1. Introduction

The technology of optical coatings has advanced significantly since the time of Joseph von Fraunhofer (1787–1826) who, in the process of etching glass surfaces, observed a reduction of its reflectivity. Along with Augustin-Jean Fresnel’s (1788–1827) formulation of the reflectance caused by an optical interface, and Lord Rayleigh’s (1842–1919) investigations into the interference effects of a multilayer stack, the field of anti-reflective coatings (ARCs) has developed tremendously to encompass a wide variety of designs suitable for most any optical application [

1]. The discovery of nano-conical structures that envelope the moth’s eye has initiated a new direction into a new type of anti-reflective surface comprising a periodic grating surface of nano-structures that are carefully shaped to provide a gradual change in refractive index toward the ambient index [

2,

3,

4].

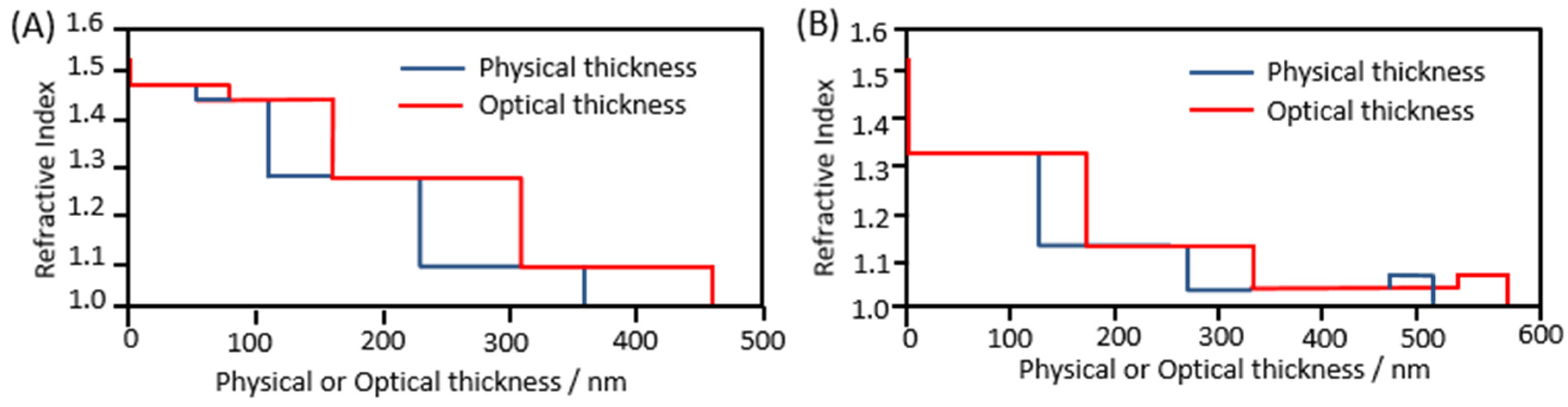

However, the field of multi-layer structures has also undergone a renaissance with the ability to layer nano-thick films in a cost efficient and scalable manner. The designs of such multi-layer structures are constrained by the material’s index of refraction which typically ranges from 1.5 to 3.0, thus necessitating elaborate designs of many layers with different types of materials in order to produce the optimal interference effects. However, it is possible to relax the material constraints by introducing a degree of porosity

f into the material packing, through which its effective refractive index then follows a simple equation

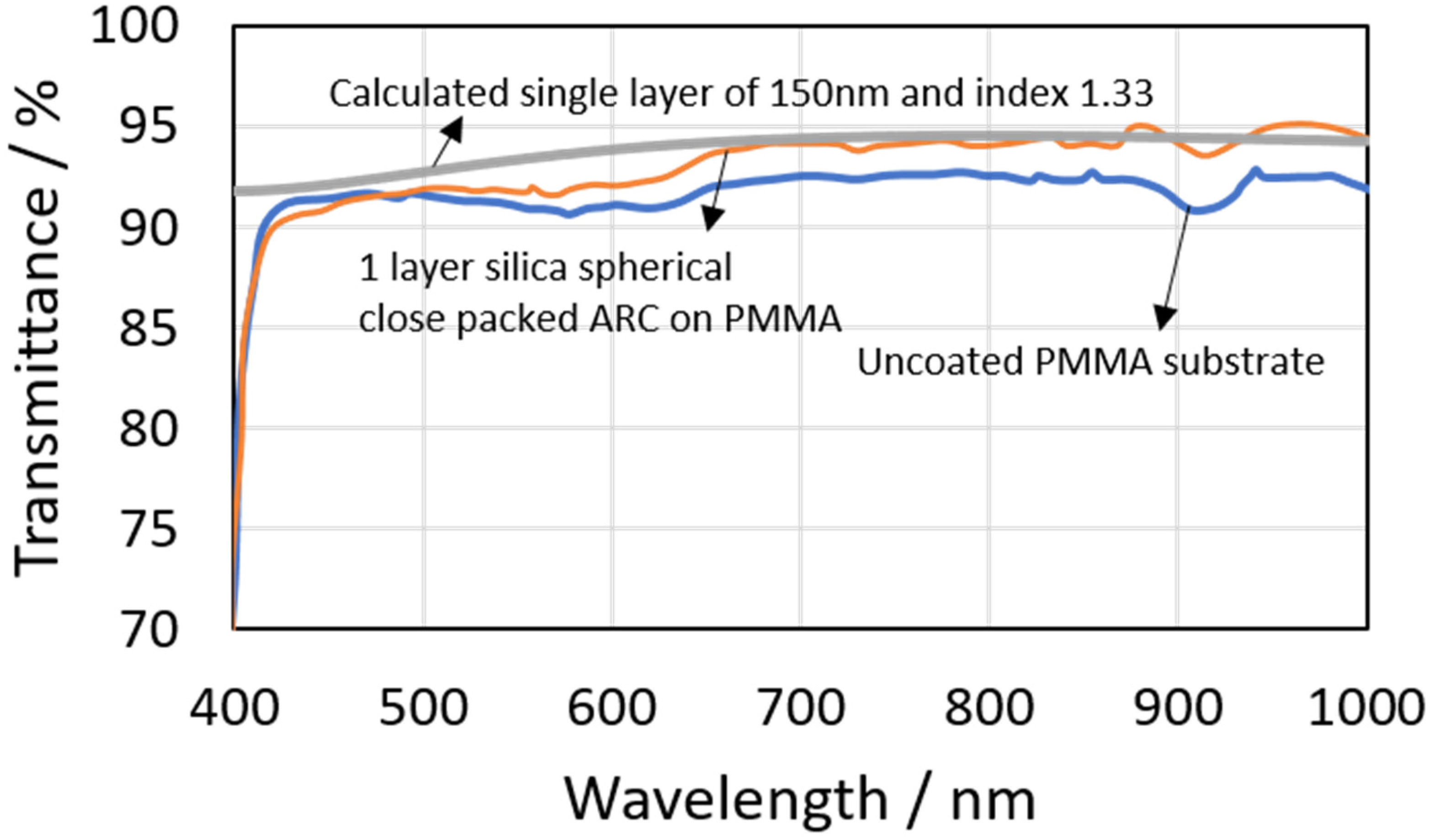

. By relaxing this fundamental constraint, it would then be possible to optimize the ARC design to only a few layers, bringing down costs and yet opening up the design space. Already, it is trivial to produce a single layer coating comprising of a dip coated 10 nm silica nanoparticle film, that by virtue of its inherent minimum 26% to 32% porosity through close packing of spheres in a Hexagonally-Closed Packed or Body-Closed Packed arrangement, reduces the reflectivity of a PMMA (Poly(methyl methacrylate)) substrate significantly (

Figure 1).

In this article, the question that we investigate is that, given the relaxed constraints of being able to relatively easily tune the refractive index of a nano-thick layer, how can one determine an optimized ARC stack that is anti-reflective even at glancing angle incidence and is relatively broadband in the visible. The solution will serve as a guide in designing the ARC stack for various applications. Here, we turn to using an established method called Admittance Loci representation to aid in understanding the solutions proposed by Genetic Algorithm optimization [

5,

6]. The challenges of fabricating and maintaining such a stack and their suggested solutions will also be discussed.

2. Materials and Methods

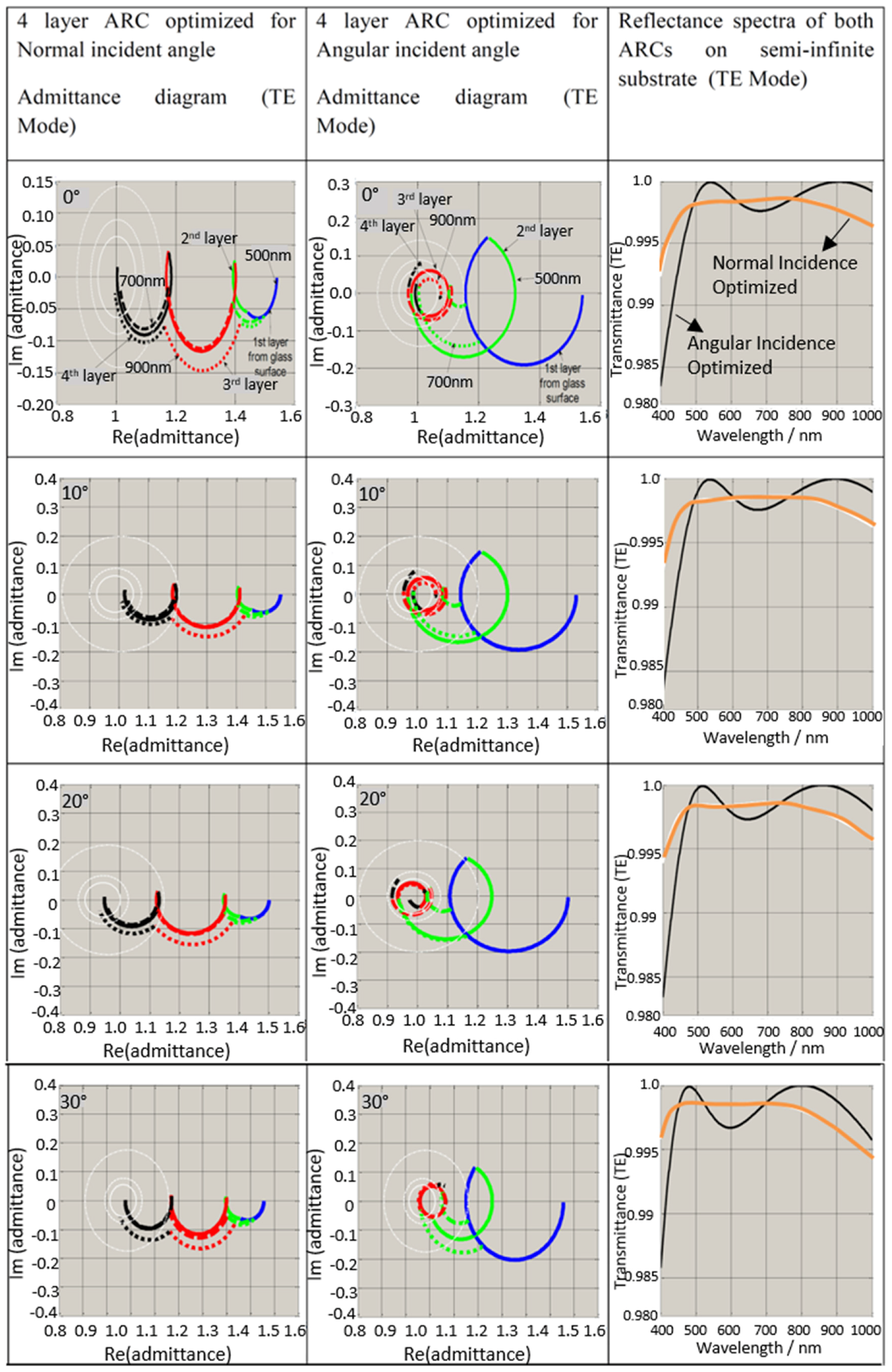

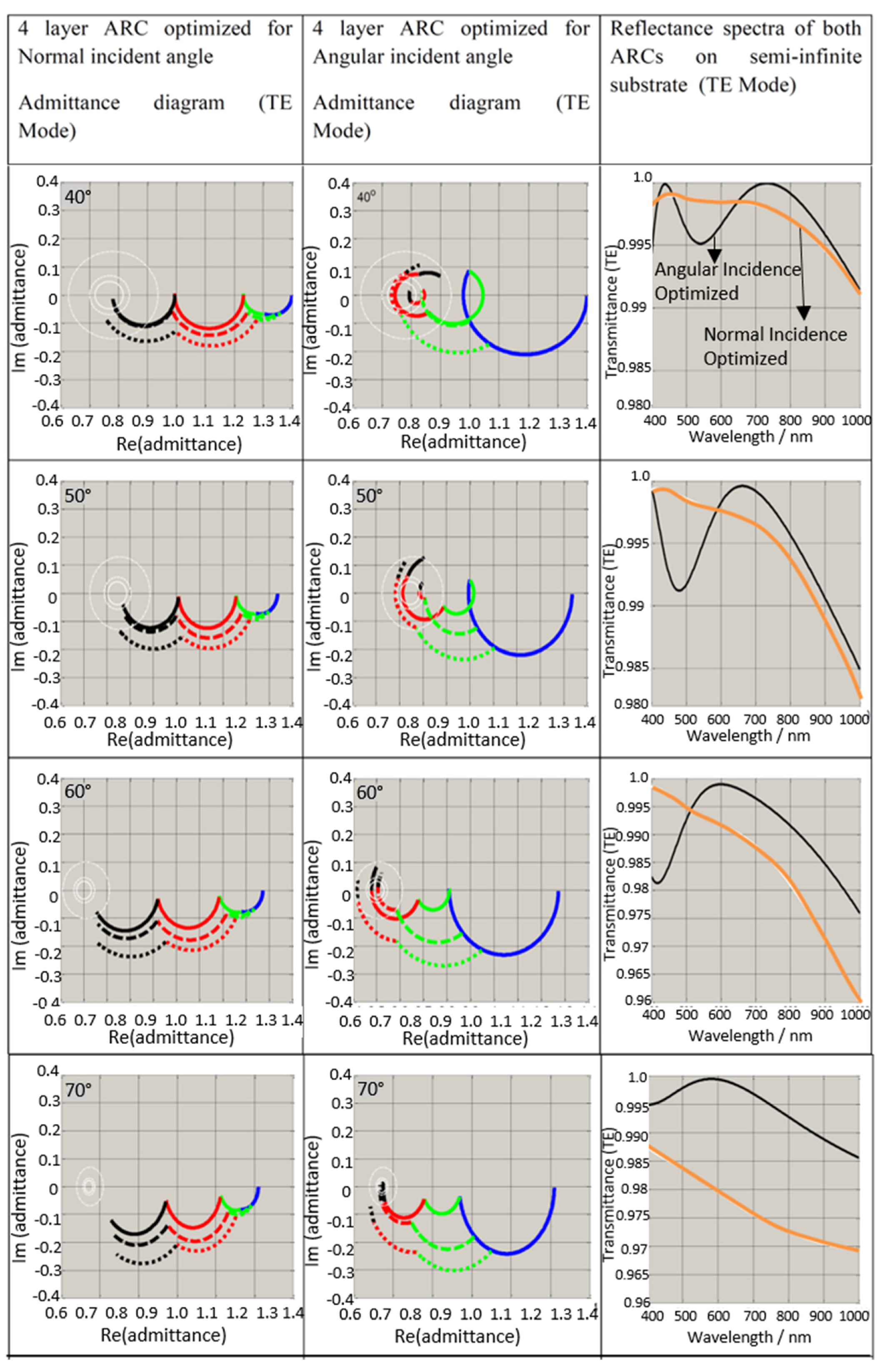

We first provide a brief summary of the Genetic Algorithm used to optimize the transmittance of 2 types of four-layer stacks for normal incidence (0°) and angular incidence (0 to 80°) on a single optical interface of a semi-infinite substrate with the refractive index of glass. A semi-infinite substrate was chosen as it can be easily represented by an admittance locus representation. 3D binary arrays representing the individuals and optical parameters were generated randomly within pre-defined constraints (1.0 <

n < 1.54 and 45 nm <

z < 120 nm). The optical parameters were fed into the Abeles transmittance matrix to produce a transmittivity curve and a corresponding normalized fitness value

Rave which is defined as

where λ

min and λ

max represent the spectral range of interest, and

RTE(λ) and

RTM(λ) are the TE (Transverse Electric) and TM (Transverse Magnetic) mode spectral reflectivities. After evaluating a series of multi-layer systems and thus creating a population of fitness values, the systems were selected for breeding via a proportionate selection process, where the normalized fitness value of each system would have a proportionately finite probability of being selected. The fitter individual system has a high chance of pairing with another fit individual system. The parent systems are replicated as their children, where crossover between the parent systems’ chromosomes has a high chance of occurring. Finally, random mutations of 1% are introduced for diversity and to decrease the chance of missing a global optimal solution. After this application of selection, crossover and mutation, a new generation of optical parameters are fed into the Abeles matrix to generate another population of fitness values. It is found that convergence to the highest fit is achieved in 23 generations while the algorithm was run for a total of 100 generations.

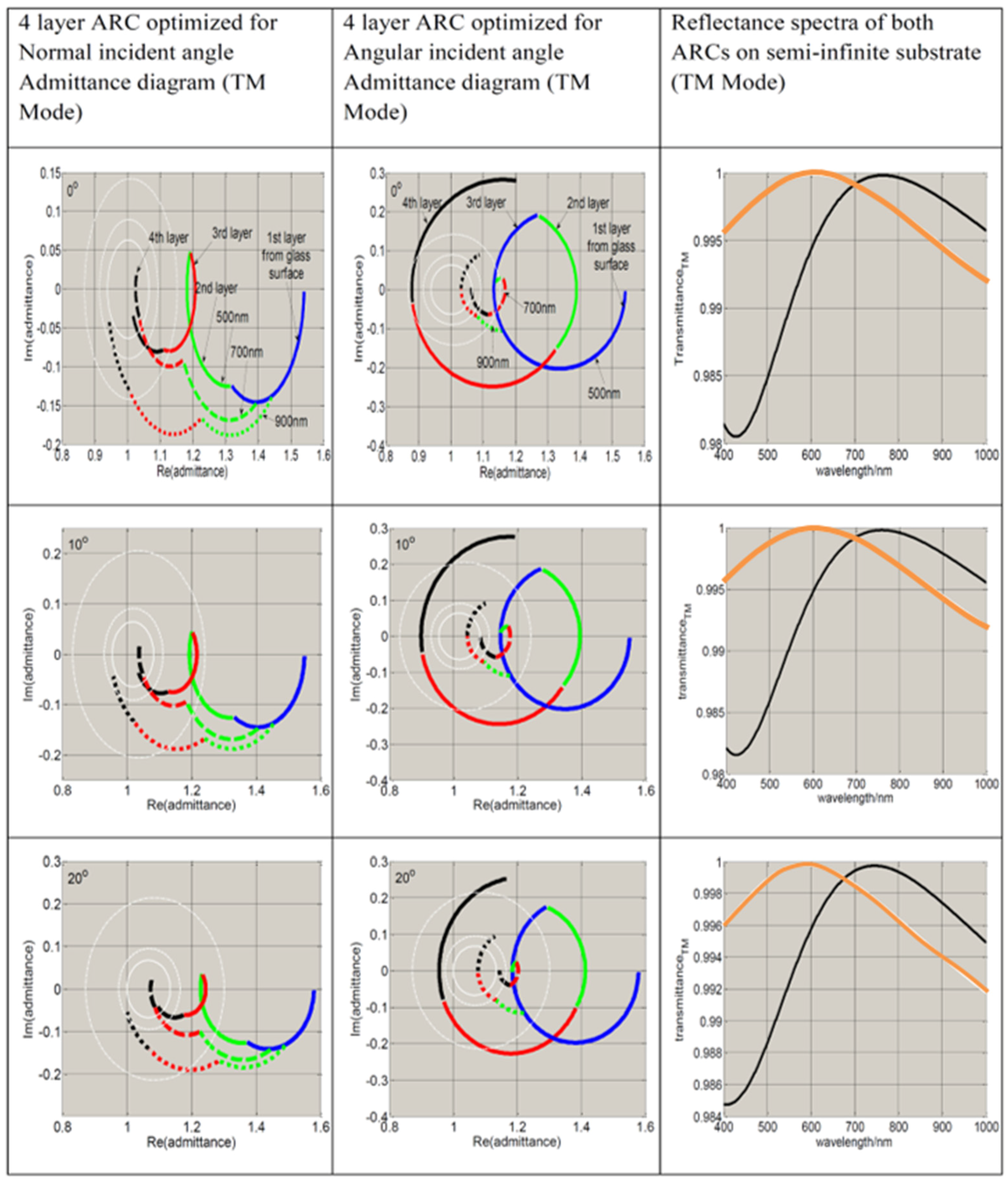

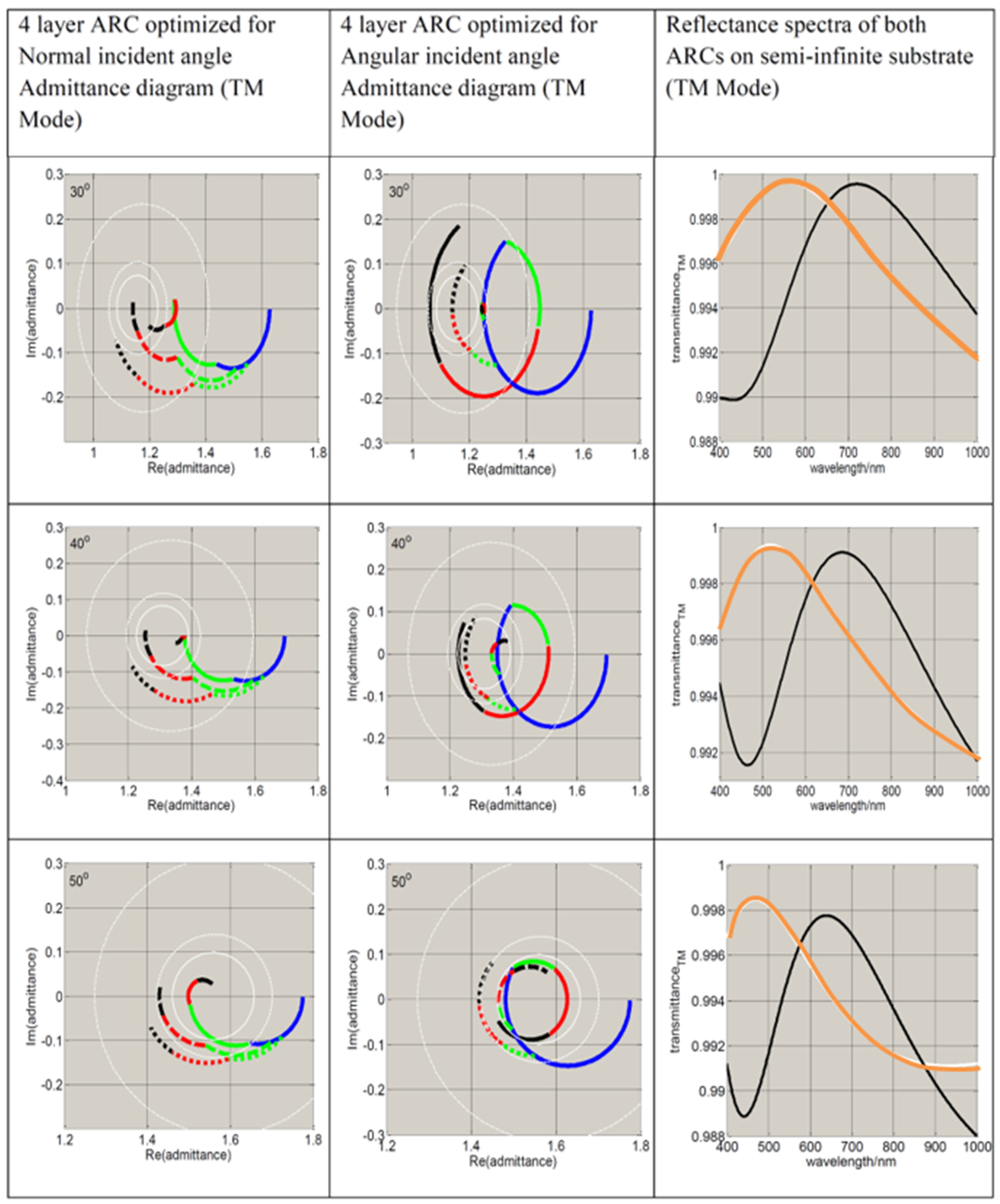

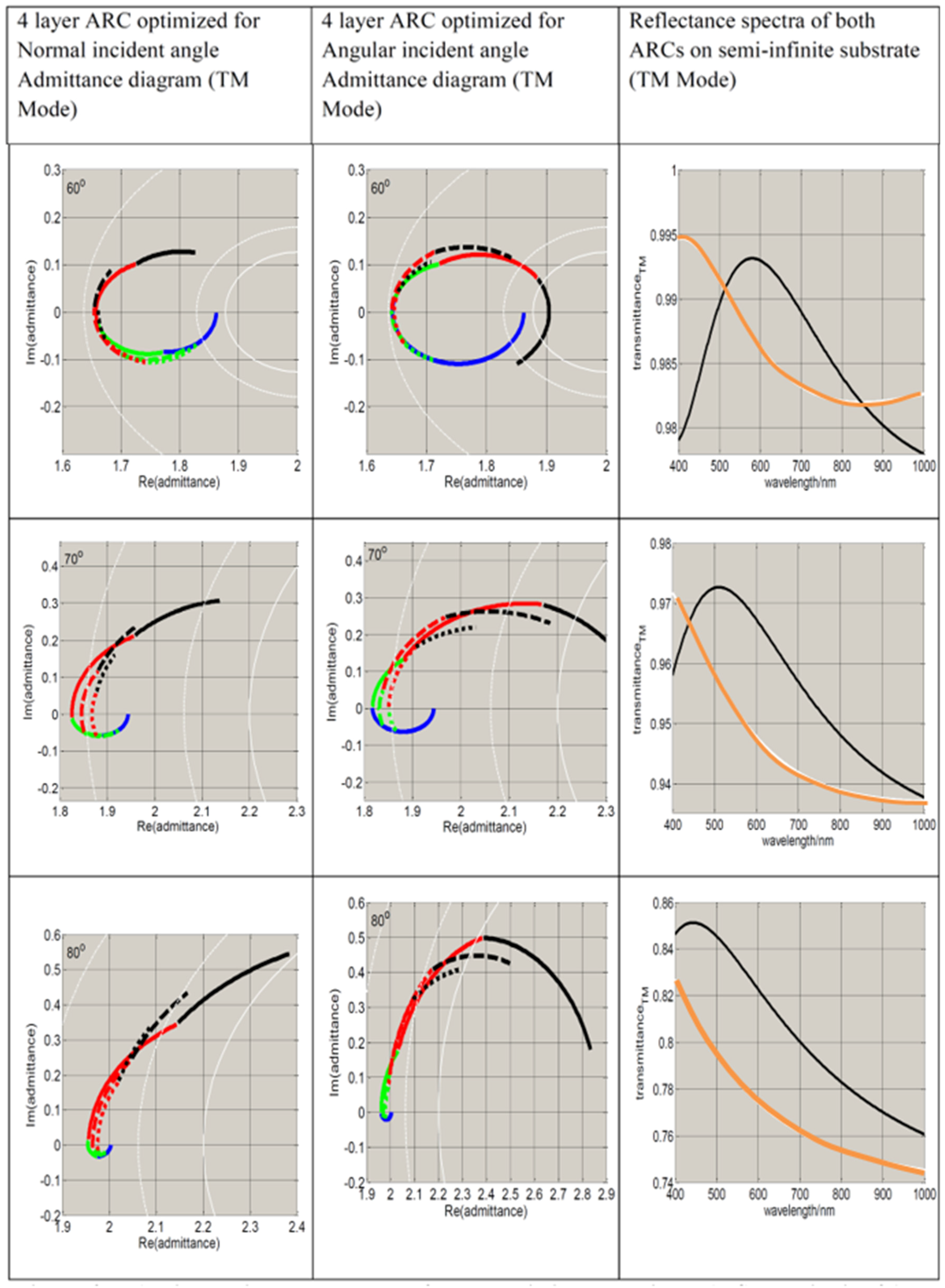

As an instructive guide, the admittance loci for the TE mode where the performance is optimized for normal incidence and for angular incidence using a four-layer ARC is presented in the next section (with corresponding TM mode admittance loci presented in the

appendix). An admittance locus, which is confined to the right-hand side of the complex plane, is a geometric representation of the performance of multilayer stack at a specific value of wavelength. It comprises a continuous series of circular arcs representing each layer of the multilayer stack with its starting point (admittance of the substrate) on the real axis. The optical thickness of each layer is represented by its degree of arc in the clockwise direction. A typical multilayer ARC stack will thus trace out a helicoid path. For example, a semicircle corresponds to a quarter wave optically thick layer, a full circle corresponding to a half wave layer. The radius of circle is described by the Equation (2):

where

n is the index of the substrate,

Yj is the admittance at the

j-th layer. The point (1,0) on the complex plane denotes zero reflectance, and the greater the distance the loci end-point is from (1,0) the greater the reflectance will be.

Before fabricating a multilayer stack, it is necessary to determine the amount of porosity required to obtain the required refractive index value. We induce porosity essentially by mixing 50 nm polystyrene spherical particles with 10 nm SiO

2 or 10 nm SnO

2 colloidal particle solutions, spin coat the mixture on a cleaned substrate and anneal it at high temperature to pyrolyse the polystyrene. The resulting layer is one of a porous network of SiO

2 or SnO

2 nanoparticles. More details on the fabrication method are provided in

Appendix B.

4. Discussion

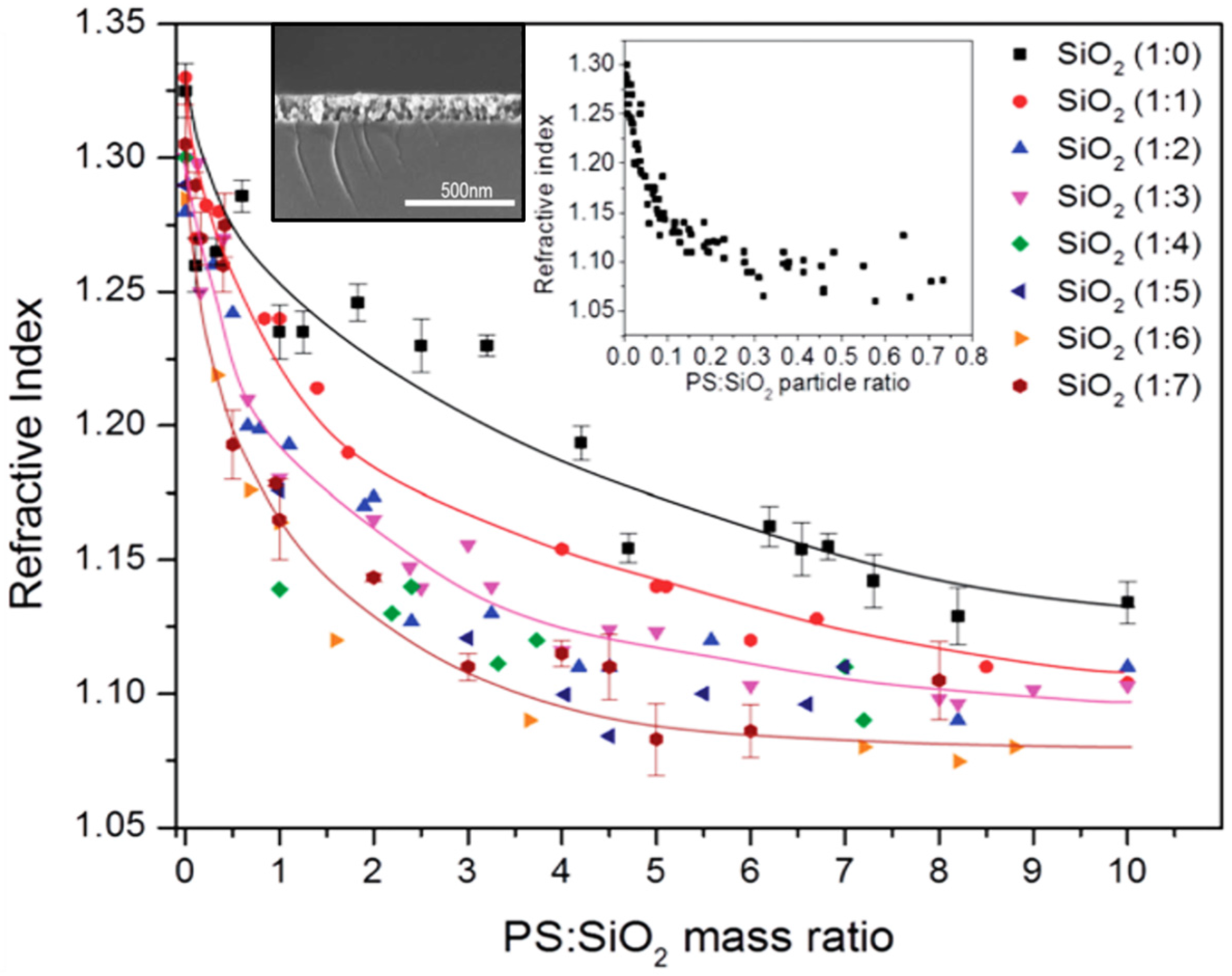

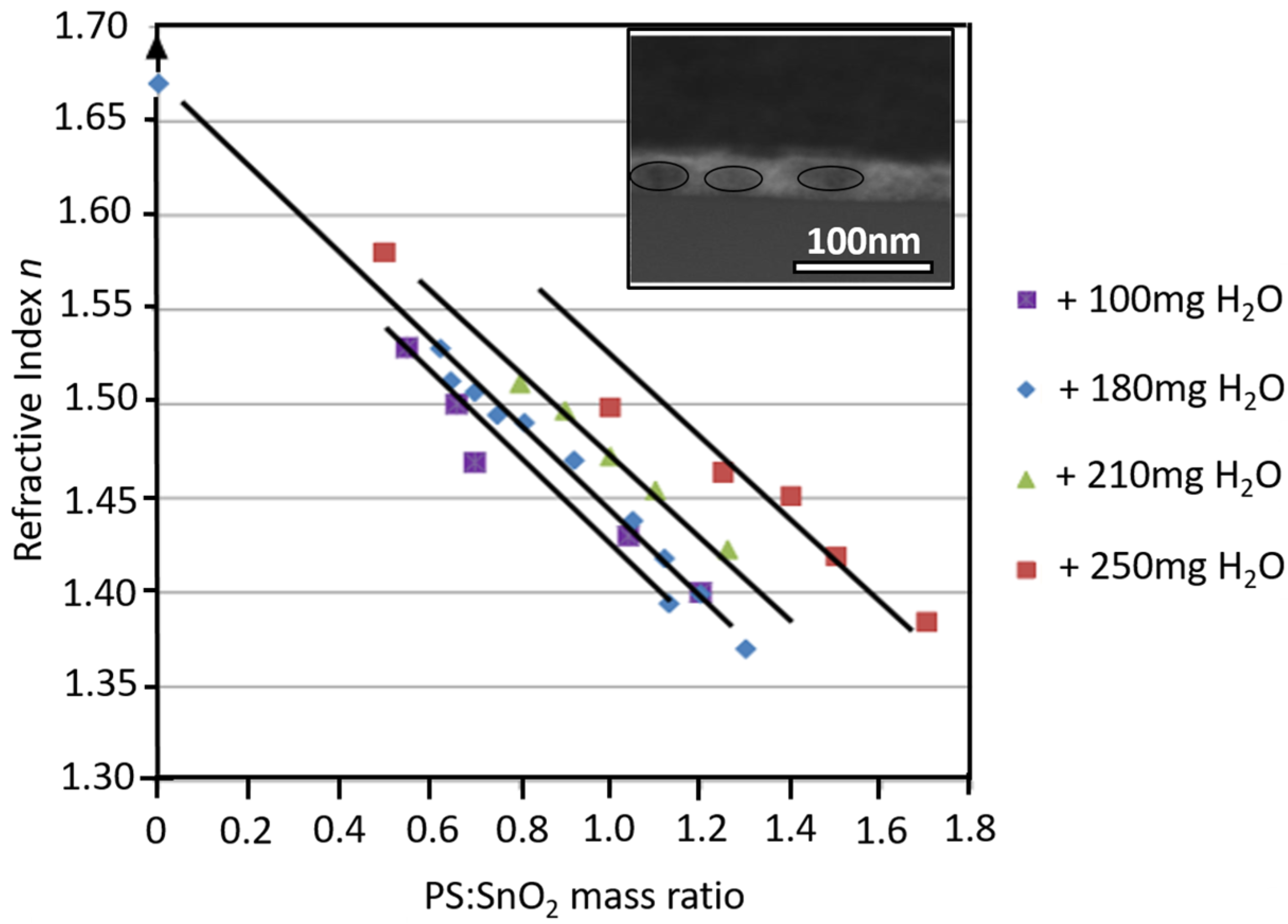

The ease of tuning the refractive index of a given material is illustrated in

Figure 5 and

Figure 6, where reduction in the refractive index of silicon oxide and tin oxide nanoparticle films [

11] is achieved by increasing introduction of polystyrene particles. With the introduction of only a small amount of polystyrene in SiO

2 nanoparticle solutions, the porosity induced by the removal of polystyrene is significant as seen by the steep drop in the refractive index. With increasing polystyrene, however, it becomes more difficult to achieve a very low refractive index as the change in index with further increase in porosity is gradual. The limit at which the internal framework of nanoparticles (hosting the induced porosity) can mechanically support itself becomes apparent as the index actually increases slightly at the largest polystyrene concentration. In

Figure 5 inset, we determined the particle ratio of the SiO

2 nanoparticles to the polystyrene nanoparticles from the density of the colloidal solution (1.22 g/mL, 30 wt % in H

2O), density of the PS solution (0.025 g/mL, 2.5 wt % in H

2O) and the dilution factor to arrive at ~10

13 silica particles and ~10

9 PS particles in the prepared solution. In sum, it is relatively easy to induce an index drop of more than 0.3 for a silica nanoparticle film, but achieving an index of less than 1.1, which requires a packing fraction of only 10%, is difficult. However, it is conceivable that by improving the chemical adhesion between nanoparticles that a highly porous and mechanically robust scaffolding could be fabricated. For tin dioxide nanoparticle films, the trend is largely a linear decrease from an index of 3.5, and hence a combination of tin-dioxide and silica nanoparticle layered stack may be suitable for high index substrates such as silicon or ITO. From SEM cross sectional images, the PS generated voids tend to conglomerate into bigger and more elliptical voids within SnO

2 particle films, whereas SiO

2 particle films show an open network of SiO

2 agglomerations.

With respect to a moth eye grating structure, this is limited by its mold template design, it is expensive to fabricate on a large scale of metric squared areas, and is not amenable to a wide variety of designs vis-à-vis every optical application or even every type of substrate such as polymeric substrates without having to make major changes to its fabrication process. Nanoparticle colloidal solutions, on the other hand, have been coated on polymeric substrates by making minor adjustments to its colloidal composition [

12]. Furthermore, the necessarily precise gradual curvature of the conical moth eye nano-structures can be easily eroded and hence significantly lose its AR effectiveness. In contrast, by implementing a slightly thicker multilayer stack of 6 layers, the first 2 layers can be eroded and the performance of the ARC will still not suffer a major loss in its effectiveness. Although nanoparticle films may also have issues with mechanical robustness, its low cost of fabrication and ease of scalability can make it attractive for large scale optical applications that demand cost effectiveness, for example, the inside interface of a glass greenhouse.

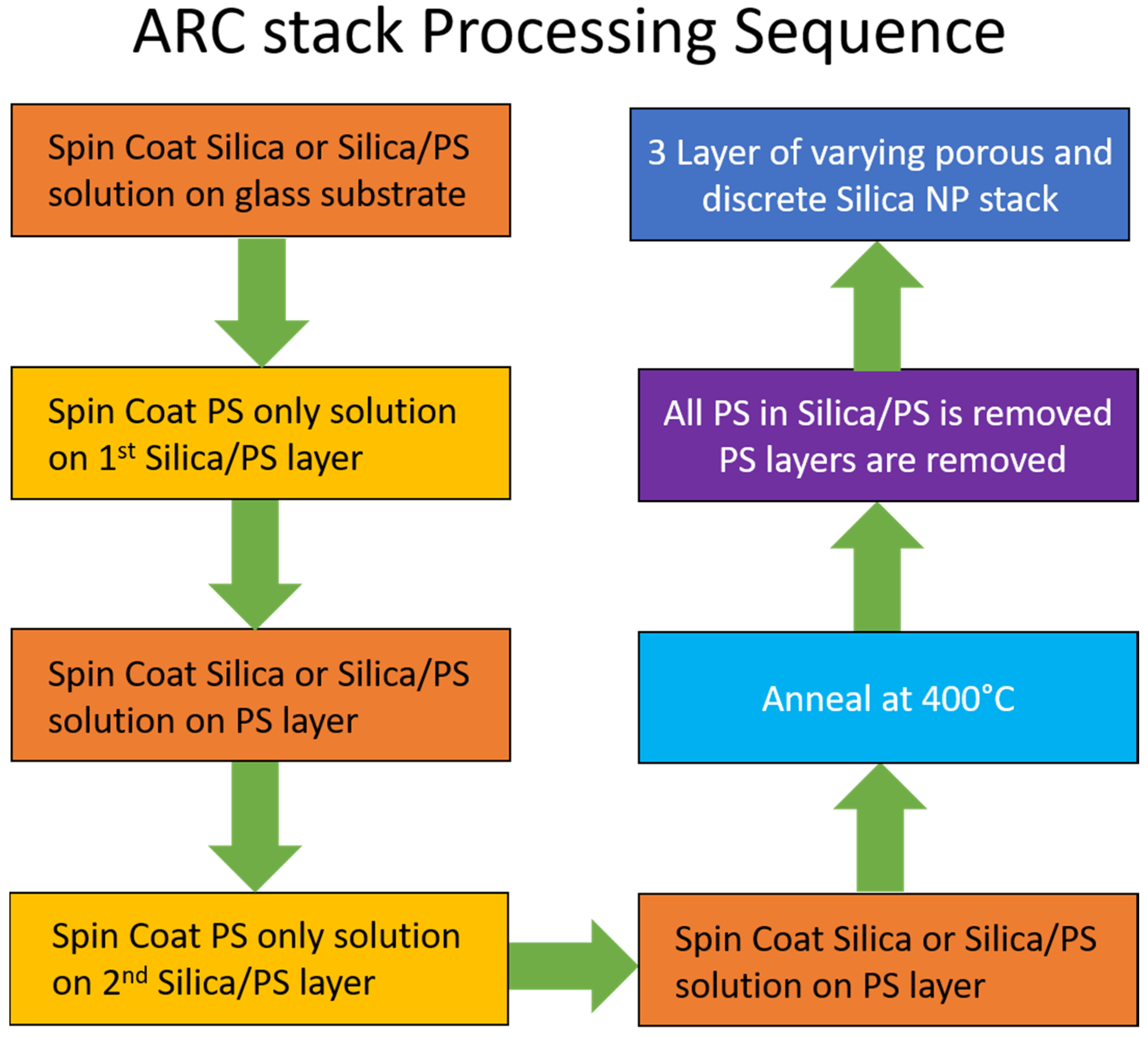

One challenge in the fabrication of a stack of discrete nano-porous layers is that when spin coating or dip coating each colloidal solution sequentially, the colloidal layers will mix and form a single continuous layer. One successful solution lies in introducing a sacrificial layer of polystyrene particles on top of each colloidal layer, which can be pyrolyzed when all layers are coated, thus enabling discrete layers with different porosities (

Figure 7). Another difficulty which is also inherent in other coating technologies is the heat treatment necessary to pyrolyze the polystyrene particles as well as forming a more mechanically stable coating. Even though a low heating temperature of 150 °C is sufficient to pyrolyze the polystyrene, it may still be difficult to implement on thermoplastic substrates such as PMMA. Therefore, other methods to remove polystyrene particles may be necessary. For example, we have observed that these polystyrene particles can also be easily removed by ozone, and therefore it may be possible to introduce a reactive gas that will remove these organics, and yet not harm the underlying substrate if it is well enveloped in a protective sleeve.

It may ultimately be necessary to pay attention to the optimal distribution of the nanoparticle packing in order to maximize mechanical robustness. Variables such as the size of the host nanoparticle and size of the pyrolyzable particles play a role, as well as deposition parameters. For example,

Table 1 shows the effect of spin coating speed on the refractive index and thickness (characterized by ellipsometry) of a single layer of a mixture of SiO

2 (diluted 1:15):PS = 1:5. It is clear that some variability in the index can be achieved by the spin coating speed. It is possible that with increasing RPM (Rotations Per Minute) the larger PS particles are more tightly compressed with the host silica film, and the rate of removal of PS versus silica solution is less when the rotational speed is high. The tighter compression may lead to a more interlinked porous network throughout the film. The final ratio of PS to silica after spin coating may also be greater. One characterization method for determining the characteristics of a porous film is the environmentally controlled ellipsometry, where the introduction of water moisture into the film and its removal can be studied through its change in the effective refractive index.

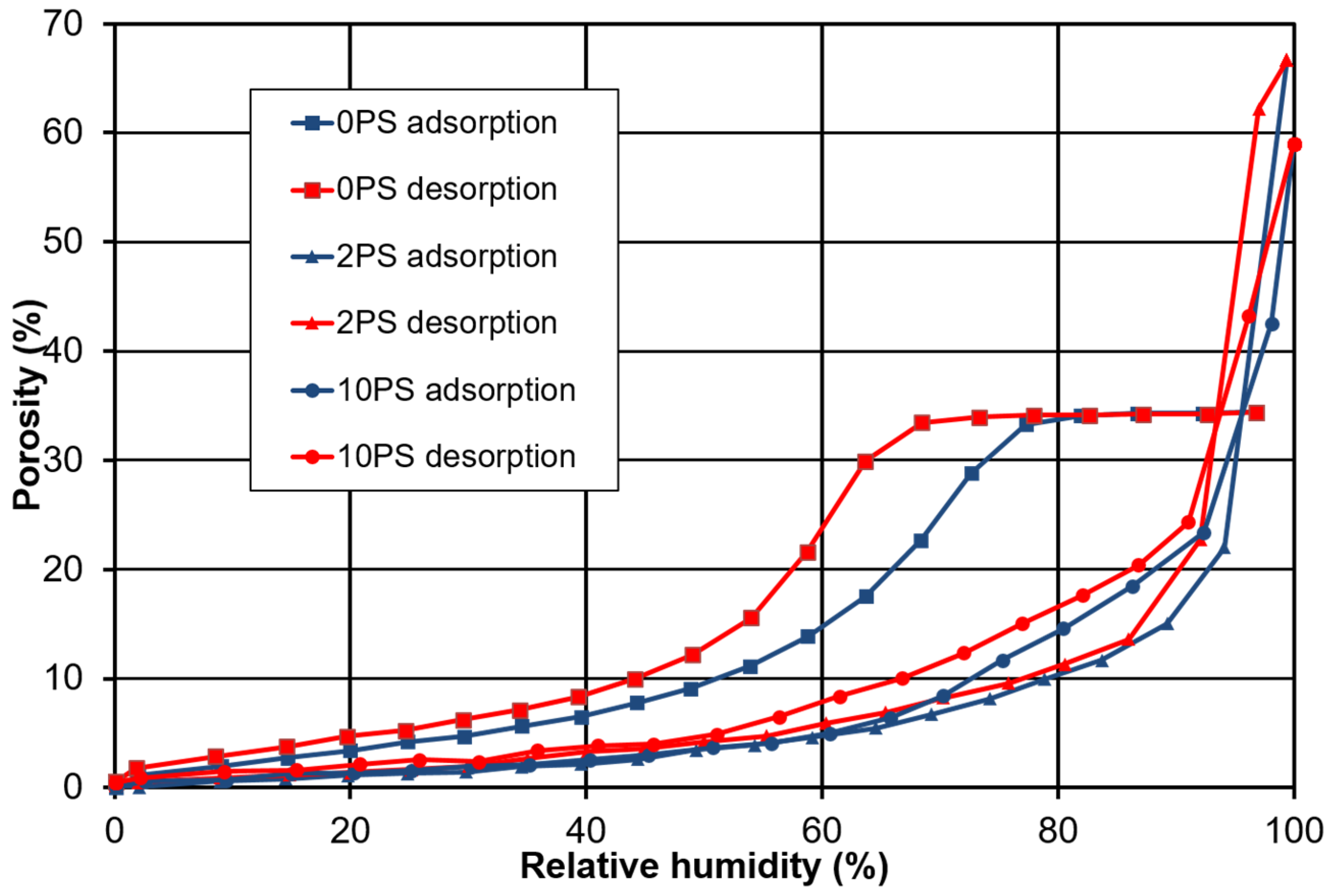

Figure 8 shows the hysteresis curves [

14] of the change in porosity as a function of increasing polystyrene (PS). If the film exhibits a large surface area due to an extensive porous network, its moisture content will be removed more rapidly as compared to a film with isolated porosity (for example, in a close-packed film of nano-spheres).

Further, other novel integrations can also be included in these porous networks. For example, one could introduce the use of hollow silica nanoparticles whereby the void fraction could be enhanced to achieve an even lower index. On the other hand, one could use close-packed calcined hollow spheres where the hollowness of the spheres could be utilized to effectively achieve the desired index and thus a more robust network. Yet another approach could be mixing of large hollow silica nanoparticles with small solid silica nanoparticles, with or without void inducing polystyrene particles, to achieve a desired combination of optical and structural properties.