Photonic Structures for Light Trapping in Thin Film Silicon Solar Cells: Design and Experiment

Abstract

:1. Introduction

2. 1D-PC Back Reflectors and Applications

2.1. High-Reflective 1D-PC Back Reflectors

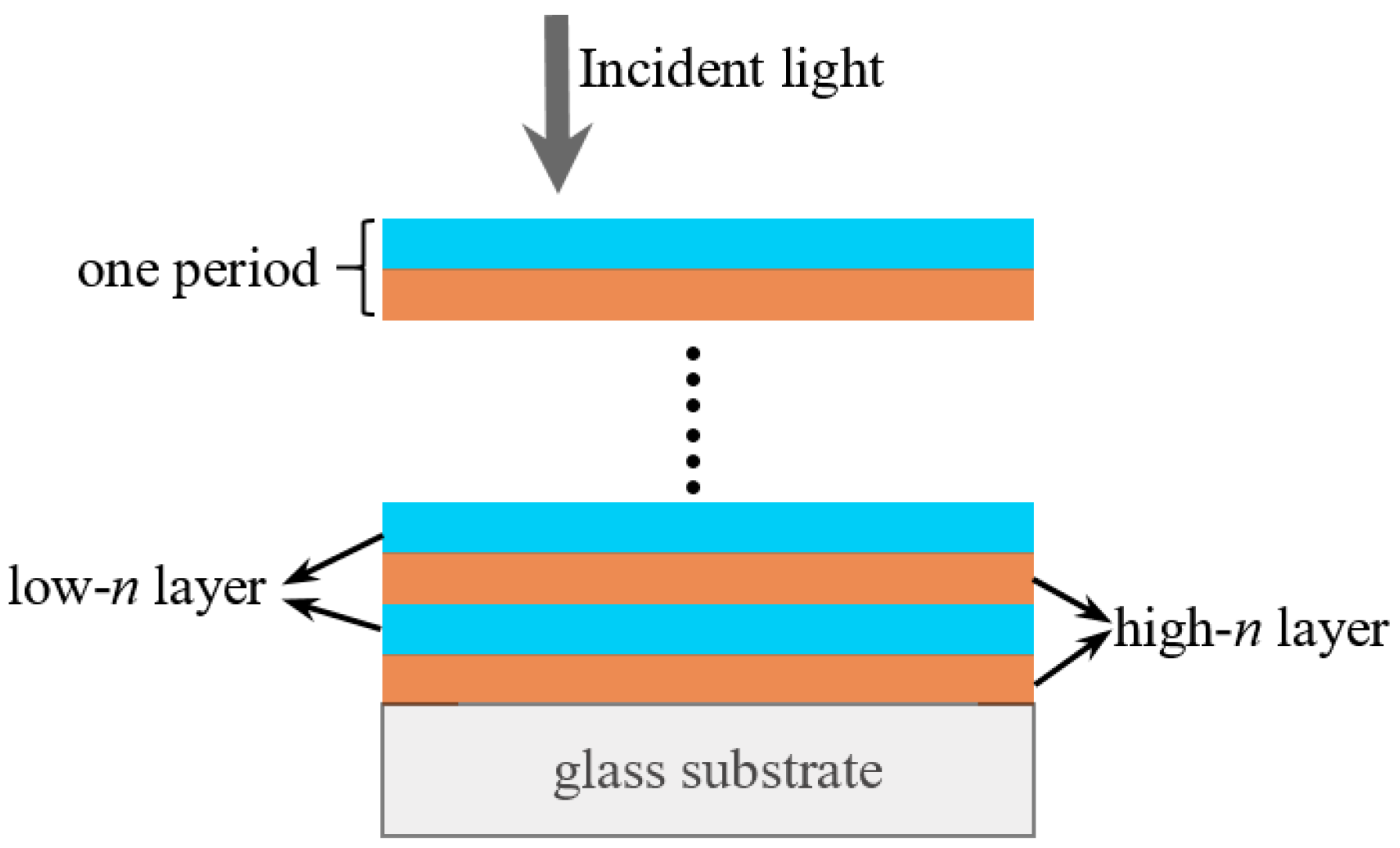

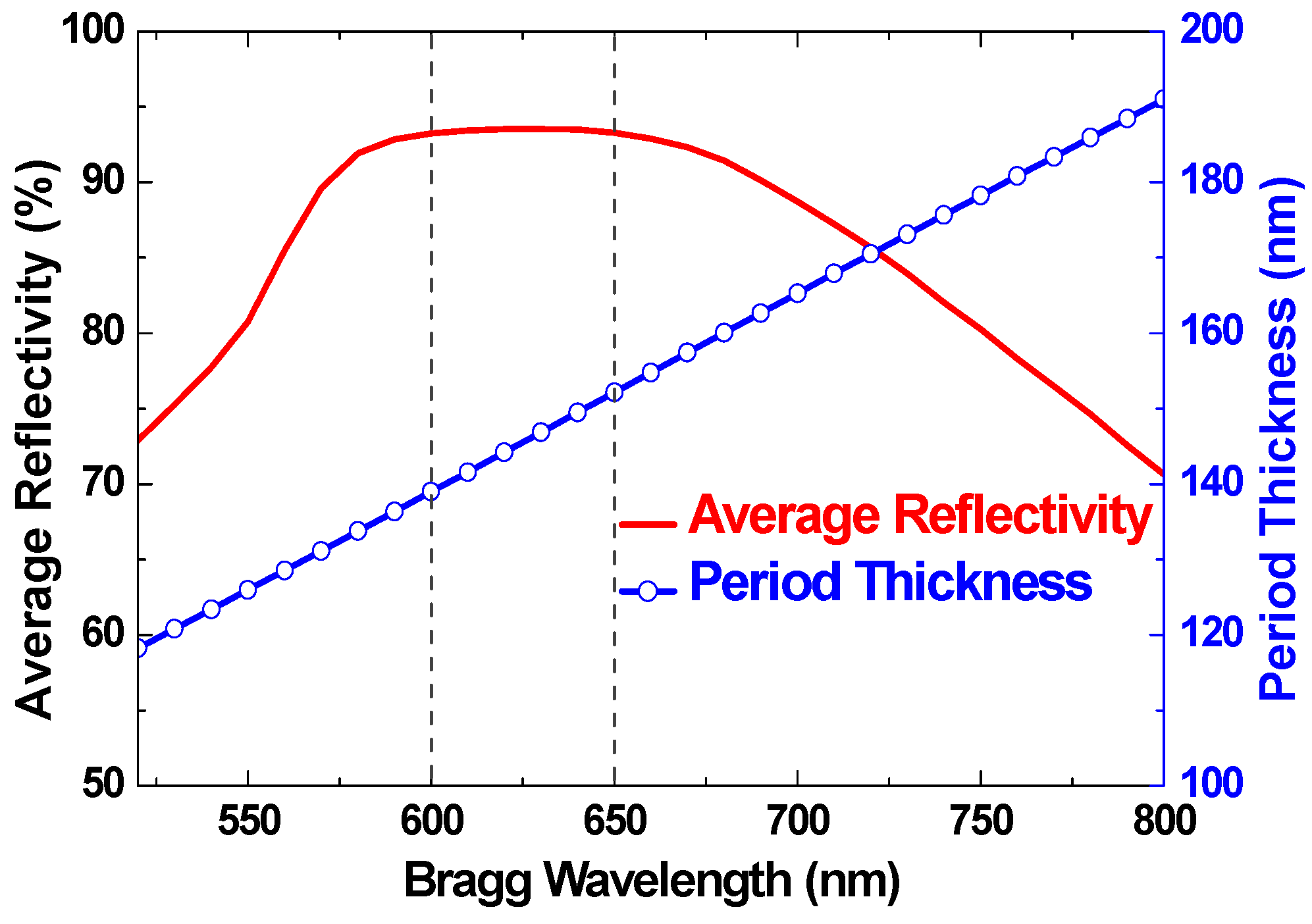

2.1.1. 1D-PC Configuration

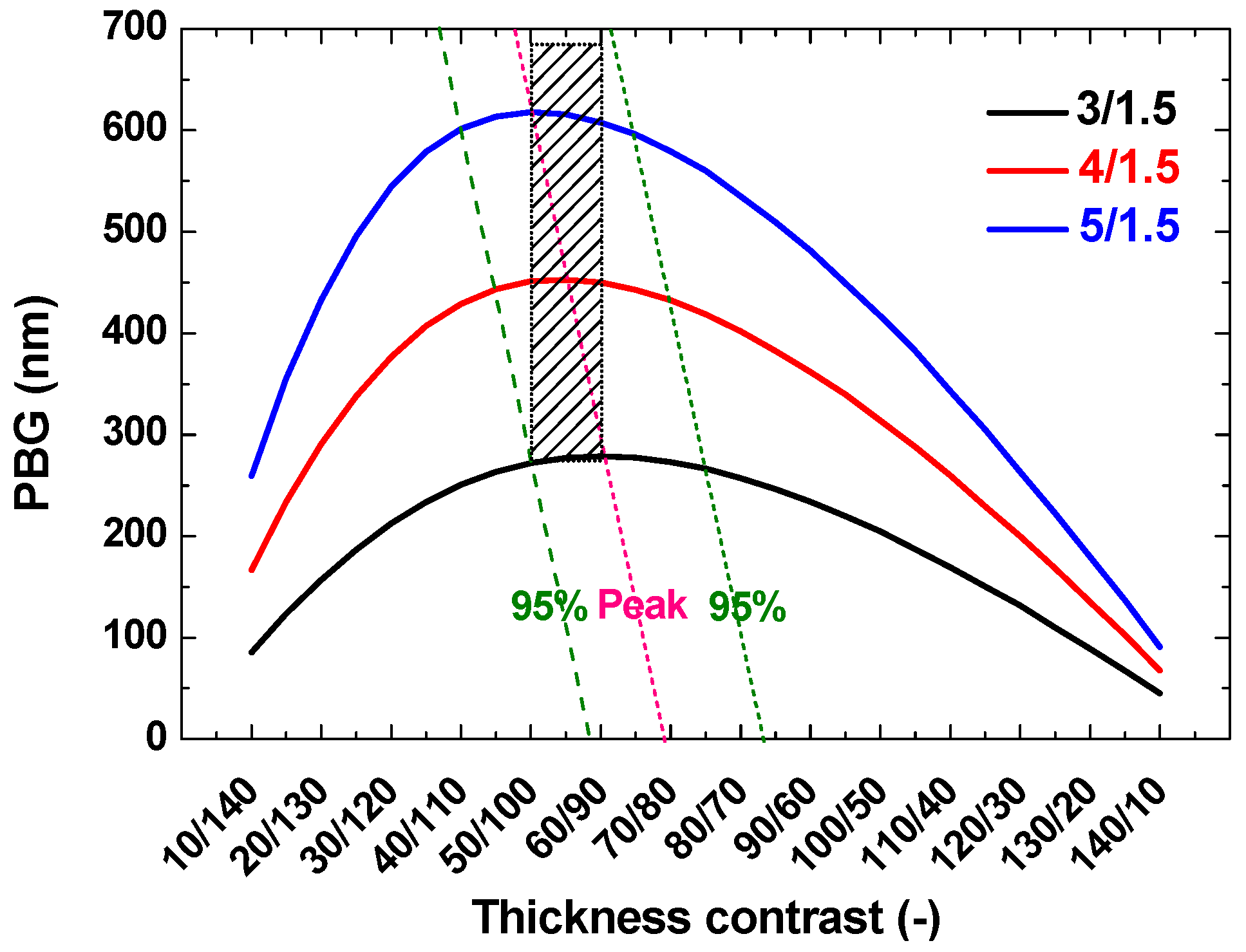

2.1.2. Influence of Layer Thickness-Contrast on the PBG

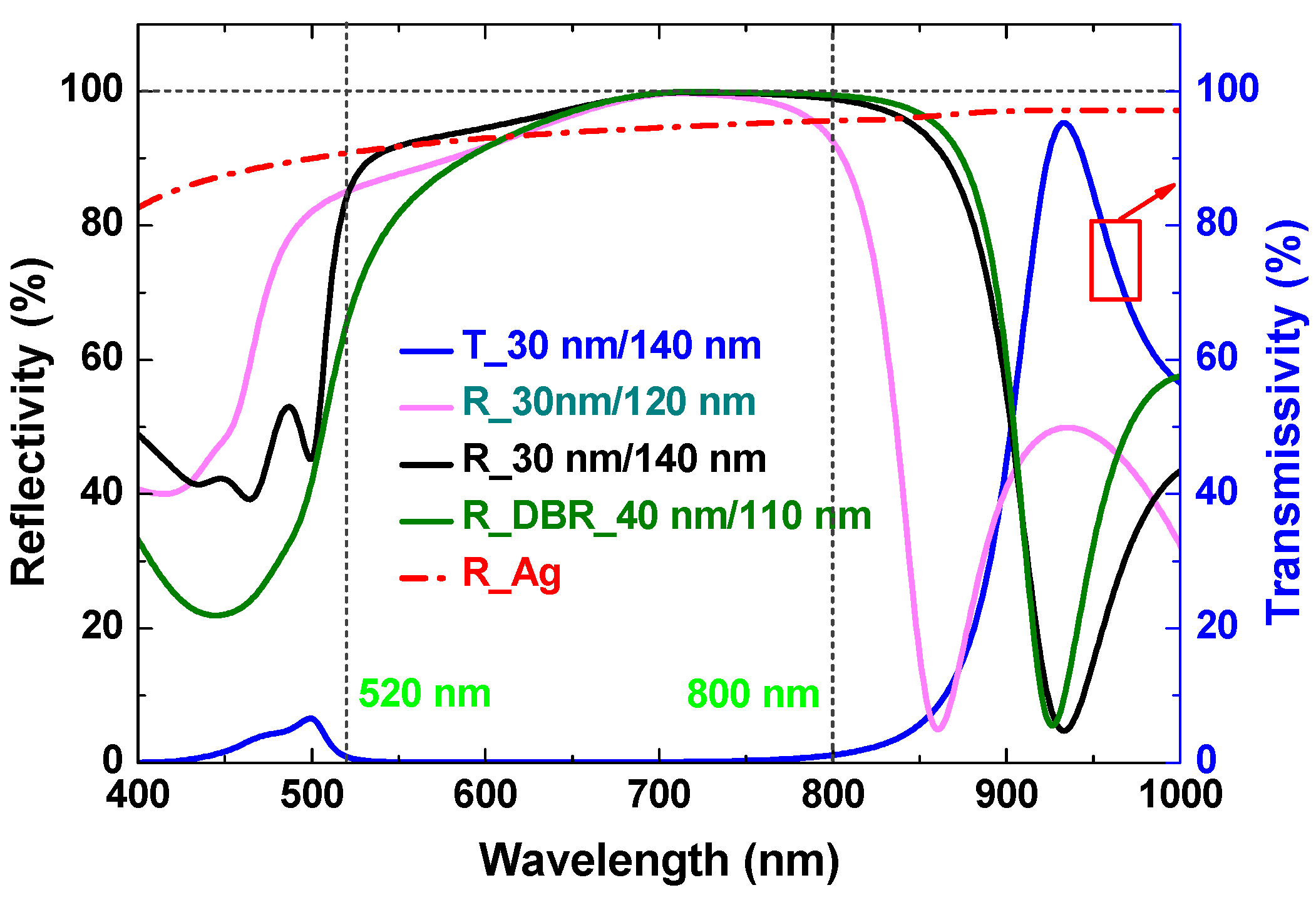

2.1.3. Reflection Comparison between DBR and Optimal 1D-PC

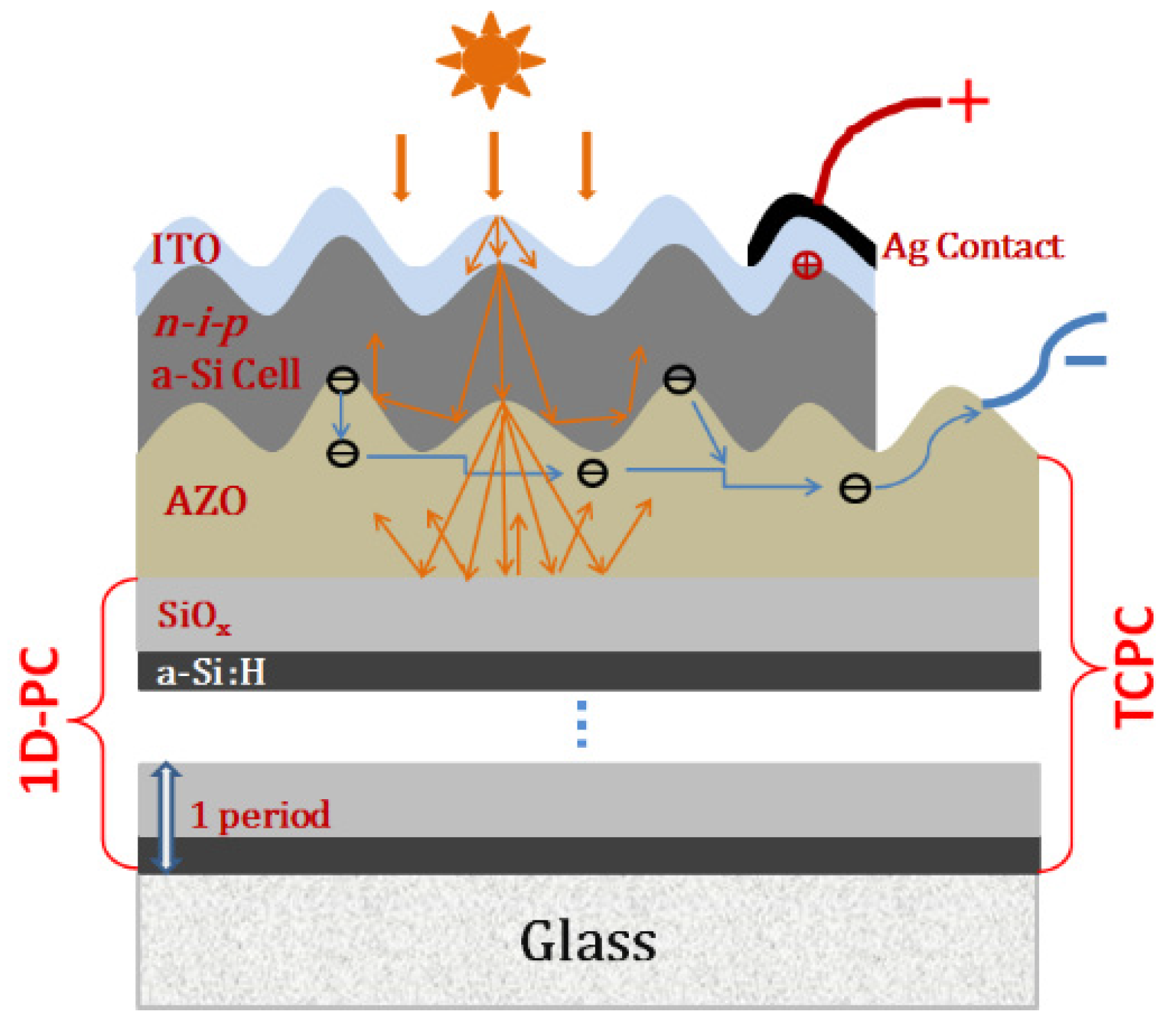

2.2. TCPC BRs Formed by 1D-PC and Textured ZnO

2.2.1. Design and Fabrication

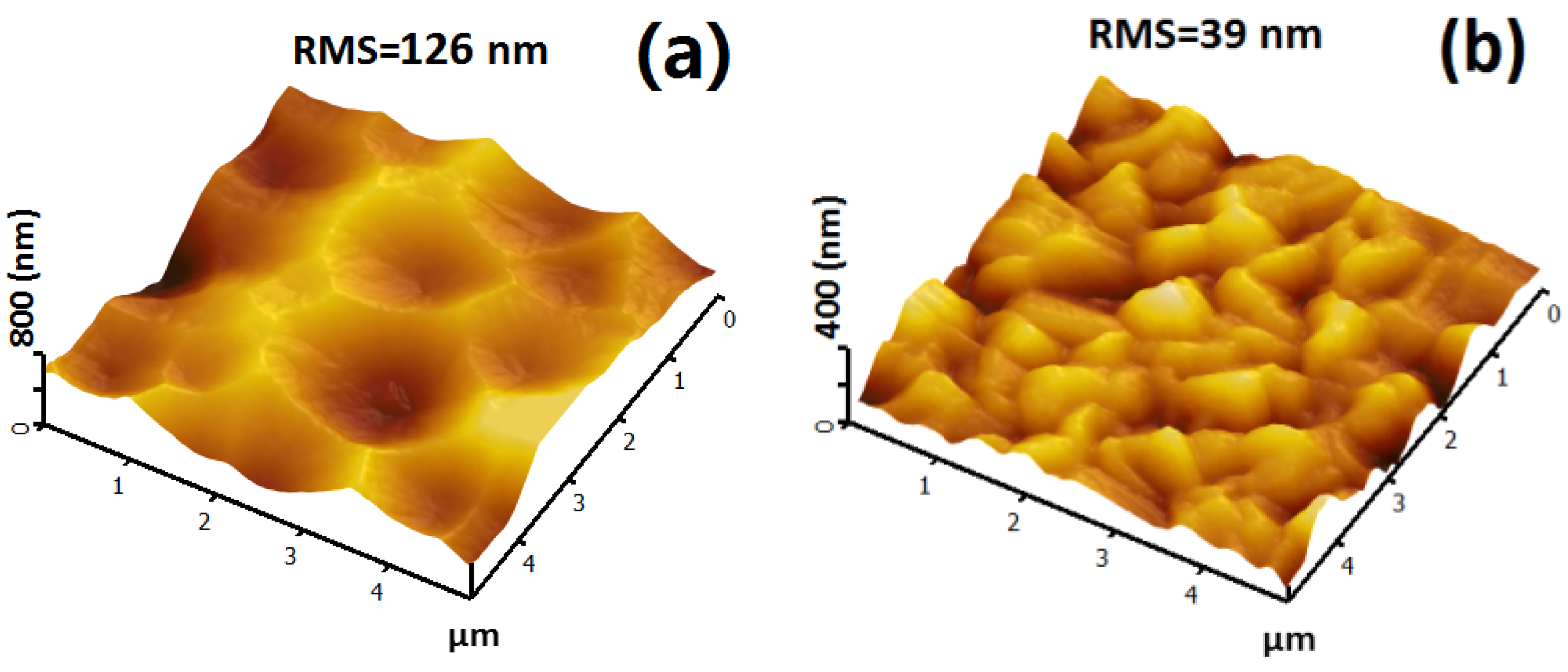

2.2.2. Structural Properties

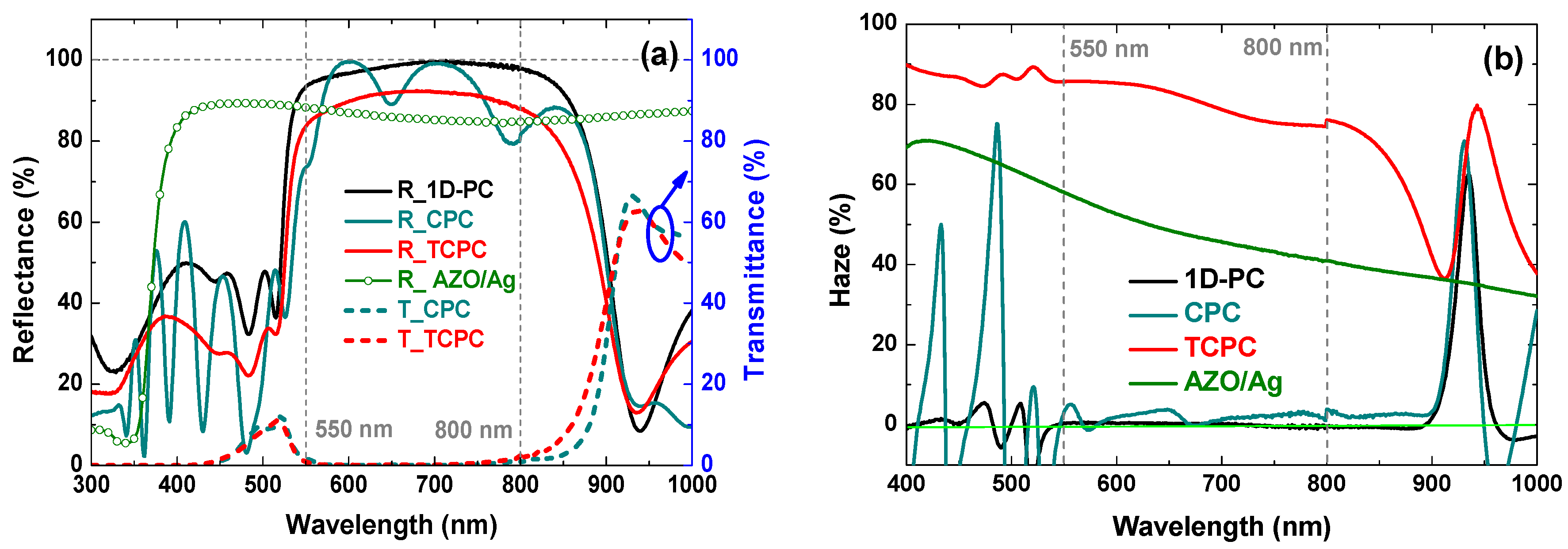

2.2.3. Optical Properties

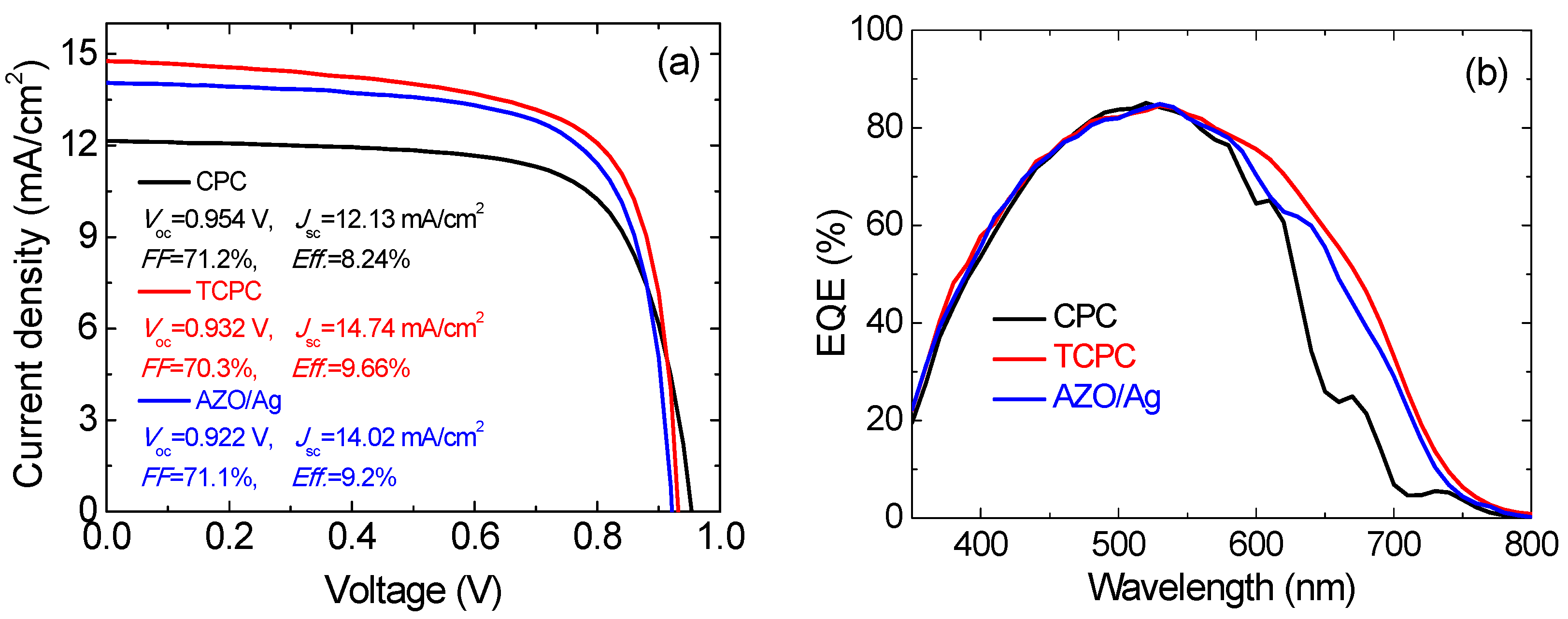

2.2.4. TCPC BRs for a-Si:H Solar Cells

2.3. RTPC BRs Formed by Textured ZnO and Textured 1D-PC

2.3.1. Design, Fabrication and Simulation

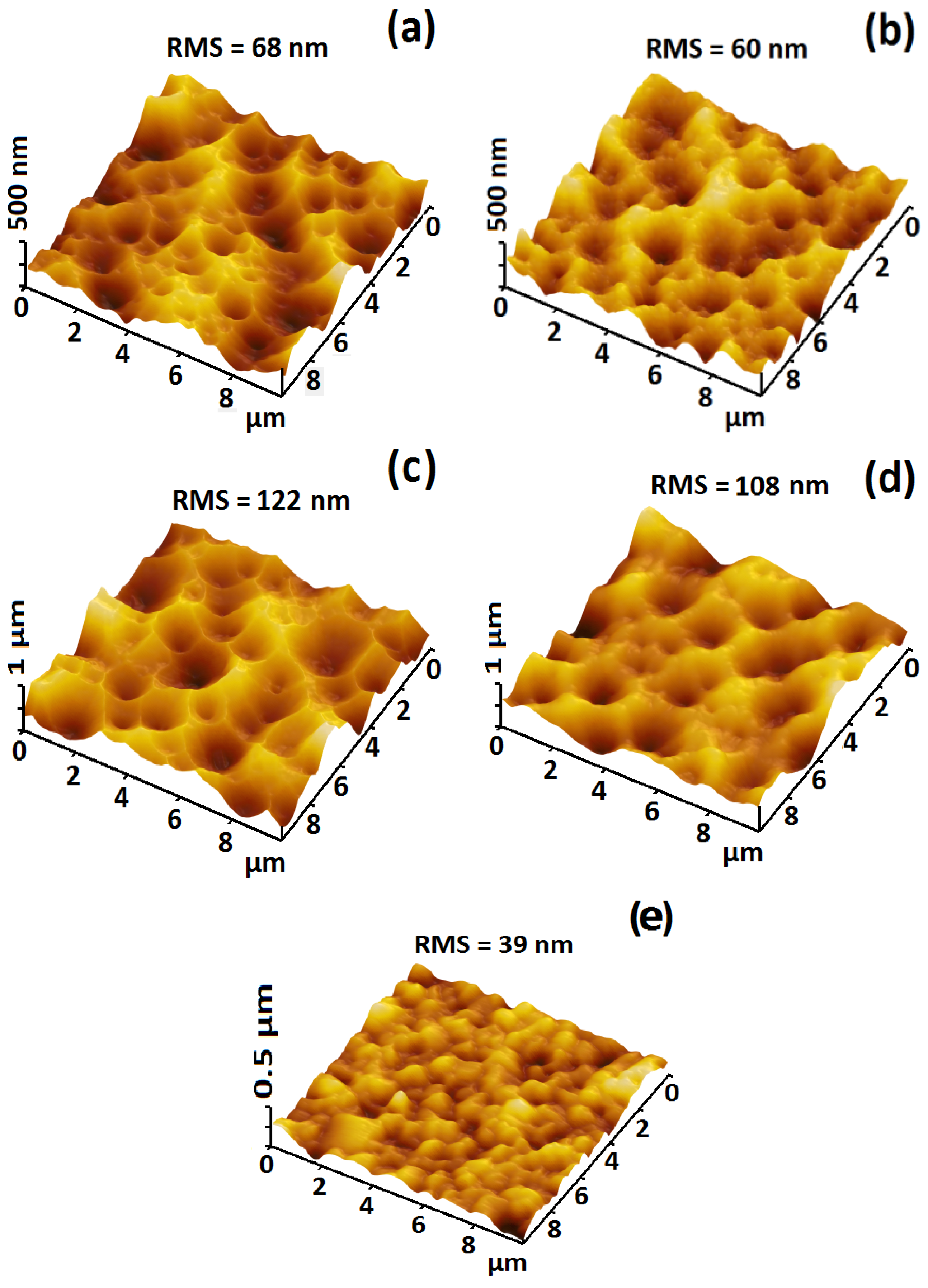

2.3.2. Surface Morphology

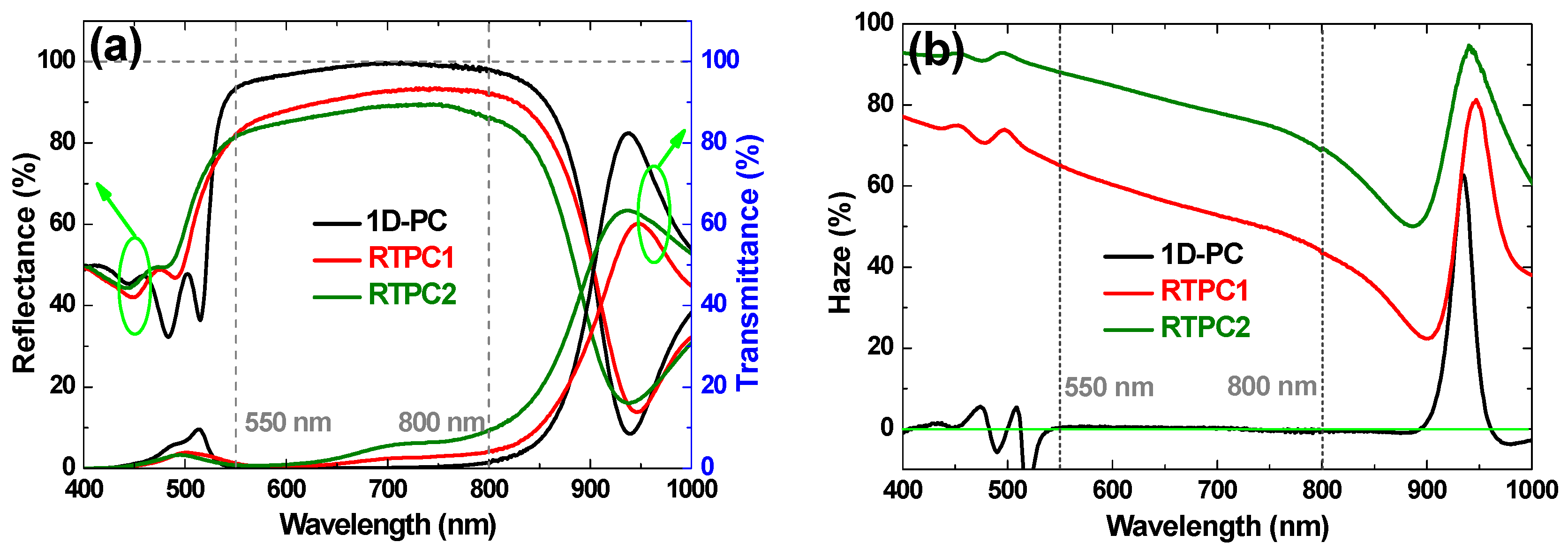

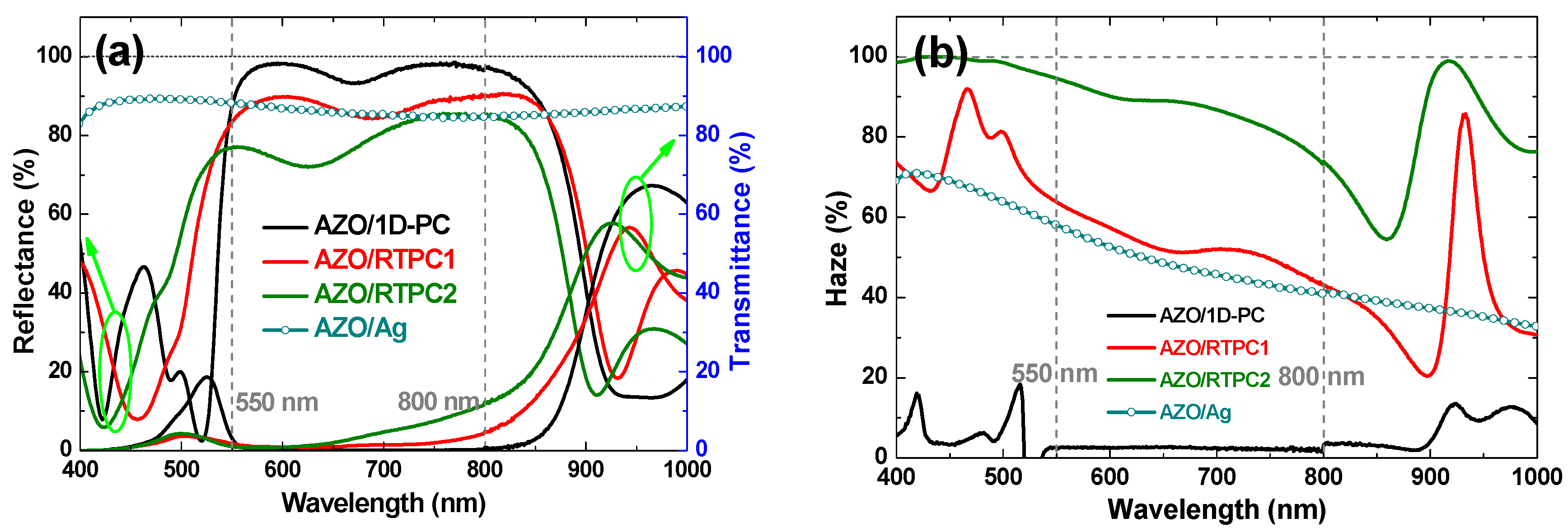

2.3.3. Optical Properties

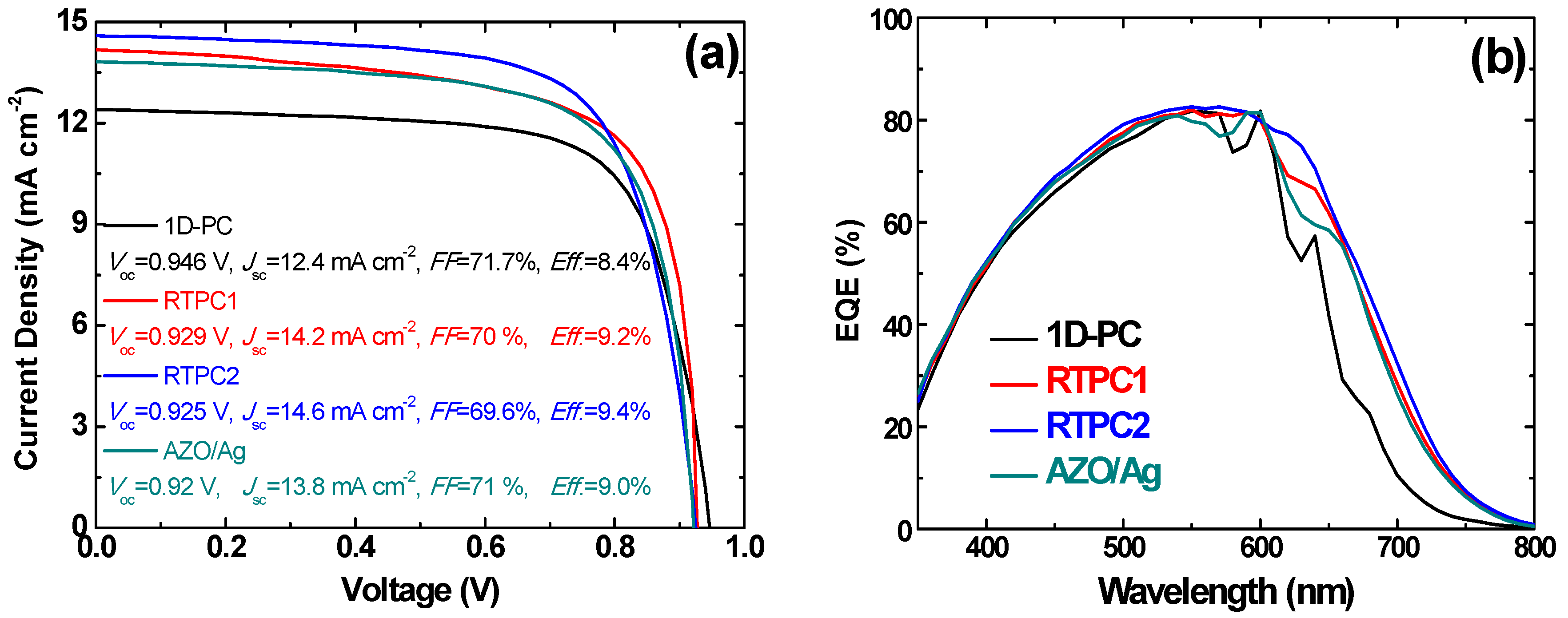

2.3.4. RTPC BRs for a-Si:H Solar Cells

3. 2D-PC Back Reflectors and Applications

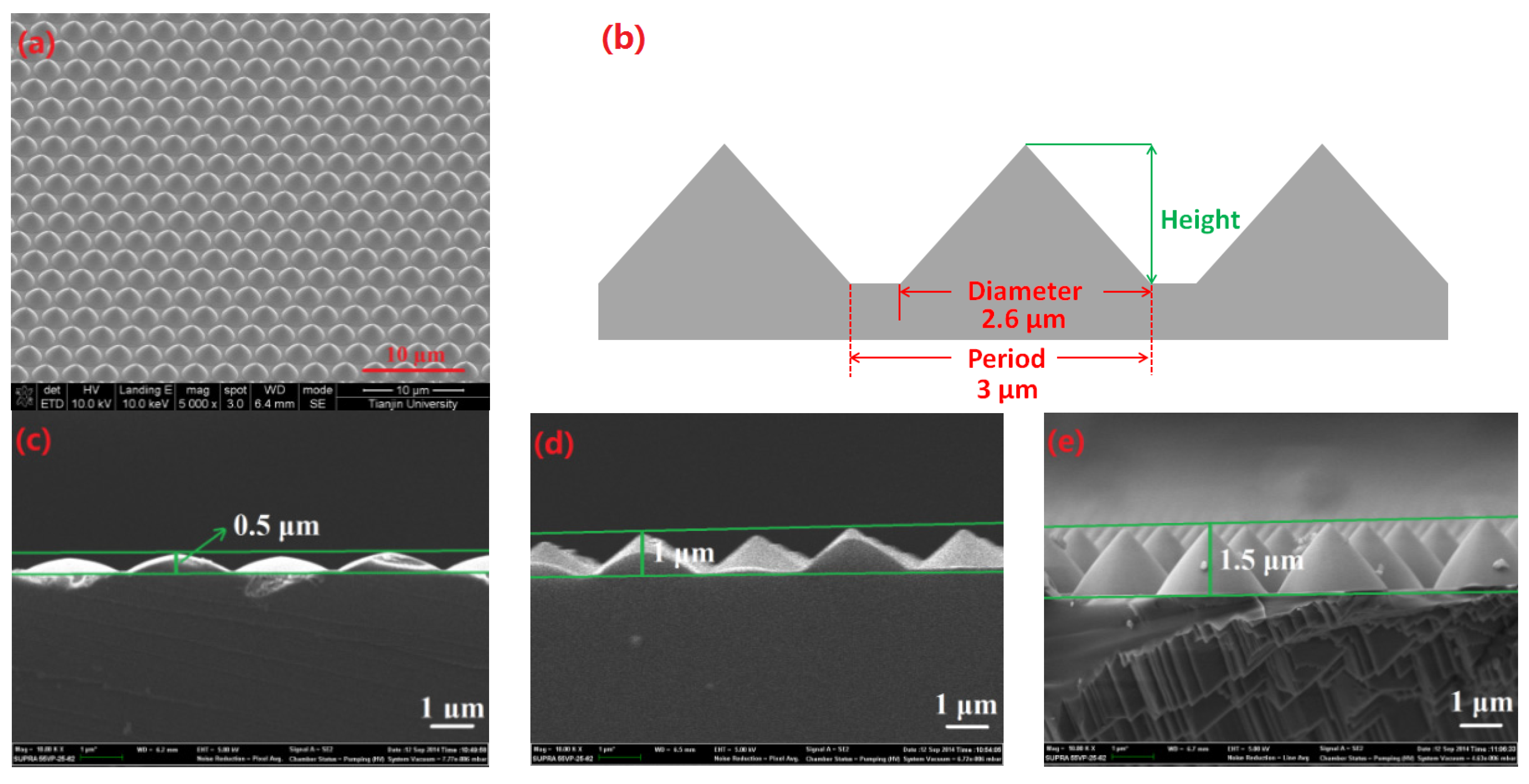

3.1. Periodically Patterned Micro-Cone Texture BRs

3.1.1. Preparation of MCPS BRs and Solar Cells

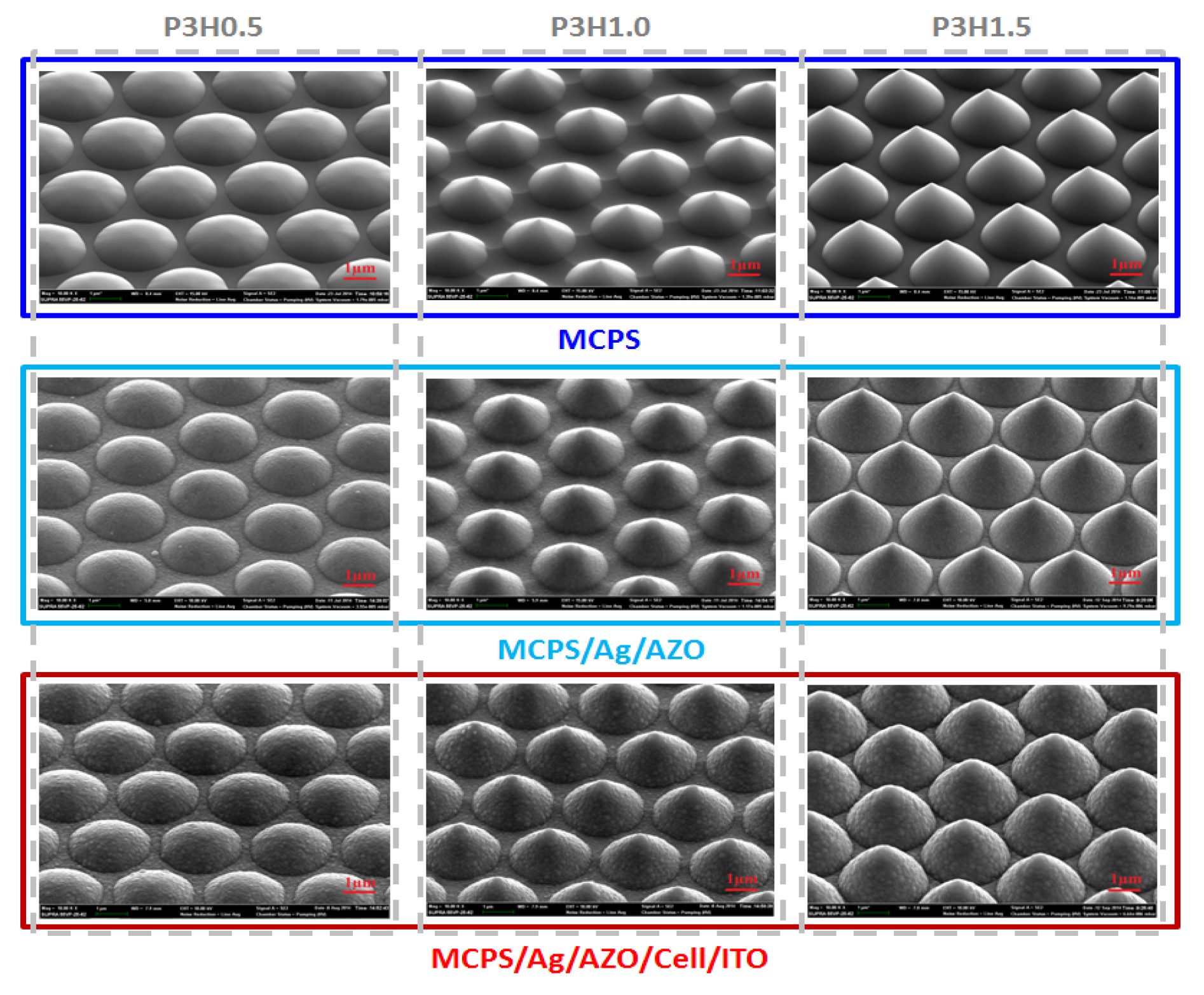

3.1.2. Structural Properties

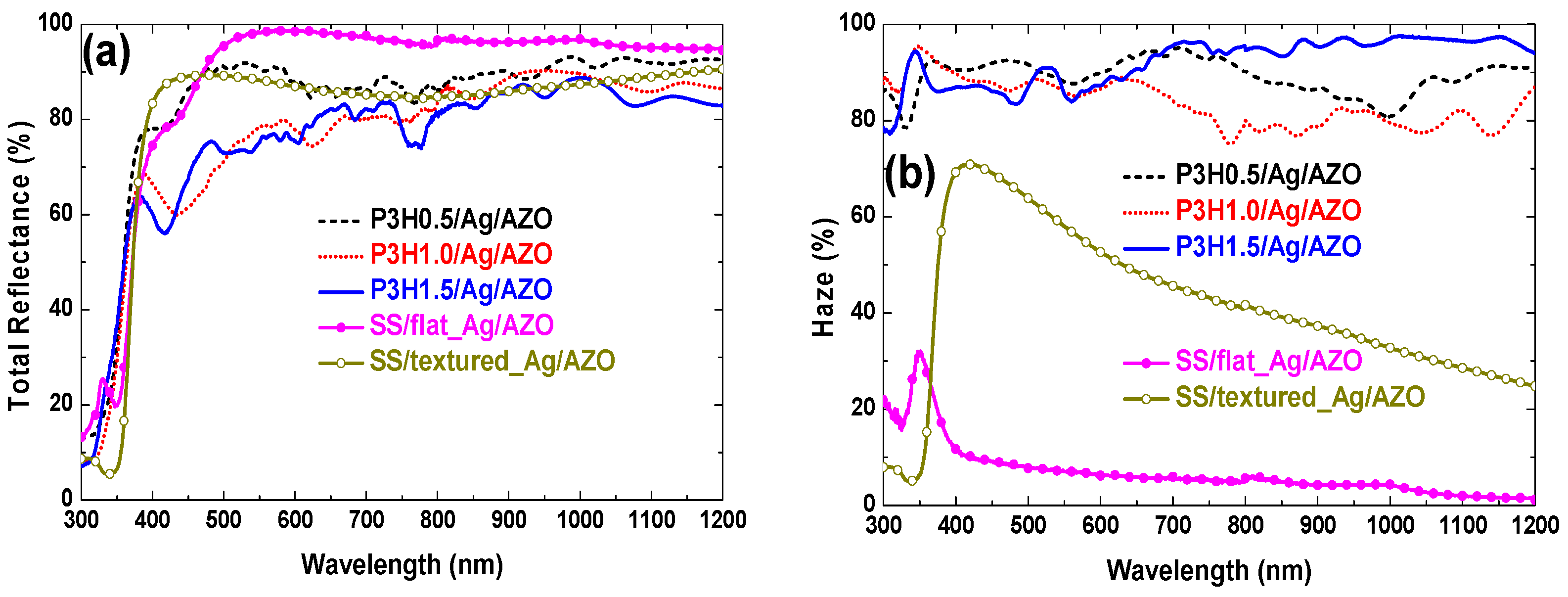

3.1.3. Optical Properties

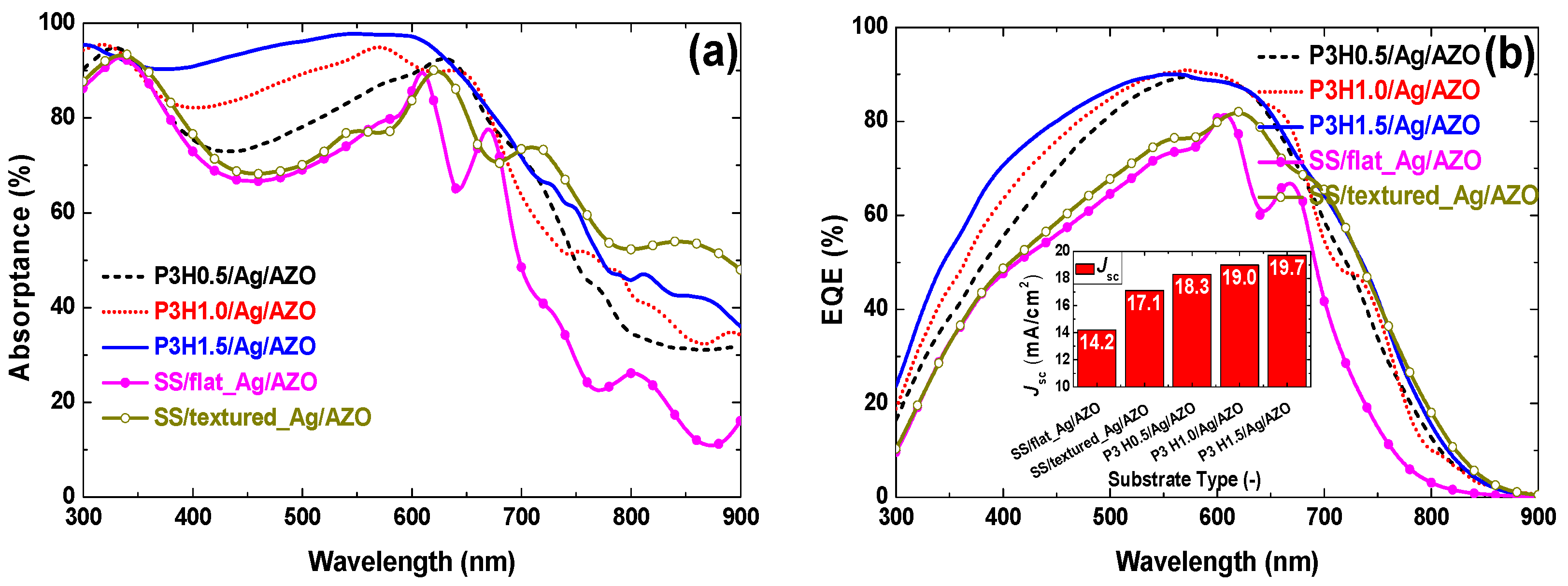

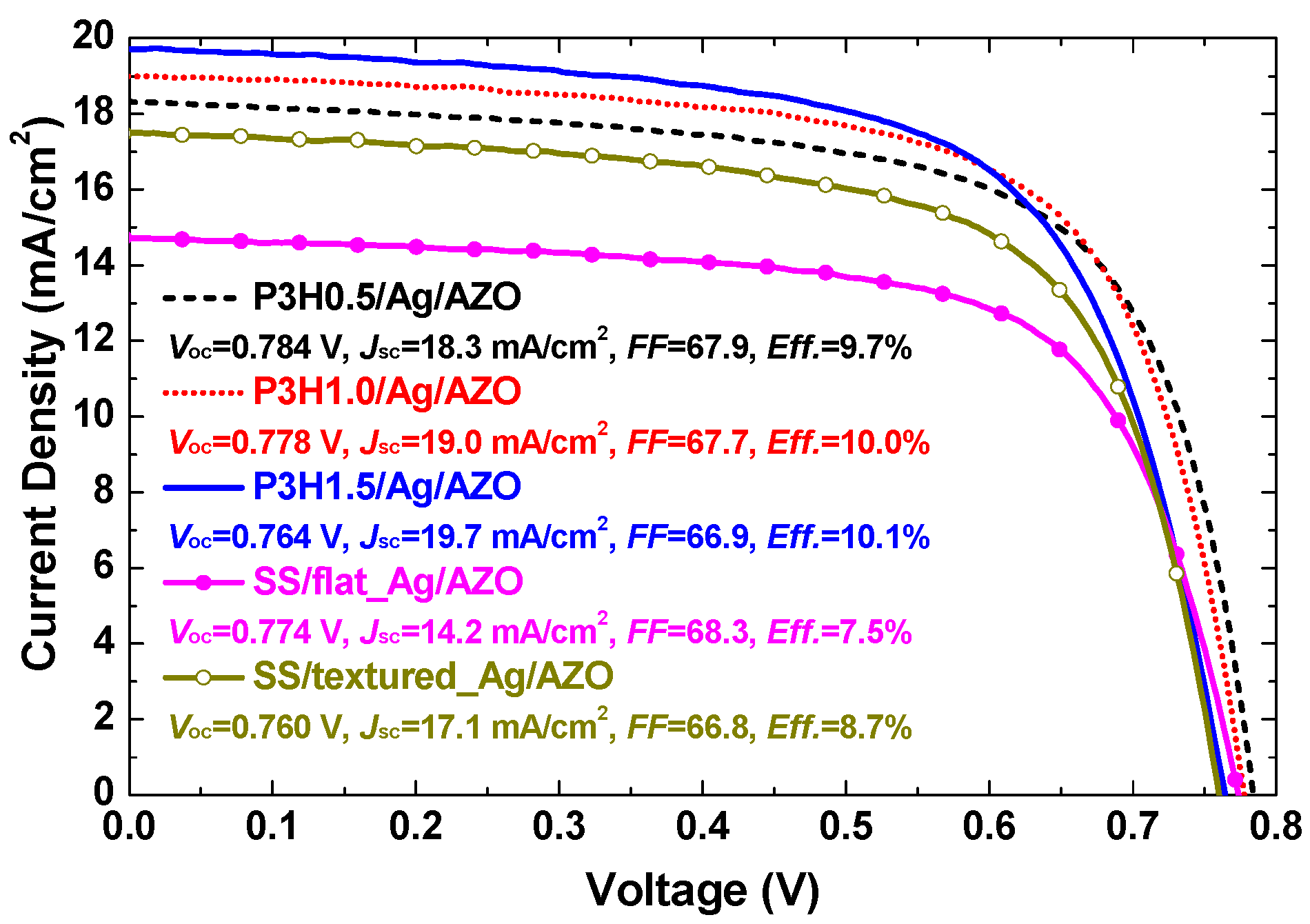

3.1.4. MCPS BRs for a-SiGe:H Solar Cells

3.2. Quasi-Crystal Structures Formed by 2D-PC and Textured Ag/ZnO

3.2.1. Experiments

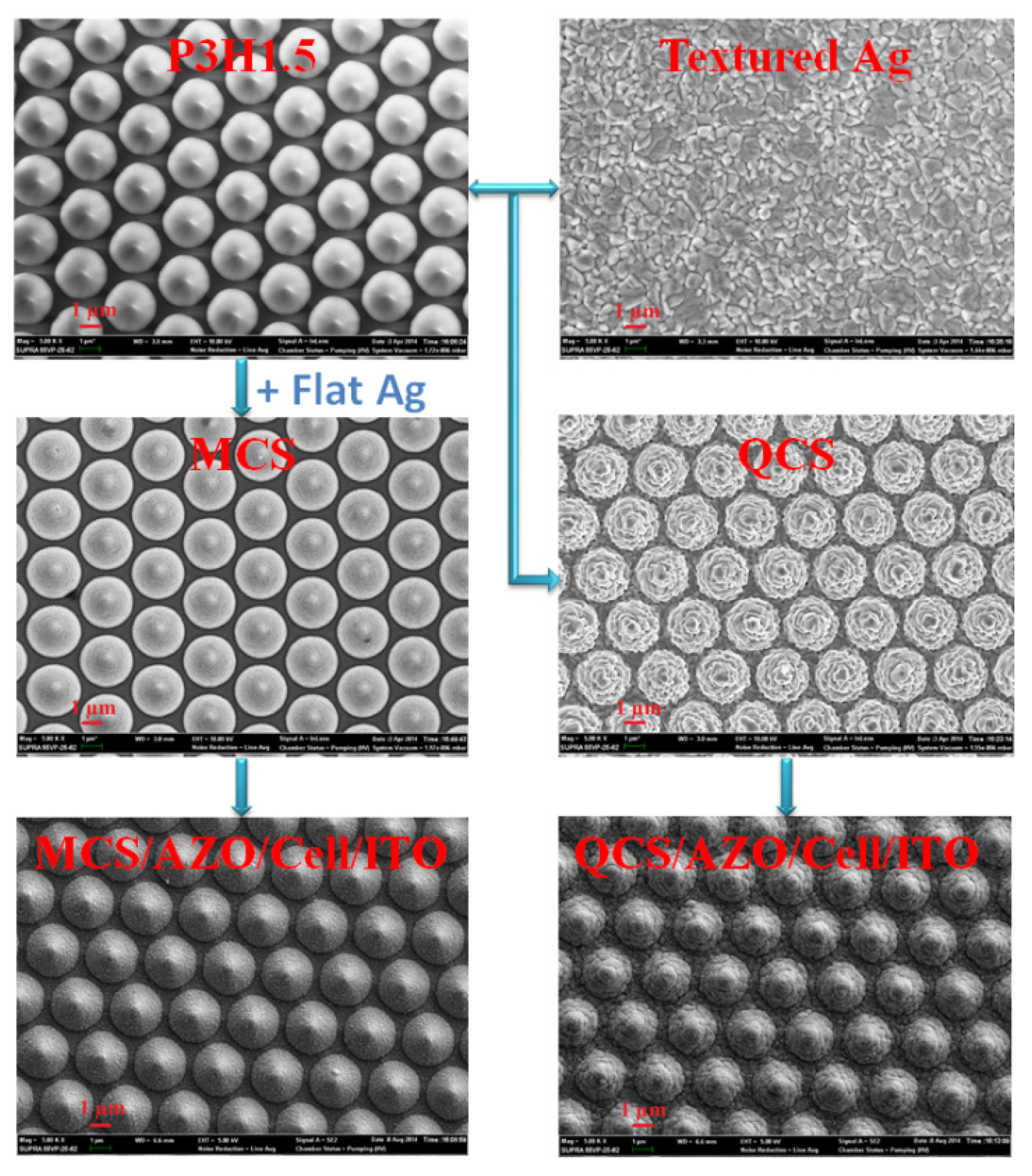

3.2.2. Surface Morphology

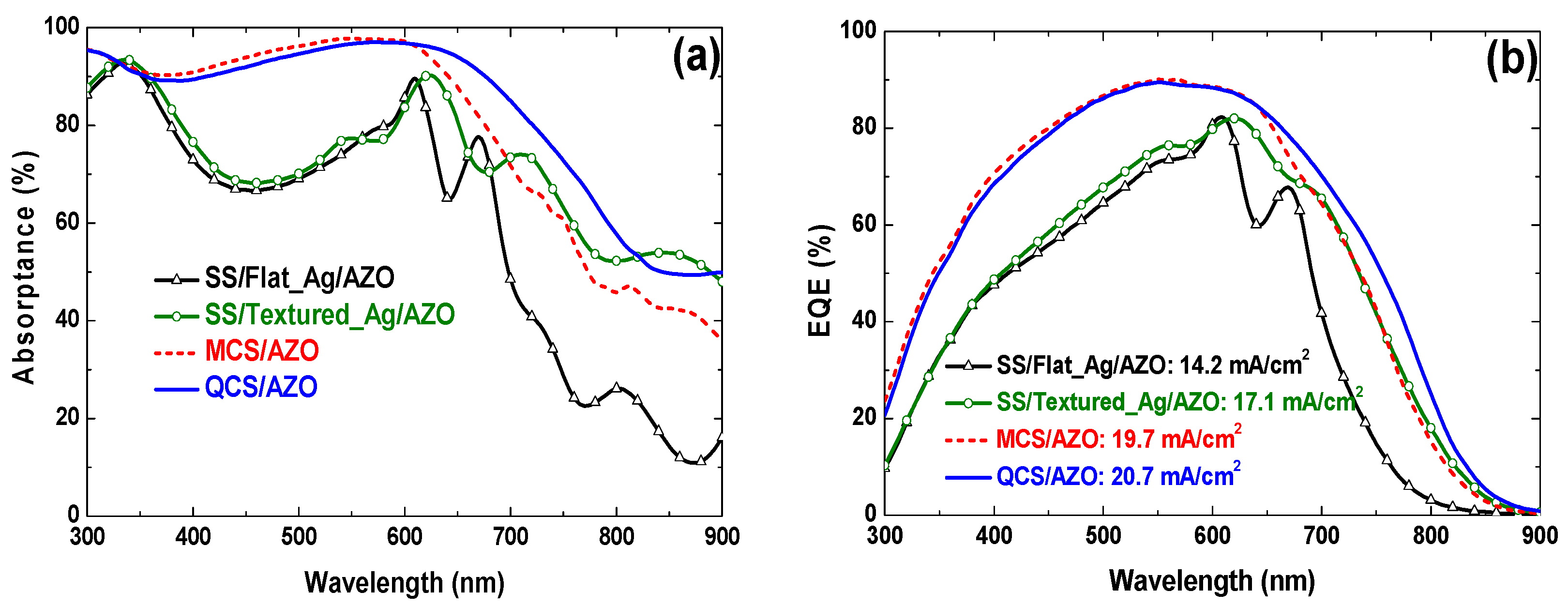

3.2.3. Optical Properties

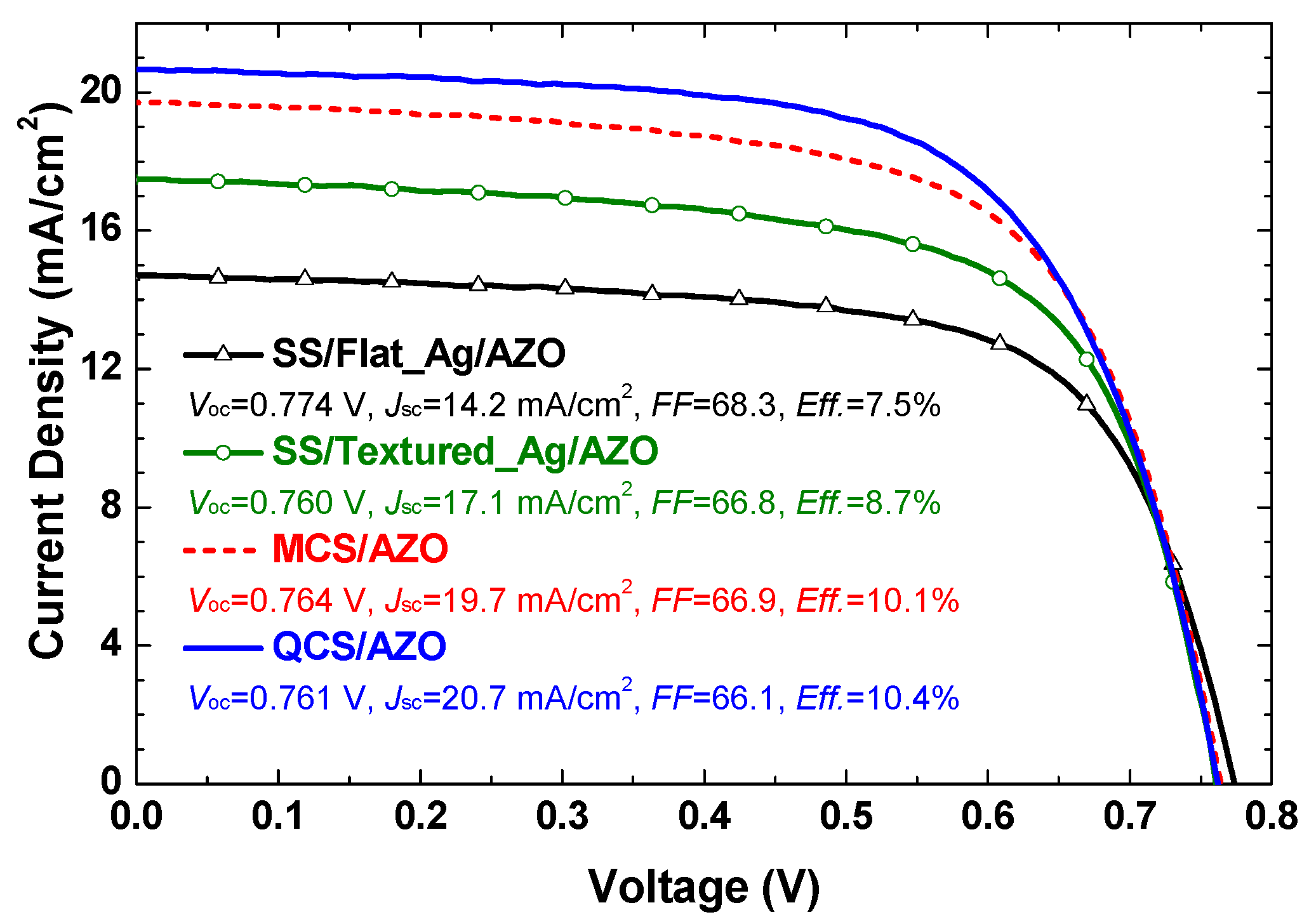

3.2.4. QCS BRs for a-Sige:H Solar Cells

4. Conclusions

- TCPC BRs formed by combining flat 1D-PC and textured AZO can provide significant light scattering while maintaining high reflectivity. The TCPC BR-based solar cell showed an improved Jsc without deterioration of Voc and FF, resulting in much better device performance.

- RTPC BRs formed by combining textured 1D-PC and flat AZO also are excellent candidates to provide both high reflectivity and strong light scattering. An increased photocurrent density and total efficiency of a-Si:H solar cells are expectable.

- For MCPS BRs-based solar cells, absorption enhancement in the short wavelength range can contribute to the improved light coupling, while in the long wavelength range, it is realized by the co-effect of light coupling and light-trapping.

- For QCS BRs, the random nanotextures are largely flattened, while the micro-cone shapes are well preserved, resulting in a full-spectrum light coupling enhancement. Light-trapping performance is significantly improved due to the rich guided mode resonances.

Acknowledgments

Conflicts of Interest

References

- Green, M.A. The passivated emitter and rear cell (PERC): From conception to mass production. Sol. Energy Mater. Sol. Cells 2015, 143, 190–197. [Google Scholar] [CrossRef]

- Yoshikawa, K.; Kawasaki, H.; Yoshida, W.; Irie, T.; Konishi, K.; Nakano, K.; Uto, T.; Adachi, D.; Kanematsu, M.; Uzu, H.; et al. Silicon heterojunction solar cell with interdigitated back contacts for photoconversion over 26%. Nat. Energy 2017, 2, 17032. [Google Scholar] [CrossRef]

- Schubert, M.B.; Werner, J.H. Flexible solar cells for clothing. Mater. Today 2006, 9, 42–50. [Google Scholar] [CrossRef]

- Yang, J.; Banerjee, A.; Guha, S. Amorphous silicon based photovoltaics-from earth to the “final frontier”. Sol. Energy Mater. Sol. Cells 2003, 78, 597–612. [Google Scholar] [CrossRef]

- Guha, S.; Yang, J.; Yan, B. High efficiency multi-junction thin film silicon cells incorporating nanocrystalline silicon. Sol. Energy Mater. Sol. Cells 2013, 119, 1–11. [Google Scholar] [CrossRef]

- Yoon, J.-H.; Song, J.; Lee, S.-J. Practical application of building integrated photovoltaic (BIPV) system using transparent amorphous silicon thin-film PV module. Sol. Energy 2011, 85, 723–733. [Google Scholar] [CrossRef]

- Lim, J.W.; Kim, G.; Shin, M.; Yun, S.J. Colored a-Si:H transparent solar cells employing ultrathin transparent multi-layered electrodes. Sol. Energy Mater. Sol. Cells 2017, 163, 164–169. [Google Scholar] [CrossRef]

- Kuang, P.; Eyderman, S.; Hsieh, M.L.; Post, A.; John, S.; Lin, S.Y. Achieving an accurate surface profile of a photonic crystal for near-unity solar absorption in a super thin-film architecture. ACS Nano 2016, 10, 6116–6124. [Google Scholar] [CrossRef] [PubMed]

- Sai, H.; Jia, H.; Kondo, M. Impact of front and rear texture of thin-film microcrystalline silicon solar cells on their light trapping properties. J. Appl. Phys. 2010, 108, 044505. [Google Scholar]

- Lin, Y.Y.; Xu, Z.; Yu, D.L.; Lu, L.F.; Yin, M.; Tavakoli, M.M.; Chen, X.Y.; Hao, Y.Y.; Fan, Z.Y.; Cui, Y.X.; et al. Dual-layer nanostructured flexible thin-film amorphous silicon solar cells with enhanced light harvesting and photoelectric conversion efficiency. ACS Apl. Mater. Interfaces 2016, 8, 10929–10936. [Google Scholar] [CrossRef] [PubMed]

- Sai, H.; Saito, K.; Kondo, M. Investigation of textured back reflectors with periodic honeycomb patterns in thin-film silicon solar cells for improved photovoltaic performance. IEEE J. Photovolt. 2013, 3, 5–10. [Google Scholar] [CrossRef]

- Paetzold, U.W.; Lehnen, S.; Bittkau, K.; Rau, U.; Carius, R. Nanoscale observation of waveguide modes enhancing the efficiency of solar cells. Nano Lett. 2014, 14, 6599–6605. [Google Scholar] [CrossRef] [PubMed]

- Tan, H.; Moulin, E.; Si, F.T.; Schuttauf, J.W.; Stuckelberger, M.; Isabella, O.; Haug, F.J.; Ballif, C.; Zeman, M.; Smets, A.H.M. Highly transparent modulated surface textured front electrodes for high-efficiency multijunction thin-film silicon solar cells. Prog. Photovolt. 2015, 23, 949–963. [Google Scholar] [CrossRef]

- Soderstrom, T.; Haug, F.J.; Niquille, X.; Ballif, C. TCOs for nip thin film silicon solar cells. Prog. Photovolt. 2009, 17, 165–176. [Google Scholar] [CrossRef]

- Yan, B.; Yue, G.; Sivec, L.; Owens-Mawson, J.; Yang, J.; Guha, S. Correlation of texture of Ag/ZnO back reflector and photocurrent in hydrogenated nanocrystalline silicon solar cells. Sol. Energ. Mat. Sol. Cells 2012, 104, 13–17. [Google Scholar] [CrossRef]

- Isabella, O.; Krc, J.; Zeman, M. Modulated surface textures for enhanced lighttrapping in thin-film silicon solar cells. Appl. Phys. Lett. 2010, 97, 101106. [Google Scholar] [CrossRef]

- Tan, H.; Santbergen, R.; Smets, H.M.; Zeman, M. Plasmonic light trapping in thin-film silicon solar cells with improved self-assembled silver nanoparticles. Nano Lett. 2012, 12, 4070–4076. [Google Scholar] [CrossRef] [PubMed]

- Van Dijk, L.; van de Groep, J.; Veldhuizen, L.W.; di Vece, M.; Polman, A.; Schropp, R.E.I. Plasmonic scattering back reflector for light trapping in flat nano-crystalline silicon solar cells. ACS Photonics 2016, 3, 685–691. [Google Scholar] [CrossRef]

- Sai, H.; Matsui, T.; Koida, T.; Matsubara, K.; Kondo, M.; Sugiyama, S.; Katayama, H.; Takeuchi, Y.; Yoshida, I. Triple-junction thin-film silicon solar cell fabricated on periodically textured substrate with a stabilized efficiency of 13.6%. Appl. Phys. Lett. 2015, 106, 213902. [Google Scholar]

- Polman, A.; Atwater, H.A. Photonic design principles for ultrahigh-efficiency photovoltaics. Nat. Mater. 2012, 11, 174–177. [Google Scholar] [CrossRef] [PubMed]

- Bermel, P.; Luo, C.; Zeng, L.; Kimerling, L.C.; Joannopoulos, J.D. Improving thin-film crystalline silicon solar cell efficiencies with photonic crystals. Opt. Express 2007, 15, 16986–17000. [Google Scholar] [CrossRef] [PubMed]

- Zeng, L.; Bermel, P.; Yi, Y.; Alamariu, B.A.; Broderick, K.A.; Liu, J.; Hong, C.; Duan, X.; Joannopoulos, J.; Kimerling, L.C. Demonstration of enhanced absorption in thin film Si solar cells with textured photonic crystal back reflector. Appl. Phys. Lett. 2008, 93, 221105. [Google Scholar] [CrossRef]

- Zeng, L.; Yi, Y.; Hong, C.; Liu, J.; Feng, N.; Duan, X.; Kimerling, L.C.; Alamariu, B.A. Efficiency enhancement in Si solar cells by textured photonic crystal back reflector. Appl. Phys. Lett. 2006, 89, 111111. [Google Scholar] [CrossRef]

- O’Brien, P.G.; Kherani, N.P.; Chutinan, A.; Ozin, G.A.; John, S.; Zukotynski, S. Silicon photovoltaics using conducting photonic crystal back-reflectors. Adv. Mater. 2008, 20, 1577–1582. [Google Scholar] [CrossRef]

- Krc, J.; Zeman, M.; Luxembourg, S.L.; Topic, M. Modulated photonic-crystal structures as broadband back reflectors in thin film solar cells. Appl. Phys. Lett. 2009, 94, 153501. [Google Scholar] [CrossRef]

- Isebella, O.; Dobrovolskiy, S.; Kroon, G.; Zeman, M. Design and application of dielectric distributed Bragg back reflector in thin-film silicon solar cells. J. Non-Cryst. Solids 2012, 358, 2295–2298. [Google Scholar] [CrossRef]

- Chen, P.Z.; Hou, G.F.; Zhang, J.J.; Zhang, X.D.; Zhao, Y. Optimal design of one-dimensional photonic crystal back reflectors for thin-film silicon solar cells. J. Appl. Phys. 2014, 116, 064508. [Google Scholar] [CrossRef]

- Hoffmann, A.; Paetzold, U.W.; Zhang, C.; Merdzhanova, T.; Lambertz, A.; Ulbrich, C.; Bittkau, K.; Rau, U. Advancing tandem solar cells by spectrally selective multilayer intermediate reflectors. Opt. Express 2014, 22, A1270–A1277. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.P.; Hou, G.F.; Fan, Q.H.; Huang, Q.; Zhao, J.; Zhang, J.J.; Ni, J.; Zhang, X.D.; Zhao, Y. An efficient light trapping scheme based on textured conductive photonic crystal back reflector for performance improvement of amorphous silicon solar cells. Appl. Phys. Lett. 2014, 105, 073506. [Google Scholar] [CrossRef]

- Zhou, D.Y.; Biswas, R. Photonic crystal enhanced light trapping in thin film solar cells. J. Appl. Phys. 2008, 103, 093102. [Google Scholar] [CrossRef]

- Mutitu, J.G.; Shi, S.Y.; Chen, C.H.; Creazzo, T.; Barnett, A.; Honsberg, C.; Prather, D.W. Thin film silicon solar cell design based on photonic crystal and diffractive grating structures. Opt. Express 2008, 16, 15238–15248. [Google Scholar] [CrossRef] [PubMed]

- Sai, H.; Kanamori, Y.; Kondo, M. Flattened light-scattering substrate in thin film silicon solar cells for improved infrared response. Appl. Phys. Lett. 2011, 98, 113502. [Google Scholar] [CrossRef]

- Vetterl, O.; Finger, F.; Carius, R.; Hapke, P.; Houben, L.; Kluth, O.; Lambertz, A.; Muck, A.; Rech, B.; Wagner, H. Intrinsic microcrystalline silicon: A new material for photovoltaics. Sol. Energy Mater. Sol. Cells 2000, 62, 97–108. [Google Scholar] [CrossRef]

- Shah, A.V.; Schade, H.; Vanecek, M.; Meier, J.; Vallat-Sauvain, E.; Wyrsch, N.; Kroll, U.; Droz, C.; Bailat, J. Thin-film silicon solar cell technology. Prog. Photovolt. 2004, 12, 113–142. [Google Scholar] [CrossRef]

- Muller, J.; Rech, B.; Springer, J.; Vanecek, M. TCO and light trapping in silicon thin film solar cells. Sol. Energy 2004, 77, 917–930. [Google Scholar] [CrossRef]

- Agashe, C.; Kluth, O.; Hupkes, J.; Zastrow, U.; Rech, B.; Wuttig, M. Efforts to improve carrier mobility in radio frequency sputtered aluminum doped zinc oxide films. J. Appl. Phys. 2004, 95, 1911–1917. [Google Scholar] [CrossRef] [Green Version]

- Haug, F.J.; Soederstroem, T.; Cubero, O.; Terrazzoni-Daudrix, V.; Ballif, C. Plasmonic absorption in textured silver back reflectors of thin film solar cells. J. Appl. Phys. 2008, 104, 064509. [Google Scholar] [CrossRef]

- Curtin, B.; Biswas, R.; Dalal, V. Photonic crystal based back reflectors for light management and enhanced absorption in amorphous silicon solar cells. Appl. Phys. Lett. 2009, 95, 231102. [Google Scholar] [CrossRef]

- Zhao, Y.; Miyajima, S.; Ide, Y.; Yamada, A.; Konagai, M. Microcrystalline silicon films and solar cells prepared by photochemical vapor deposition on textured SnO2 with high haze factors. Jpn. J. Appl. Phys. 2002, 41, 6417. [Google Scholar] [CrossRef]

- Yue, G.; Sivec, L.; Owens, J.M.; Yan, B.; Yang, J.; Guha, S. Optimization of back reflector for high efficiency hydrogenated nanocrystalline silicon solar cells. Appl. Phys. Lett. 2009, 95, 263501. [Google Scholar] [CrossRef]

- Sai, H.; Saito, K.; Hozuki, N.; Kondo, M. Relationship between the cell thickness and the optimum period of textured back reflectors in thin-film microcrystalline silicon solar cells. Appl. Phys. Lett. 2013, 102, 053509. [Google Scholar]

- Yin, J.; Zhu, H.; Wang, Y.; Wang, Z.; Gao, J.; Mai, Y.; Ma, Y.; Wan, M.; Huang, Y. A study of ZnO:B films for thin film silicon solar cells. Appl. Surf. Sci. 2012, 259, 758–763. [Google Scholar] [CrossRef]

- Chen, P.; Hou, G.; Fan, Q.; Ni, J.; Zhang, J.; Huang, Q.; Zhang, X.; Zhao, Y. Combining randomly textured surfaces and one-dimensional photonic crystals as efficient light-trapping structures in hydrogenated amorphous silicon solar cells. Sol. Energy Mater. Sol. Cells 2015, 143, 435–441. [Google Scholar] [CrossRef]

- Yan, B.; Yue, G.; Sivec, L.; Yang, J.; Guha, S.; Jiang, C.-S. Innovative dual function nc-SiOx:H layer leading to a 16% efficient multi-junction thin-film silicon solar cell. Appl. Phys. Lett. 2011, 99, 113512. [Google Scholar] [CrossRef]

- Hsu, Y.T.; Yu, C.C.; Huang, K.F.; Lan, W.H.; Huang, J.E.; Lin, J.C.; Lin, W.J. Improved output power of nitride-based light-emitting diodes with convex-patterned sapphire substrates. IEEE Photonic. Tech. Lett. 2012, 24, 1686–1688. [Google Scholar] [CrossRef]

- Zhou, S.J.; Cao, B.; Liu, S.; Ding, H. Improved light extraction efficiency of gan-based leds with patterned sapphire substrate and patterned ITO. Opt. Laser Technol. 2012, 44, 2302–2305. [Google Scholar] [CrossRef]

- Chen, P.; Niu, P.; Yu, L.; Zhang, J.; Fan, Q.H.; Yang, G.; Ning, P.; Hou, G. Periodically patterned micro-cone textures as high-efficiency light harvesting structure for broadband absorption enhancement in thin film silicon solar cells. Sol. Energy 2018, 159. [Google Scholar]

- Tan, H.; Sivec, L.; Yan, B.; Santbergen, R.; Zeman, M.; Smets, A.H.M. Improved light trapping in microcrystalline silicon solar cells by plasmonic back reflector with broad angular scattering and low parasitic absorption. Appl. Phys. Lett. 2013, 102, 153902. [Google Scholar] [CrossRef]

- Yang, X. Study of Transparent Conducting Oxides and Back Reflectors for Amorphous and Nanocrystalline Silicon Based Thin Film Solar Cells. Ph.D. Thesis, The university of Toledo, Toledo, OH, USA, December 2007. [Google Scholar]

- Sai, H.; Matsui, T.; Saito, K.; Kondo, M.; Yoshida, I. Photocurrent enhancement in thin-film silicon solar cells by combination of anti-reflective sub-wavelength structures and light-trapping textures. Prog. Photovolt. 2015, 23, 1572–1580. [Google Scholar] [CrossRef]

- Chang, C.H.; Dominguez-Gaballero, J.A.; Choi, H.J.; Barbastathis, G. Nanostructured gradient-index antireflection diffractive optics. Opt. Lett. 2011, 36, 2354–2356. [Google Scholar] [CrossRef] [PubMed]

- Rowlands, S.F.; Livingstone, J.; Lund, C.P. Optical modelling of thin film solar cells with textured interfaces using the effective medium approximation. Sol. Energy 2004, 76, 301–307. [Google Scholar] [CrossRef]

- Dewan, R.; Shrestha, S.; Jovanov, V.; Hupkes, J.; Bittkau, K.; Knipp, D. Random versus periodic: Determining light trapping of randomly textured thin film solar cells by the superposition of periodic surface textures. Sol. Energ. Mat. Sol. Cells 2015, 143, 183–189. [Google Scholar] [CrossRef]

- Sun, Y.Q.; Wu, Z.H.; Yin, J.; Fang, Y.Y.; Wang, H.; Yu, C.H.; Hui, X.O.; Chen, C.Q.; Wei, Q.Y.; Li, T.; et al. High quality a-plane GaN films grown on cone-shaped patterned r-plane sapphire substrates. Thin Solid Films 2011, 519, 2508–2512. [Google Scholar] [CrossRef]

- Chen, P.; Niu, P.; Yu, L.; Zhang, J.; Fan, Q.H.; Yang, G.; Fu, X.; Hou, G. Quasi-crystal photonic structures for fullband absorption enhancement in thin film silicon solar cells. Sol. Energy Mater. Sol. Cells 2018, 175. [Google Scholar]

- Sheng, P.; Bloch, A.N.; Stepleman, R.S. Wavelength selective absorption enhancement in thin-film solar cells. Appl. Phys. Lett. 1983, 43, 579–581. [Google Scholar] [CrossRef]

- Eisele, C.; Nebel, C.E.; Stutzmann, M. Periodic light coupler gratings in amorphous thin film solar cells. J. Appl. Phys. 2001, 89, 7722–7726. [Google Scholar] [CrossRef]

- Stiebig, H.; Senoussaoui, N.; Zahren, C.; Haase, C.; Müller, J. Silicon thin-film solar cells with rectangular-shaped grating coupler. Prog. Photovolt. 2006, 14, 13–24. [Google Scholar] [CrossRef]

- Ferry, V.E.; Verschuuren, M.A.; van Lare, M.C.; Schropp, R.E.I.; Atwater, H.A.; Polman, A. Optimized spatial correlations for broadband light trapping nanopatterns in high efficiency ultrathin film a-Si:H solar cells. Nano Lett. 2011, 11, 4239–4245. [Google Scholar] [CrossRef] [PubMed]

- Battaglia, C.; Hsu, C.; Soderstrom, K.; Escarre, J.; Haug, F.; Charriere, M.; Boccard, M.; Despeisse, M.; Alexander, D.T.L.; Cantoni, M.; Cui, Y.; Ballif, C. Light trapping in solar cells: Can periodic beat random? ACS Nano 2012, 6, 2790–2797. [Google Scholar] [CrossRef] [PubMed]

- Dewan, R.; Jovanov, V.; Hamraz, S.; Knipp, D. Analyzing periodic and random textured silicon thin film solar cells by rigorous coupled wave analysis. Sci. Rep. 2014, 4, 6029. [Google Scholar] [CrossRef] [PubMed]

- Martins, E.R.; Li, J.; Liu, Y.; Depauw, V.; Chen, Z.; Zhou, J.; Krauss, T.F. Deterministic quasi-random nanostructures for photon control. Nat. Commun. 2013, 4, 2665. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Y.; Chen, P.; Fan, Q.H.; Hou, G. Photonic Structures for Light Trapping in Thin Film Silicon Solar Cells: Design and Experiment. Coatings 2017, 7, 236. https://doi.org/10.3390/coatings7120236

Ding Y, Chen P, Fan QH, Hou G. Photonic Structures for Light Trapping in Thin Film Silicon Solar Cells: Design and Experiment. Coatings. 2017; 7(12):236. https://doi.org/10.3390/coatings7120236

Chicago/Turabian StyleDing, Yi, Peizhuan Chen, Qi Hua Fan, and Guofu Hou. 2017. "Photonic Structures for Light Trapping in Thin Film Silicon Solar Cells: Design and Experiment" Coatings 7, no. 12: 236. https://doi.org/10.3390/coatings7120236