3.1. Morphology, Structure, and Formation Mechanism of SnO2 Nanosheets

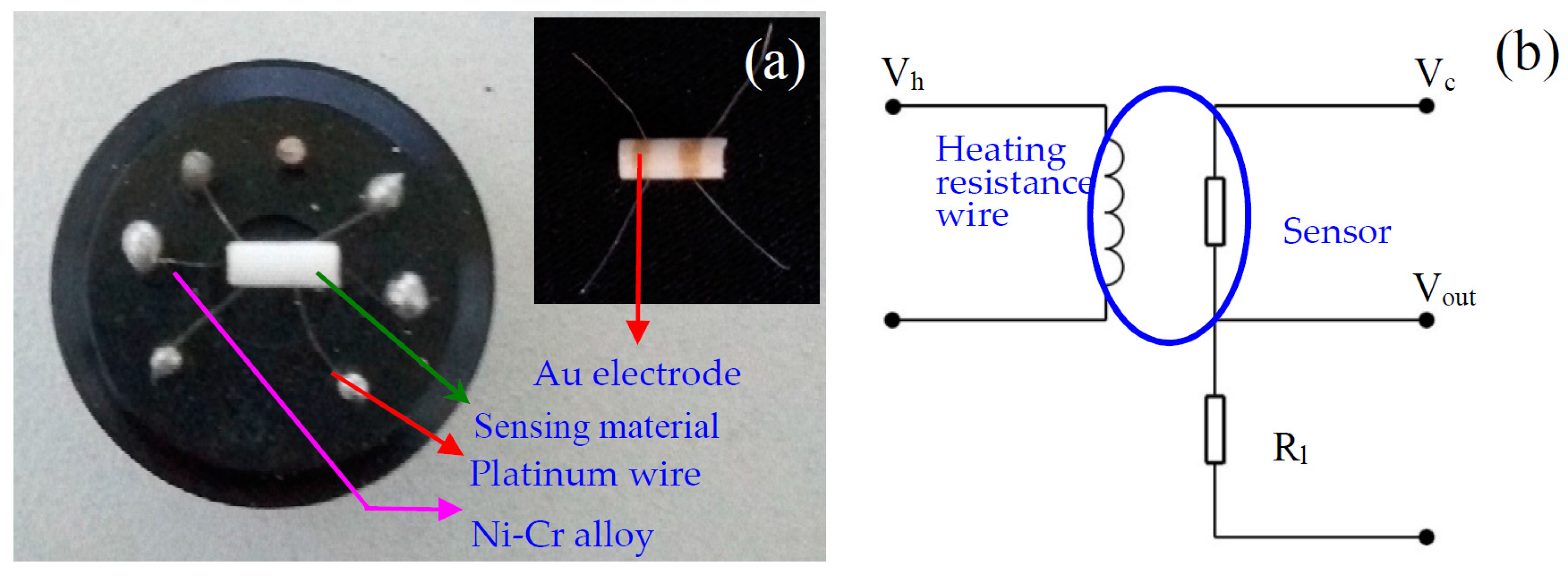

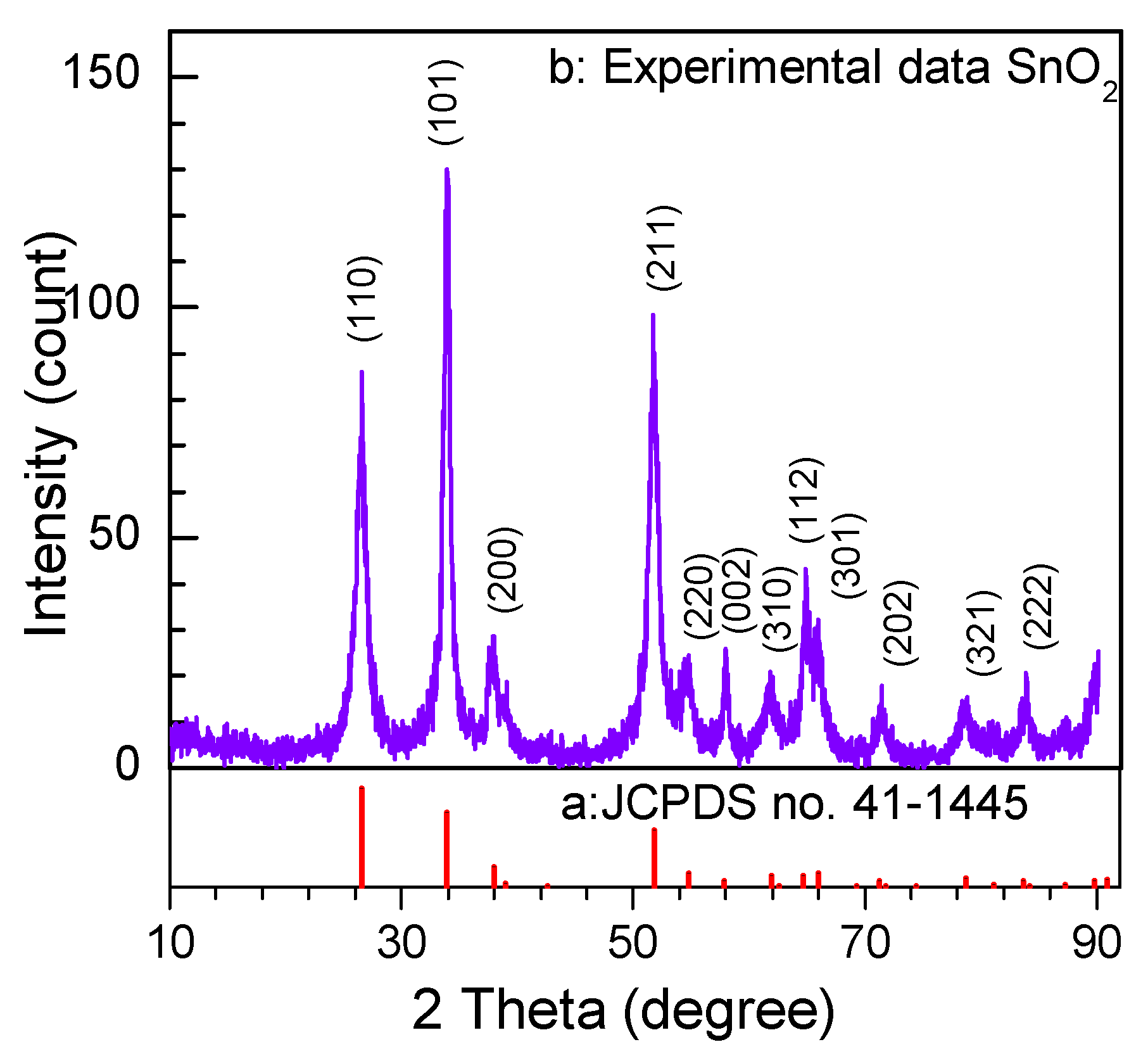

The XRD of the as-prepared product is shown in

Figure 2. It exhibits a texture effect corresponding to anisotropy and orientation of the crystal shape. All diffraction peaks are indexed to the phase of rutile-type SnO

2 with the tetragonal lattice parameters of

a =

b = 4.738 Å, c = 3.187 Å and the space group of P

42/mnm (136) according to JCPDS file no. 41-1445. No peaks of other impurities exhibit the high purity of the as-prepared products. The relative high intensity of peaks indicates a good crystallinity of the as-prepared SnO

2 nanosheets, and a large width of the full width at half maximum (FWHM) of the peaks suggests the small grain size of the SnO

2 nanosheets, which can calculate via Scherer’s equation:

where

k is the Scherer constant taking the value of 0.89,

λ is the wavelength of the X-ray source taking the value of 1.5406 Å,

β is the full width at half maximum (FWHM), and

θ is the Bragg angle. According to Scherer’s equation, the mean particle size of the as-prepared products that correspond to the (101) plane diffraction peak is about 7.8 nm. The small size effect of the nanoparticles may lead to a large specific surface which is beneficial to the performance of the gas sensor. On the other hand, it is obvious from

Figure 2 that the (101) peak is relatively stronger than (110), which demonstrates that the dominant expose surface is (101), but not (110). It is an important result that the exposed special high-energy surface of SnO

2 will result in a good effect on the gas-sensing performance.

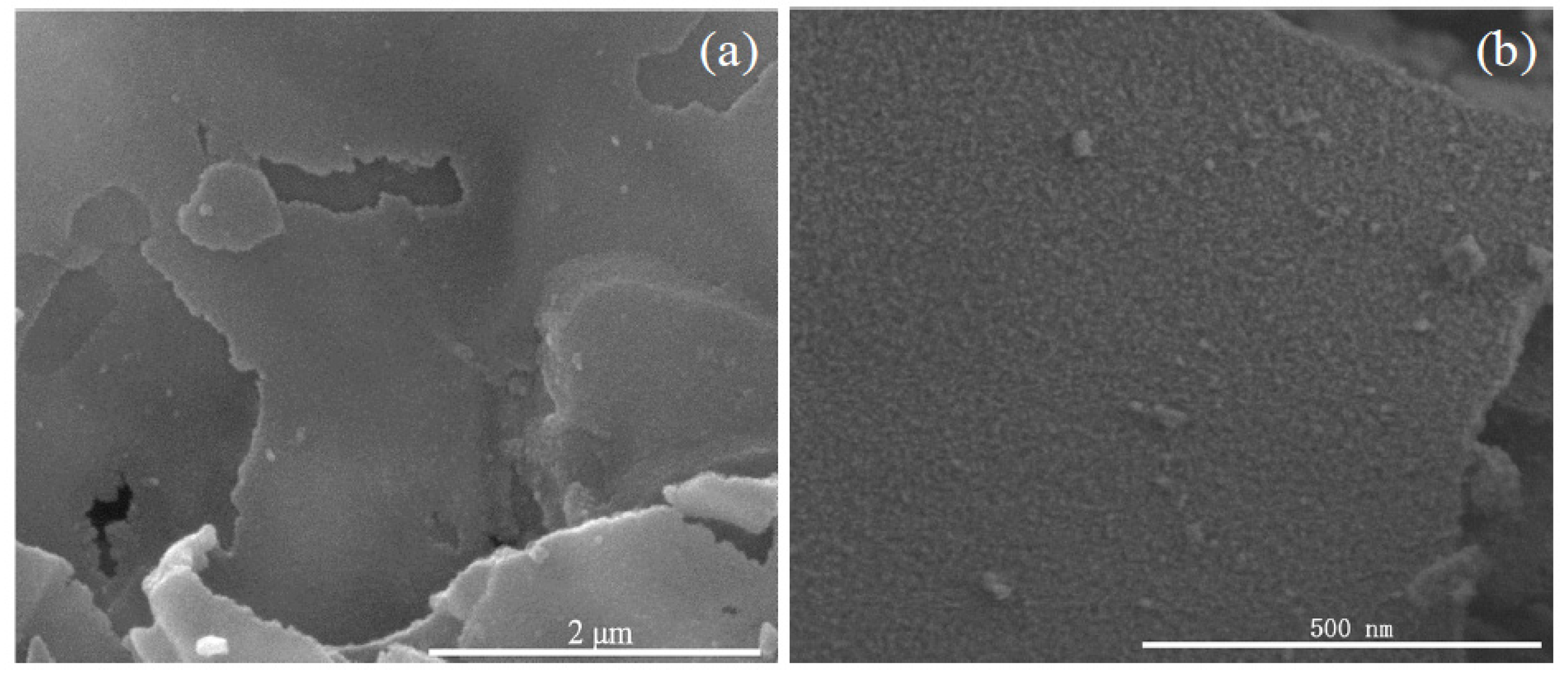

The FESEM images of the as-prepared products are shown in

Figure 3. As shown in

Figure 3a, the panoramic image reveals that the as-prepared nanosheets display a large and continuous area, and a smooth surface. From

Figure 3b, it is clear that there is an abundance of protuberant pots on the surface of the nanosheets, which illustrates that the nanosheets are formed by a mass of small SnO

2 nanoparticles. In order to further observe the microstructure of the nanosheets, FESEM was employed to acquire the higher magnification image, as shown in

Figure 3c. It can be seen that the nanosheets are assembled by an abundance of uniformly-sized particles with diameters of 6–12 nm. A cross-edge section FESEM image of the nanosheets, as shown in

Figure 3d, displays that SnO

2 nanoparticles are densely distributed and tightly packed to form the layers of nanosheets. Moreover, it is obvious that the SnO

2 nanosheet is tightly combined by 4–8 nanoparticle layers with an apparent interface in the center of the nanosheet, and the edge thickness of the nanosheet is about 58.3 nm. All of these observations are in good agreement with the XRD results. Due to the large and continuous area of nanosheets and the small size of nanoparticles, the as-prepared nanosheets might yield good gas-sensing properties.

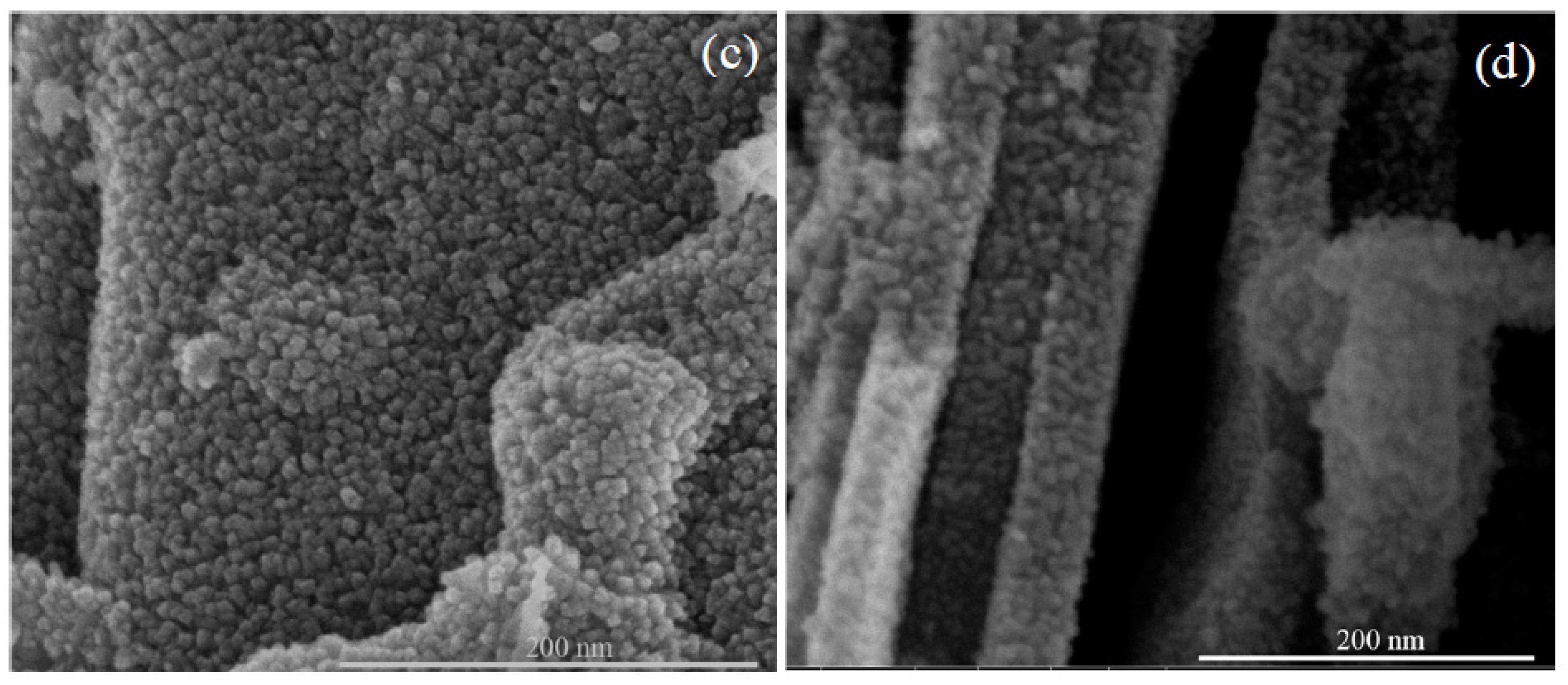

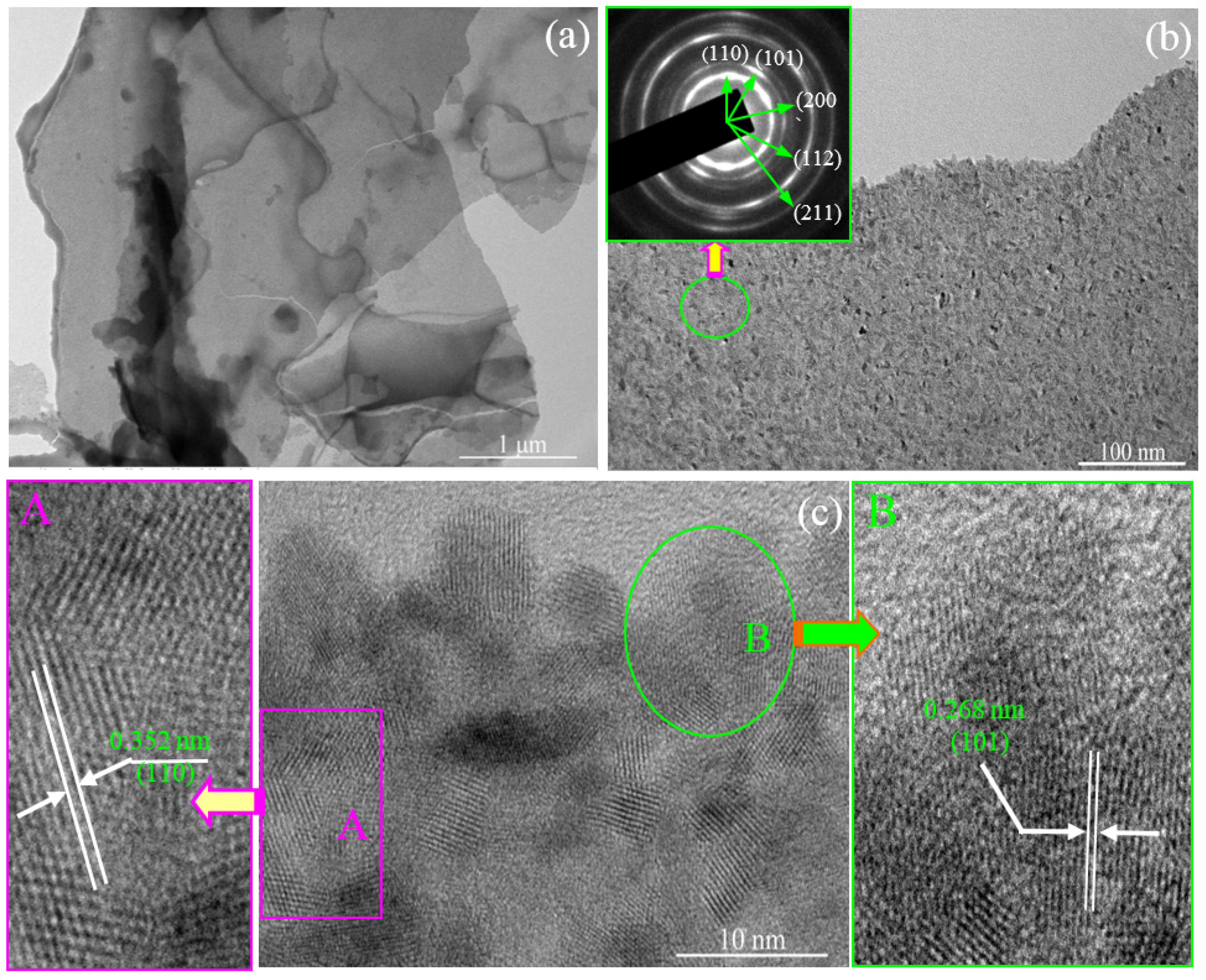

Detailed morphologies and microstructures for the as-prepared products are shown in

Figure 4. As the low-magnification TEM image shows in

Figure 4a, the morphology of the as-prepared nanosheets depict a large and continuous area with a smooth surface. At the same time, the see-through image suggests a thin thickness of the nanosheets. The high-magnification TEM image is shown as

Figure 4b, which displays the dense and wide distribution of the nanoparticles. From

Figure 4b, an abundance of protuberant pots can be seen on the surface of the nanosheets. The inset image of

Figure 4b shows the corresponding selected area electron diffraction (SAED) pattern of the SnO

2 nanosheets. This suggests the polycrystalline nature of the as-prepared products, which could be assigned to (110), (101), and (211) lattice planes of tetragonal rutile-type SnO

2. HRTEM was employed for further observation of the detailed microstructure of the as-prepared SnO

2 nanosheets. As shown in

Figure 4c, these nanoparticles are combined with each other closely. The nanoparticles exhibit approximate uniform grain size, whose diameter ranges from 6 to 10 nm. Those results are in accordance with FESEM and XRD results. Furthermore, high-quality and clear lattice fringes of single SnO

2 nanoparticles are observed in

Figure 4c. However, it is obvious that the

d-spacing between two adjacent lattice fringes of the SnO

2 nanoparticles is not uniform at first glance. It can be divided into two cases according to the space of the adjacent lattice fringes, which are marked as A and B areas, as shown in enlarged images, respectively. The image marked A depicts a clear and uniform lattice fringe with a

d-spacing of 0.352 nm, corresponding to the (110) lattice planes of SnO

2 with a tetragonal structure. This indicates that the exposed facet of the SnO

2 nanoparticles is the (110) plane and the oriented growth is preferentially along the [001] direction [21]. Additionally, most of the other SnO

2 nanoparticles exhibit a narrower

d-spacing as shown in area B. The

d-spacing is approximately 0.268 nm, which corresponds to the (101) lattice plane. These results prove that the preferential growth lattice plane is (101), rather than the conventional (110) plane. This discovery agrees nicely with the XRD results that the intensity of the (101) peak is stronger than that intensity of the (110) plane.

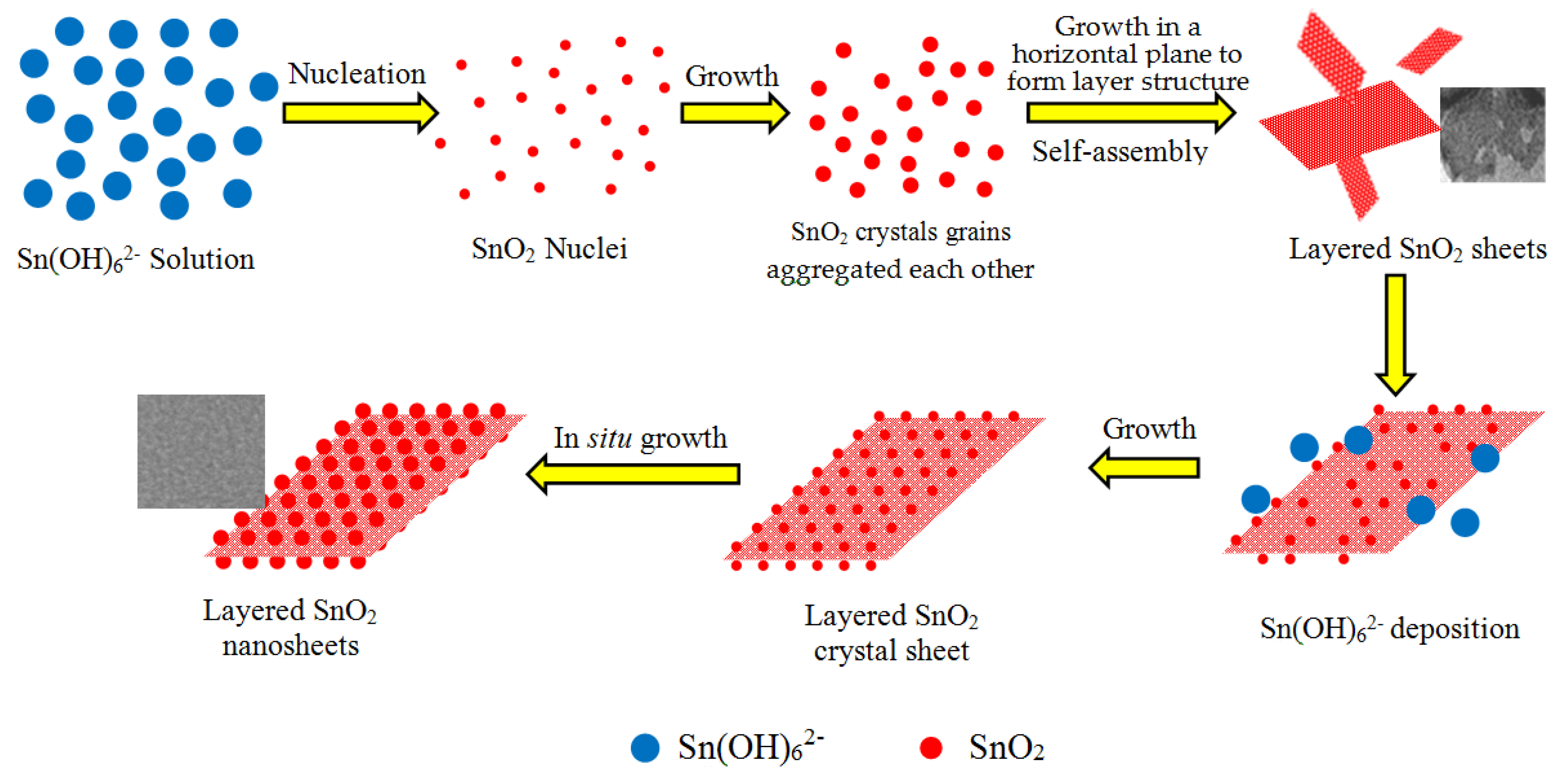

A possible formation process of the SnO

2 nanosheets can be speculated. As an unstable chemical compound, after the sodium stannate is added to alkaline deionized water, the Sn

4+ ions are rapidly hydrolyzed and oxidized to form the oversaturated solution of dissoluble Sn(OH)

62− complex ions according to the chemical reactions from (3) to (5) [

21]:

Under the hydrothermal conditions, high temperature and pressure induce the Sn(OH)

62− ions to decompose into the SnO

2 nanocrystals according to Reaction (6). With the hydrothermal reaction proceeding, the initial SnO

2 nuclei grow into crystals with different sizes. According to Ostwald ripening mechanism [

22], to reduce the Gibbs free energy of the system, molecules on the surface of the crystals dissolve in the solvent, and then deposit on the larger crystal’s surface. Finally, the smaller crystal grains disappear and the larger crystal grains are formed. On the other hand, driven by the high surface energy, the initial crystal grains are aggregated side-by-side in an orderly manner to self-assemble layered SnO

2 via an oriented attachment growth. In order to minimize the total surface area, it can be considered that the orderly attachment growth in the same horizontal plane is a priority [

22], which is observed from

Figure 4a. Hence, it is acceptable that these crystal grains form a layered sheet structure through the oriented attachment growth. This initial layered sheet structure is important for the formation of the later SnO

2 nanosheet in the absence of substrates. According to Bailey’s works [

23,

24], the formation of the mesoscale assembly process may be based on self-organization of crystalline building blocks through the spontaneous coalescence of primary nanoparticles into colloidal aggregates. The driving force for this spontaneous oriented attachment is that the elimination of the pairs of high-energy surfaces will lead to a substantial reduction in the surface energy. Subsequently, the layered sheet structure of SnO

2 nanocrystal grains is formed by in situ growth. The growth progress of nanoparticles relates to the intrinsic anisotropic characters of the hexagonal rutile SnO

2 crystal structure. For the rutile SnO

2 structure, the sequence of surface energy in different crystallographic orientations is (001) > (101) > (100) > (110). Therefore, according to the lowest energy principle, active sites of the nuclei offered may induce the nanoparticles to grow along with the most stable crystal face of (110) and (101) (natural growth faces) [

25,

26]. The schematic illustration of the possible formation process and growth mechanism of the SnO

2 nanosheets is depicted in

Figure 5. In this work, all hypotheses can be confirmed by HRTEM images shown in

Figure 4 and the result of XRD is shown as

Figure 2. Of note is that the (101) surface has not been investigated very often in other reports.

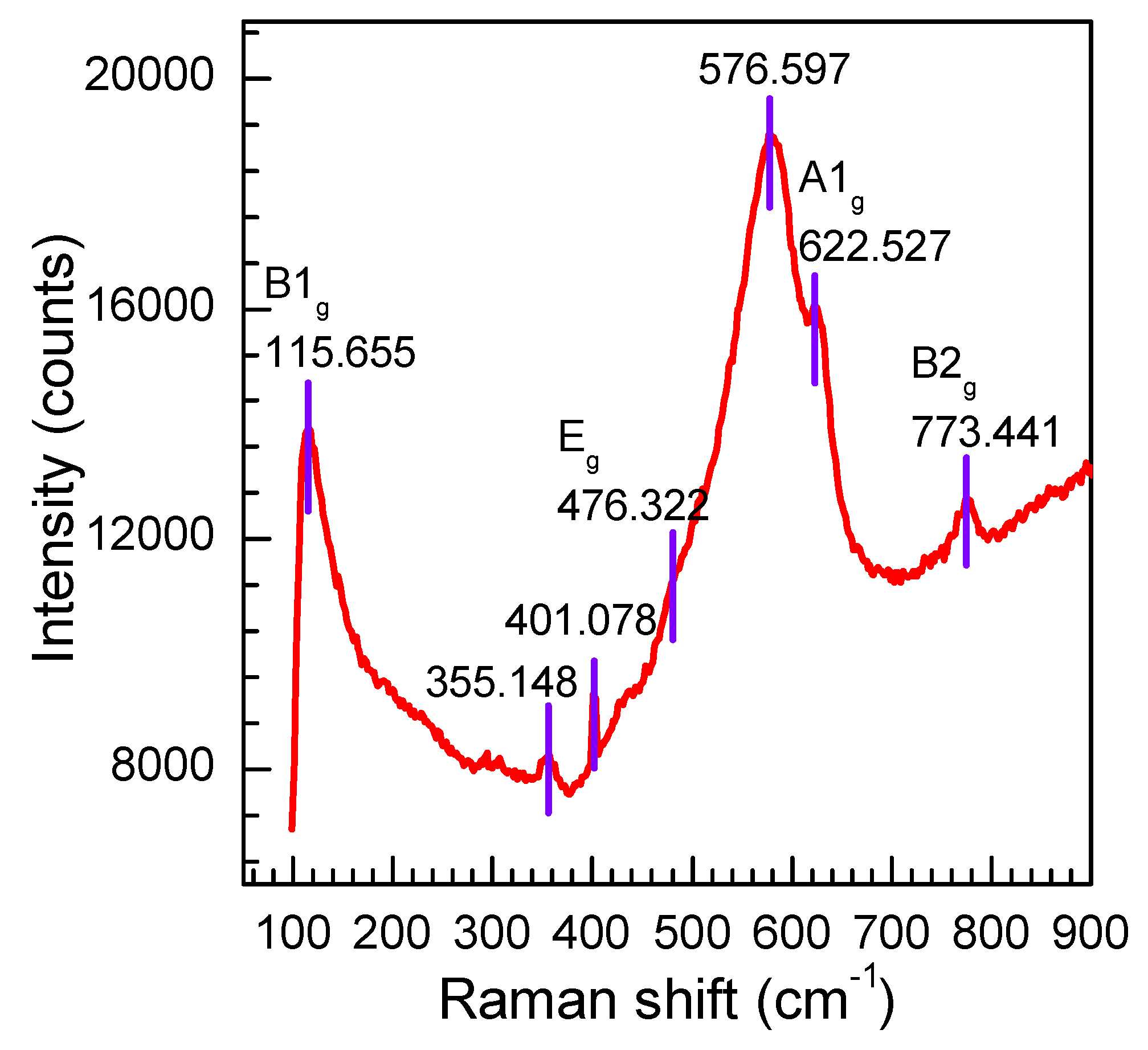

Raman was employed to analyze the lattice defects and surface properties of the as-prepared products [

27,

28]. It is well known that the tetragonal rutile structure SnO

2 has six atoms (two Sn and four O ions) in each unit cell, and the symmetry normal lattice vibrational modes at the Γ point of the Brillouin zone are given on the basis of group theory [

29]:

The Raman active modes of

B1g,

Eg,

A1g, and

B2g are permitted on rutile SnO

2 with the point group of D

I44h and the space group of P

42/mnm [

30].

Figure 6 shows the Raman scattering spectra of the as-prepared products. The peaks located at 115.655, 476.322, 622.527, and 773.441 cm

−1 correspond to

B1g,

Eg,

A1g, and

B2g vibrations, respectively, which agreed with the results reported by Lu et al. [

31]. This confirms that the as-prepared product is the tetragonal rutile SnO

2. Moreover, a broad and strong peak at 576.597 cm

−1 and a weak peak at 355.148 cm

−1 is observed in the spectra. These two peaks were also observed by Cheng et al. [

32]. It has been proved that they are not the Raman active modes of tetragonal rutile SnO

2 and cannot be observed in general. That they are observed here may be related to the facet surface area of the nanosheets, which are caused by the small size effect of the nanoparticles. In addition, a new peak at 401 cm

−1 is also detected in the spectra. Although this vibrational mode needs further study, it is believed that it is attributed to the reduction of the nanoparticle size or high concentration of surface defects, such as oxygen vacancies according to the relaxation of the Raman selection rule. As a conjecture, the small size and surface defects of the SnO

2 nanosheets may be a positive effect on the gas sensitivity of the sensor.

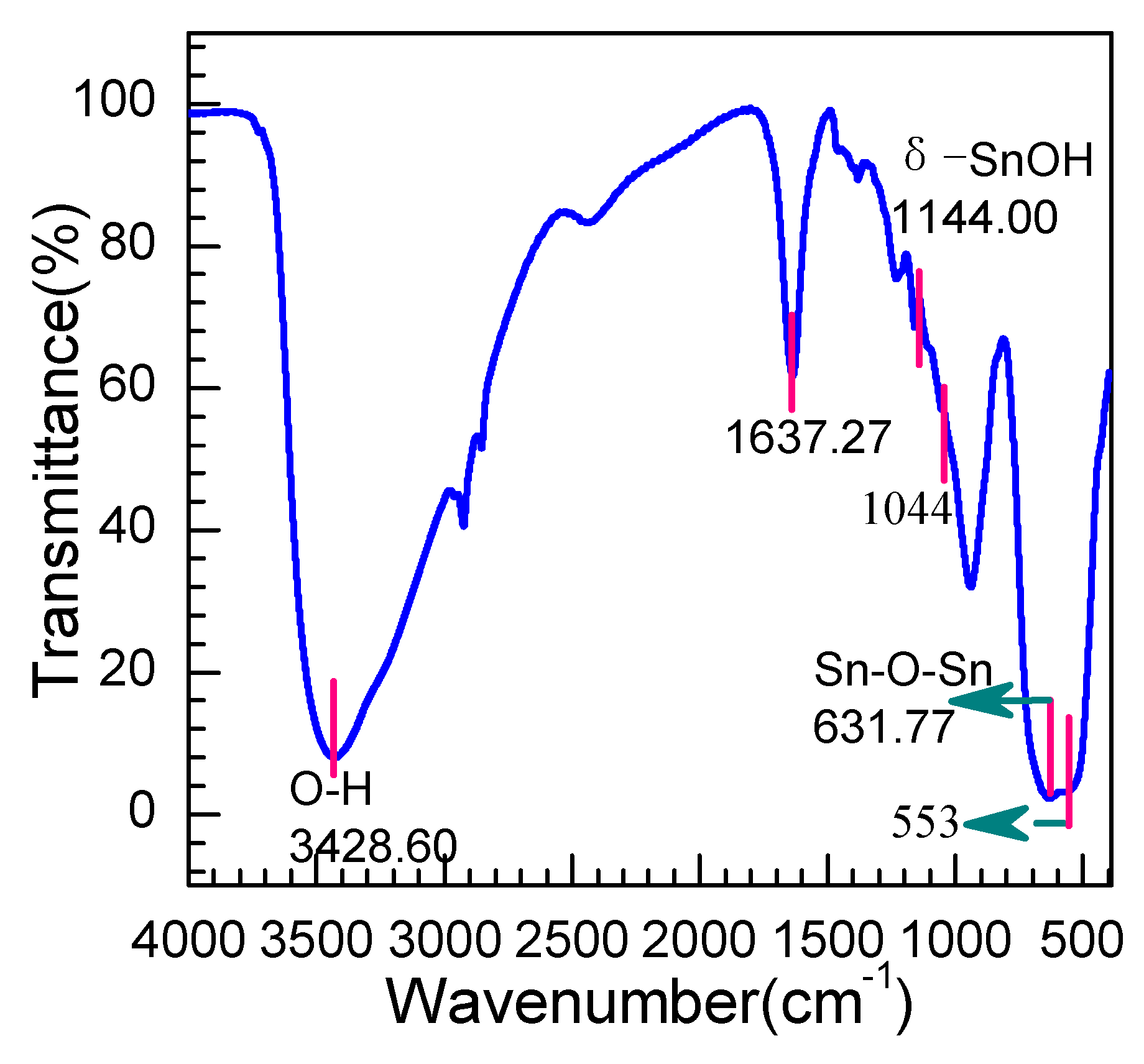

From the IR spectra shown in

Figure 7, several absorption peaks are observed at wavelengths of 3428, 1637, 670, and 553 cm

−1, respectively. The peaks around 3428.60 and 1637.27 cm

−1 are ascribed to hydroxyl group stretching vibrations and bending mode vibrations associated with the absorption of a few molecules of water [

33], which suggests a good adsorption capability of the as-prepared products. The bonds in the wavelength range from 1500 to 1060 cm

−1 are ascribed to a bending mode of different types of trace hydroxyl hybrid produced of the as-prepared SnO

2, such as the weak peak at 1144 cm

−1 being due to the δ–(SnOH) stretching vibrations [

34]. The key characteristic peaks at low wavenumbers, including 632 cm

−1 and 553 cm

−1, are assigned to the antisymmetric and symmetric Sn–O–Sn vibration [

35], which is derived from the active IR modes E

u (TO) mode at 618 cm

−1 and the A

2u (TO) mode at 477 cm

−1 [

36]. The shift of peaks toward the higher wavenumber may be related to the small nanoparticle size and the morphology of the SnO

2 nanosheets.

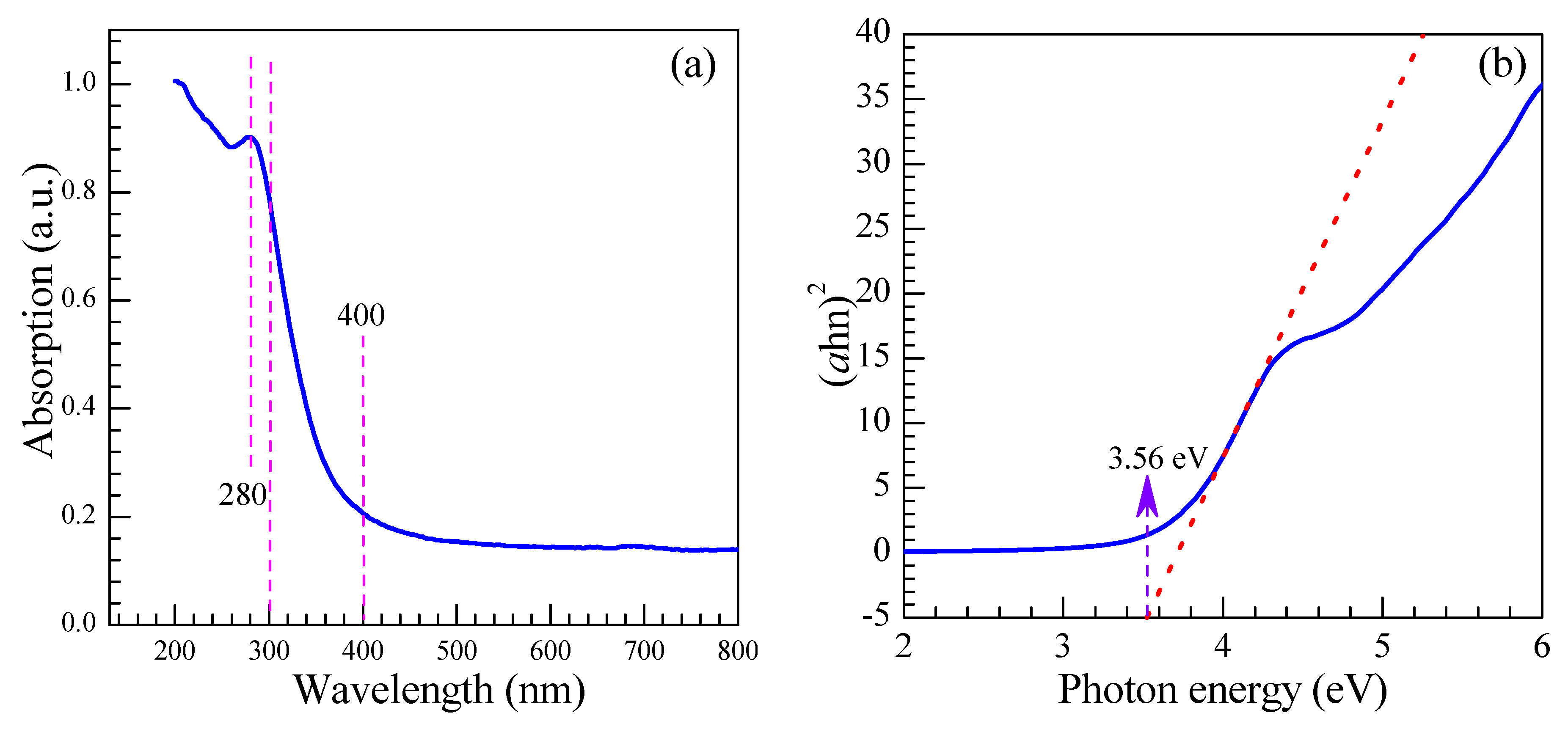

The UV-VIS spectrum of the as-prepared SnO

2 nanosheets in the wavelength range of 200 to 800 nm is shown in

Figure 8a. It indicates that a strong absorption has taken place in the ultraviolet region near the visible light. However, beyond that, a weak absorption peak around 275 nm can be seen in the spectrum, which is also observed by Luo et al. [

37]. As displayed in

Figure 8b, the optical band gap (

Eg) of the as-prepared SnO

2 nanosheets is calculated to be 3.56 eV via the equation: (αh

v)

2 =

B(h

v − Eg). It is found to be close to 3.6 eV, which is the theoretical value of the tetragonal rutile SnO

2.

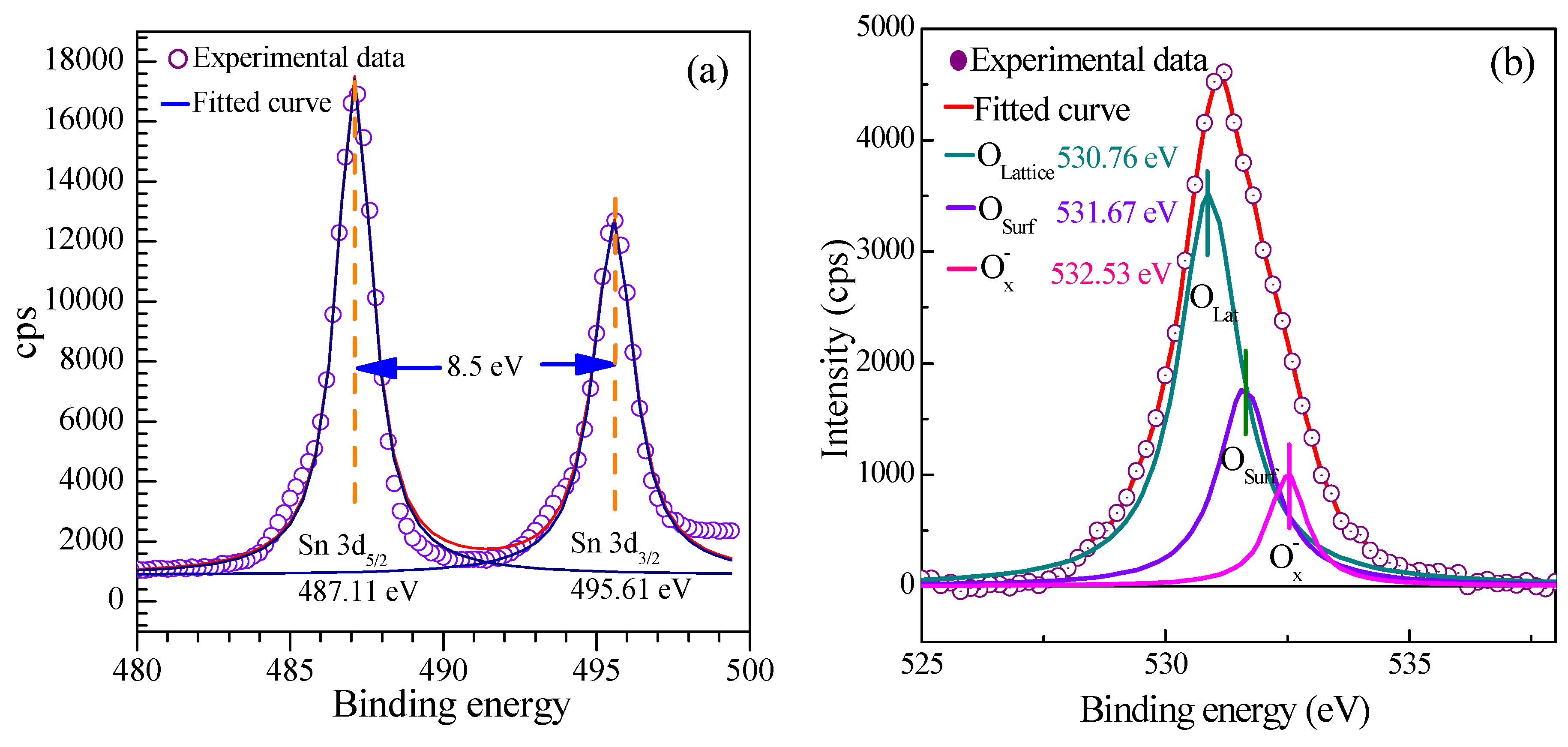

The XPS spectra were carried out to survey the chemical composition and the surface valence state of the as-prepared SnO

2 nanosheets. The measured spectra was decomposed into Gaussian components with a Shirley background using XPSPEAK.

Figure 9 shows the Sn 3d and O 1s spectra of SnO

2 nanosheets, respectively.

Figure 9a depicts the better symmetrical high-resolution XPS spectra of Sn 3d. The classical doublet 3d

3/2–3d

5/2 splitting peaks at 495.61 and 487.11 eV can be assigned to the lattice tin in SnO

2. The 8.50 eV of the energy difference between Sn 3d

5/2 and Sn 3d

3/2 is in good agreement with the energy splitting reported for SnO

2 [

11]. The Sn 3d

5/2 peak is closely consistent with the standard data of SnO

2 (486.70 eV), indicating that Sn is present in a chemical state of +4. As shown in

Figure 9b, the narrow scan XPS spectrum of the O 1s demonstrates the broad and asymmetric characteristics, suggesting various coordinations of oxygen in the nanosheets. The obtained O1s peak can be carefully convoluted into three symmetrical peaks located at 530.76 eV, 531.67 eV, and 532.53 eV, respectively, indicating the presence of three kinds of oxygen species in the nanosheets. The main peak centered at 530.23 eV is assigned to oxygen ions in the SnO

2 crystal lattice (O lattice) under completely-oxidized stoichiometric conditions [

38]. The peaks located at 531.67 eV can be ascribed to the defective oxygen caused by oxygen vacancy (V

O), oxygen interstitial (O

i), and oxygen antisite (O

Sn) [

39], suggesting a high hole concentration within oxygen-deficient region. Those holes can promote the absorption of oxygen from the atmosphere. The peak located at 532.53 eV stems from the absorbed O

x− species (O

− or O

2− ions), which indicates that rich oxygen species adsorbed on the surface of the SnO

2 nanosheets. The adsorbed O

x− ions are reactable with the ethylene glycol gas molecules, which then enhance the holes concentration. Thus, the increase of adsorbed oxygen ions can promote the gas sensitivity of the SnO

2 nanosheets.

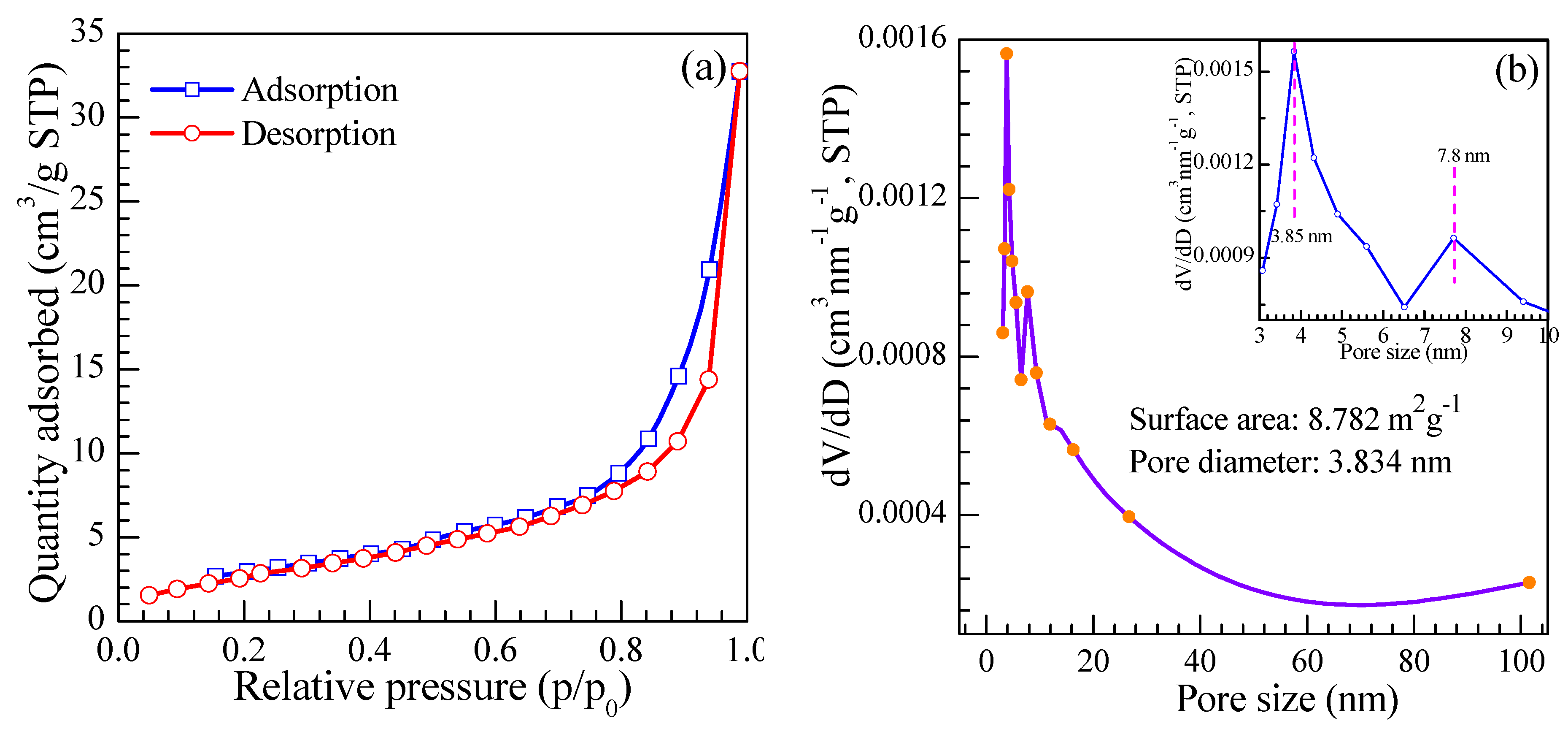

Figure 10a exhibits the typical nitrogen adsorption-desorption isotherm of the as-prepared nanosheets. The isotherm of the SnO

2 products displays a hysteresis loop at relative pressure ranging from 0.05 to 0.95, being attributed to the injection and release of N

2 in the as-prepared SnO

2 caused by capillary condensation. This illustrates the existence of mesopores between the SnO

2 nanoparticles. Meanwhile, the capillary condensation step is sharp, which indicates a narrow distribution of pore size. From the pore size distribution plot of the SnO

2 nanosheets calculated by the BJH method, as shown in

Figure 10b, a narrow peak is observed in the pore size ranging from 0–10 nm. The inset image shown in

Figure 10b depicts that the top value of pore size is located at 3.834 nm. These pores will offer more space for adsorption of the gas to stay, so that the diffusion and reaction of gas molecules can be carried out better. The specific surface area of the as-prepared product is calculated to be 68.782 m

2/g by the BET method. The relatively large specific surface may be advantageous for the chemical adsorption of gas molecules during the gas sensing process.

3.2. Gas Sensing Performance and Gas-Sensing Mechanism

The large specific surface area and thin thickness of the nanosheets render them very useful candidates for the gas sensing material with unique response properties. This is due to the fact that all the component SnO2 nanoparticles in the subnanometer-thick 2D nanosheet are exposed to its surface and can remarkably interact with the foreign gas species.

In order to investigate the influence of operating voltage and response to different gases, a series of tests were performed for various gases to the concentration of 300 ppm at an operating voltage ranging from 2.5 to 5.5 V, and the results are shown in

Figure 11. It demonstrates a similar change trend of the response to all kinds of gases. With the increase of operating voltage, the response increases firstly, reaches its maximum at a suitable temperature, and then decreases rapidly. This phenomenon can be explained by the mechanism of oxygen adsorption and desorption on the surface of SnO

2 [

40]. As an n-type metal oxide semiconductor, SnO

2 can adsorb oxygen from the air in the species of O

2− and O

− at different temperatures. Among of them, the O

− can react violently with reducing volatile organic compound vapors, such as ethylene glycol, while the interaction of the O

2− between the volatile organic compound vapors is slower, comparatively. Hence, the operating temperature has a significant influence on the response for volatile organic compound vapors. At a relatively low heating voltage (operating temperature), the sensor shows a lower response because the dominant process, in this case, is the superficial adsorption of O

2−. With the increase of the operating voltage, the dominant process becomes the O

− adsorption and the response increases, whereas, if the heating voltage increases continuously, the process turns into the adsorption of all oxygen ionic species and the response decreases [

41]. From

Figure 11, it can be found that the sensor made of SnO

2 nanosheets exhibits an excellent response to ethylene glycol. The maximum of the gas sensitivity achieves 295 at the lower heating voltage 3.4 V. However, the maximum response to ethanol, acetone, formaldehyde, ammonia, benzene, diethyl ether, and xylene, at their respective optimum heating voltages, is much lower. It can be calculated that the response to ethylene glycol is 16, 28, 44, 199, 66, 62, and 110 times higher than that of those gases. Even for ethanol, the maximum response reaches 18 times higher at the optimum heating voltage of 4.0 V. Obviously, the gas sensor based on SnO

2 nanosheets shows the high response, good selectivity, and lower optimum temperature for ethylene glycol. As a surface-controlled n-type semiconductor, the gas-sensing properties of SnO

2 are dominantly controlled by surface adsorption, which made the surface energy and conductance change. In other words, the selectivity of the sensor is affected by several factors, such as LUMO (lowest unoccupied molecule orbit) energy of the gas molecule, activation energy of the reaction between gas molecules, and adsorbed oxygen and the amount of gas adsorption on the sensing material at different operating temperatures. For a different value of the LUMO energy for the tested gases, the energy needed for the gas-sensing reaction will be different. This indicates that the needed conditions of the reaction between the gas molecules and the adsorbed oxygen is not the same for different gases. Thus, the sensors can detect the different target gases at suitable operating temperatures. The SnO

2 nanosheet material here shows a comparably lower response to ethanol, acetone, formaldehyde, ammonia, benzene, diethyl ether, and xylene, which means relatively good selectivity.

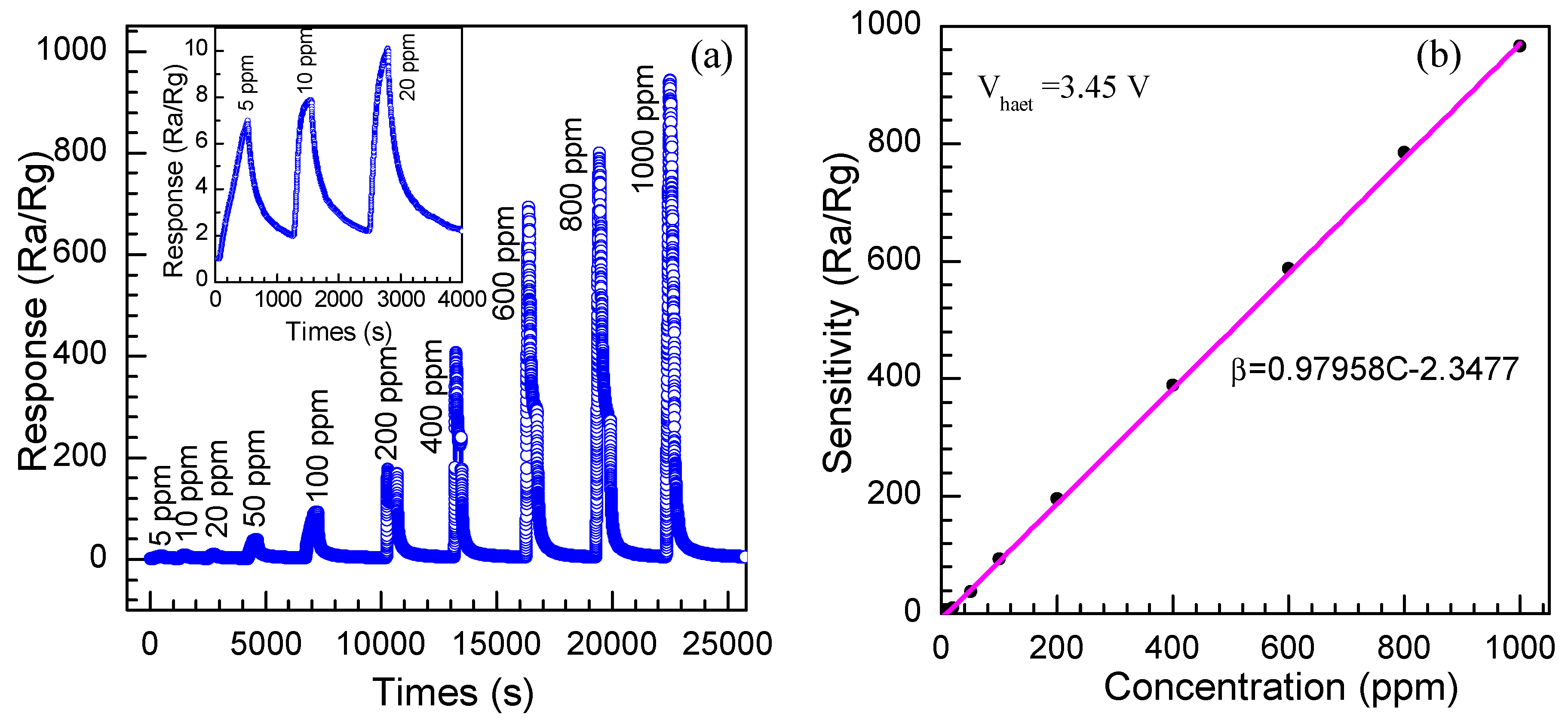

The dynamic response and recovery process of the SnO

2 nanosheet sensor were investigated and the results are shown in

Figure 12a. Ten cycles are successively recorded at the optimum operating voltage of 3.4 V, corresponding to concentrations of 5, 10, 20, 50, 100, 200, 400, 600, 800, and 1000 ppm, respectively. As performed in

Figure 12a, the curve rises fast when the ethylene glycol is injected into the test system and declines rapidly when the ethylene glycol is released. The response amplitude of the sensors gradually increases with the increasing gas concentration from 5 to 1000 ppm. The response and recovery characteristics are almost reproducible, which indicates the stability of the response of the SnO

2 nanosheets. All of those are important characteristics for the commercial use of any electronic devices. Noticeably, as shown in the inset of

Figure 12a, the sensor presents a considerable response of 6.9 to low concentrations of 5 ppm, 7.8 to 10 ppm and 12.0 to 20 ppm, suggesting the sensor based on SnO

2 nanosheets is favorable to detect ethylene glycol with lower concentration.

The correlation curve between concentration of the ethylene glycol and the response function of the SnO

2 nanosheet sensor at the optimum heating voltage of 3.4 V is depicted in

Figure 12b. It can be seen that the response of the sensors increased with the increase of gas concentration. The responses of the nanosheets sensor reaches 38.1, 92.9, 175.5, 298.7, 682.5, 785.4, and 936.7 at 50, 100, 200, 400, 600, 800, and 1000 ppm, respectively. A linear dependence of the sensitivity on the ethylene glycol concentration is observed from 5 to 1000 ppm, suggesting that our sensor material will be able to measure a wide concentration range in practical application. It can be considered that the linear dependence of the response on concentration may be associated with the effect of the small size. The straight line of the response to the concentration of ethylene glycol is the calibration curve and the experimental data are fitted as:

where [

C] is the concentration of ethylene glycol gas and

R is the response. According to the results, a lower detection limit of 1.3758 ppm can be extrapolated to ethylene glycol in dry air. Generally, the gas response of the semiconductor metal-oxide gas-sensitive resistors can be empirically represented as [

42]:

where

A is an empirical parameter, [

C] is the concentration of the target gas, and exponent

β has some rational fraction value (the value is usually 1 or ½, depending on the size of the particles). Ogawa et al. suggested that

β could be assumed to be 1 for SnO

2 with a diameter around 15 nm, which illustrated a linear relation between the response and concentration, and 0.5 for SnO

2 nanoparticles with a diameter larger than 20 nm [

43]. Moreover, such similar results of linear dependence were also observed in 4–15 nm thin SnO

2 nanorods [

44]. Therefore, the above reports all indicate that the linear dependence is related to the small size effect of SnO

2 materials. However, the detailed reason needs further investigation since the sensing property of SnO

2 nanomaterials is not only affected by the small size effect, but also related to their exposed crystalline surface [

45,

46].

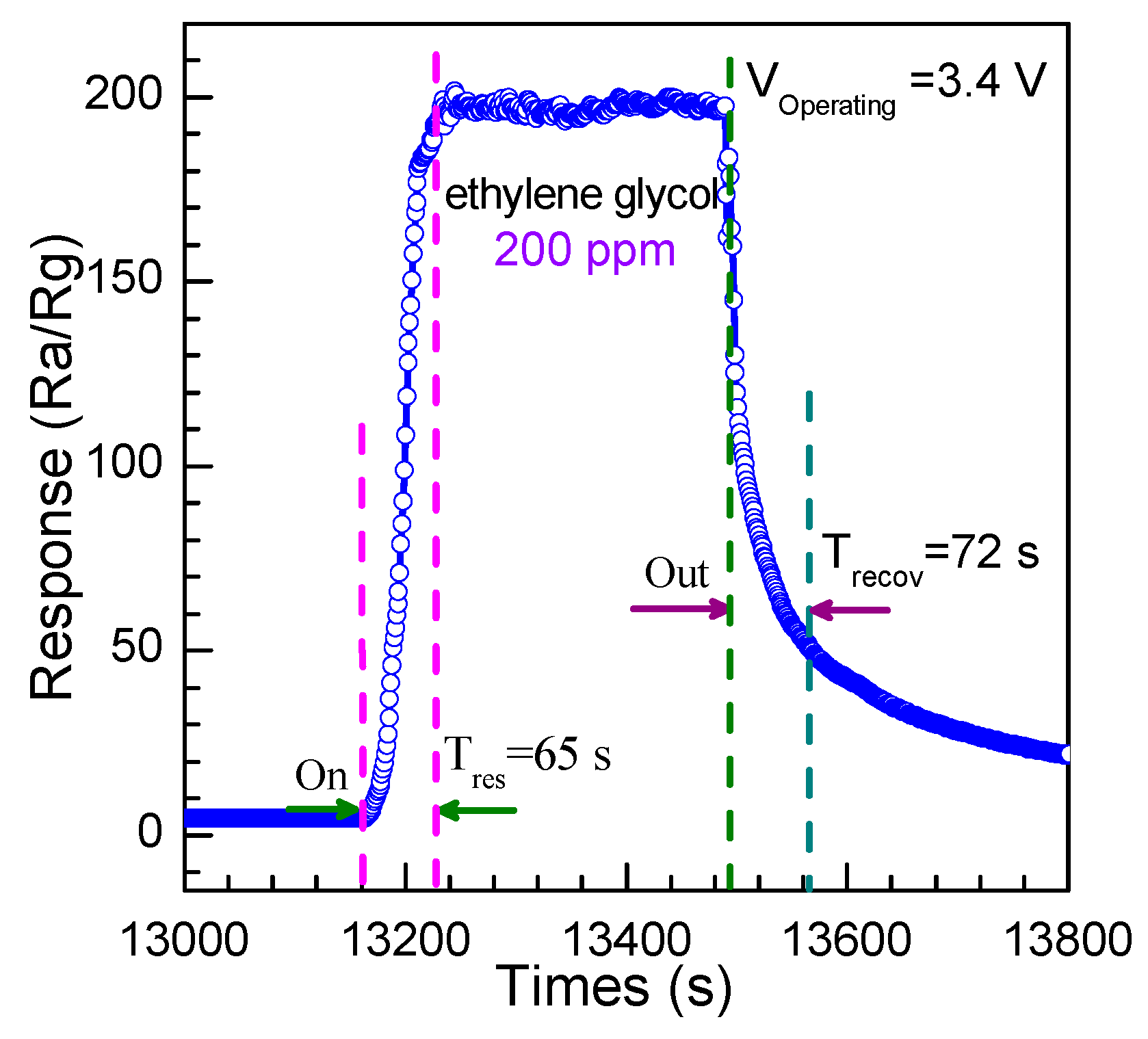

The time of the response and recovery are key parameters to evaluate the performance of the gas sensor. The response time is defined as the time when the resistance becomes stable after the injection of ethylene glycol, while the recovery time is defined as the time when the resistance returns to 90% of the original value in the air. The response curve of the sensor to 200 ppm ethylene glycol gas at 3.4 V is displayed as

Figure 13. One could obvserve that the response time is 65 s and the recovery time is 72 s, suggesting a relatively slightly longer time of response and recovery. This may be ascribed to the slower speed of the adsorption and desorption of ethylene glycol, and the vast pores with sizes of about 3.834 nm between each nanoparticles and the nanosheets, which acted as reaction rooms to force oxygen and ethanol molecules to stay long enough to complete the gas-sensing reaction.

Finally, the long-term stability of the nanosheet gas sensors is inspected. The gas response evolution of the SnO

2 nanosheet sensors was measured by repeating the measurement a number of times at concentrations of 100, 200, 400, 600, 800, and 1000 ppm at the optimum operation voltage of 3.4 V for 60 days.

Figure 14 demonstrates the response changes are measured on the 5th, 10th, 15th, 20th, 25th, 30th, 35th, 40th, 45th, 50th, 55th, and 60th day after the first measurement. It can be calculated that the slight vibration of the 60-days-later response is ±8.3%, ±5.8%, ±6.5%, ±10.2%, ±9.4%, and 11.2% for 100, 200, 400, 600, 800, and 1000 ppm ethylene glycol gas, respectively, which illustrates a good stability and reliability of the SnO

2 nanosheet sensor for practical application.

Until now, gas sensors for glycol detection have been rarely reported. Recently, there exist a few reports on ethylene glycol sensors that are based on porous SnO

2 nanotubes and SnO

2 nanosheets [

47,

48,

49]. A comparison between the sensing performance of the SnO

2 nanosheets and these SnO

2 nanostructures previously reported is summarized in

Table 1. As can be seen, the sensor made of SnO

2 nanosheets in the present work displays a higher response than those reported in other studies, which confirms that SnO

2 nanosheets have an obvious advantage over the others for ethylene glycol gas sensing. This indicates that the as-prepared SnO

2 nanosheets could be a competitive candidate for ethylene glycol gas-sensing detection.

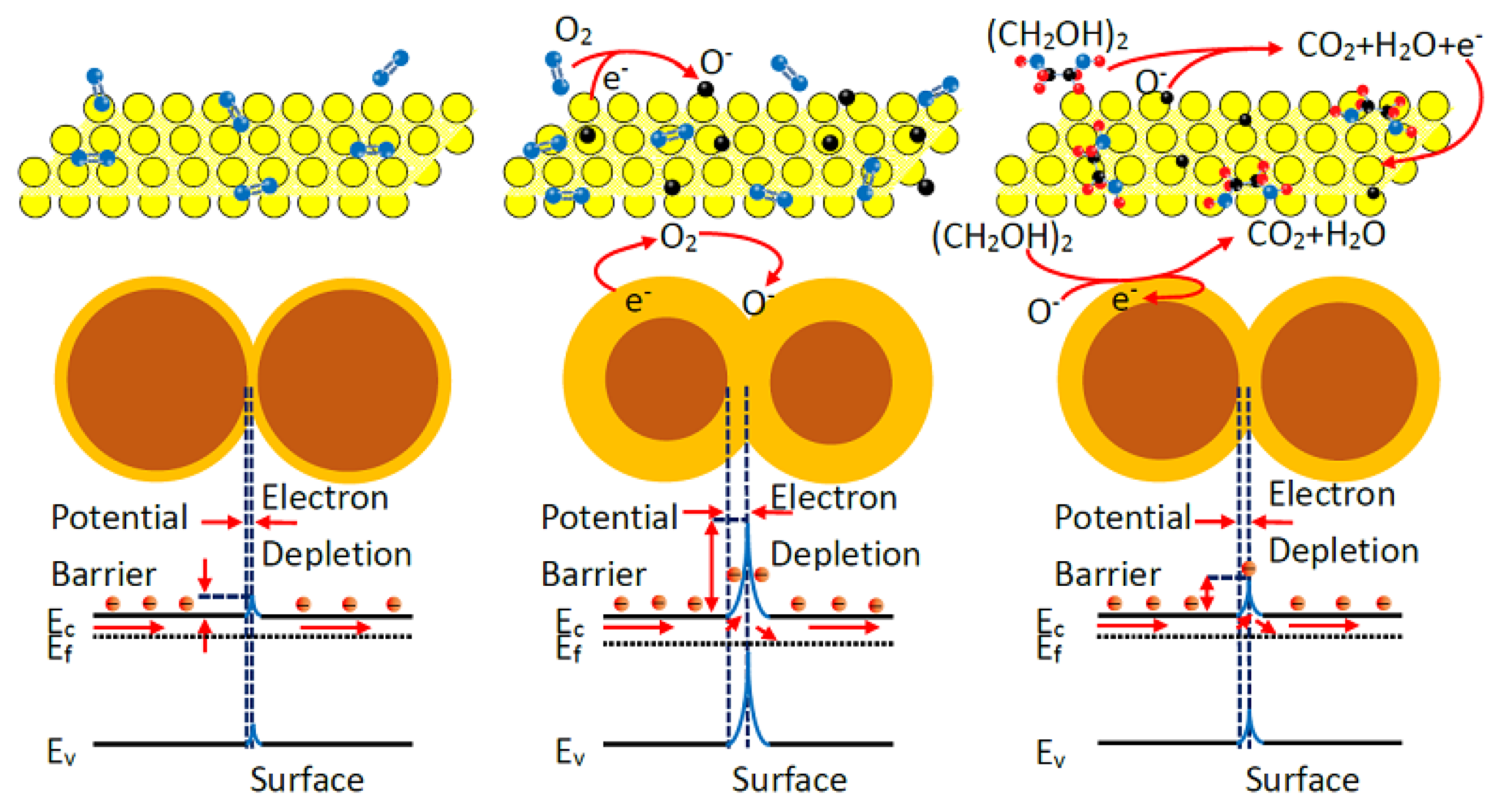

3.3. Gas Sensing Mechanism

The gas sensing performance of the surface-controlled n-type semiconductor can be ascribed to the change of electrical conductivity caused by the chemical interaction between gas molecules and the SnO

2 nanosheet surface. When the sensor is exposed in the air, the oxygen molecules adsorbed on the SnO

2 nanosheets can capture electrons from the surface and transfer oxygen into oxygen ions such as O

2−, O

−, and O

2− (Reaction (10)) [

8]. These oxygen ions result in the formation of an electron, depleted layer within the SnO

2 surface, which can lead to the decline of the Fermi level and a large increase of the potential barrier. As a consequence, the electrical conductivity will reduce and the electrical resistance will increase, obviously. When the target gas, such as ethylene glycol, is injected, the gas molecules are oxidized by O

− and O

2− adsorbed on the surface (Reaction (10)). Those electrons captured by O

2 molecules are released to the conduction band of SnO

2, which cause the depletion layer thickness decrease. At the same time, the Fermi level shifts upwards and the potential barrier reduces, resulting in the electrical resistance decrease. The detailed gas sensing process and mechanism is displayed in

Figure 15 and the whole reaction process can be illustrated by Reactions (10) and (11):

Based on the above gas-sensing results, it shows that the sensor fabricated by the SnO

2 nanosheets exhibits an excellent response to ethylene glycol at a lower operating temperature. A possible mechanism of the excellent gas-sensing properties of SnO

2 nanosheets is discussed here. The excellent gas-sensing properties of nanosheets is the result of the synergistic effect of multiple factors. On the one hand, the excellent ethylene glycol response is attributed to the large and continuous area and smooth surface of the nanosheets. The large specific surface area can enrich absorbed oxygen on the surface of the SnO

2 nanosheets, which is confirmed by the XPS results, as shown in

Figure 9b. It can provide more active sites for gas adsorption on the surface, contributing to a higher sensor sensitivity. On the other hand, the grain size (

D) of SnO

2 nanosheets has a great influence to the gas sensing performance of the sensors. As discussed above, when SnO

2 nanosheets are exposed to air, the chemisorption of oxygen leads to the formation of a depletion region within the surface. Upon exposure to ethylene glycol vapor, the trapped electrons are released back into the conduction band of SnO

2 and the thickness of the depletion region decreases, resulting in the sensor resistance decreasing. When a crystallite size is comparable to the Debye screening length (

D~2

LD), the depletion layer has a strong effect and the sensor sensitivity is strongly dependent on an average crystallite size. It was reported that the value

LD is about 7 nm for SnO

2 [

50]. Therefore, the crystal grains with a size smaller than 14 nm (2

LD) will contribute more to the enhancement of SnO

2 electrical conductivity upon ethylene glycol vapor exposure. Such consideration resolves around the observed response results as displayed in

Figure 11, where the SnO

2 nanosheet-based sensor shows a higher sensitivity to ethylene glycol vapor due to the structural evidence that SnO

2 nanosheets are composed of crystallites (grains) with an average size smaller than 2

LD. Moreover, the structural result shows that crystal grains of SnO

2 nanosheets expose the dominant facet of (101), which is the high-energy facet compared with the (110) facet of the SnO

2. As is well known, the high energy of the exposed facets, such as (211) or (111), always lead to an active surface due to high-density atom steps, ledges, and dangling bonds [

51]. Therefore, those high energy of the exposed facets of (101) will enhance the activity of the gas molecules chemisorption, turning to prompt the response of the ethylene glycol vapor. Although, it is involuted that the reasons of the SnO

2 nanosheets exhibit excellent response to ethylene glycol and needs to be further studied in detail, the mechanism can be explained by the aspects discussed above.