Effect of Sharp Diameter Geometrical Modulation on the Magnetization Reversal of Bi-Segmented FeNi Nanowires

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tailor-Made Nanoporous Alumina Templates with Geometrically Tunable Pore Diameters

2.2. Template Assisted Electrodeposition of FeNi Alloy Nanowires

2.3. Characterization of the Morphological, Magnetic and Magneto-Optic Properties of Samples

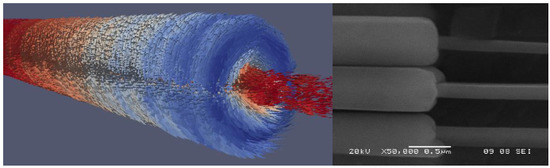

2.4. Micromagnetic Simulations of Diameter Modulated Single Nanowires

3. Results

3.1. Morphological and Compositional Characterization of Bi-Segmented FeNi Nanowires

3.2. Micromagnetic Simulations of Single Bi-Segmented FeNi Nanowires

3.3. Magnetic Characterization of Arrays and Single Bi-Segmented FeNi Nanowires

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shimanovich, D.L.; Vorobjova, A.I.; Tishkevich, D.I.; Trukhanov, A.V; Zdorovets, M.V; Kozlovskiy, A.L. Preparation and morphology-dependent wettability of porous alumina membranes. Beilstein J. Nanotechnol. 2018, 9, 1423–1436. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Porta-i-Batalla, M.; Xifré-Pérez, E.; Eckstein, C.; Ferré-Borrull, J.; Marsal, L.F. 3D Nanoporous Anodic Alumina Structures for Sustained Drug Release. Nanomaterials 2017, 7, 227. [Google Scholar] [CrossRef] [PubMed]

- Martín, J.; Martín-González, M.; Francisco Fernández, J.; Caballero-Calero, O. Ordered three-dimensional interconnected nanoarchitectures in anodic porous alumina. Nat. Commun. 2014, 5, 5130. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Porta-i-Batalla, M.; Eckstein, C.; Xifré-Pérez, E.; Formentín, P.; Ferré-Borrull, J.; Marsal, L.F. Sustained, Controlled and Stimuli-Responsive Drug Release Systems Based on Nanoporous Anodic Alumina with Layer-by-Layer Polyelectrolyte. Nanoscale Res. Lett. 2016, 11, 372. [Google Scholar] [CrossRef] [PubMed]

- Jeon, G.; Yang, S.Y.; Kim, J.K. Functional nanoporous membranes for drug delivery. J. Mater. Chem. 2012, 22, 14814–14834. [Google Scholar] [CrossRef]

- Banerjee, P.; Perez, I.; Henn-Lecordier, L.; Lee, S.B.; Rubloff, G.W. Nanotubular metal–insulator–metal capacitor arrays for energy storage. Nat. Nanotechnol. 2009, 4, 292. [Google Scholar] [CrossRef] [PubMed]

- Saranti, K.; Alotaibi, S.; Paul, S. A new approach for two-terminal electronic memory devices—Storing information on silicon nanowires. Sci. Rep. 2016, 6, 27506. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Romero, V.; Vega, V.; García, J.; Prida, V.M.; Hernando, B.; Benavente, J. Effect of Porosity and Concentration Polarization on Electrolyte Diffusive Transport Parameters through Ceramic Membranes with Similar Nanopore Size. Nanomaterials 2014, 4, 700–711. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumeria, T.; Santos, A.; Rahman, M.M.; Ferré-Borrull, J.; Marsal, L.F.; Losic, D. Advanced Structural Engineering of Nanoporous Photonic Structures: Tailoring Nanopore Architecture to Enhance Sensing Properties. ACS Photonics 2014, 1, 1298–1306. [Google Scholar] [CrossRef]

- Santos, A.; Kumeria, T.; Wang, Y.; Losic, D. In situ monitored engineering of inverted nanoporous anodic alumina funnels: On the precise generation of 3D optical nanostructures. Nanoscale 2014, 6, 9991–9999. [Google Scholar] [CrossRef] [PubMed]

- Hanawa, T. Materials for metallic stents. J. Artif. Organs 2009, 12, 73–79. [Google Scholar] [CrossRef] [PubMed]

- Swan, E.E.L.; Popat, K.C.; Grimes, C.A.; Desai, T.A. Fabrication and evaluation of nanoporous alumina membranes for osteoblast culture. J. Biomed. Mater. Res. Part A 2005, 72A, 288–295. [Google Scholar] [CrossRef] [PubMed]

- Osmanbeyoglu, H.U.; Hur, T.B.; Kim, H.K. Thin alumina nanoporous membranes for similar size biomolecule separation. J. Memb. Sci. 2009, 343, 1–6. [Google Scholar] [CrossRef]

- Fernández-Pacheco, A.; Streubel, R.; Fruchart, O.; Hertel, R.; Fischer, P.; Cowburn, R.P. Three-dimensional nanomagnetism. Nat. Commun. 2017, 8, 15756. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Coïsson, M.; Celegato, F.; Barrera, G.; Conta, G.; Magni, A.; Tiberto, P. Bi-Component Nanostructured Arrays of Co Dots Embedded in Ni80Fe20 Antidot Matrix: Synthesis by Self-Assembling of Polystyrene Nanospheres and Magnetic Properties. Nanomaterials 2017, 7, 232. [Google Scholar] [CrossRef] [PubMed]

- Sander, D.; Valenzuela, S.O.; Makarov, D.; Marrows, C.H.; Fullerton, E.E.; Fischer, P.; McCord, J.; Vavassori, P.; Mangin, S.; Pirro, P.; et al. The 2017 Magnetism Roadmap. J. Phys. D Appl. Phys. 2017, 50, 363001. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Xu, C.; Zhou, Y.; Maaz, K.; Yao, H.; Mo, D.; Lyu, S.; Duan, J.; Liu, J. Temperature- and Angle-Dependent Magnetic Properties of Ni Nanotube Arrays Fabricated by Electrodeposition in Polycarbonate Templates. Nanomaterials 2016, 6, 231. [Google Scholar] [CrossRef] [PubMed]

- Abad, B.; Maiz, J.; Ruiz-Clavijo, A.; Caballero-Calero, O.; Martin-Gonzalez, M. Tailoring thermal conductivity via three-dimensional porous alumina. Sci. Rep. 2016, 6, 38595. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lavrijsen, R.; Lee, J.-H.; Fernández-Pacheco, A.; Petit, D.C.M.C.; Mansell, R.; Cowburn, R.P. Magnetic ratchet for three-dimensional spintronic memory and logic. Nature 2013, 493, 647. [Google Scholar] [CrossRef] [PubMed]

- Wagner, M.F.P.; Völklein, F.; Reith, H.; Trautmann, C.; Toimil-Molares, M.-E. Fabrication and thermoelectrical characterization of three-dimensional nanowire networks. Phys. Status Solidi 2016, 213, 610–619. [Google Scholar] [CrossRef]

- Van Thiem, L.; Tu, L.T.; Phan, M.-H. Magnetization Reversal and Magnetic Anisotropy in Ordered CoNiP Nanowire Arrays: Effects of Wire Diameter. Sensors 2015, 15, 5687–5696. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Caballero-Calero, O.; Martín-González, M. Thermoelectric nanowires: A brief prospective. Scr. Mater. 2016, 111, 54–57. [Google Scholar] [CrossRef]

- Bochmann, S.; Fernandez-Pacheco, A.; Mačković, M.; Neff, A.; Siefermann, K.R.; Spiecker, E.; Cowburn, R.P.; Bachmann, J. Systematic tuning of segmented magnetic nanowires into three-dimensional arrays of ‘bits’. RSC Adv. 2017, 7, 37627–37635. [Google Scholar] [CrossRef] [Green Version]

- Cisternas, E.; Vogel, E.E. Inscription and stabilization of ferromagnetic patterns on arrays of magnetic nanocylinders. J. Magn. Magn. Mater. 2013, 337–338, 74–78. [Google Scholar] [CrossRef]

- Cisternas, E.; Vogel, E.E. Improving information storage by means of segmented magnetic nanowires. J. Magn. Magn. Mater. 2015, 388, 35–39. [Google Scholar] [CrossRef]

- Cisternas, E.; Faúndez, J.; Vogel, E.E. Stabilization mechanisms for information stored in magnetic nanowire arrays. J. Magn. Magn. Mater. 2017, 426, 588–593. [Google Scholar] [CrossRef]

- Prida, V.M.; García, J.; Iglesias, L.; Vega, V.; Görlitz, D.; Nielsch, K.; Barriga-Castro, E.D.; Mendoza-Reséndez, R.; Ponce, A.; Luna, C. Electroplating and magnetostructural characterization of multisegmented Co54Ni46/Co85Ni15 nanowires from single electrochemical bath in anodic alumina templates. Nanoscale Res. Lett. 2013, 8, 263. [Google Scholar] [CrossRef] [PubMed]

- Méndez, M.; González, S.; Vega, V.; Teixeira, M.J.; Hernando, B.; Luna, C.; Prida, M.V. Ni-Co Alloy and Multisegmented Ni/Co Nanowire Arrays Modulated in Composition: Structural Characterization and Magnetic Properties. Crystals 2017, 7, 66. [Google Scholar] [CrossRef]

- Palmero, E.M.; Béron, F.; Bran, C.; del Real, R.P.; Vázquez, M. Magnetic interactions in compositionally modulated nanowire arrays. Nanotechnology 2016, 27, 435705. [Google Scholar] [CrossRef] [PubMed]

- Ivanov, Y.P.; Chuvilin, A.; Lopatin, S.; Kosel, J. Modulated Magnetic Nanowires for Controlling Domain Wall Motion: Toward 3D Magnetic Memories. ACS Nano 2016, 10, 5326–5332. [Google Scholar] [CrossRef] [PubMed]

- Trukhanov, A.V; Grabchikov, S.S.; Vasiliev, A.N.; Sharko, S.A.; Mukhurov, N.I.; Gasenkova, I. V Specific features of formation and growth mechanism of multilayered quasi-one-dimensional (Co-Ni-Fe)/Cu systems in pores of anodic alumina matrices. Crystallogr. Rep. 2014, 59, 744–748. [Google Scholar] [CrossRef]

- Trukhanov, A.V; Grabchikov, S.S.; Sharko, S.A.; Trukhanov, S.V; Trukhanova, K.L.; Volkova, O.S.; Shakin, A. Magnetotransport properties and calculation of the stability of GMR coefficients in CoNi/Cu multilayer quasi-one-dimensional structures. Mater. Res. Express 2016, 3, 065010. [Google Scholar] [CrossRef]

- Rodríguez, L.A.; Bran, C.; Reyes, D.; Berganza, E.; Vázquez, M.; Gatel, C.; Snoeck, E.; Asenjo, A. Quantitative Nanoscale Magnetic Study of Isolated Diameter-Modulated FeCoCu Nanowires. ACS Nano 2016, 10, 9669–9678. [Google Scholar] [CrossRef] [PubMed]

- Salem, M.S.; Tejo, F.; Zierold, R.; Sergelius, P.; Moreno, J.M.M.; Goerlitz, D.; Nielsch, K.; Escrig, J. Composition and diameter modulation of magnetic nanowire arrays fabricated by a novel approach. Nanotechnology 2018, 29, 065602. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bran, C.; Berganza, E.; Fernandez-Roldan, J.A.; Palmero, E.M.; Meier, J.; Calle, E.; Jaafar, M.; Foerster, M.; Aballe, L.; Fraile Rodriguez, A.; et al. Magnetization Ratchet in Cylindrical Nanowires. ACS Nano 2018, 12, 5932–5939. [Google Scholar] [CrossRef] [PubMed]

- Grabchikov, S.S.; Trukhanov, A.V.; Trukhanov, S.V.; Kazakevich, I.S.; Solobay, A.A.; Erofeenko, V.T.; Vasilenkov, N.A.; Volkova, O.S.; Shakin, A. Effectiveness of the magnetostatic shielding by the cylindrical shells. J. Magn. Magn. Mater. 2016, 398, 49–53. [Google Scholar] [CrossRef]

- Wai, P.; Dmitrenko, V.; Grabchikov, S.; Vlasik, K.; Novikov, A.; Petrenko, D.; Trukhanov, V.; Ulin, S.; Uteshev, Z.; Chernysheva, V.; et al. Application peculiarities of magnetic materials for protection from magnetic fields. J. Phys. Conf. Ser. 2016, 675, 042006. [Google Scholar] [CrossRef] [Green Version]

- Trukhanov, A.V.; Grabchikov, S.S.; Solobai, A.A.; Tishkevich, D.I.; Trukhanov, S.V.; Trukhanova, E.L. AC and DC-shielding properties for the Ni80Fe20/Cu film structures. J. Magn. Magn. Mater. 2017, 443, 142–148. [Google Scholar] [CrossRef]

- Prida, V.M.; Salaheldeen, M.; Pfitzer, G.; Hidalgo, A.; Vega, V.; González, S.; Teixeira, J.M.; Fernández, A.; Hernando, B. Template Assisted Deposition of Ferromagnetic Nanostructures: From Antidot Thin Films to Multisegmented Nanowires. Acta Phys. Pol. A 2017, 131, 822–827. [Google Scholar] [CrossRef]

- Nielsch, K.; Choi, J.; Schwirn, K.; Wehrspohn, R.B.; Gösele, U. Self-ordering Regimes of Porous Alumina: The 10 Porosity Rule. Nano Lett. 2002, 2, 677–680. [Google Scholar] [CrossRef]

- Proenca, M.P.; Sousa, C.T.; Leitao, D.C.; Ventura, J.; Sousa, J.B.; Araujo, J.P. Nanopore formation and growth in phosphoric acid Al anodization. J. Non. Cryst. Solids 2008, 354, 5238–5240. [Google Scholar] [CrossRef]

- Bachmann, J.; Zierold, R.; Chong, Y.T.; Hauert, R.; Sturm, C.; Schmidt-Grund, R.; Rheinländer, B.; Grundmann, M.; Gösele, U.; Nielsch, K. A Practical, Self-Catalytic, Atomic Layer Deposition of Silicon Dioxide. Angew. Chemie. Int. Ed. 2008, 47, 6177–6179. [Google Scholar] [CrossRef] [PubMed]

- Zierold, R.; Wu, Z.; Biskupek, J.; Kaiser, U.; Bachmann, J.; Krill, C.E.; Nielsch, K. Magnetic, Multilayered Nanotubes of Low Aspect Ratios for Liquid Suspensions. Adv. Funct. Mater. 2010, 21, 226–232. [Google Scholar] [CrossRef]

- Vega, V.; Böhnert, T.; Martens, S.; Waleczek, M.; Montero-Moreno, J.M.; Görlitz, D.; Prida, V.M.; Nielsch, K. Tuning the magnetic anisotropy of Co–Ni nanowires: Comparison between single nanowires and nanowire arrays in hard-anodic aluminum oxide membranes. Nanotechnology 2012, 23, 465709. [Google Scholar] [CrossRef] [PubMed]

- Raposo, V.; Zazo, M.; Flores, A.G.; Garcia, J.; Vega, V.; Iñiguez, J.; Prida, V.M. Ferromagnetic resonance in low interacting permalloy nanowire arrays. J. Appl. Phys. 2016, 119, 143903. [Google Scholar] [CrossRef]

- Vansteenkiste, A.; Leliaert, J.; Dvornik, M.; Helsen, M.; Garcia-Sanchez, F.; Van Waeyenberge, B. The design and verification of MuMax3. AIP Adv. 2014, 4, 107133. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Song, Q.; Yang, S.-H.; Su, T.; Yuan, W.; Parkin, S.S.P.; Shi, J.; Han, W. Experimental Investigation of Temperature-Dependent Gilbert Damping in Permalloy Thin Films. Sci. Rep. 2016, 6, 22890. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Salem, M.S.; Sergelius, P.; Corona, R.M.; Escrig, J.; Gorlitz, D.; Nielsch, K. Magnetic properties of cylindrical diameter modulated Ni80Fe20 nanowires: Interaction and coercive fields. Nanoscale 2013, 5, 3941–3947. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, L.A.; Deen, L.; Córdoba, R.; Magén, C.; Snoeck, E.; Koopmans, B.; De Teresa, J.M. Influence of the shape and surface oxidation in the magnetization reversal of thin iron nanowires grown by focused electron beam induced deposition. Beilstein J. Nanotechnol. 2015, 6, 1319–1331. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wieser, R.; Nowak, U.; Usadel, K.D. Domain wall mobility in nanowires: Transverse versus vortex walls. Phys. Rev. B 2003, 69, 064401. [Google Scholar] [CrossRef]

- Bran, C.; Fernandez-Roldan, J.A.; Palmero, E.M.; Berganza, E.; Guzman, J.; del Real, R.P.; Asenjo, A.; Rodriguez, A.F.; Foerster, M.; Aballe, L.; et al. Direct Observation of Transverse and Vortex Metastable Magnetic Domains observed in Cylindrical Nanowires. Phys. Rev. B 2017, 96, 125415. [Google Scholar] [CrossRef]

- Fernandez-Roldan, J.; Perez del Real, R.; Bran, C.; Vazquez, M.; Chubykalo-Fesenko, O. Magnetization pinning in modulated nanowires: From topological protection to the “corkscrew” mechanism. Nanoscale 2018, 10, 5923–5927. [Google Scholar] [CrossRef] [PubMed]

- Sergelius, P.; Fernandez, J.G.; Martens, S.; Zocher, M.; Böhnert, T.; Martinez, V.V.; de la Prida, V.M.; Görlitz, D.; Nielsch, K. Statistical magnetometry on isolated NiCo nanowires and nanowire arrays: A comparative study. J. Phys. D Appl. Phys. 2016, 49, 145005. [Google Scholar] [CrossRef]

- Encinas-Oropesa, A.; Demand, M.; Piraux, L.; Huynen, I.; Ebels, U. Dipolar interactions in arrays of nickel nanowires studied by ferromagnetic resonance. Phys. Rev. B 2001, 63, 104415. [Google Scholar] [CrossRef]

- Vega, V.; Prida, V.M.; García, J.A.; Vazquez, M. Torque magnetometry analysis of magnetic anisotropy distribution in Ni nanowire arrays. Phys. Status Solidi 2010, 208, 553–558. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Méndez, M.; Vega, V.; González, S.; Caballero-Flores, R.; García, J.; Prida, V.M. Effect of Sharp Diameter Geometrical Modulation on the Magnetization Reversal of Bi-Segmented FeNi Nanowires. Nanomaterials 2018, 8, 595. https://doi.org/10.3390/nano8080595

Méndez M, Vega V, González S, Caballero-Flores R, García J, Prida VM. Effect of Sharp Diameter Geometrical Modulation on the Magnetization Reversal of Bi-Segmented FeNi Nanowires. Nanomaterials. 2018; 8(8):595. https://doi.org/10.3390/nano8080595

Chicago/Turabian StyleMéndez, Miguel, Víctor Vega, Silvia González, Rafael Caballero-Flores, Javier García, and Víctor M. Prida. 2018. "Effect of Sharp Diameter Geometrical Modulation on the Magnetization Reversal of Bi-Segmented FeNi Nanowires" Nanomaterials 8, no. 8: 595. https://doi.org/10.3390/nano8080595