1. Introduction

Grain raising, the lifting of fibres when water is applied to sanded wood surfaces, increases the roughness of wood, and is mentioned as one of the reasons why companies in North America are reluctant to finish wood products using water-borne coatings [

1]. Grain raising can be avoided by finishing wood with solvent-based finishes [

2], but this approach is becoming less acceptable due to environmental legislation limiting the solvent content of finishes [

3]. Grain raising can be eliminated by lightly sanding wood to remove “fibres” projecting from surfaces [

2,

4], or its severity can be reduced by using modified finishes containing resins or hydrophobes [

5,

6,

7,

8]. Alternative approaches to reducing grain raising might be developed if the mechanisms responsible for the phenomenon were fully understood. However, there are only a handful of scientific papers on grain raising [

9,

10,

11,

12].

The first paper on grain raising by Koehler in 1932 used reflectance microscopy to examine the surface of planed or sanded mahogany (

Swietenia sp.) and oak (

Quercus sp.) woods, before and after wetting [

9]. Koehler’s images clearly revealed that increases in roughness of wood surfaces following wetting were more pronounced at sanded surfaces than planed surfaces, and also greater in oak than in mahogany [

9]. Koehler claimed that increases in roughness were due to “fragments of fibres and pore wall projecting over the pores” at sanded wood surfaces [

9]. However, his photographs were taken at low magnification (4:1) and it is not possible to see in his photographs if the woody element projecting from wood surfaces are fibre fragments, fibres, fibre bundles, or larger woody elements [

9]. Higher magnification reflectance microscopy was used by Marra in his study of the factors responsible for grain raising of oak (

Quercus sp.), and maple (

Acer sp.) [

10]. His observations suggested that fragments of thin-walled vessels, which are the conducting elements in oak and other hardwoods, projected from sanded oak surfaces after wetting and drying [

10]. He also suggested that raised grain occurred due to swelling of the ridges between sanding scratches, and also as a result of the separation of fibres or groups of fibres that are attached at one end to sanded surfaces. Marra looked at the effects of wood structure and sanding variables on grain raising and concluded that wood structure, particularly grain angle, had a greater influence on the development of raised grain than sanding variables [

10]. He also pointed out that the lack of a method of quantifying the raised grain was a problem [

10]. This problem was overcome by Nakamura and Takachio in 1961 [

11]. They used stylus profilometry to quantify the changes in roughness of wood following sanding and wetting. Roughness was defined as the difference in maximum peak and valley height in a 10 mm long profilometry traverse [

11]. The roughness value of sanded wood surfaces after wetting minus the initial roughness was used as an index of gain raising. Nakamura and Takachios’ profilometry results showed that grain raising was positively correlated with sanding pressure and coarseness of the abrasives used to sand wood surfaces [

11]. Non-contact profilometry was used recently by Landry and coworkers to examine grain raising of yellow birch (

Betula alleghaniensis Britt.) finished with water-based and solvent-based stains [

12]. Their findings accorded with previous research, including our own unpublished research [

13], indicating “that sanding method has an important role in grain raising generation”.

To date each of the studies on grain raising has focused on only one or two species, with the exception of the work by Nakamura and Takachio in Japan that examined grain raising of seven wood species whose density varied from 0.37 to 0.71 [

11]. However, their study did not find a relationship between density and grain raising, even though earlier work by Marra suggested that lower density springwood in oak was more susceptible to grain raising than summerwood [

10]. Furthermore, the woody elements that rise up from sanded wood surfaces and are responsible for grain raising have not been precisely identified. In this paper, we seek to clarify the effects of wood density on grain raising and determine the microstructural feature responsible for grain raising. We hypothesize that the use of high-resolution profilometry and electron microscopy, in combination with physical modelling, will make it possible to answer these outstanding questions. Our ultimate aim is similar to those of Koehler [

9] and Marra [

10] who both sought to obtain a deeper understanding of the microstructure of grain raising to help develop better methods of selecting and machining wood to avoid the problem of grain raising.

3. Results

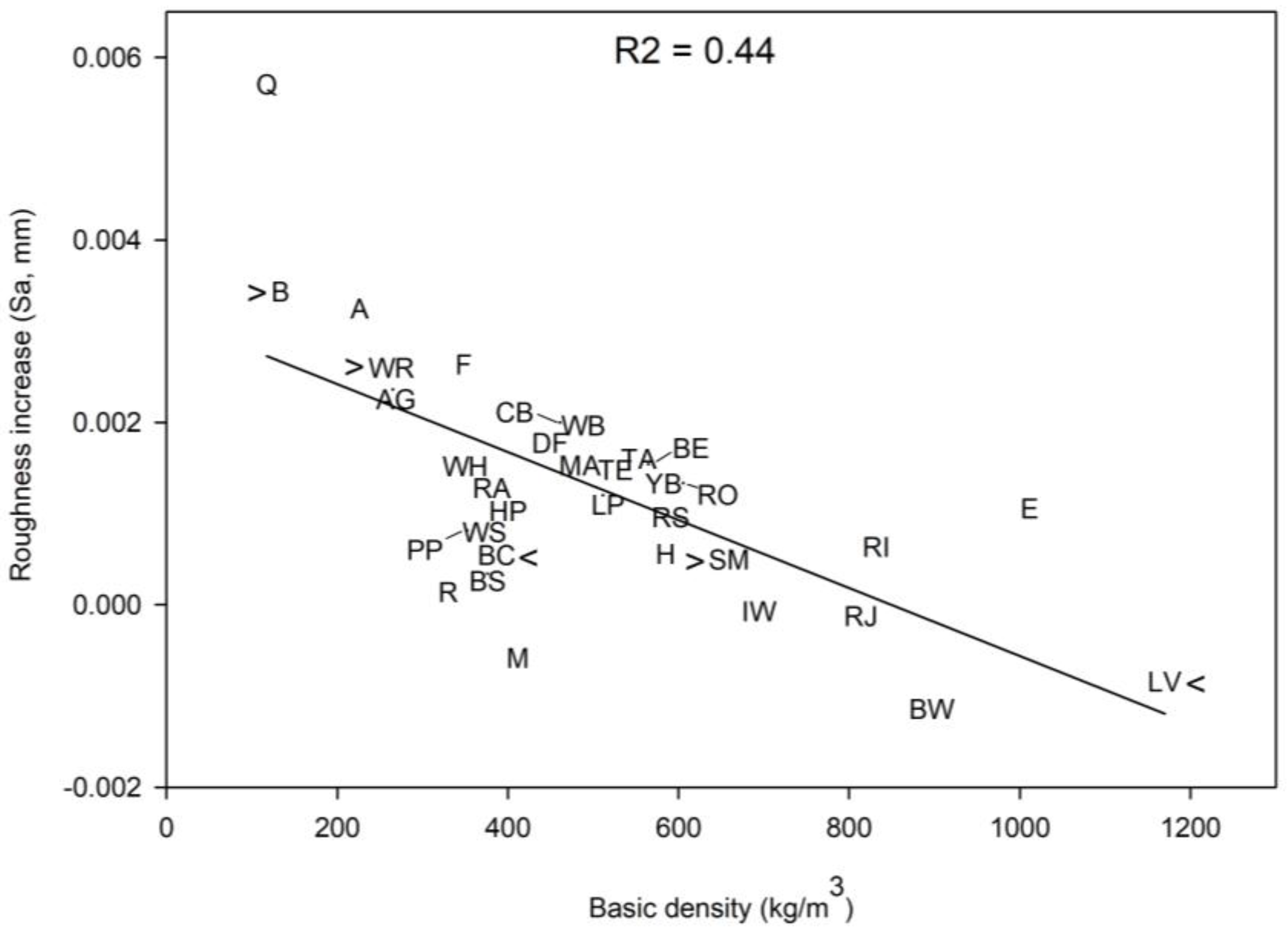

The difference in surface roughness of the various wood species after sanding and wetting and air drying, hereafter referred to as grain raising, is shown in

Figure 1. There are large differences in the grain raising of the different wood species. Some of the denser woods show no grain raising, whereas grain raising is much more pronounced in lower density species. There is a significant (

p < 0.001) inverse relationship between grain raising and the density of the different woods, but the proportion of the variance in grain raising that is explained by density is modest (

R2 = 0.44), because there is significant deviation between observed and fitted values. For example, grain raising of the world’s lowest density wood species, quipo (Q), is much higher than predicted from linear regression. There was a stronger and more linear relationship between the logarithm (ln) of density and grain raising.

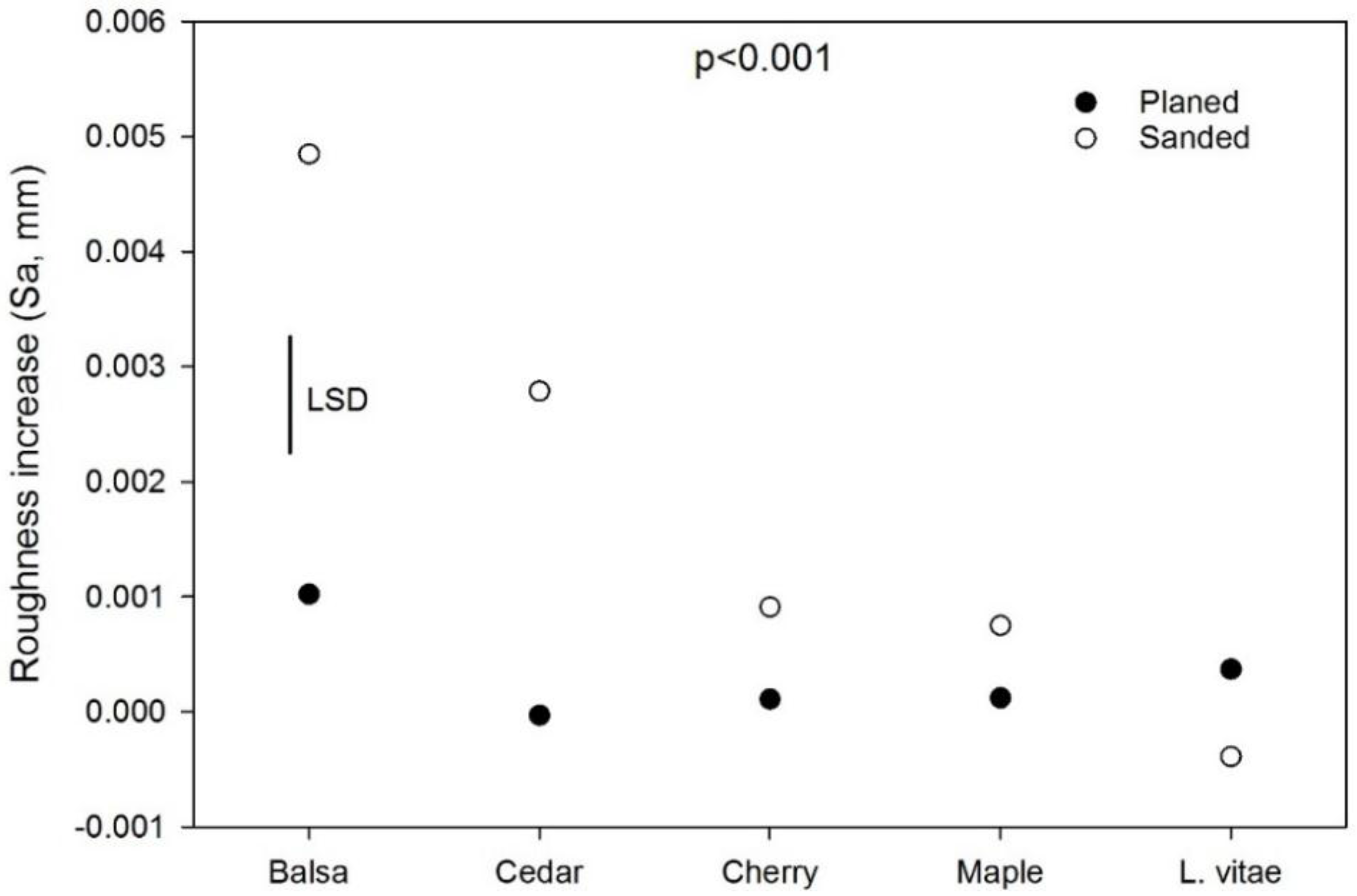

The five species arrowed in

Figure 1 were examined in more detail to explore the effects of “species” and surfacing methods on grain raising. These species span almost the entire natural range of wood densities and include balsa (B), western red cedar (WR), black cherry (BC), sugar maple (SM) and lignum vitae (LV). Grain raising of the lowest density woods (balsa and western red cedar) is significantly (

p < 0.05) greater than those of higher density woods (black cherry and sugar maple) and, particularly, lignum vitae, which showed no grain raising (

Figure 2). Analysis of variance indicated that the main effects of wood species (S), surface preparation (SP), and the interaction of S × SP (

F(4, 383) = 11.01,

p < 0.001) were statistically significant (

p < 0.001). The latter interaction occurred because there is no significant difference (

p > 0.05) in the grain-raising of the higher density sanded wood samples and the planed wood samples (

Figure 2).

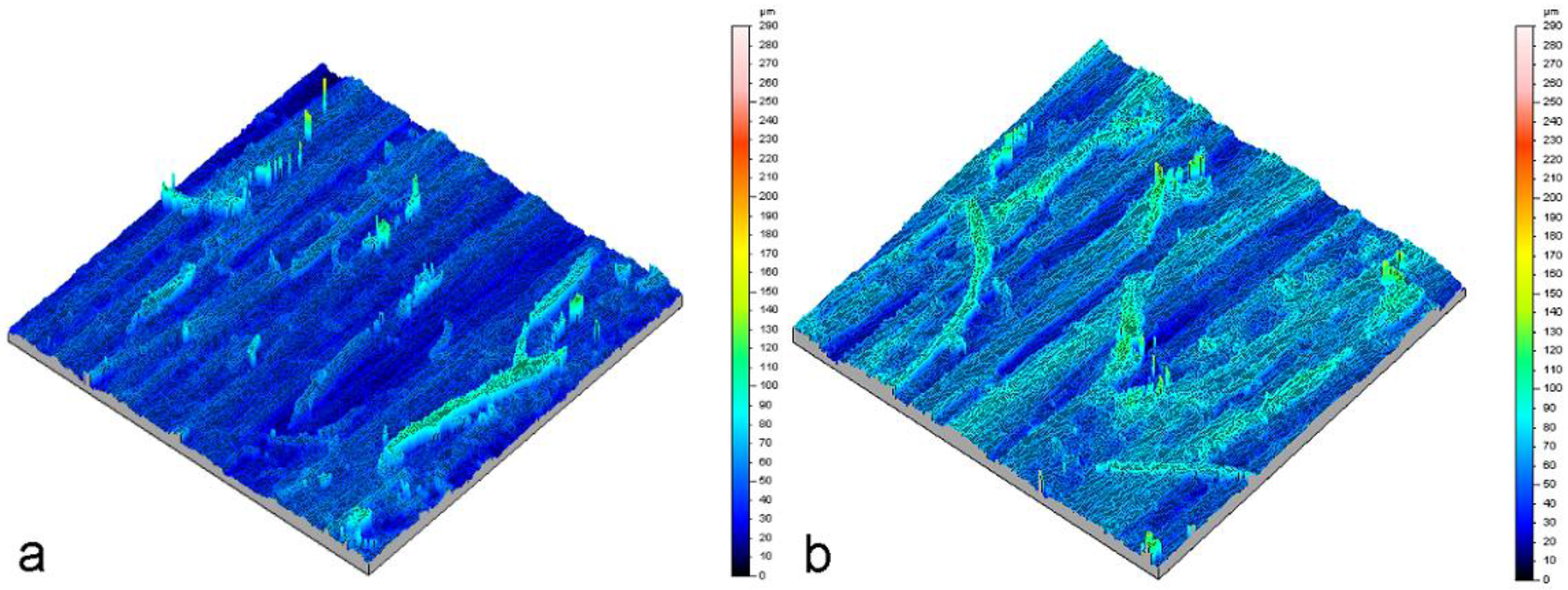

Confocal profilometry images of samples after sanding and wetting and redrying are shown in

Figure 3. In all sanded samples (

Figure 3a,c,e,g) there are ridges of material, and in balsa there are strips that are elevated above the ridges and oriented at an angle to the ridges (

Figure 3a). Confocal profilometry images of sanded surfaces after wetting and drying are shown in

Figure 3b,d,f,h. Strips of material oriented at an angle to the ridges are present in all samples (except lignum vitae,

Figure 3h), although they are most obvious in balsa (

Figure 3b). These strips are elevated above the surface of the samples. The microstructure of these strips and the effects on sanding and planing on the structure of wood surfaces was examined using scanning electron microscopy(SEM) (

Figure 4,

Figure 5,

Figure 6 and

Figure 7).

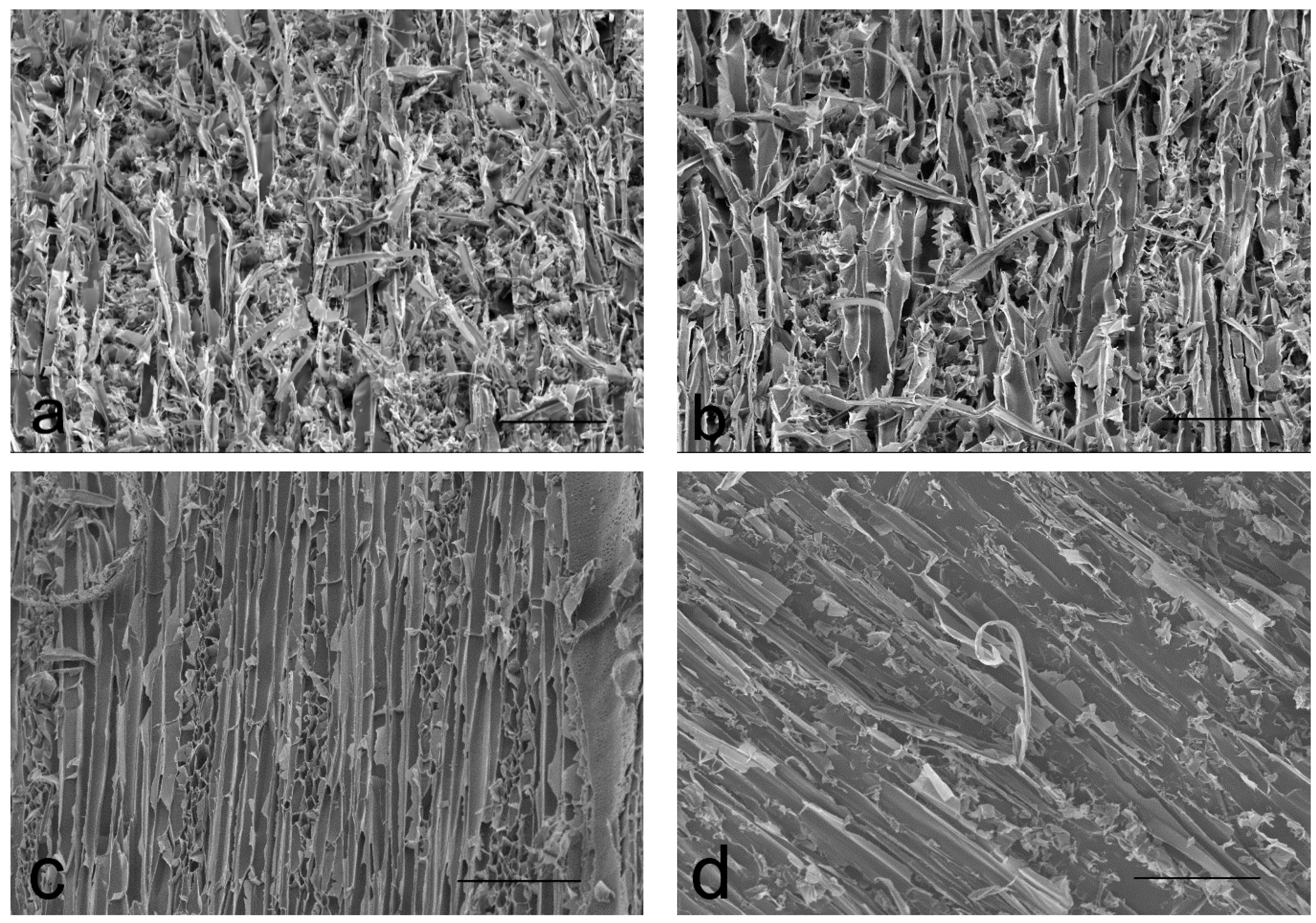

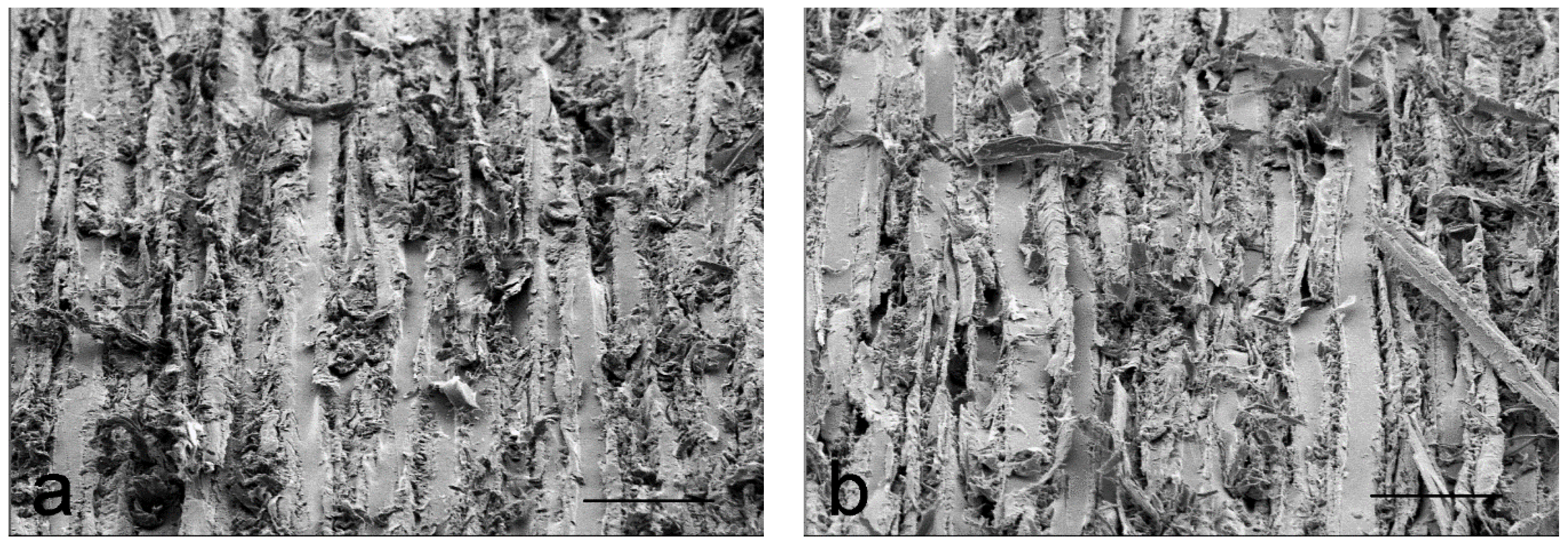

Figure 4 shows SEM images of balsa wood. Sanding of balsa created a mat of degraded cell wall material that obscured the underlying anatomical features of the wood (

Figure 4a). This mat consisted of slivers of cell wall material that were mainly aligned in the fibre direction, although some slivers were bent and aligned tangentially to fibres (

Figure 4a). These slivers were attached at one end to their parent fibres and there was a greater tendency for them to project vertically from the surface following wetting and drying (

Figure 4b). In contrast, it was possible to see the underlying structure of balsa wood in the planed surface after wetting and drying, although there is evidence that planing caused tearing of fibre walls and the torn material projected from planed balsa wood surfaces (

Figure 4c).

Figure 4d shows cell wall fragments removed from a sanded balsa wood surface following wetting and drying. The material removed from the surface consisted of long slivers of cell wall material, and much smaller fragments. Far less material was removed from the surface of planed balsa wood following wetting and drying.

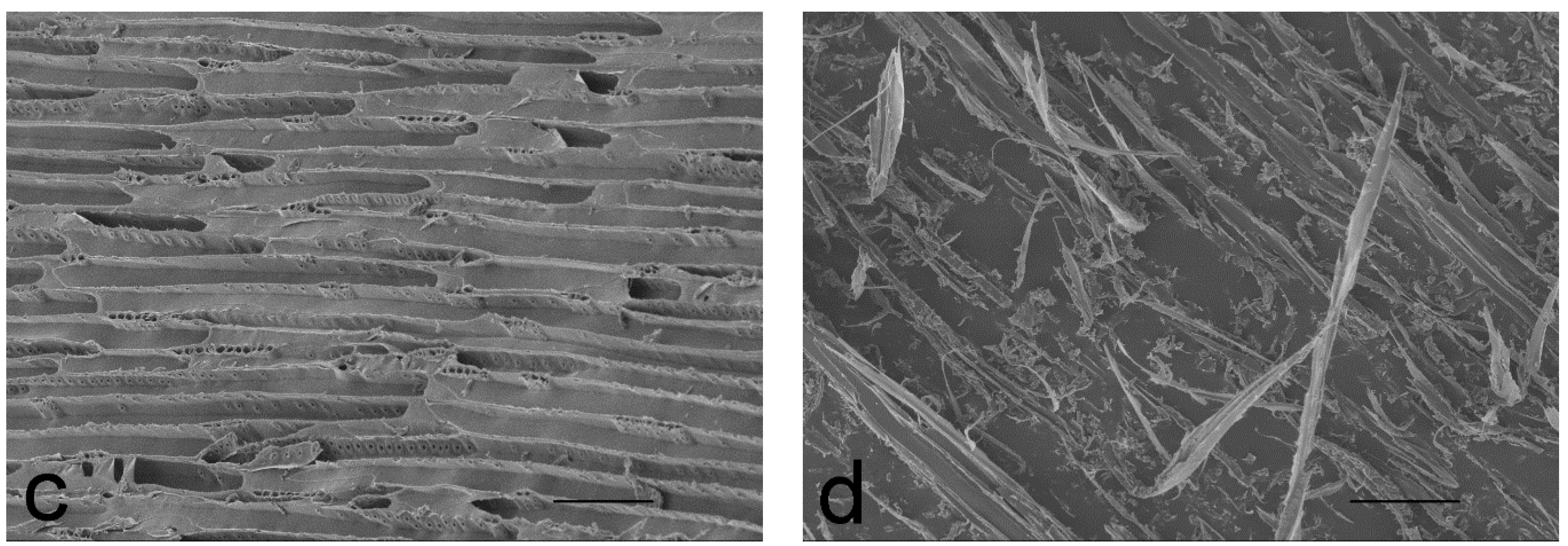

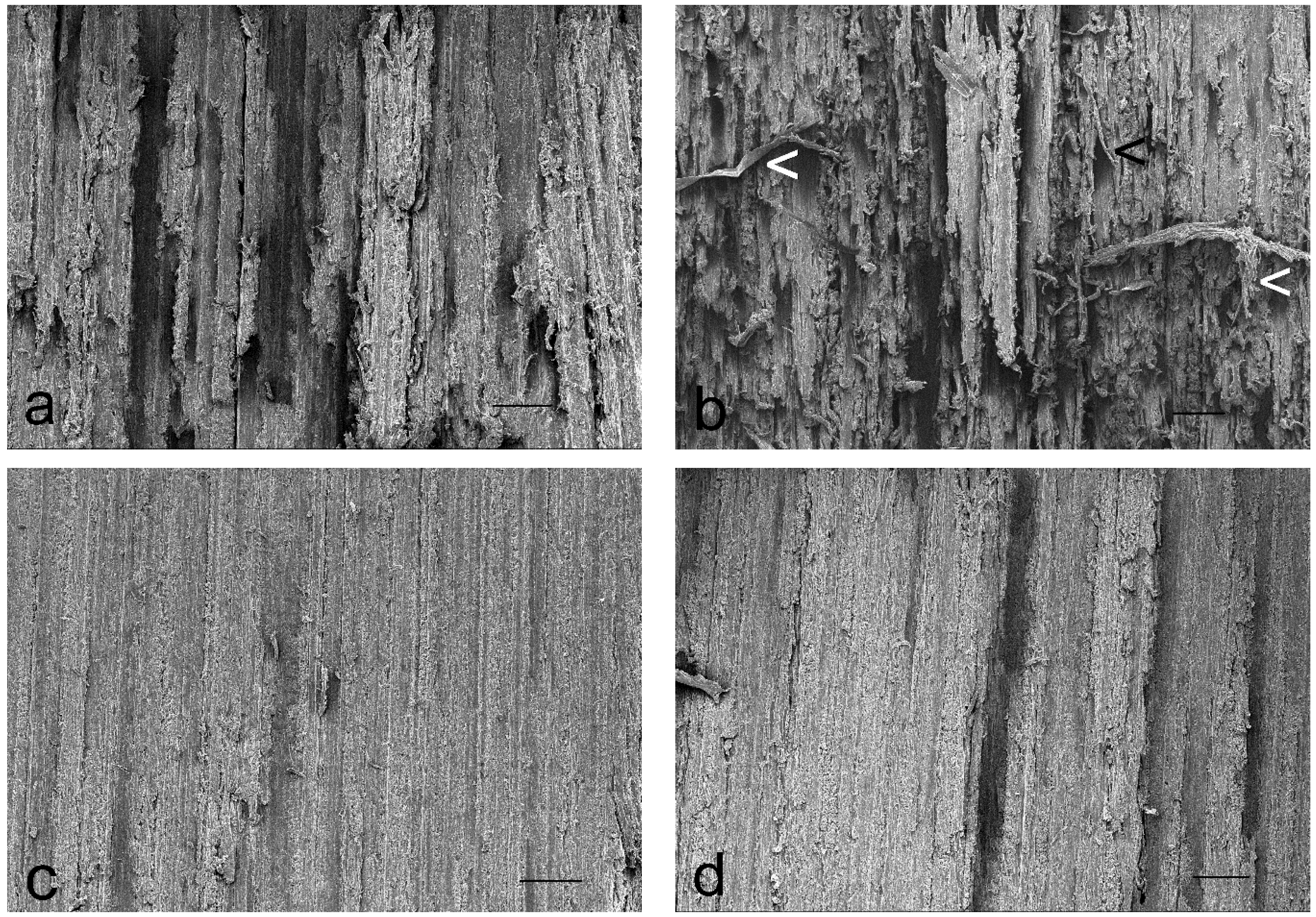

Sanding of western red cedar surfaces left cell wall material attached to the vertical walls of tracheids that appeared as ridges in confocal profilometry images (

Figure 5a). This material is more obvious in the sample that was wetted and then dried (

Figure 5b). In this sample, you can see ribbons or slivers of cell wall material that are bent-over and projecting from the wood surface. They are absent from the planed surface (

Figure 5c), but are easily seen in the photograph that shows the cell wall material removed by tape testing (

Figure 5d).

Sanding of sugar maple surfaces also left slivers of cell wall material attached to the underlying wood, although they are smaller than those observed on sanded balsa or cedar surfaces (

Figure 6a). Sanding of maple surfaces created grooves at the surface of the wood, in addition to slivers of wood attached to cell walls. These slivers of wood projected from wood surfaces after wetting and drying (

Figure 6c), as was observed at balsa and western red cedar surfaces. In addition, we observed hollow tubular elements projecting from maple surfaces indicating that “fibre rise” contributed to grain raising in maple. Maple surfaces showed little damage as a result of planing and very little material was removed by tape testing. In contrast, the tape removed a variety of different materials from maple wood that had been subjecting to the sanding and the grain raising procedure, including parts of thin-walled vessel elements containing helical windings, parts of fibres and cell wall slivers, and smaller debris (

Figure 6d).

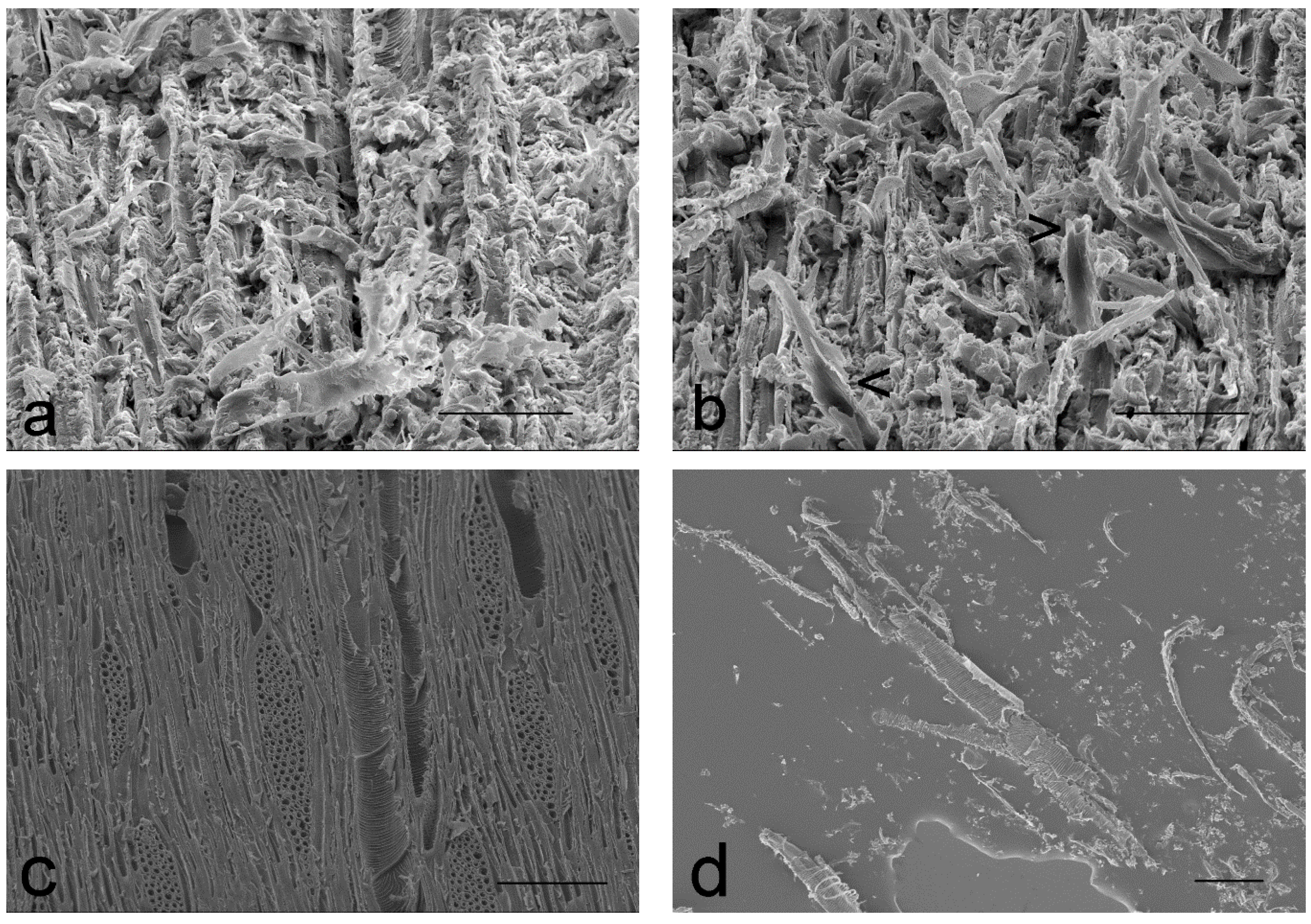

Sanding did not create loosely-bonded cell wall material at the surface of lignum vitae wood, in contrast to its effects on balsa, cedar, cherry, and maple. Instead sanding created a series of grooves at the surface of the wood (

Figure 7a). The surface was largely unchanged after the grain-raising procedure (

Figure 7b), and very little material was removed from lignum vitae by tape testing (

Figure 7d). Lignum vitae is the world’s densest wood and is very difficult to section, which accounts for why the surface of the planed lignum vitae sample is uneven (

Figure 7c).

Our observations of grain raising (above) on sanded wood samples were complemented by physical modelling of the effects of sanding on wood surfaces. Arrays of plastic tubes modelled the porous microstructure of wood and a serrated tool drawn across the tubes simulated the abrasive action of sandpaper on the microstructure of wood (

Figure 8). The serrated tool completely removed parts of the uppermost layer of plastic tubes when it was drawn across the surface of the tubes. It also created strips of plastic that were still attached to the sides of the tubes (

Figure 8). These strips projected above the surface of the uppermost layer of tubes, and were oriented in the direction of the tubes, or at an angle to the tubes (depending on the width and length of the strips,

Figure 8).

Our observations of grain raising of wood described above were carried out on hand-sanded solid wood samples. These observations are relevant to small craft-based industries that employ hand sanding of solid wood. However, larger industrial facilities use machine-sanding and often process composite panels with a decorative face veneer in addition to solid wood. Therefore, we examined grain raising of maple veneer-faced panels that were machine-sanded. There was a significant effect of sanding on grain raising (

F(2, 22) = 5.15,

p = 0.015) and a positive relationship between abrasive size and grain raising (

Figure 9). In other words, sanding with finer abrasives (150 and 180 grit) resulted in significantly (

p < 0.005) less grain raising than sanding with a coarser abrasive (120 grit).

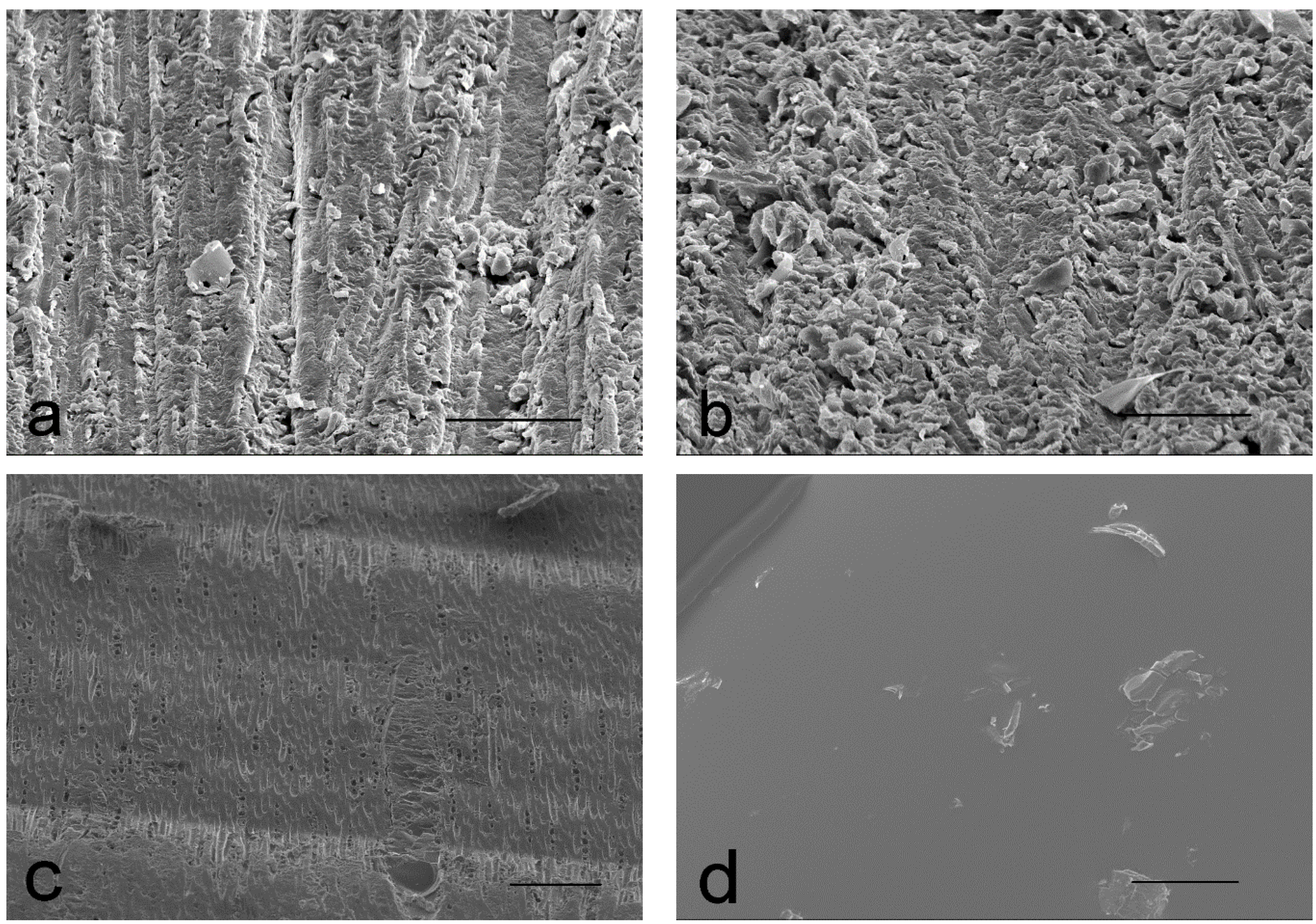

Scanning electron microscopy was used to examine the surface structure of maple veneer-faced panels after sanding and then again after wetting and drying. Sanding with 120 grit abrasive paper created grooves and ridges, and loosely-bonded material at the surface of the veneer (

Figure 10a). After wetting and drying a variety of woody material projected from the sanded surface (

Figure 10b) including slivers of wood cell wall (arrowed left), ends of fibres (arrowed right of centre), and bundles of fibres (arrowed extreme right). Sanding surfaces with abrasive paper with finer abrasive grits caused progressively less damage to the wood surface, and there was less grain raising after wetting and drying (

Figure 10c,d). These observations accord with measurements of the differences in roughness of surfaces after sanding and wetting and drying (

Figure 9).

4. Discussion

Our results show an inverse relationship between the density of wood species and grain raising, and suggest a mechanism to account for this relationship. In low-density wood species, such as balsa and western red cedar, “fibres” are thin walled and are easily perforated and shredded during sanding resulting in the formation of slivers of cell walls that are loosely bonded to the underlying wood surface. These slivers, which were also formed when we modelled the effects of abrasives on a tubular wood model, project from wood surfaces after sanding and also to a greater extent after surfaces become wet and then dry. This phenomenon was observed under ambient conditions using confocal profilometry, and also under low vacuum scanning electron microscopy. The phenomenon appears to account for grain raising in low-density wood species. In the highest density wood species, such as lignum vitae, sanding did not create slivers of cell wall material and grain raising did not occur. Grain raising occurred in species whose density fell between those of balsa and lignum vitae, for example, sugar maple, and can be explained in part by the mechanism we have just proposed, particularly the shredding of thin-walled vessel elements. In addition, the partial detachment of fibres and fibre bundles also appears to contribute to grain raising in maple. However, we find little evidence that swelling of ridges created by the ploughing effect of abrasive particles during sanding contributes to grain raising because such ridges were prominent in higher-density species that did not develop significant grain raising.

The mechanism for grain raising we have proposed helps to explain some of the results of previous studies that examined grain raising. For example, the relationships between grain raising and abrasive size observed by Nakamura and Takachio [

11], and also here, may be explained by the increased ability of larger abrasive grains to slice open fibre walls leaving partially-detached slivers of wood at sanded surfaces. Increased sanding pressure might produce a similar effect, as observed by Nakamura and Takachio [

11], because there would be more intimate contact between abrasive particles and cell walls. The observations by Marra [

10] that species such as oak are susceptible to grain raising may be explained by the presence of abundant large and thin-walled earlywood vessel elements that are more easily shredded during sanding than thicker-walled fibres. Evidence here for such an effect was the presence of shredded vessel walls in the debris removed from sanded hardwoods. Sanding wood at an oblique angle to fibres results in greater grain raising according to Marra [

10], possibly because it would increase the partial shredding of fibres along their length, creating more slivers of wood that are partially attached to the underlying wood.

Our results confirm the observations of Koehler [

9] that sanding can create a surface that is susceptible to grain raising, because grain raising was present in sanded wood surfaces and absent from carefully-matched wood samples that had been planed. However, grain raising was minimal in maple that was sanded with an industrial-scale (wide-belt) sander using 120, 150, and 180 grit abrasive belts. This finding suggests that grain raising can be minimized by using a sanding sequence that is tailored to particular wood species. Low-density wood species, or ones that possess an abundance of thin-walled cells, for example, ring porous species such as oaks, may benefit from an additional finer sanding step. However, fine sanding reduces the ability of stains and dyes to colour wood [

21] and this would need to be taken into account when deciding whether to introduce a final fine sanding step to reduce grain raising in lower-density woods. Other alternatives, as suggested by the patent literature, include the use of stains containing binders that presumably bond projecting woody slivers to the underlying wood and make them easier to remove using denibbing and inter-coat sanding steps [

5,

6,

7,

8].

Our research sheds no light on whether grain raising occurs when water is applied to wood surfaces or when it subsequently dries. Marra [

10] suggested that grain raising occurred during the wetting phase as wood elements swell and presumably curl away from the underlying wood surface. This suggestion is supported by unpublished industry observations. The alternative, that curling of wood elements occurs during drying, is supported by observations of the tendency of pulp fibres to curl during drying [

22]. This issue would benefit from further research to measure the moisture-induced strains that develop when sanded wood surfaces become wet and then dry. Further research is also needed on the grain raising of medium-density fibreboard (MDF), which is a problem when products made from MDF are finished with water-borne coatings. This is a fertile area for industrially-important research and the approaches used here to better understand grain raising of solid wood could provide insights into the grain raising of MDF and possibly other wood composites that are commonly finished with water-borne coatings.