NiCo2O4 nanosheet arrays on flexible carbon fabric for high-performance supercapacitors. Acs Appl. Mater. Interface 2013, 5, 7405–7409. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Peng, S.; Cheah, Y.; Teh, P.; Wang, J.; Wee, G.; Ko, Y.; Wong, C.; Srinivasan, M. Electrospun porous NiCo2O4 nanotubes as advanced electrodes for electrochemical capacitors. Chem. Eur. J. 2013, 19, 5892–5898. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Lou, X.W. General solution growth of mesoporous NiCo2O4 nanosheets on various conductive substrates as high-performance electrodes for supercapacitors. Adv. Mater. 2013, 25, 976–979. [Google Scholar] [CrossRef] [PubMed]

- Gao, G.; Wu, H.B.; Ding, S.; Liu, L.M.; Lou, X.W.D. Hierarchical NiCo2O4 nanosheets grown on Ni nanofoam as high-performance electrodes for supercapacitors. Small 2015, 11, 804–808. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.; Fan, Z.; Chen, S.; Ding, S.; Yang, G. Hierarchical NiCo2O4 nanosheets@halloysite nanotubes with ultrahigh capacitance and long cycle stability as electrochemical pseudocapacitor materials. Chem. Mater. 2014, 26, 4354–4360. [Google Scholar] [CrossRef]

- Jiang, H.; Ma, J.; Li, C. Hierarchical porous NiCo2O4 nanowires for high-rate supercapacitors. Chem. Commun. 2012, 48, 4465–4467. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Wu, Z.; Jing, M.; Hou, H.; Yang, Y.; Zhang, Y.; Yang, X.; Song, W.; Jia, X.; Ji, X. Porous NiCo2O4 spheres tuned through carbon quantum dots utilised as advanced materials for an asymmetric supercapacitor. J. Mater. Chem. A 2014, 3, 866–877. [Google Scholar] [CrossRef]

- Lei, Y.; Li, J.; Wang, Y.; Gu, L.; Chang, Y.; Yuan, H.; Xiao, D. Rapid microwave-assisted green synthesis of 3D hierarchical flower-shaped NiCo2O4 microsphere for high-performance supercapacitor. Acs Appl. Mater. Interface 2014, 6, 1773–1780. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.Q.; Wu, H.B.; Hoster, H.E.; Chan-Park, M.B.; Lou, X.W.D. Single-crystalline NiCo2O4 nanoneedle arrays grown on conductive substrates as binder-free electrodes for high-performance supercapacitors. Energ. Environ. Sci. 2012, 5, 9453–9456. [Google Scholar] [CrossRef]

- Zhou, Q.; Xing, J.; Gao, Y.; Lv, X.; He, Y.; Guo, Z.; Li, Y. Ordered assembly of NiCo2O4 multiple hierarchical structures for high-performance pseudocapacitors. Acs Appl. Mater. Interface 2014, 6, 11394–11402. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Gao, Q.; Jiang, L. Facile approach to prepare nickel cobaltite nanowire materials for supercapacitors. Small 2011, 7, 2454–2459. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Wang, X.; Liu, B.; Yu, G.; Hou, X.; Chen, D.; Shen, G. NiCo2O4 nanowire arrays supported on Ni foam for high-performance flexible all-solid-state supercapacitors. J. Mater. Chem. A 2013, 1, 2468–2473. [Google Scholar] [CrossRef]

- Garg, N.; Basu, M.; Ganguli, A.K. Nickel cobaltite nanostructures with enhanced supercapacitance activity. J. Phys. Chem. C 2014, 118, 17332–17341. [Google Scholar] [CrossRef]

- Mondal, A.K.; Su, D.; Chen, S.; Kretschmer, K.; Xie, X.; Ahn, H.J.; Wang, G. A microwave synthesis of mesoporous NiCo2O4 nanosheets as electrode materials for lithium-ion batteries and supercapacitors. ChemPhysChem 2015, 16, 169–175. [Google Scholar] [CrossRef] [PubMed]

- Padmanathan, N.; Selladurai, S. Controlled growth of spinel NiCo2O4 nanostructures on carbon cloth as a superior electrode for supercapacitors. Rsc Adv. 2014, 4, 8341–8349. [Google Scholar] [CrossRef]

- Shen, L.; Yu, L.; Yu, X.Y.; Zhang, X.; Lou, X.W.D. Self-templated formation of uniform NiCo2O4 hollow spheres with complex interior structures for lithium-ion batteries and supercapacitors. Angew. Chem. Int. Ed. 2015, 54, 1868–1872. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.W.; Lu, C.; Liang, K.; Tay, B.K. A three dimensional vertically aligned multiwall carbon nanotube/NiCo2O4 core/shell structure for novel high-performance supercapacitors. J. Mater. Chem. A 2014, 2, 5100–5107. [Google Scholar] [CrossRef]

- Ramadoss, A.; Kang, K.N.; Ahn, H.J.; Kim, S.I.; Ryu, S.T.; Jang, J.H. Realization of high performance flexible wire supercapacitors based on 3-dimensional NiCo2O4/Ni fibers. J. Mater. Chem. A 2016, 4, 4718–4727. [Google Scholar] [CrossRef]

- Mitchell, E.; Jimenez, A.; Gupta, R.K.; Gupta, B.K.; Ramasamy, K.; Shahabuddin, M.; Mishra, S.R. Ultrathin porous hierarchically textured NiCo2O4-graphene oxide flexible nanosheets for high-performance supercapacitors. New J. Chem. 2015, 39, 2181–2187. [Google Scholar] [CrossRef]

- Zeng, W.; Wang, L.; Shi, H.; Zhang, G.; Zhang, K.; Zhang, H.; Gong, F.; Wang, T.; Duan, H. Metal-organic-framework-derived ZnO@C@NiCo2O4 core-shell structures as an advanced electrode for high-performance supercapacitors. J. Mater. Chem. A 2016, 4, 8233–8241. [Google Scholar] [CrossRef]

- Xu, K.; Zou, R.; Li, W.; Liu, Q.; Liu, X.; An, L.; Hu, J. Design and synthesis of 3D interconnected mesoporous NiCo2O4@CoxNi1−x(OH)2 core-shell nanosheet arrays with large areal capacitance and high rate performance for supercapacitors. J. Mater. Chem. A 2014, 2, 10090–10097. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Shim, J.J. Three-dimensional nickel foam/graphene/NiCo2O4 as high-performance electrodes for supercapacitors. J. Power Sources 2015, 273, 110–117. [Google Scholar] [CrossRef]

- Huang, L.; Chen, D.; Ding, Y.; Wang, Z.L.; Zeng, Z.; Liu, M. Hybrid composite Ni(OH)2@NiCo2O4 grown on carbon fiber paper for high-performance supercapacitors. Acs Appl. Mater. Interface 2013, 5, 11159–11162. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Wang, T.; Yu, X.; Zhang, H.; Duan, H.; Lu, B. Nanoforest of hierarchical Co3O4@NiCo2O4 nanowire arrays for high-performance supercapacitors. Nano Energy 2013, 2, 586–594. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, H.; Di, G.; Ma, J.; Li, Q.; Chen, L.; Wang, T. Porous NiCo2O4-reduced graphene oxide (rGO) composite with superior capacitance retention for supercapacitors. Electrochim. Acta 2014, 132, 332–337. [Google Scholar] [CrossRef]

- Ding, R.; Qi, L.; Wang, H. A facile and cost-effective synthesis of mesoporous NiCo2O4 nanoparticles and their capacitive behavior in electrochemical capacitors. J. Solid State Electr. 2012, 16, 3621–3633. [Google Scholar] [CrossRef]

- Khalid, S.; Cao, C.; Wang, L.; Zhu, Y. Microwave assisted synthesis of porous NiCo2O4 microspheres: Application as high performance asymmetric and symmetric supercapacitors with large areal capacitance. Sci. Rep. 2016, 6, 22699. [Google Scholar] [CrossRef] [PubMed]

- Shanmugavani, A.; Selvan, R.K. Microwave assisted reflux synthesis of NiCo2O4/NiO composite: Fabrication of high performance asymmetric supercapacitor with Fe2O3. Electrochim. Acta 2016, 189, 283–294. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, X.; Zhang, D.; Yao, C.; Ma, Y. Facile and low-cost fabrication of nanostructured NiCo2O4 spinel with high specific capacitance and excellent cycle stability. Electrochim. Acta 2012, 63, 220–227. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, L.; Cao, P.; Cai, C.; Fu, Y.; Ma, X. Mesoporous composite nickel cobalt oxide/graphene oxide synthesized via a template-assistant co-precipitation route as electrode material for supercapacitors. J. Power Sources 2016, 306, 742–752. [Google Scholar] [CrossRef]

- Long, C.; Zheng, M.; Xiao, Y.; Lei, B.; Dong, H.; Zhang, H.; Hu, H.; Liu, Y. Amorphous Ni–Co binary oxide with hierarchical porous structure for electrochemical capacitors. Acs Appl. Mater. Interface 2015, 7, 24419–24429. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Miao, Y.-E.; Lu, H.; Liu, T. Hierarchical ZnCo2O4@NiCo2O4 core-sheath nanowires: Bifunctionality towards high-performance supercapacitors and the oxygen-reduction reaction. Chem. Eur. J. 2015, 21, 10100–10108. [Google Scholar] [CrossRef] [PubMed]

- Yuan, C.; Li, J.; Hou, L.; Yang, L.; Shen, L.; Zhang, X. Facile template-free synthesis of ultralayered mesoporous nickel cobaltite nanowires towards high-performance electrochemical capacitors. J. Mater. Chem. 2012, 22, 16084–16090. [Google Scholar] [CrossRef]

- Chen, J.S.; Lou, X.W.D. SnO2-based nanomaterials: Synthesis and application in lithium-ion batteries. Small 2013, 9, 1877–1893. [Google Scholar] [CrossRef] [PubMed]

- Ma, F.X.; Yu, L.; Xu, C.Y.; Lou, X.W.D. Self-supported formation of hierarchical NiCo2O4 tetragonal microtubes with enhanced electrochemical properties. Energy Environ. Sci. 2016, 9, 862–866. [Google Scholar] [CrossRef]

- Cheng, J.; Lu, Y.; Qiu, K.; Zhang, D.; Wang, C.; Yan, H.; Xu, J.; Zhang, Y.; Liu, X.; Luo, Y. Hierarchical multi-villous nickel-cobalt oxide nanocyclobenzene arrays: Morphology control and electrochemical supercapacitive behaviors. CrystEngComm 2014, 16, 9735–9742. [Google Scholar] [CrossRef]

- Wu, T.; Li, J.; Hou, L.; Yuan, C.; Yang, L.; Zhang, X. Uniform urchin-like nickel cobaltite microspherical superstructures constructed by one-dimension nanowires and their application for electrochemical capacitors. Electrochim. Acta 2012, 81, 172–178. [Google Scholar] [CrossRef]

- An, C.; Wang, Y.; Huang, Y.; Xu, Y.; Xu, C.; Jiao, L. Novel three-dimensional NiCo2O4 hierarchitectures: Solvothermal synthesis and electrochemical properties. CrystEngComm 2014, 16, 385–392. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, M.; Yang, J.; Su, H.; Huang, W.; Dong, X. Selective synthesis of hierarchical mesoporous spinel NiCo2O4 for high-performance supercapacitors. Nanoscale 2014, 6, 4303–4308. [Google Scholar] [CrossRef] [PubMed]

- Xiong, W.; Gao, Y.; Wu, X.; Hu, X.; Lan, D.; Chen, Y.; Pu, X.; Zeng, Y.; Su, J.; Zhu, Z. Composite of macroporous carbon with honeycomb-like structure from mollusc shell and NiCo2O4 nanowires for high-performance supercapacitor. Acs Appl. Mater. Interface 2014, 6, 19416–19423. [Google Scholar] [CrossRef] [PubMed]

- Cai, F.; Kang, Y.; Chen, H.; Chen, M.; Li, Q. Hierarchical CNT@NiCo2O4 core-shell hybrid nanostructure for high-performance supercapacitors. J. Mater. Chem. A 2014, 2, 11509–11515. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, S.; Su, D.; Sun, B.; Zhu, J.; Wang, G. 3D mesoporous hybrid NiCo2O4@graphene nanoarchitectures as electrode materials for supercapacitors with enhanced performances. J. Mater. Chem. A 2014, 2, 8103–8109. [Google Scholar] [CrossRef]

- Wang, H.W.; Hu, Z.A.; Chang, Y.Q.; Chen, Y.L.; Wu, H.Y.; Zhang, Z.Y.; Yang, Y.Y. Design and synthesis of NiCo2O4-reduced graphene oxide composites for high performance supercapacitors. J. Mater. Chem. 2011, 21, 10504–10511. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.; Xiao, X.; Xu, F.; Sun, Y.; Li, Z. Reduced graphene oxide/nickel cobaltite nanoflake composites for high specific capacitance supercapacitors. Electrochim. Acta 2013, 111, 937–945. [Google Scholar] [CrossRef]

- Sun, S.; Wang, S.; Li, S.; Li, Y.; Zhang, Y.H.; Chen, J.; Zhang, Z.; Fang, S.; Wang, P. Asymmetric supercapacitors based on NiCo2O4/three dimensional graphene composite and three dimensional graphene with high energy density. J. Mater. Chem. A 2016, 4, 18646–18653. [Google Scholar] [CrossRef]

- Zou, R.; Yuen, M.; Zhang, Z.; Hu, J.; Zhang, W. Three-dimensional networked NiCo2O4/MnO2 branched nanowire heterostructure arrays on nickel foam with enhanced supercapacitor performance. J. Mater. Chem. A 2015, 3, 1717–1723. [Google Scholar] [CrossRef]

- Xiong, W.; Hu, X.; Wu, X.; Zeng, Y.; Wang, B.; He, G.; Zhu, Z. A flexible fiber-shaped supercapacitor utilizing hierarchical NiCo2O4@polypyrrole core-shell nanowires on hemp-derived carbon. J. Mater. Chem. A 2015, 3, 17209–17216. [Google Scholar] [CrossRef]

- Cai, D.; Liu, B.; Wang, D.; Wang, L.; Liu, Y.; Li, H.; Wang, Y.; Li, Q.; Wang, T. Construction of unique NiCo2O4 nanowire@CoMoO4 nanoplate core/shell arrays on Ni foam for high areal capacitance supercapacitors. J. Mater. Chem. A 2014, 2, 4954–4960. [Google Scholar] [CrossRef]

- Hu, H.; Guan, B.; Xia, B.; Lou, X.W. Designed formation of Co3O4/NiCo2O4 double-shelled nanocages with enhanced pseudocapacitive and electrocatalytic properties. J. Am. Chem. Soc. 2015, 137, 5590–5595. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.; Li, W.; Liu, Q.; Li, B.; Liu, X.; An, L.; Chen, Z.; Zou, R.; Hu, J. Hierarchical mesoporous NiCo2O4@MnO2 core-shell nanowire arrays on nickel foam for aqueous asymmetric supercapacitors. J. Mater. Chem. A 2014, 2, 4795–4802. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, G.; Yuan, C.; Lou, X.W.D. Hierarchical NiCo2O4@ MnO2 core-shell heterostructured nanowire arrays on Ni foam as high-performance supercapacitor electrodes. Chem. Commun. 2013, 49, 137–139. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Shi, S.; Xiong, Q.; Li, L.; Zhang, Y.; Tang, H.; Gu, C.; Wang, X.; Tu, J. Hierarchical NiCo2O4@NiCo2O4 core/shell nanoflake arrays as high-performance supercapacitor materials. Acs Appl. Mater. Interface 2013, 5, 8790–8795. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, S.; Huang, Z.; Yu, Y. High-performance NiCo2O4@Ni3S2 core/shell mesoporous nanothorn arrays on Ni foam for supercapacitors. J. Mater. Chem. A 2014, 2, 17595–17601. [Google Scholar] [CrossRef]

- Huang, L.; Chen, D.; Ding, Y.; Feng, S.; Wang, Z.L.; Liu, M. Nickel–cobalt hydroxide nanosheets coated on NiCo2O4 nanowires grown on carbon fiber paper for high-performance pseudocapacitors. Nano Lett. 2013, 13, 3135–3139. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Guo, J.; Qing, C.; Sun, D.; Wang, B.; Tang, Y. Novel topotactically transformed carbon–CoO–NiO–NiCo2O4 nanosheet hybrid hetero-structured arrays as ultrahigh performance supercapacitors. Chem. Commun. 2014, 50, 8697–8700. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Li, W.; Xu, K.; Zou, R.; Chen, Z.; Hu, J. Sponge-like NiCo2O4/MnO2 ultrathin nanoflakes for supercapacitor with high-rate performance and ultra-long cycle life. J. Mater. Chem. A 2014, 2, 7738–7741. [Google Scholar] [CrossRef]

- Jabeen, N.; Xia, Q.; Yang, M.; Xia, H. Unique Core-Shell Nanorod Arrays with Polyaniline Deposited into Mesoporous NiCo2O4 Support for High-Performance Supercapacitor Electrodes. Acs Appl. Mater. Interface 2016, 8, 6093–6100. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Kong, D.; Huang, Z.X.; Mo, R.; Wang, Y.; Han, Z.; Cheng, C.; Yang, H.Y. Three-dimensional hierarchical NiCo2O4 nanowire@Ni3S2 nanosheet core/shell arrays for flexible asymmetric supercapacitors. Nanoscale 2016, 8, 10686–10694. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Xia, C.; Wei, N.; Alshareef, H.N. NiCo2O4@TiN core-shell electrodes through conformal atomic layer deposition for all-solid-state supercapacitors. Electrochim. Acta 2016, 196, 611–621. [Google Scholar] [CrossRef]

- Wang, J.G.; Jin, D.; Zhou, R.; Shen, C.; Xie, K.; Wei, B. One-step synthesis of NiCo2S4 ultrathin nanosheets on conductive substrates as advanced electrodes for high-efficient energy storage. J. Power Sources 2016, 306, 100–106. [Google Scholar] [CrossRef]

- Shen, L.; Yu, L.; Wu, H.B.; Yu, X.Y.; Zhang, X.; Lou, X.W.D. Formation of nickel cobalt sulfide ball-in-ball hollow spheres with enhanced electrochemical pseudocapacitive properties. Nat. Commun. 2015, 6, 6694. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.-G.; Zhou, R.; Jin, D.; Xie, K.; Wei, B. Controlled synthesis of NiCo2S4 nanostructures on nickel foams for high-performance supercapacitors. Energy Storage Mater. 2016, 2, 1–7. [Google Scholar] [CrossRef]

| Material | Preparation Methods //Annealing Condition | Specific Capacitance //Loading Mass | Rate Performance | Capacity Retention | Potential Window//Electrolyte | Ref. |

|---|---|---|---|---|---|---|

| urchin-like NiCo2O4 | hydrothermal 120 °C/6 h //300 °C/3 h in air | 1650 F/g (at 1 A/g) | 1348 F/g (at 15 A/g) | 90.8% (after 2000 cycles ) | 0–0.41 V vs. SCE// 3 M KOH | [33] |

| flowerlike NiCo2O4 | hydrothermal 180 °C/6 h //300 °C/2 h in air | 658 F/g (at 1 A/g) | 78% (at 20 A/g) | 93.5% (after 10,000 cycles) | 0–0.55 V vs. Hg/HgO// 6 M KOH | [34] |

| NiCo2O4 nanosheets | electrodeposition (−1.0 V vs. SCE) //300 °C/2 h | 2010 F/g (at 2 A/g) //0.8 mg/cm2 | 72% (at 20 A/g) | 94% (after 2400 cycles) | −0.1–0.3 V vs. SCE// 3 M KOH | [37] |

| NiCo2O4 double-shell hollow spheres | hydrothermal 90 °C/4 h //300 °C/4 h | 718 F/g (at 1 A/g) //3.76 mg/cm2 | 80% (at 10 A/g) | 89.9% (after 2000 cycles) | 0–0.4 V vs. SCE// 6 M KOH | [38] |

| flower-like nickel-cobalt Oxides | hydrothermal 120°C/2h //300 °C/2h | 750F/g (at 1A/g) 2.2mg/cm2 | 498F/g (at 10 A/g) | 102% (after 3000 cycles) | 0-0.5V vs. Ag/AgCl// 2M KOH | [39] |

| NiCo2O4 nanowires | hydrothermal 100 °C //300 °C/3 h | 1283 F/g (at 1 A/g) //1.2 mg/cm2 | 79% (at 20 A/g) | 100% (after 5000 cycles ) | 0–0.4 V vs. SCE// 6 M KOH | [42] |

| NiCo2O4 nanorods/nanosheets | oil bath 80 °C/6 h //300 °C/2 h 90 °C/4 h //350 °C/2 h | nanorods 1023.6 F/g (at 1 A/g) nanosheets 1002 F/g (at 1 A/g) | 500 F/g (at 20 A/g) 520 F/g (at 20 A/g) | 81.5% (after 2000 cycles) 96.4% (after 2400 cycles) | 0–0.45 V (nanorods) 0–0.55 V (nanosheets) vs. SCE// 2 M KOH | [43] |

| chain-like NiCo2O4 nanowires | hydrothermal 100 °C/6 h //300 °C/2 h in air | 1284 F/g (at 2 A/g) | 72% (at 20 A/g) | 97.5% (3000 cycles) | 0–0.43 V vs. Ag/AgCl// 6 M KOH | [44] |

| NiCo2O4 spinel thin-film | potentiostatic deposition //200 °C | 580 F/g (at 0.5 A/g) | 570 F/g (at 50 A/g) | 94% (after 2000 cycles) | 0.1–0.45 V vs. Ag/AgCl// 1 M KOH | [45] |

| NiCo2O4 NSs@hollow microrod arrays | electrochemical deposition //300 °C/2 h | 678 F/g (at 6 A/g) | 367 F/g (at 47 A/g) | 96.06% (after 1500 cycles) | 0-0.5 V vs. SCE// 1 M KOH | [46] |

| NiCo2O4 nanosheet | electrochemical deposition //300 °C/2 h in air | 2658 F/g (at 2 A g−1) //0.6 mg/cm2 | 70% (at 20 A g−1) | 80% (after 3000 cycles ) | −0.1–0.35 V vs. Hg/Hg2Cl2// 3 M KOH | [47] |

| NiCo2O4 nanotubes | electrospun //450 °C/2 h in air | 1647 F/g (at 1 A/g) | 77.3% (at 25 A/g) | 93.6% (after 3000 cycles) | 0–0.41 V vs. Ag/AgCl// 2 M KOH | [48] |

| NiCo2O4 nanosheets | hydrothermal 90 °C/10 h //320 °C/2 h in air | 3.51 F/cm2 (at 1.8 mA/cm2) //1.2 mg/cm2 | 39% (at 48.6 mA/cm2) | 93.3% (8.5 mA/cm2) 82.9% (25 mA/cm2) (after 3000 cycles) | 0–0.45 V vs. SCE// 2 M KOH | [49] |

| NiCo2O4 nanosheets | oil bath 90 °C/6 h //300 °C/2 h | 899 F/g (at 1 A/g) //1.54 mg/cm2 | 67.9% (at 20 A/g) | 93.2% (6000 cycles//2 A/g) 84.9% (6000 cycles//5 A/g) | 0–0.45 V vs. SCE// 6 M KOH | [50] |

| NiCo2O4 nanosheets @halloysite nanotubes | oil bath 90 °C/6 h //350 °C/3.5 h in air | 1886.6 F/g (at 6 A/g) | 79.5% (at 30 A/g) | 94.74% (after 6000 cycles) | 0–0.5 V vs. SCE// 2 M KOH | [51] |

| NiCo2O4 nanowires | precipitate //250 °C/3 h | 743 F/g (at 1 A/g) | 78.6% (at 40 A/g) | 93.8% (after 3000 cycles) | −0.05–0.45 V vs. Ag/AgCl// 1 M KOH | [52] |

| NiCo2O4 spheres | oil bath 180 °C/3 h //300 °C/3 h | 856 F/g (at 1 A/g) | 60.8% (at 100 A/g) | 98.75% (after 10,000 cycles) | 0–0.5 V vs. Hg/HgO// 2 M KOH | [53] |

| flower-shaped NiCo2O4 microsphere | microwave-assisted 100 °C/15 min //300 °C/2 h in air | 1006 F/g (at 1 A/g) //3 mg/cm2 | 72.2% (at 20 A/g) | 93.2% (after 1000 cycles ) | 0-0.5 V vs. Hg/HgO// 6 M KOH | [54] |

| NiCo2O4 nanoneedle | hydrothermal 85 °C/8 h //250 °C/1.5 h | 3.12 F/cm2 (at 1.11 mA/cm2) //0.9 mg/cm2 | 18.9% (at22.24 mA/cm2) | 94.74% (after 2000 cycles ) | 0–0.4 V vs. SCE// 2 M KOH | [55] |

| NiCo2O4 multiple hierarchical structures | hydrothermal 120 °C/7 h //350 °C/3 h | 2623.3 F/g (at 1 A/g) //2.09 mg/cm2 | 1785.5 F/g (at 40 A/g) | 94% (after 3000 cycles) | 0–0.5 V vs. Hg/HgO// 3 M KOH | [56] |

| Nickel cobaltite nanowire | hydrothermal 150 °C/6 h //350 °C/3 h in air | 760 F/g (at 1 A/g) //1 mg/cm2 | 70% (at 20 A/g) | 81% (after 3000 cycles) | −0.05–0.50 vs. Hg/HgO// 6 M KOH | [57] |

| NiCo2O4 nanowire | hydrothermal 120 °C /6 h //400 °C/3 h | 2681 F/g (at 2 A/g) //3 mg/cm2 | 2305 F/g (at 8 A/g) | 100% (after 3000 cycles) | 0–0.45 V vs. SCE// 3 M KOH | [58] |

| NiCo2O4 square sheet | hydrothermal 180 °C/24 h //350 °C/3 h | 980 F/g (at 0.5 A/g) | 384 F/g (at 10 A/g) | 91% (after 1000 cycles) | 0–0.5 V vs. Ag/AgCl// 1 M KOH | [59] |

| NiCo2O4 nanosheets | microwave 140 °C/30 min //300 °C/3 h in air | 560 F/g (at 2 A/g)// 1 mg/cm2 | 71% (at 20 A/g) | 95.2% (after 5000 cycles) | 0–0.6 V vs. SCE// 2 M KOH | [60] |

| Materials | Preparation Methods //Annealing Condition | Specific Capacitance //Loading Mass | Rate Performance | Capacity Retention | GCD Potential Window//Electrolyte | Ref. |

|---|---|---|---|---|---|---|

| carbon nanotube/NiCo2O4 | electrochemical deposition //300 °C/2 h | 694 F/g (at 1 A/g) | 82% (at 20 A/g) | 91% (1500 cycles) | 0–0.41 V vs. SCE// 6 M KOH | [63] |

| NiCo2O4 @CoxNi1-x(OH)2 | electrochemical deposition //300 °C/2 h | 5.71 F/cm (at 5.5 mA/cm2) (x = 0.33) //5.5 mg/cm2 | 83.7% (at 273 mA/cm2) (x = 0.33) | 80% (3000 cycles) (at x = 0.33) | −0.15–0.45 V vs. SCE// 1 M KOH | [67] |

| graphene/NiCo2O4 | electrochemical deposition //300 °C/2 h | 15 mg/cm2 | 1950 F/g (at 7.5 A g−1) | 92.8% (10,000 cycles) | −0.1–0.3 V vs. SCE// 3 M KOH | [68] |

| Ni(OH)2@NiCo2O4 | electrochemical deposition// 300 °C/2 h | 5.2 F/cm 3200 F/g (at 2 mA/cm2) //0.6 mg/cm2 | 79% (at 50 mA/cm2) | 36% (1000 cycles) | 0–0.45 V vs. SCE// 1 M KOH | [69] |

| NiCo2O4@polypyrrole nanowires | hydrothermal 110 °C/12 h //300 °C/2 h in air | 2055 F/g (at 1 A/g) //1.67 mg | 742 F/g (at 50 A/g) | 90% (5000 cycles) | −0.2–0.45 V vs. SCE// 3 M NaOH | [93] |

| NiCo2O4 nanowires/mollusc shell based macroporous carbon | hydrothermal 110 °C/12 h //300 °C/2 h | 1696 F/g (at 1 A/g)// 1.5 mg/cm2 | 24.9% (at 50 A/g) | 88% (2000 cycles) | 0–0.4 V vs. SCE// 2 M KOH | [86] |

| NiCo2O4@graphene nanoarchitectures | hydrothermal 90 °C/12 h //350 °C/2 h | 778 F/g (at 1 A/g) | 48% (at 80 A/g) | 90% (10,000 cycles) | 0–0.5 V vs. SCE// 2 M KOH | [88] |

| NiCo2O4–RGO composite | self-assembly //800 °C/8 h in air | 835 F/g (at 1 A/g)//2 mg/cm2 | 615 F/g (at 20 A/g) | higher than the initial value (4000 cycles) | 0.1–0.5 V vs. Hg/HgO// 6 M KOH | [89] |

| CNT@NiCo2O4 | precipitate //300 °C/3 h | 1038 F/g (at 0.5 A/g) | 64% (at 10 A/g) | 100% (1000 cycles) | −0.1–0.36 V vs. SCE// 6 M KOH | [87] |

| NiCo2O4@CoMoO4 | hydrothermal 120 °C/6 h //400 °C/3 h in air | 14.67 F/cm (at 10 mA/cm2) //2.3 mg/cm2 | 65.8% (at 60 mA/cm2) | 89.3% (1000 cycles) | −0.1–0.5 V vs. SCE// 2 M KOH | [94] |

| Co3O4/NiCo2O4 double-shelled nanocages | template 70 °C/10 h //350 °C/2 h | 972 F/g (at 5 A/g) //1 mg/cm2 | 63.2% (at 50 A/g) | 92.5% (12,000 cycles) | 0–0.42 V vs. SCE// 1 M KOH | [95] |

| NiCo2O4@MnO2 nanowire arrays | hydrothermal 120 °C/6 h //300 °C/2 h | 2.224 F/cm2 (at 2 mA/cm2) //1.2 mg/cm2 | 55.3% (at 50 mA/cm2) | 113.6% (8000 cycles) | 0–0.45 V vs. SCE// 1 M NaOH | [96] |

| NiCo2O4@MnO2 core-shellnanowire arrays | hydrothermal 90 °C/8 h //350 °C/2 h | 3.31 F/cm2 (at 2 mA/cm2) //1.4 mg/cm2 | 1.66 F/cm2 (at 20 mA/cm2) | 88% (2000 cycles) | 0–0.6 V vs. SCE// 1 M LiOH | [97] |

| NiCo2O4@NiCo2O4 nanoflake arrays | hydrothermal 120 °C/3 h //350 °C/2 h in argon | 1.55 F/cm2 (at 2 mA/cm2) //1.97 mg/cm2 | 1.16 F/cm2 (at 40 mA/cm2) | 98.6% (4000 cycles) | 0–0.55 V vs. Hg/HgO// 2 M KOH | [98] |

| NiCo2O4@Ni3S2 nanothorn arrays | hydrothermal 85 °C/9 h //350 °C/3 h in air | 1716 F/g (at 1 A/g) //2.1 mg/cm2 | 1104 F/g (at 20 A/g) | 83.7% (2000 cycles) | 0–0.5 V vs. Hg/HgO/ 2 M KOH | [99] |

| nickel-cobalt double hydroxide nanosheets on NiCo2O4 nanowires (x = 0.67) | hydrothermal 120 °C/16 h (x = 0.67) //300 °C/2 h in air | 1.64 F/cm2 (at 2 mA/cm2) (x = 0.67) //1 mg/cm2 | 67.55% (at 90 mA/cm2) (x = 0.67) | 81.3% (2000 cycles ) (x = 0.67) | −0.1–0.45 V vs. SCE// 1 M KOH | [100] |

| carbon–CoO–NiO-NiCo2O4 nanosheet hybrid hetero-structured arrays | hydrothermal 120 °C/6 h //350 °C/3 h | 5.23 F/cm2 2602.0 F/g (at 2 mA/cm2) //2 mg/cm2 | 76.1% (at 50 mA/cm2) | higher than the initial value (7000 cycles) | 0–0.48 V vs. SCE// 6 M KOH | [101] |

| sponge-like NiCo2O4/MnO2 ultrathin nanoflakes | electrochemical deposition //250 °C/2 h | 935 F/g (at 1 A/g) //0.55 mg/0.4 cm2 | 74.9% (at 50 A/g) | 103.1% (25,000 cycles) | −0.1–0.5 V vs. Ag/AgCl// 1 M KOH | [102] |

| NiCo2O4/MnO2 branched nanowire heterostructure arrays | hydrothermal 180 °C/8 h //300 °C/2 h in air | 2827 F/g (at 2 mA/cm2) //0.92 mg/0.4 cm2 | 66.8% (at 100 mA/cm2) | 98.4% (3000 cycles ) | 0–0.5 V vs. SCE// 1 M KOH | [92] |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Zhou, E.; He, W.; Deng, X.; Huang, J.; Ding, M.; Wei, X.; Liu, X.; Xu, X. NiCo2O4-Based Supercapacitor Nanomaterials. Nanomaterials 2017, 7, 41. https://doi.org/10.3390/nano7020041

Wang C, Zhou E, He W, Deng X, Huang J, Ding M, Wei X, Liu X, Xu X. NiCo2O4-Based Supercapacitor Nanomaterials. Nanomaterials. 2017; 7(2):41. https://doi.org/10.3390/nano7020041

Chicago/Turabian StyleWang, Chenggang, E Zhou, Weidong He, Xiaolong Deng, Jinzhao Huang, Meng Ding, Xianqi Wei, Xiaojing Liu, and Xijin Xu. 2017. "NiCo2O4-Based Supercapacitor Nanomaterials" Nanomaterials 7, no. 2: 41. https://doi.org/10.3390/nano7020041